Recycling, breaking and cleaning line for polyethylene terephthalate (PET) mineral water bottle

A mineral water bottle and cleaning line technology, applied in the field of waste plastic recycling equipment, can solve the problems of not conforming to the production concept of the enterprise, the cleaning quality cannot be guaranteed, and the manual cleaning environment is harsh, and achieve the effect of continuous automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

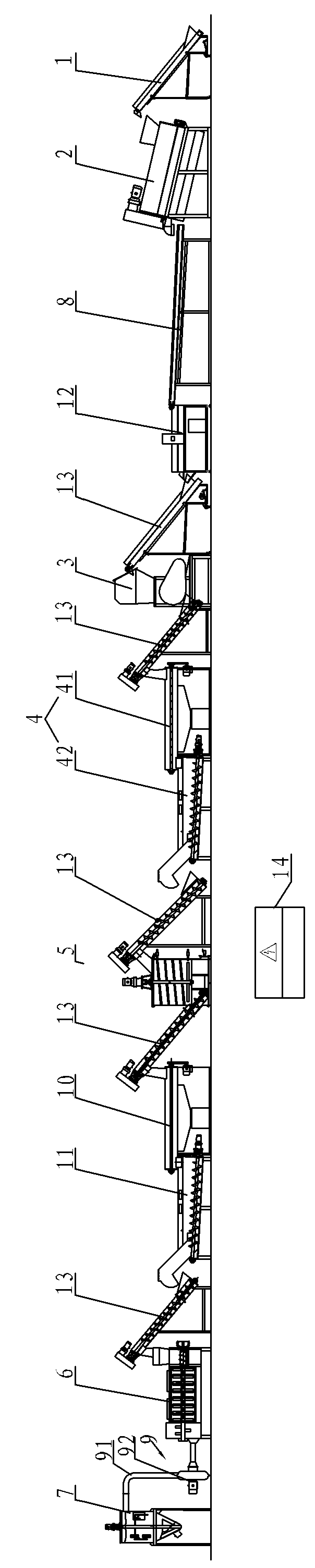

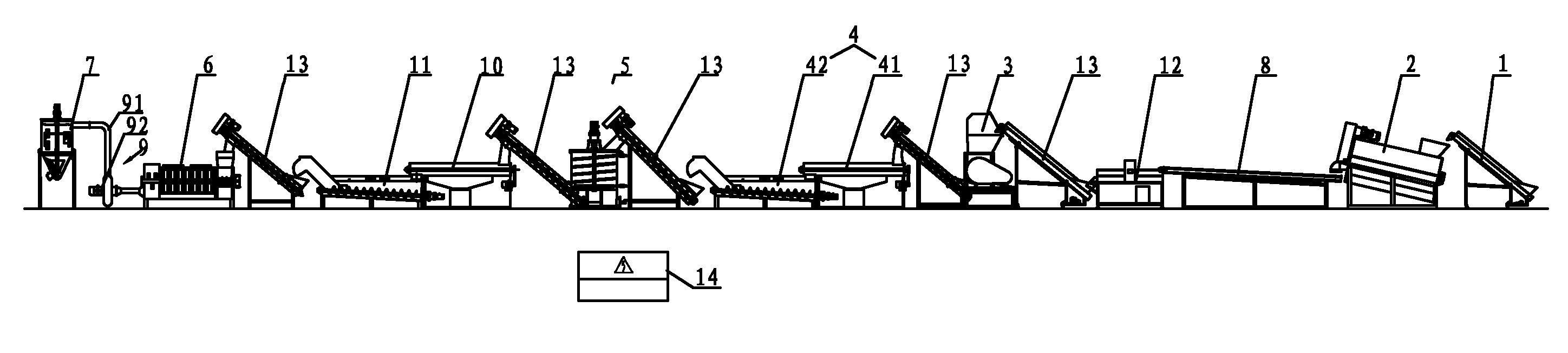

[0020] Below in conjunction with accompanying drawing, the optimized implementation mode of the present invention is further described:

[0021] Such as figure 1 In the cleaning line shown, each equipment is distributed from right to left according to the process, including: conveyor belt 1, label remover 2, sorting table 8, metal detector 12, crusher 3, washing machine 4, steamer 5, The dehydrator 6 and the silo 7, wherein the conveyor belt 1 is used to transport the mineral water bottles placed on it to the delabeling machine 2, and the dehydrating machine 2 is used to separate the labels on the mineral water bottles, and can remove about 50% of the labels at the same time the bottle caps; the sorting table 8 is used to sort the bottles after the label removal, and select 5% of the bottles that have not taken off the label, and the bottles that have not taken off the label will be transported to the label remover 2 again for secondary removal Standard; Crusher 3 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com