Relay flat iron core machining method and apparatus

A processing method and technology of processing device, applied in relay, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problems of inability to realize automatic production, easy generation of burrs and burrs, shape limitation of cold forging parts, etc., and achieve continuous automation. The effect of producing and eliminating burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

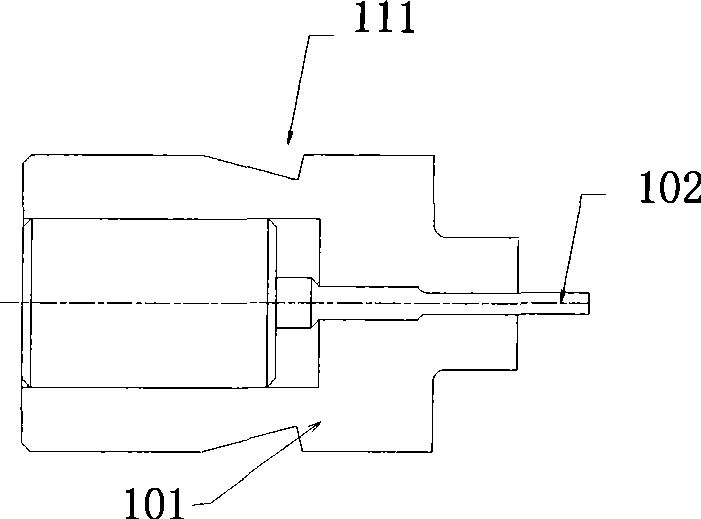

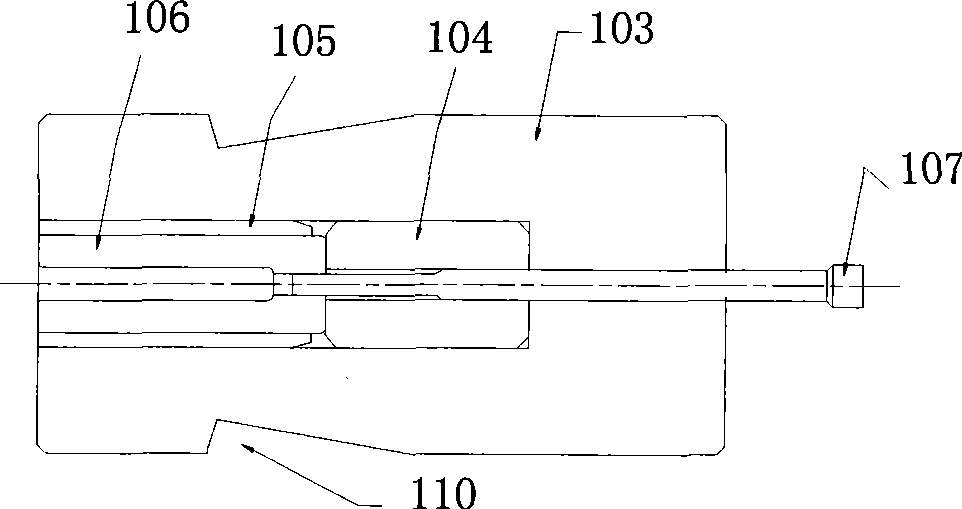

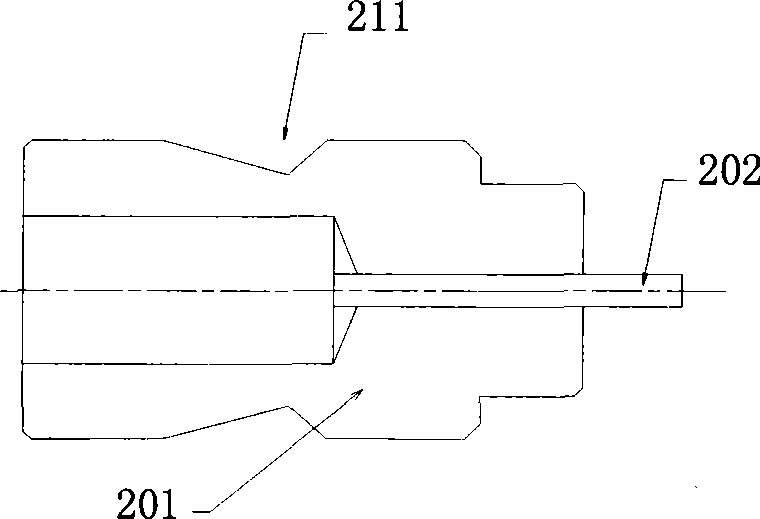

[0030] The specific embodiment of the processing method of relay flat iron core of the present invention is to utilize three-die three-blow cold forging to process relay flat iron core, comprising the following steps:

[0031] (S1) After the flat wire rod is cut into a blank of a certain length in the cutting fixed die, it is poked out by a thimble, and then the blank is transported to the cavity entrance of the first main mold by the first conveying clip;

[0032] (S2) The punching needle of the first die pushes the blank into the first main die and extrudes one end of the billet, then the semi-finished product is ejected by the ejector pin of the first main die, and the semi-finished product is transported to the second main die by the second transfer clamp The cavity entrance of the mold;

[0033] (S3) The punch pin of the second die pushes the semi-finished product into the second main mold and upsets the other end of the semi-finished product, and then the semi-finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com