Device for manufacturing metal matrix composite or semisolid slurry and using method thereof

A semi-solid slurry and composite material technology, which is applied in the field of equipment for preparing composite materials or slurry, can solve the problems of difficulty in preparing large-volume composite materials with stirring rods, short service life of stirring rods, thermal corrosion of stirring rods, etc., to achieve Simple structure, avoid pollution, even mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

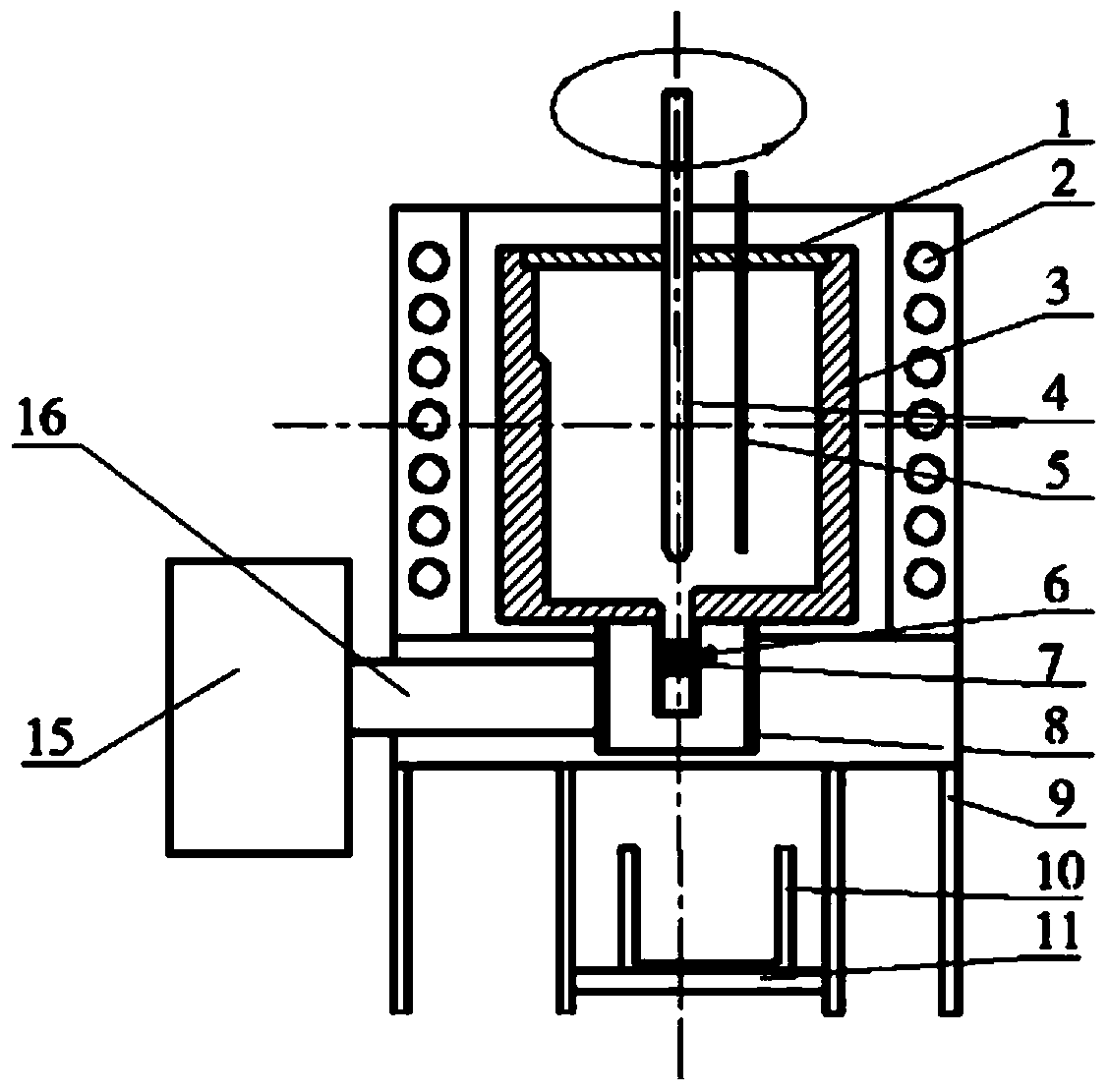

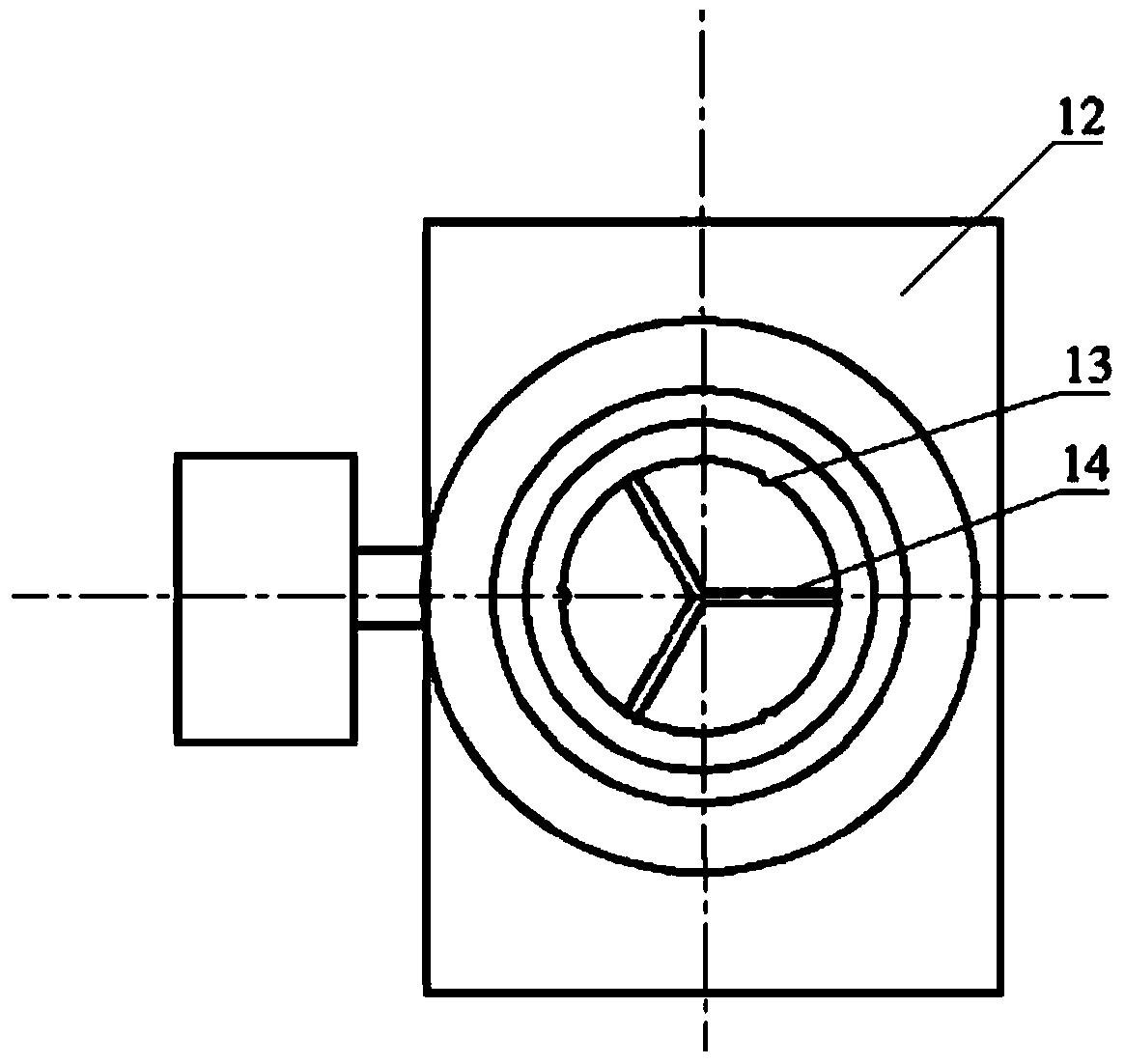

[0027] Specific implementation mode one: combine figure 1 and figure 2 Describe this specific embodiment. A device for preparing metal matrix composite materials or semi-solid slurry in this embodiment is composed of a container end cover 1, a heating element 2, a melting container 3, an ultrasonic device 4, a thermocouple 5, and a valve switch 6. The discharge channel 7, the rotating device 8, the device support structure 9, the material collection container 10, the transmission device 11, the device shell 12, the side wall rib 13, the bottom rib 14, the motor 15 and the speed reduction device 16 are composed; the container end Cover 1, smelting container 3, valve switch 6 and discharge channel 7 form a material preparation chamber, the side wall ribs 13 and bottom ribs 14 are in the smelting container 3, the ultrasonic device 4 and thermocouple 5 are connected from the container end cover 1 The part is introduced into the smelting container 3 , the material collection cont...

specific Embodiment approach 2

[0028] Specific embodiment 2: A method for using a device for preparing metal matrix composite materials or semi-solid slurry according to this embodiment is specifically completed according to the following steps:

[0029] 1. Put the raw material metal in the smelting container 3, melt it under the action of the heating part 2, and keep it warm until the metal material is completely melted, then cool down the smelting container 3 until the temperature reaches the semi-solid temperature of the metal material, Put reinforcement material into container 3;

[0030] 2. Start the ultrasonic device 4, start the motor rotation device 8, control the entire material preparation chamber to rotate clockwise and counterclockwise alternately for 10 to 30 minutes through stepless speed change, then stop the motor, open the valve switch 6, and move along the discharge channel 7 The outflowing product is received through the container 10, and the resulting material is the metal matrix composi...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 2 in that: in step 1, the reinforcing material is SiC particles. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com