Reversible semi-ladle temperature measuring and sampling device

A technology of sampling device and rotating device, which is applied in the direction of manufacturing converters, etc., can solve the problems of long time of manual temperature measurement and heating, shortening the service life of the device, and occupying a large space, so as to achieve good promotion and use value, reduce labor intensity, and avoid data loss. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

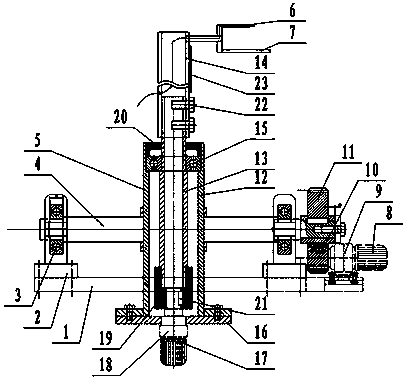

[0020] The invention consists of a steel beam base 1, a bearing seat 2, an overturning bearing 3, an overturning shaft 4, a gun rack 5, a temperature measuring gun 6, a sampling gun 7, an overturning shaft driving device, and a gun rack rotating device.

[0021] As shown in the figure, two bearing housings 2 are respectively fixedly connected to the steel beam base 1, the overturning bearing 3 is installed in the bearing housing 2, the two ends of the overturning shaft 4 are respectively connected with the overturning bearing 3, and one end of the overturning shaft 4 is connected to the overturning shaft The driving device is connected, and the turning shaft driving device drives the turning shaft 4 to rotate in the turning bearing 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com