High-temperature wear-resistant water beam of air-guiding wall

A technology of air guide wall and high temperature resistance, applied in the field of water beams, which can solve the problems of short service life and achieve the effects of improving service life, maintaining uniformity of wall thickness and less non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

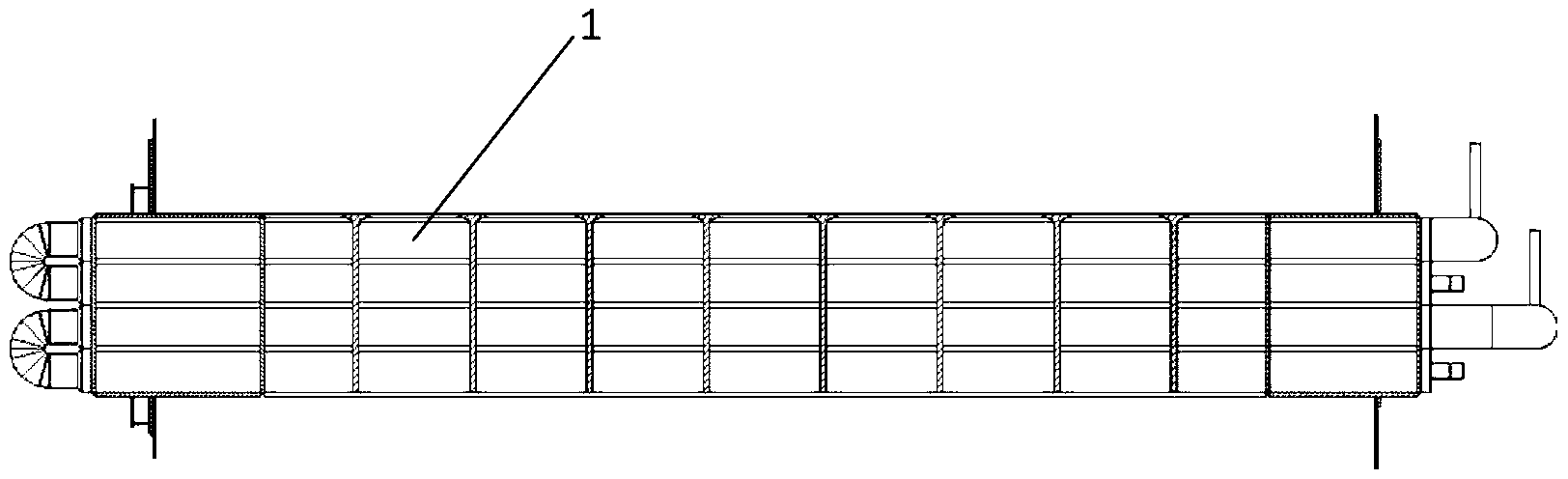

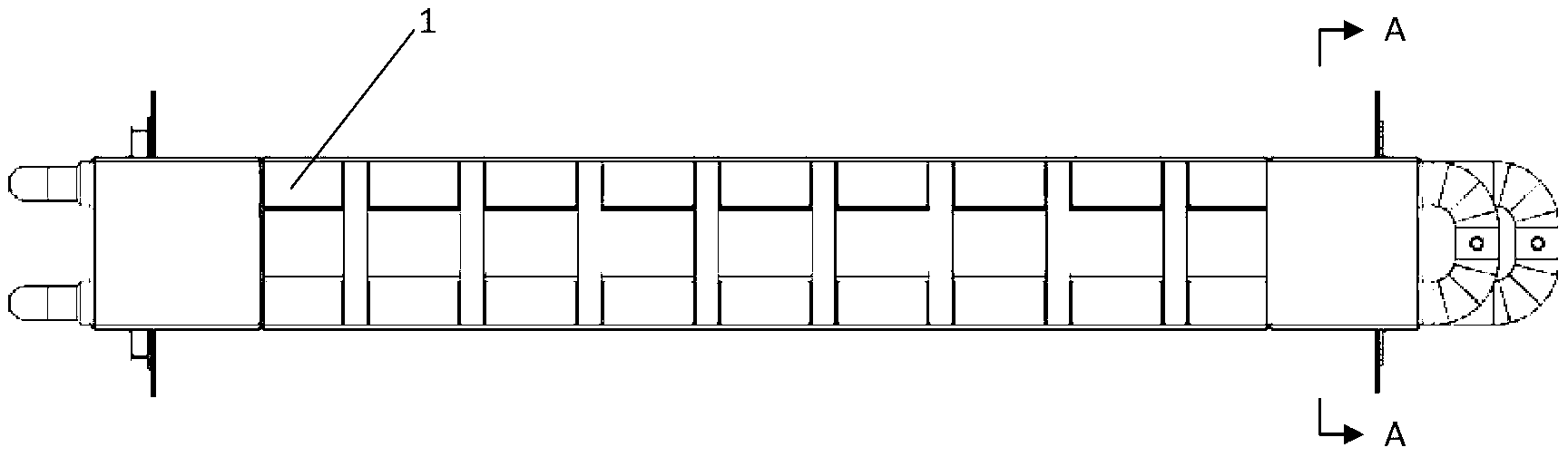

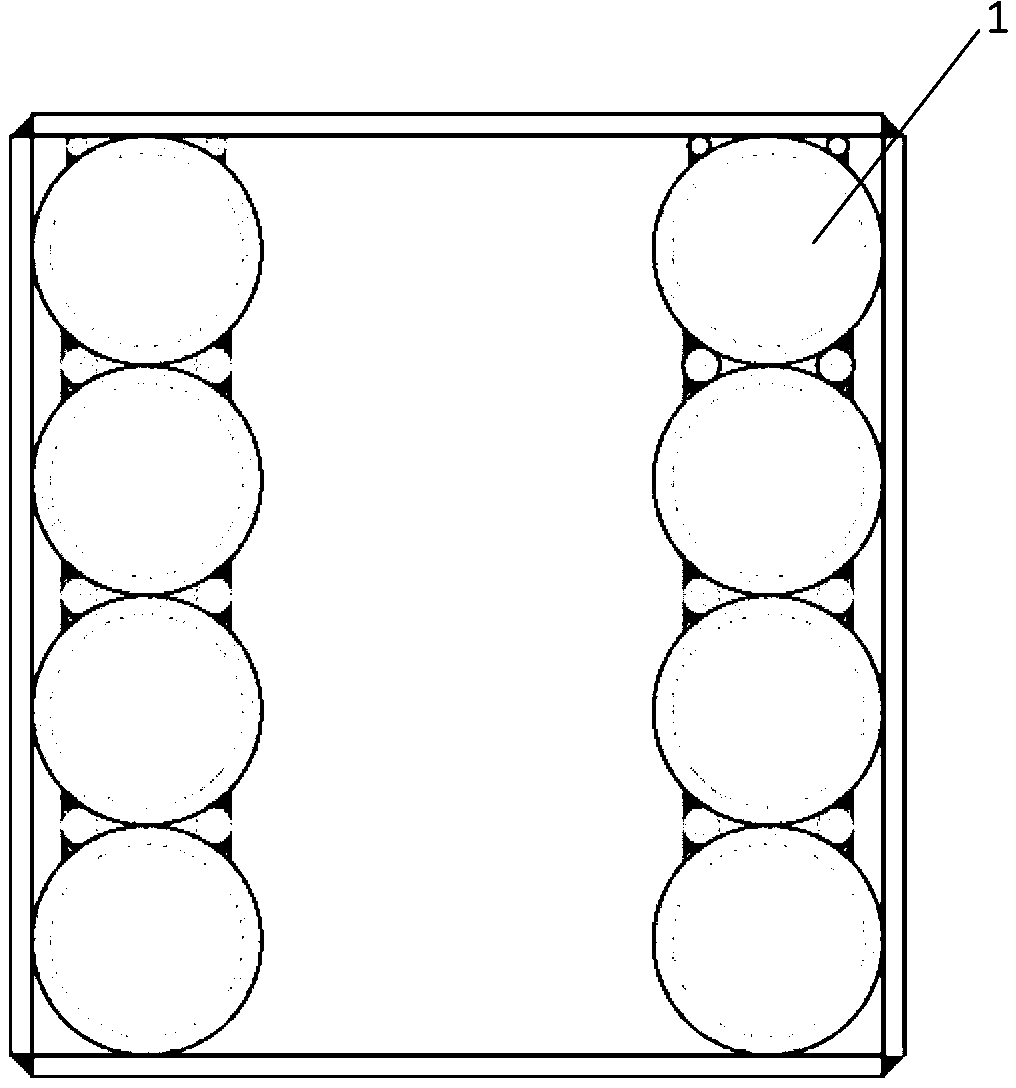

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Figure 1 to Figure 3 It shows the main structure of the high-temperature-resistant and wear-resistant wind-guiding wall water beam of the present invention, in which the main component is the water-passing steel pipe 1 (that is, the water beam pipe mentioned in the background art). As pointed out in the background technology section, the working environment of the water-passing steel pipe 1 is harsh, which is the main reason for the short service life of the water-passing steel pipe of the water beam of the wind guide wall in the prior art.

[0024] Improving the ability of water-passing steel pipes to withstand harsh working environments is an important means to increase the service life of the water beams of the wind-guiding wall. The water-passing steel pipe 1 of the water beam of the wind guide wall of the present invention adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com