Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

292results about How to "High marking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

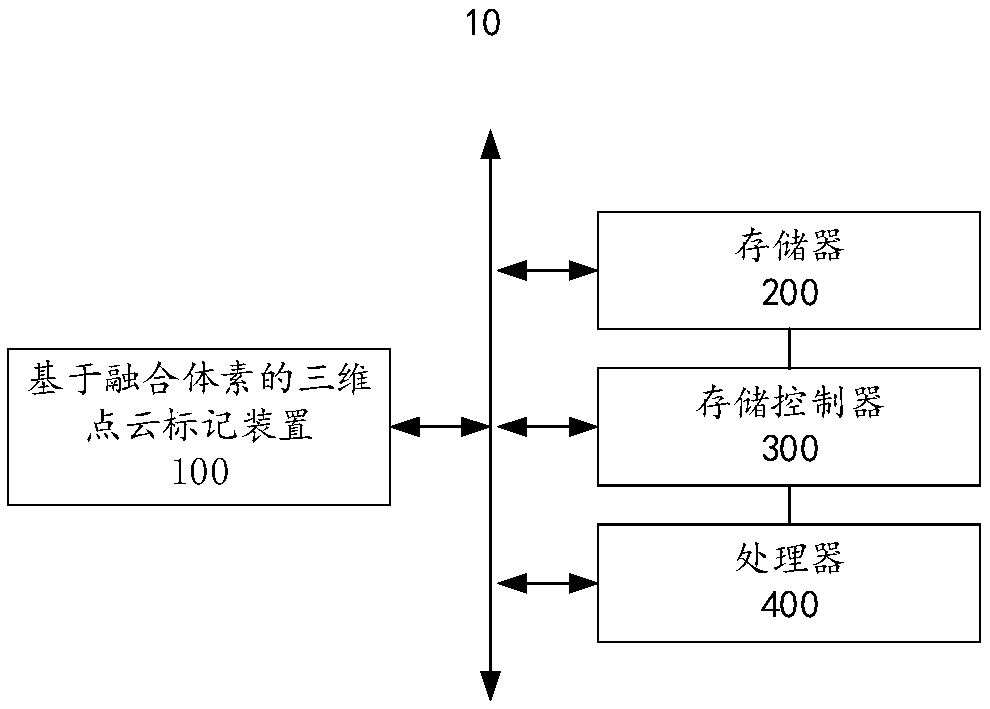

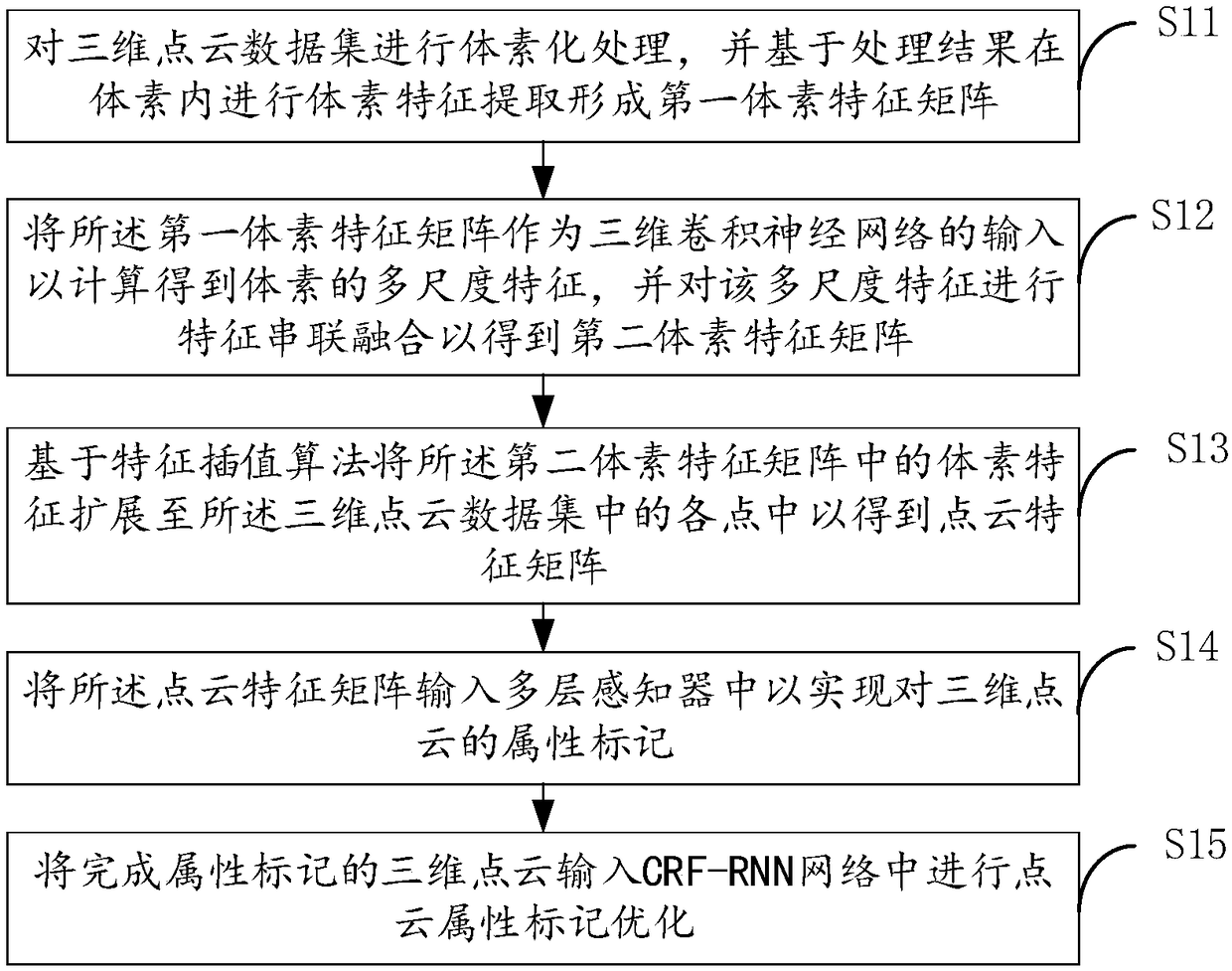

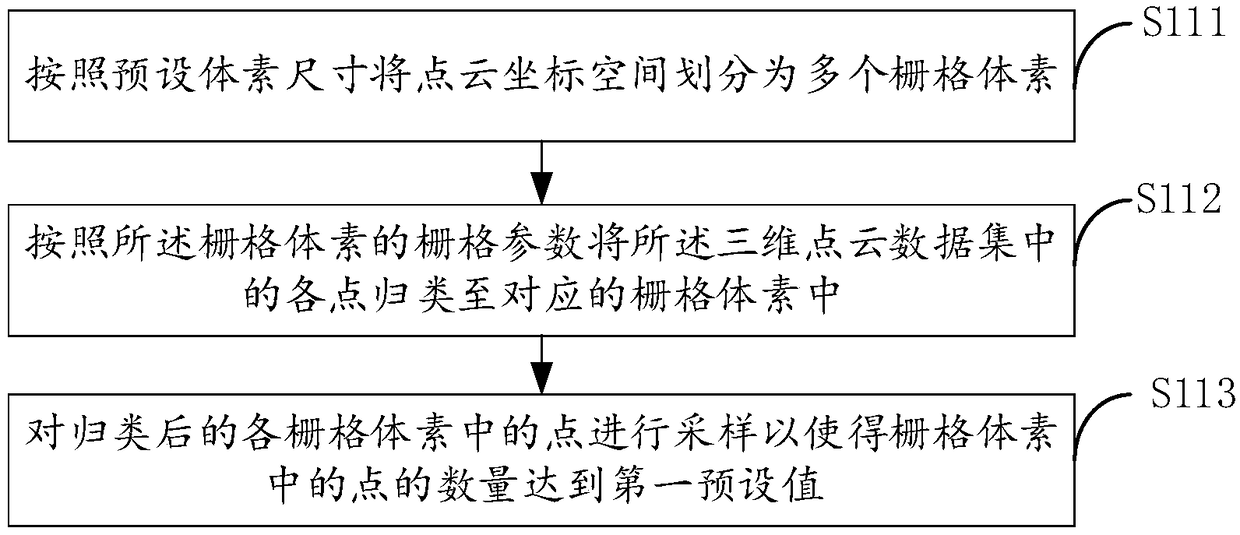

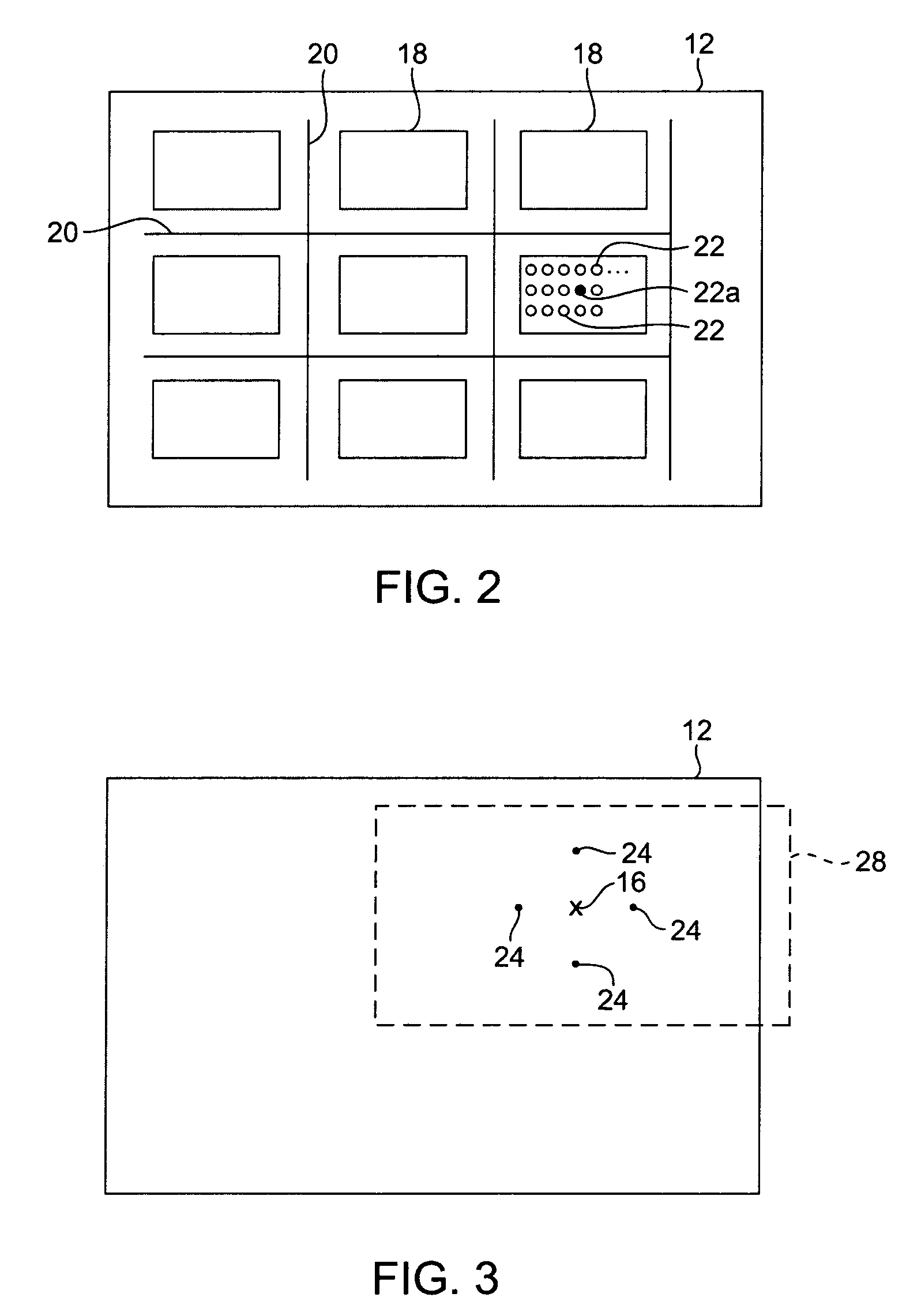

Method and apparatus for marking three-dimensional point cloud based on fusion voxel

PendingCN109118564AFine identificationFine Point Cloud LabelingNeural architectures3D-image renderingData setPoint cloud

Embodiments of the present invention provide a three-dimensional point cloud marking method and apparatus based on a fusion voxel. The method comprises the following steps: the data set of the three-dimensional point cloud is voxelized and voxel features in the voxels are extracted based on the processing results to form a first voxel feature matrix; the first voxel feature matrix is used as the input of the three-dimensional convolution neural network to calculate the multi-scale feature of the voxel, and the multi-scale feature is fused in series to obtain the second voxel feature matrix. The first voxel feature matrix is used as the input of the three-dimensional convolution neural network to calculate the multi-scale feature of the voxel. Based on the feature interpolation algorithm, the voxel features in the second voxel feature matrix are extended to the points in the three-dimensional point cloud data set to obtain the point cloud feature matrix. The feature matrix of point cloud is inputted into the multilayer perceptron to mark the attributes of three-dimensional point cloud. The invention can realize fine classification and recognition point by point, so as to further improve the performance of point cloud marking.

Owner:HUNAN VISUALTOURING INFORMATION TECH CO LTD

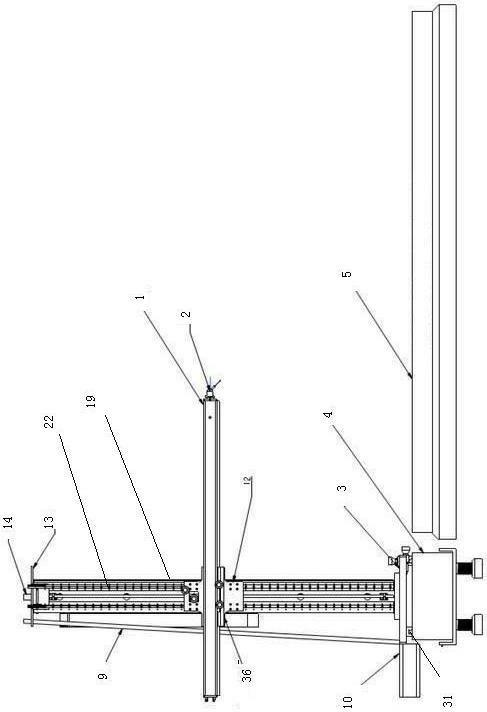

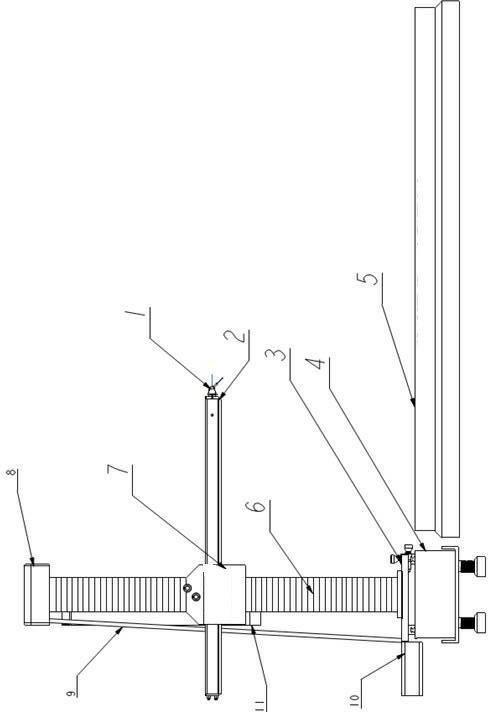

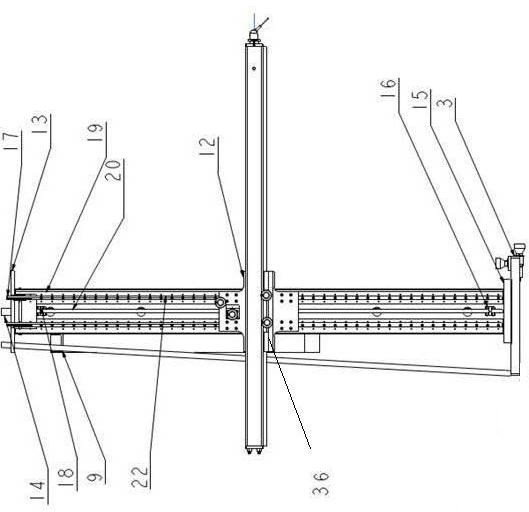

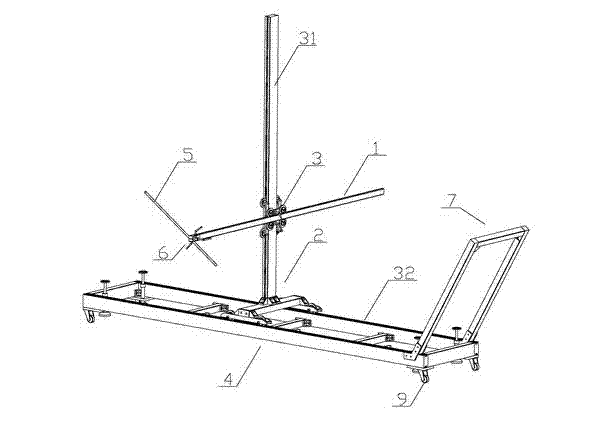

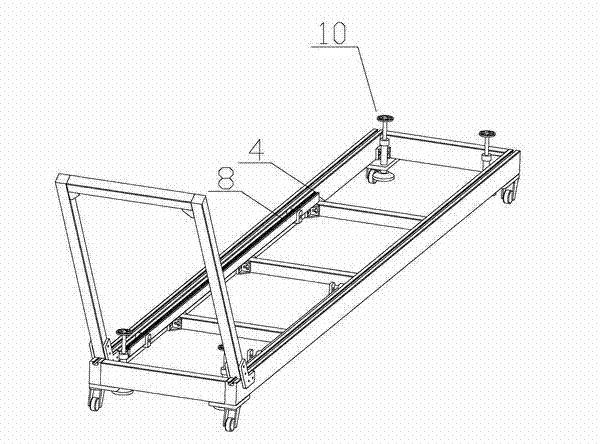

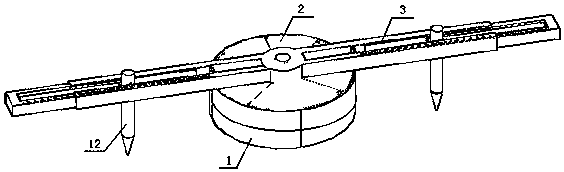

Horizontal arm type three-coordinate measuring and ruling machine

InactiveCN102679929ALower acquisition costsGuarantee stabilityMeasurement devicesOther workshop equipmentThree-dimensional spaceCoordinate-measuring machine

The invention discloses a horizontal arm type three-coordinate measuring and ruling machine, which includes a base, an upright column and a horizontal arm, wherein the upright column and the horizontal arm are made of lighter material, namely aluminum; all three shafts adopt two sets of linear slides; and the linear slide of the horizontal arm is mounted by adopting two mutually vertical surfaces, and an adjustable pull rod is mounted in the horizontal arm for adjusting the curve and deformation caused by other causes as self weight. The horizontal arm type three-coordinate measuring and ruling machine solves the problems in the market that the existing three-coordinate ruling machine has unstable mechanism, complex structure and high cost, and is complex to machine the parts and inflexible to operate. The shafts are mutually vertical and matched with the precise linear slides to realize the three-dimensional movement, so as to achieve the measuring and ruling functions in the three-dimensional space; and the three-coordinate measuring and ruling machine can support all sorts of triggering, analog scanning and non-contact optical measuring heads, and can be widely applied to the measuring and ruling of large mechanical parts as automobiles, motorcycles, excavators, ship engines and dies.

Owner:SHANDONG JINMA UNIONTECH METROLOGICAL TECH

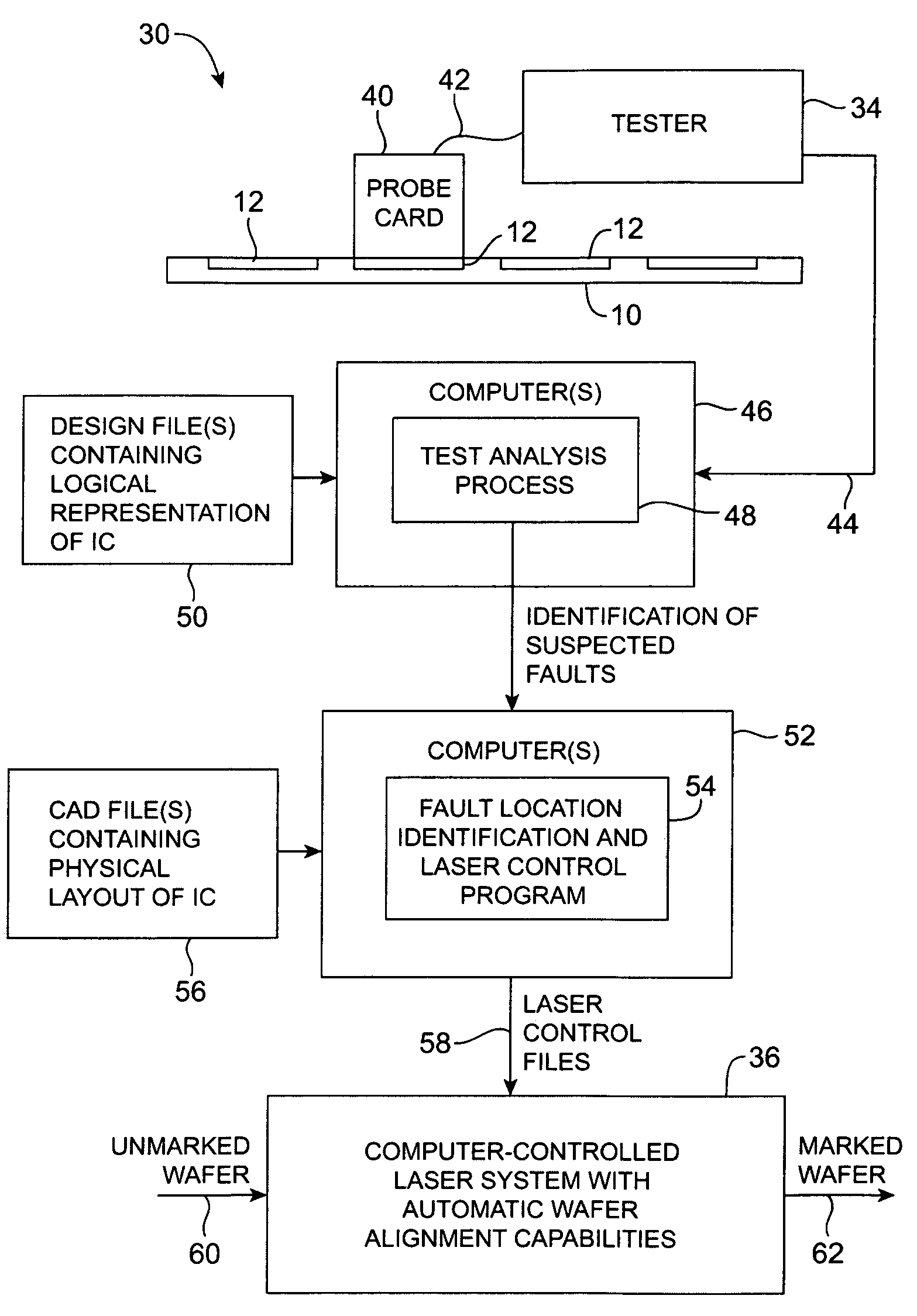

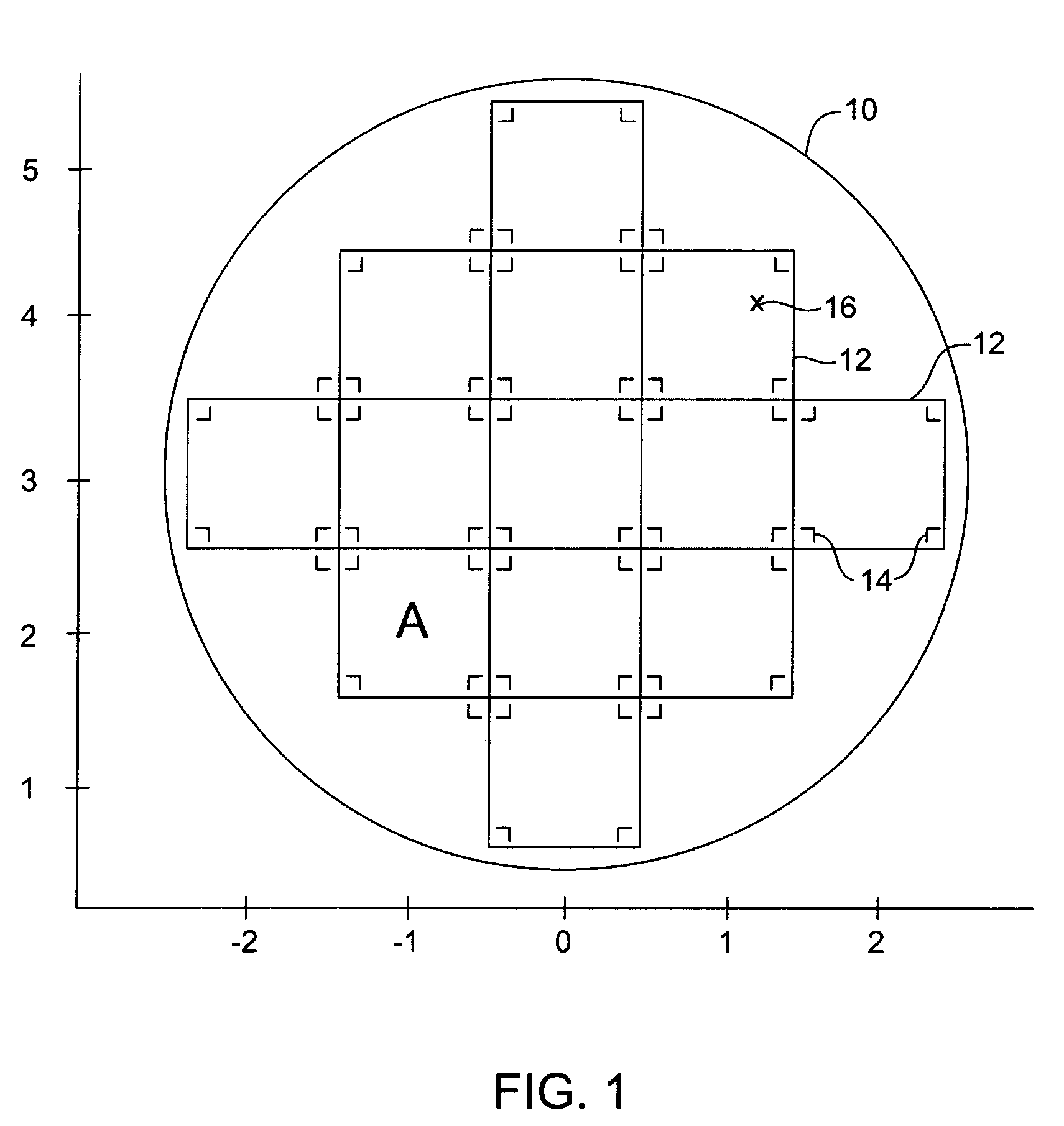

Methods and apparatus for laser marking of integrated circuit faults

InactiveUS7020582B1High marking accuracyImprove throughputElectronic circuit testingElectric discharge tubesTester deviceElectron microscope

Systems and methods are provided for marking integrated circuit defects on wafers to facilitate failure analysis. A wafer containing integrated circuits can be tested using a tester. Test data from the tester can be analyzed using integrated circuit design files to identify suspected faults. A fault location program can be used to identify the physical location of the faults. The fault location program uses information on the faults identified and CAD file information on the physical layout of the integrated circuit to map identified faults to actual physical positions. The fault location program may also generate laser control files. The laser control files can be used to control a laser system so that the laser system creates laser marks on the wafer surrounding each of the faults. The marked faults can be polished and examined under an electron microscope or analyzed using other failure analysis tools.

Owner:ALTERA CORP

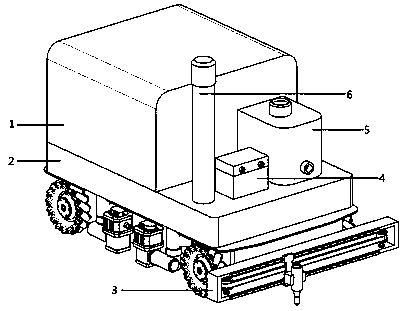

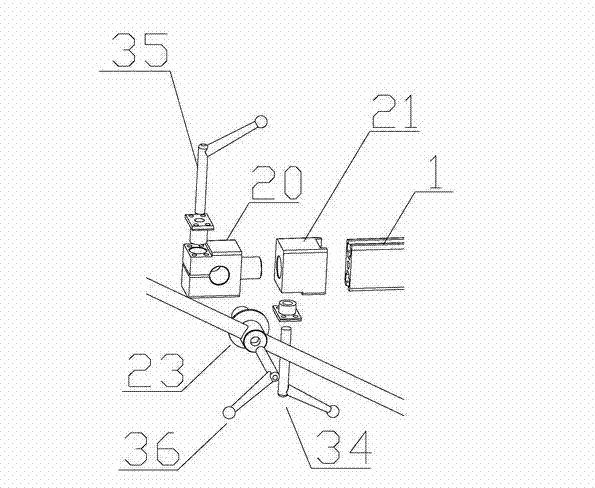

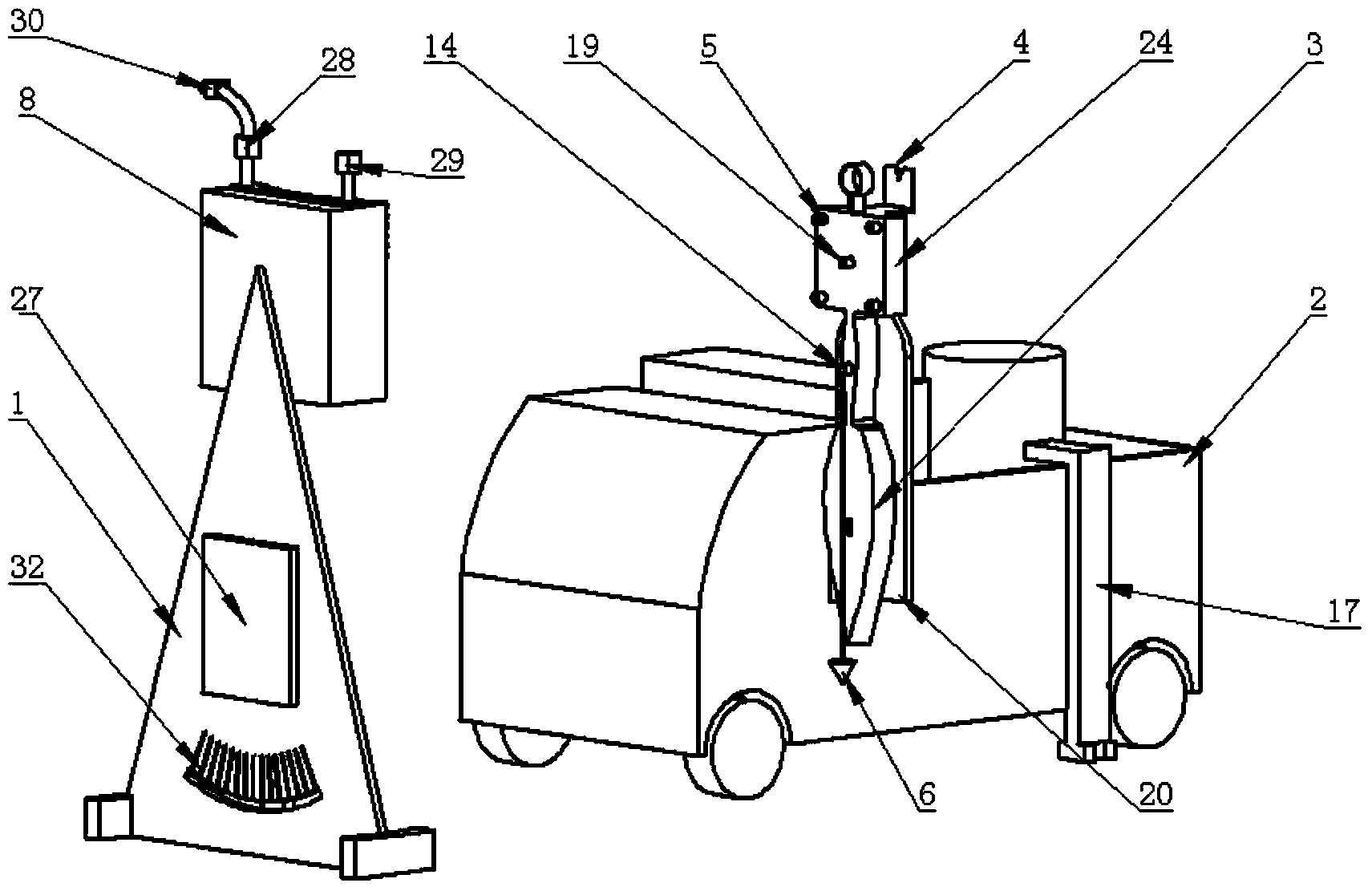

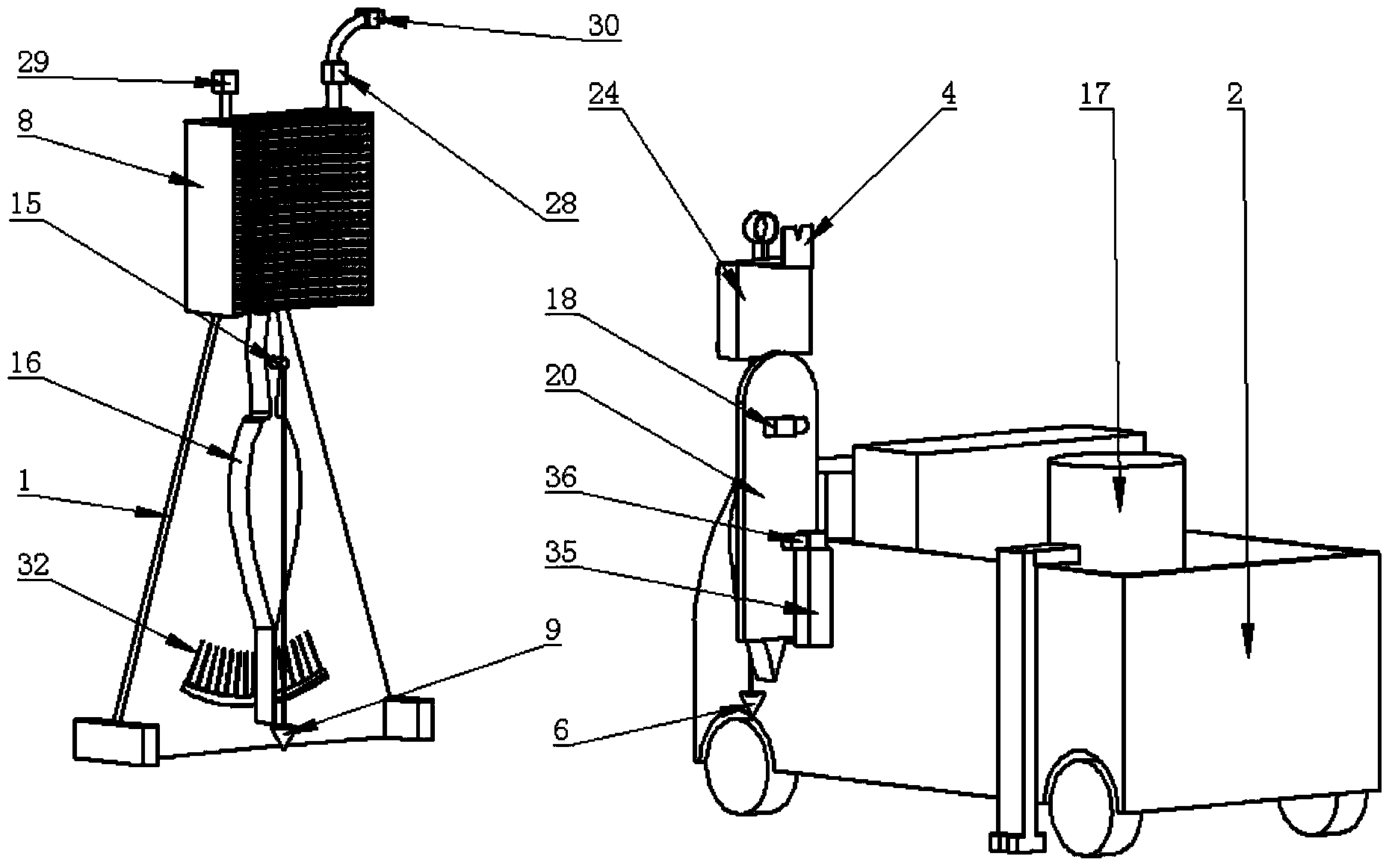

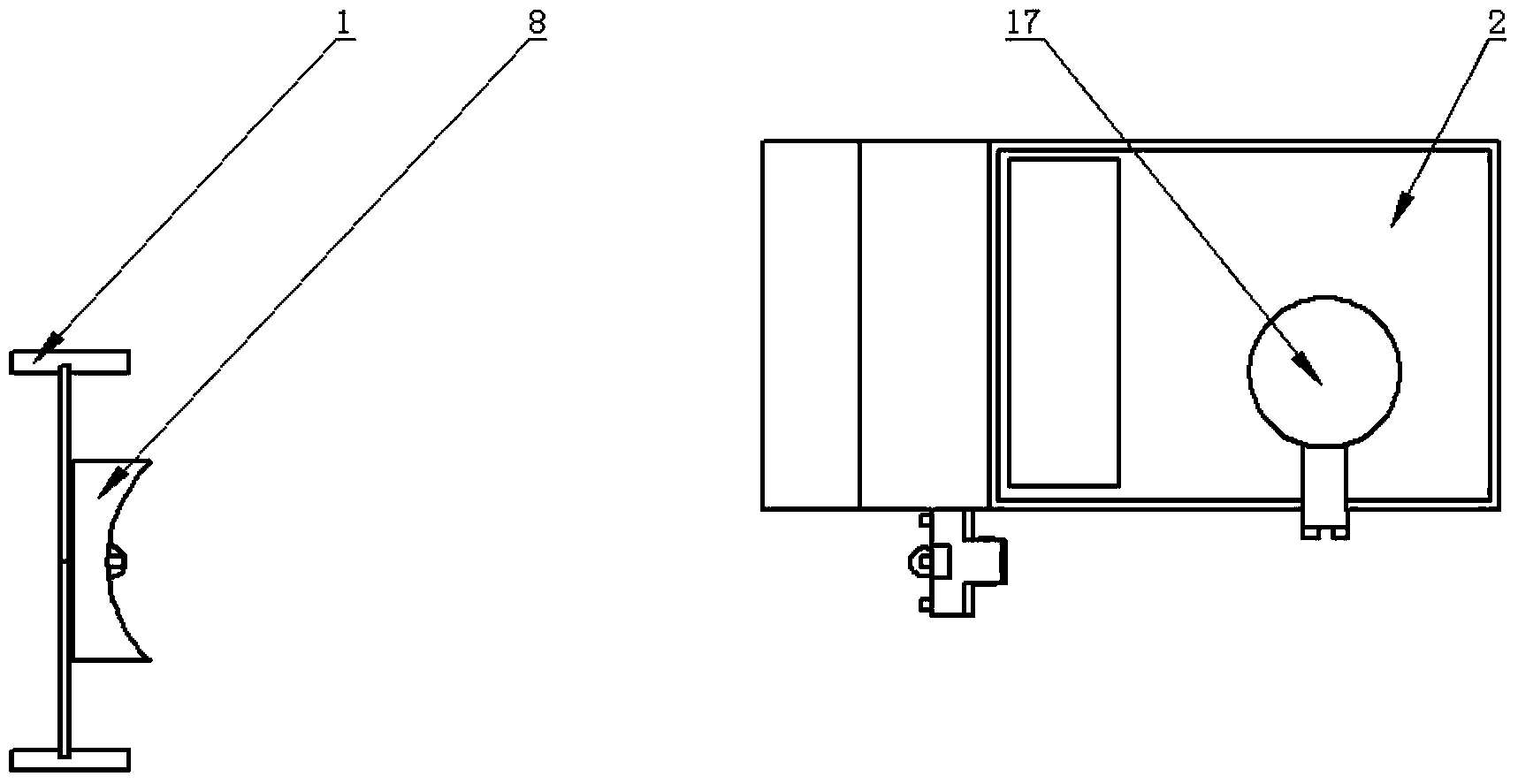

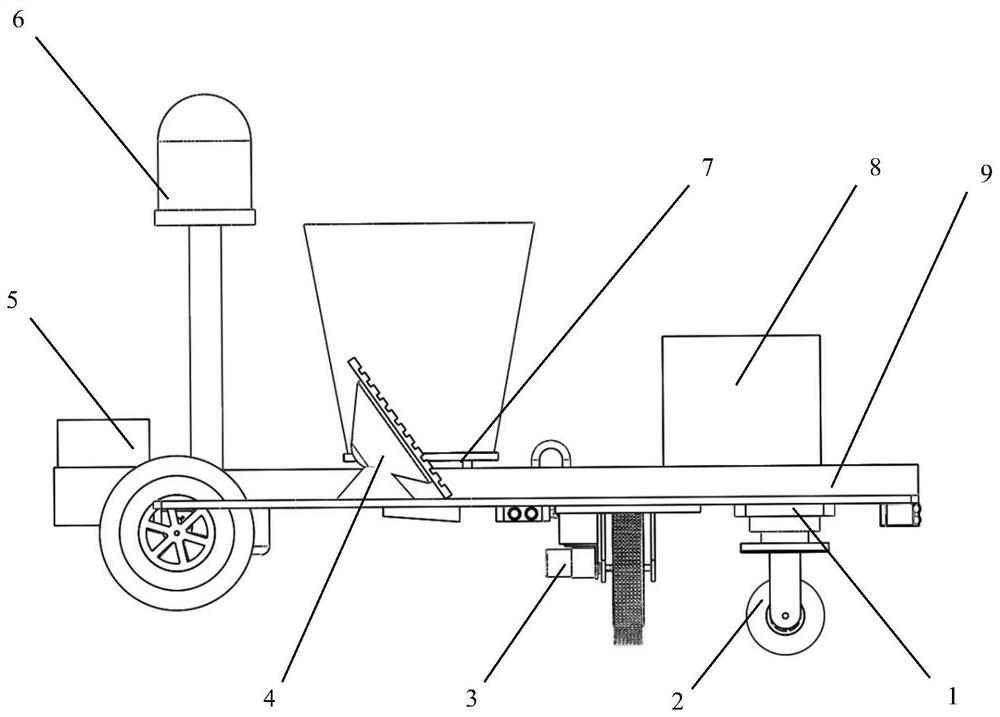

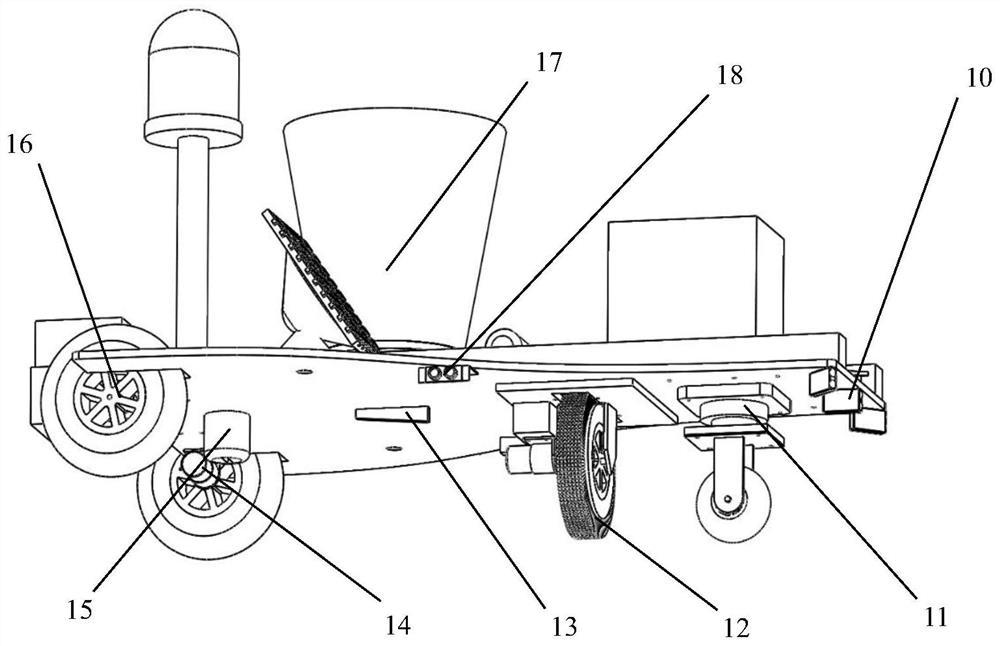

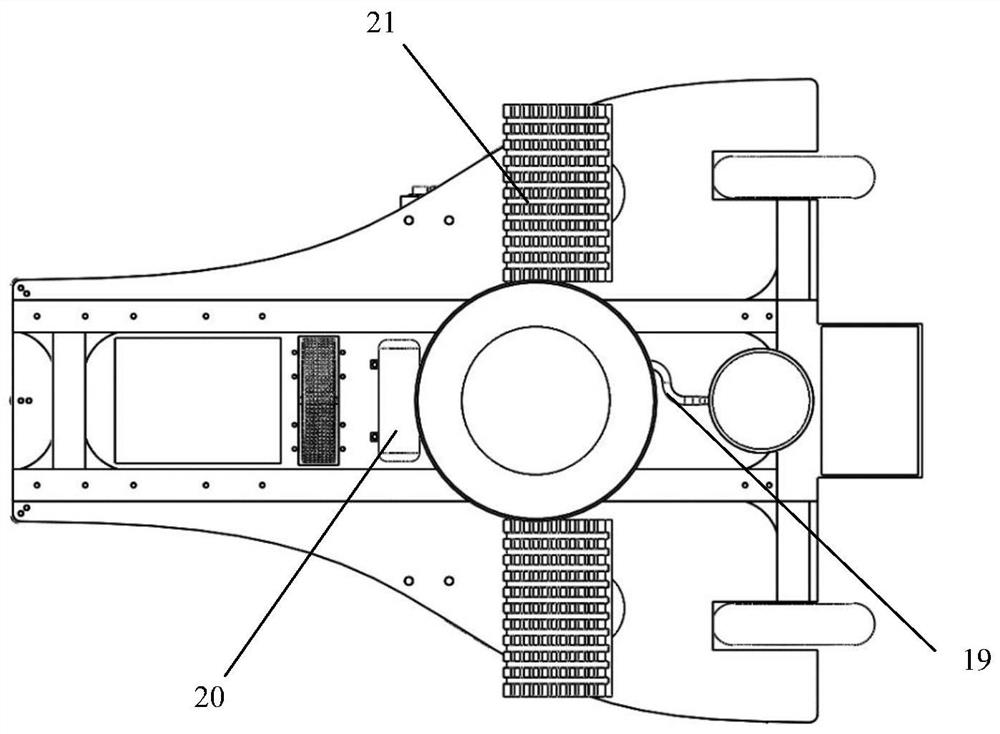

Intelligent lineation vehicle guided by unmanned aerial vehicle

The invention discloses an intelligent lineation vehicle guided by an unmanned aerial vehicle. The intelligent lineation vehicle comprises an AGV cart, a servo driving motor provided with an optical-electricity encoder is arranged on each wheel of the AGV cart, a diaphragm pump, a material box, an ultrasonic distance measuring meter and a flash alarm are arranged at the upper end of the vehicle body, and a frame is fixedly installed at the front end of the vehicle body. According to the intelligent lineation vehicle guided by the unmanned aerial vehicle, the cart is driven in an unmanned-aerial-vehicle guiding mode to do longitudinal uniform linear motion, a nozzle achieves transverse front-and-back moving operation on guiding rails through the frame, and the nozzle can do accurate curvilinear motion along with a preset track. The intelligent lineation vehicle guided by an unmanned aerial vehicle is small and exquisite, visual, intelligent, efficient, easy to operate, high in lineationquality and capable of guaranteeing safety of constructors.

Owner:HENAN UNIV OF URBAN CONSTR

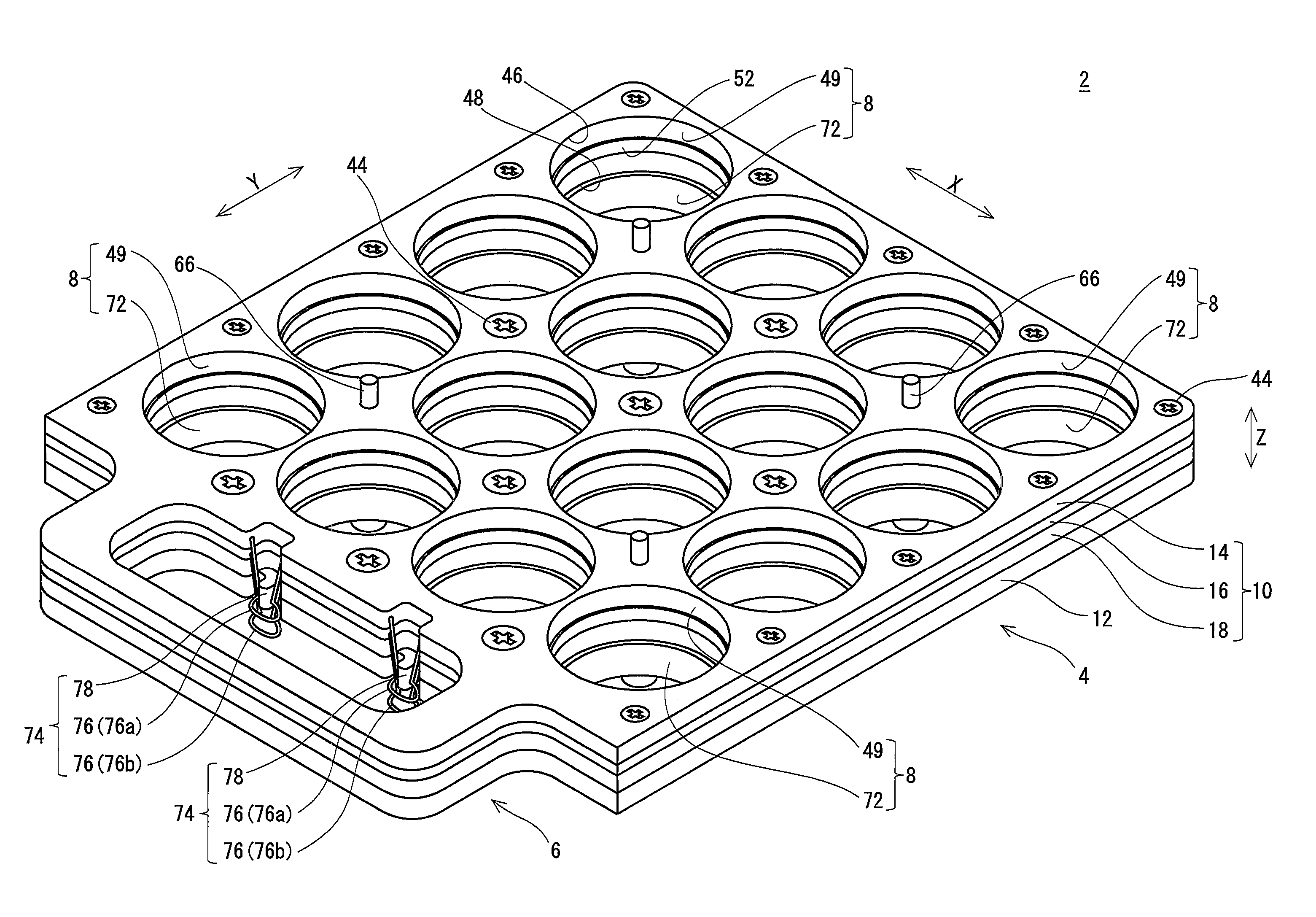

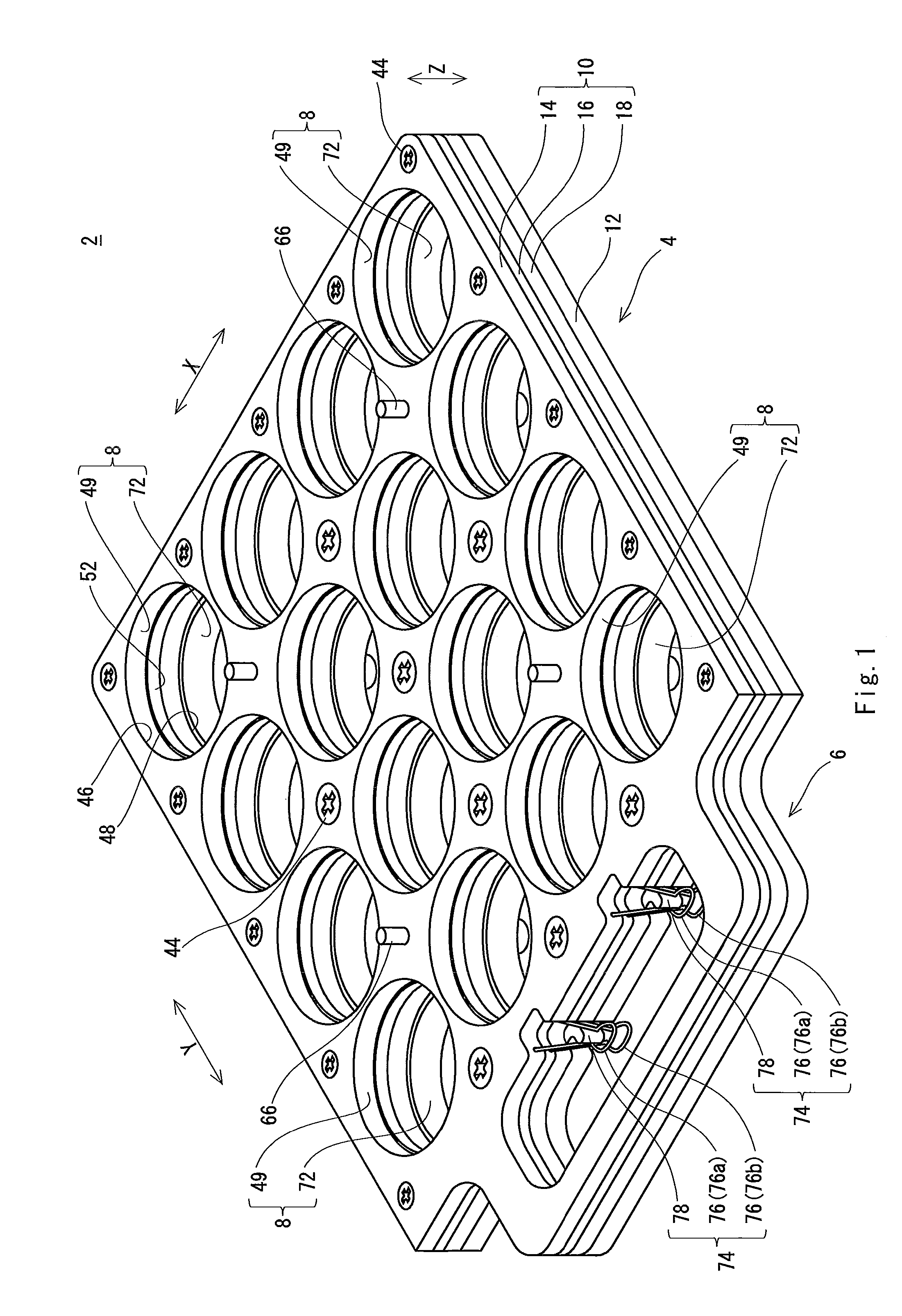

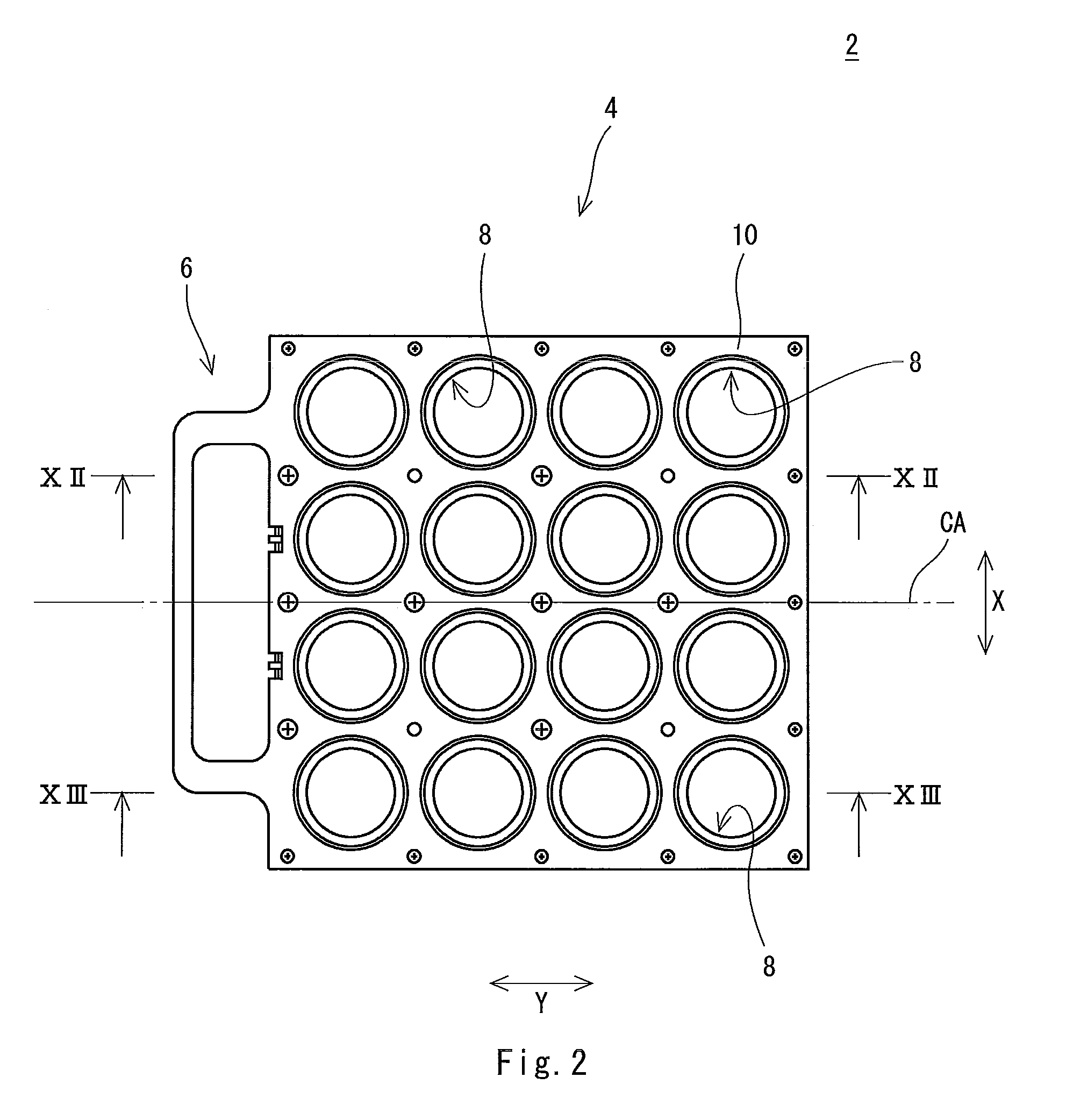

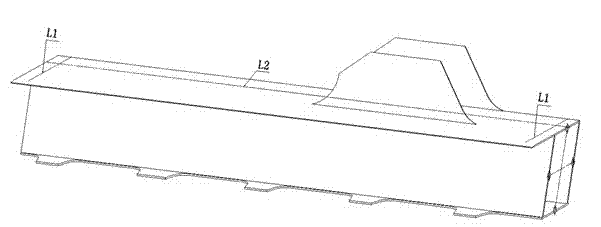

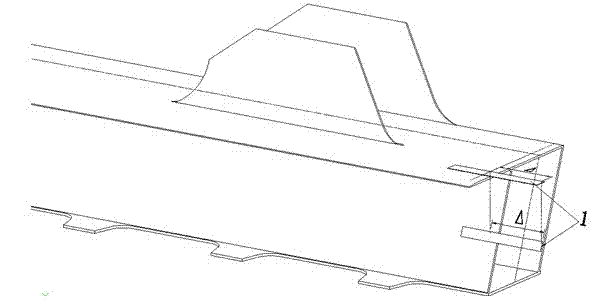

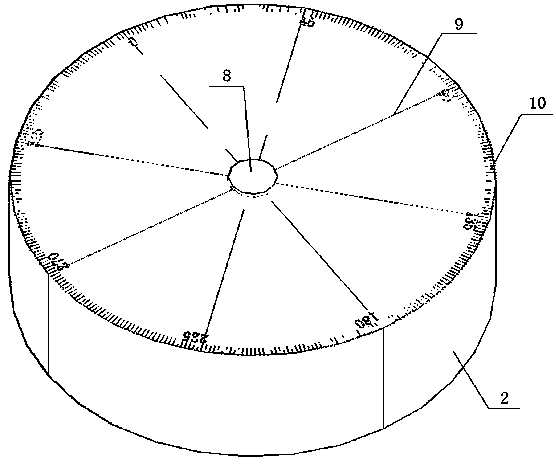

Tray for ink jet printer and method of manufacturing golf ball having mark

InactiveUS20100182368A1High marking accuracyImprove customer satisfactionTypewritersGolf ballsEngineeringGolf Ball

A tray 2 includes a holder 10 into which a golf ball is to be set. The holder 10 has: in an upper surface thereof and a lower surface thereof, openings 46 and 48 from which parts of the golf ball are exposed, respectively; and a contact portion 52 that comes into contact with the golf ball to fix in place the golf ball. The holder 10 is invertible. Preferably, the tray 2 further includes a base plate 12 on which the holder 10 is mounted. The base plate 12 has a stopper 72 that comes into contact with the golf ball set into the holder 10. The golf ball is fixed to the holder 10 such that the position of the center of the golf ball is caused to agree with the position of the center of the holder 10 in a thickness direction thereof due to this contact.

Owner:SUMITOMO RUBBER IND LTD

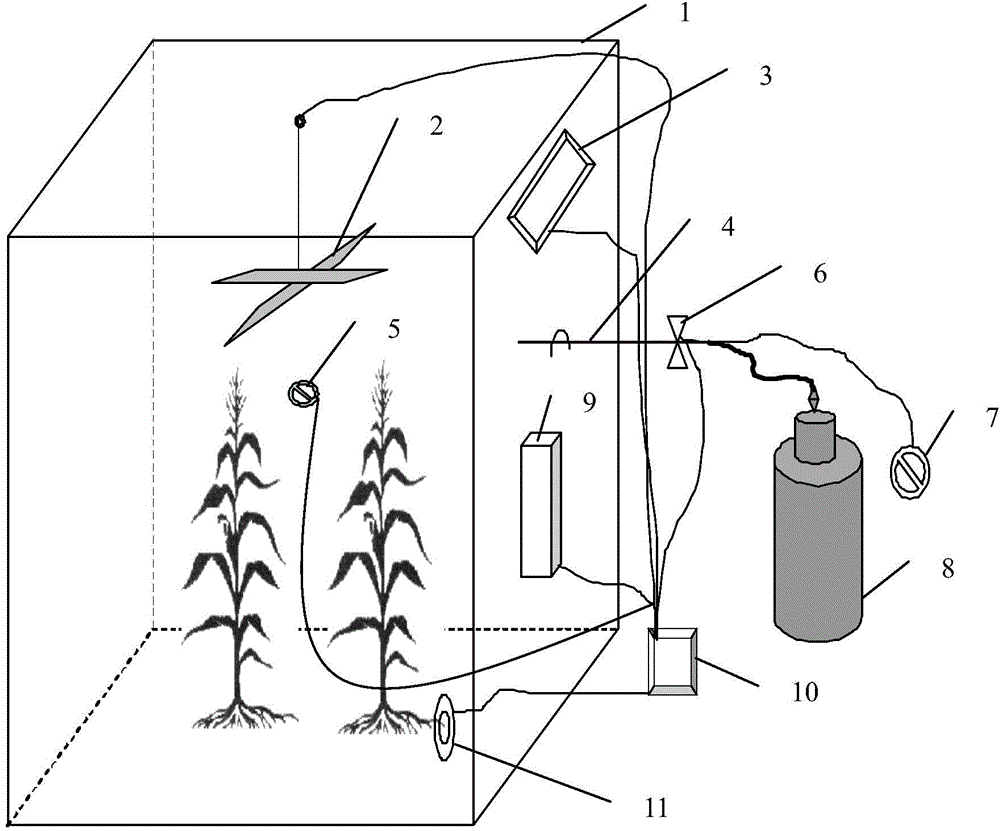

Field in-situ continuous low-abundance 13CO2 isotope labeling device and method

InactiveCN103598025AMark time is longReduce marking costsHorticulture methodsMaterial analysisAutomatic controlCombustor

The invention discloses a field in-situ continuous low-abundance 13CO2 isotope labeling device and method, relates to a simulator for detecting crop rhizosphere respiration and labeling plants, and solves the problems of low labeling precision and high cost of a pulse labeling mode of a traditional C element labeling device or method for the plants. A labeling box is a transparent box with a through hole in the side wall, a combustion end of a combustor penetrates the through hole of the labeling box and extends into the labeling box, the tail end of the combustor is simultaneously communicated with a gas outlet of a liquefied gas bottle and a gas outlet of an oxygen bottle, an electronic fire maker is arranged at the combustion end of the combustor, a fan is fixed to the middle of the inner top of the labeling box, an air conditioner is fixed to the upper portion of the side wall of the labeling box, a CO2 measurement and control device and a humidifier are positioned in the labeling box, a dehumidifier is fixed to the lower portion of the side wall of the labeling box, and the fan, the air conditioner, the CO2 measurement and control device, the electronic fire maker, the dehumidifier and the humidifier are controlled by an automatic control system. The device and the method are used for performing continuous low-abundance 13CO2 labeling for crops.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

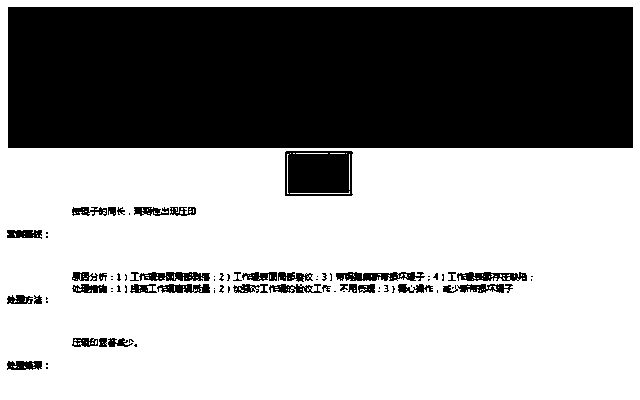

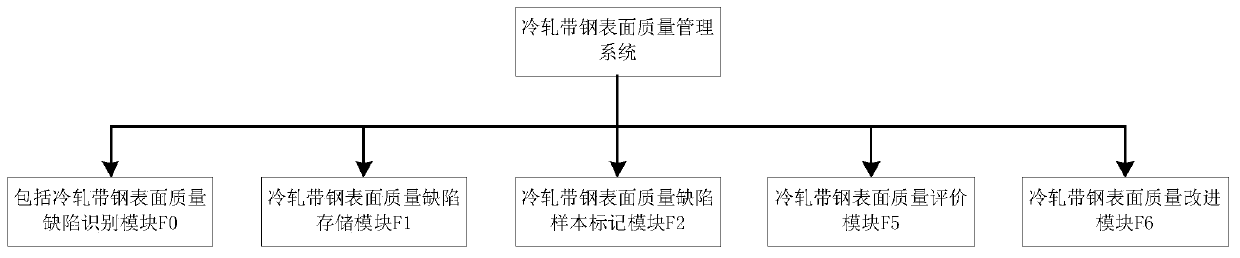

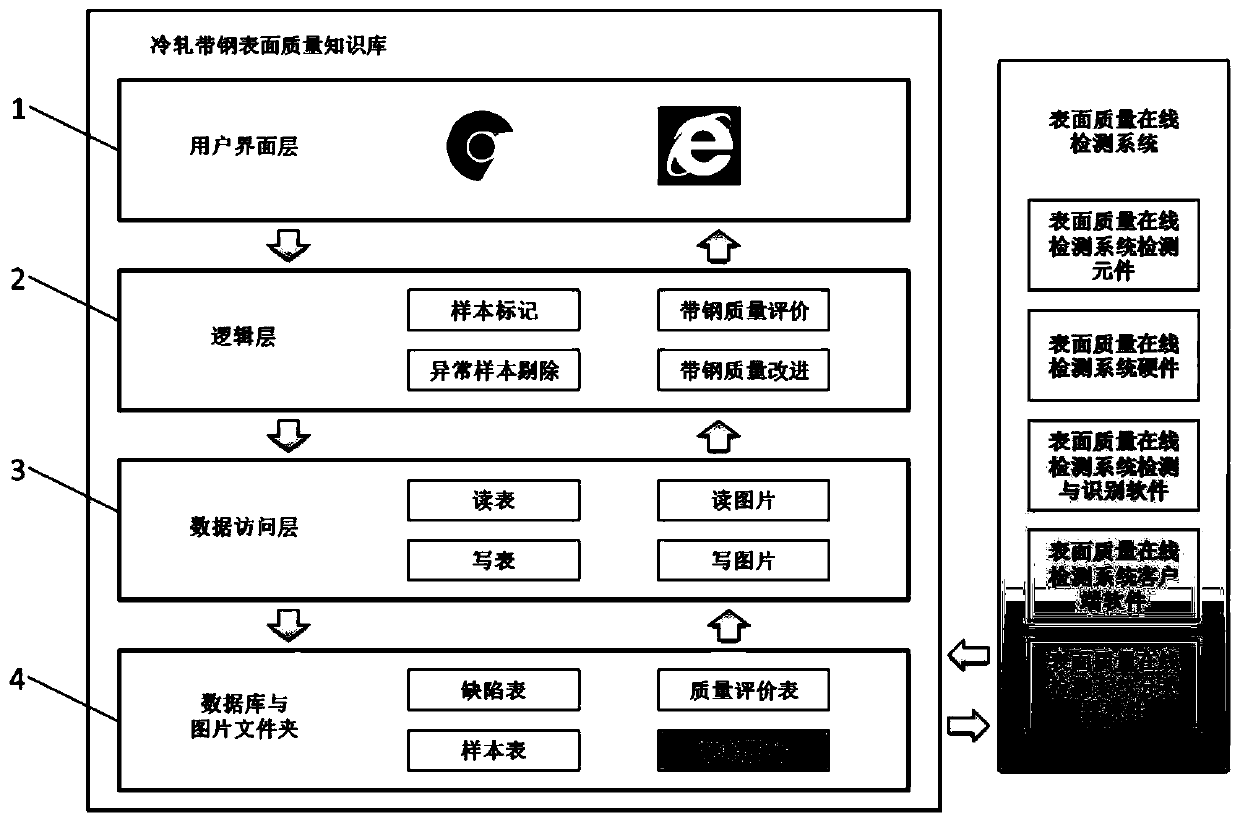

Cold-strip steel surface quality management system and method

ActiveCN109692877AImprove surface qualityHigh marking accuracyRoll mill control devicesMeasuring devicesCountermeasureStrip steel

The invention belongs to the technical field of cold-strip steel, and particularly relates to a cold-strip steel surface quality management system and method. To overcome the deficiency of an existingon-line cold-strip steel surface quality detection system, a defect sample is established, a cold-strip steel surface quality defect handling countermeasure table is established, the cold-strip steelsurface quality detection is associated with quality improvement, the cold-strip steel surface detects are matched with the defect sample to judge the surface quality grade of strip steel with the cold-strip steel surface quality defects, and therefore the production technology is guided to be improved, and the cold-strip steel surface quality is improved. In addition, the angular distance methodis adopted to eliminate abnormal samples, and therefore the defect sample marking accuracy rate can be improved.

Owner:WISDRI ENG & RES INC LTD

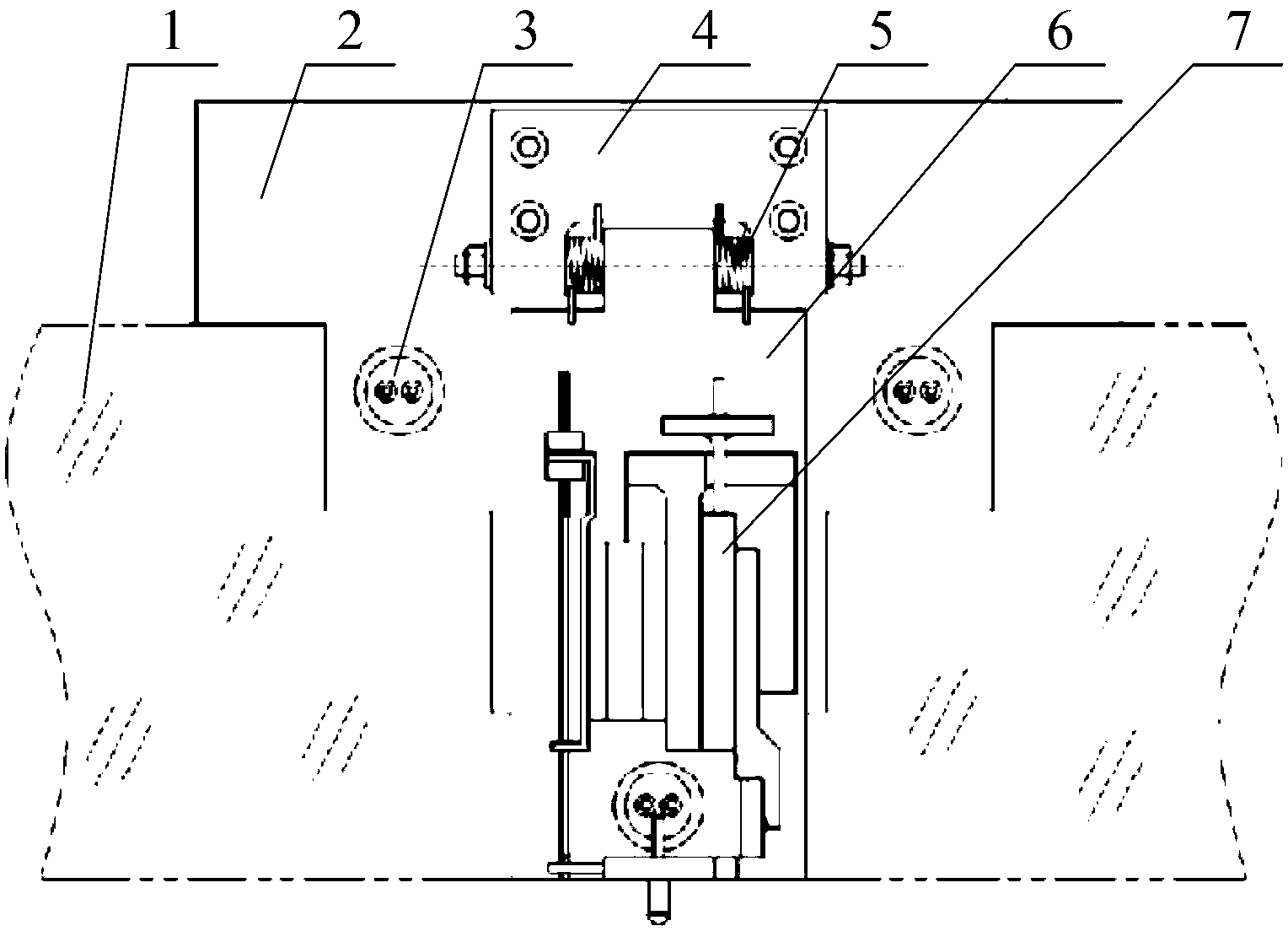

Pedestrian protecting vehicle scriber used for collision test

ActiveCN102501237AEasy to operateImprove marking efficiencyOther workshop equipmentUniversal jointScriber

The invention discloses a pedestrian protecting vehicle scriber used for a collision test, which comprises a movable base arranged in the Y direction, a horizontal moving rack, a longitudinal moving rod and a scribing rod, wherein the movable base is provided with a self-arranged leveling and fixing device; the horizontal moving rack and the movable base are in Y-direction sliding fit; a Z-direction extending vertical strut is fixed on the horizontal moving rack; the longitudinal moving rod is horizontally arranged on the vertical strut along the X direction; the longitudinal moving rod can horizontally slide along the X direction and the Z direction on the vertical strut and is locked and positioned; the scribing rod is arranged on one end of the longitudinal moving rod by a universal joint; and a space angle between the scribing rod and the longitudinal moving rod can be regulated at will. The pedestrian protecting vehicle scriber has the characteristics of low working intensity, high scribing efficiency and high scribing precision, is convenient and simple to operate, is convenient to move and saves space, can be made of belt trough aluminium profile, aluminium alloy plates and few steel materials to guarantee integral strength and have portability. The pedestrian protecting vehicle scriber is suitable for various vehicle collision test processes to serve as an auxiliary tool to carry out pedestrian protecting scribing operation.

Owner:长城汽车股份有限公司平湖分公司

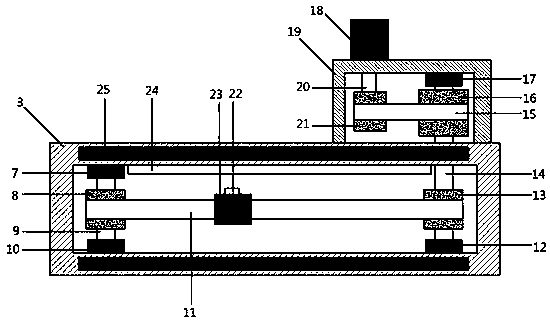

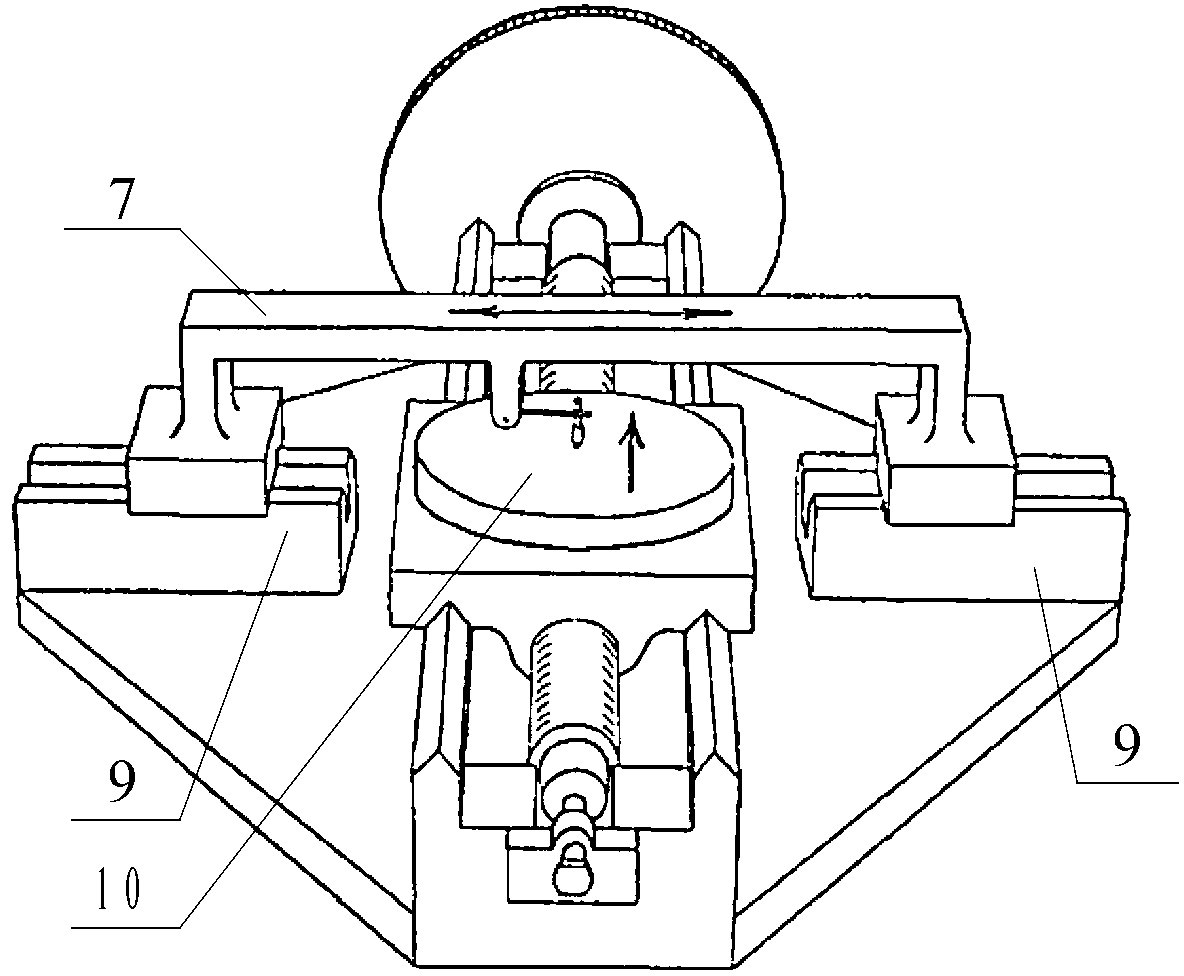

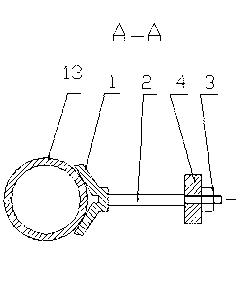

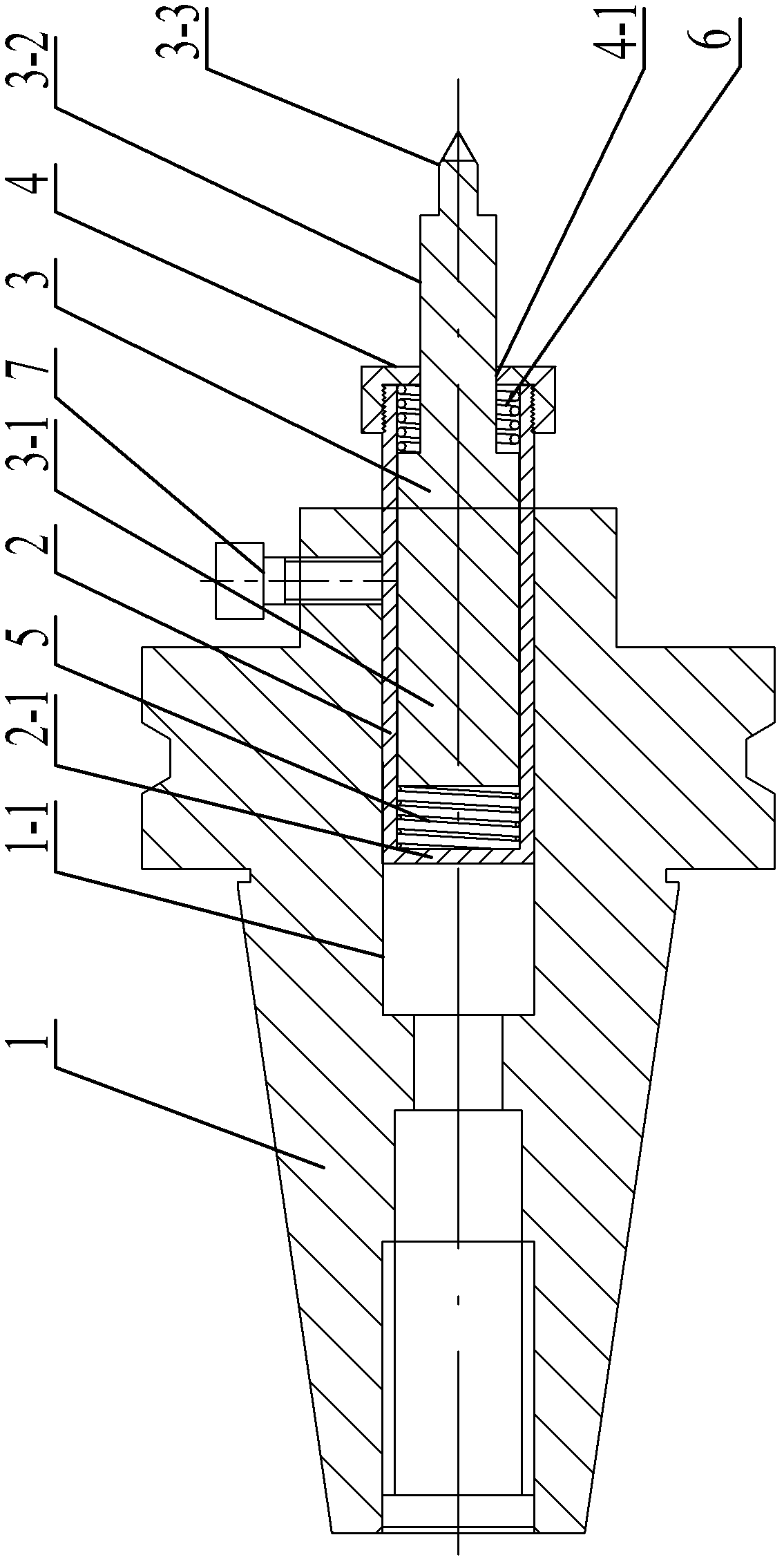

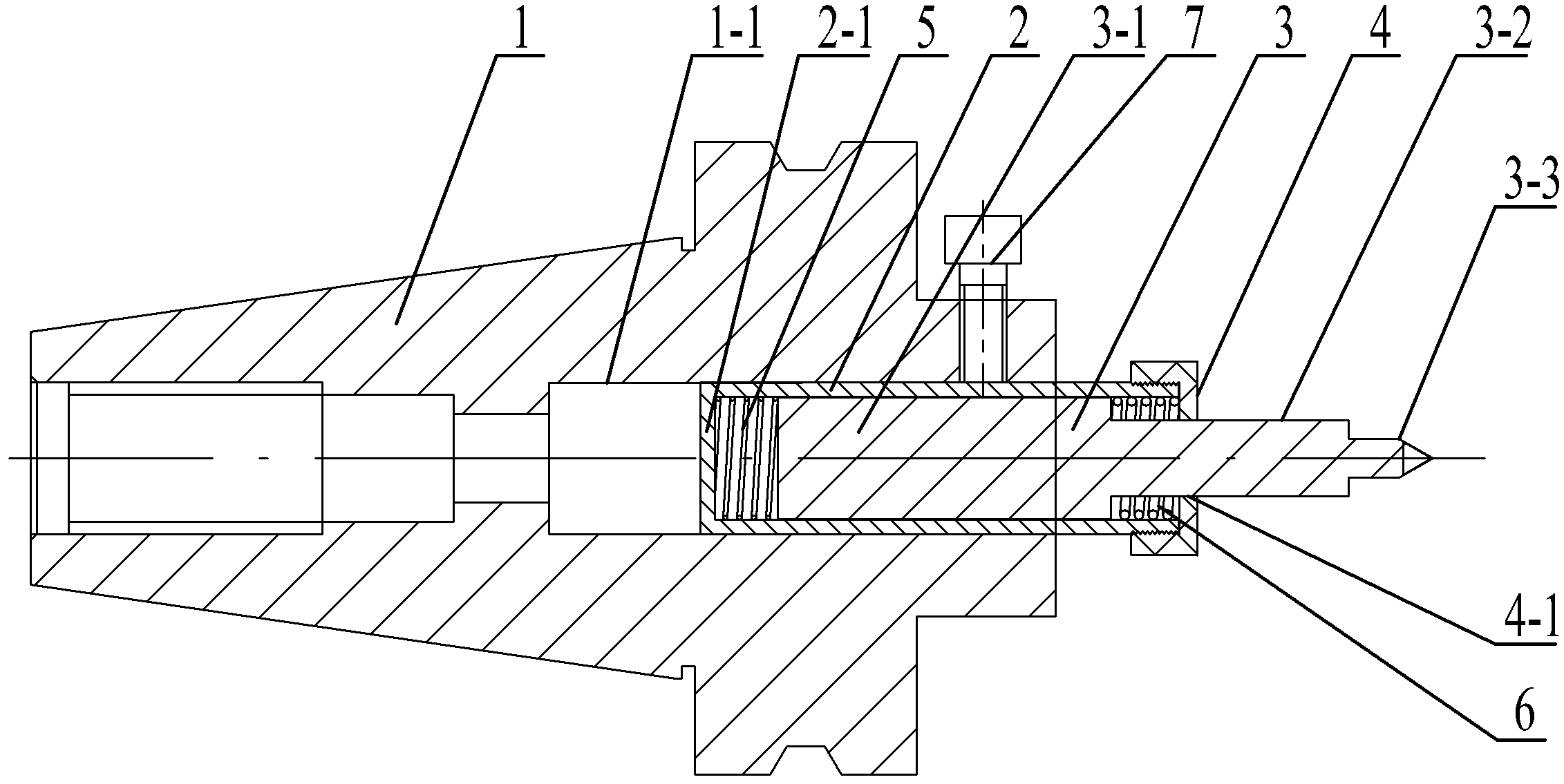

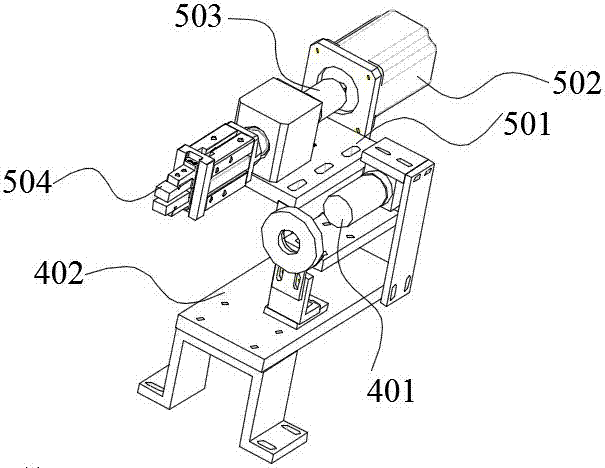

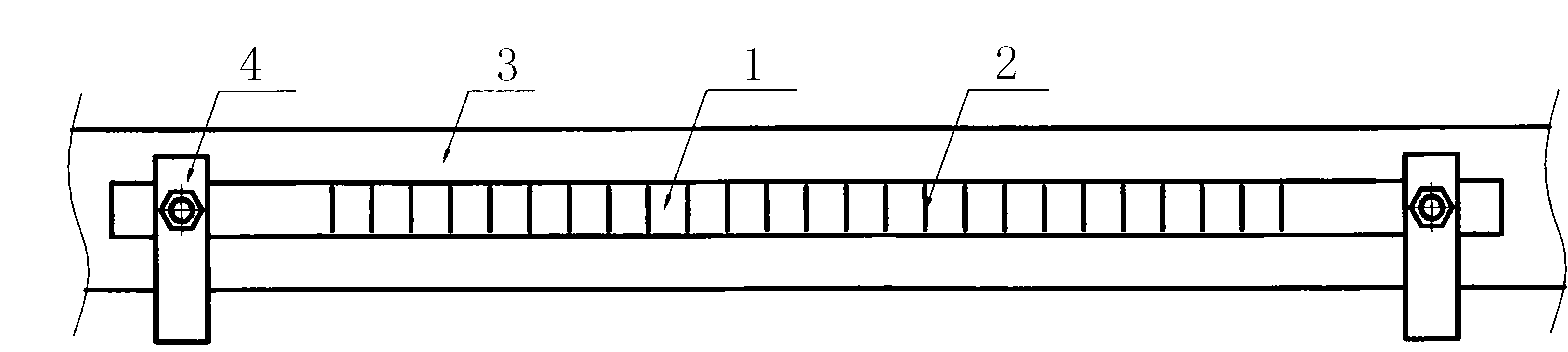

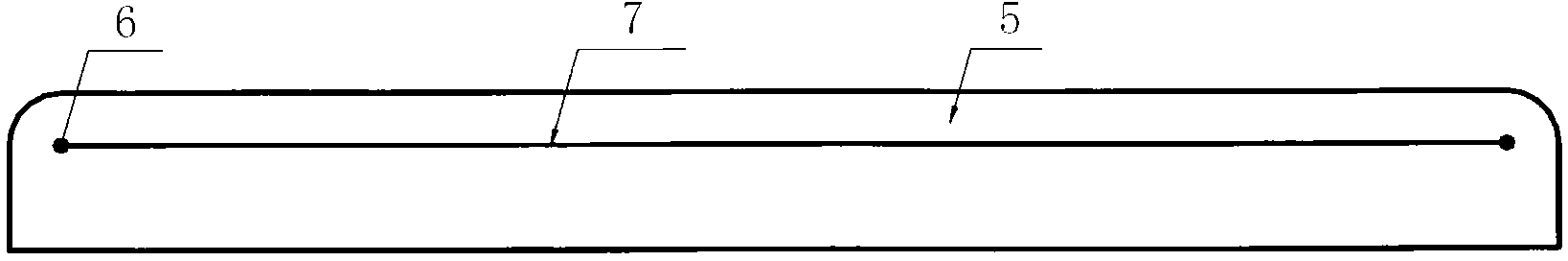

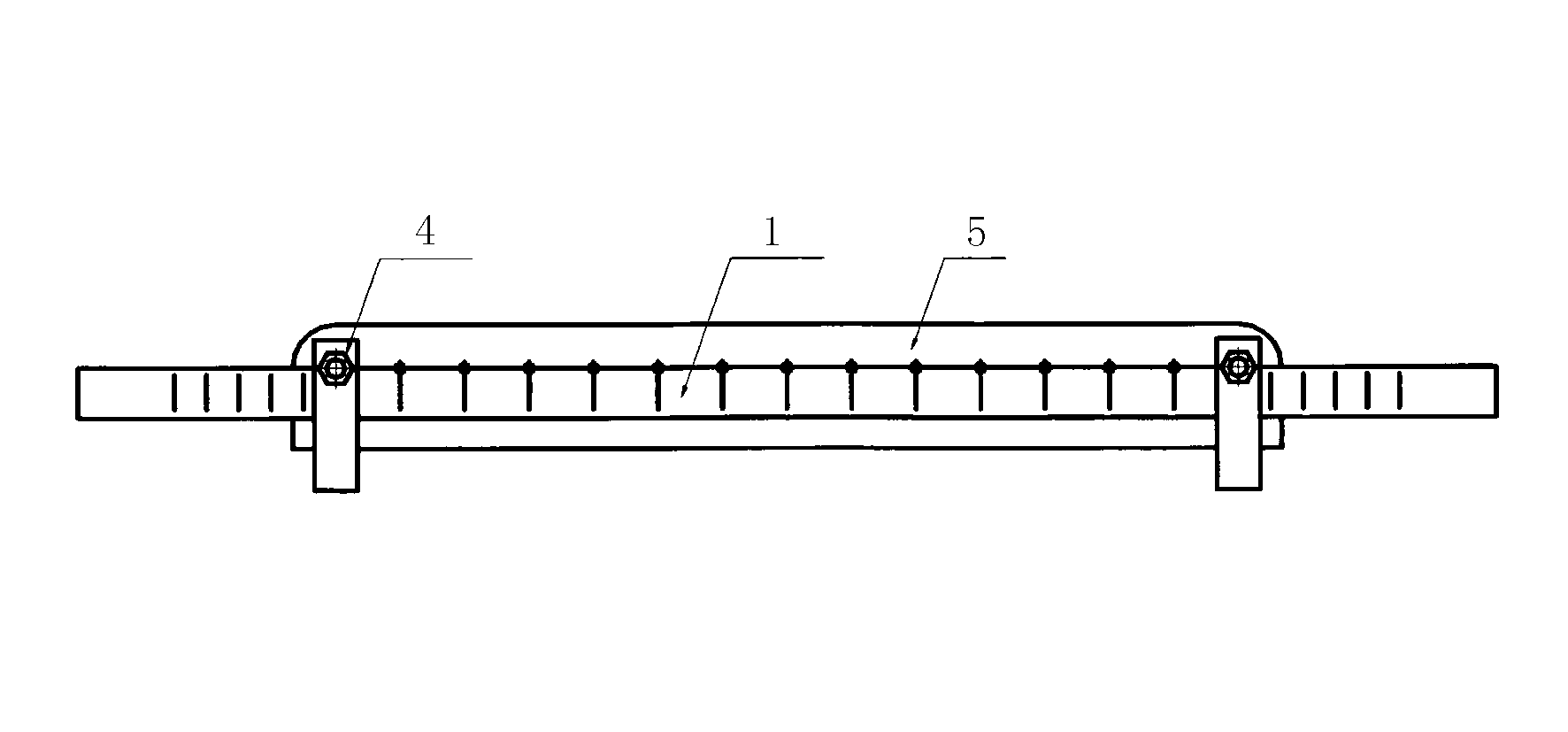

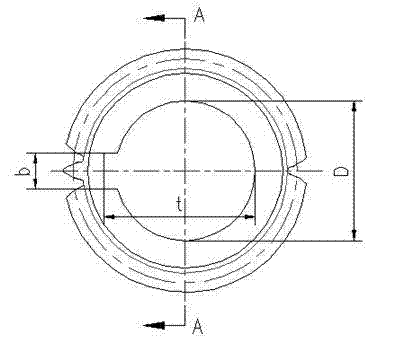

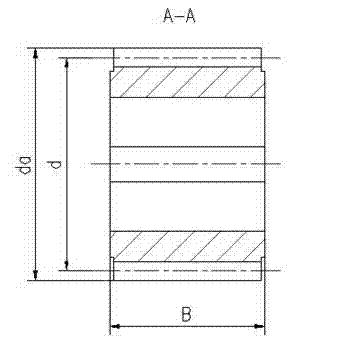

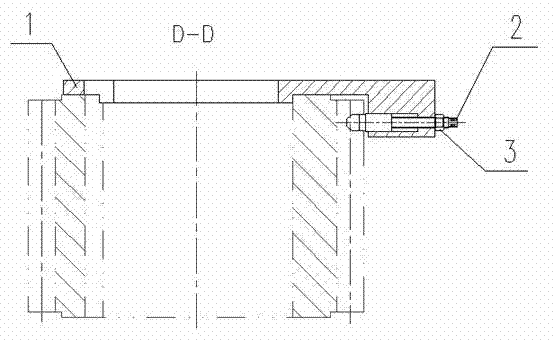

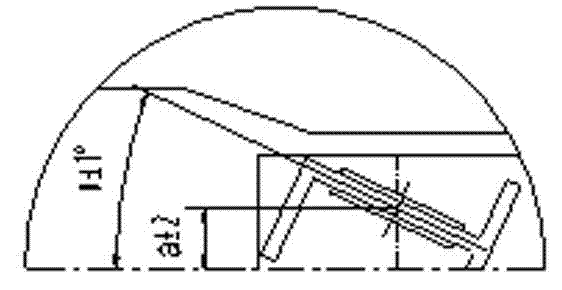

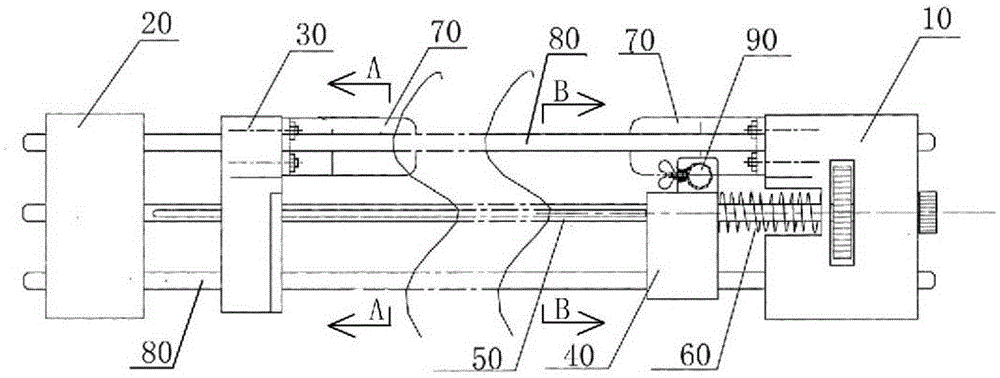

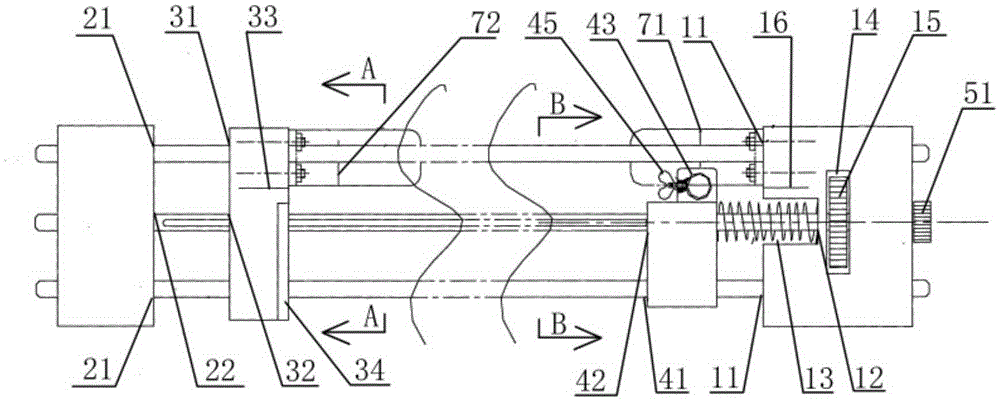

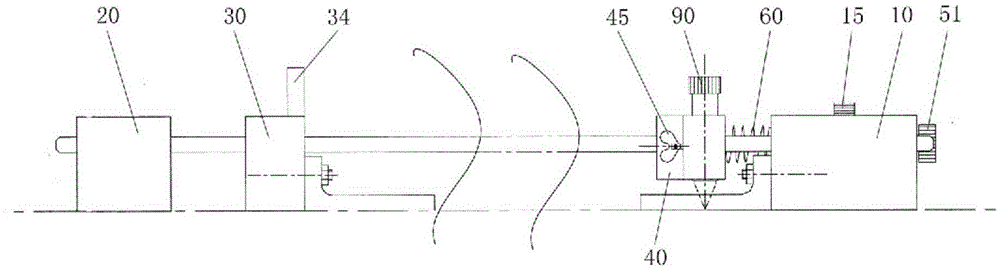

Cutter frame system of grating ruling engine

The invention provides a cutter frame system of a grating ruling engine, and belongs to the field of grating ruling machinery. The cutter frame system aims at solving the problems that machining and assembly in the prior art are large in difficulty and large-area grating ruling is not benefited. A sliding block of the cutter frame system is arranged on a guide rail in a cross mode and slides along the guide rail. A horizontal surface and a second side surface of the sliding block are provided with guide sliding feet, a first side surface is provided with elastic sliding feet, and the elastic sliding feet and the guide sliding feet are contacted with the guide rail. A cutter frame installation plate is movably connected with a joint through a pin shaft, the lower end of the cutter frame installation plate is provided with guide sliding feet which are contacted with the guide rail, a ruling cutter frame is fixedly connected with the cutter frame installation plate, and the elastic sliding feet tightly press one guide sliding foot of the ruling cutter frame on a guide face of the guide rail. A single rectangular guide rail is used, the top face of the guide rail is used for bearing, side faces of the guide rail are used for guiding, a bearing function and a guide function are integrated on one guide rail, and therefore difficulty of the machining and the assembly is reduced. The size of the system is small and the weight of the system is low, and therefore the cutter frame system is suitable for the large-area grating ruling.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

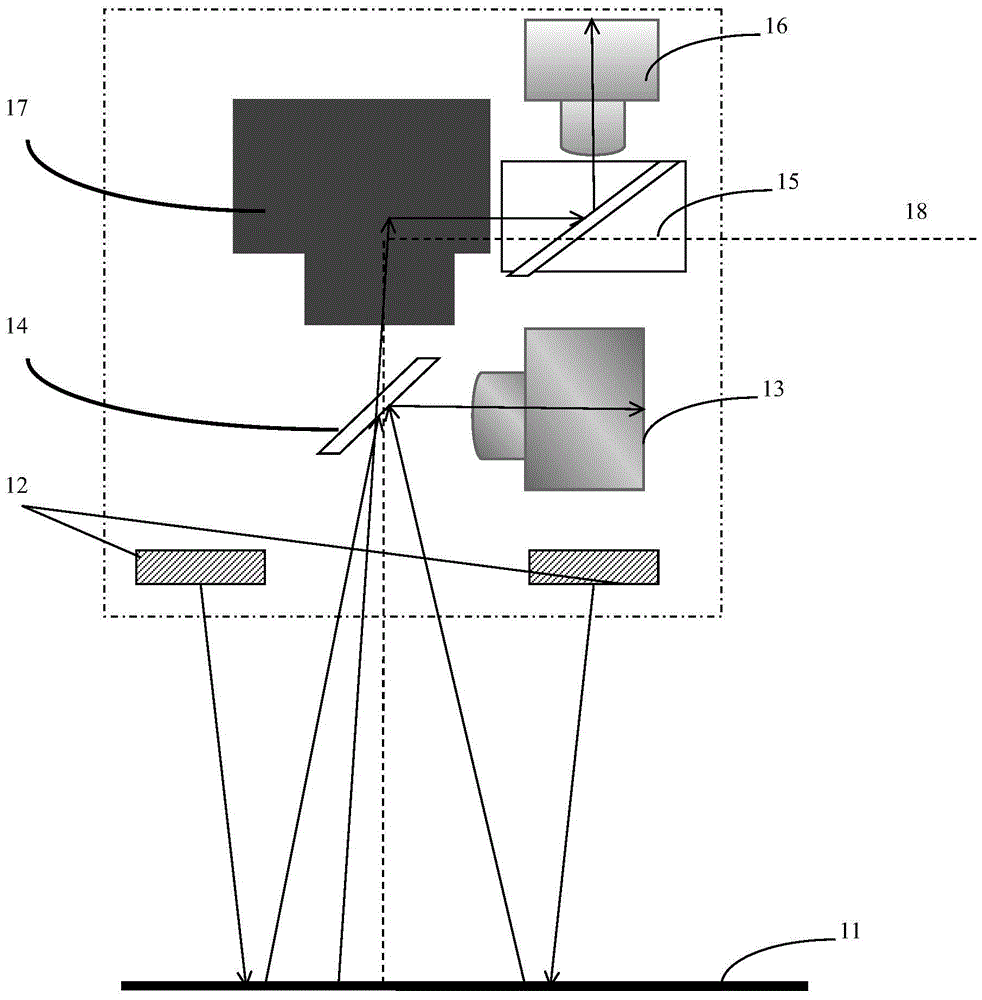

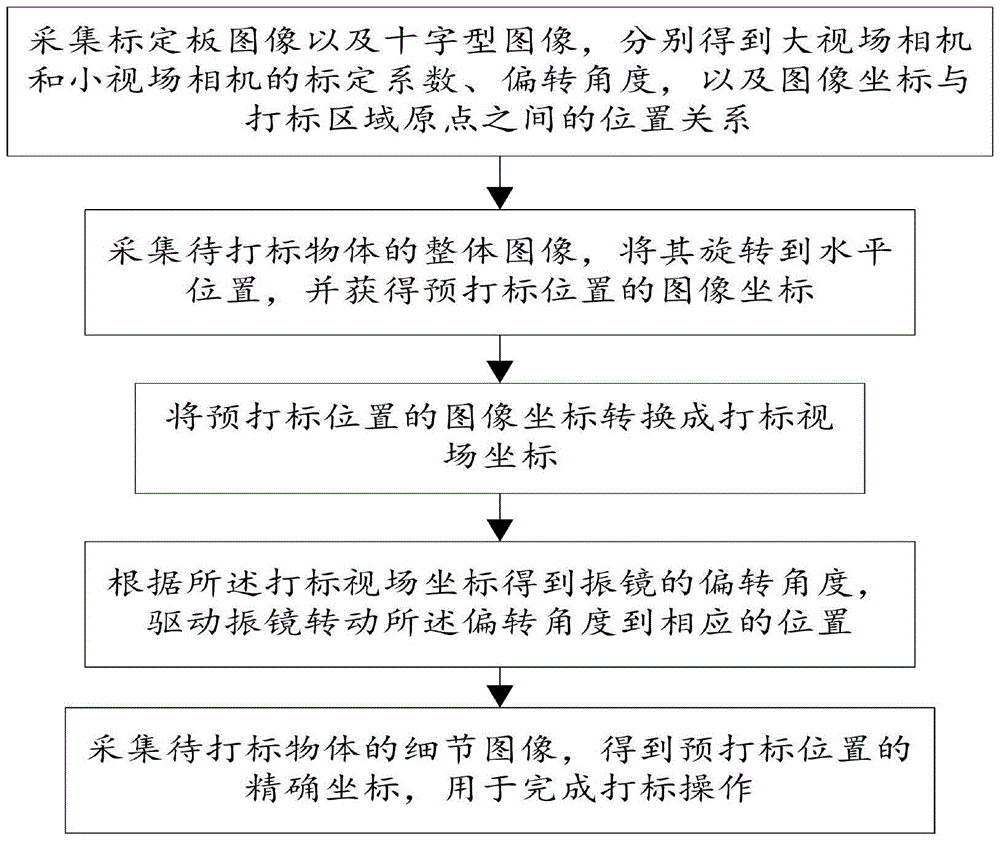

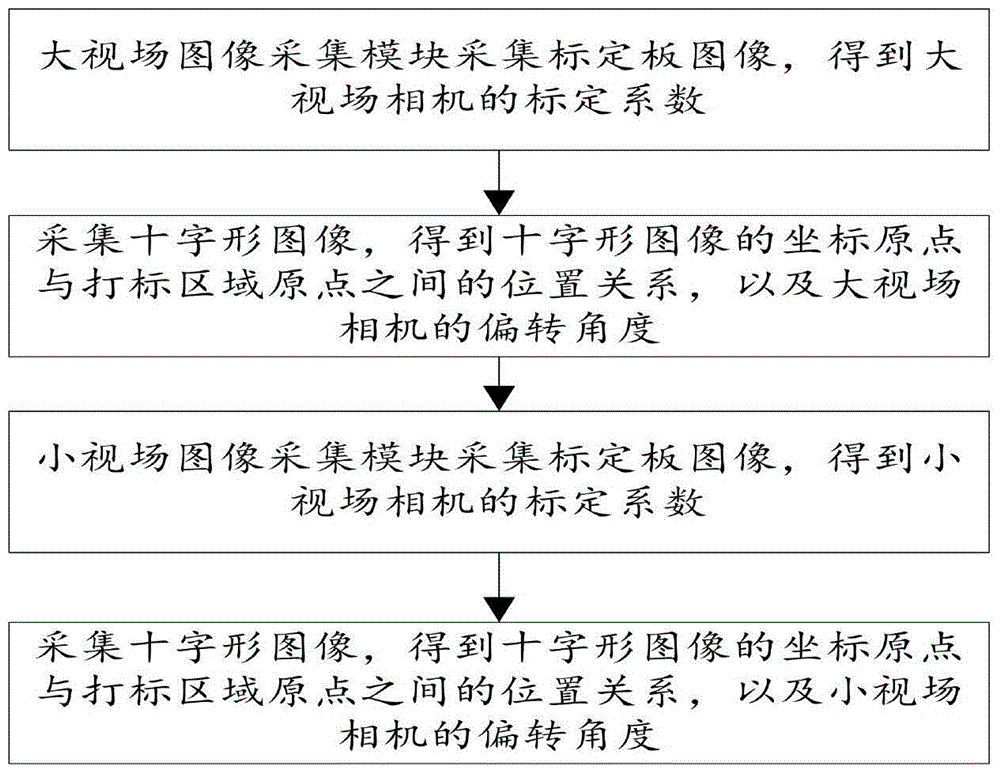

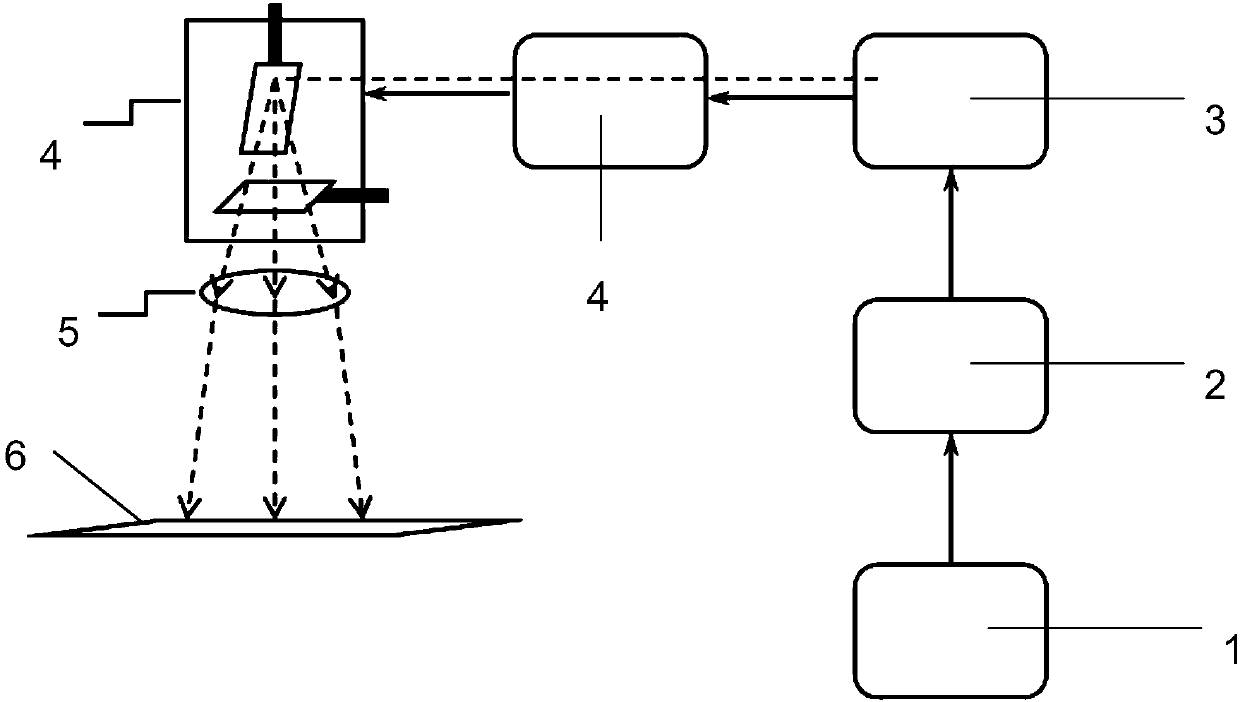

Imaging system and method of square scanning head of dual-light-path dual-imaging visual galvanometer

ActiveCN106392309AHigh marking accuracyImaging method is easy to implementLaser beam welding apparatusVisual field lossDual imaging

The invention relates to the technical field of laser processing, and discloses an imaging system and method of a square scanning head of a dual-light-path dual-imaging visual galvanometer. The imaging method comprises the steps that external laser beams reach the galvanometer through a second lens, and act on a to-be-marked object through a first lens after being reflected by the galvanometer, and then the to-be-marked object is marked; a white light source emits an illuminating light path to brighten the to-be-marked object, the illuminating light path is reflected to the first lens, then partially reflected to a large-visual-field image acquisition module through the first lens, and used for acquiring the overall image of the to-be-marked object, coordinates of an image in a pre-marking position are obtained accordingly, the swinging angle of the galvanometer is further obtained, and the galvanometer is driven to rotate by the swinging angle; and part of the illuminating light path reaches the galvanometer through the first lens, enters a small-visual-field image acquisition module after being reflected to the second lens, and is used for acquiring detailed images of the to-be-marked object, and the accurate coordinates of the pre-marking position are obtained according to the detailed images. By adoption of the imaging system and method of the square scanning head of the dual-light-path dual-imaging visual galvanometer, the marking precision of the square marking head can be greatly improved.

Owner:深圳市大族机器人有限公司

Combined scribing instrument

InactiveCN101758493ARealize one machine with multiple functionsImprove marking efficiencyOther workshop equipmentEngineeringRocker arm

The invention discloses a combined scribing instrument consisting of a base, an upright post, a rocker arm shaft, a vertical shaft, a horizontal shaft, a positioning sleeve, a sliding sleeve and scratch awls, wherein the rocker arm shaft is parallel to the horizontal shaft; the scratch awls are respectively arranged at one end of the rocker arm shaft and one end of the horizontal shaft; and a short shaft is parallel to the vertical shaft; the scratch awls are respectively arranged at one end of the short shaft and one end of the vertical shaft and are respectively mutually connected and positioned through the sliding sleeve and the positioning sleeve so as to form a basic structure with two horizontal devices and two vertical devices. With the structures of the rocker arm shaft, the vertical shaft, the horizontal shaft and the short shaft and by up-down and left-right movement or rotation of the sliding sleeve, the invention not only can align, scribe and singly scribe on the plane, but also can scribe three-dimensional parallel lines, three-dimensional vertical lines, circles, side circles, tip circles and the like, thereby realizing multifunction by one machine and improving the efficiency and the precision for scribing.

Owner:苏华礼

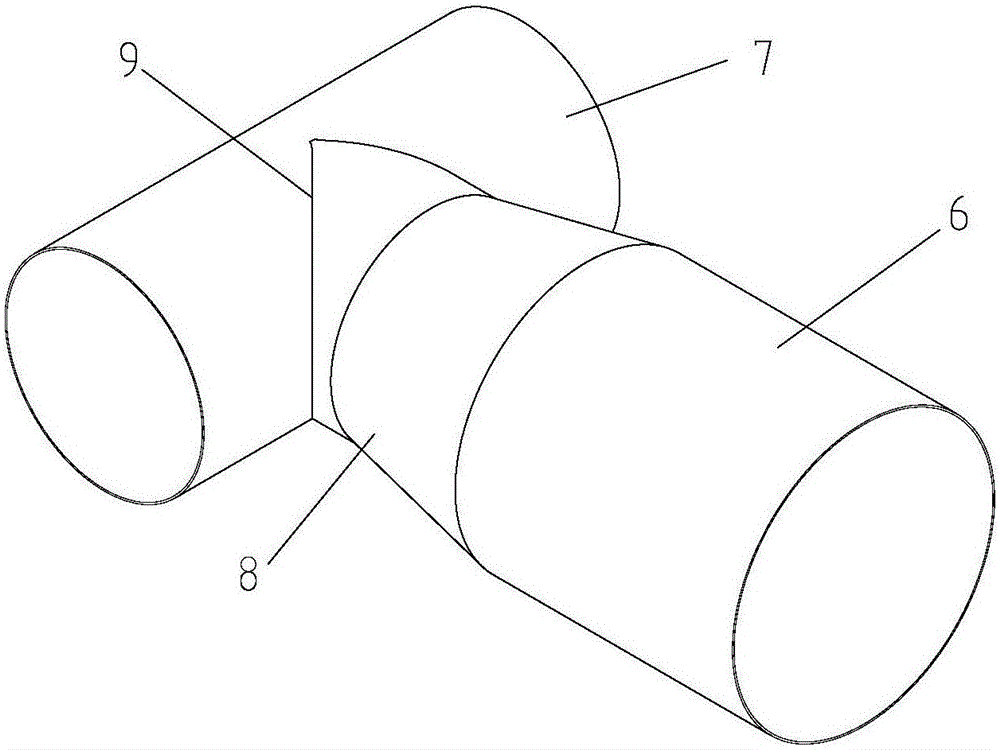

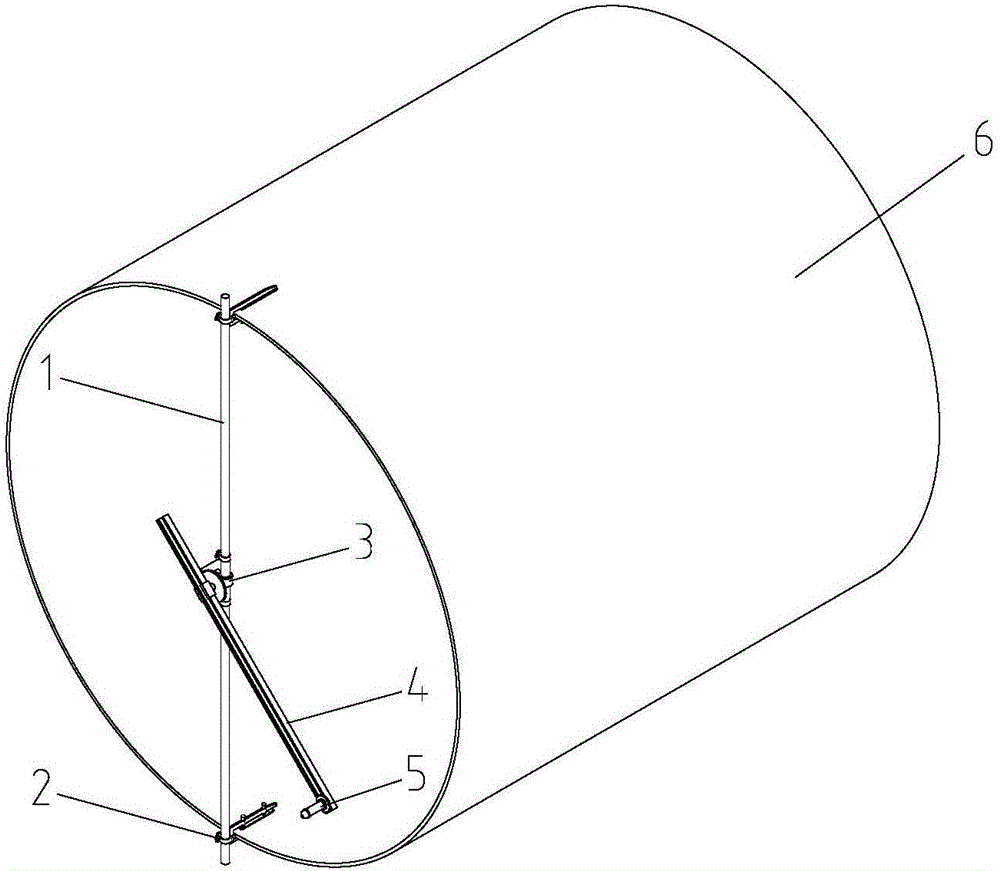

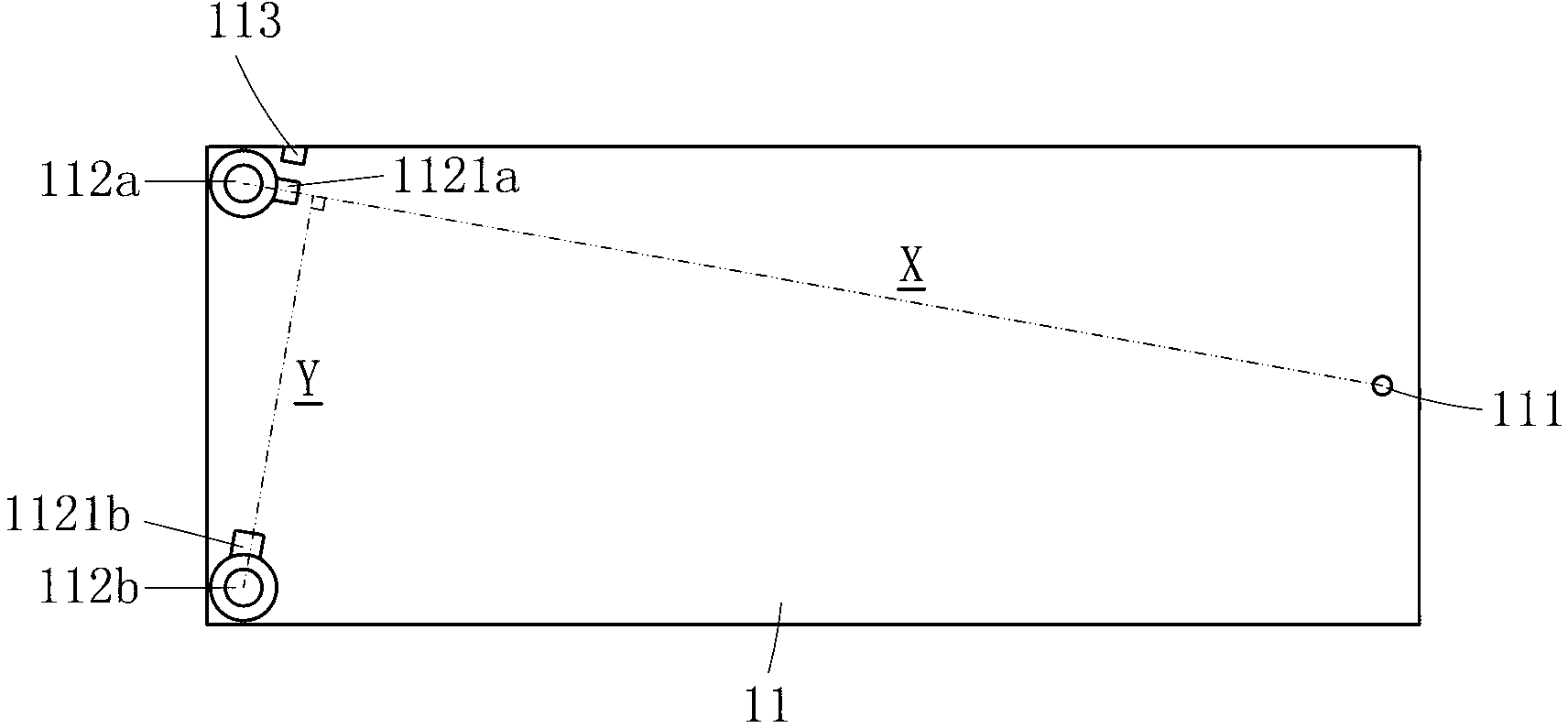

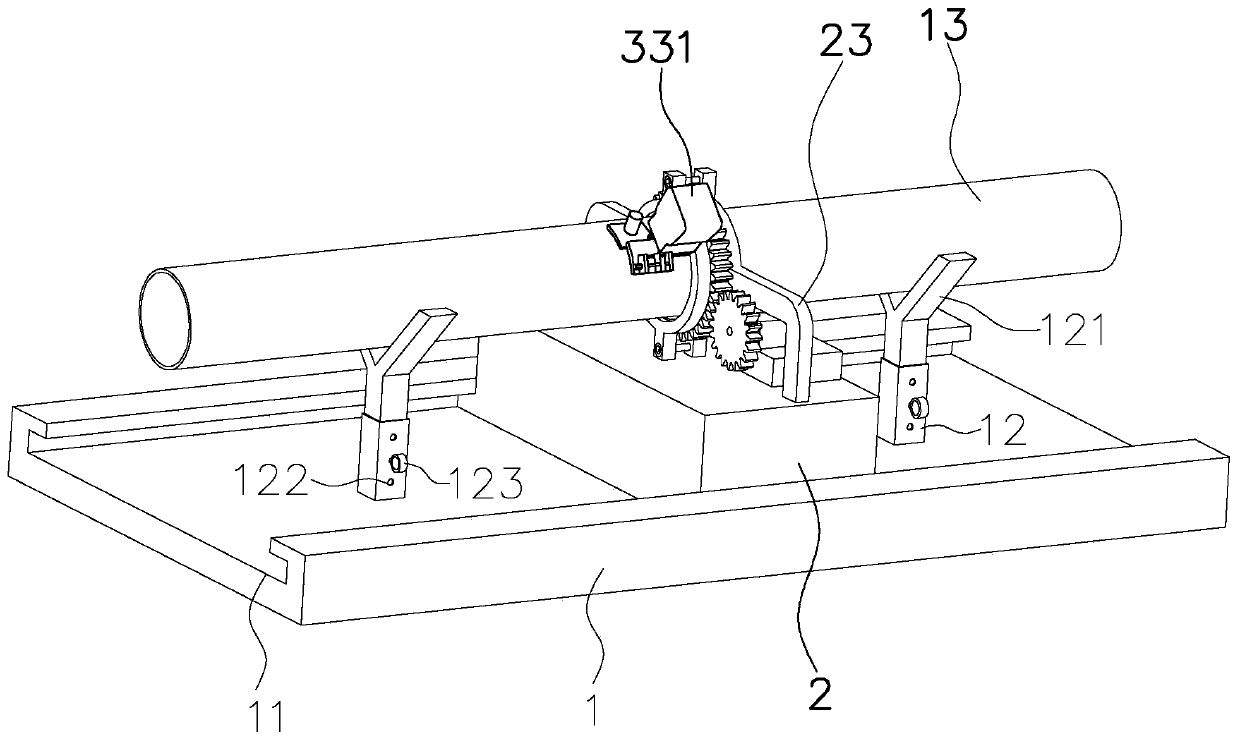

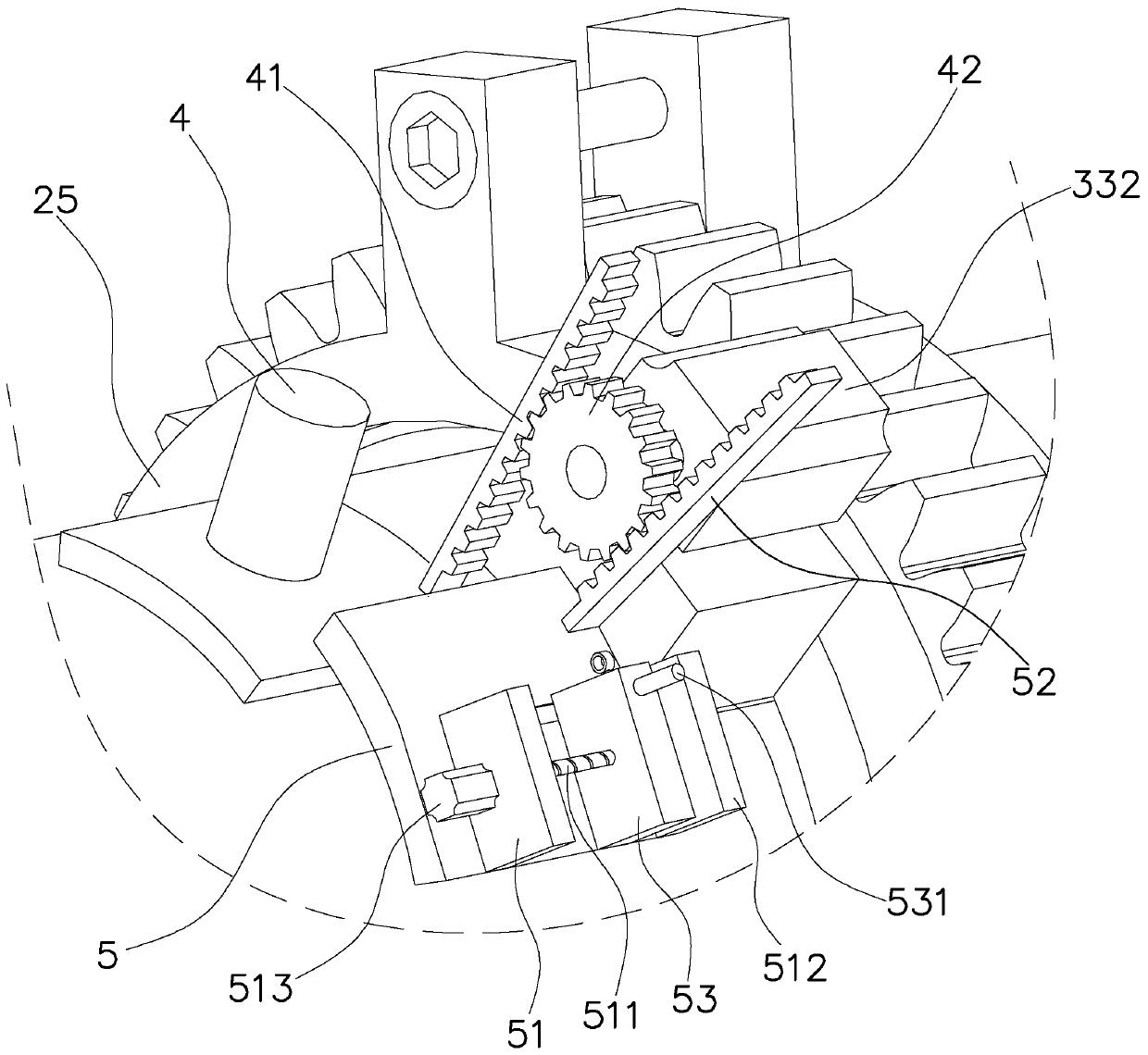

Intersecting line lineation instrument and method

ActiveCN105835023AQuick scribing operationHigh marking accuracyOther workshop equipmentEngineeringTransmitter

The invention discloses an intersecting line lineation instrument and method. The lineation instrument comprises a linear support, pipe wall clamps, an original point base, an inserting rod and an infrared projection device. The pipe wall clamps are arranged at the two ends of the linear support. The original point base is arranged on the linear support. The inserting rod is arranged on the original point base. The infrared projection device is arranged at one end of the inserting rod. Compared with the prior art, the intersecting line lineation instrument and method have the beneficial effects that firstly, the operation that the large radius of a pipeline is changed into the small radius, the small radius of the pipeline is changed into the large radius, and intersecting lines of pipelines with different elevations are subjected to lineation can be rapidly finished; and secondly, the linear support can be rapidly installed on the pipeline through the pipe wall clamps, the moving radius of an infrared transmitter can be rapidly adjusted on the original point base, a drive mechanism on the original point base is automatically rotated, the intersecting line lofting work is rapidly finished, and the lineation precision and work efficiency are improved.

Owner:CHINA THIRD METALLURGICAL GRP

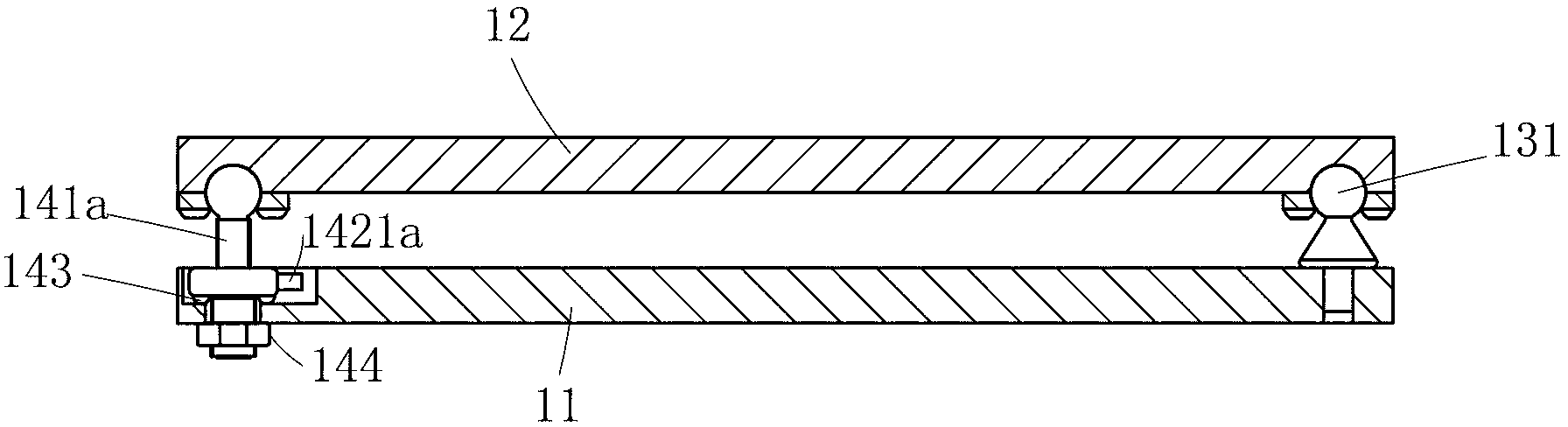

Plane trimming device and laser marking machine using plane trimming device

The invention discloses a plane trimming device and a laser marking machine using the plane trimming device, and relates to the technical field of plane adjusting equipment of precision machinery. The plane trimming device comprises an adjusting plate and a fixing plate, wherein the fixing plate and the adjusting plate are vertically connected together by three groups of support assemblies, the three groups of support assemblies are arranged in a triangle way, one of three groups of support assemblies is fixed support assemblies, and the other two groups of support assemblies are adjusting support assemblies. The plane trimming device has the advantages that the structure is simple, and the cost is low; a principle of using three points not in a common line to form a plane is utilized, so the precise adjusting of the parallel degree or the inclination degree between the two planes is realized, and easiness, convenience and easy implementation are realized; and the plane trimming device is applied to the laser marking machine, and on the premise of slight increase of the cost, the marking precision and the marking quality are greatly improved, and further the price-performance ratio of a product and the market competitiveness are improved.

Owner:WEIFANG LOKOMO PRECISION IND

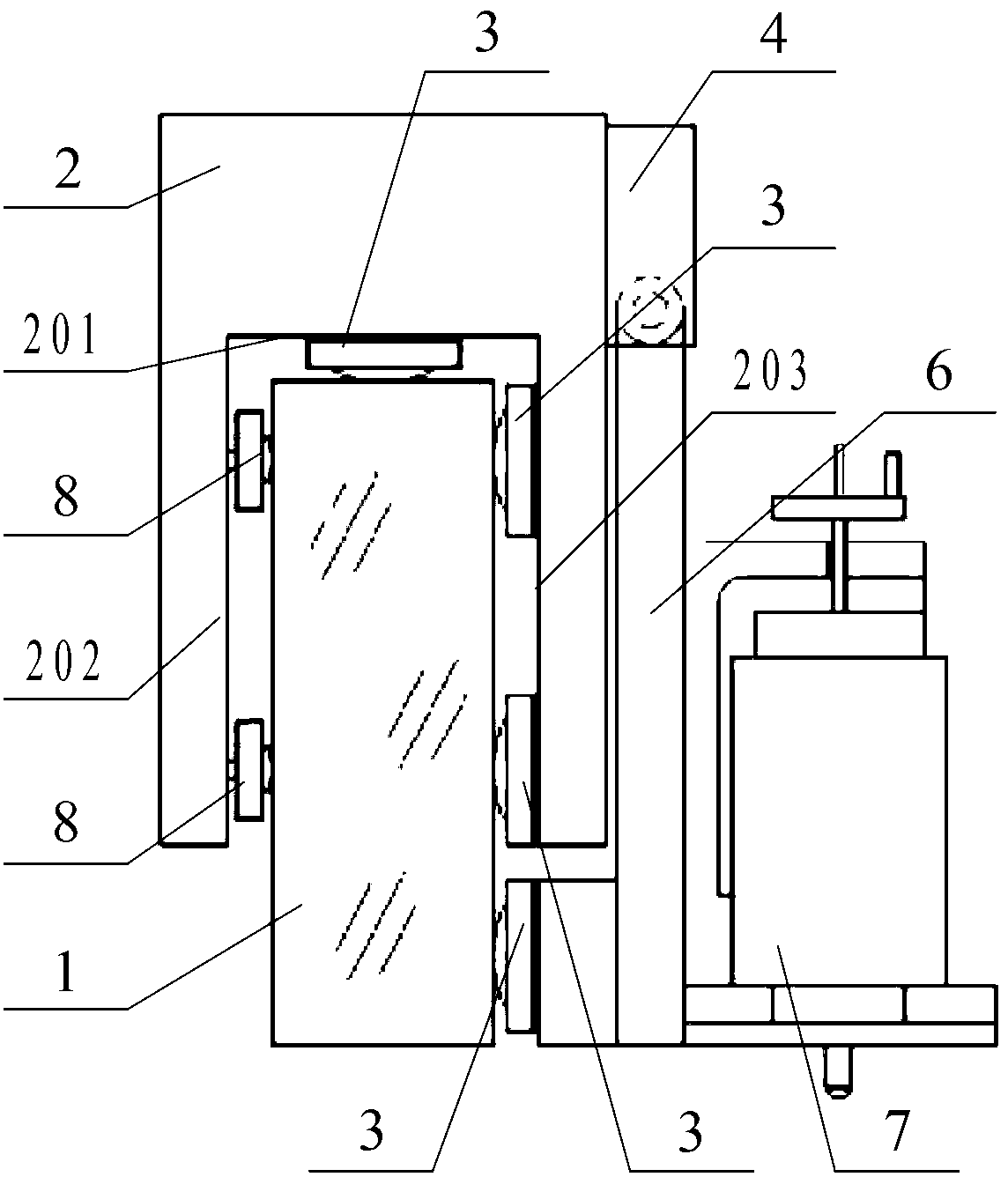

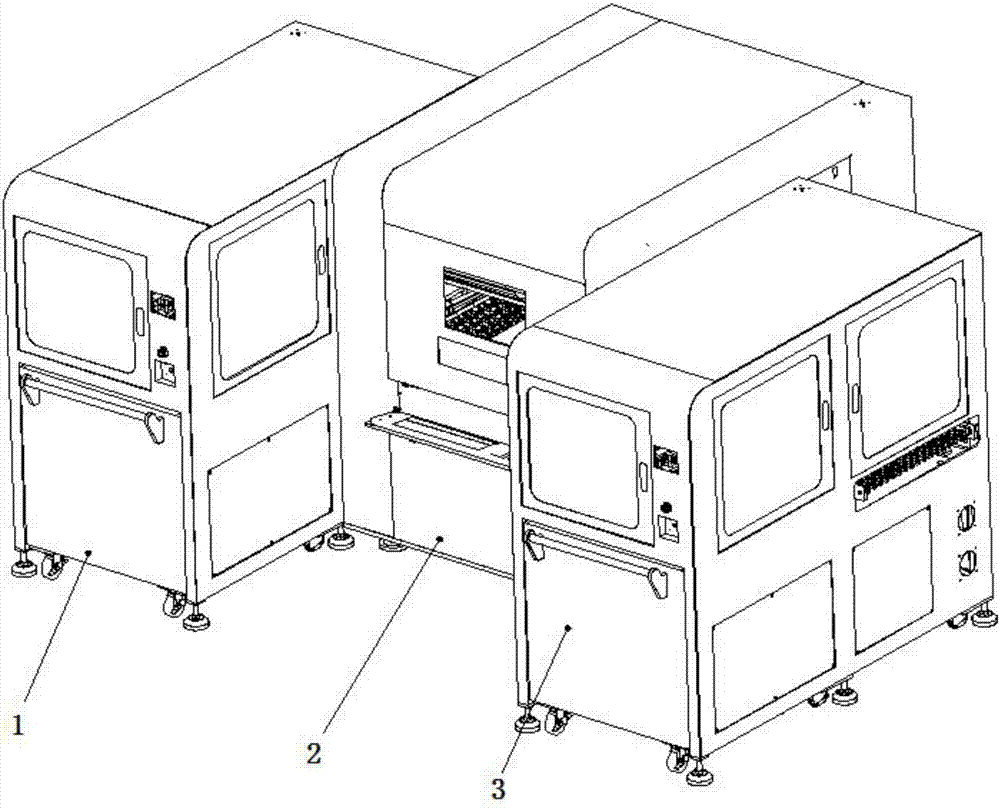

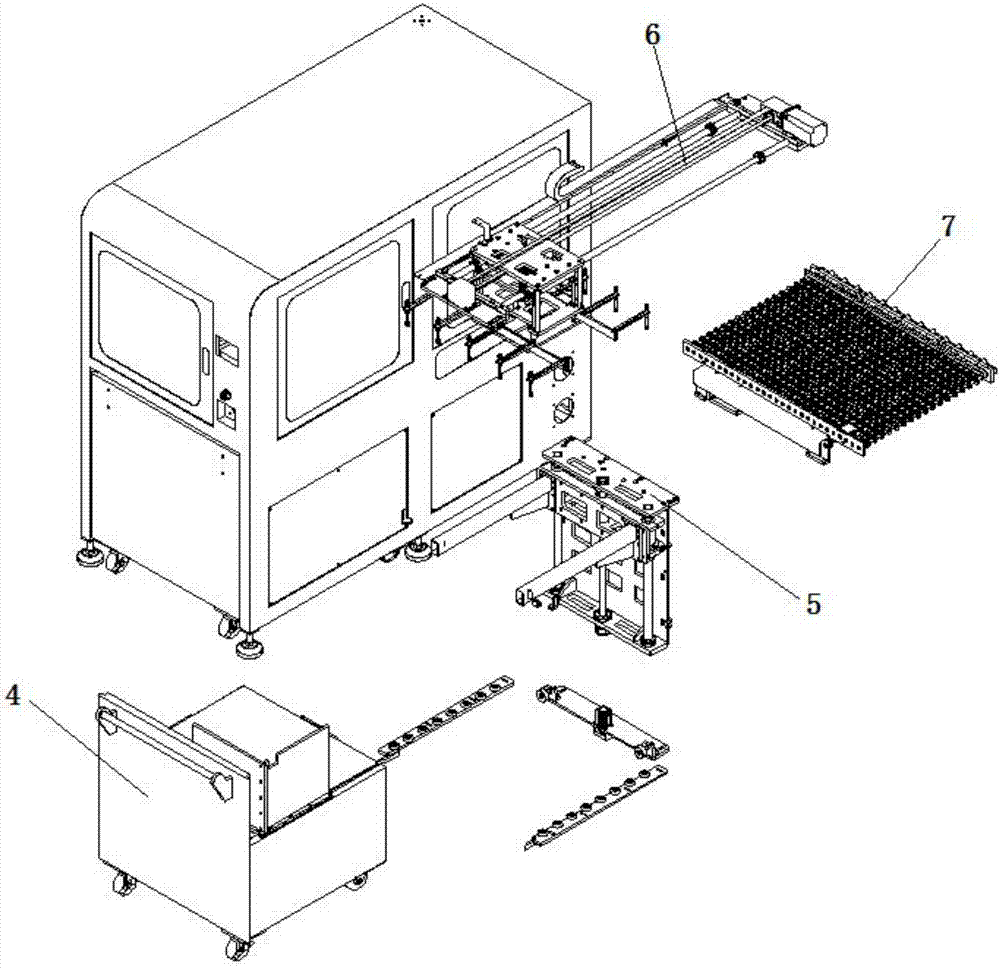

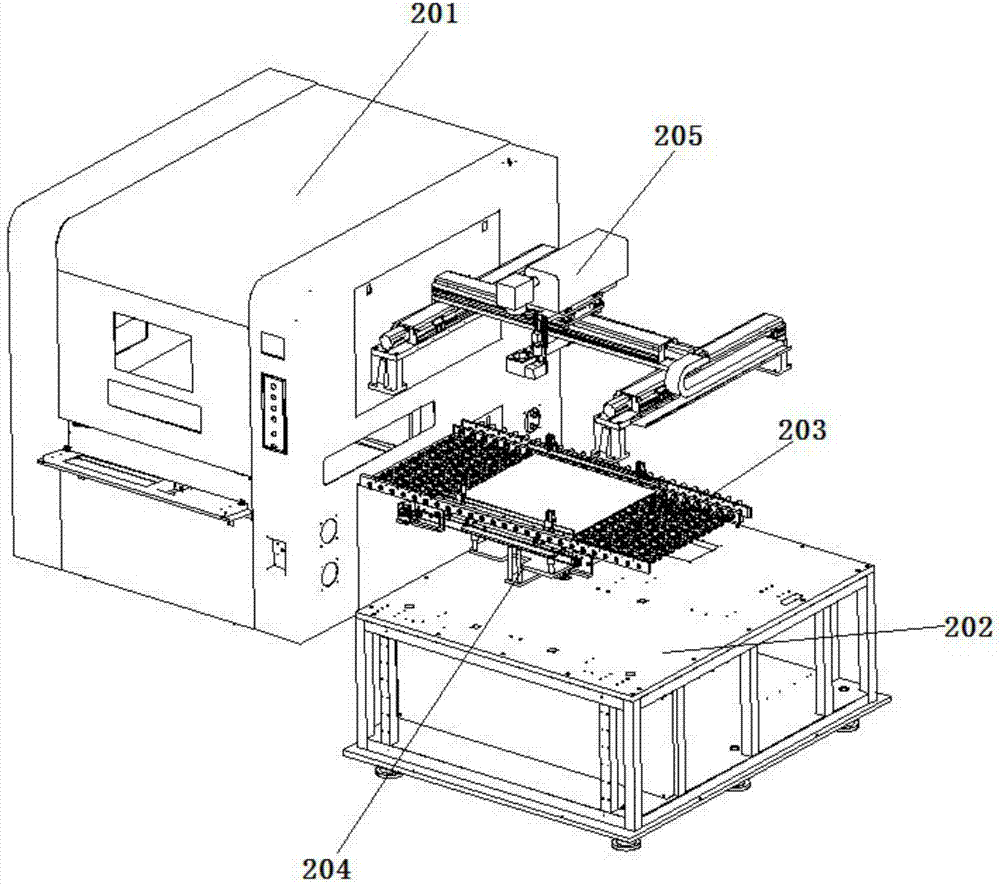

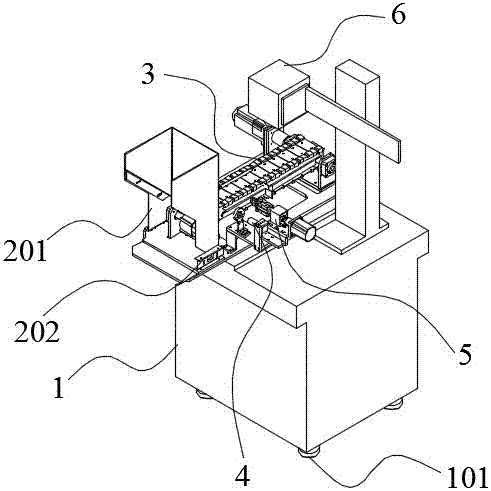

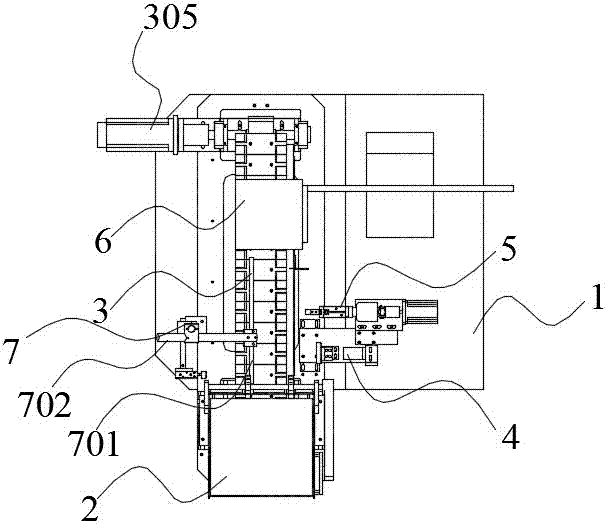

Automatic marking system

ActiveCN107009028AClosely connectedCooperate smoothlyLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses an automatic marking system which comprises a plate feeding device, a laser marking device and a plate discharging device, wherein a plate outlet of the plate feeding device corresponds to a plate inlet of the laser marking device; and a plate outlet of the laser marking device is opposite to a plate inlet of the plate discharging device. According to the system provided by the invention, the plate feeding device and the plate discharging device can realize automatic plate feeding and discharging; and all the components of the system are closely connected, and different working procedures are cooperated smoothly. A portal assembly in the laser marking device is of a dual-Y-shaft and X-shaft cooperation driving structure, and the double Y shafts can solve the problems of asynchronization of the two Y shafts, heavy shaking and the like in case of a large cross beam span. The marking speed and the precision are improved to a relatively large extent; and the height of a laser device can be finely adjusted (within a range of positive and negative 15 mm) through a screw rod, so that the automatic marking system can adapt to marking procedures of various PCBs with different thicknesses.

Owner:SHENZHEN SHENGDAKANG TECH CO LTD

Intelligent marking-out system for traffic marker line

InactiveCN103452034AAvoid interferenceAvoid exposureRoads maintainencePosition/course control in two dimensionsLaser transmitterIn vehicle

The invention relates to the technical field of traffic construction equipment and particularly relates to a marking-out system. An intelligent marking-out system for a traffic marker line comprises a movable vehicle body, wherein a marking-out device is placed on the movable vehicle body; the intelligent marking-out system further comprises a reference bracket; the reference bracket is provided with a guide frame and an auxiliary control module; a photosensitive element array is arranged on the surface of the guide frame; the movable vehicle body is provided with a vehicle-mounted bracket; the vehicle-mounted bracket is provided with a main laser transmitting device and a main control module; a transmitting end of the main laser transmitting device is arranged towards a receiving end of the photosensitive element array. A direction adjusting mechanism is arranged on the movable vehicle body. The main control module is connected with a control end of the main laser transmitting device and the direction adjusting mechanism respectively. The auxiliary control module is connected with a signal output end of a photosensitive element. The main control module is in signal connection with the auxiliary control module. With the adoption of the technical scheme, the function of automatically adjusting the direction is realized in the marking-out process; manual adjustment is not needed and the whole marking-out process is simple and convenient; the marking-out precision is high.

Owner:SHANDONG UNIV OF TECH

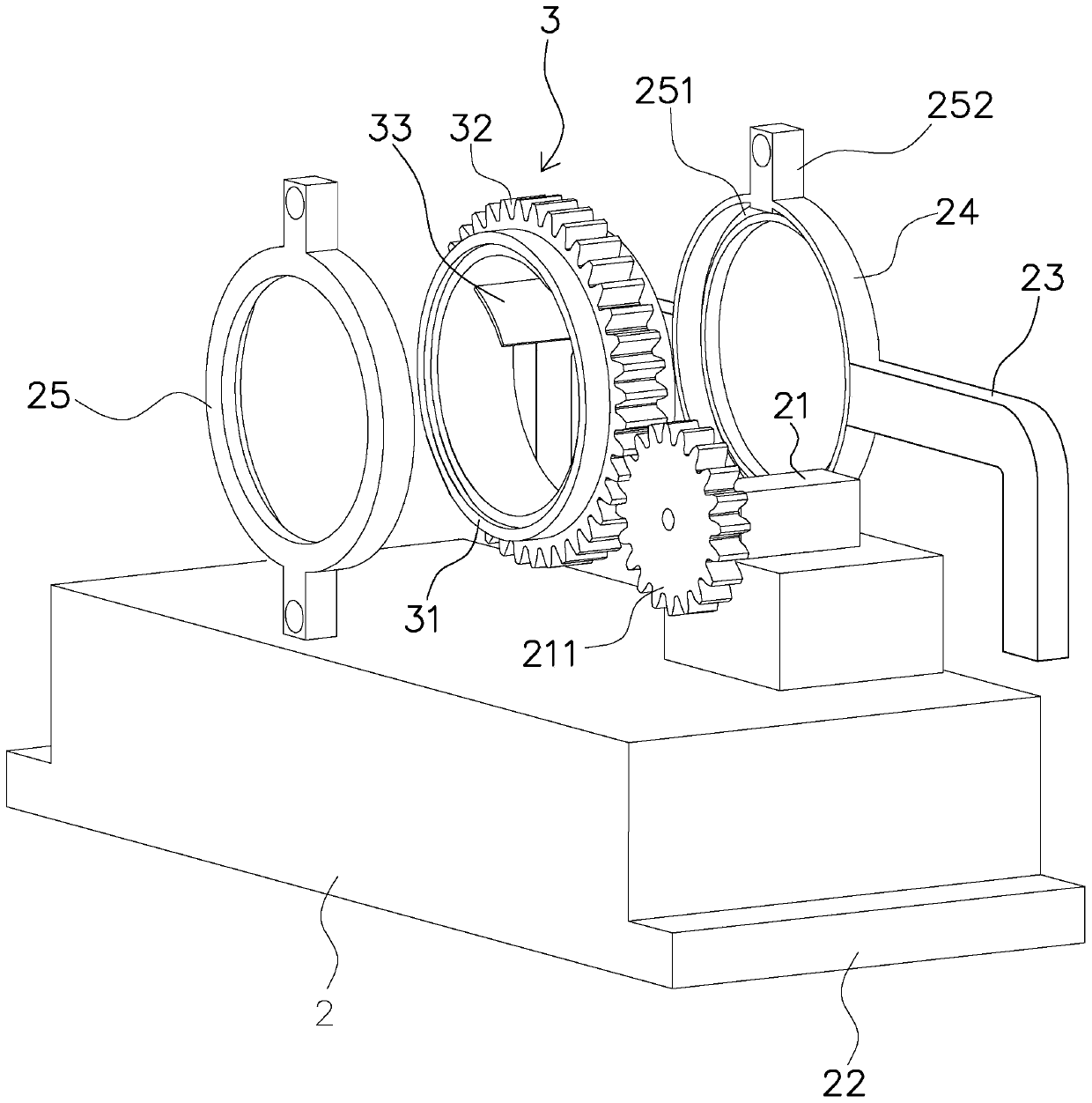

Flaw detection device of round pipe type steel member

ActiveCN109917004AEasy to replaceImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesArchitectural engineeringUltrasound probe

The invention relates to the technical field of weld joint detection, in particular to a flaw detection device of a round pipe type steel member. The detection device comprises a substrate for carrying a round pipe type steel member; a base is mounted on the substrate; a positioning ring sleeved to the outside of the round pipe type steel member is arranged on the base; a detecting ring coaxiallydisposed with the positioning ring is installed on the positioning ring in a rotating manner; and an ultrasonic probe and a scribing device that slide radially relative to the detecting ring and are abutted against the outer surface of the round pipe type steel member are installed at the detecting ring. According to the detection device, while the weld joint position is detected, the boundary ofthe weld joint can be marked accurately, so that the efficiency of the weld joint detection is improved effectively.

Owner:深圳市联天钢结构桥梁工程有限公司

Image pixel labeling method based on super pixel level features

The invention discloses a method, for labeling object categories which pixels belong to, based on super pixel level features and belongs to the field of scene understanding and image semantic segmentation. Labeled training set images are used for training, and a to-be-labeled image is labeled by using the steps of firstly, extracting and encoding the features of each pixel; secondly, acquiring super pixels through 'over-segmentation; building different-level neighborhood areas for each super pixel according to different distances; for each area, using Max-Pooling comprehensive features to connect the features of different levels so as to obtain the level features of the super pixels; thirdly, using the level features to build and solve random field models based on the super pixels through linear SVM to obtain image pixel labels. By the method, pixel labelling time can be reduced, and labeling precision can be increased. In addition, the CUDA parallel calculation technology can be used during labeling so as to further increase labeling speed.

Owner:CHONGQING UNIV OF TECH

Laser marking machine and marking method thereof

ActiveCN107745589AEven energy distributionIncrease energy densityAblative recordingEngravingHigh energy

The present invention provides a laser marking machine and a marking method thereof. The laser marking machine comprises marking software, an electric control part, a laser device, a beam expanding lens, a galvanometer system and an optical focusing lens, wherein the marking software, the electric control part, the laser device, the beam expanding lens, the galvanometer system and the optical focusing lens are sequentially connected. Compared to the common large-area laser marking machine, the laser marking machine of the present invention has advantages of high energy density, high marking precision, fine marking effect and uniform energy distribution in the working range. According to the present invention, the with the marking machine and the marking method, a variety of materials can be correspondingly processed, the precise marking requirements can be met, and the fine marking quality can be ensured; the laser marking machine and the marking method can be used in consumer electronics, handicrafts, kitchen and toilet, metal molds and other marking industrial with laser such as metal surface engraving, marking, ink jetting and the like, and can replace the traditional printing and dying process, the traditional drawing process, the traditional grinding process and other processes, wherein the operation is safe and simple due to the non-contact processing, no pollution is generated during the processing, the chemicals are not used, and the cost is low.

Owner:HANS LASER TECH IND GRP CO LTD

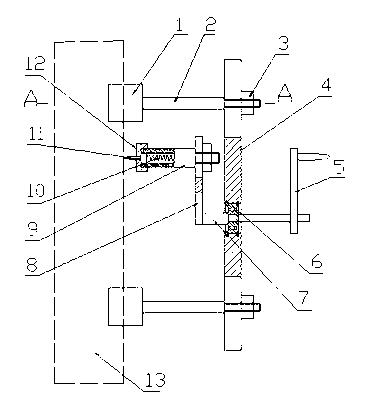

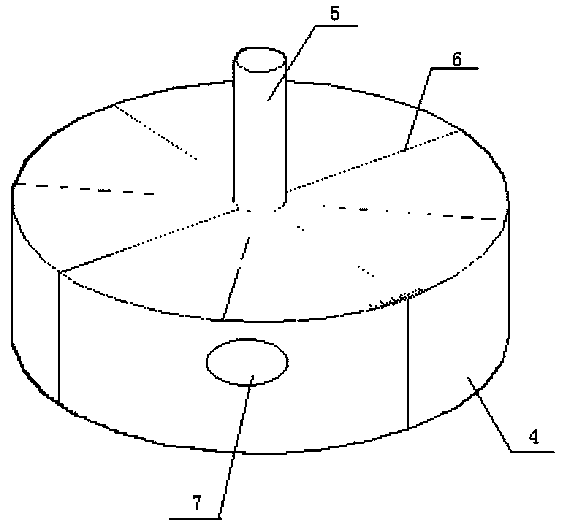

Pipeline connection position intersecting line marking tool

InactiveCN103042518AEasy to produceIntersecting lines are convenientOther workshop equipmentEngineeringLocknut

The invention discloses a pipeline connection position intersecting line marking tool. Supporting rods are symmetrically and fixedly arranged in sliding chutes arranged at two ends of a connection bridge through locking nuts, and a magnetic lock of a V-shaped structure is fixedly arranged at the bottom of each supporting rod. A center shaft is fixedly arranged in the middle of the connection bridge through a bearing, a rotating arm is fixedly arranged at the bottom of the center shaft, and a marking awl barrel is vertically fixedly arranged in a sliding chute of the rotating arm. A spring and a marking awl are arranged on the inner portion of the marking awl barrel; and the marking awl is fixed in the marking awl barrel through a positioning screw sleeve. The pipeline connection position intersecting line marking tool has the advantages of being convenient in marking awl intersecting line and high in marking accuracy, and can effectively facilitate pipe construction and production.

Owner:JIANGSU ZHONGSHENG CONSTR GROUP

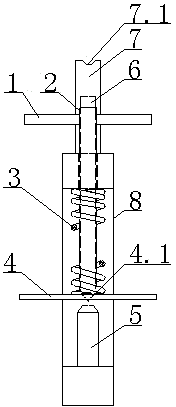

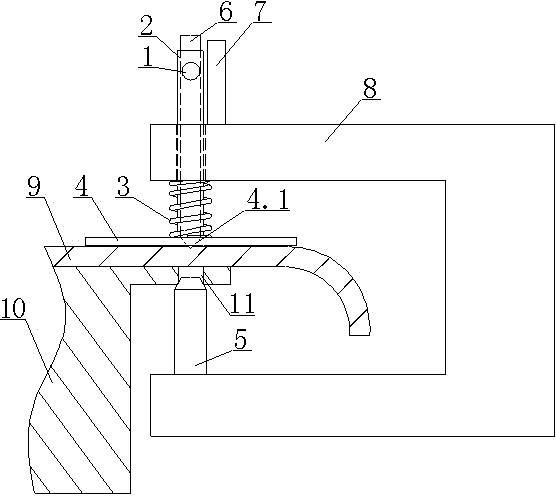

Line-marking tool for numerical control milling machine and line-marking method thereof

The invention provides a line-marking tool for a numerical control milling machine and a line-marking method thereof and relates to a line-marking tool and a line-marking method. The invention aims to solve the problems that no special line-marking tool for the numerical control milling machine exists at present and a traditional datum line marking method is low in line-marking precision and processing efficiency. The bottom of a sleeve is plugged in a stepped through hole; a first spring is located in the sleeve; one end of the first spring is in contact with the bottom of the sleeve; a big cylindrical section, a small cylindrical section and a line-marking head are fixedly and integrally connected in turn; the other end of the first spring is in contact with the big cylindrical section; a second spring passes through the small cylindrical section; one end of the second spring is in contact with the big cylindrical section; an end cover passes through the small cylindrical section and is fixedly mounted at an opening end of the sleeve; and the other end of the second spring is in contact with the end cover. The line-marking method comprises the following steps: clamping the line-marking tool on a spindle of a machine tool; setting a program of the numerical control milling machine according to a required line-marking track; and marking lines on a workpiece by the line-marking tool according to the set program of the numerical control milling machine. The line-marking tool and the line-marking method are used for marking the lines on a special tool.

Owner:HARBIN TURBINE

Parallelogram cross-section whole node rod piece lineation drilling technique

The invention discloses a parallelogram cross-section whole node rod piece lineation drilling technique, which solves the problems of pore-making precision of the opposite surfaces of the parallelogram whole node rob piece and the pore-making precision of the internal side node through the ultra wide top plate. The technique has the characteristics of high lineation precision and high working efficiency and is strong in operability; , and is suitable for drilling construction of the steel truss girder bridge by adopting the an upper chord member, the a lower chord member of the wide flange parallelogram cross-section of the whole node.

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG +1

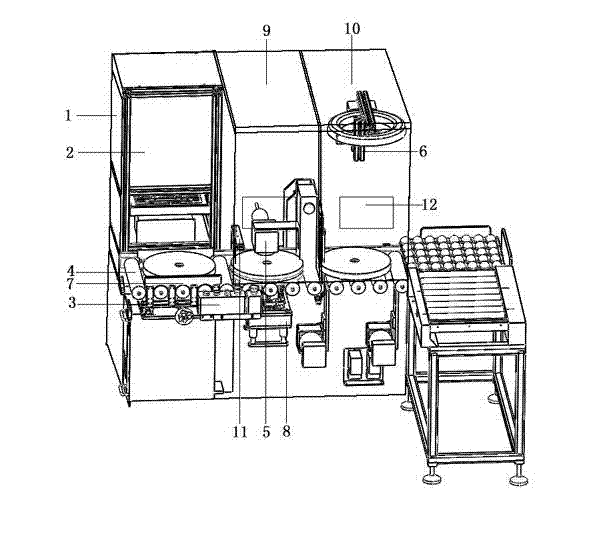

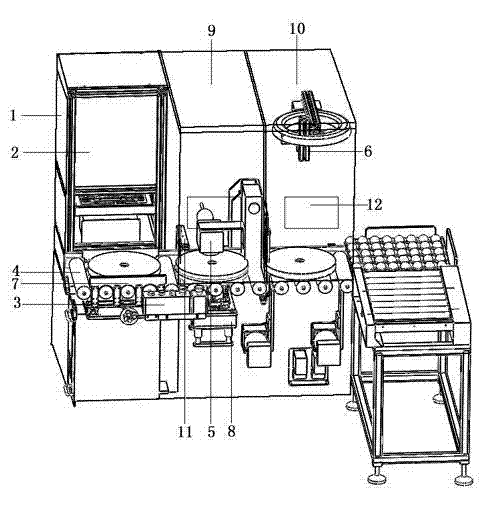

Fully-automatic marker

InactiveCN106853717AFast processingHigh marking accuracyOther printing apparatusFully automaticMaximum density

The invention relates to a fully-automatic marker. The fully-automatic marker comprises a rack; the rack is a hollow cube working table formed by profiles; a blanking device is arranged at one side of the upper surface of the rack and comprises a hopper and a fixing block for fixing the hopper; the bottom end of the front surface of the hopper is provided with a discharge port; the discharge port is connected with the starting end of a conveying device; the conveying device is placed on the rack; and an image recognition device, a turnover device and a marking device are sequentially arranged at the same side of the conveying device. According to the fully-automatic marker provided by the invention, fully-automatic laser printing is adopted, quick blanking can be realized through the blanking device, the material is accurately conveyed to the image recognition device and the marking device through the conveying device, the maximum density surface is quickly acquired through the image recognition device to acquire the best printing effects, the marking precision is high, the processing speed is quick, the cost is low, the automatic level is high, no mechanical extrusion or mechanical stress is generated to damage a processed object, and vigorous promotion is worthy.

Owner:ZHEJIANG AET INTELLIGENT TECH

Drilling marking-off method of equal-spaced holes

ActiveCN103286768AHigh marking accuracyImprove marking efficiencyOther workshop equipmentEngineering

The invention relates to a drilling marking-off method of equal-spaced holes. According to the drilling marking-off method of the equal-spaced holes, the uniform tensile property of stretching of a rubber band is utilized, a fixed number of ink lines within the distance between two fixed points are formed, and then the fixed distance can be divided in an equalized mode. According to the drilling marking-off method, hole location marking-off accuracy and efficiency of the equal-spaced holes are improved, and machining cost of parts is lowered.

Owner:SHENYANG AIRCRAFT CORP

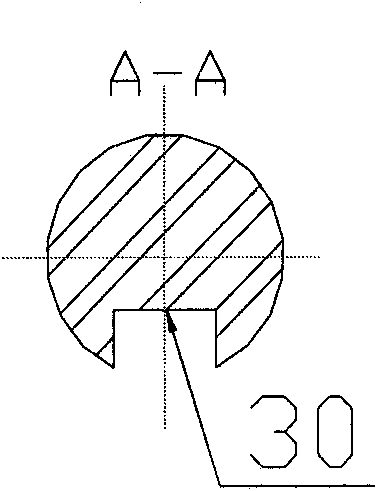

Key groove lineation method for making aligned tooth sample plate and used for helical gear with odd teeth

The invention discloses a key groove lineation method for making an aligned tooth sample plate and used for a helical gear with odd teeth. The aligned tooth sample plate consists of a sample plate body (1), a bulb moving rod (2) and a nut (3). The method comprises the following steps of: screwing a screw of the bulb moving rod into an internal thread hole of a stepped through hole of the sample plate body till the bulb of a sphere exceeds the end face A of a lug boss at the lower end of the right side of the sample plate body; arranging the sample plate body provided with the bulb moving rod into an inner hole of the helical gear with odd teeth; negatively screwing the bulb moving rod, gradually screwing the bulb moving rod into a tooth groove between two adjacent oblique teeth of the helical gear with odd teeth till complete contact with the tooth groove, and then tightening the bulb moving rod at the screw of the bulb moving rod through the nut; marking a key groove width b and a key groove depth t of the helical gear with odd teeth through a key groove formed at the left end face of the inside diameter of the sample plate body and by means of a lineation pen, wherein the key groove width b can correspond to the tooth outline of the end face of a random odd tooth; and then machining the helical gear with odd teeth according to the key groove width b and the key groove depth t.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Solar road marking vehicle with automatic alignment function

PendingCN111851249AResolve tremorsLow technical requirementsInstruments for road network navigationBatteries circuit arrangementsMicrocontrollerSolar battery

The invention provides a solar road marking vehicle with an automatic alignment function. The solar road marking vehicle comprises a power supply device, a material storage device, a walking device, amarking device and an electric control device. The power supply device comprises a solar cell panel, a solar cell panel steering table and an energy accumulator; the storage device comprises a paintstorage tank, a paint level sensor, a pressure sensor, a stirrer, a non-polar floating ball, a floating rod, a floating rod handle, a paint storage tank cover and an alarm switch; the walking device comprises propelling wheels, a propelling wheel motor, a steering wheel, a steering wheel steering engine, a steering wheel and an infrared sensor; the marking device comprises a cleaning rolling brush, a rolling brush motor, a paint spraying pump, a paint spraying pipeline, a paint spraying nozzle and a marking instrument; the electric control device comprises an ultrasonic range finder, a single-chip microcomputer, a motor driving module, a PWM speed regulation module, a control panel and an alarm. The distance between the marking vehicle and the road edge stone is accurately measured throughthe ultrasonic range finder, during work, under the control of the electric control device, the steering wheel steering engine makes a position adjustment response, the marking vehicle achieves the automatic alignment scribing function, and the problem that manual scribing errors are large is effectively solved; the solar power supply device is installed, two solar cell panels are arranged, and the marking vehicle is dragged by electric power so that energy consumption is effectively reduced, and the problem of trembling of scribing equipment of an internal combustion engine is effectively solved. The vehicle overcomes the defects of high labor intensity, high technical requirements and low scribing precision of the traditional manual scribing, and has the technical advantages of simple structure, convenience in operation, high system efficiency, safety, reliability, high precision and low energy consumption and popularization value.

Owner:QINGDAO UNIV OF SCI & TECH

Carriage bottom plate drilling locator

ActiveCN104096882AReduce labor intensityReduce maintenance costsDrilling/boring measurement devicesCentre punchesData transformationEngineering

The invention relates to a carriage bottom plate drilling locator, belongs to machining auxiliary equipment and in particular relates to a drilling locating device. The carriage bottom plate drilling locator is characterized in that the locator consists of an arch-shaped support, a locating pin and an anvil engraving mechanism in a connecting way, the anvil engraving mechanism with an anvil is arranged on an upper wing of the arch-shaped support, the locating pin is arranged on a lower wing of the arch-shaped support, and the central axis of an anvil head and the central axis of the locating pin are on the same plumb line. The carriage bottom plate drilling locator has the advantages that the concept is novel and the structure is simple, compact and reasonable; by using the drilling locator, multi-person and multi-process operations such as processing a wood strip, measuring hole distance on the wood strip, extending and snapping the line, measuring hole distance by using the wood strip and punching anvil holes one by one can be omitted, the operation is simple and convenient, rivet hole anvil holes can be easily, accurately and inerrably punched side beam bottom plates on two sides by one person in one step, each hole takes a corresponding bottom beam rivet hole as a datum, errors caused by datum transformation are avoided, the bottom plate rivet hole marking accuracy is greatly improved, the labor intensity of workers and the repair costs are reduced, the working efficiency and the repair quality are improved, the safety and the reliability are high and the potential safety hazards are eliminated.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Self-checking marking apparatus with observation windows

The invention discloses a self-checking marking apparatus with observation windows. The apparatus comprises a body and a universal shaft transmission device. The apparatus is characterized in that: an upper part of the body is provided with a display screen; a central part of the body is provided with an operating console and a controller; the controller is arranged out of the operating console; the operating console comprises a roll shaft transmission apparatus, a marking apparatus, a self-checking apparatus and case bodies; the marking apparatus and the self-checking apparatus are respectively arranged in a first case body and a second case body of the operating console and are arranged along a transmission direction of the roll shaft transmission apparatus; the first case body and the second case body are provided with the observation windows; driving devices of the roll shaft transmission apparatus, the marking apparatus and the self-checking apparatus are all arranged on a lower part of the operating console; the marking apparatus is the laser marking apparatus and the self-checking apparatus is the optical detection apparatus. The marking apparatus of the invention has a high marking accuracy. Examination can be performed immediately after completing the marking and real-time monitoring of a marking process can be achieved.

Owner:SIP GOLDWAY TECH

Lineation method utilizing portal lineation device

The invention discloses a lineation method utilizing a portal lineation device. The lineation method utilizing the portal lineation device specifically includes the following steps that a to-be-lineated position is found out on a main board; the portal lineation device is fixed to the to-be-lineated position; left and right two lineation pens are adjusted to proper positions, and then a two-way telescopic connection plate is rotated in the circumferential direction to draw a boundary line for hole opening; and the positions of the lineation pens are kept unchanged, the two-way telescopic connection plate is adjusted to a set orientation, then the two lineation pens are moved in the direction of the center of the two-way telescopic connection plate, and a component installing line is drawnwithin the boundary line for hole opening. The lineation method utilizing the portal lineation device is easy to use, convenient to operate and capable of effectively lowering the measuring operationcost, improves the lineation efficiency and the lineation precision to a very large extent, lowers the labor force consumption of lineation operation, and shortens the construction period.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

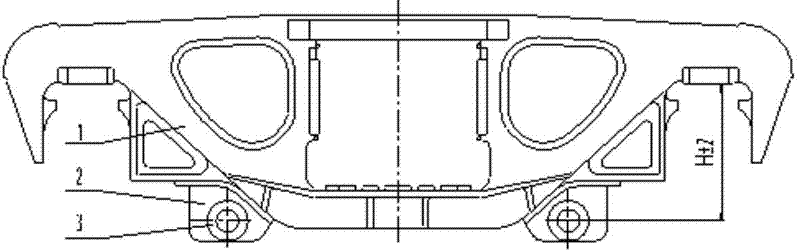

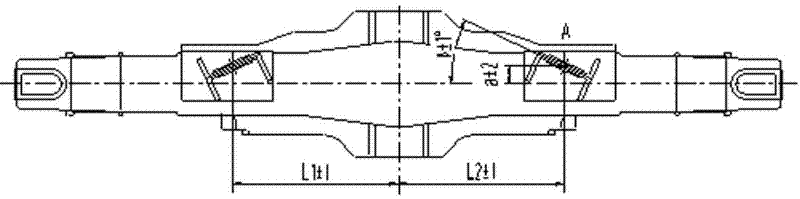

Method for scribing and measuring side frame

InactiveCN102564264ASolve the marking accuracyImprove marking efficiencyAngles/taper measurementsMechanical clearance measurementsEngineeringBearing surface

The invention belongs to the technical field of vehicle measurement of railway locomotives and particularly relates to a method for scribing and measuring a side frame. The purpose of the method for scribing and measuring the side frame is to improve scribing efficiency and scribing precision of a central line. The method for scribing and measuring the side frame comprises the steps of: measuring a distance from a bearing surface of a load-bearing saddle of the side frame to a platform; measuring distances from centers of support bases of the side frame to the bearing surface of the load-bearing saddle; leading the center of a retaining ring to the support bases by wires; measuring the position of vertical central point A of the retaining ring; measuring distances from a guide frame to the support bases, a distance between the two support bases and distances from the support bases of the side frame to the central line of the side frame; and measuring included angles between the support bases and a longitudinal centre line of the side frame. According to the method for scribing and measuring the side frame, disclosed by the invention, the scribing efficiency and scribing precision of the central line are improved, and the scribing precision difference caused by different scribing engineering levels of skilled workers is eliminated.

Owner:CRRC TAIYUAN CO LTD

Sliding rail type automatic lineation ruler and method

ActiveCN105269551ASimple structureEasy to processOther workshop equipmentEngineeringMechanical engineering

The invention relates to a sliding rail type automatic lineation ruler and method. The sliding rail type automatic lineation ruler is provided with a component I, a component II, a positioning sliding block, a lineation sliding block, a cross-shaped sliding bar, a spring, two lineation correcting sheets and a configuration bar. The component I, the component II, the positioning sliding block and the lineation sliding block are all provided with configuration bar assembly holes and cross-shaped sliding bar assembly holes. The component I is provided with a spring groove. The lineation sliding block is provided with a pen hole into which a lineation pen is inserted. One end the cross-shaped sliding bar penetrates through the lineation sliding block and the component I to be connected with a knob I, and the other end of the cross-shaped sliding bar penetrates through the positioning sliding block and the component II. The cross-shaped sliding bar is sleeved with the spring, one end of the spring is installed in the spring groove in the component I, and the other end of the spring makes contact with the lineation sliding block. The two lineation correcting sheets are symmetrically installed on the component I and the positioning sliding block respectively. The component I, the lineation sliding block, the positioning sliding block and the component II are connected together through the configuration bar. The sliding rail type automatic lineation ruler increases the success rate of lineation and improves the accuracy of lineation.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com