Laser marking machine and marking method thereof

A laser marking machine and laser technology, which is applied in printing, burning, etc., can solve the problems of limiting the application prospect of large-format laser marking, degrading the fineness of marking, and different sizes of focus spots, so as to achieve fine marking The effect of quality, uniform energy distribution, fine marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The laser marking machine of the present invention can obtain higher energy density, finer marking effect and uniform energy illuminance distribution while increasing the marking range, and solve the problem that laser marking is suitable for many industrial applications because the working range cannot meet the requirements. It is forced to give up, or in order to make up for the insufficient scope of work, it is necessary to use a mobile platform for splicing, but the quality of marking at the splicing is reduced, which broadens the application space of laser marking processing to a certain extent.

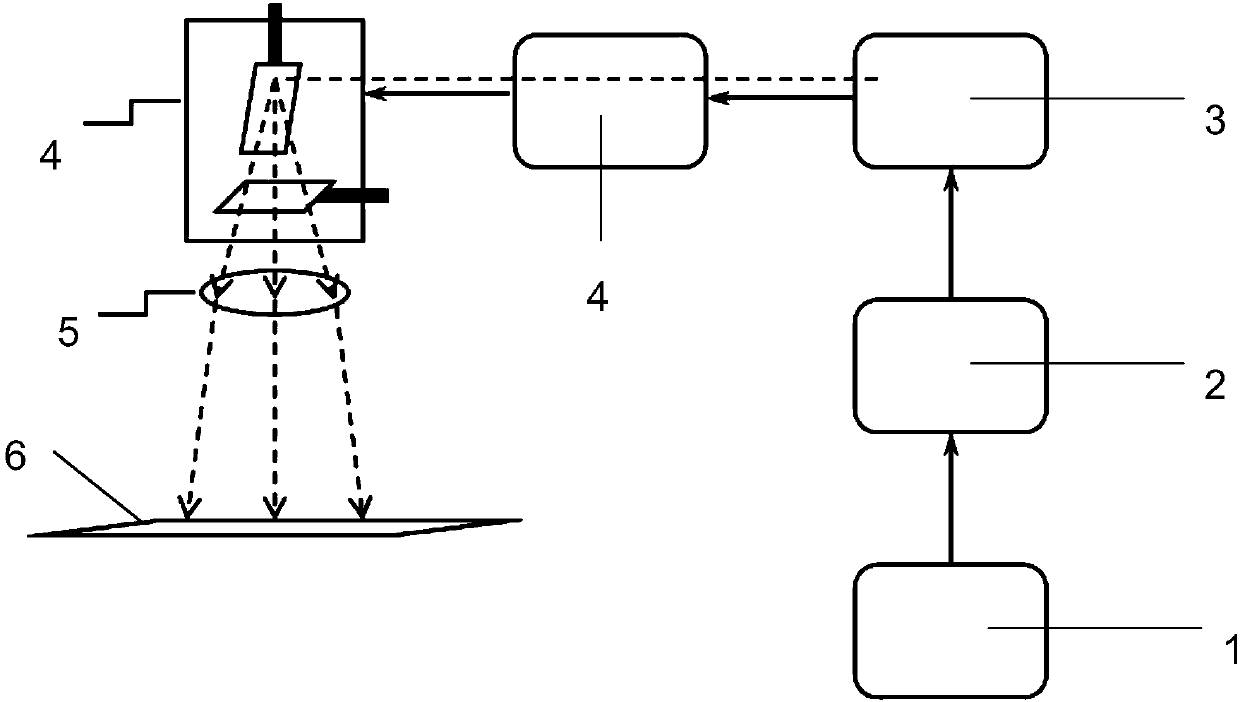

[0022] The laser marking machine of the present invention is used for large-scale laser energy uniform marking equipment, such as figure 1 As shown, the laser marking machine includes: marking software 1, electrical control unit 2, laser 3, beam expander 4, vibrating mirror system 5, and optical focusing lens 6, wherein marking software 1, electrical control unit 2, The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com