Self-checking marking apparatus with observation windows

A technology of self-inspection device and observation window, which is applied in the direction of printing device, printing, etc., can solve the problems of low working precision, batch error, labor and material resources consumption, etc., and achieve the effect of high marking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

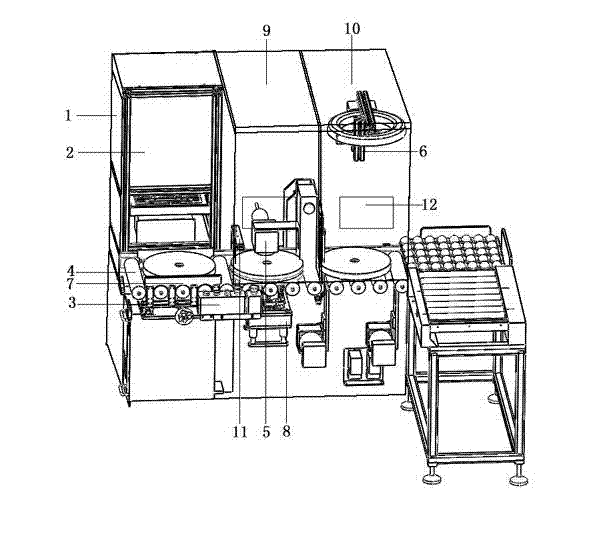

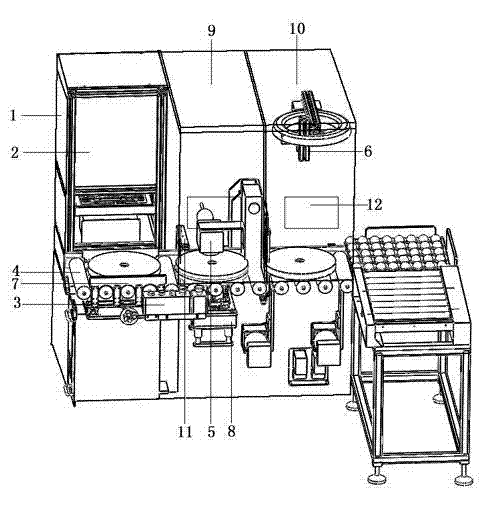

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the upper part of the body 1 is provided with a display screen 2, and the state parameters during the marking process can be displayed on the display screen 2, so as to facilitate the statistical analysis of the staff. The middle part of the body is provided with an operation console and a controller 3. 3 is located outside the operating table, through the control of the operating table and the controller 3, to operate the marking work, the operating table includes the roller shaft transmission device 4, the laser marking device 5, the optical detection device 6 and the box, the roller shaft The transmission device 4 is provided with a tensioning device inside, and the lower part is provided with a clamping and positioning device 7 and a supporting positioning device 8 in sequence along the transmission direction. Among the first box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com