Horizontal arm type three-coordinate measuring and ruling machine

A technology of three-coordinate measurement and horizontal arm, which is applied in the field of measurement and marking, can solve the problems of lowering the measurement accuracy of the device, affecting the measurement or marking accuracy, and weak stability of the marking function, so as to ensure the reliability of stability and function. performance, reduce operational complexity and labor intensity, optimize installation time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

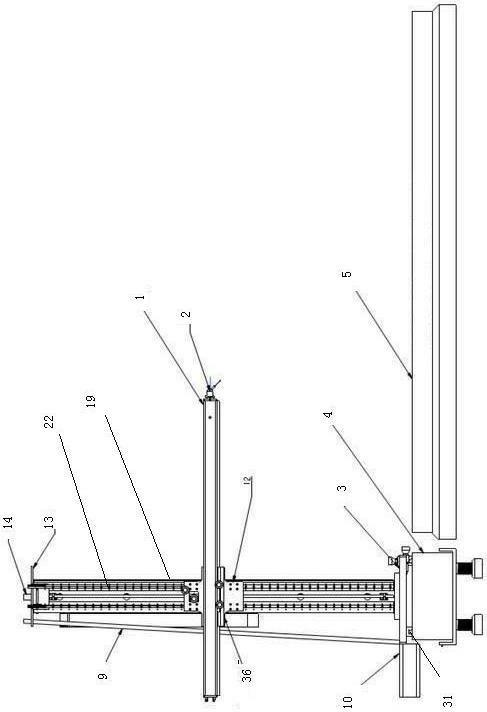

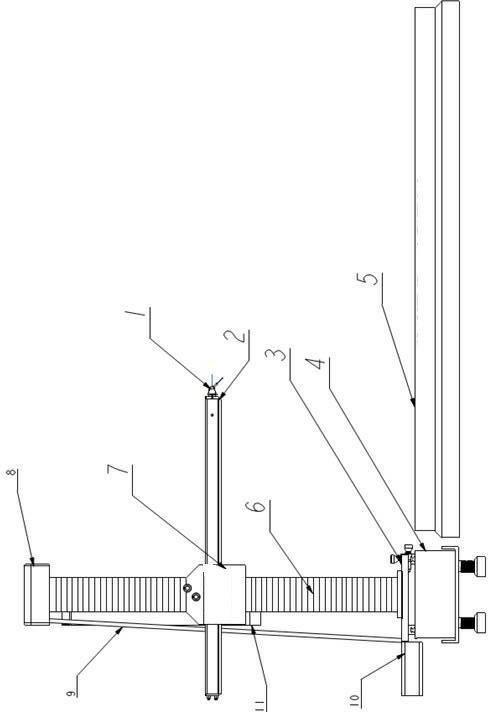

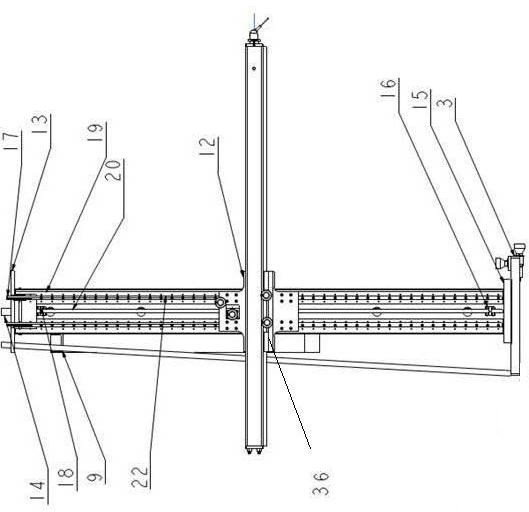

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

[0046] like figure 1 As shown, the left side of the detection platform 5 is provided with a marble platform 4 for installing the base. The base is two sets of X-direction linear slide rails parallel to each other, which are installed on the marble platform 4 . The slide blocks 31 of the two X-direction linear slide rails are provided with X slide plates 3 to form the X axis of the three-coordinate measuring scriber. The X-axis drag chain 10 is provided on the left side of the X-slide 3 .

[0047] The upright column 19 is installed on the X slide plate 3 and is perpendicular to the base, and a Z-axis linear slide rail 22 is installed on the upright column 19, which constitutes the Z-axis of the three-coordinate measuring scriber. The side skew-stayed support rods 9 and the rear skew-stayed support rods 14 are used to maintain the stability of the Z-axis.

[0048] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com