Manufacturing method of flexible OLED (Organic Light Emitting Diode) display panels

A technology for display panels and manufacturing methods, which is applied in the field of flexible OLED display panel manufacturing, can solve the problems of increased manufacturing costs, expensive laser cutting machines, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

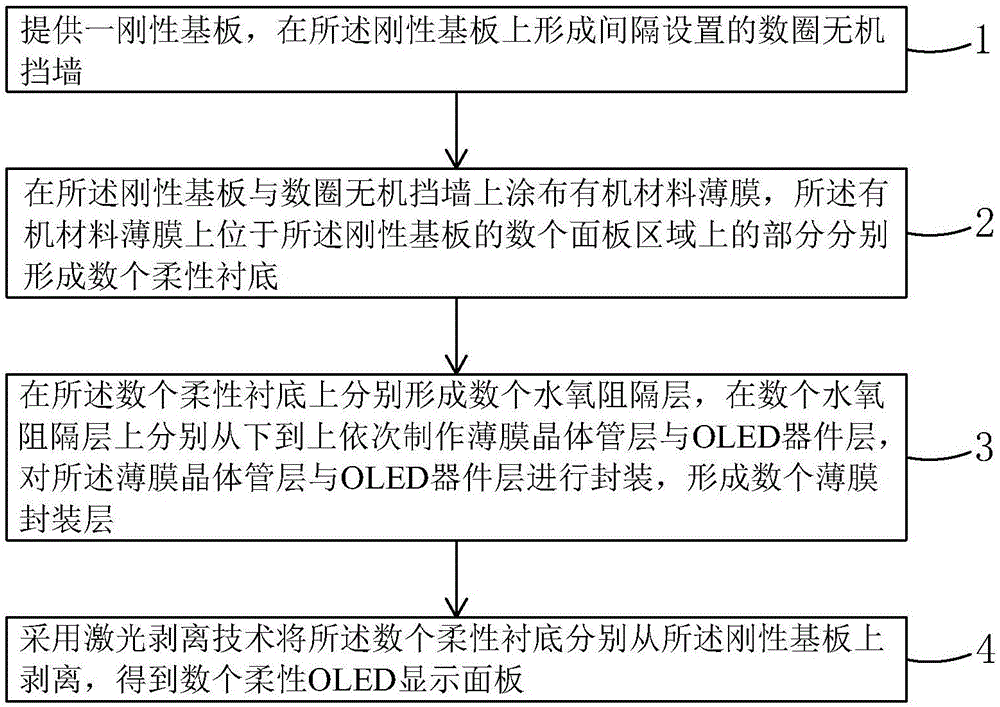

[0035] See figure 1 , The present invention provides a method for manufacturing a flexible OLED display panel, including the following steps:

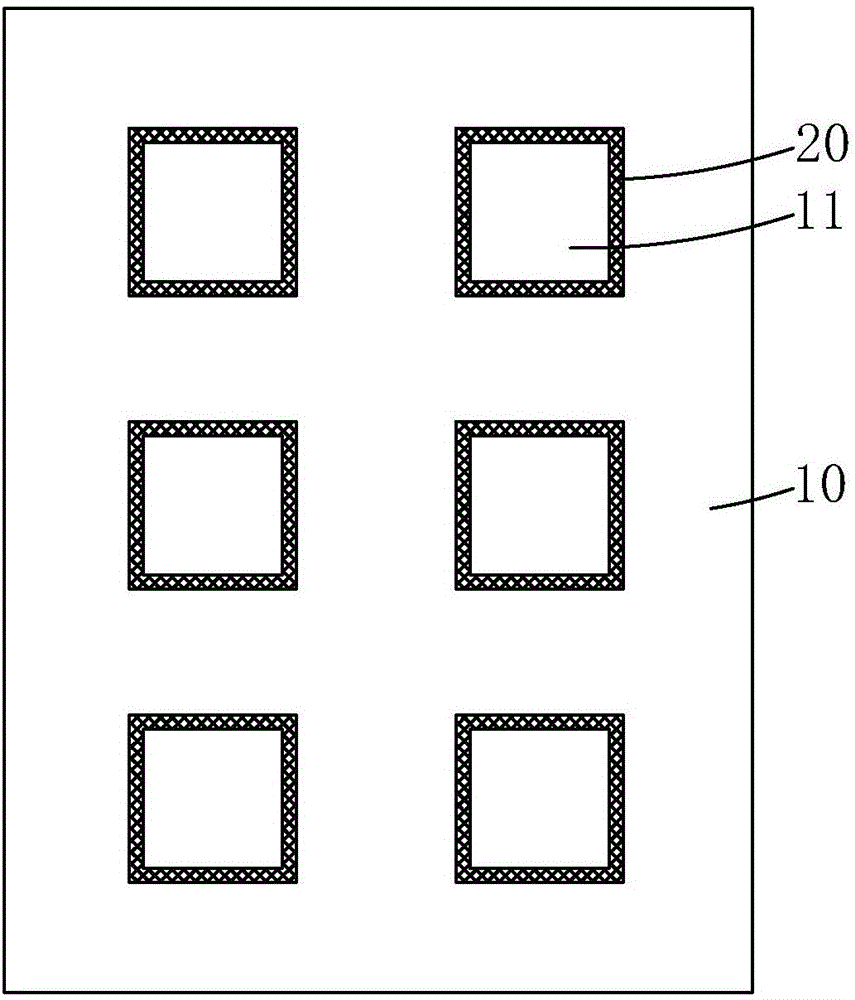

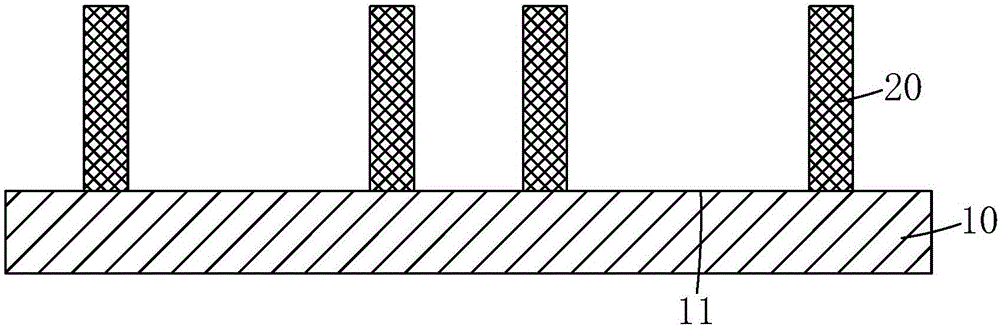

[0036] Step 1, such as figure 2 versus image 3 As shown, a rigid substrate 10 is provided. On the rigid substrate 10, several circles of inorganic barrier walls 20 are formed at intervals, and the several circles of inorganic barrier walls 20 enclose several panel areas 11 on the rigid substrate 10.

[0037] Specifically, the rigid substrate 10 is a glass substrate.

[0038] Specifically, the material of the number-turn inorganic retaining wall 20 includes silicon oxide (SiO x ), silicon nitride (SiN x ), and silicon oxynitride (SiO x N x ) At least one of.

[0039] Preferably, the material of the inorganic retaining wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com