Desktop plate blow-molding apparatus

A technology of blow molding device and desktop board, applied in the field of desktop board blow molding device, can solve the problems of slow manual sealing efficiency, easy sticking to the mold, trouble for operators to take and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

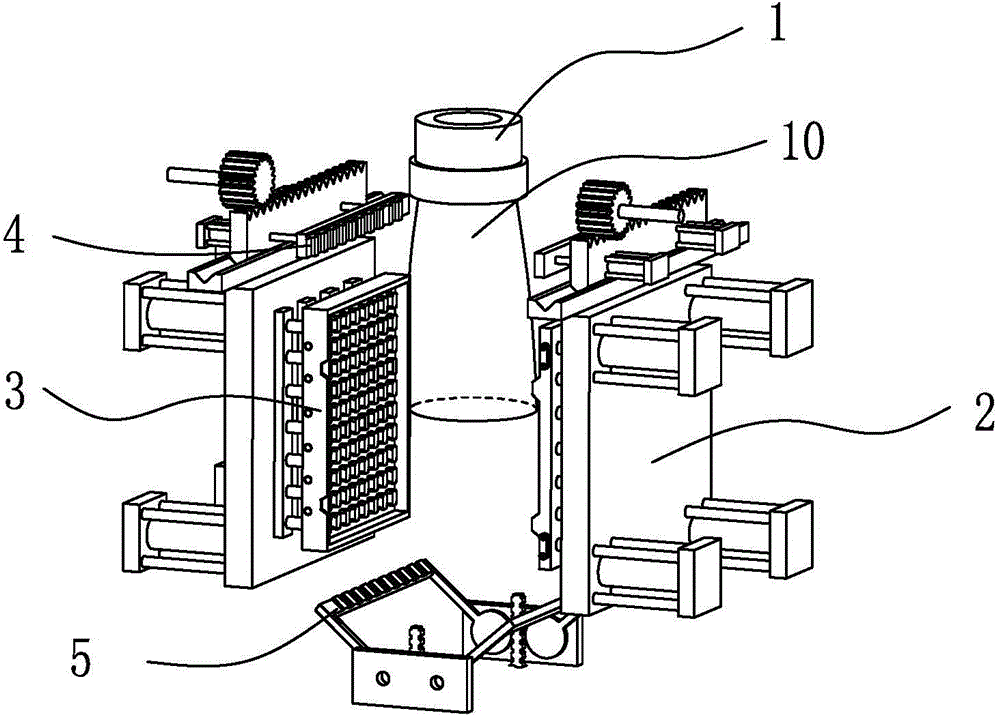

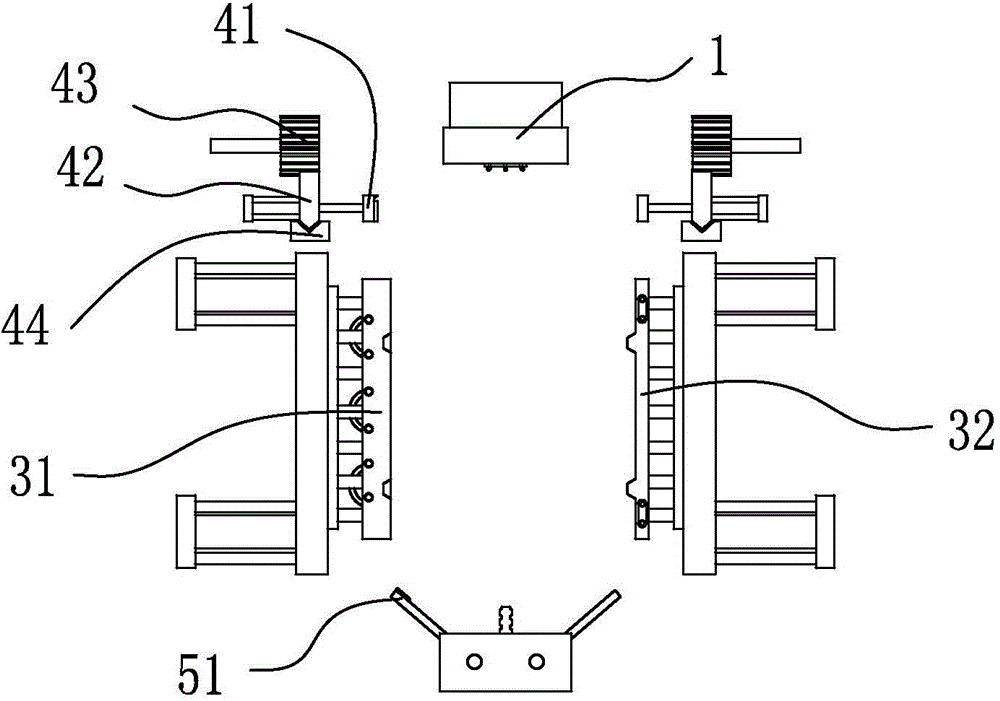

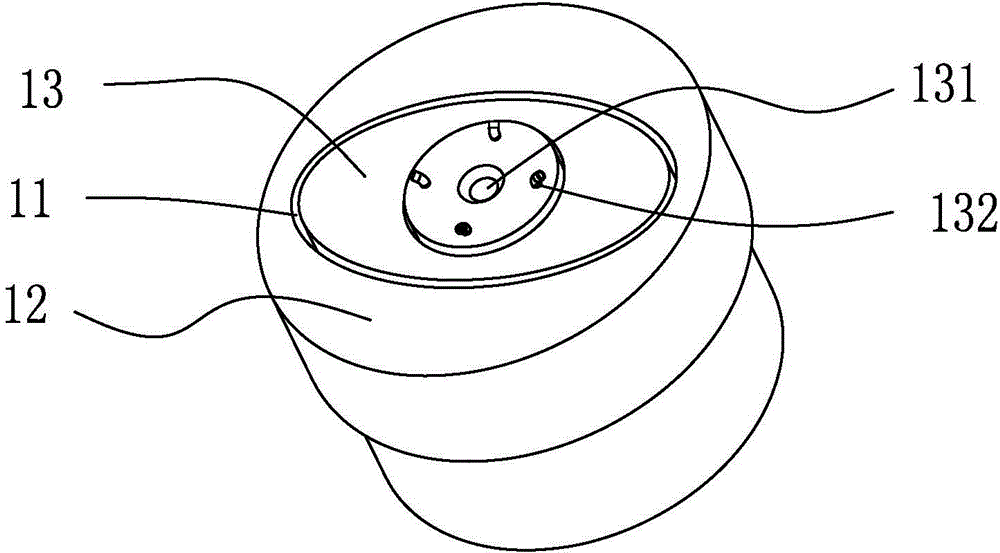

[0022] like Figure 1 to Figure 6 As shown, a desktop board blow molding device includes a blow molding mouth 1, a blow molding clamping machine 2 and a blow mold 3 fixed inside the blow molding clamping machine, and the blow molding mold includes a left half mold 31 and Right half mold 32, described blow molding mouth is provided with elliptic discharge port 11, and raw material 10 is extruded in the shape of the curtain of ring from discharge port, and the raw material after extruding is corresponding oval ring-shaped curtain, so Said left half-mold or right half-mold all comprise mold core plate 33, and the inner side of mold core plate is the surface that matches with finished product desktop, and the outside of mold core plate is provided with more than 2 independent fixing plates 34, directly fix with pressing plate when fixing. The plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com