Automobile interior front door handle rear firing method gas-assisted injection mold

A gas-assisted injection molding and automotive interior technology, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as uneven wall thickness of injection molded products, achieve the goals of shortening the production injection molding cycle, reducing loss, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation

[0021] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

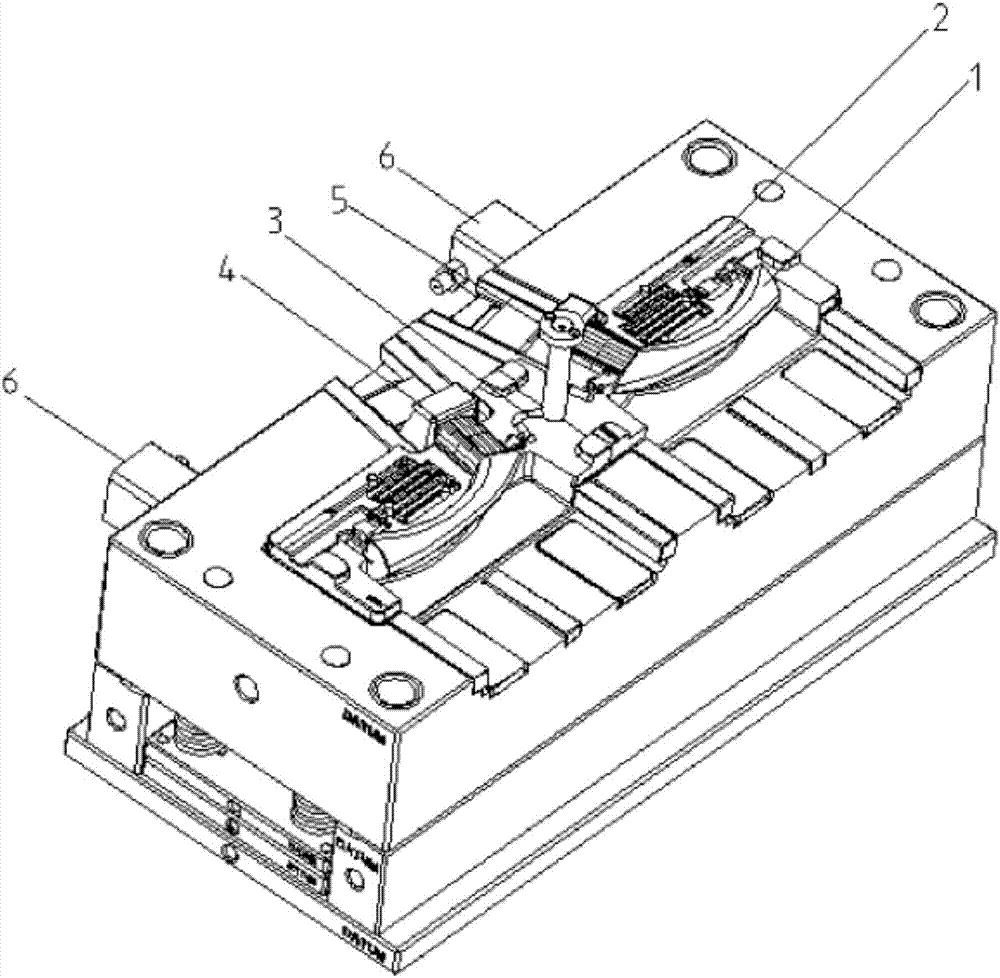

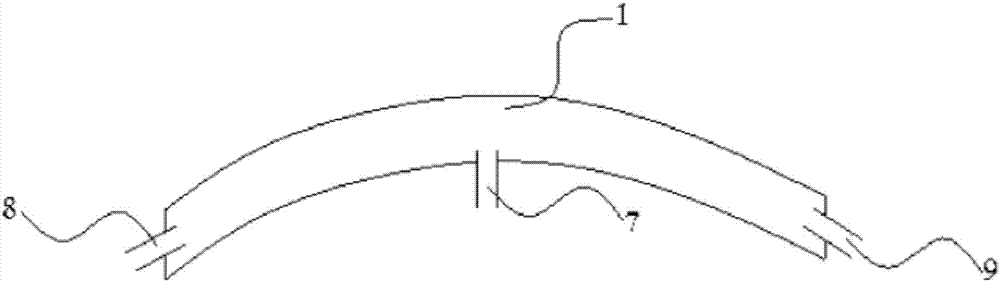

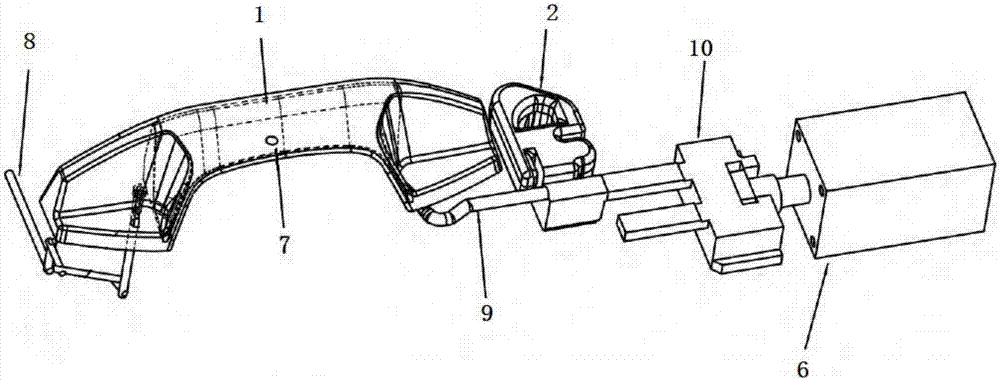

[0022] as attached figure 1 , attached figure 2 As shown in the figure, the rear-shot gas-assisted injection molding mold for the front door handle of the automobile interior decoration of the present invention includes a cavity 1 with a feed port 8 at one end and a discharge port 9 at the other end, and a cavity 1 for blowing the inside of the cavity 1. In the air blowing device 4 , the bottom of the cavity 1 is provided with an air inlet 7 , and the air inlet 7 is connected with the air blowing device 4 .

[0023] The mold sets the air inlet 7 at the bottom of the cavity 1, which can prevent the material from accumulating on the bottom of the cavity 1 due to the gravity of the material itself, thereby causing uneven wall thickness of the injection molded product.

[0024] The air inlet 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com