Double-column radiator and manufacturing method thereof

A technology of radiator and combination, applied in the field of radiators, can solve the problems of compression resistance, reduced impact resistance, complex structure of radiators, easy grinding and excessive grinding, etc., and achieves guaranteed quality, harmonious and beautiful overall appearance, and convenient and firm welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

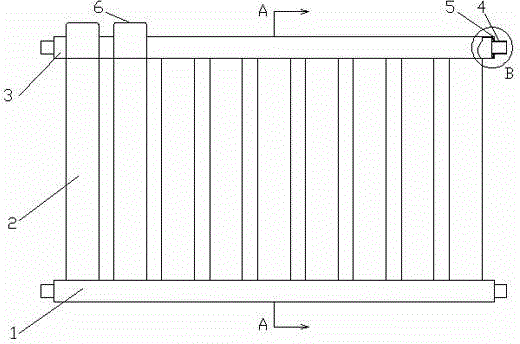

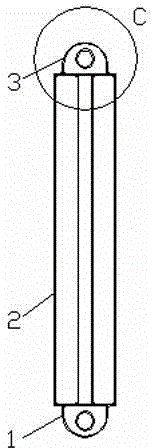

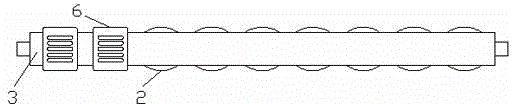

[0039] like Figure 1~5 As shown, a double-column radiator includes a lower beam 1 and an upper beam 3, a heat dissipation pipe 3 is arranged between the lower beam 1 and the upper beam 3, and the lower beam 1, the upper beam 3 and the heat dissipation pipe 2 are fixed connected and communicated in the inner cavity, the lower beam 1 and the upper beam 3 have the same structure and both include an upper cover 3-1 and a bottom plate 3-2, and the upper cover 3-1 and the bottom plate 3-2 pass through two side-by-side The radiating pipes 2 are connected together; both ends of the lower beam 1 and the upper beam 3 are provided with connecting nozzles 4, and the connecting nozzles 4 are connected with the lower beam 1 and the upper beam 3 through the sealing plate 5 .

[0040] Specifically, the ends of the radiating pipes 2 are welded together with the upper cover 3-1 and the bottom plate 3-2, and the welding position is set horizontally, which is convenient for welding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com