Metallurgical slag basin model-free casting method

A model-free and metallurgical slag technology, which is applied to casting molding equipment, cores, casting molds, etc., can solve the problems of low mold applicability, high model cost, and large wood consumption, so as to improve wall thickness accuracy and avoid wall thickness. Unevenness, the effect of reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

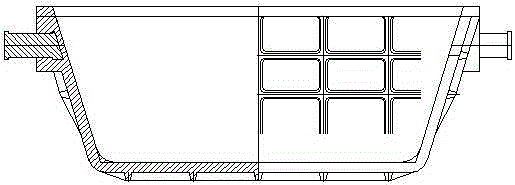

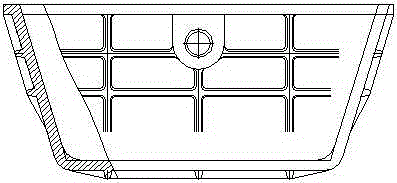

[0023] A metallurgical slag basin modelless casting method, it comprises the following steps:

[0024] (1) Use the corner core box 1 to make the sand cores 2 at the four corners of the slag basin to obtain the external contours of the four corners of the slag basin. Auxiliary contour line, according to the auxiliary contour line, place the four corner sand cores 2. After the four corner sand cores 2 are placed, the four corner contours of the main body of the slag basin have been formed, and then the shape of the slag basin casting is formed by scraper molding. Outer contour sand molds of other parts 7;

[0025] (2) Skin repair: The skin repair uses multi-layer boards or molding sand to fill and assemble the cavity of the mold to form the outline of the slag basin sand mold. The regular surface patching part is replaced by multi-layer boards. The multi-layer boards are placed directly, or the fillers are added to adjust to an appropriate thickness. The multi-layer boards can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com