Forming technology of ultra-deep taper thin-wall part

A forming process and technology of thin-walled parts, which are applied in the field of deep drawing of thin-plate and ultra-deep conical parts, can solve the problems of material cracking and uneven wall thickness, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

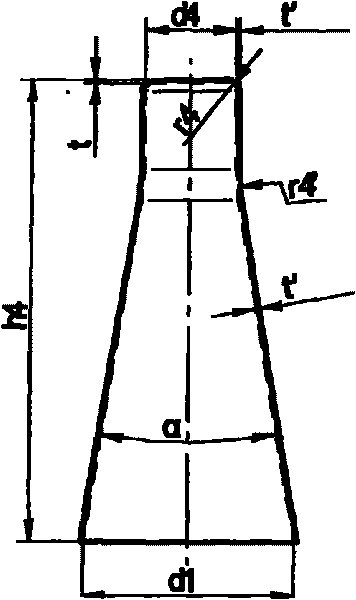

[0020] The following combination Figure 1-Figure 8 Describe the process:

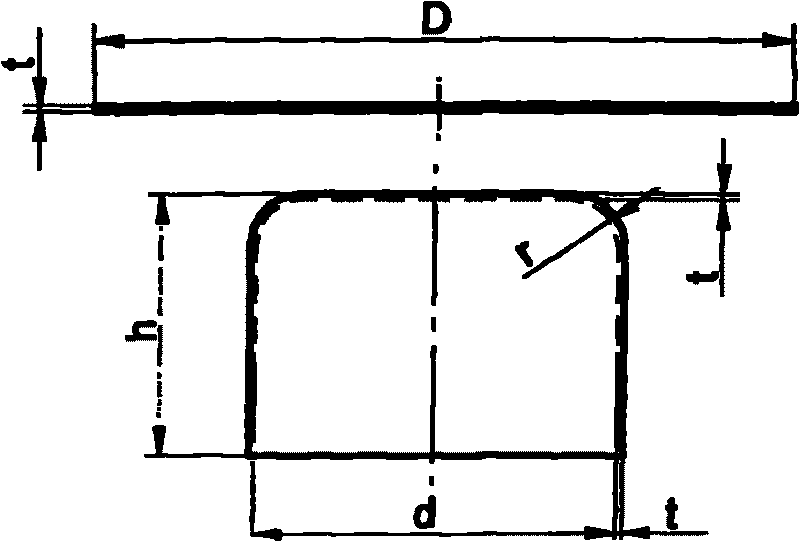

[0021] 1. Blanking and punching bowl. Coat the surface of 10 steel strips with thickness t=0.7mm with lubricating oil (trichlorethylene C12=CHC1 diluent and SH150 molding oil at a ratio of 1:5) and put it into the blanking die with blank holder , punched with a 400kN open punching machine, blanking size D = Ф88mm, the workpiece after punching is a cylindrical piece with a bottom, its inner diameter d = Ф45mm, height h = 34mm, bottom fillet r = 6mm, workpiece thickness t=0.7mm.

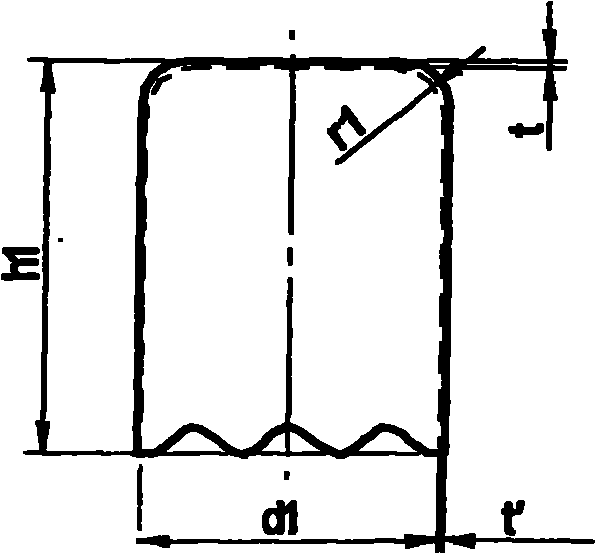

[0022] 2. Thinning and deep drawing. Put the workpiece after blanking and punching into the thinning and drawing die, and punch it with a 400kN open punching machine. After thinning and drawing, the hole diameter d1=Ф35.5mm is the same as the inner diameter of the large end of the tapered hole of the finished product, and the cylinder wall is formed by t= 0.7mm is thinned to t′=0.55mm, which is equal to the finished wall th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com