Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Extended speed range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

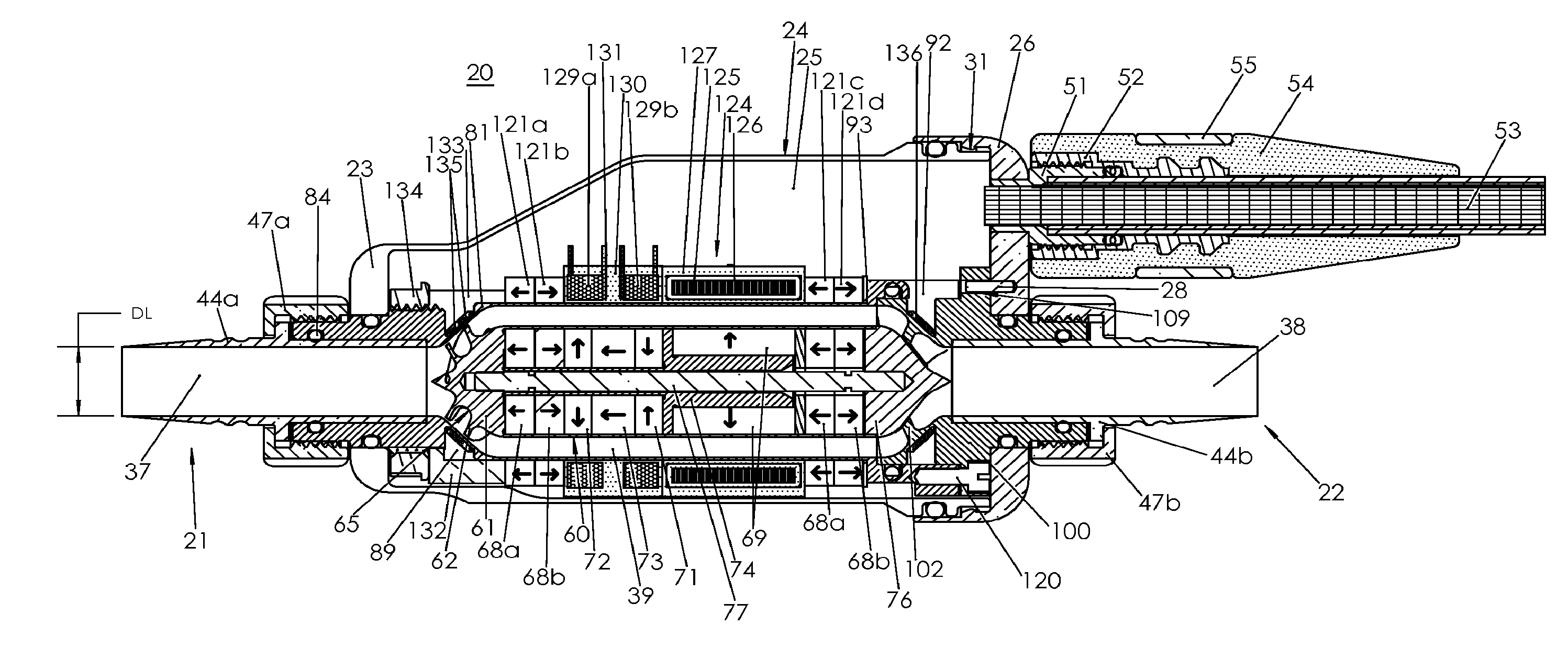

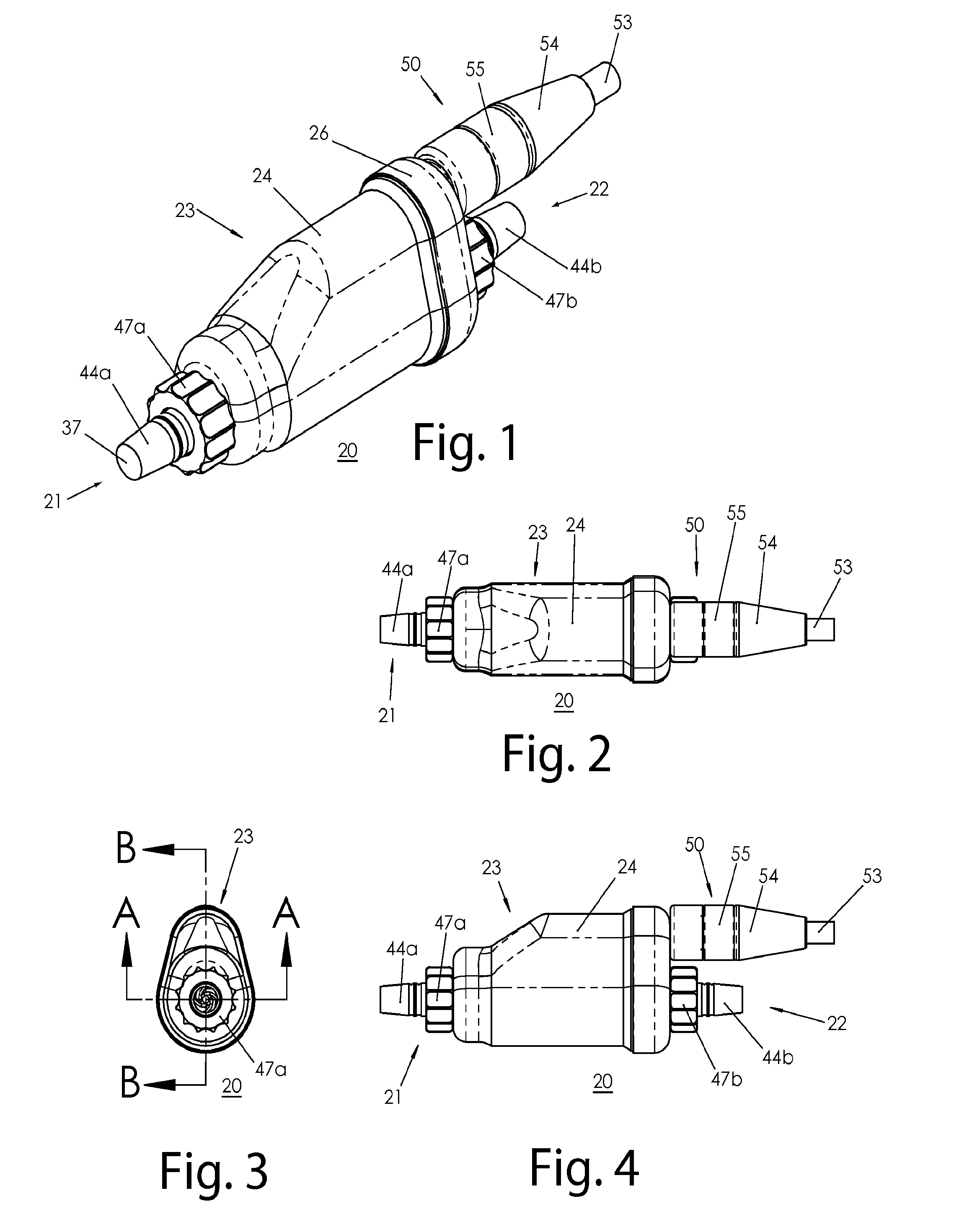

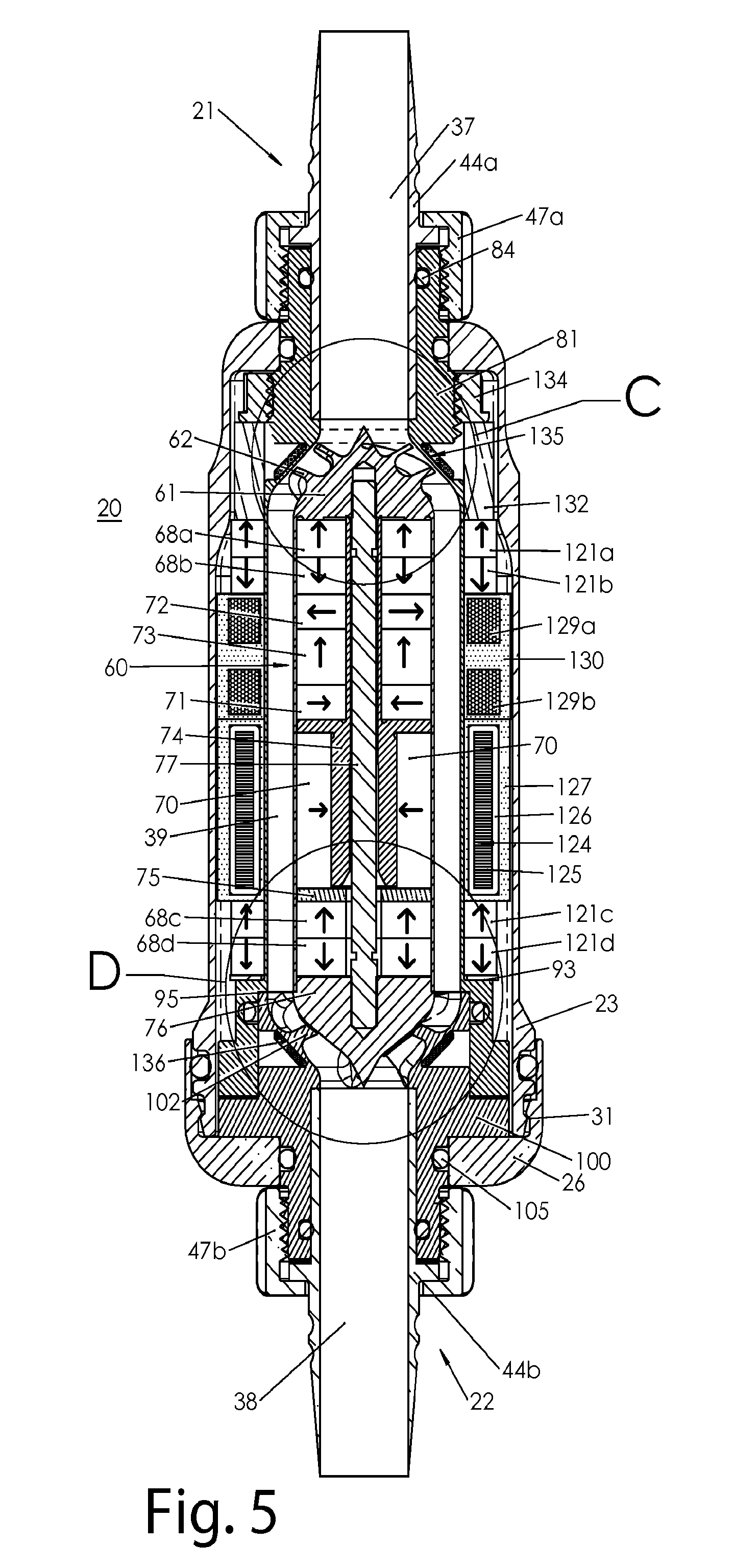

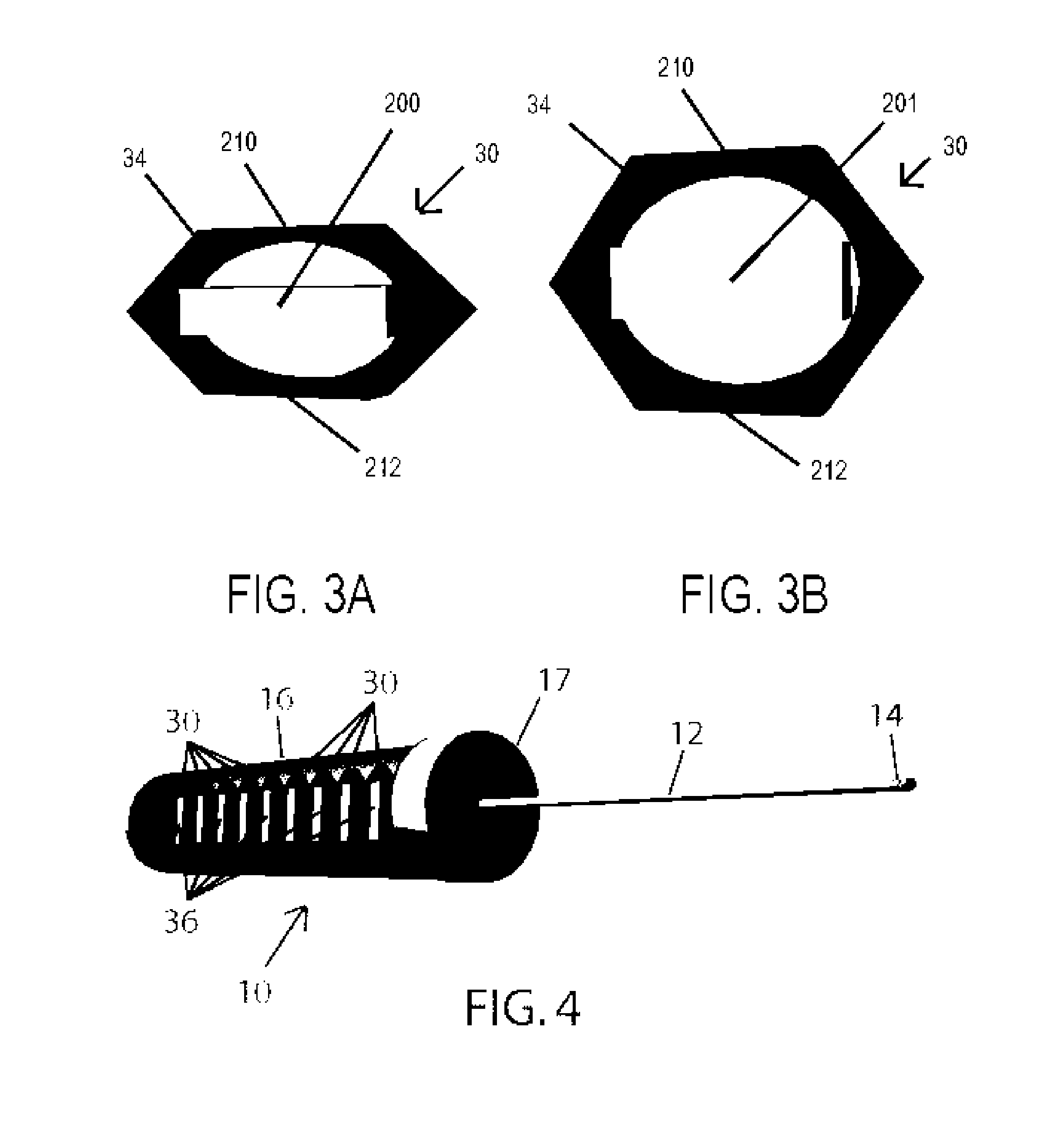

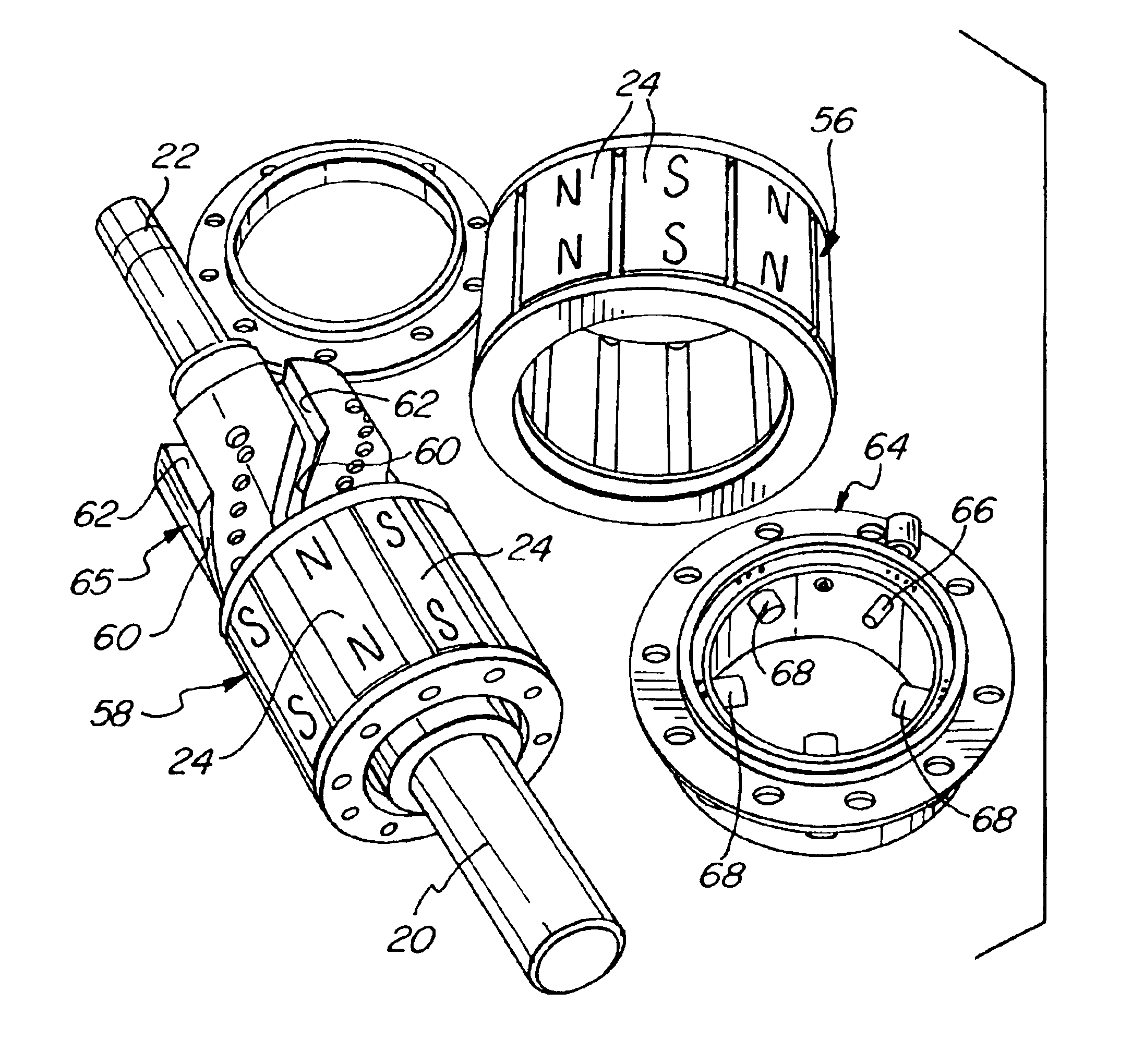

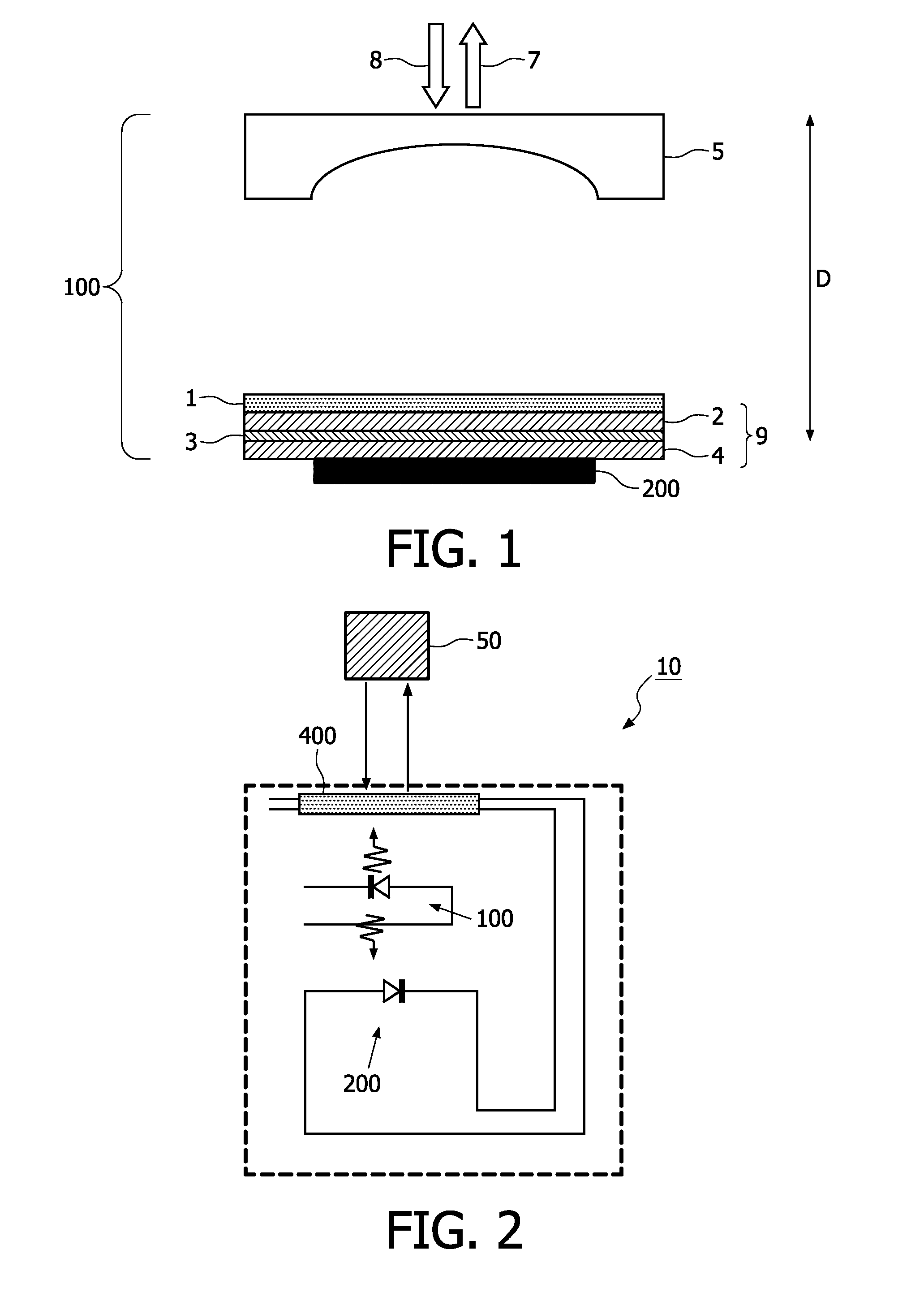

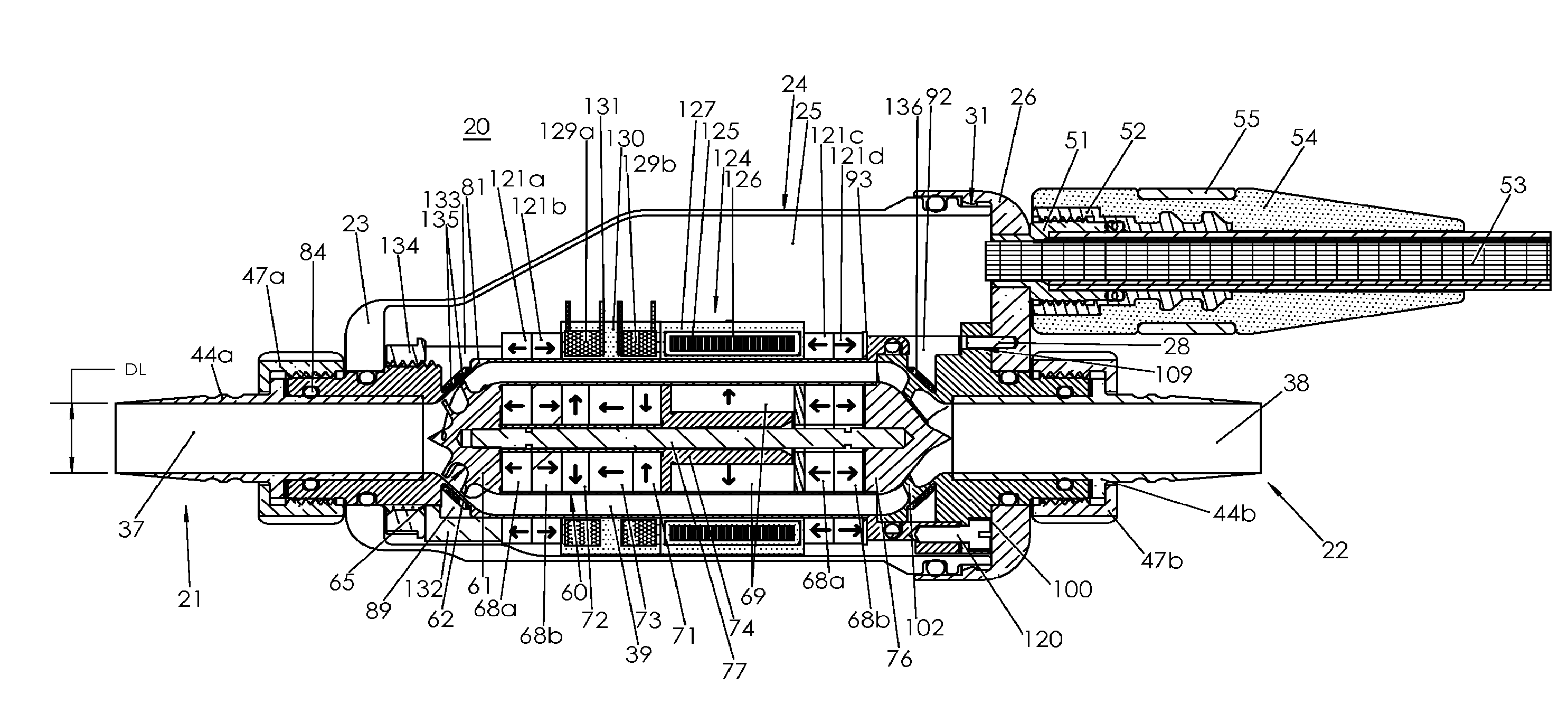

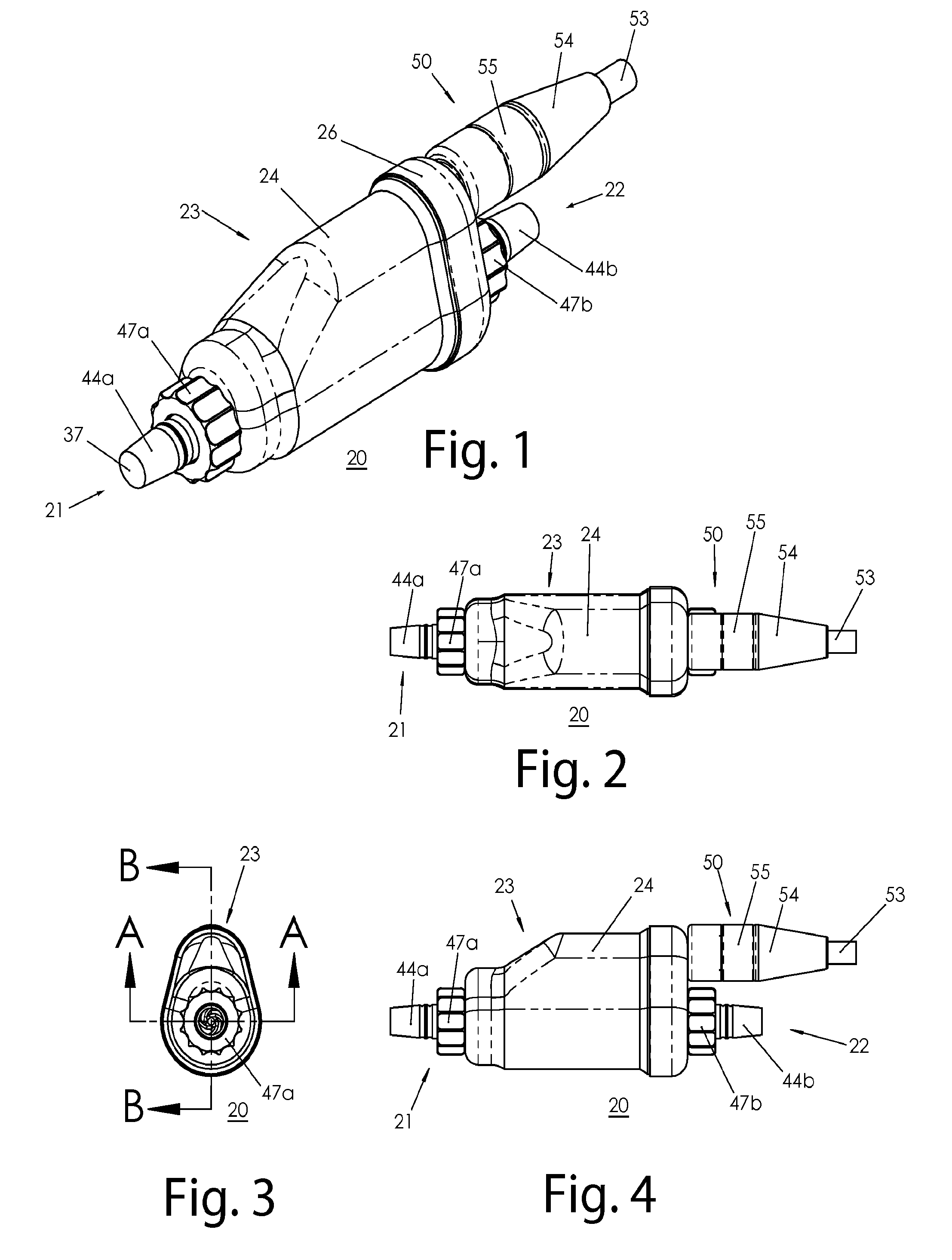

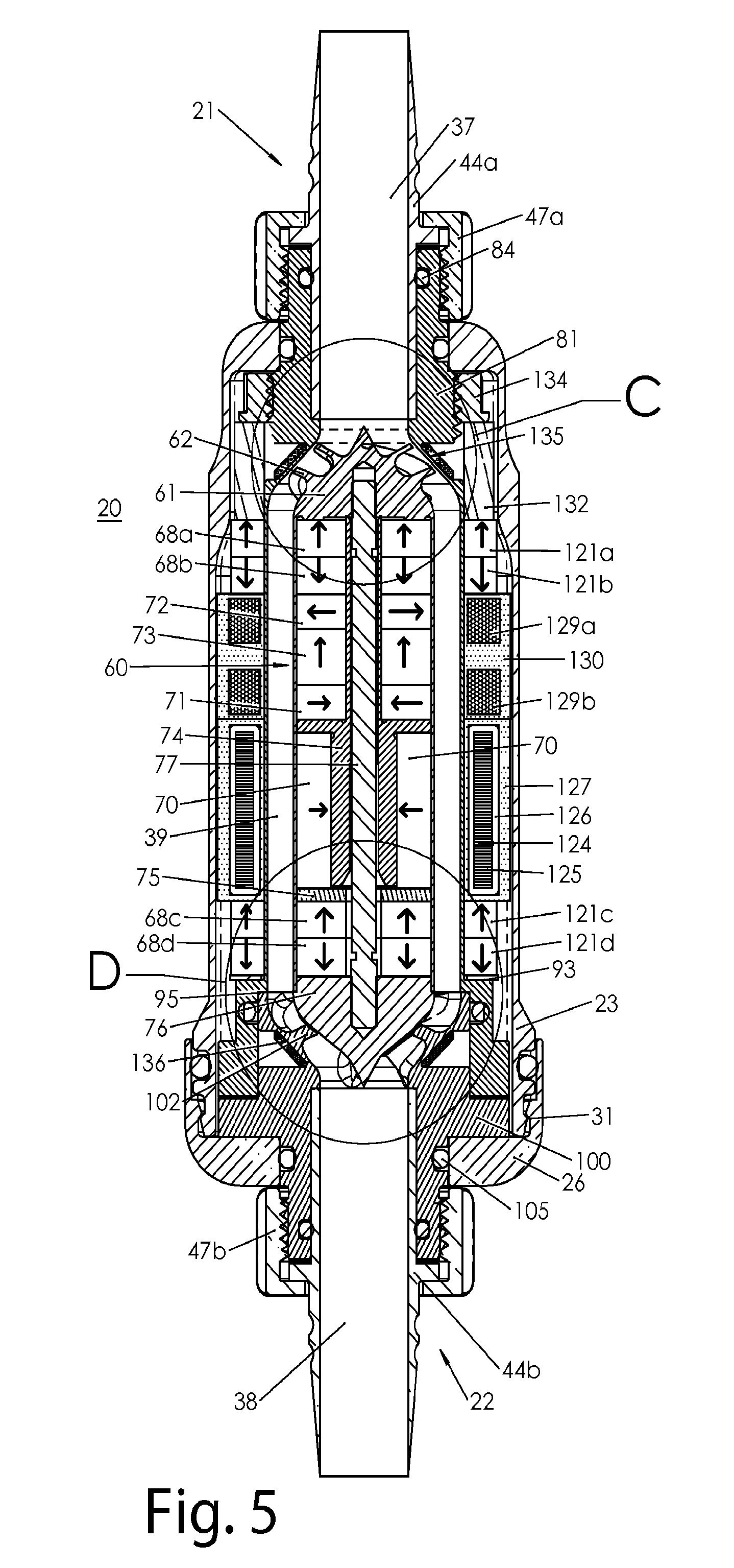

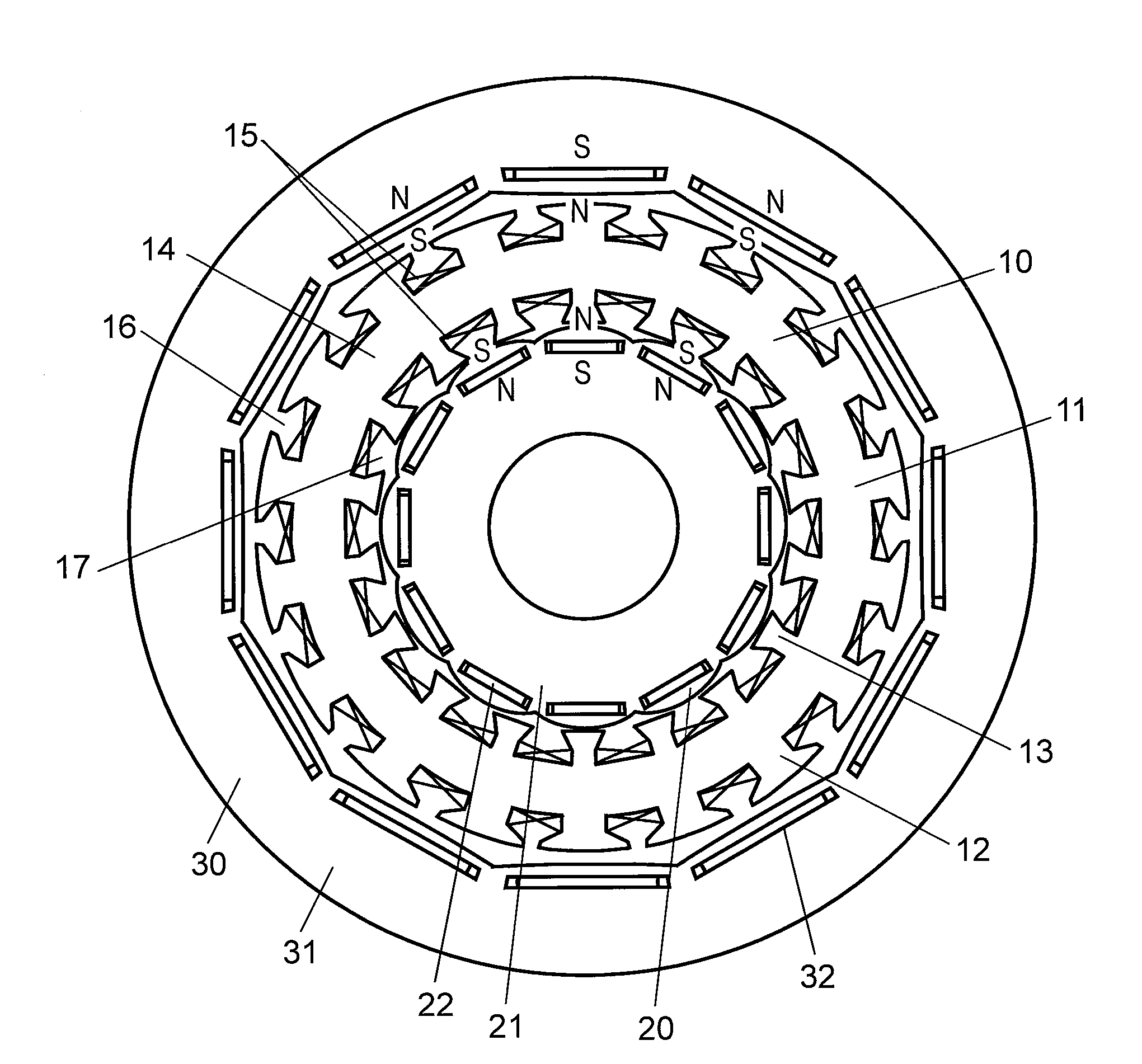

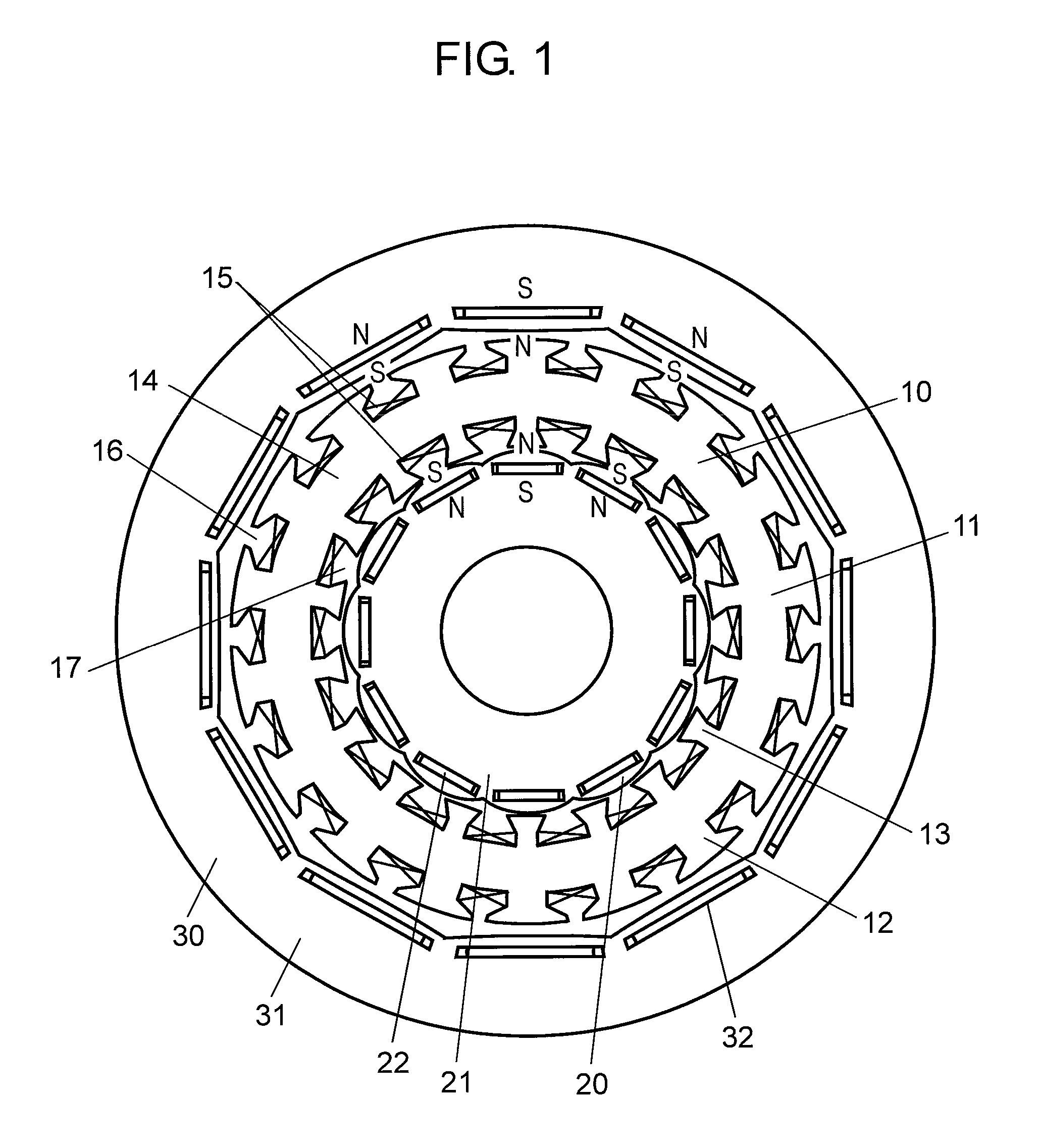

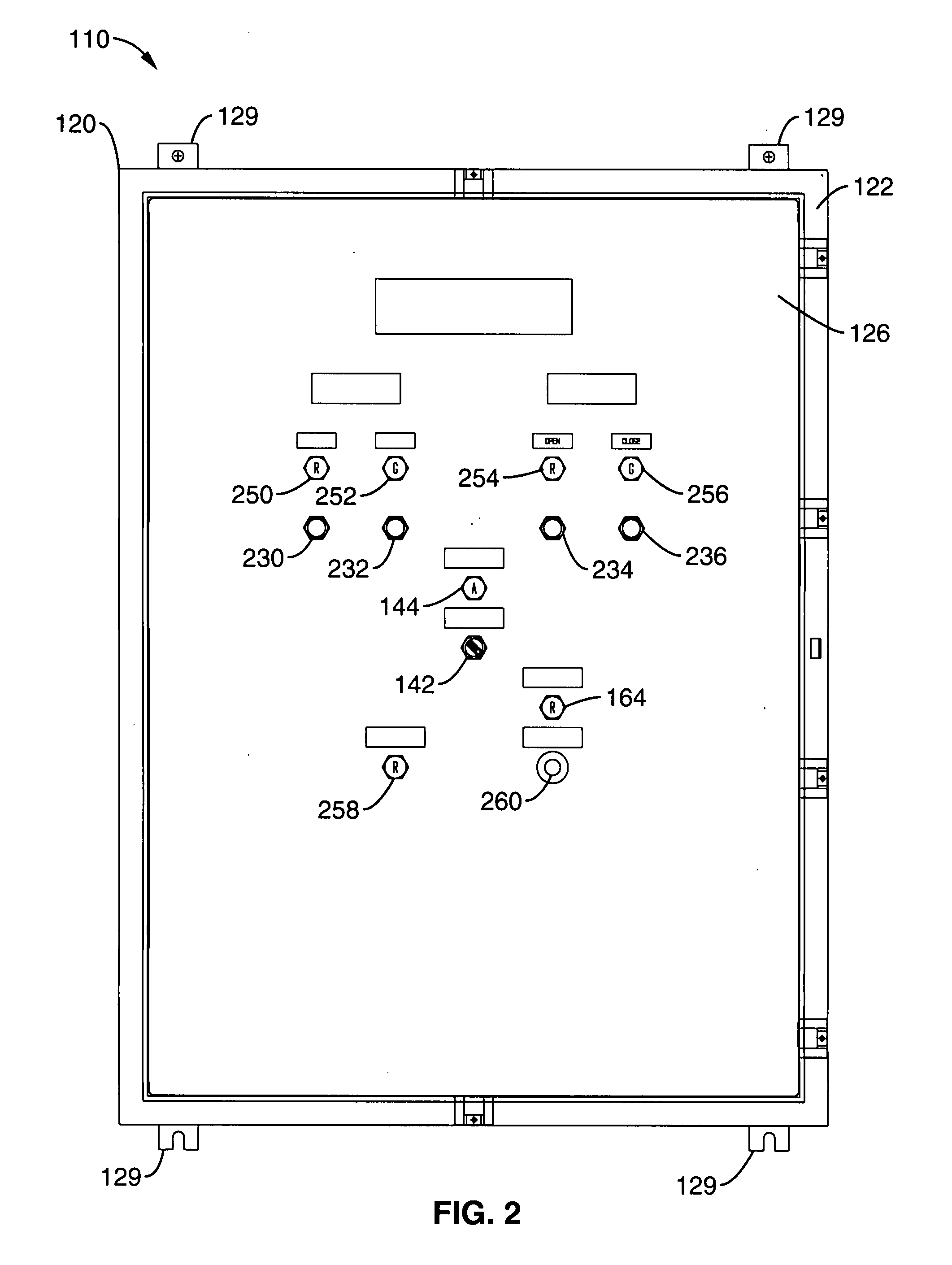

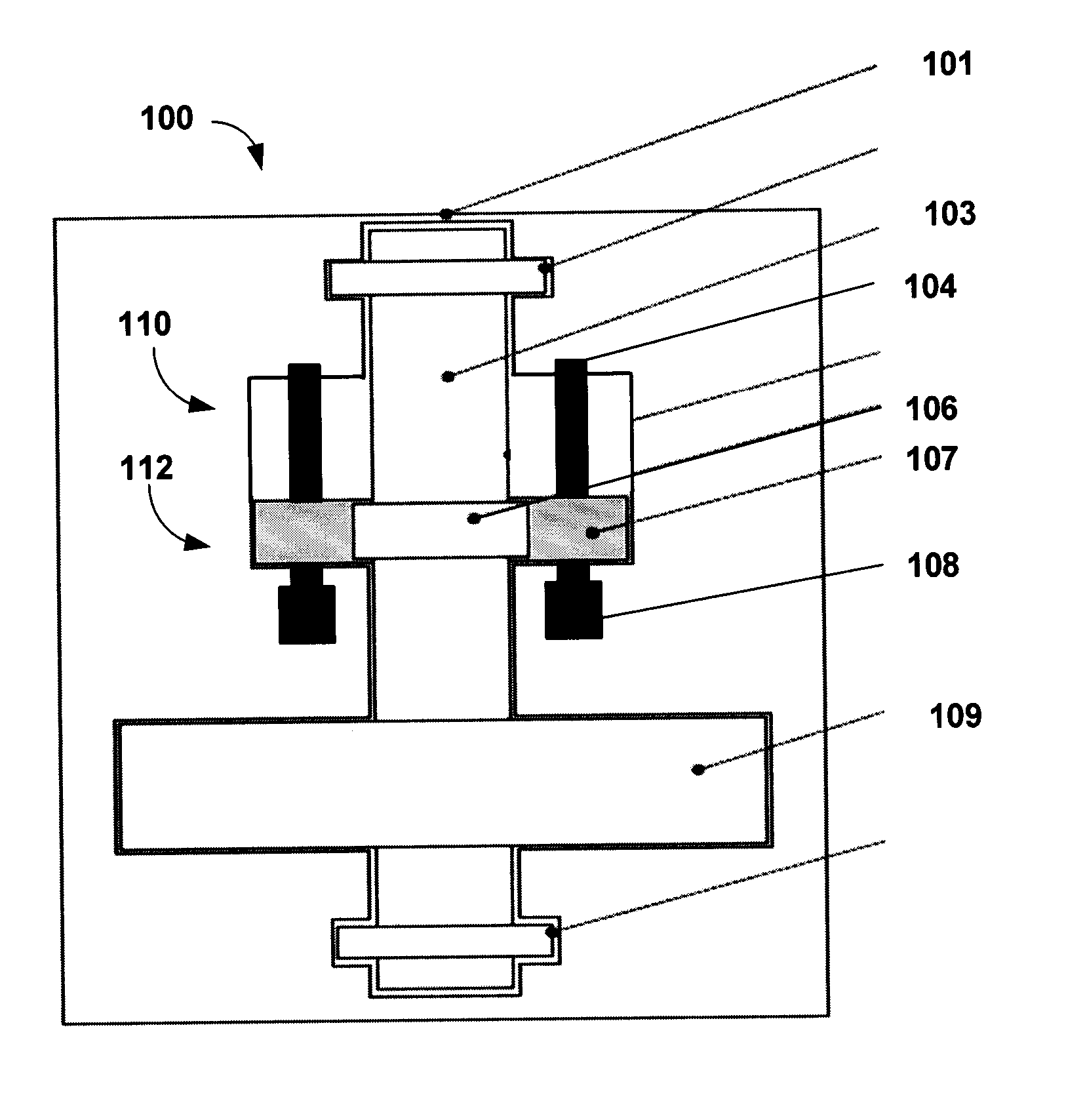

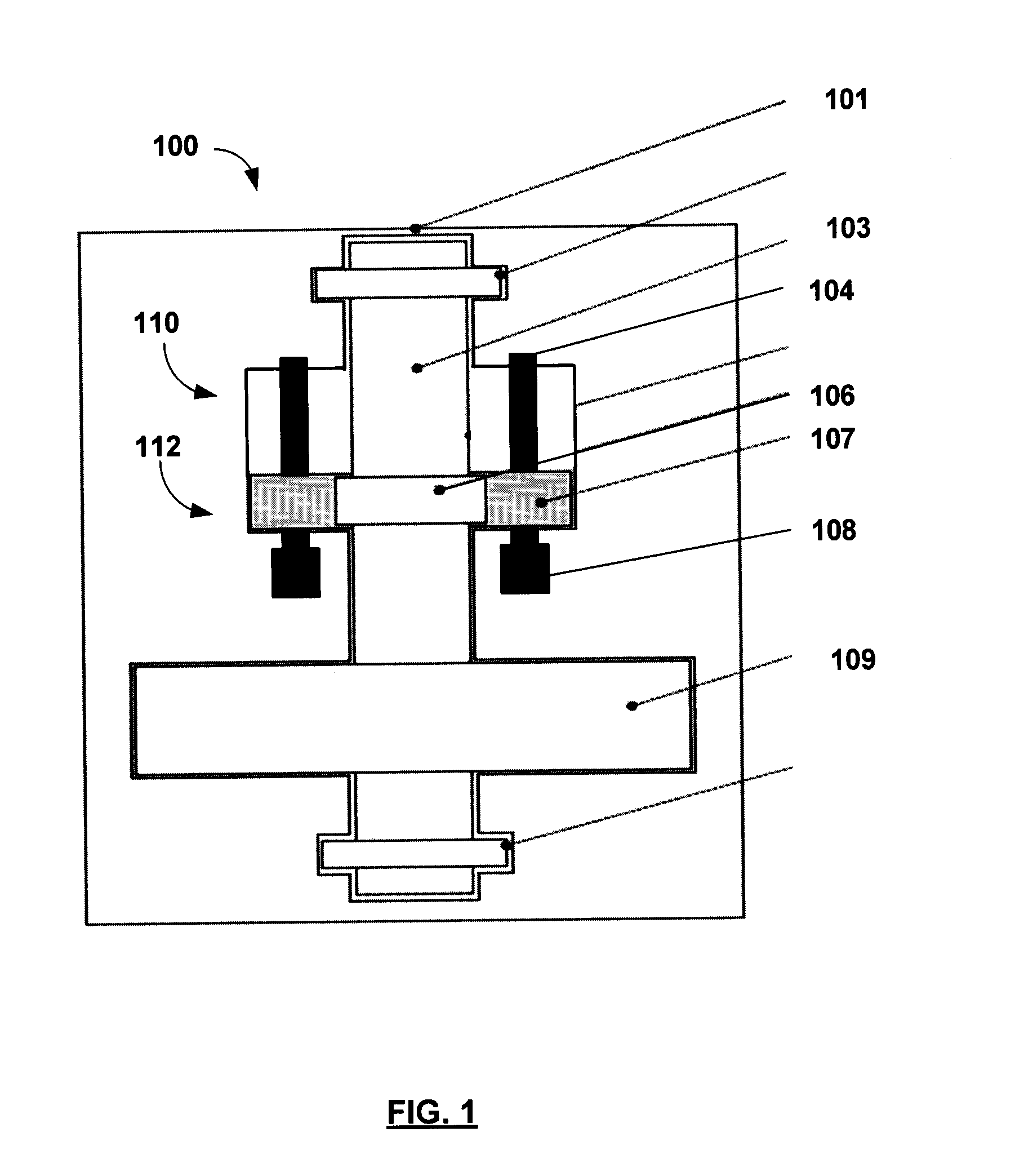

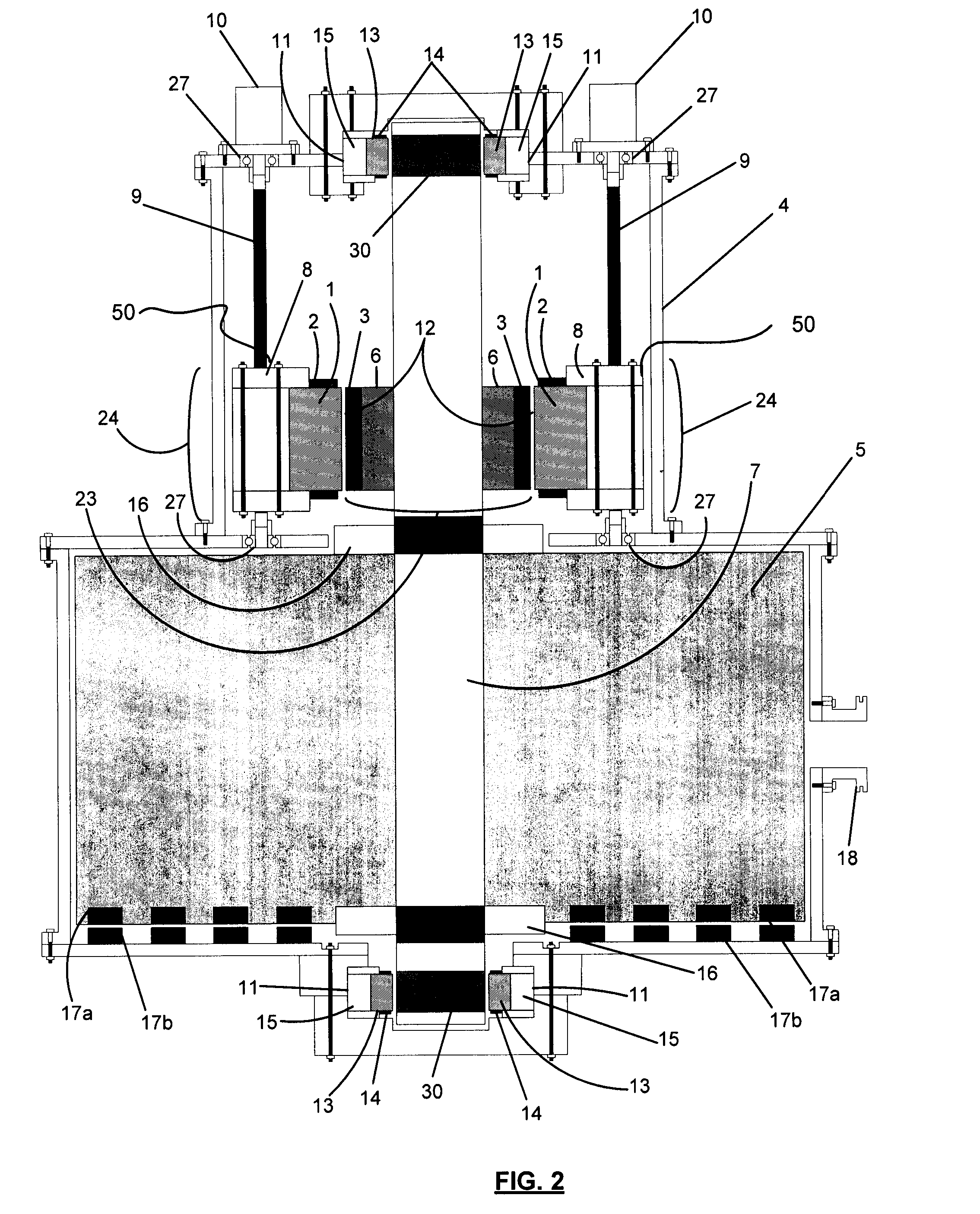

Magnetically-levitated blood pump with optimization method enabling miniaturization

ActiveUS20110237863A1Quality improvementReduce stiffnessControl devicesBlood pumpsBlood pumpMiniaturization

A magnetically-levitated blood pump with an optimization method that enables miniaturization and supercritical operation. The blood pump includes an optimized annular blood gap that increases blood flow and also provides a reduction in bearing stiffness among the permanent magnet bearings. Sensors are configured and placed optimally to provide space savings for the motor and magnet sections of the blood pump. Rotor mass is increased by providing permanent magnet placement deep within the rotor enabled by a draw rod configuration.

Owner:WORLD HEART +1

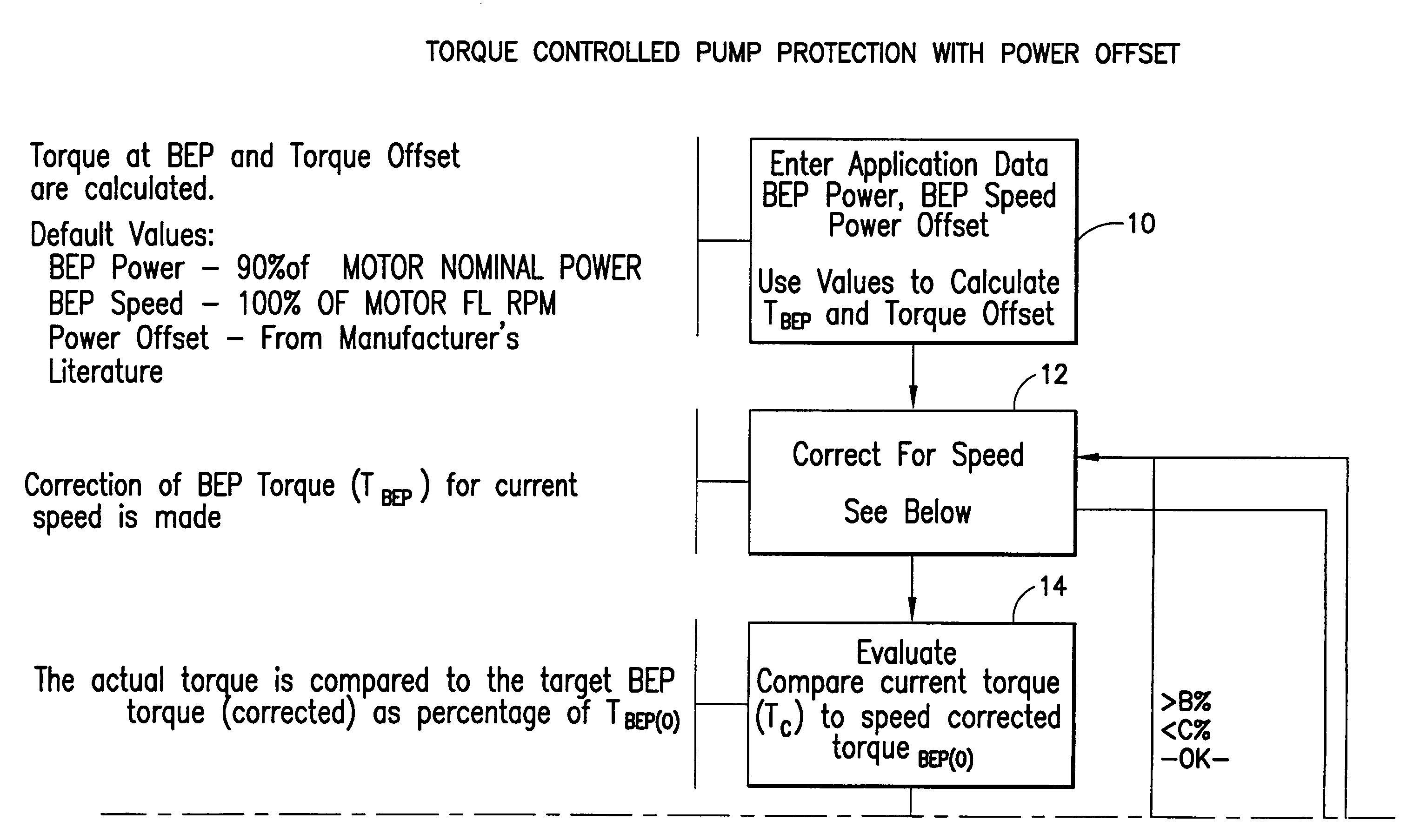

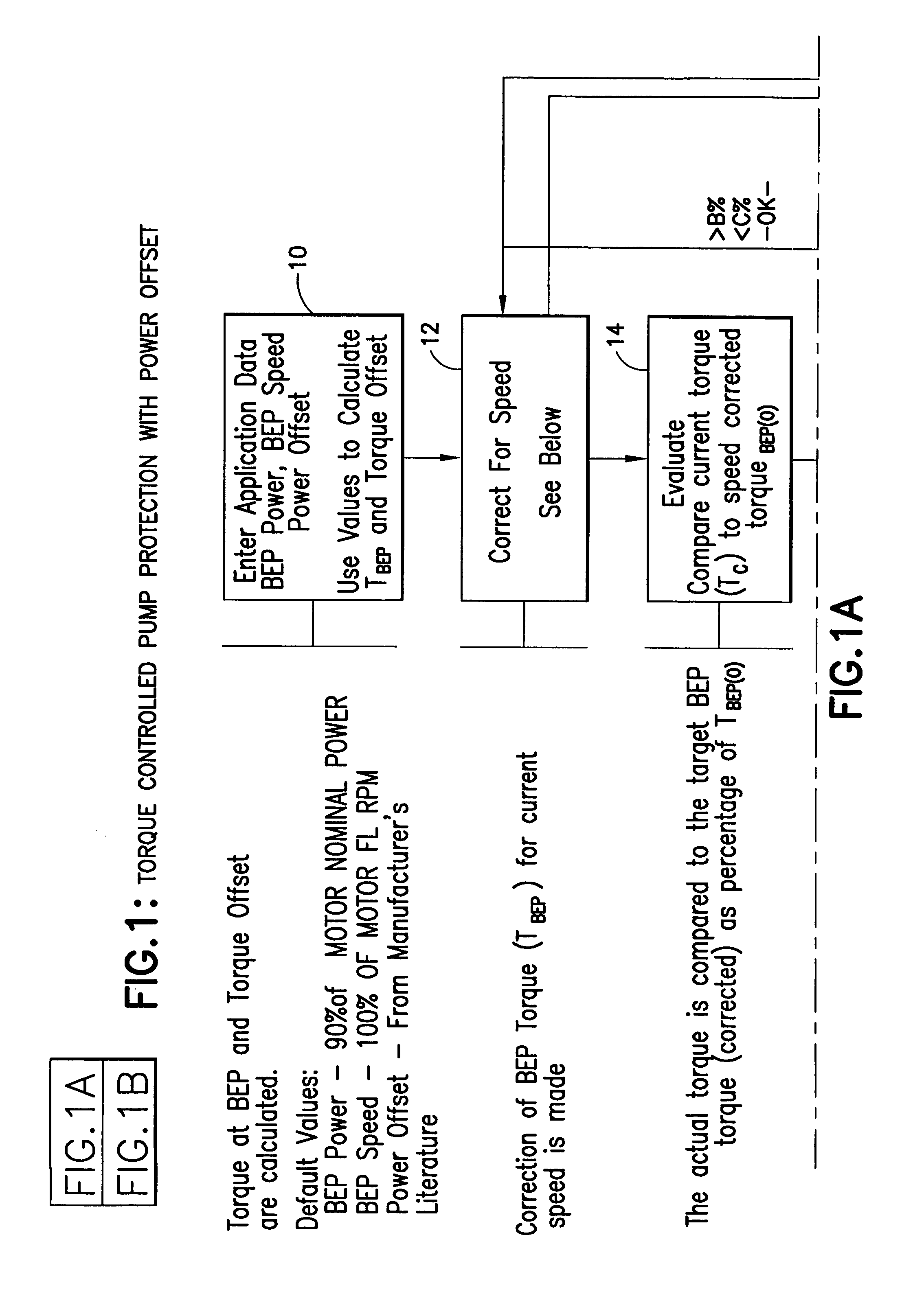

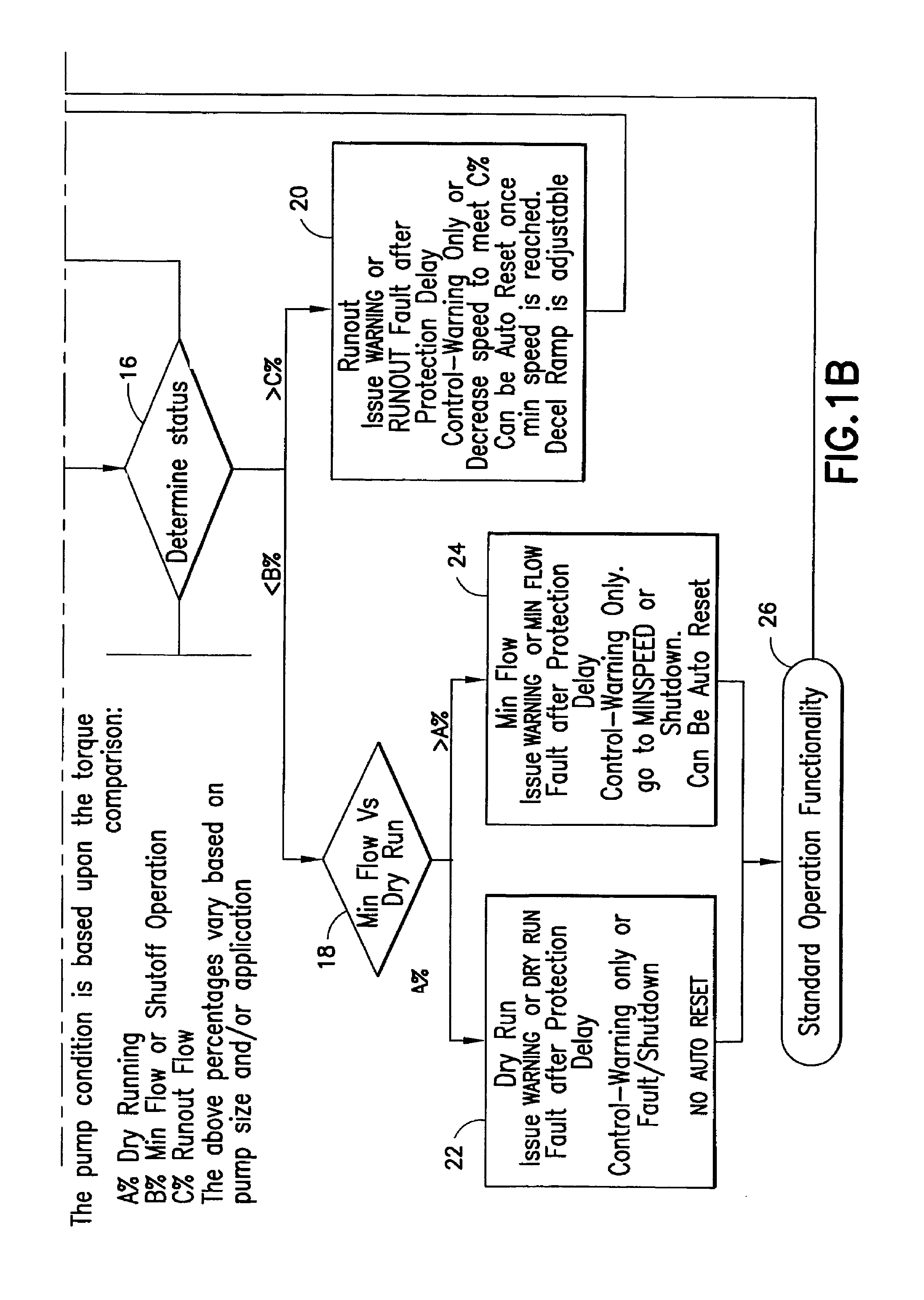

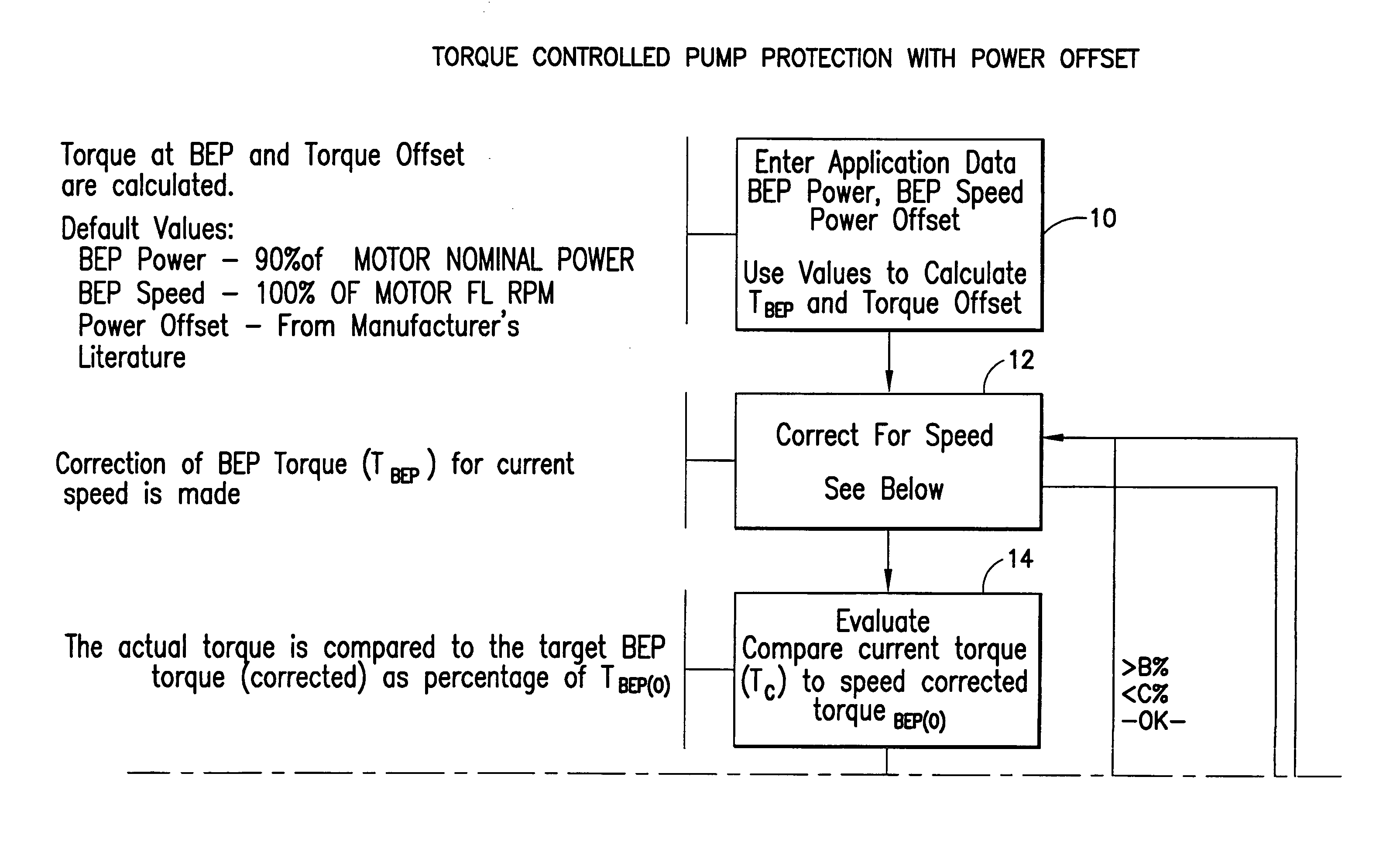

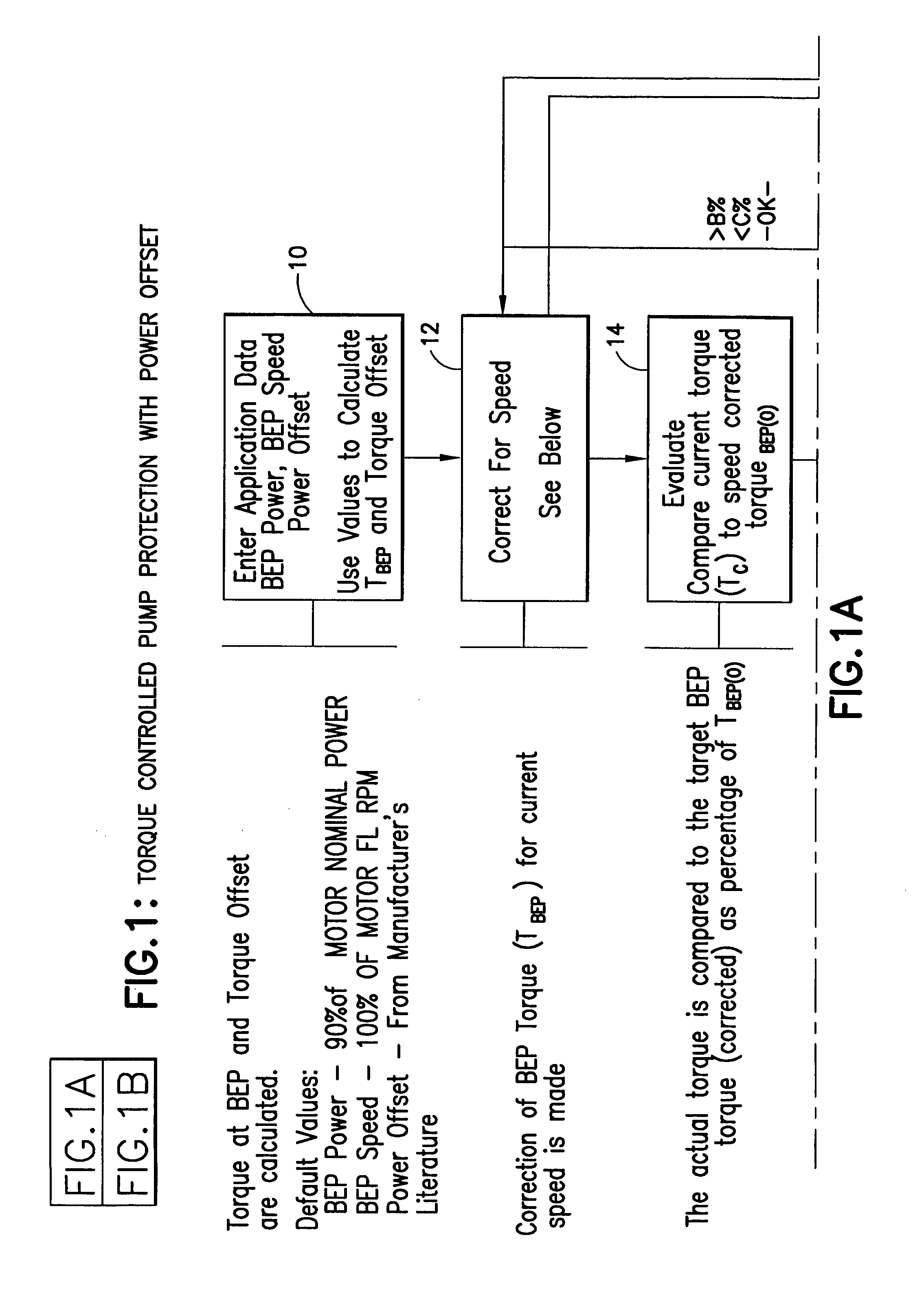

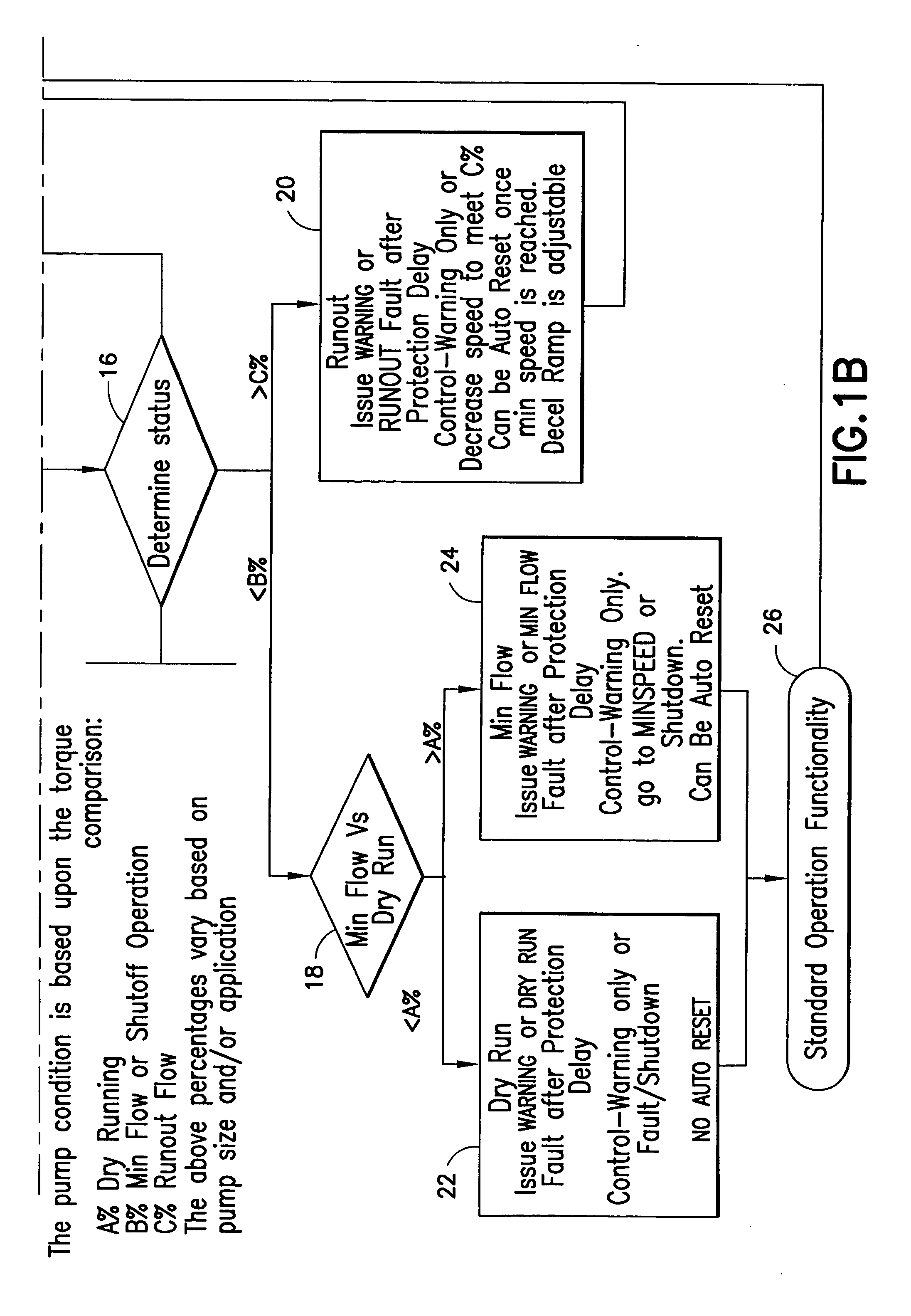

Torque controlled pump protection with mechanical loss compensation

ActiveUS7080508B2Eliminate needExtended speed rangeFluid couplingsFlexible member pumpsEngineeringControl theory

A method and apparatus are provided for controlling the operation of a pump, such as a centrifugal pump, featuring steps of either adjusting the operation of the pump, or issues a warning to a user of the pump of an undesirable operating condition, or both, based on a comparison of an actual torque value and a corrected torque value either alone or in combination with a further step of compensating the corrected torque value based on a mechanical power offset correction. The corrected torque value may include a Best Efficiency Point (BEP) torque value and may also be compensated for based on at least the current operating speed of the pump. The pump has a controller for performing the steps of the method. The controller can compensate the corrected torque value based on the square of the speed change of the pump. The comparison may include a ratio of the actual torque value to the corrected torque value.

Owner:ITT MFG ENTERPRISES LLC

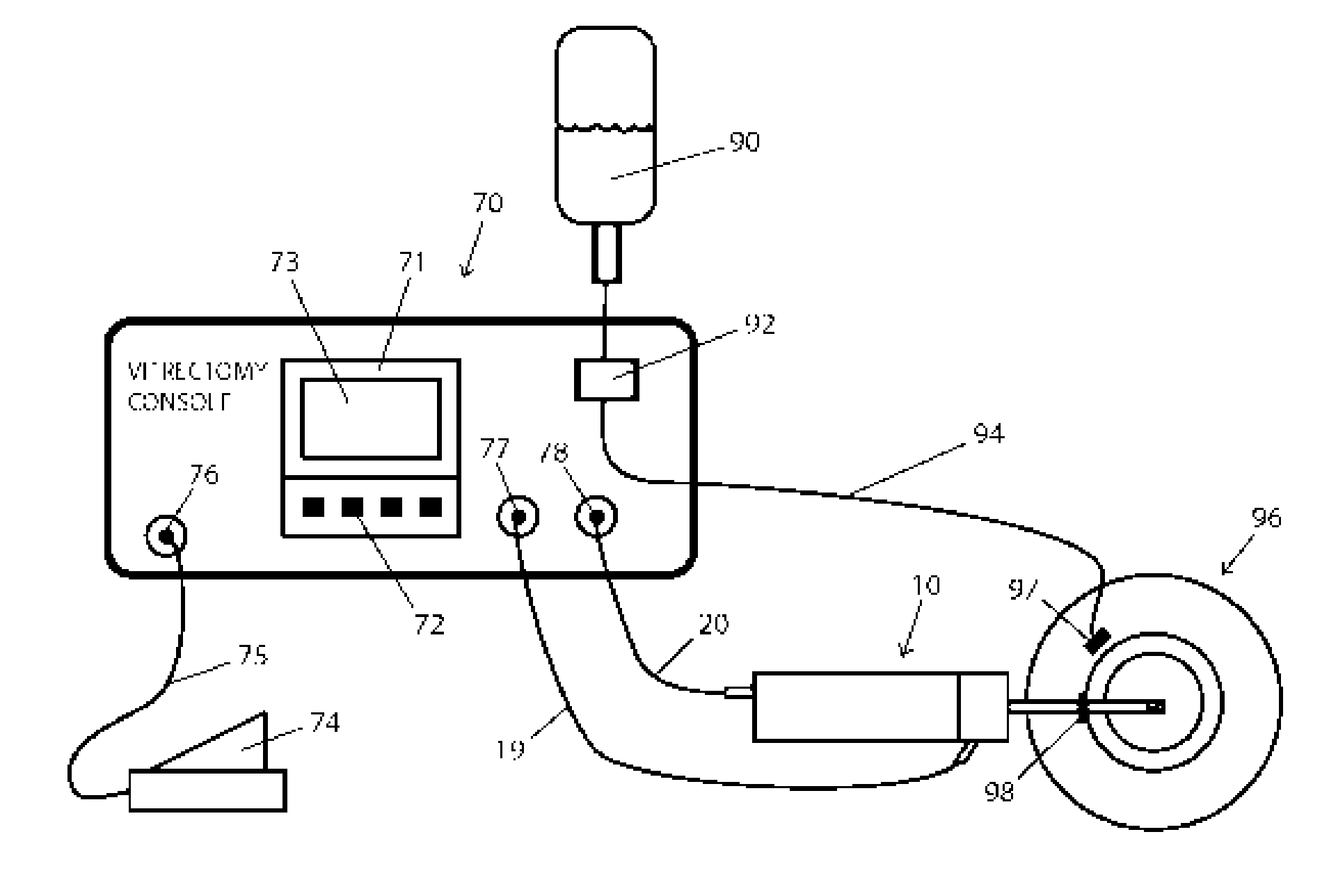

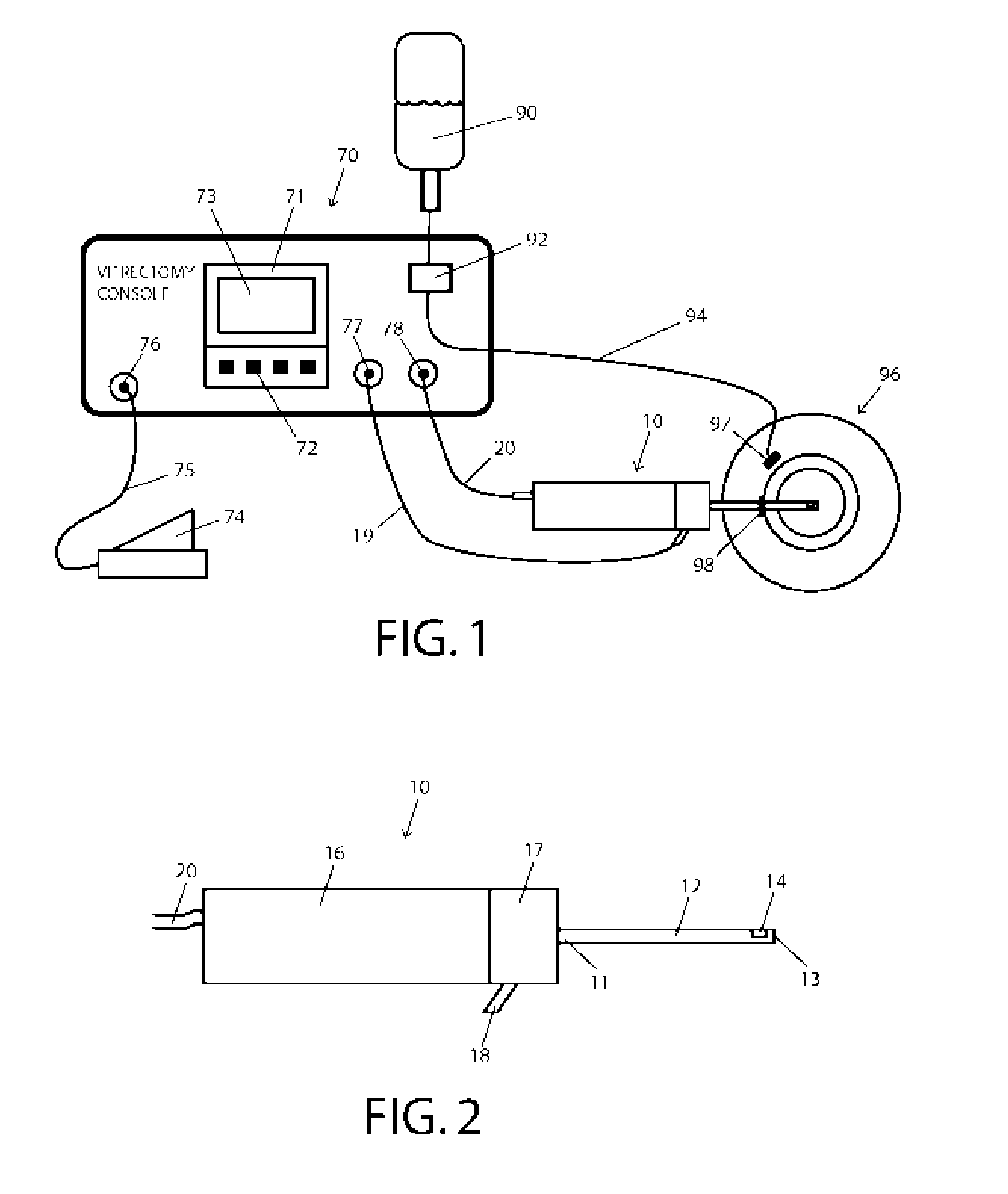

Precision Surgical System

InactiveUS20070173870A2Extended speed rangeIncrease speedEye surgeryEndoscopic cutting instrumentsNoise generationElectricity

A high-speed surgical handpiece (10) suitable for vitreoretinal surgery having a cutter (42) and actuators (36). The cutter (42) is a guillotine-type cutter activated by an array of leveraged piezoelectric actuators (30) that receive a driving signal from a driving controller. The controller can have control and display units with a plurality of input mechanisms receiving input from a user who selects a desired cutting rate and frequency for the cutter. The control unit produces a piezoelectric actuator output signal based on the inputs received. Fast cutting rates with reduced duty cycle as well as a proportional mode of operation are available, allowing slow controlled cutting action, for example proportional to depression of a foot-pedal (74). Low degrees of vibration and noise generation are produced.

Owner:DR ZACHARIAS JAIME

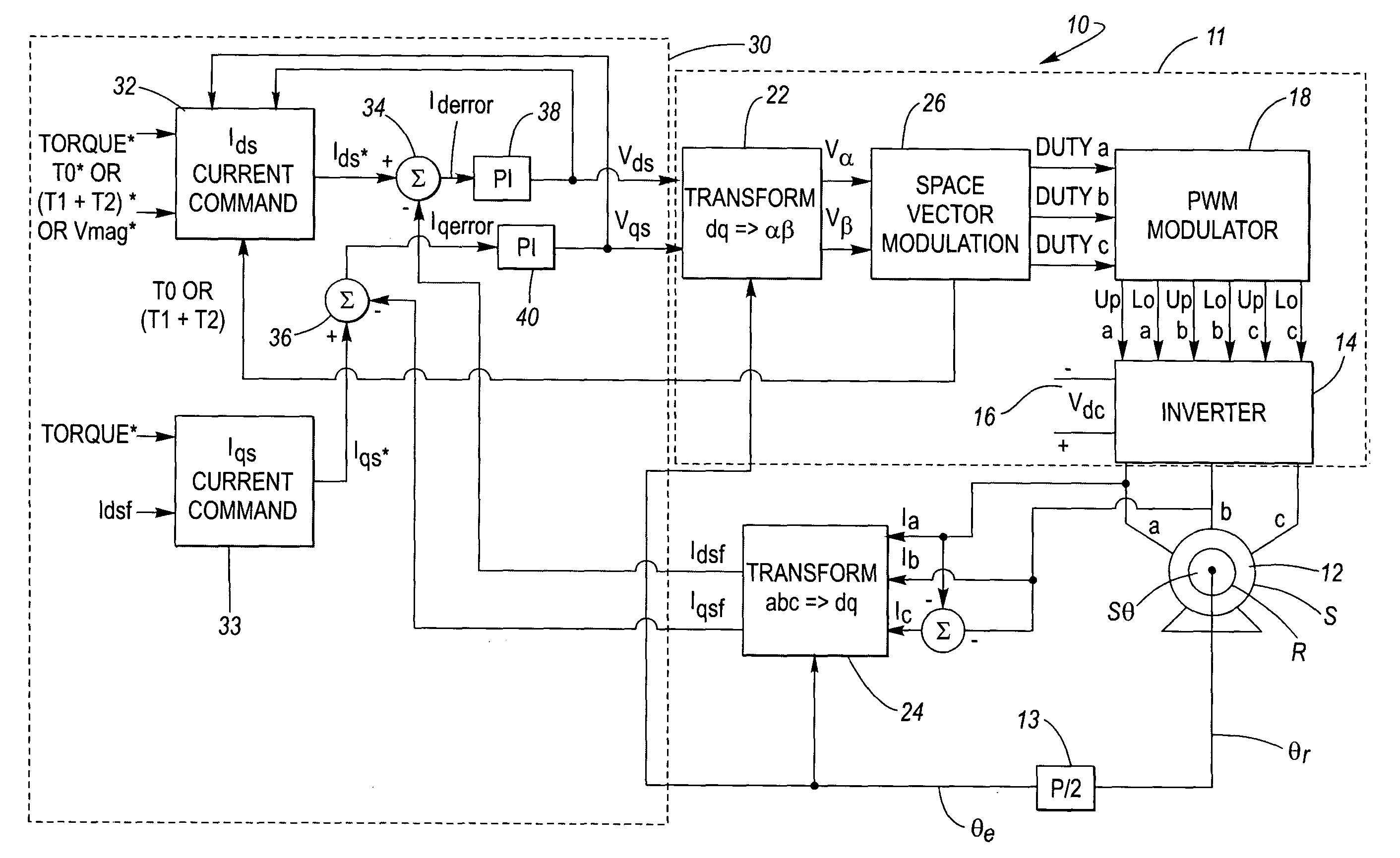

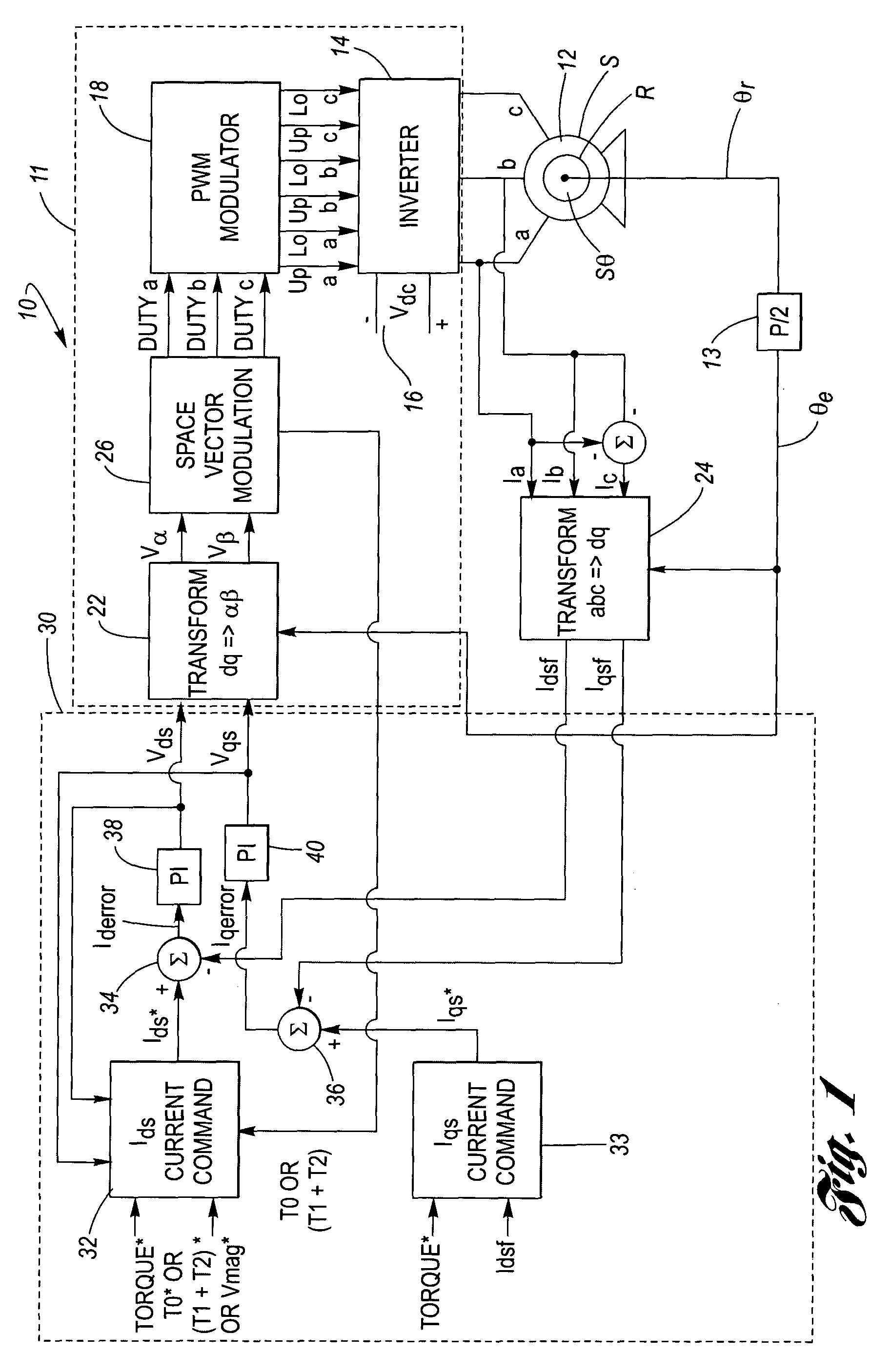

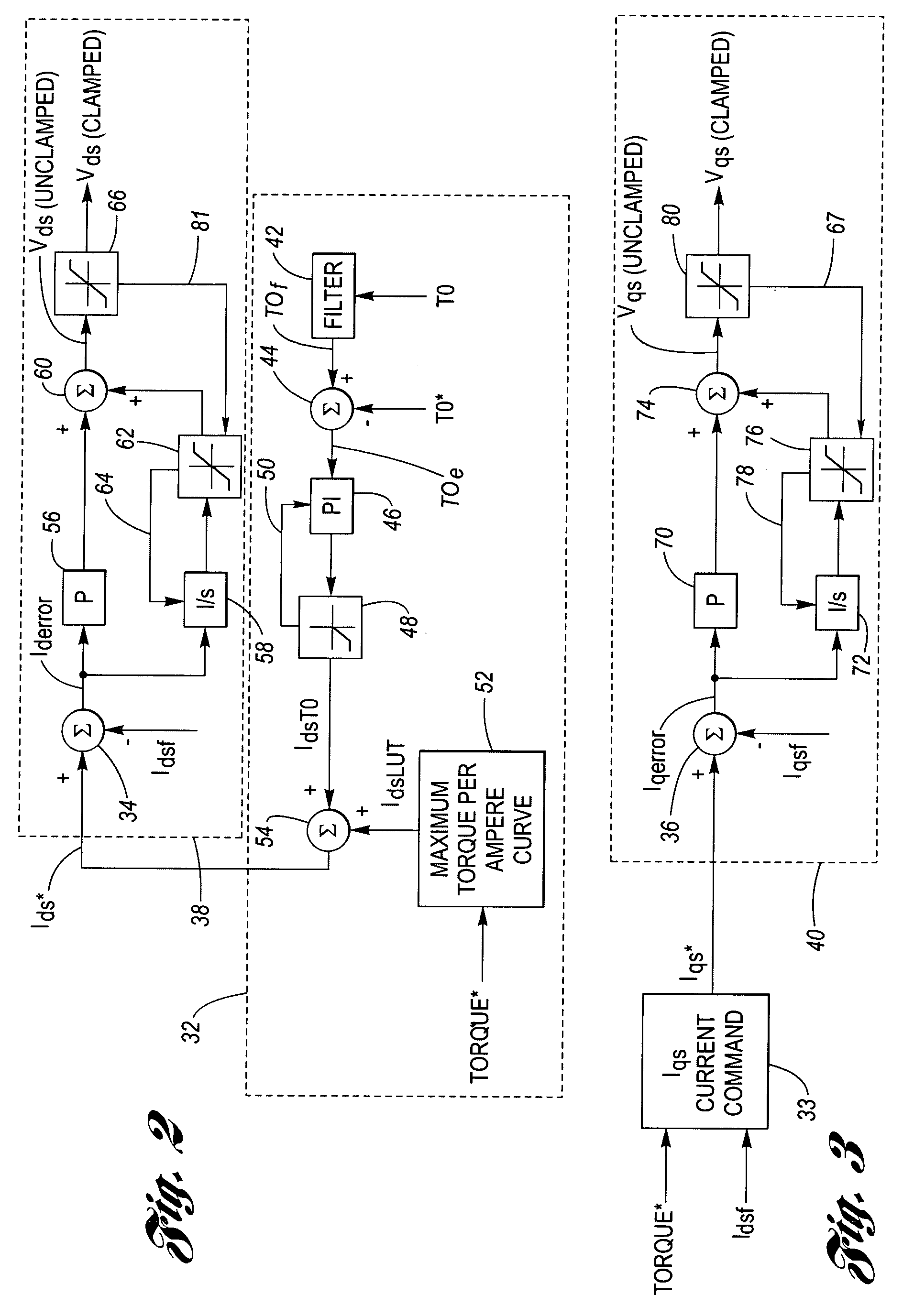

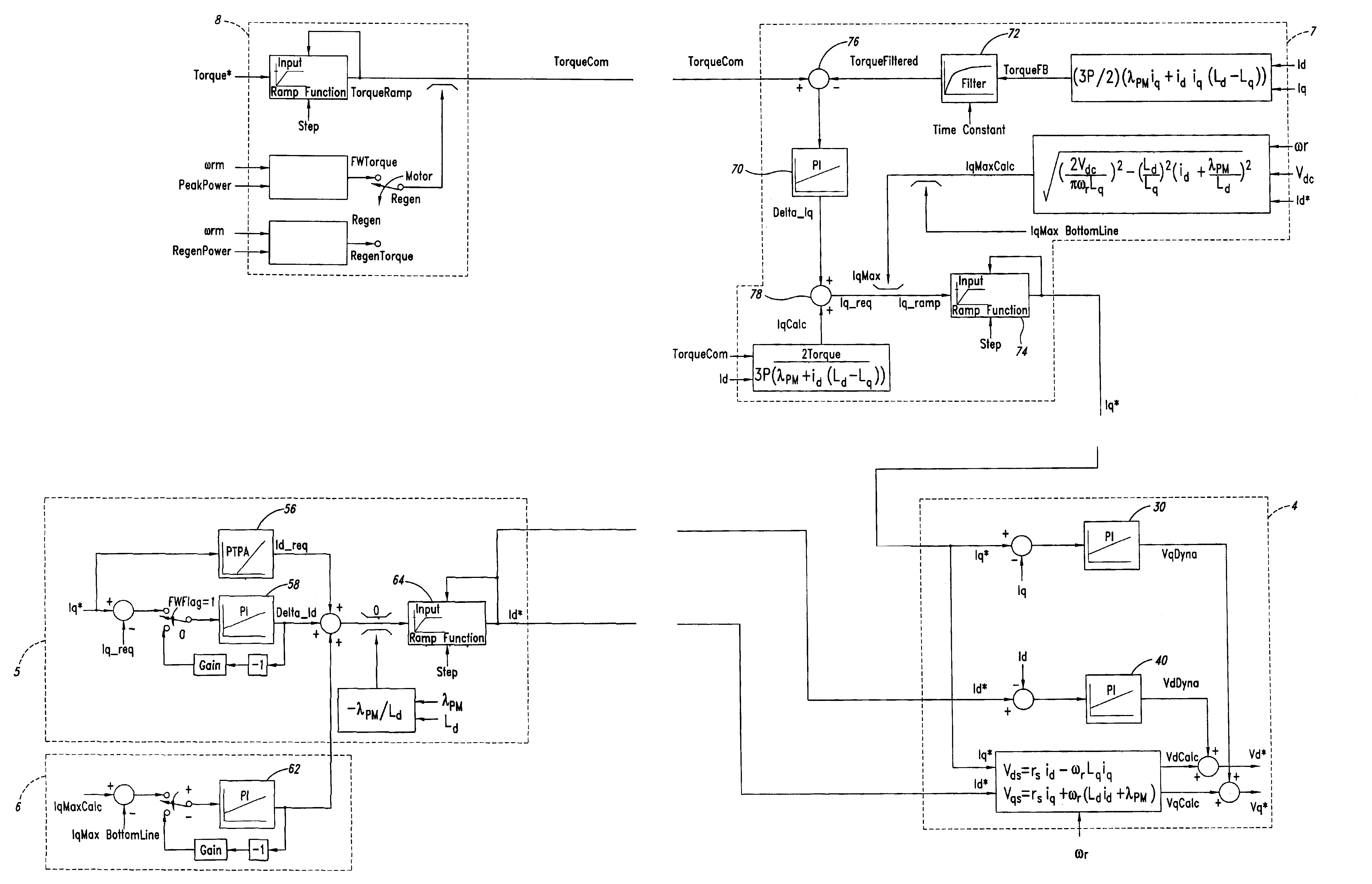

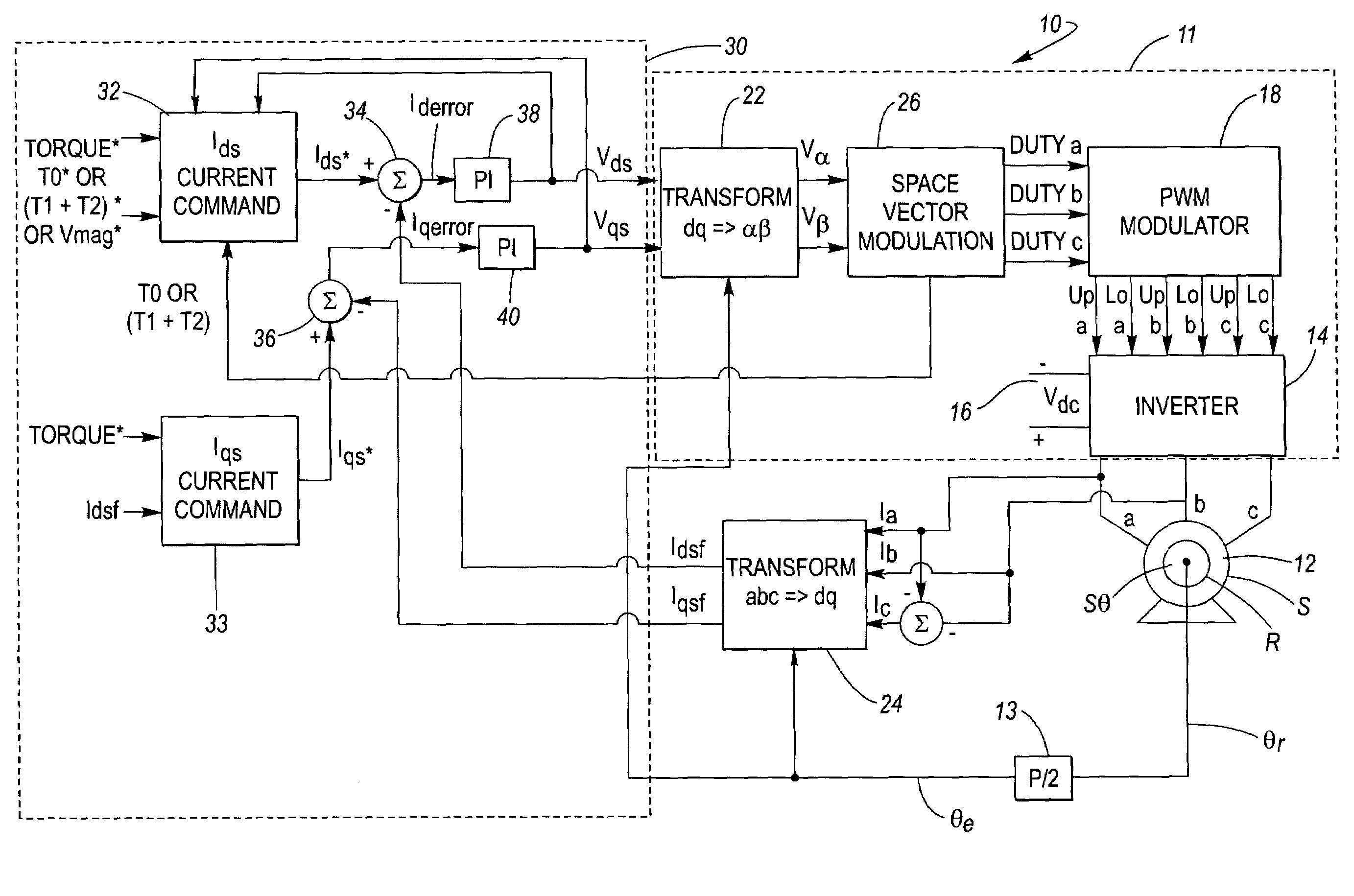

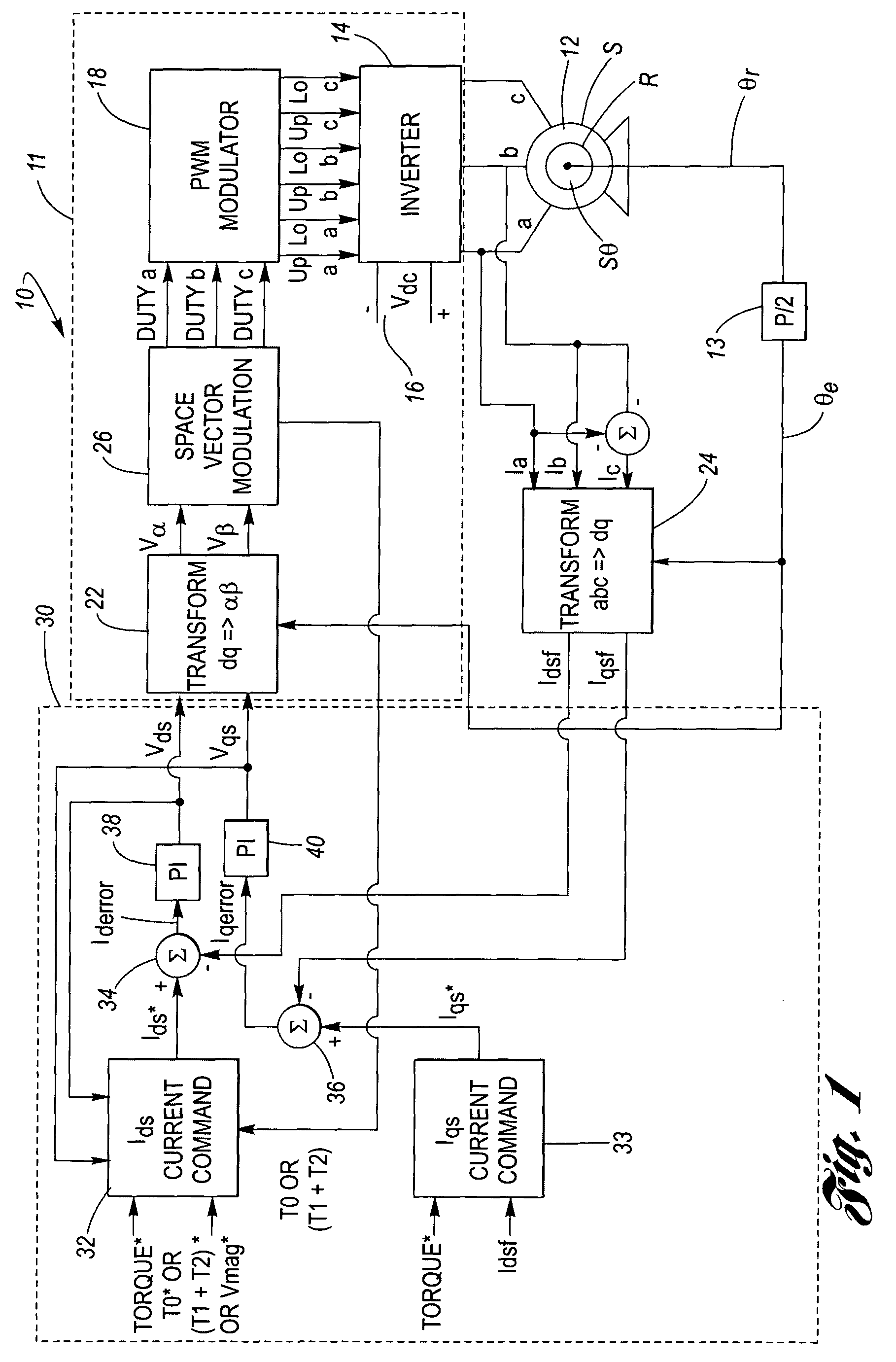

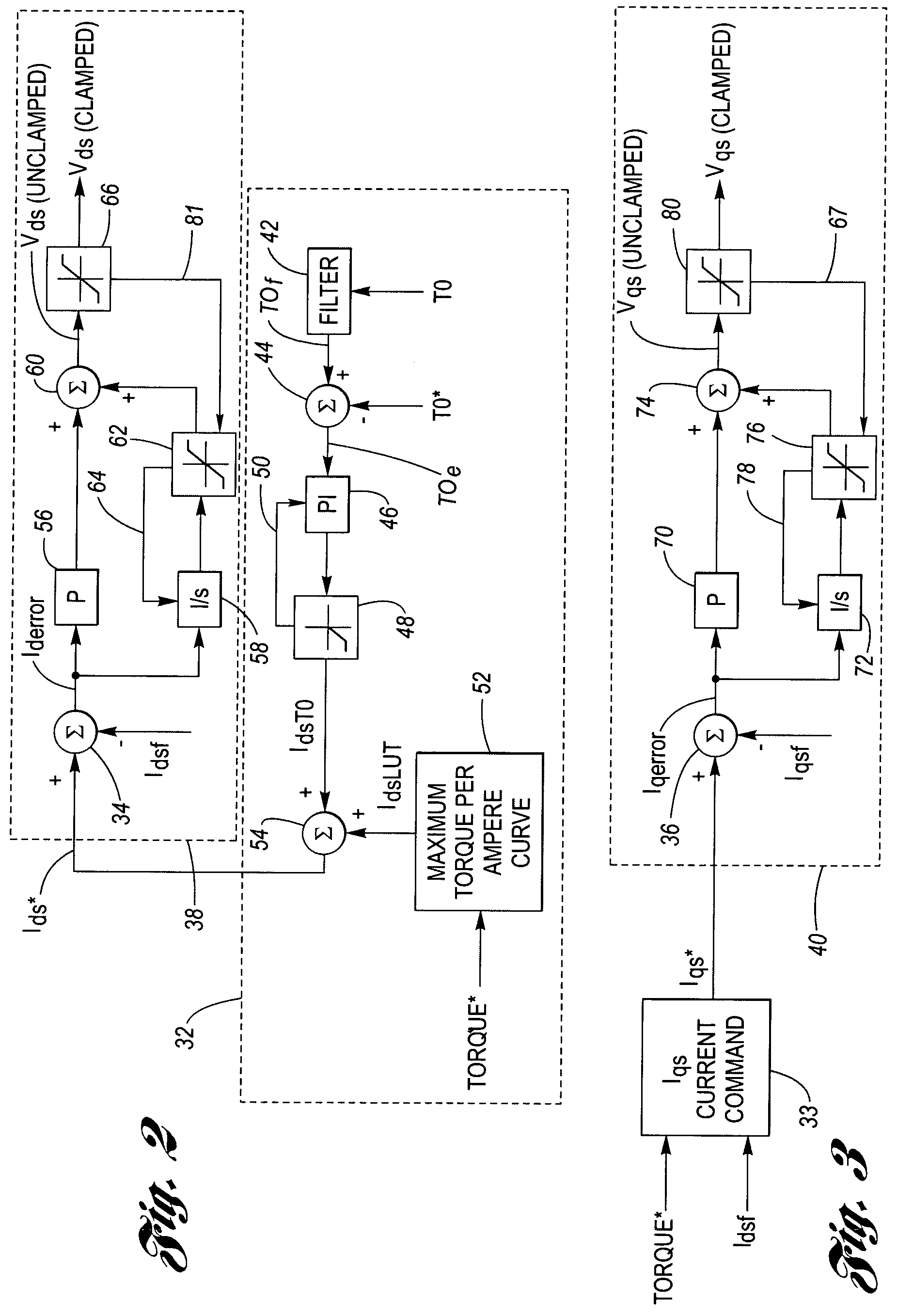

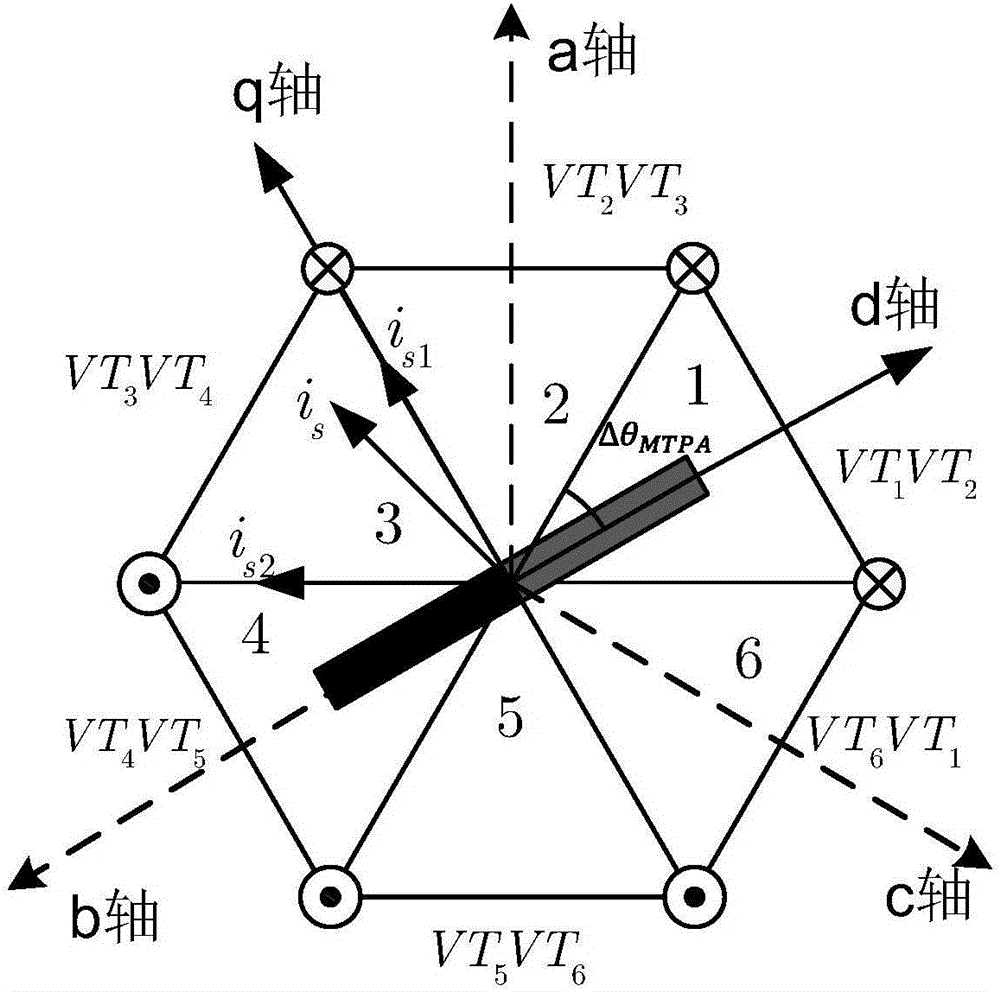

System and method for clamp current regulation in field-weakening operation of permanent magnet (PM) machines

ActiveUS20050046370A1Maximize processing efficiencyMaximum possible torqueAC motor controlDC motor speed/torque controlPhase currentsIntegrator

A device to regulate current produced by a permanent magnet machine responsive to a plurality of phase current signals. The motor produces torque for application on a shaft. A processing and drive circuit responsive to a direct current command signal and a quadrature current command signal produces phase current signals for input to the motor. A command circuit responsive to the phase current signals, an angular position of said shaft, and a voltage input command signal to produce a direct current error signal and a quadrature current error signal. A control circuit responsive to the direct and quadrature current error signals produces the direct voltage signal command and the quadrature voltage signal command. The control circuit has a direct and quadrature proportional gain, integrator and clamp circuits. An algorithm produces limited or clamped voltage modulation index signals to obtain maximum efficiency and maximum torque per ampere in the speed range. The algorithm ensures that the current regulator does not run out of voltage by limiting the voltage vector to the achievable voltage vector range that provides maximum torque per ampere and maximum efficiency.

Owner:DELPHI TECH IP LTD

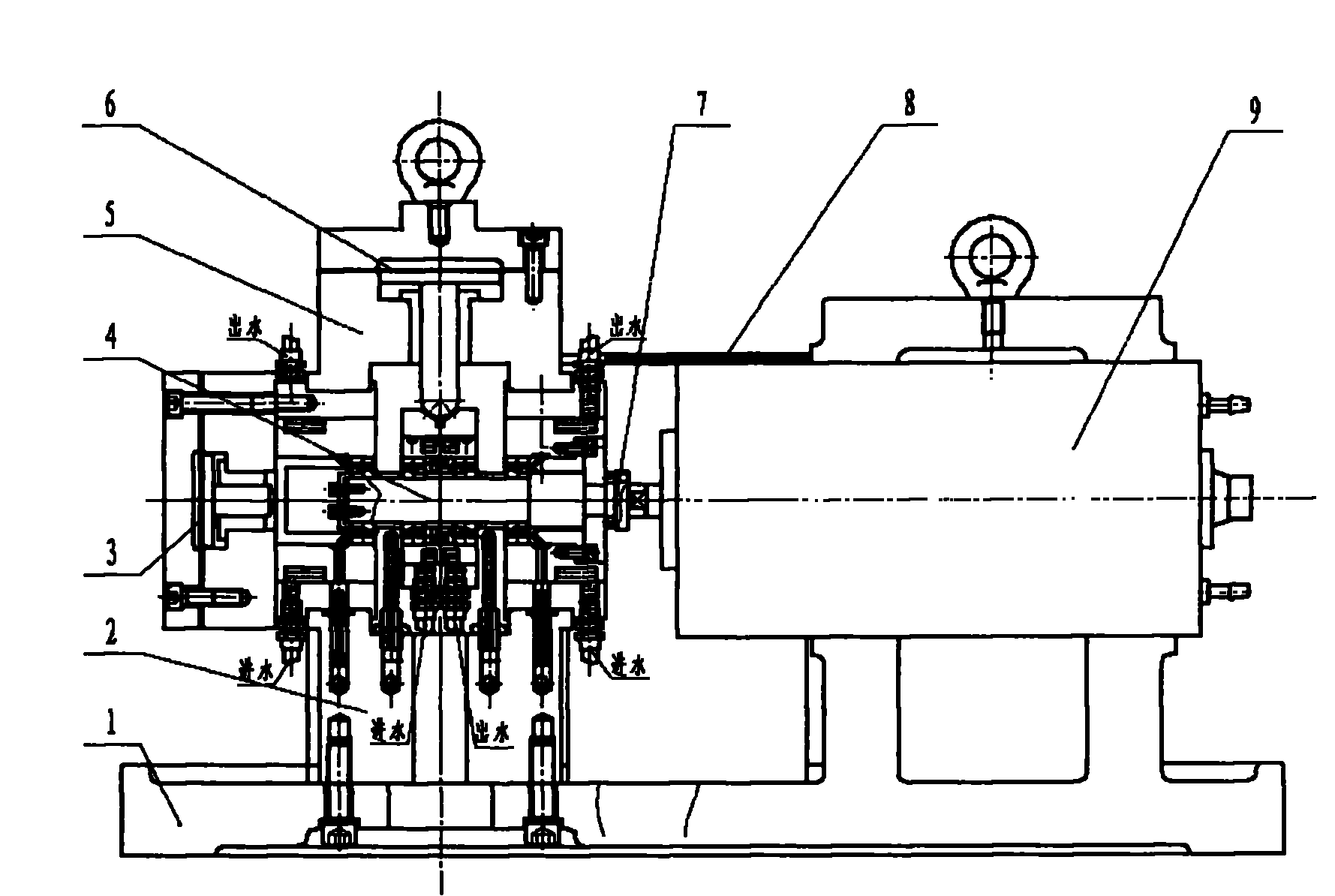

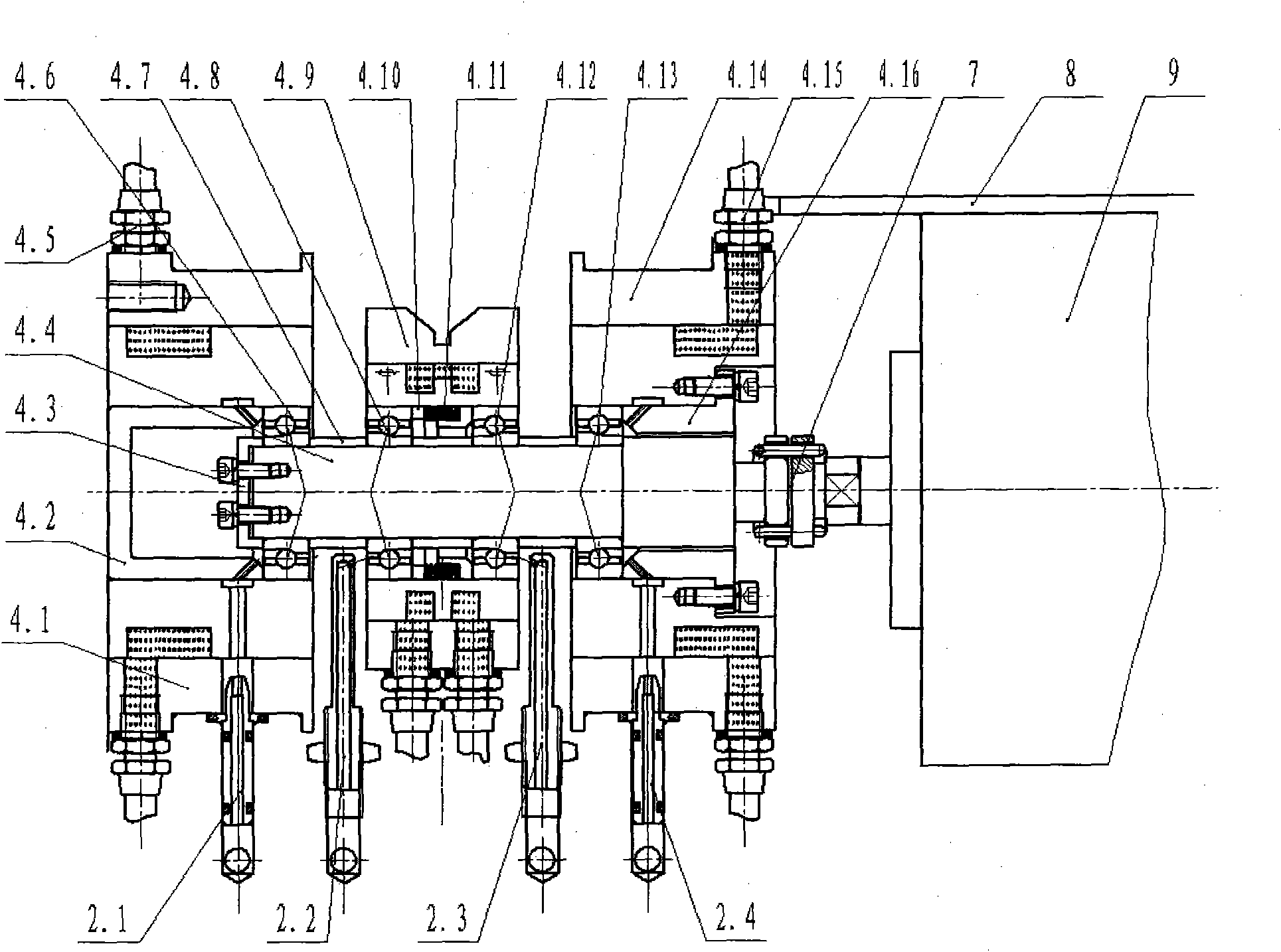

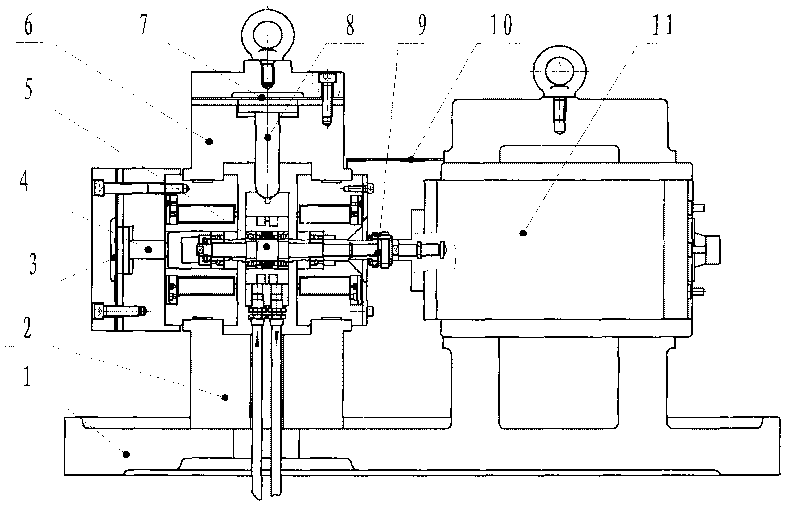

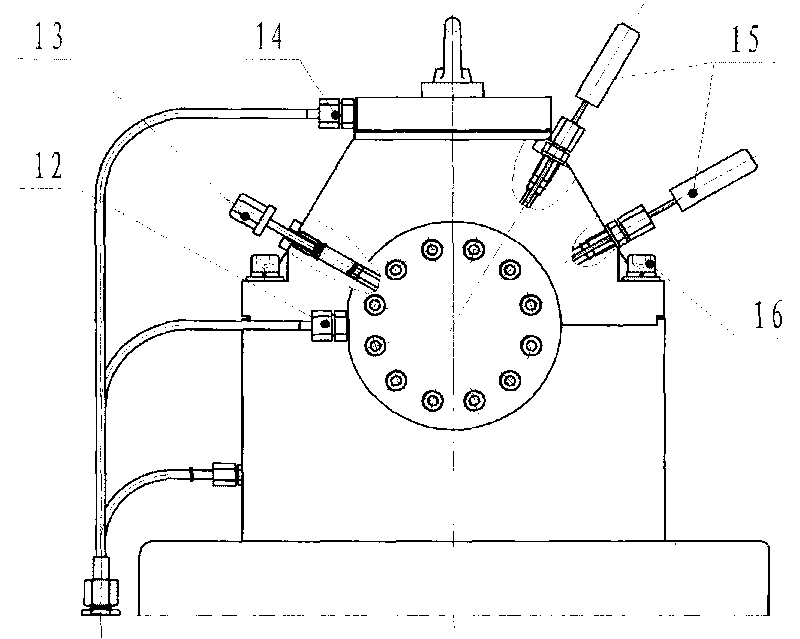

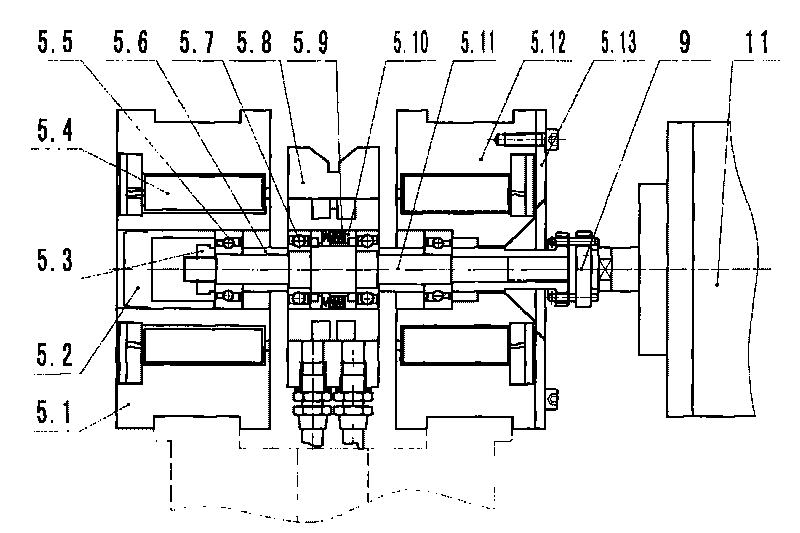

High-speed dynamic simulation test method for electric mainshaft bearing

ActiveCN101975659AEasy to achieve high speedRealize stepless speed regulationMachine bearings testingComputer databasePetroleum engineering

The invention relates to a high-speed dynamic simulation test method used for an electric mainshaft bearing. The electric mainshaft bearing comprises a frame, a main body pedestal, an axial loading cylinder, a test head assembly, a main body gland, a radial loading cylinder, a shaft coupling, a protecting hood, an electric mainshaft, a lubricating oil pipe, an axial loading oil pipe, a vibration sensor, a radial loading oil pipe and a temperature sensor and also a final assembly of all the parts. A hydraulic loading system is started to provide pressure oil to the axial loading cylinder and the radial loading cylinder, the electric mainshaft drives a test mainshaft to rotate, the radial loading cylinder exerts radial force on a first test accompanying bearing and a second test accompanying bearing through a radial loading sleeve, and the radial loading cylinder exerts axial force on a first test bearing and a second test bearing through an axial loading sleeve. The entire test is controlled by a computer to display parameters of the rotating speed, the axial load and the radial load, the oil pressure, the cooling water temperature, the bearing temperature, the bearing vibration, the power current of the electric mainshaft and the test time, and the parameters are saved in a computer database and analyzed.

Owner:国创(洛阳)轴承产业技术研究院有限公司

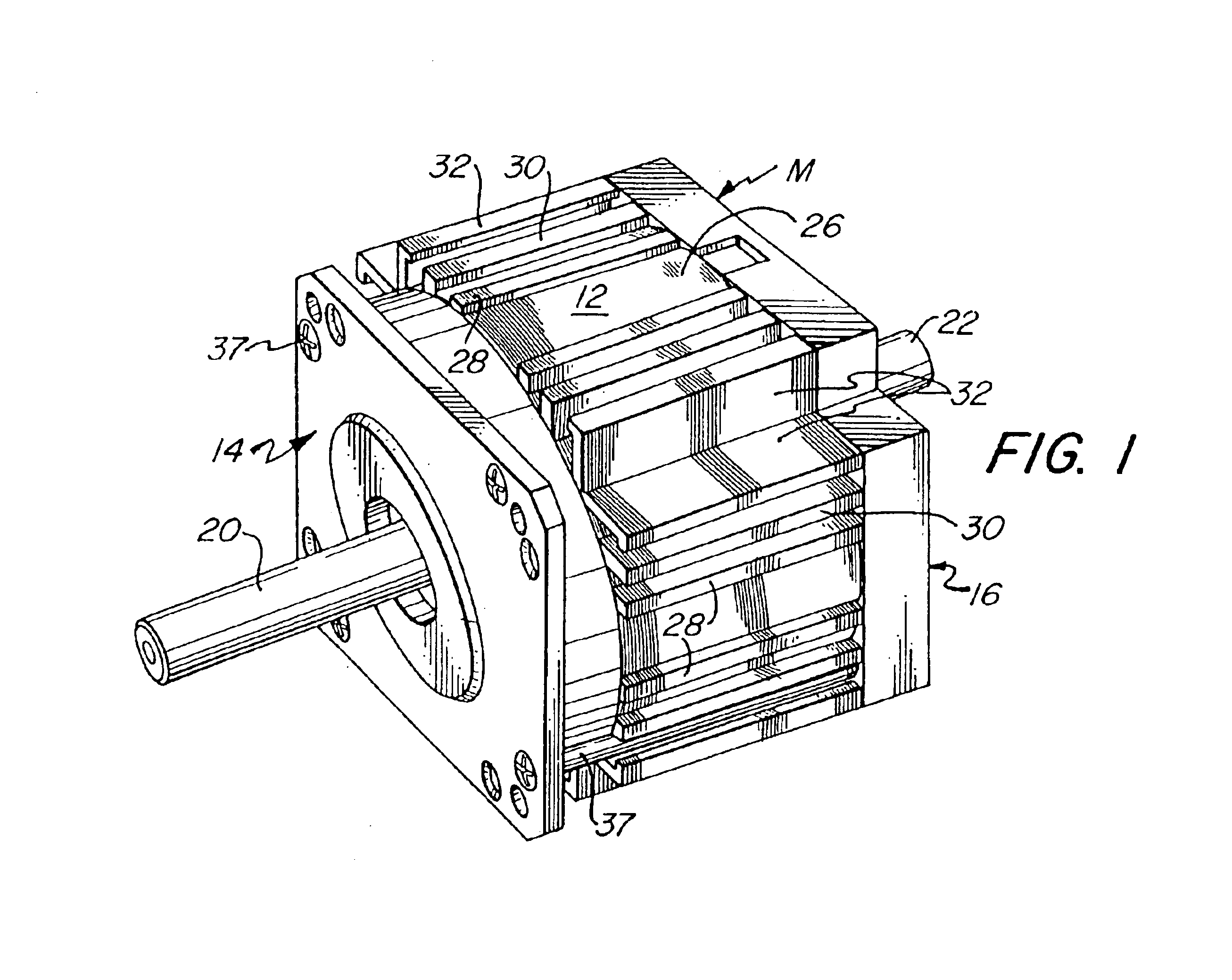

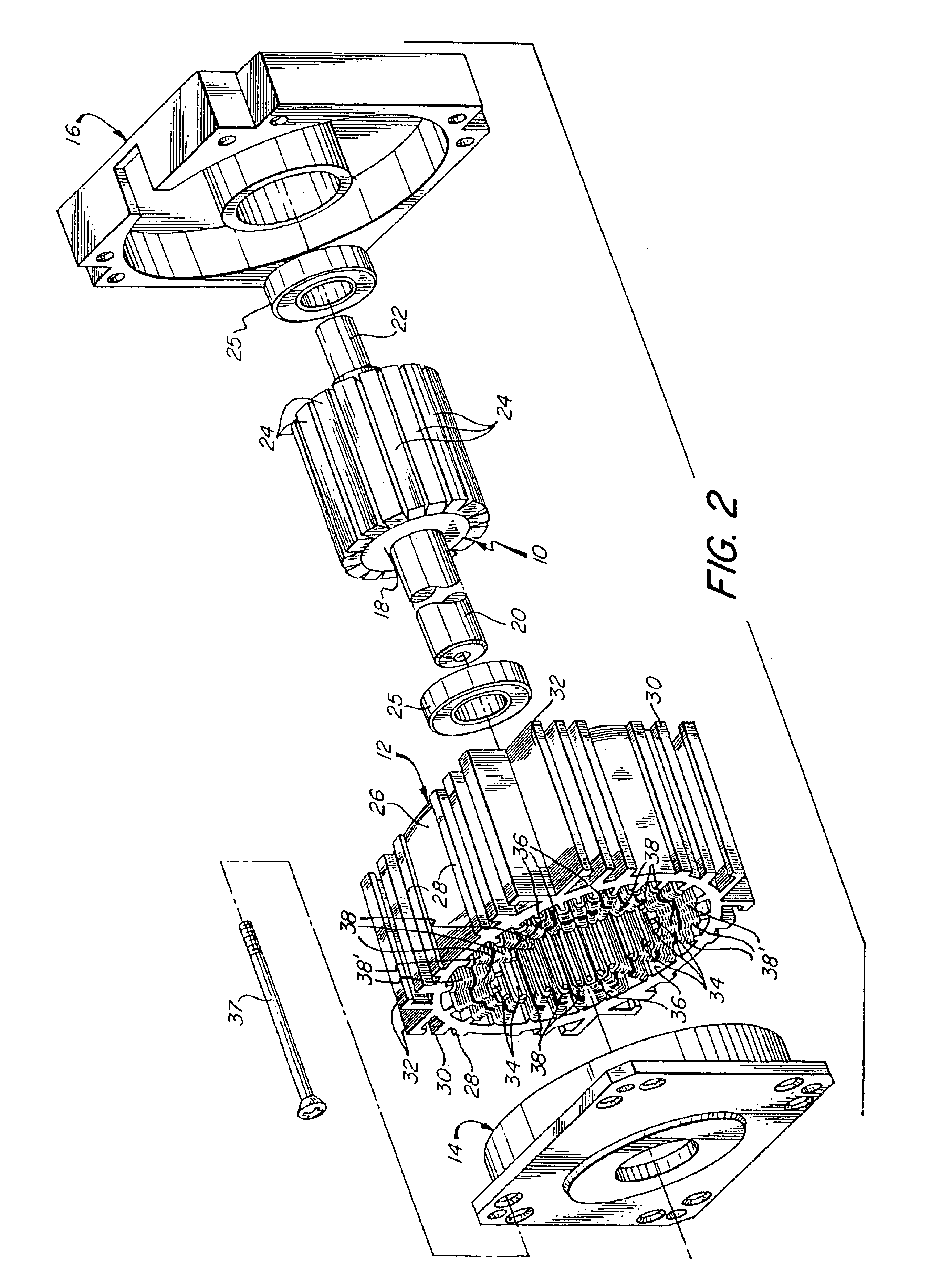

Permanent magnet motor having flux density characteristics that are internally variable

InactiveUS6844647B2Improve efficiencyEnsure constant power outputSynchronous generatorsMagnetic circuit rotating partsBrushless motorsLow speed

The permanent magnet brushless motor permits dynamic change of output characteristics by varying the positional relationships of rotor components, with respect to each other and with respect to the stator, to progressively effect field weakening with increasing speeds. The force required to impart the limited range of motion involved is transmitted to the rotor component by way of bearings and / or an actuation motor, and a helical guide path is used to great advantage for constraining such movement. The wide, dynamically adjustable motor output range of the motor effectively provides the equivalent of an efficient, continuously variable transmission. High torque at low speeds, and efficient, constant power output over a wide high speed range, uniquely adapt the motor for use as the prime mover for electric / hybrid vehicles.

Owner:ORIENTAL MOTOR BOSTON TECH GROUP

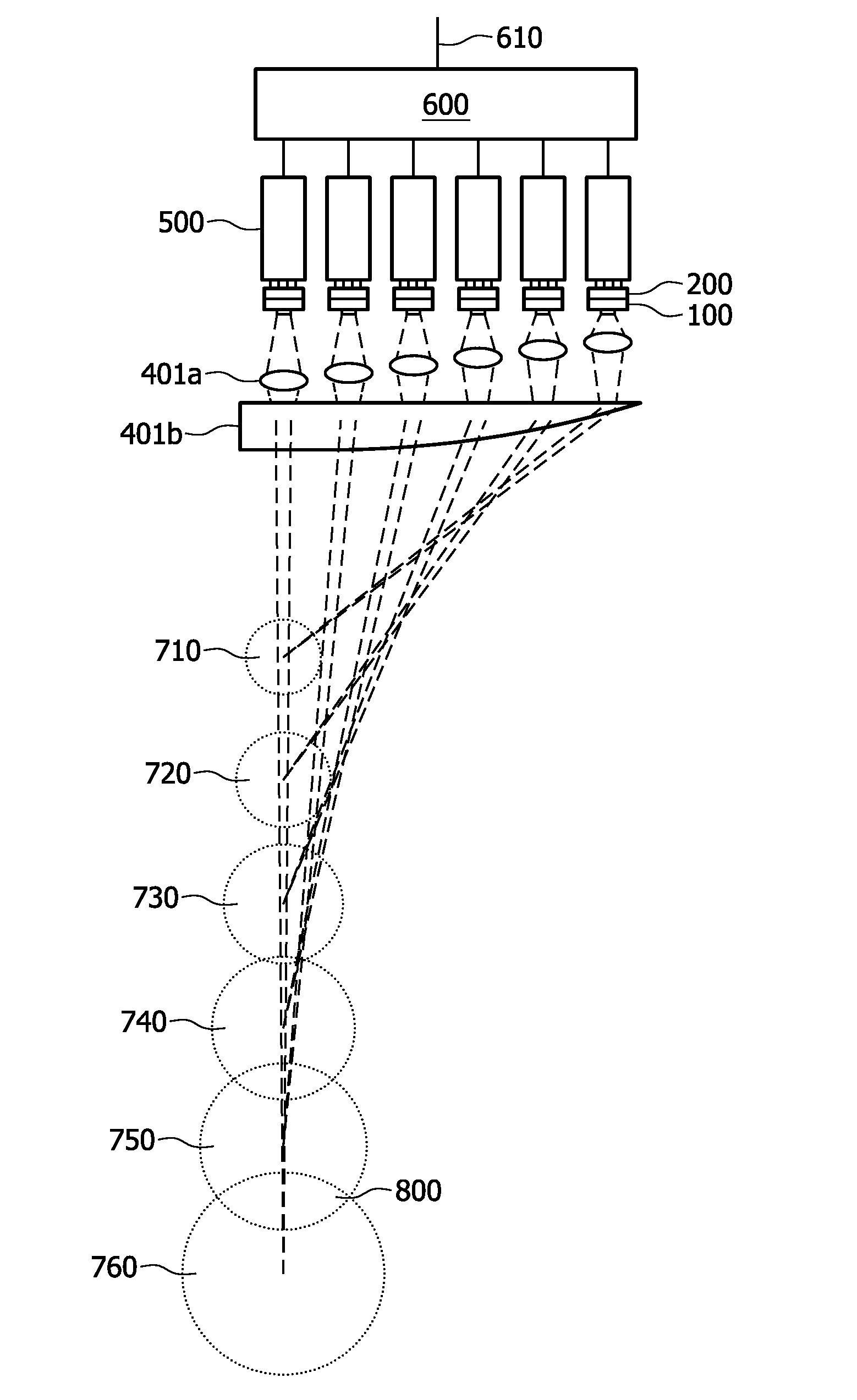

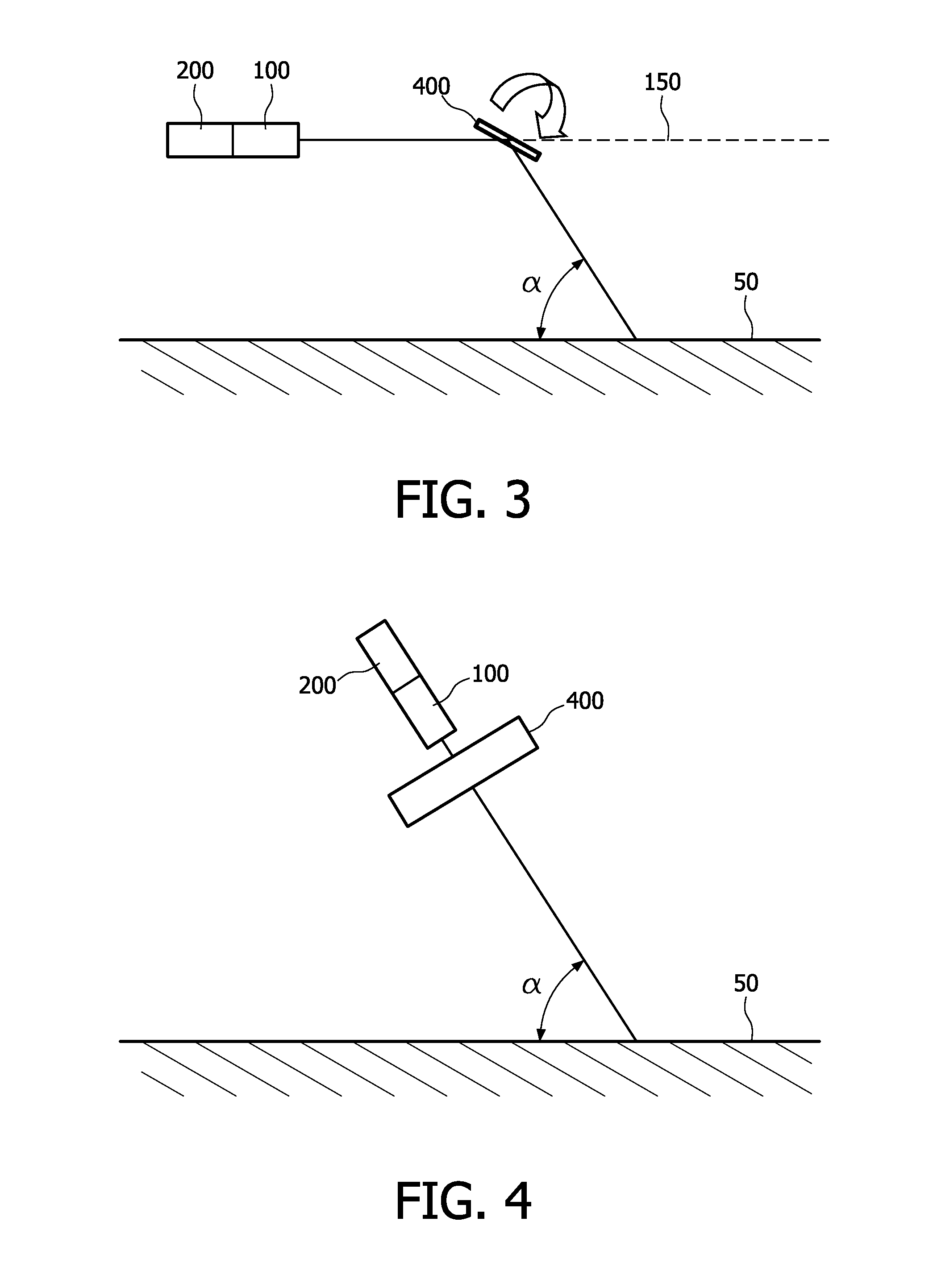

Laser sensor system based on self-mixing interference

ActiveUS20110007299A1Improve signal-to-noise ratioExpand the scope of detectionOptical rangefindersLinear/angular speed measurementLaser sensorLaser light

A sensor module (1) for measuring the distance to a target and / or the velocity of the target (50), the sensor module (1) comprising at least one laser source (100), at least one detector (200) being adapted to detect modulated laser light and at least one control element the control element (400) being adapted to vary the focus point of the laser light and / or the intensity of the laser light and / or the direction of the laser light. The control of the laser light emitted by the laser source (100) either by active optical devices as variable focus lenses or controllable attenuators or passive optical elements in combination with arrays of laser sources (100) and detectors (200) enable flexible and robust sensor modules.

Owner:TRUMPF PHOTONIC COMPONENTS GMBH

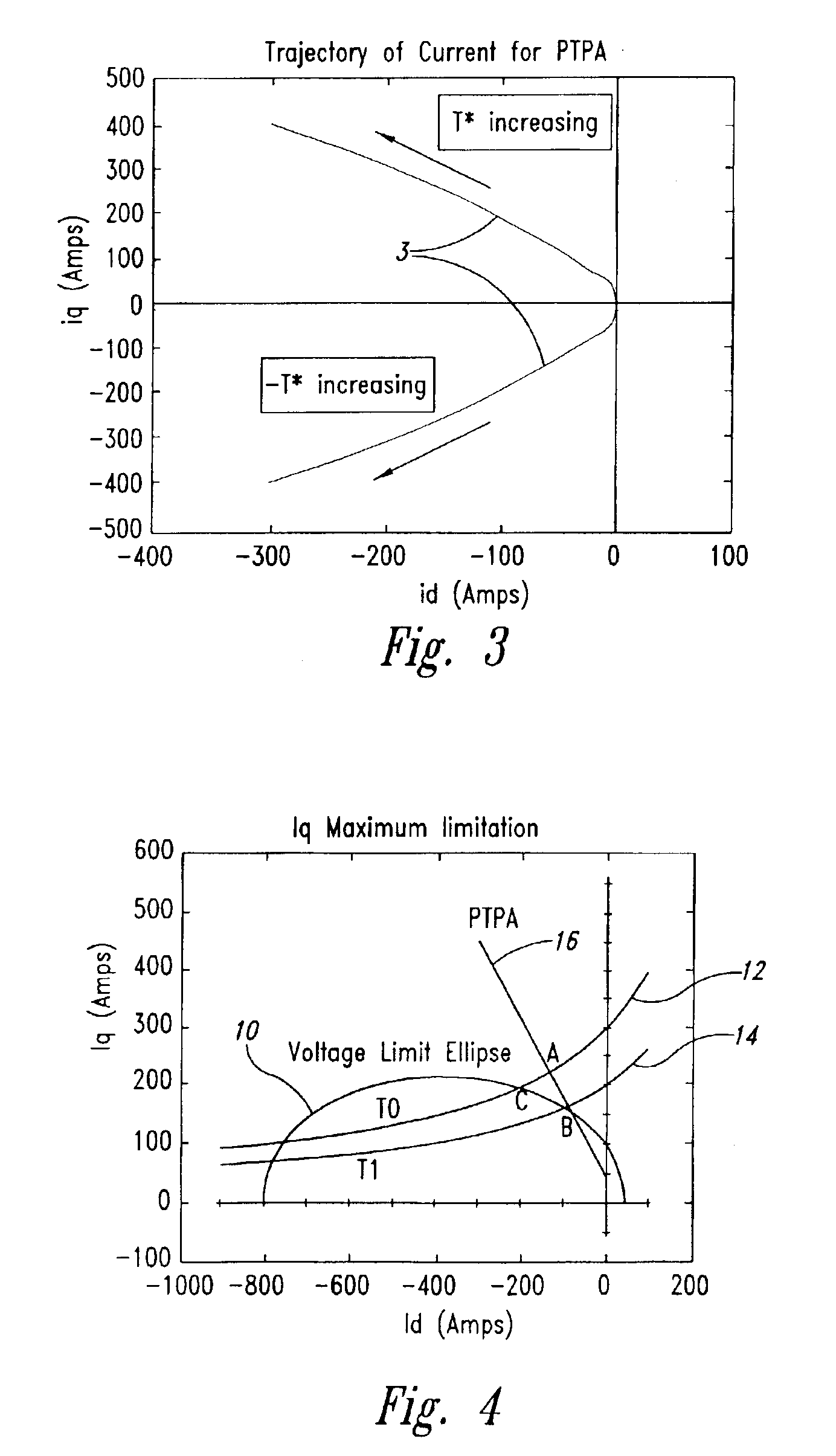

Method and apparatus for motor control

ActiveUS6936991B2Exceeds capabilityImprove stabilityMotor/generator/converter stoppersAC motor controlMaximum torqueCurrent limiting

A closed-loop permanent magnet motor control method and system optimally partitions torque and flux-weakening currents to produce a desired torque without exceeding the capability of the DC source. A maximum limit for allowable torque current and a minimum threshold for the maximum torque current are determined, and the flux current is varied based at least in part on whether the maximum torque current limit is above or below the minimum threshold while operating in a flux-weakening region to compensate for the variability of the DC source voltage.

Owner:VITESCO TECH USA LLC

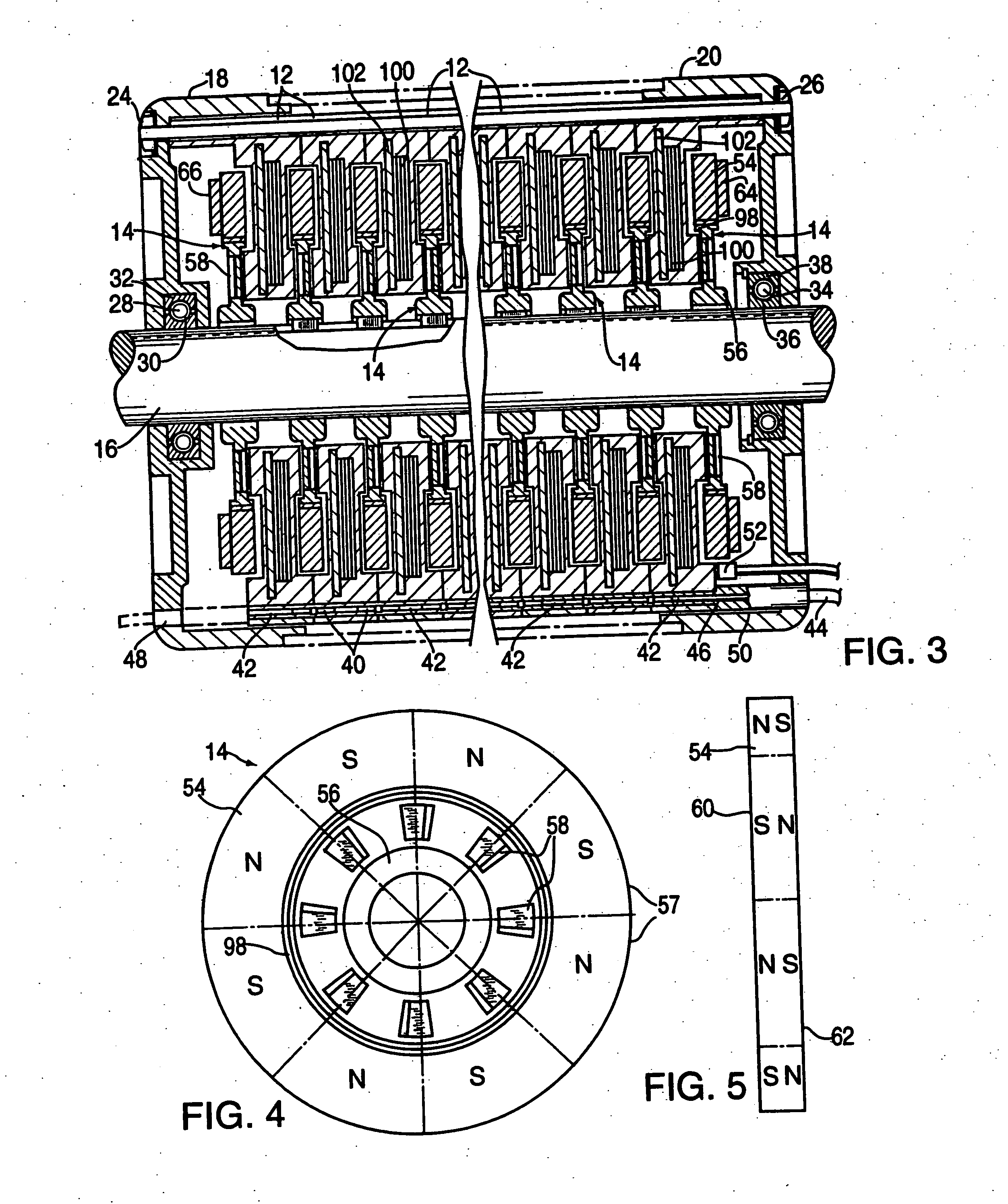

Axial field electric machine

InactiveUS20060012263A1Minimizes inventoryMaximize constantWindings insulation shape/form/constructionMagnetic circuit rotating partsElectrical conductorElectric machine

An axial field electric machine having an improved efficiency includes a number of magnetic elements (e.g., as a rotor) as annular disks magnetized to provide multiple sector-shaped poles. Each sector has a polarity opposite that of an adjacent sector, and each sector is polarized through the thickness of the disk. The poles of each disk are aligned with opposite poles of each adjacent magnet. Metal members adjacent the outermost disks contain the flux; The axial field electric machine also includes one or more conductor elements (e.g., as a stator) which include a number of conductor phases that traverse the flux emanating between poles of axially adjacent magnetic elements. The design of the axial field electric machine including the gap spacing between adjacent magnetic elements, the transition width between adjacent poles on each magnetic element, the number of poles, the number and width or conductor phases in the conductor element is based on the physical characteristics of the magnetic elements to increase efficiency.

Owner:SMITH STEPHEN H +1

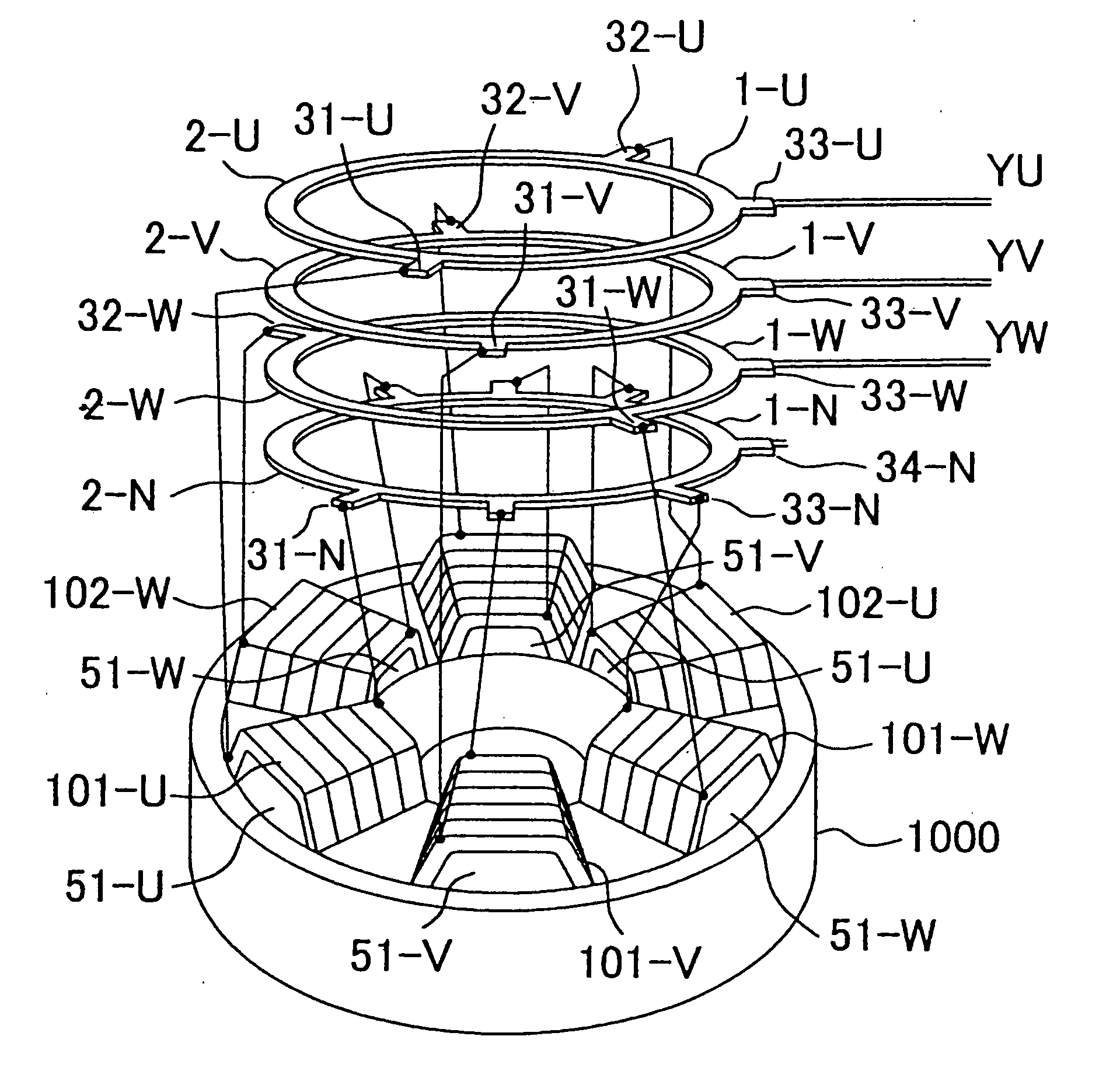

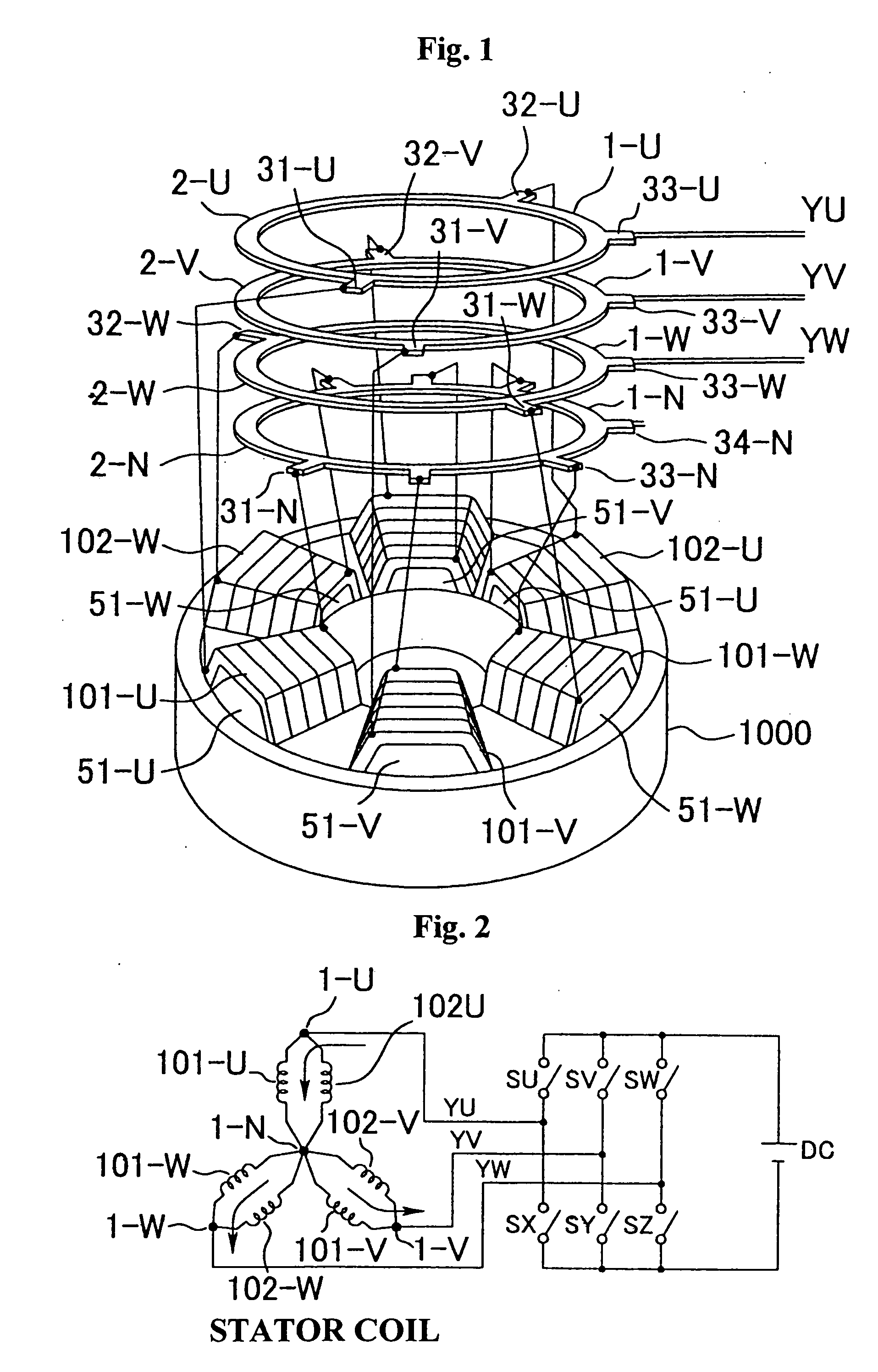

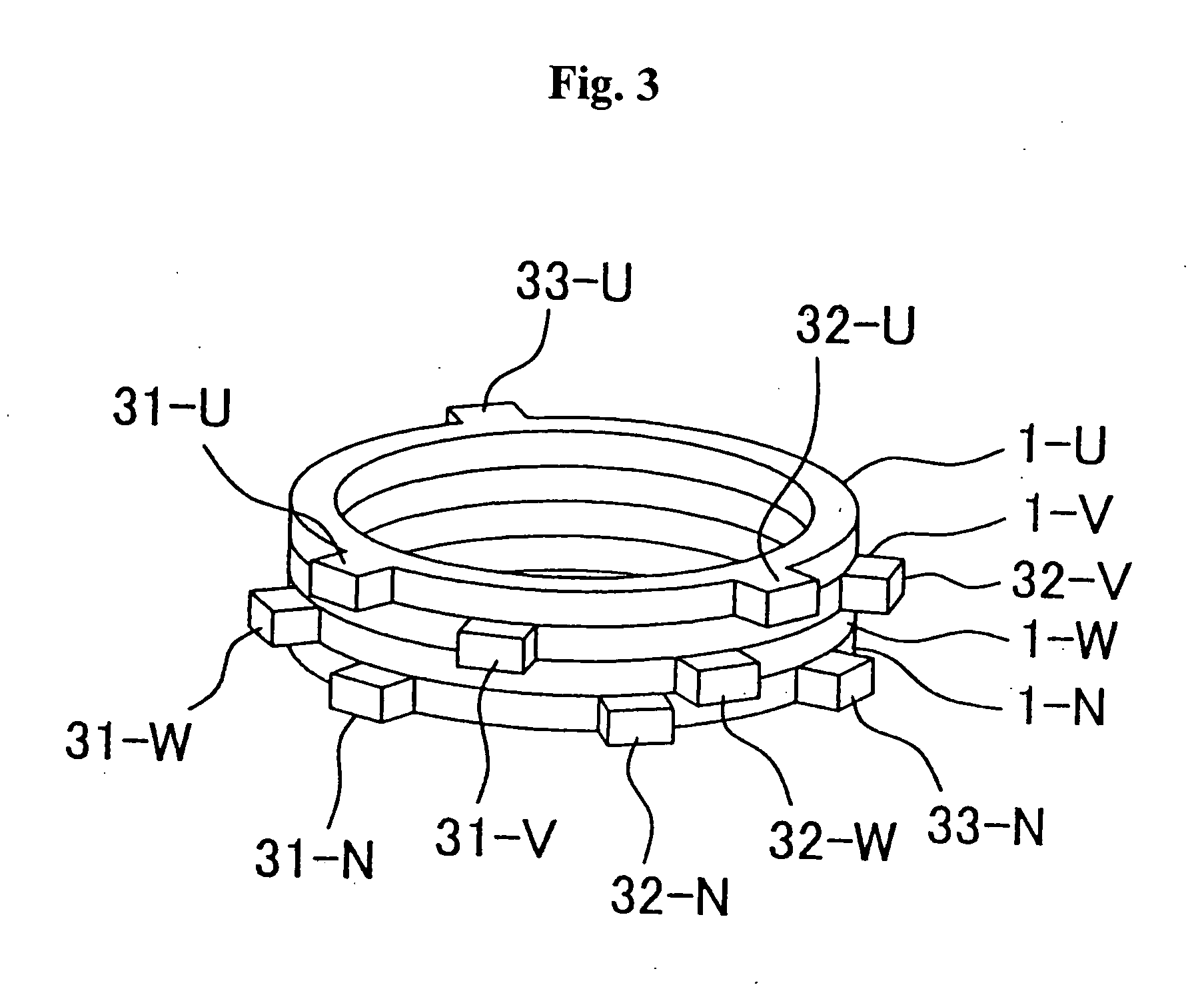

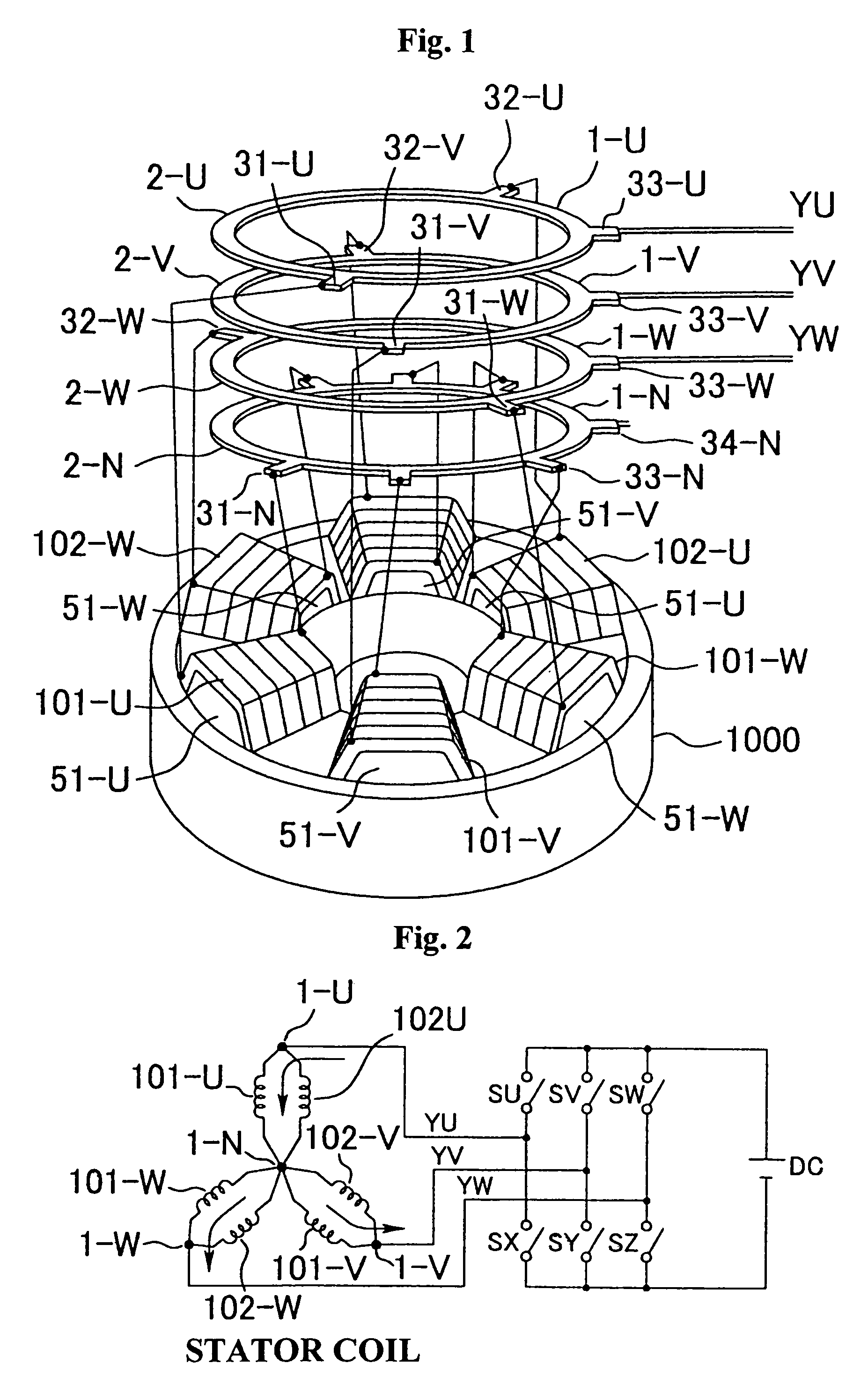

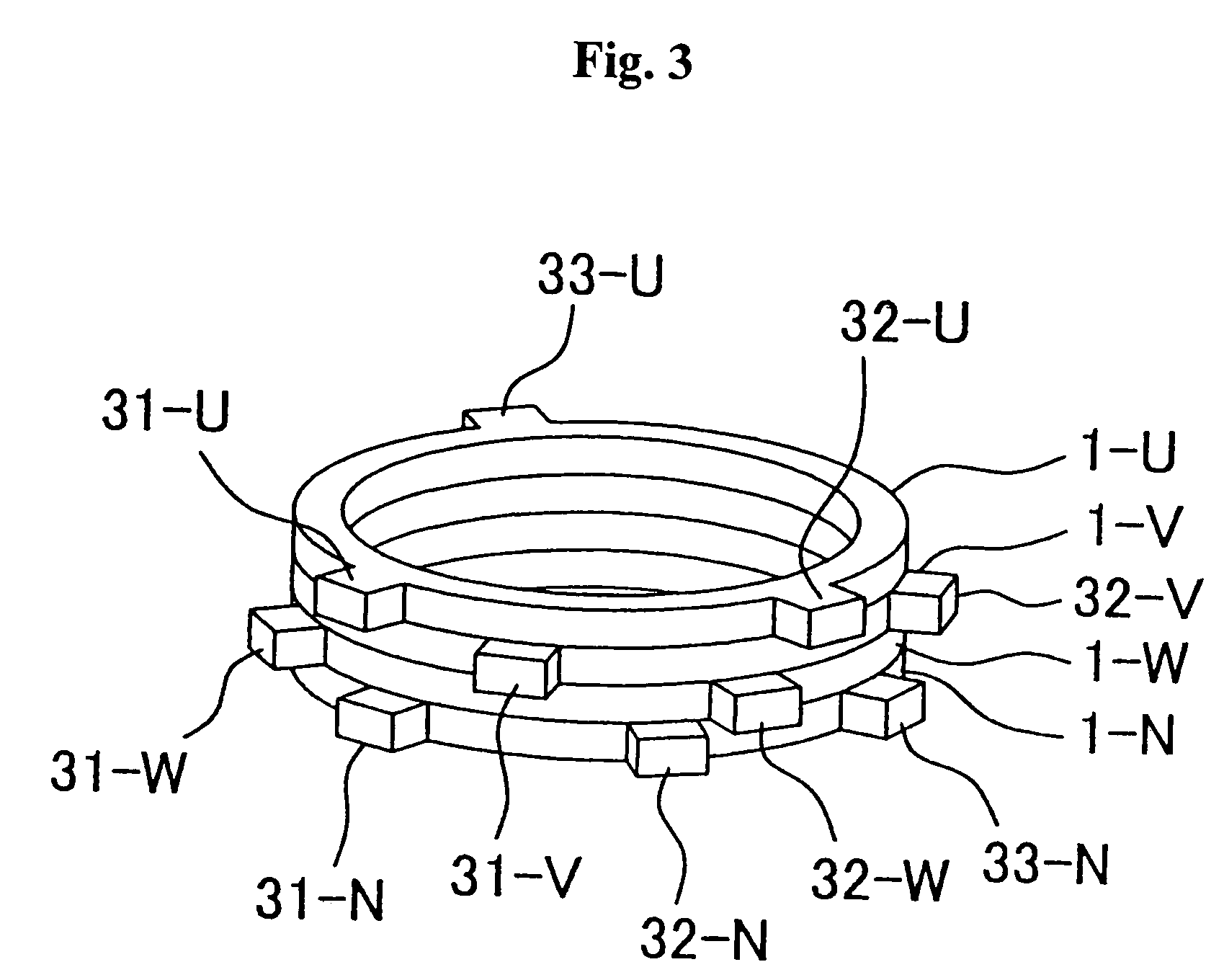

Motor, method for manufacturing motor, and motor drive controller

ActiveUS20050189828A1Increase productionSmall sizeSynchronous generatorsTorque ripple controlElectrical conductorMotor drive

A motor comprising a motor-wiring bus bar including a plurality of annular ring conductors connecting lead wires of the motor including a stator in which a plurality of stator cores having the lead wires is arranged in a circle or connecting the lead wires and a power line together and a plurality of terminals attached to the ring conductors. The ring conductors are different in diameter and arranged concentrically on a same plane.

Owner:NSK LTD

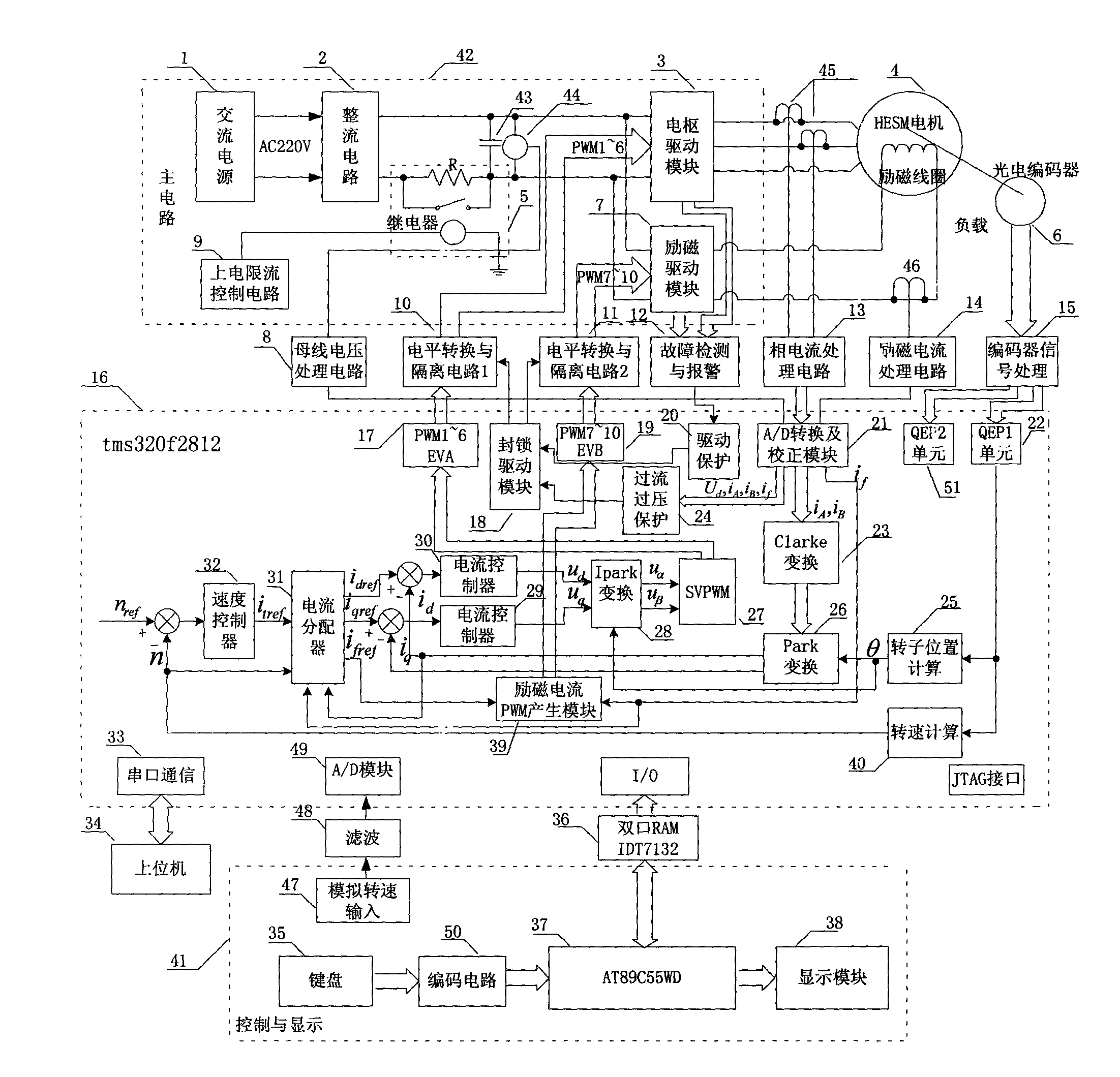

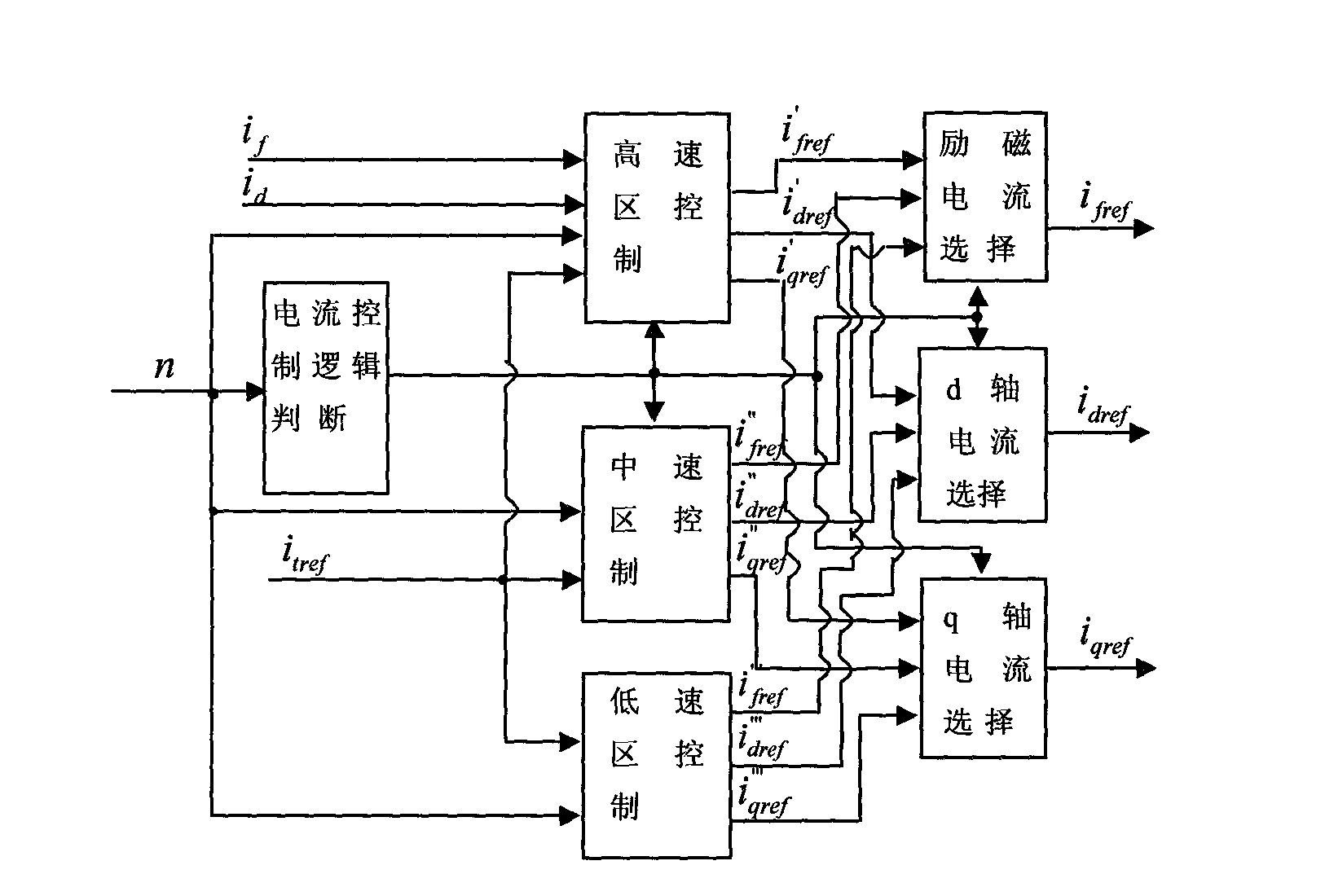

Wide range speed control system and current distribution method for hybrid excitation synchronous machine

InactiveCN102324882AIncrease starting torqueShort transition timeVector control systemsEmergency protective circuit arrangementsLow speedConstant power

The invention discloses a wide range speed control system and current distribution method for a hybrid excitation synchronous machine. A control policy is applied to armature drive and excitation drive simultaneously. When the motor is in the starting period, a rated forward magnetism strengthening current is applied to the exciting winding to increase the starting torque of the motor, so that the motor obtains electromagnetic torque exceeding the rated torque under the condition of no overcurrent, and the transition time of motor starting is shortened. When the motor is in the low speed operating interval, if the motor load exceeds the rated load, the electromagnetic torque of the motor is increased by applied the forward magnetism strengthening current, so that the motor obtains excessive loading capacity under the condition of no overcurrent and no overheat. When the motor operates at high speed, a constant power operating interval far above the rated rotating speed can be obtainedby applying an appropriate reverse exciting current to HESM (Hybrid Excitation Synchronous Machine) and performing weak magnetic regulation on the d-axis armature current.

Owner:HENAN INST OF ENG

System and method for clamp current regulation in field-weakening operation of permanent magnet (PM) machines

ActiveUS7242163B2Extended speed rangeFunction increaseAC motor controlDC motor speed/torque controlPhase currentsVoltage vector

A device to regulate current produced by a permanent magnet machine responsive to a plurality of phase current signals. The motor produces torque for application on a shaft. A processing and drive circuit responsive to a direct current command signal and a quadrature current command signal produces phase current signals for input to the motor. A command circuit responsive to the phase current signals, an angular position of said shaft, and a voltage input command signal to produce a direct current error signal and a quadrature current error signal. A control circuit responsive to the direct and quadrature current error signals produces the direct voltage signal command and the quadrature voltage signal command. The control circuit has a direct and quadrature proportional gain, integrator and clamp circuits. An algorithm produces limited or clamped voltage modulation index signals to obtain maximum efficiency and maximum torque per ampere in the speed range. The algorithm ensures that the current regulator does not run out of voltage by limiting the voltage vector to the achievable voltage vector range that provides maximum torque per ampere and maximum efficiency.

Owner:DELPHI TECH IP LTD

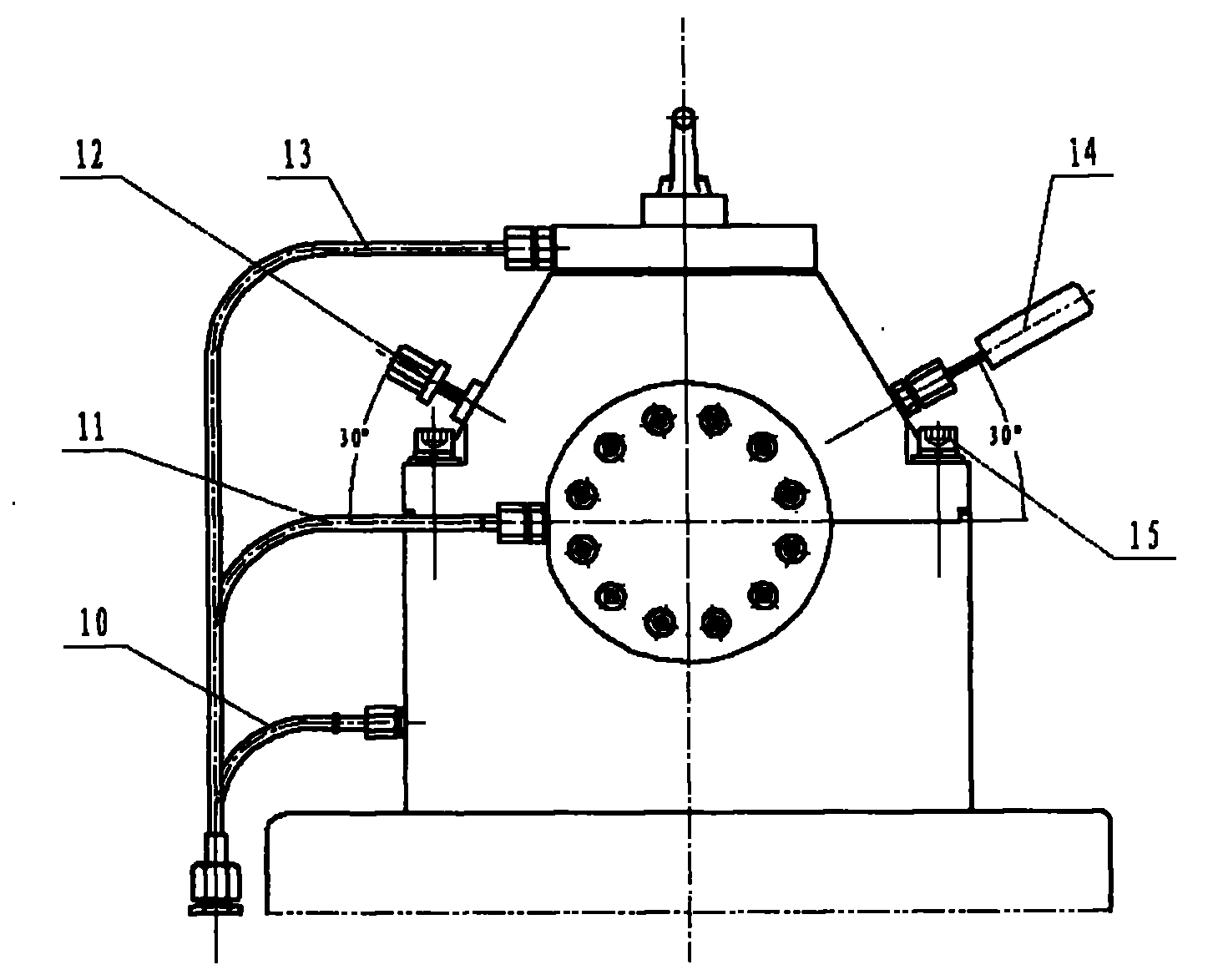

High-temperature high-speed test method for sealed bearing

InactiveCN101718625AImprove the state of stressEasy to achieve high speedMachine bearings testingElectricityComputer control system

The invention relates to a high-temperature high-speed test method for a sealed bearing, which comprises the following steps of: firstly designing a testing device, installing two sets of testing accompanying bearings on a testing main shaft, and pretightening through a set of spring and a pressure ring; installing the two sets of testing bearings at the left end and the right end of the testing main shaft, connecting an electric main shaft through a shaft coupling and additionally covering a shield; starting cooling circulating water, adding cooling water into a loading sleeve, starting a hydraulic station, an electric main shaft variable-frequency driving system and a computer control system, applying 20-30 percent of the maximum axial test load and 20-30 percent of the maximum radial test load to the testing bearings, starting the electric main shaft to reach 15-20 percent of the highest rotational speed and running for 15-25 minutes after the heating temperature reaches a set value, and then sequentially adding axial loads and radial loads and increasing the rotational speed of the electric main shaft so as to reach the highest rotational speed when the power consumption current of the electric main shaft tends to be steady; and carrying out computer data processing for the data and images in different time periods of the whole testing process and working out a test conclusion.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Torque controlled pump protection with mechanical loss compensation

ActiveUS20050252205A1Eliminate needExtended operating speed rangeFluid couplingsFlexible member pumpsControl theoryOperant conditioning

A method and apparatus are provided for controlling the operation of a pump, such as a centrifugal pump, featuring steps of either adjusting the operation of the pump, or issues a warning to a user of the pump of an undesirable operating condition, or both, based on a comparison of an actual torque value and a corrected torque value either alone or in combination with a further step of compensating the corrected torque value based on a mechanical power offset correction. The corrected torque value may include a Best Efficiency Point (BEP) torque value and may also be compensated for based on at least the current operating speed of the pump. The pump has a controller for performing the steps of the method. The controller can compensate the corrected torque value based on the square of the speed change of the pump. The comparison may include a ratio of the actual torque value to the corrected torque value, and the ratio of the actual torque value to the corrected torque value may also be compared to ratios corresponding to either a dry run condition, a minimum flow condition, a runout condition, or some combination thereof.

Owner:ITT MFG ENTERPRISES LLC

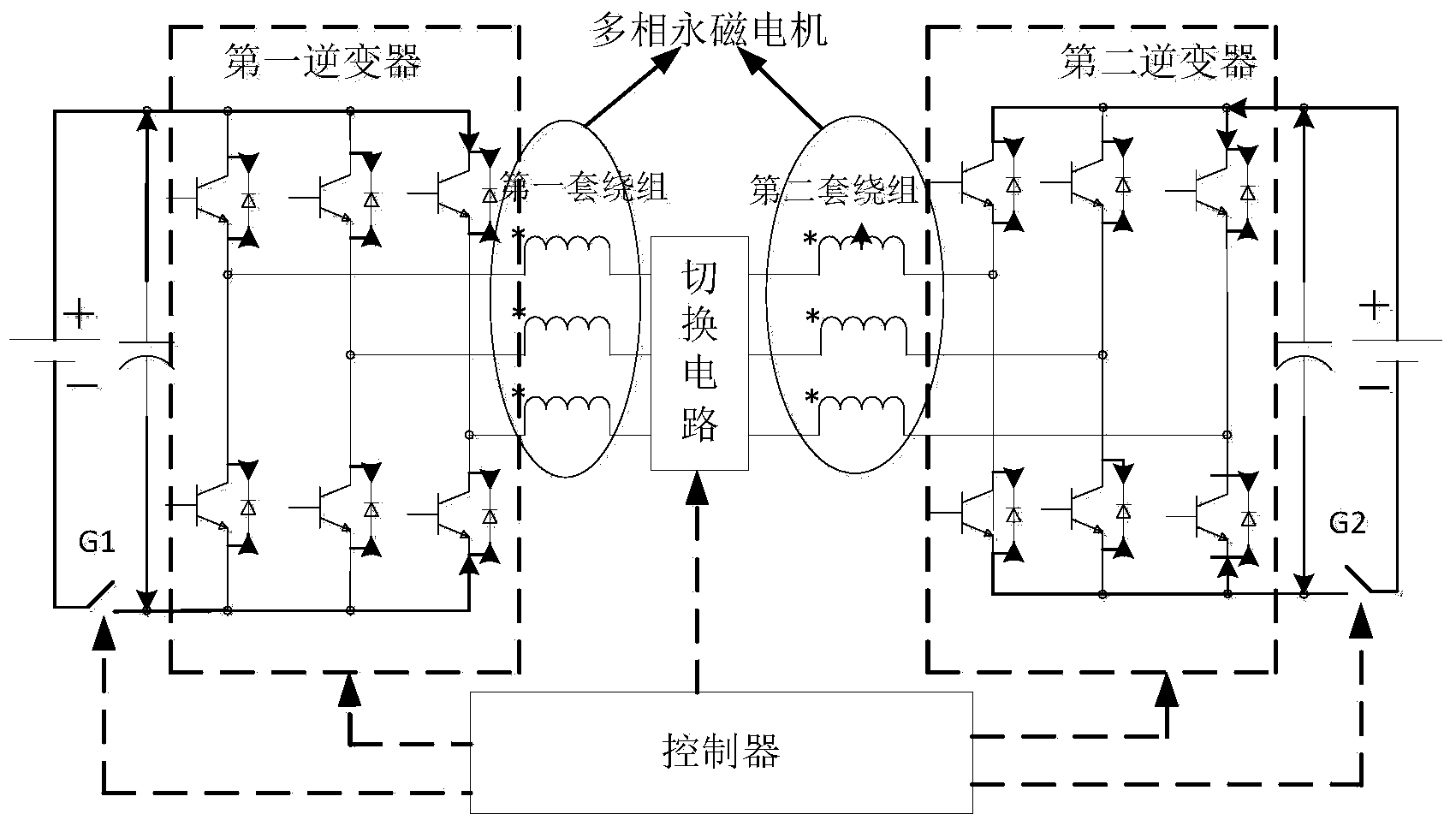

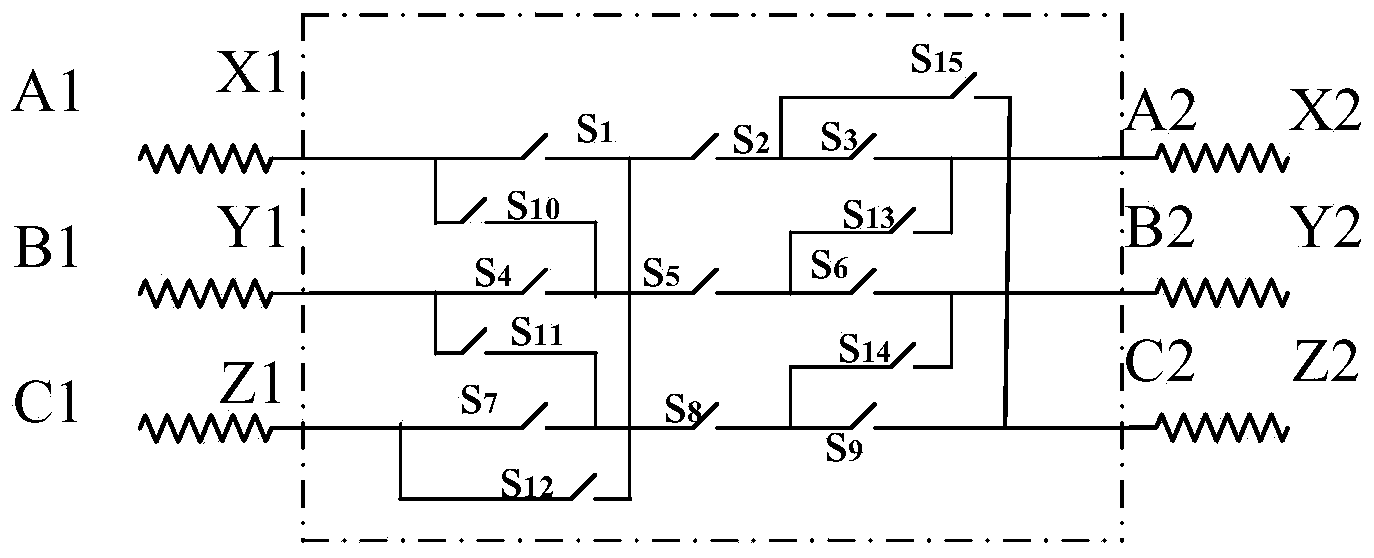

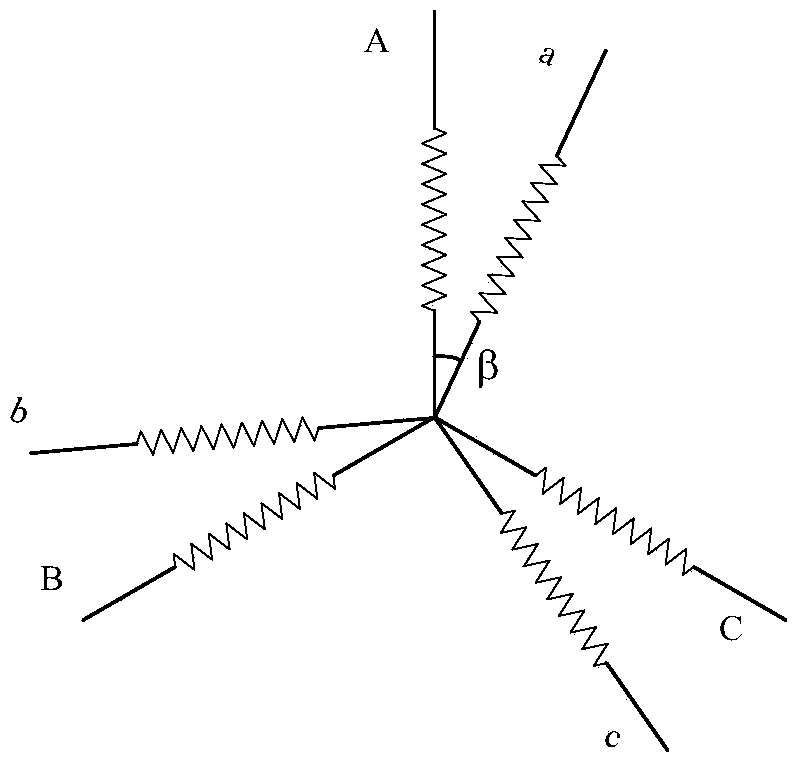

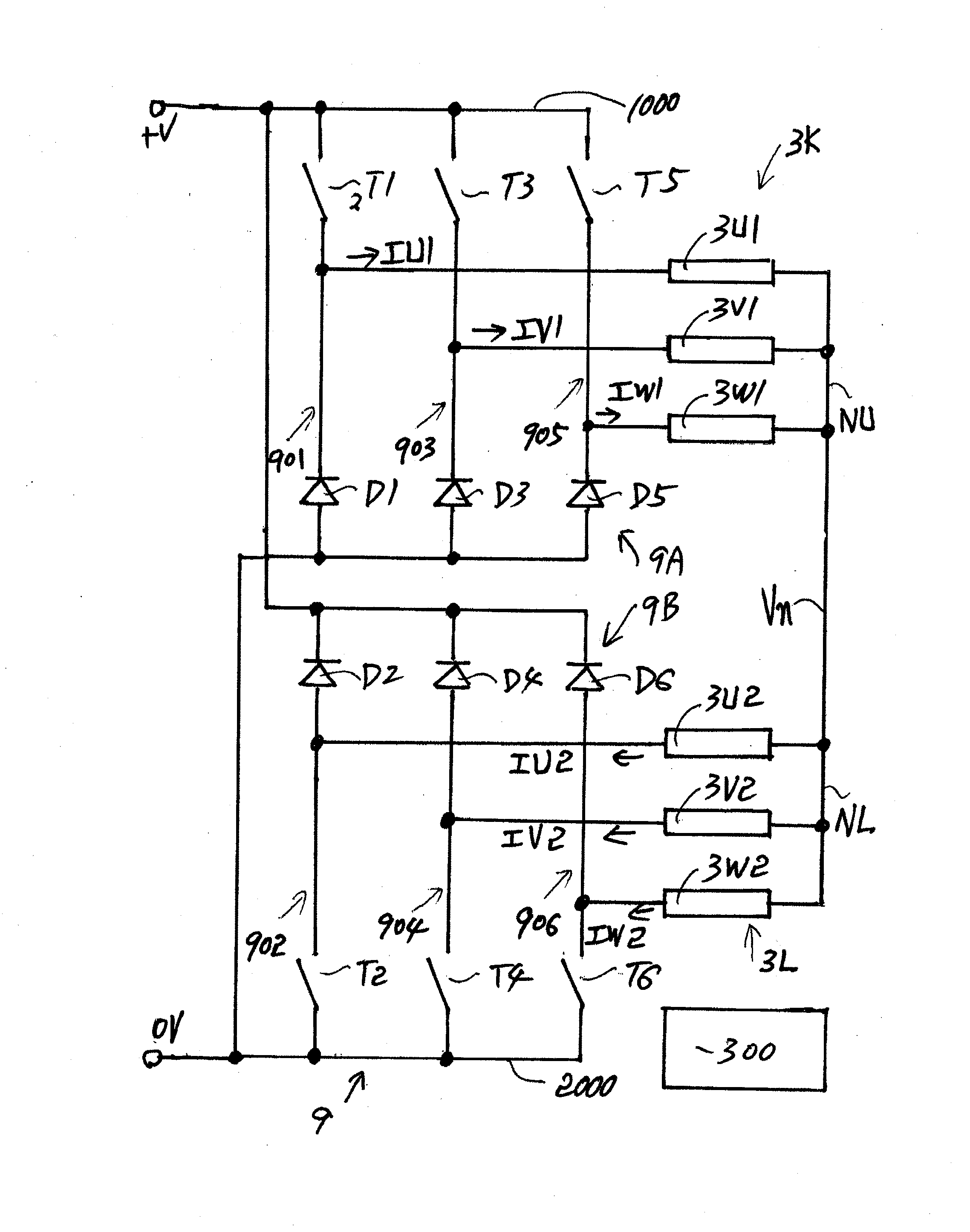

Multiphase permanent magnet motor speed regulating system based on phase switching and speed regulating method thereof

InactiveCN104167975AReduce back EMFAvoid the risk of demagnetizationAC motor controlPermanent magnet motorConductor Coil

The invention discloses a multiphase permanent magnet motor speed regulating system based on phase switching and a speed regulating method thereof. The multiphase permanent magnet motor speed regulating system comprises a first inverter, a second inverter, a change-over circuit, a first circuit breaker, a second circuit breaker and a multiphase permanent magnet motor. The multiphase permanent magnet motor is of a structure including two three-phase windings. The three-phase output end of the first inverter is respectively connected with the three-phase positive end of the first winding of the motor, the three-phase negative end of the first winding is respectively connected with the three-phase positive end of the second winding of the motor, and the three-phase negative end of the second winding is respectively connected with the three-phase output end of the second inverter. The first inverter and the second inverter are respectively powered on by two independent direct current power supplies, the first circuit breaker and the second circuit breaker are respectively arranged at the low potential ends of direct current buses of the first inverter and the second inverter. The change-over circuit is used for adjusting connecting modes of the first winding and the second winding so as to adjust counter potential of the motor. The multiphase permanent magnet motor speed regulating system can widen a speed regulating range and improve speed regulating flexibility of the permanent magnet motor and the error-tolerant rate.

Owner:HUAZHONG UNIV OF SCI & TECH

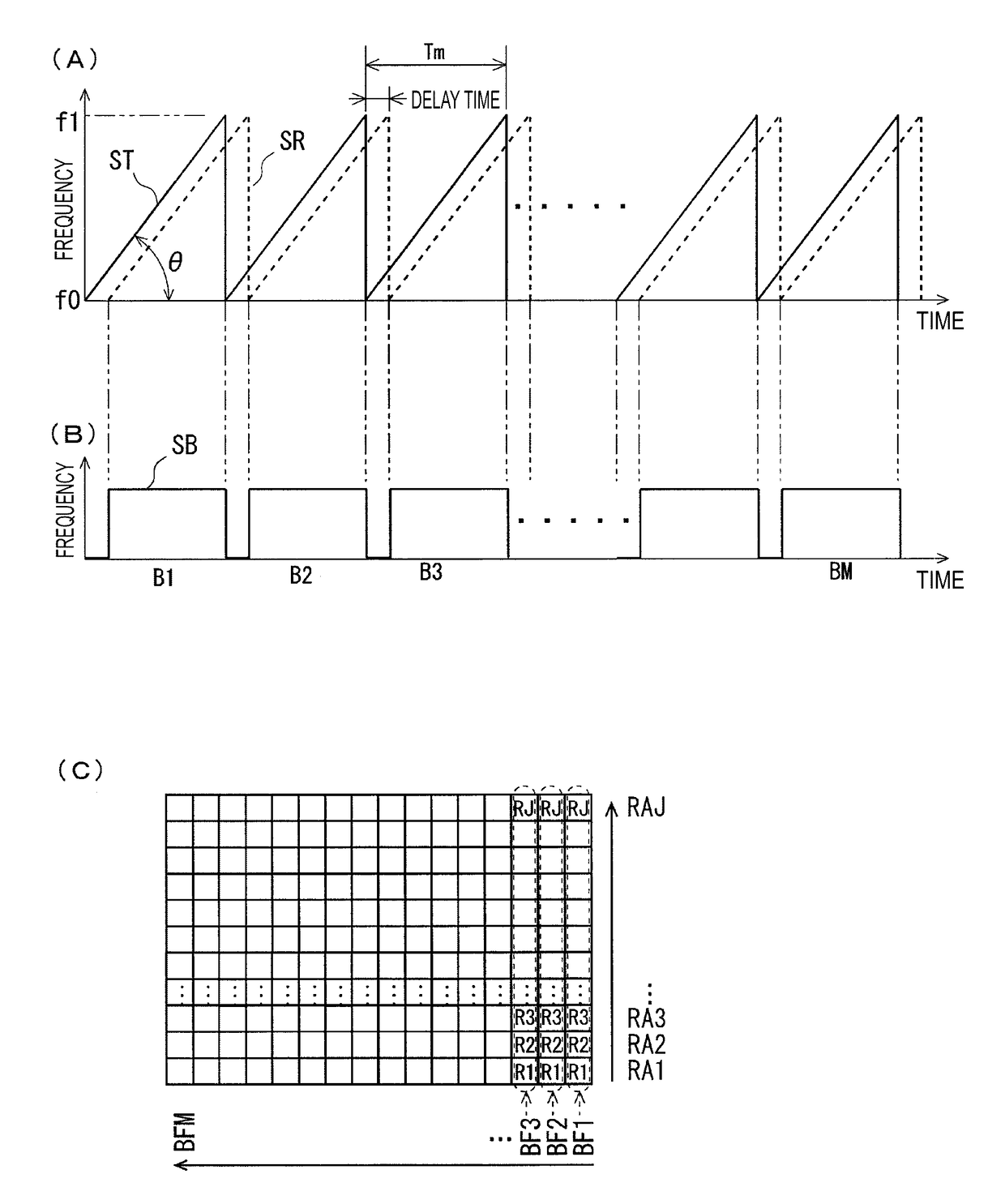

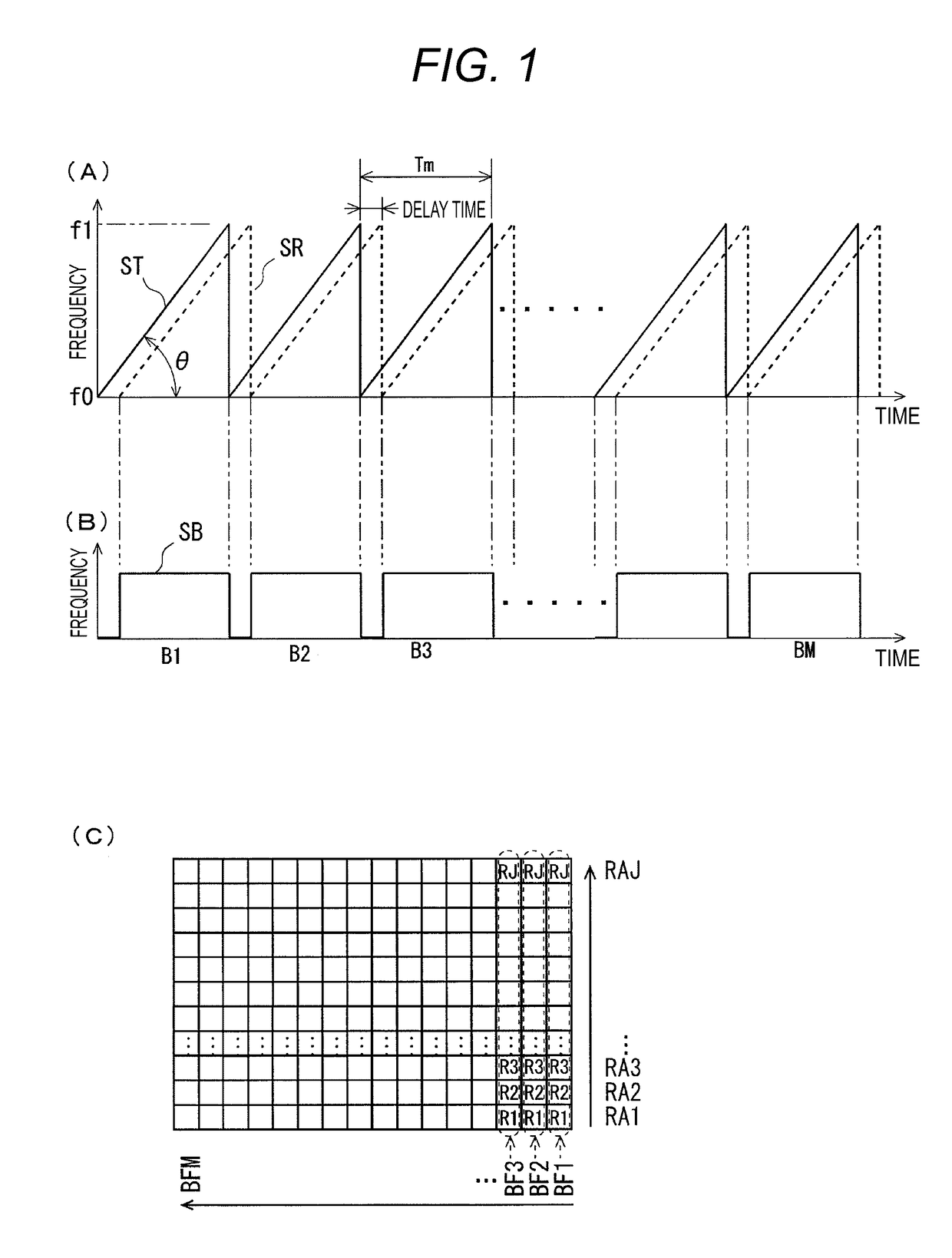

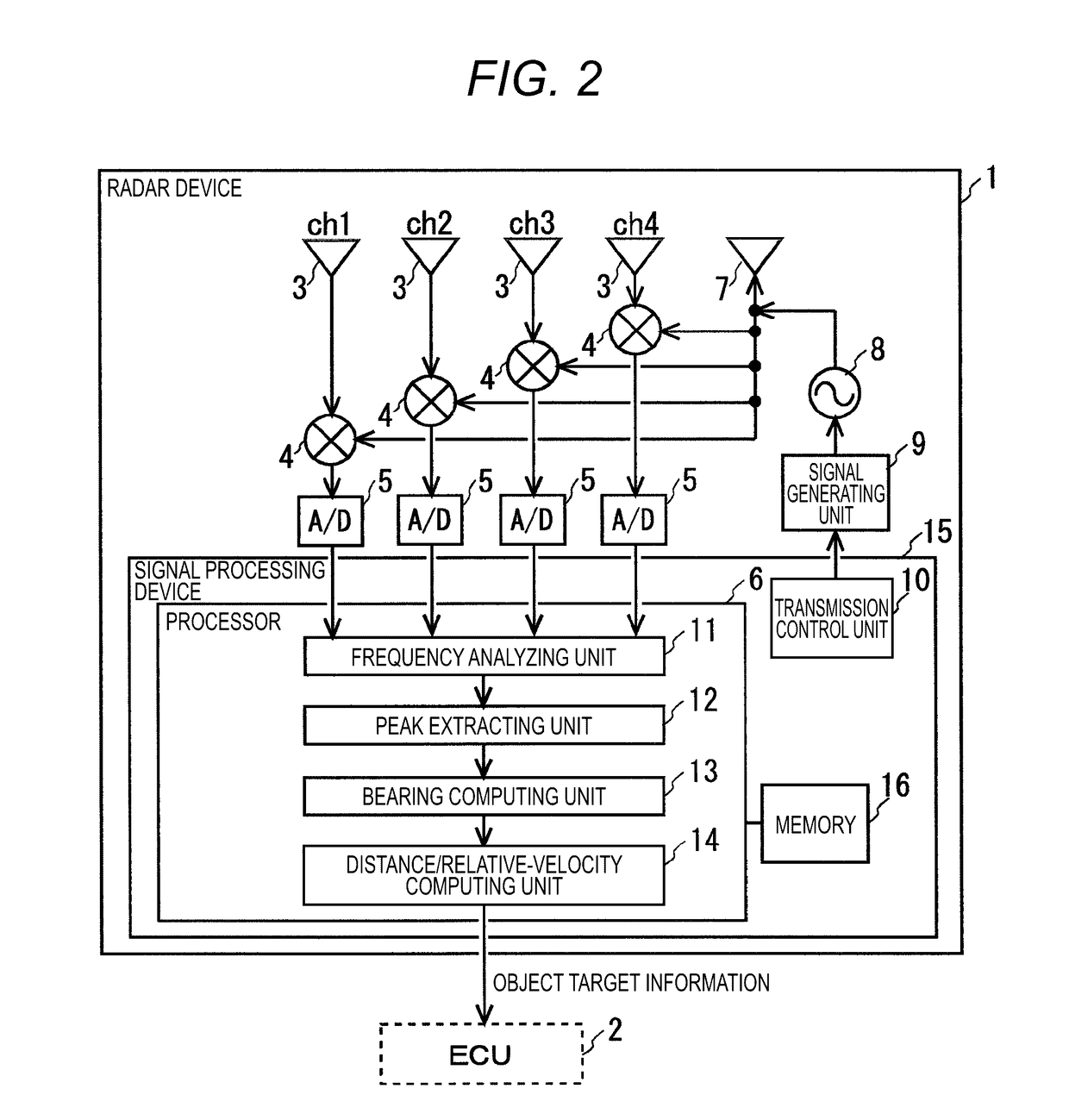

Radar device, signal processing device for radar device and velocity measuring method for radar device

ActiveUS20170082744A1Accurate speedExtended speed rangeRadio wave reradiation/reflectionRadarReflected waves

There is provided a radar device. A transmitting unit transmits first and second transmission signals generated based on first and second parameters for computing relative velocities in first and second detection velocity ranges, respectively. The second detection velocity range is narrower than the first detection velocity range. A receiving unit receives the reflected waves of the first and second transmission signals from a target as first and second reception signals, respectively. A velocity measuring unit computes first and second relative velocities in the first and second detection velocity ranges based on the first and second reception signals, respectively and obtains the velocity measurement result of the relative velocity of the target based on the combination of the first and second relative velocities.

Owner:FUJITSU GENERAL LTD

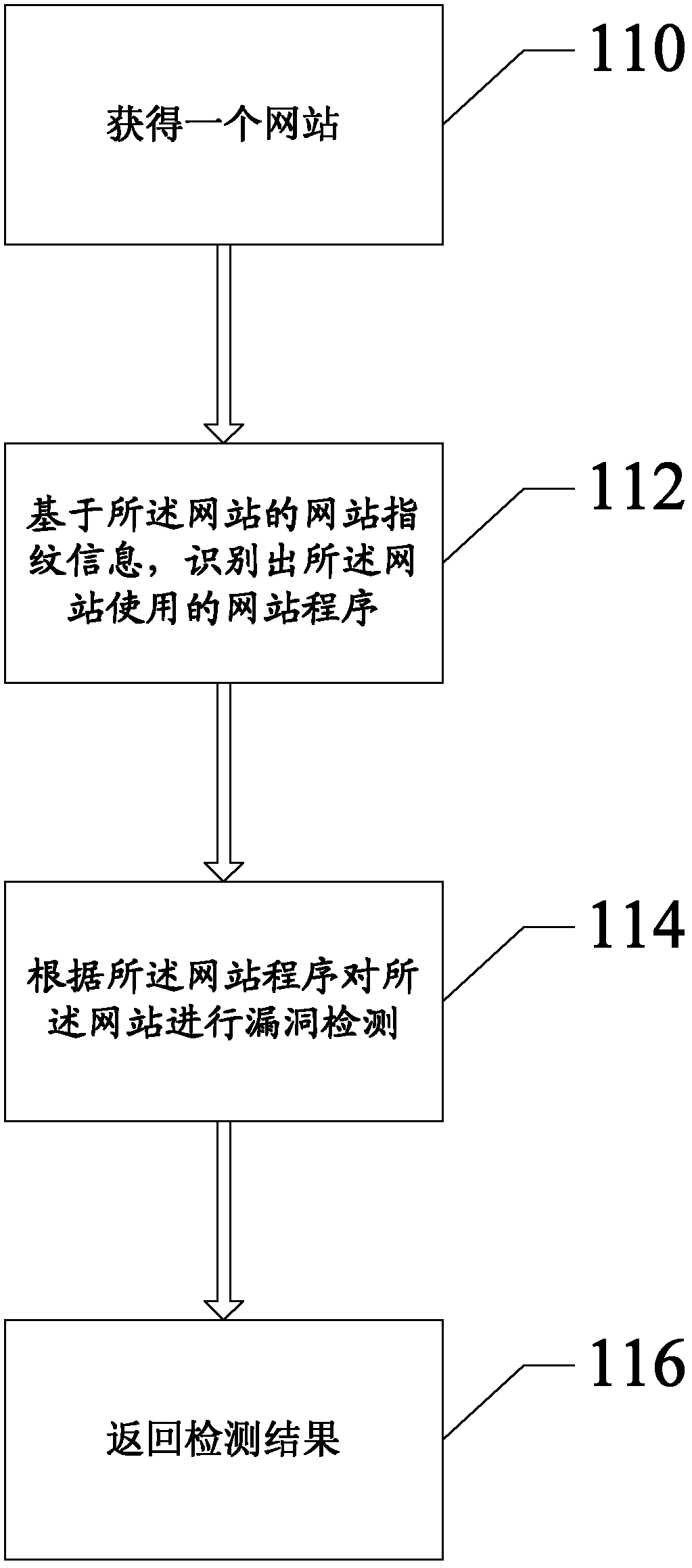

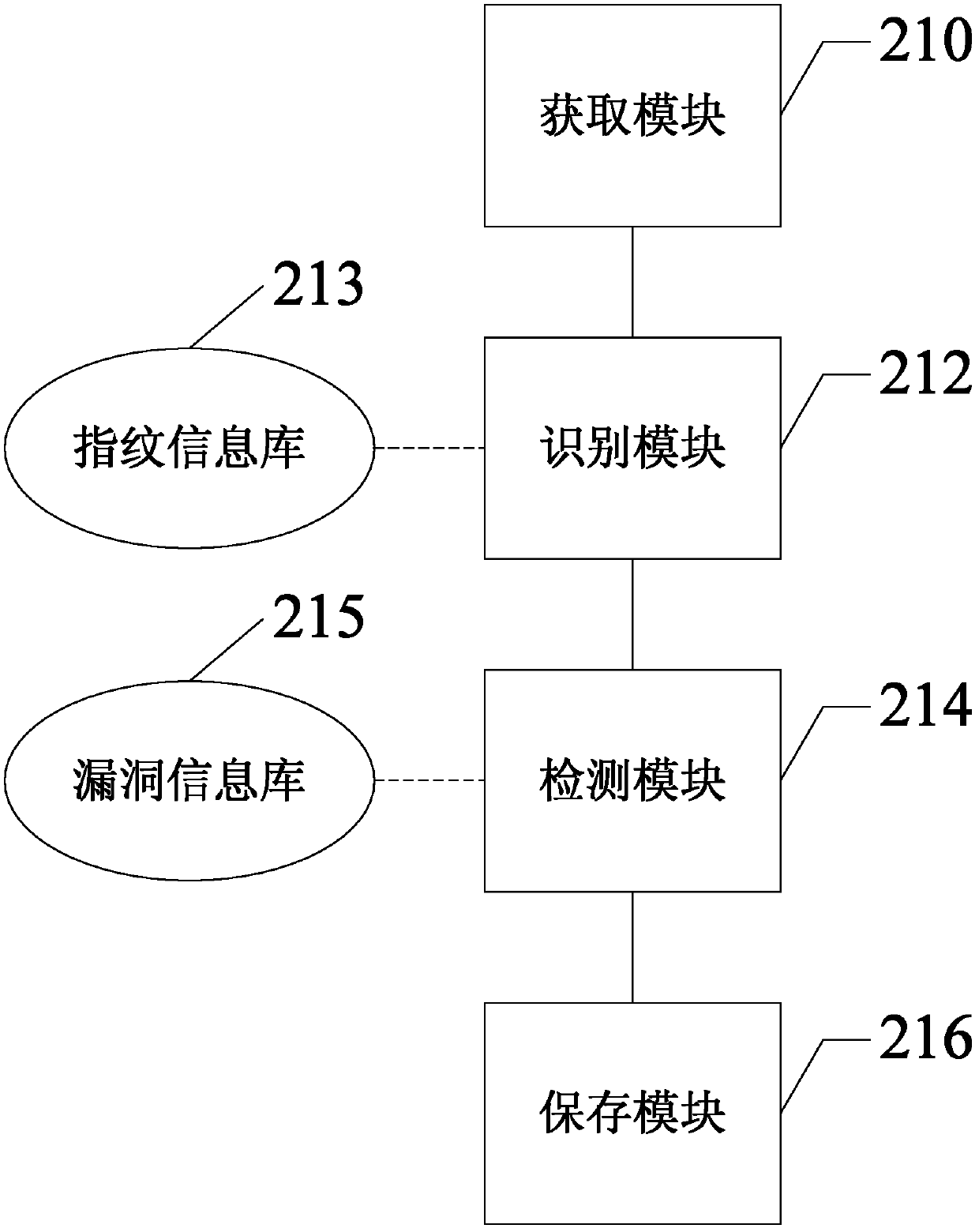

Website security detection method and device

The invention discloses a website security detection method and device. The website security detection method comprises the steps that a website is obtained; website programs used by the website are identified based on website fingerprint information of the website, and loophole detection is conducted on the website according to the website programs; lastly, a detection result is returned. By means of the website security detection method and device, the cost of the loophole detection on the website can be reduced obviously, the loophole detection speed can be increased, and the rate of missing report can be decreased.

Owner:ALIBABA GRP HLDG LTD

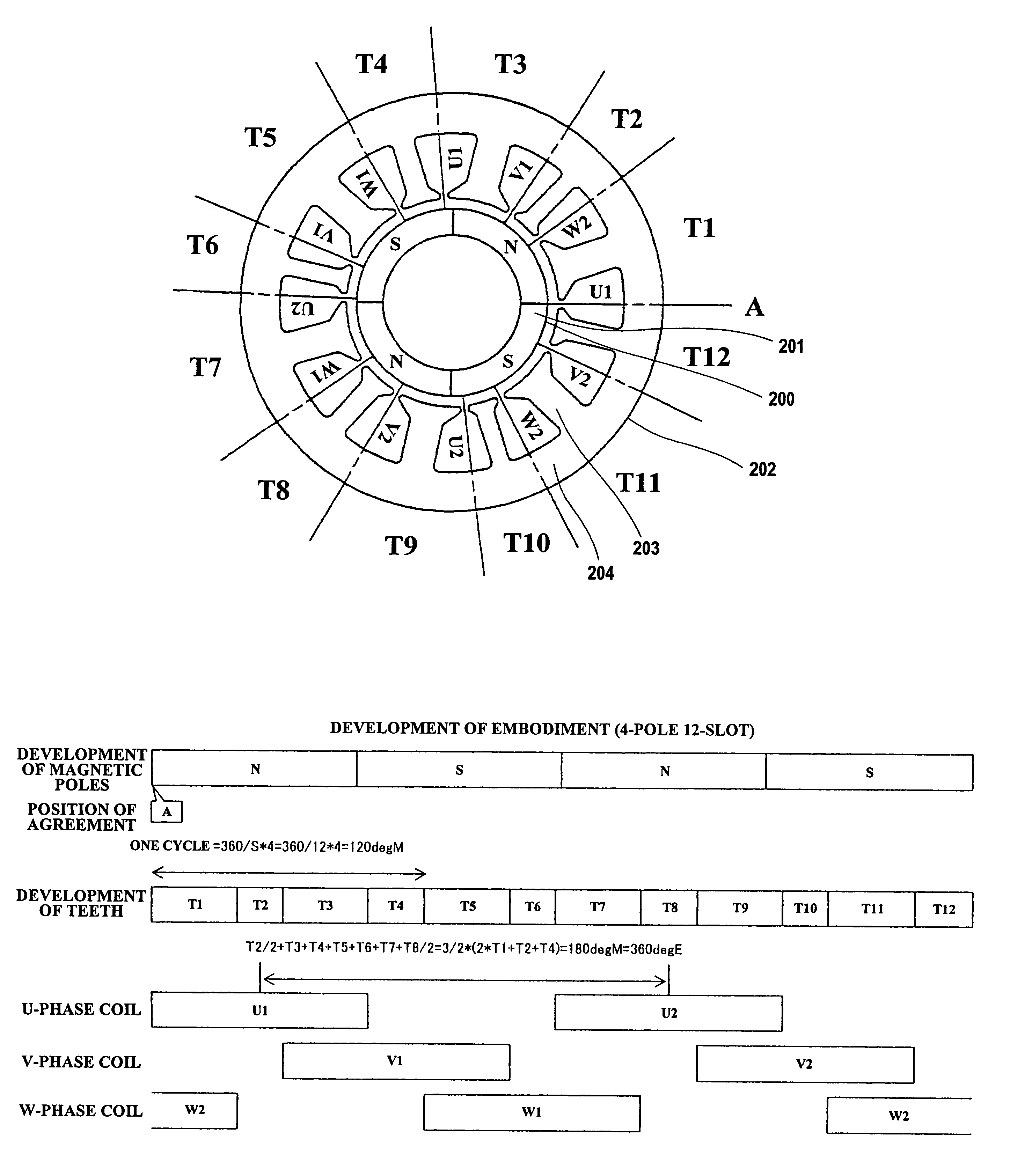

Motor, method for manufacturing motor, and motor drive controller

InactiveUS7180217B2Torque ripple is reducedLow load rangeSynchronous generatorsTorque ripple controlMotor driveElectrical conductor

A motor comprising a motor-wiring bus bar including a plurality of annular ring conductors connecting lead wires of the motor including a stator in which a plurality of stator cores having the lead wires is arranged in a circle or connecting the lead wires and a power line together and a plurality of terminals attached to the ring conductors. The ring conductors are different in diameter and arranged concentrically on a same plane.

Owner:NSK LTD

Magnetically-levitated blood pump with optimization method enabling miniaturization

Owner:WORLD HEART +1

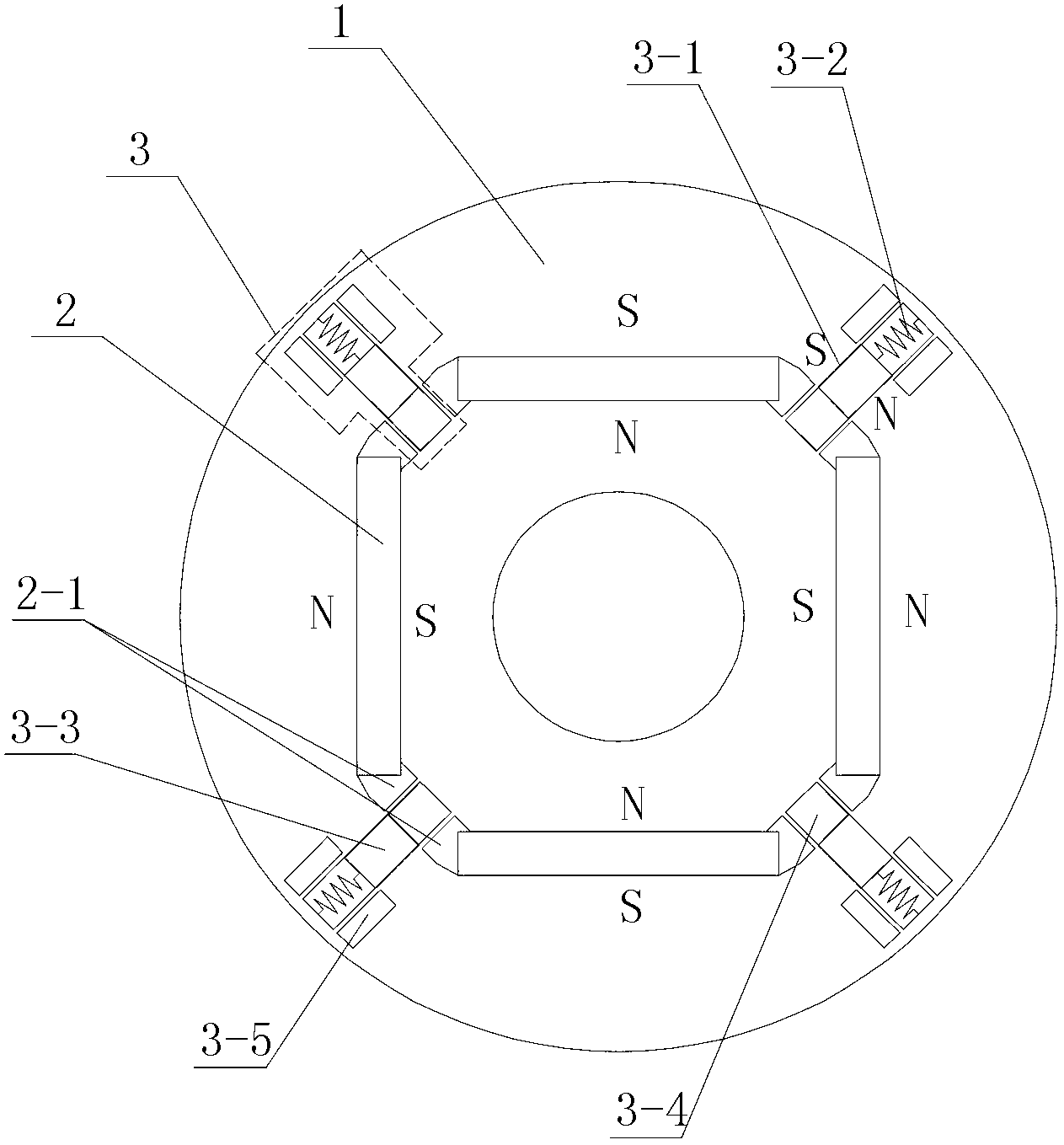

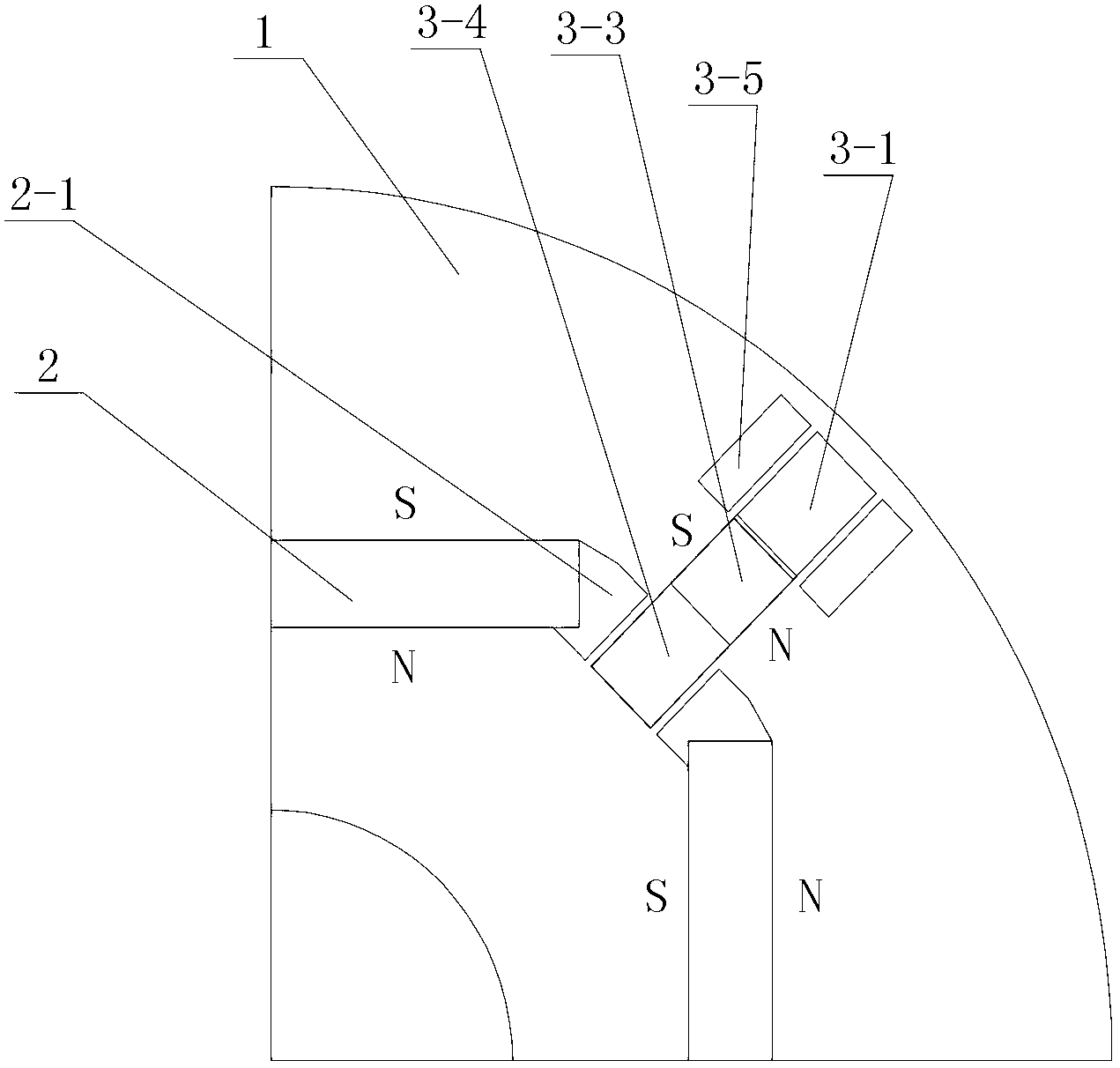

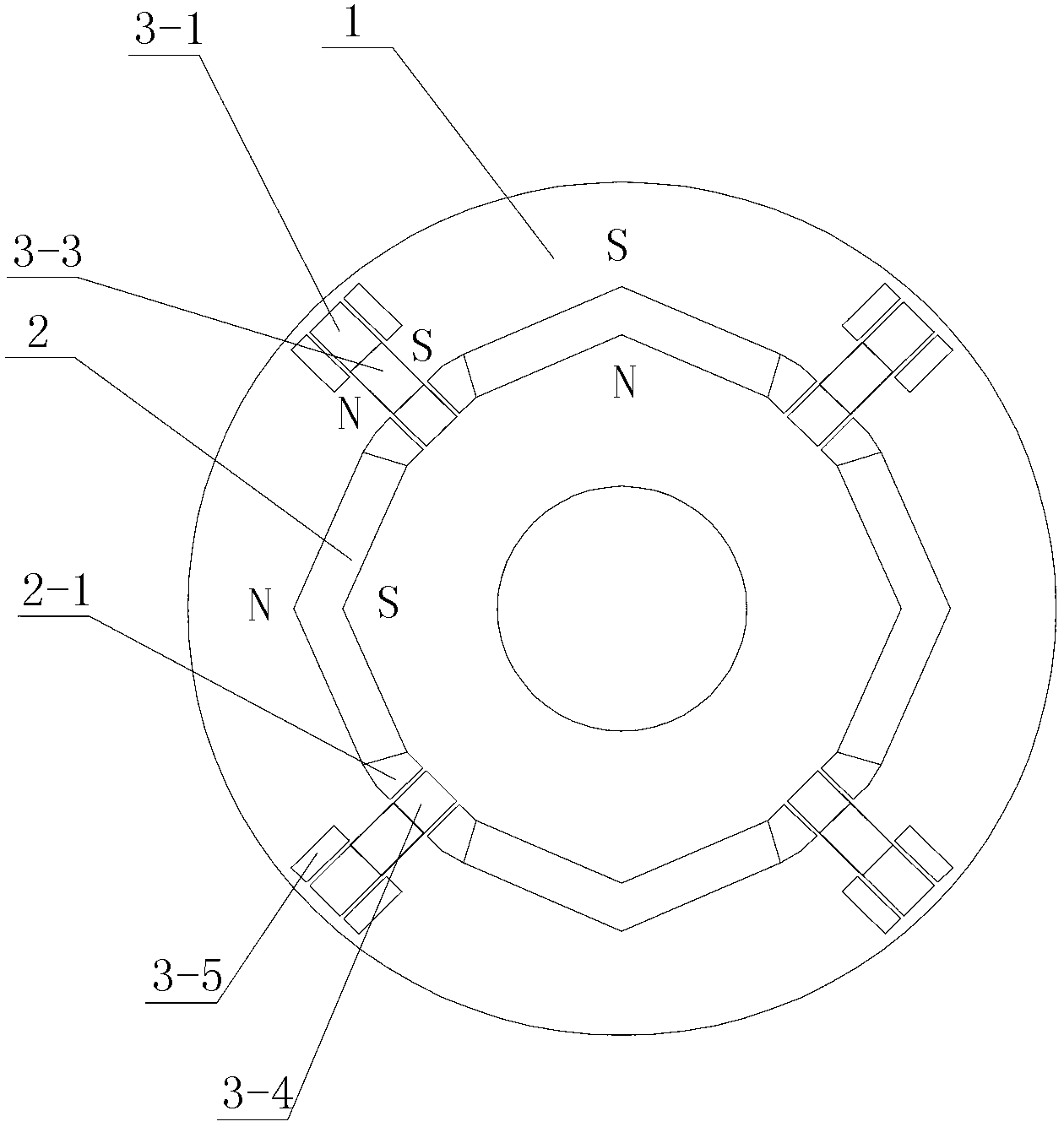

Permanent magnet motor rotor with excitation circuit variable reluctance and leakage flux path function

InactiveCN102710043ALarge output torqueImprove efficiencyMagnetic circuit rotating partsPhysicsPermanent magnet motor

The invention discloses a permanent magnet motor rotor with an excitation circuit variable reluctance and leakage flux path function, which belongs to the technical field of the motor and solves the problem that in the weak magnet speed regulation technology of the traditional synchronous permanent magnet motor, the permanent magnet motor is difficult in weak magnet speed regulation because excitation can not be regulated. The permanent magnet motor rotor with the excitation circuit variable reluctance and leakage flux path function comprises a rotor iron core, 2n main permanent magnets and 2n weak magnet units, wherein n is a positive integer; 2n trough slots are arranged along the axial direction of the rotor iron core and are evenly distributed along the peripheral direction of the rotor iron core; one main permanent magnet with a shape matched with the shape of each through slot is respectively embedded in each trough; a weak magnet unit is arranged between every two adjacent main permanent magnets along the peripheral direction of the rotor iron core; magnetic isolation grooves are arranged among two ends of the main permanent magnets along the peripheral direction and the adjacent weak magnet units; the main permanent magnet adopts radial magnetization; and the magnetization directions of the adjacent main permanent magnets are opposite. The invention is suitable for the permanent magnet motor.

Owner:HEILONGJIANG UNIV

Motor

ActiveUS8816554B2Extended speed rangeGenerate great torqueSynchronous generatorsWindingsCouplingMagnetic poles

Owner:PANASONIC CORP

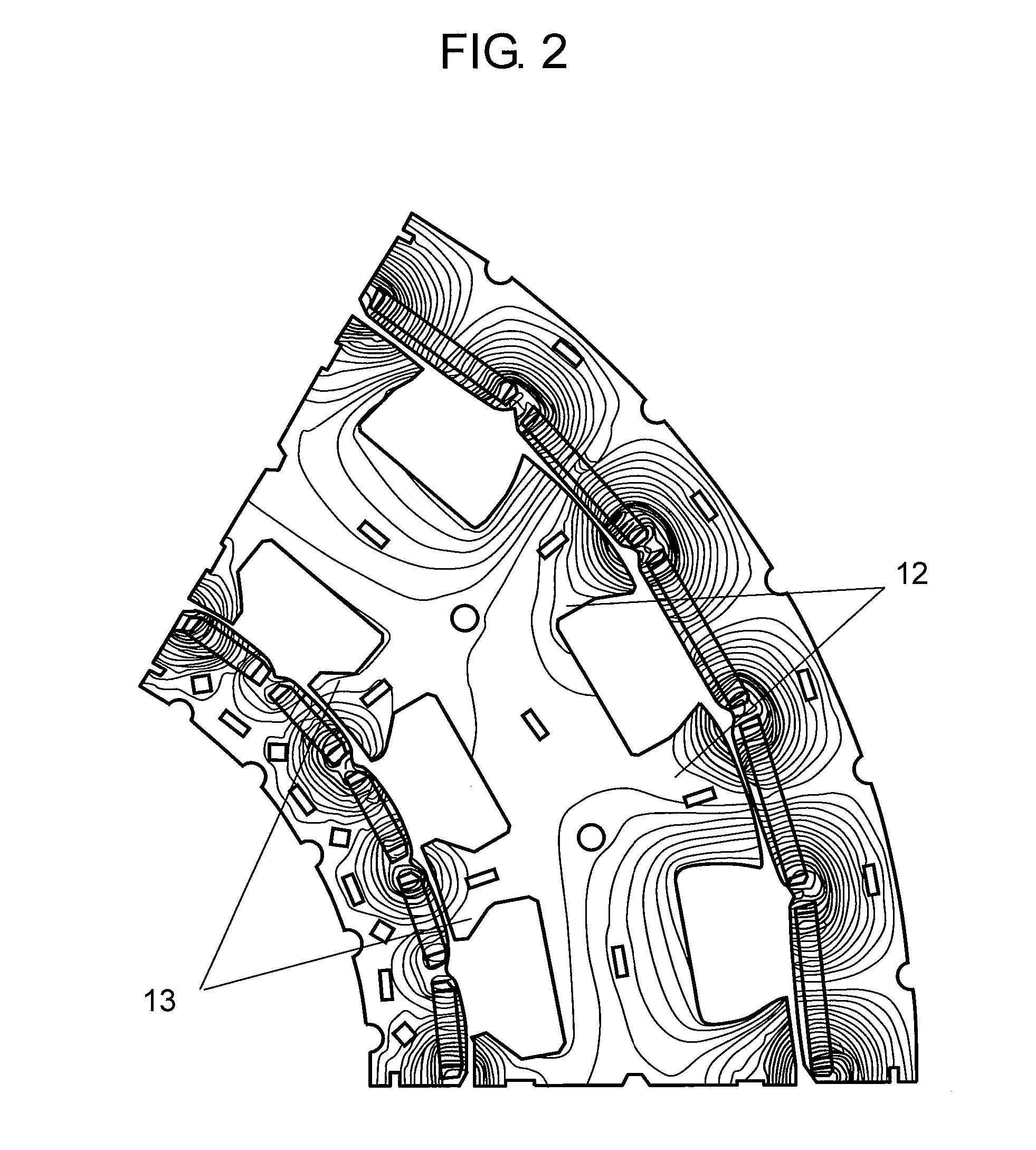

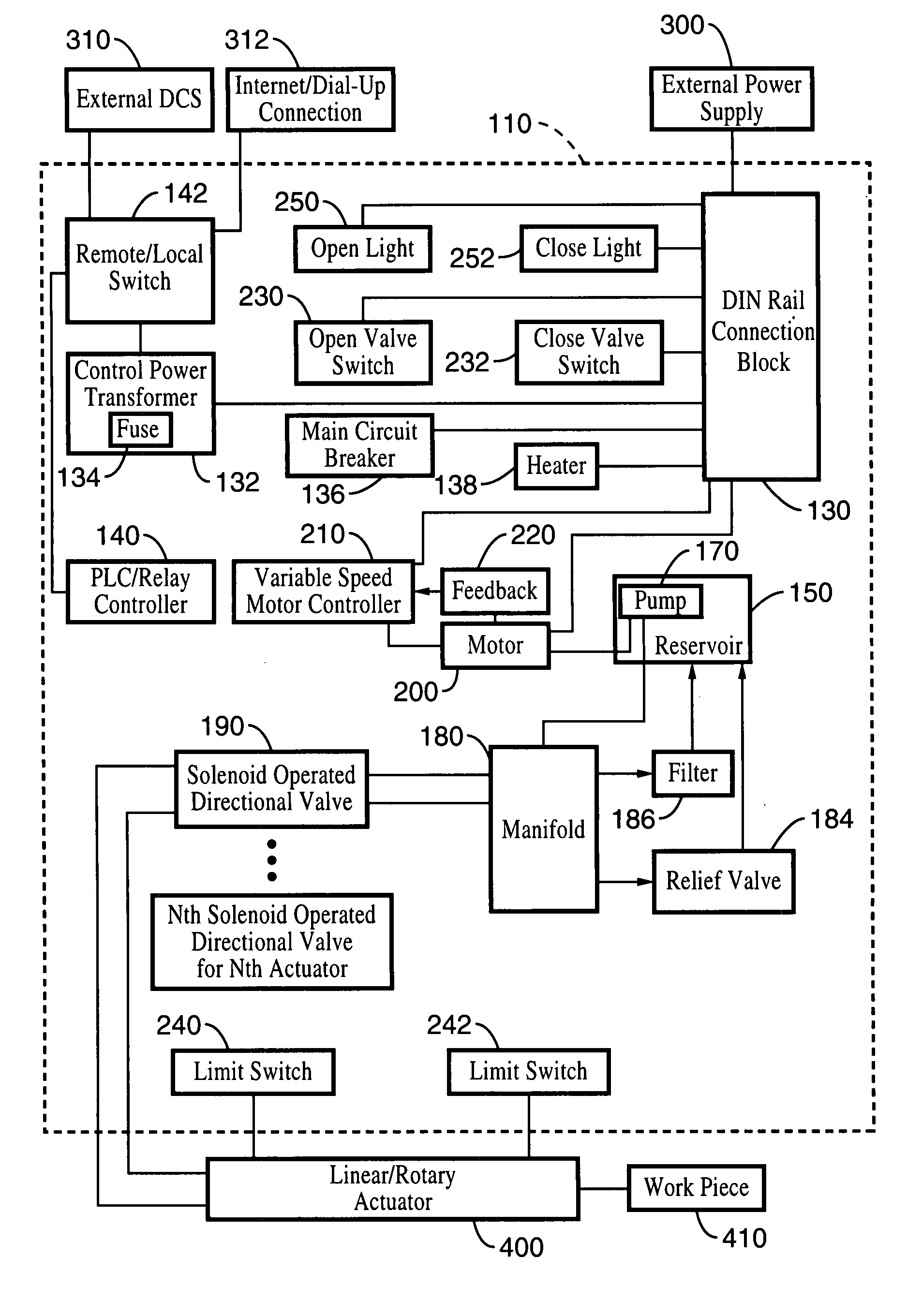

Actuator control system and method

InactiveUS20070204603A1Eliminating centralized high-pressure hydraulic system high-pressure hydraulicEliminating high-pressure hydraulic costly high-pressure plant wide hydraulic plumbingFluid couplingsServometer circuitsControl systemHydraulic pump

Actuator control system and method comprising an electric motor driving a hydraulic pump in fluid delivery communication with a source of hydraulic fluid; a variable speed controller operatively coupled to the motor for driving the pump at variable speeds; an external hydraulic actuator in fluid delivery communication with the pump for receiving pressurized fluid flow from the pump; and a feedback loop operatively coupled from the motor to the controller for providing feedback signals correlative to a pressure of the pressurized fluid flow through the driven pump for driving the external hydraulic actuator in response to the feedback signals for providing electronic velocity and force control of actuation of the external hydraulic actuator. The actuator control system and method can operate on one or many high-pressure hydraulic linear and / or rotary actuators on different pieces of hydraulically driven equipment and with different velocity requirements actuating in different directions.

Owner:JACOBS MICHAEL H +2

System for decoupling a rotor from a stator of a permanent magnet motor and flywheel storage system using the same

InactiveUS20120176074A1Extended speed rangeConstant powerDC motor speed/torque controlMagnetic circuitConstant powerEngineering

A system for decoupling a rotor from a stator of a permanent magnet motor and a flywheel storage system using the same are provided. The flywheel storage system uses the permanent magnet motor as a magnetic active coupler to minimize magnetic losses in flywheel energy storage system during the motor-generator electric power transfer for enabling a magnetic field weakening method and a way of cancelling the losses during a conservative mode where the stator is totally decoupled from the rotor. Also, the present invention enables the optimal sizing of a permanent motor-generator to be able to supply a constant power over a large range of rotating speeds.

Owner:UNIV LAVAL

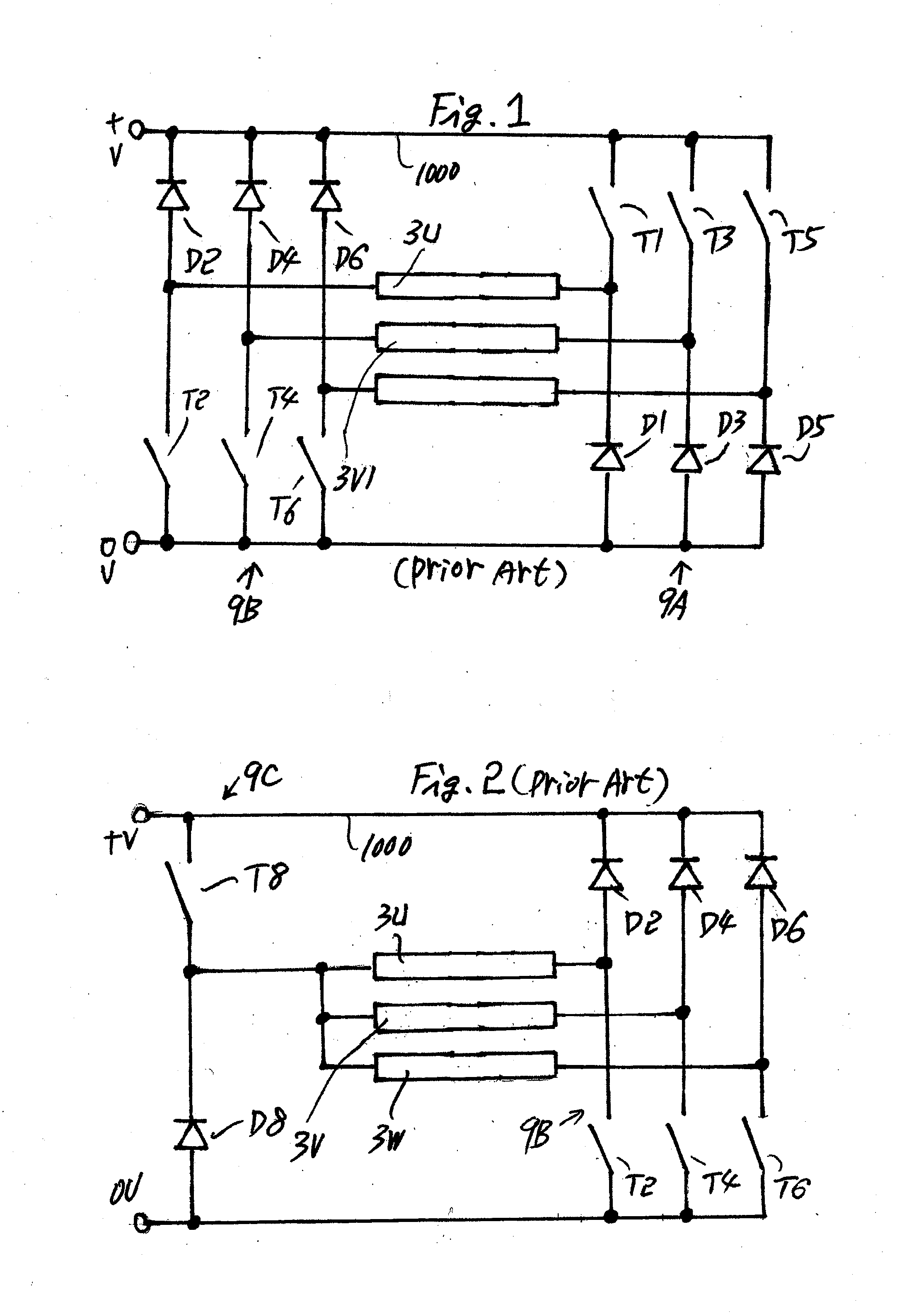

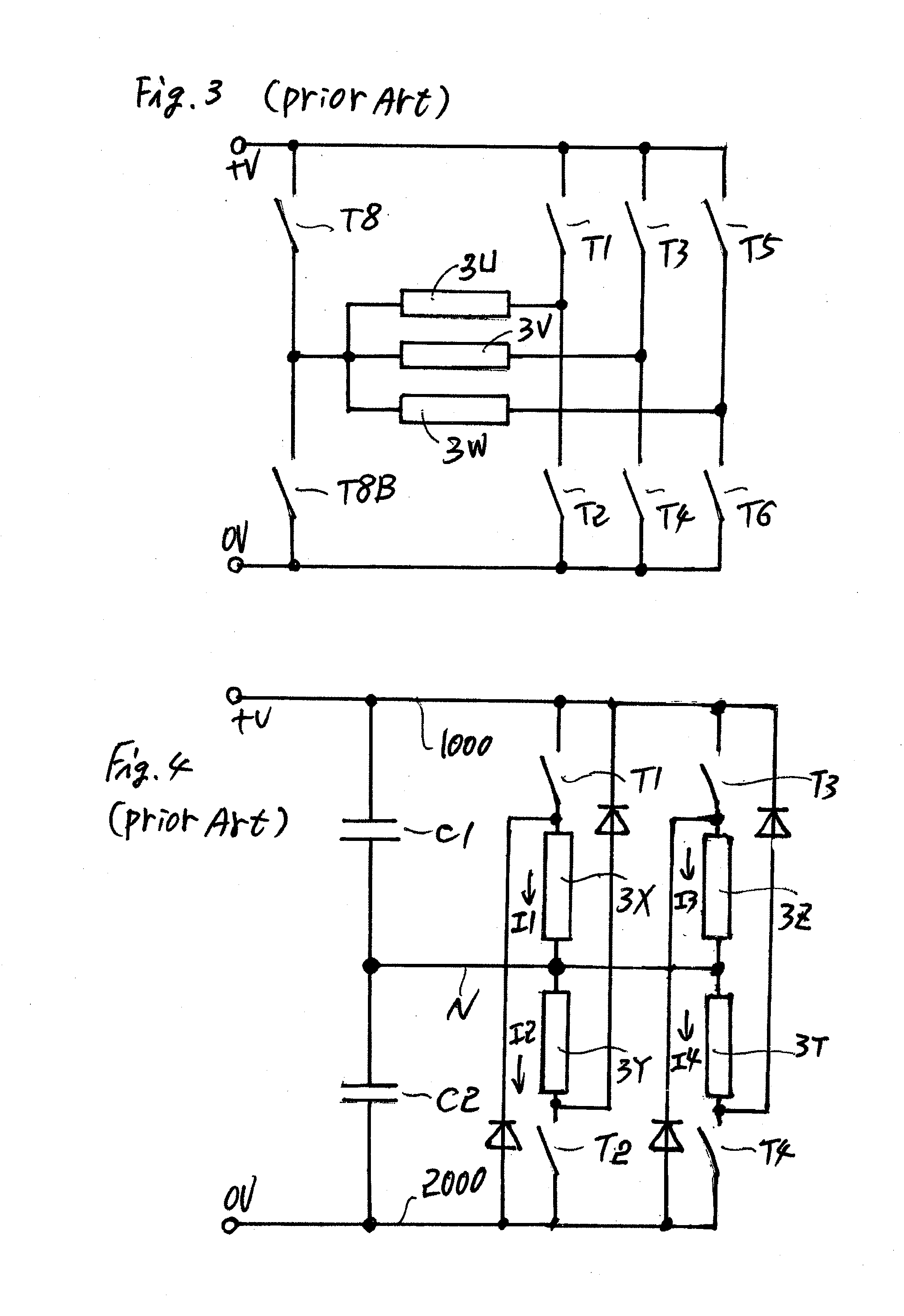

Power converter for driving switched reluctance motor

InactiveUS20130234638A1Sufficient torqueImprove power reliabilityMotor/generator/converter stoppersAC motor controlConvertersSwitched current

Owner:TANAKA SHOUICHI

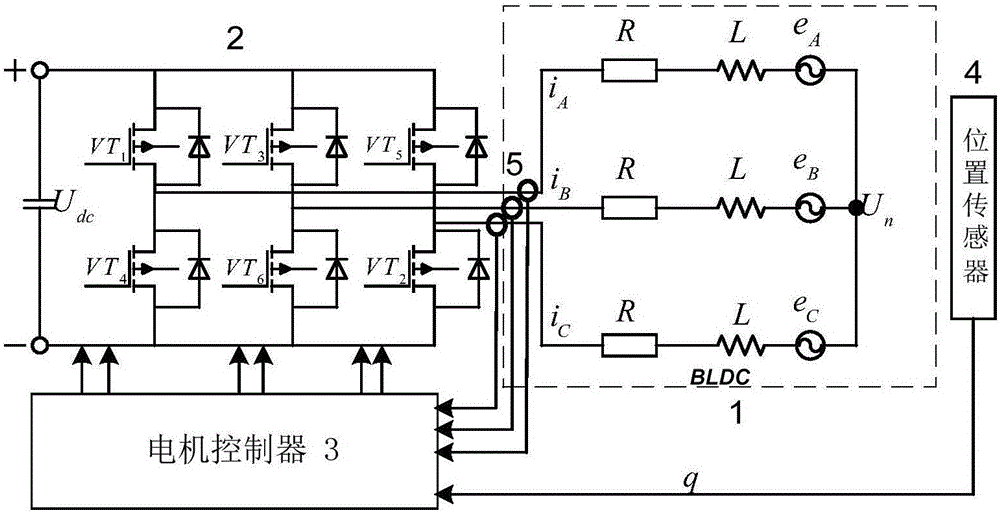

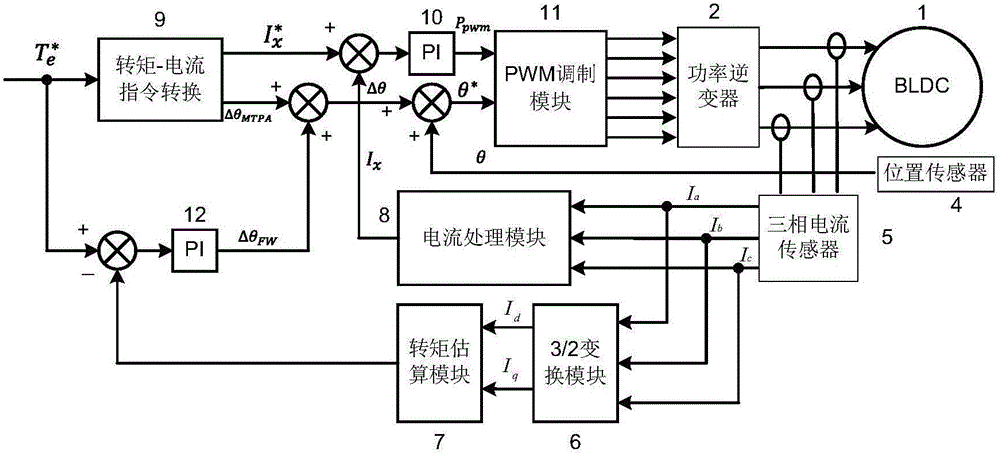

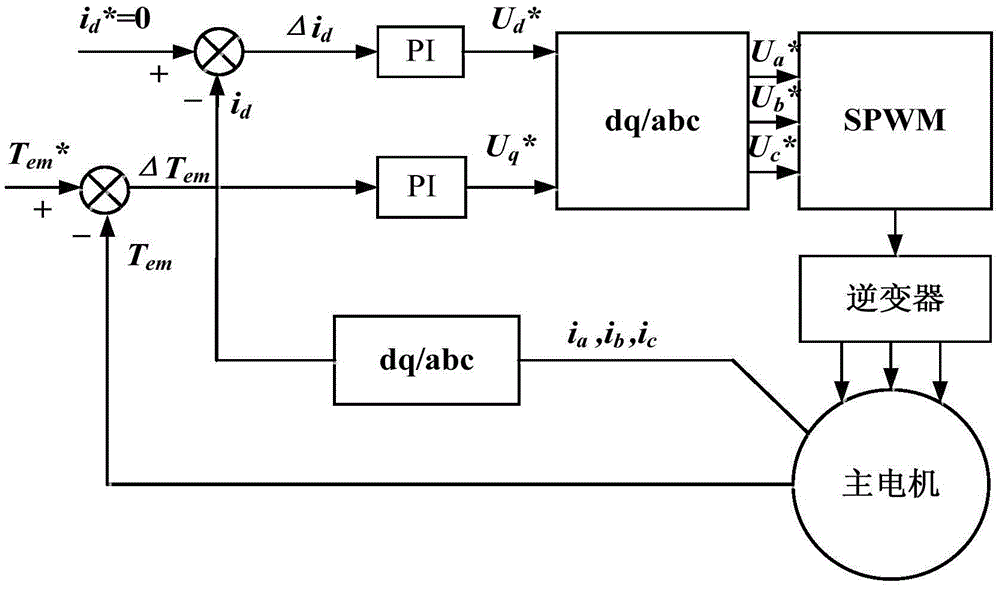

Vector type permanent magnetic brushless motor control method

InactiveCN106059431ASolve the problem of low controllable speedExtended speed rangeVector control systemsDynamo-electric converter controlBrushless motorsConstant power

The invention discloses a vector type permanent magnetic brushless motor control method. When a motor starts, by use of a constant-torque zone current closed-loop control method, a permanent magnetic brushless motor is controlled, when a PWM duty ratio output by an electric current loop proportional integral controller reaches a set threshold, by use of a constant-power weak-magnetic zone torque closed-loop control method, the permanent magnetic brushless motor is controlled; and in the constant-power weak-magnetic zone torque closed-loop control method, when a weak-magnetic control advanced conduction overlap angle delta theta FW output by a torque ring proportional integral controller is lower than a set threshold, by use of a constant-torque zone current closed-loop control method, the permanent magnetic brushless motor is controlled.

Owner:CHINA FIRST AUTOMOBILE

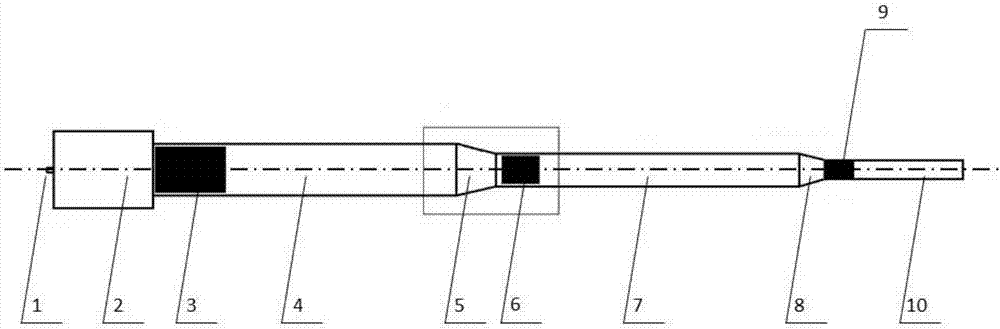

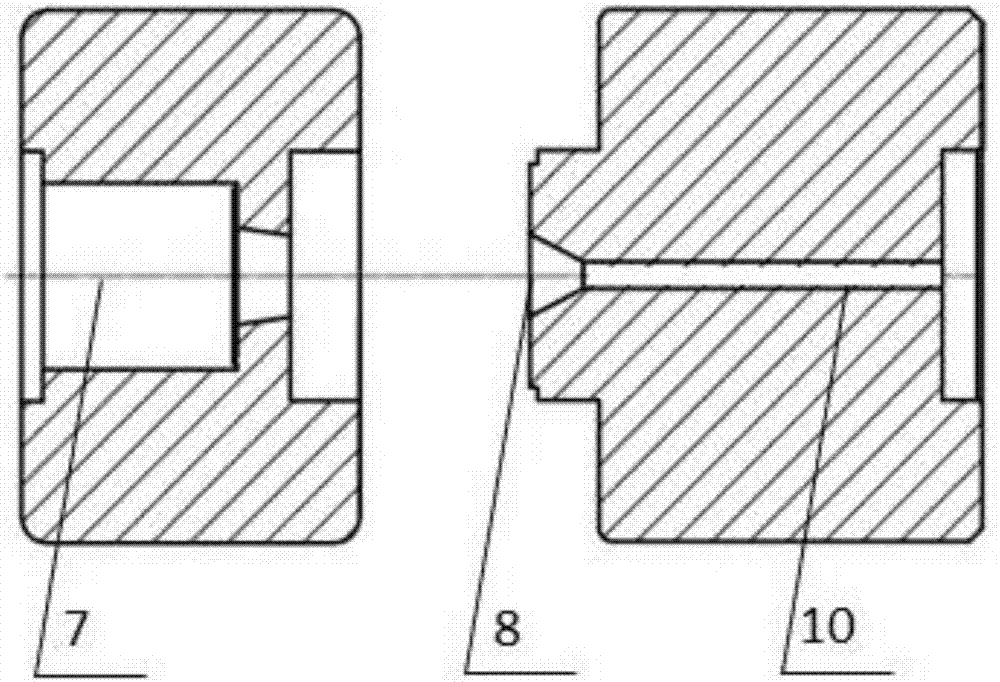

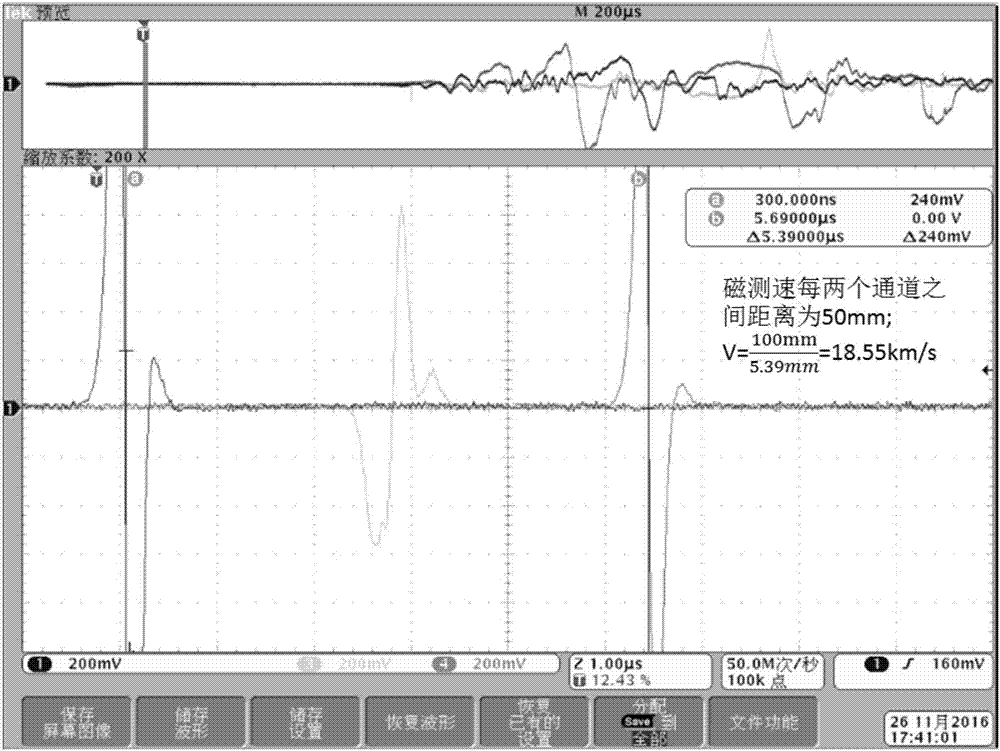

Three-stage light gas gun based on hydrogen and oxygen mixed detonation driving

InactiveCN106895739AReduce the risk of insecurity and instabilityImprove experimental efficiencyCompressed gas gunsCombustion chamberDetonation

The invention belongs to the technical field of ultra-high-speed impact loading test, in particular to a three-stage light gas gun. The technical scheme of the three-stage light gas cannon driven by hydrogen-oxygen mixed detonation is: the ratio of the inner diameter of the first-stage pump tube to the inner diameter of the second-stage pump tube is 2 to 4, and the ratio of the inner diameter of the second-stage pump tube to the inner diameter of the launch tube Between 3 and 5; the aspect ratio of the primary pump tube is 3 to 5, the aspect ratio of the secondary pump tube is 4 to 7, and the aspect ratio of the launching tube is 1 to 2; the cone angle of the primary high pressure cone section The cone angle of the secondary high-pressure cone section is 5°-25°; the combustion chamber is filled with a mixture of hydrogen, oxygen and nitrogen, and the primary pump tube and the secondary pump tube are respectively filled with hydrogen gas to launch The tube is vacuumed. The invention adopts hydrogen-oxygen mixed gas as a driving source, has stronger loading capacity, low pollution, and stably launches a projectile with a mass of 1g at a speed exceeding 10km / s.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

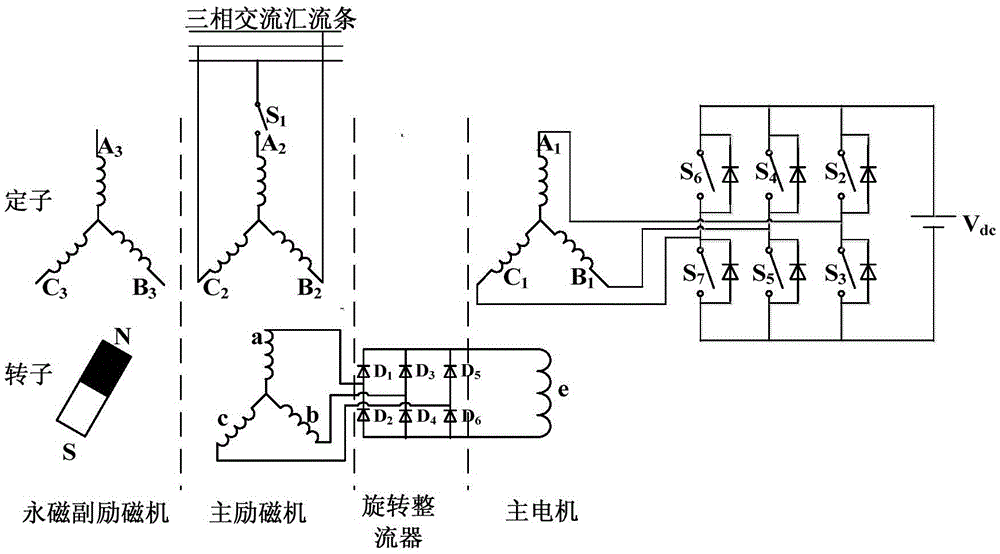

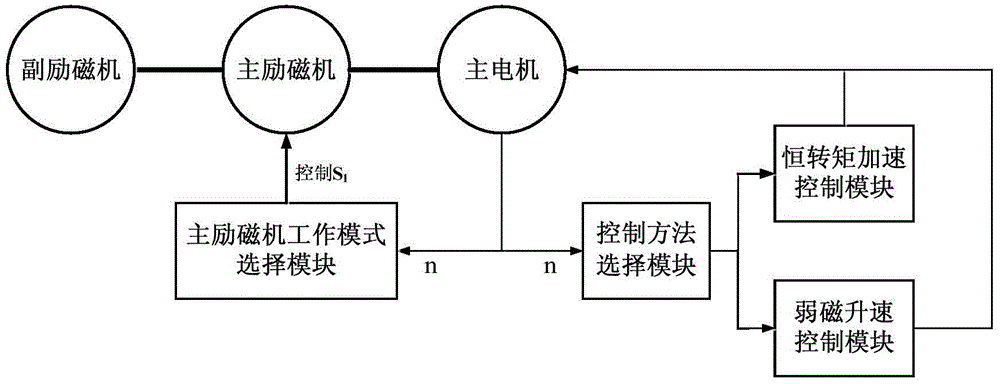

Three-stage brushless synchronous start generator structure and start control method thereof

ActiveCN105553211ALow costReduce complexityElectronic commutation motor controlVector control systemsThree stageElectric machine

The invention discloses a three-stage brushless synchronous start generator structure and a start control method thereof. The three-stage brushless synchronous start generator structure comprises an auxiliary permanent magnet exciter, a main exciter, a main motor, a rotary rectifier and a three-phase full-bridge inverter; the main exciter, the main motor and the rotary rectifier are sequentially connected; and the three-phase full-bridge inverter is connected with the main motor. The structural complexity of the three-stage brushless synchronous start generator can be reduced; the working reliability can be improved; the start control method can be simplified; the rotation speed range of the main motor can be expanded; the design capacity of the main motor can be reduced; and start of the generator can be completed effectively and stably.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

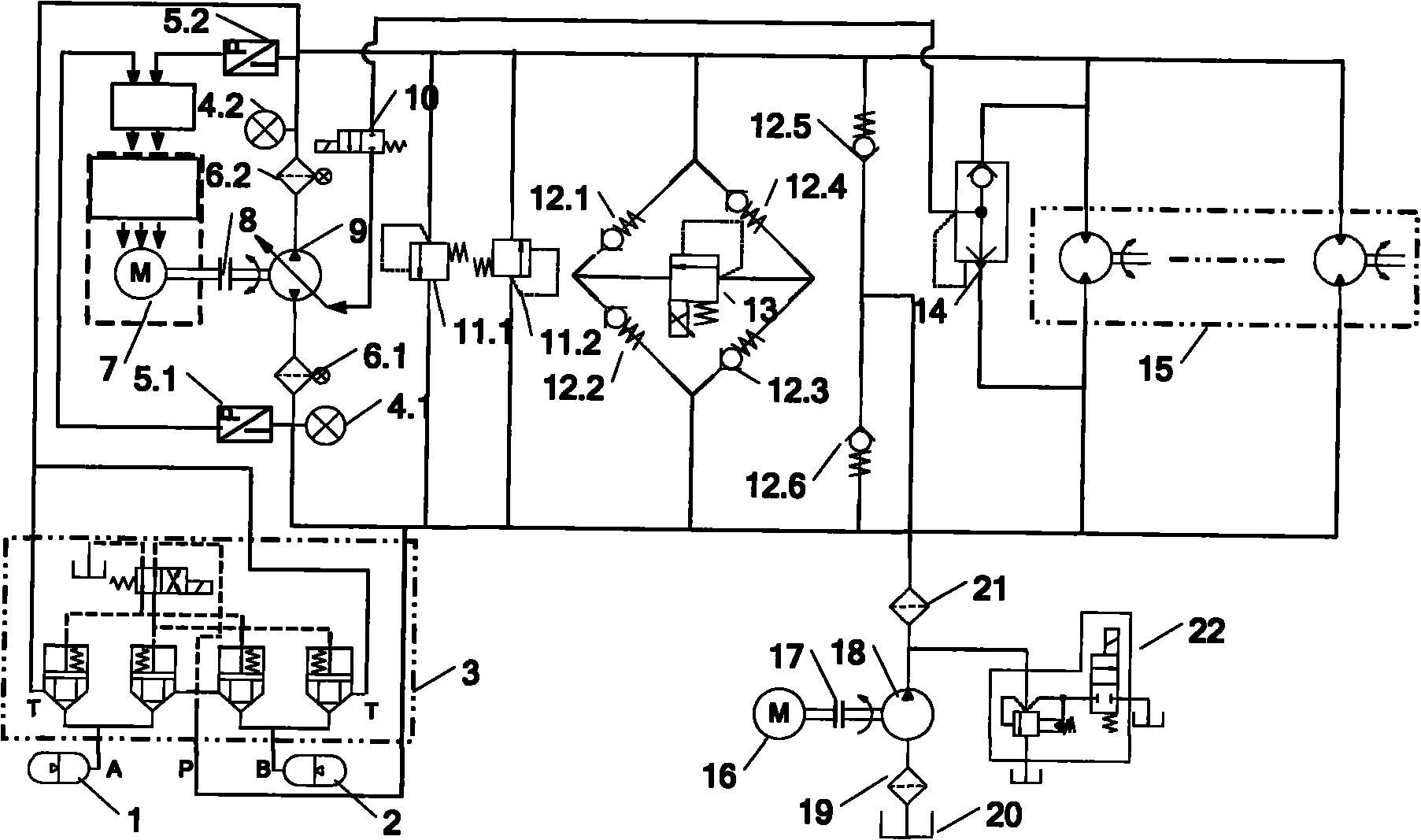

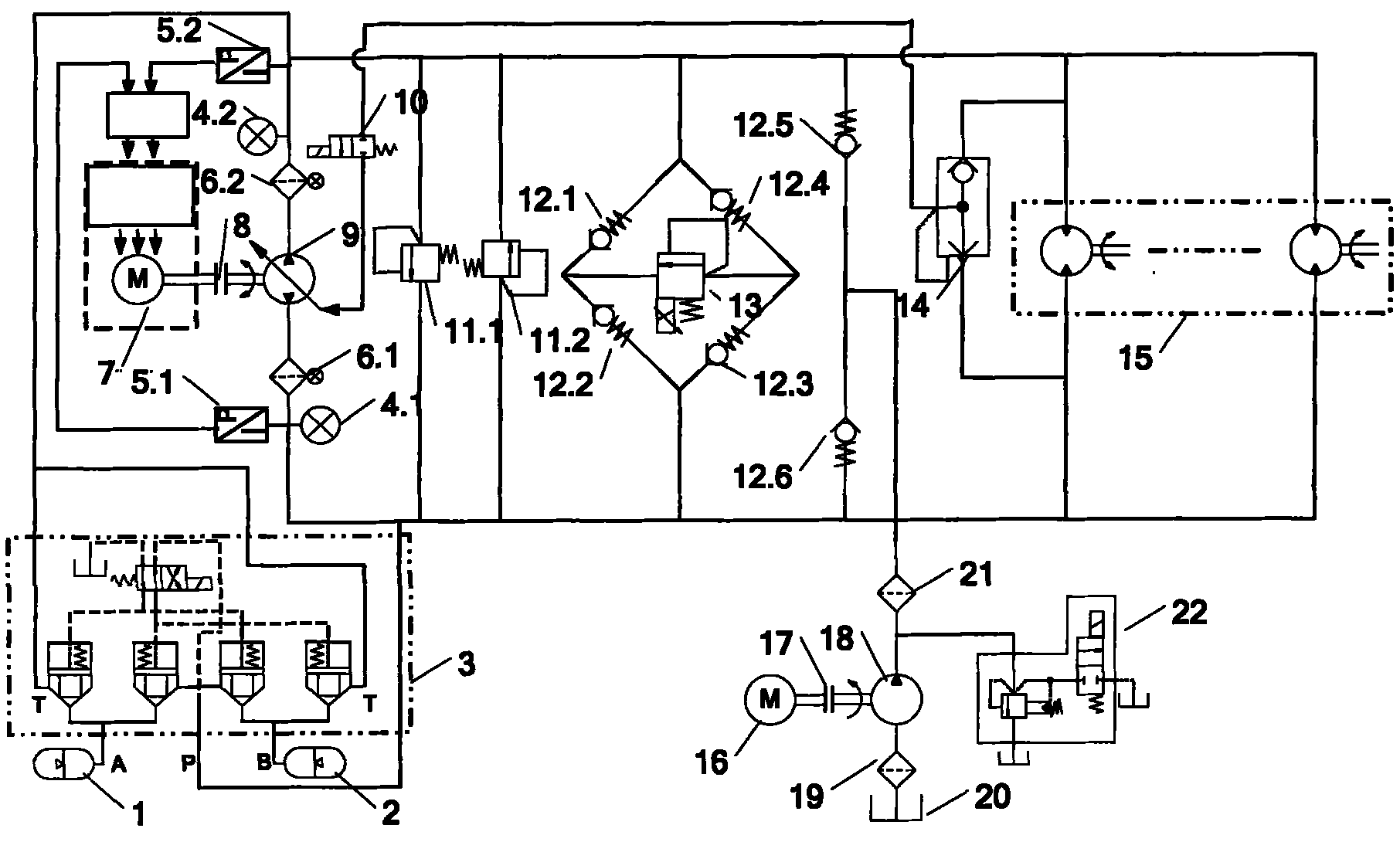

Cutterhead closed type hydraulic drive system adopting revolving speed-variable and displacement-variable compound control

InactiveCN101967980AContinuously adjustable pressureExtended speed rangeMechanical apparatusTunnelsControl theoryType system

The invention discloses a cutterhead closed type hydraulic drive system adopting revolving speed-variable and displacement-variable compound control. In the invention, a main oil line adopts a pump control motor closed type system taking revolving speed-variable control as first class speed-regulating control and displacement-variable speed-regulating control as second class speed-regulating control, thereby having good frequency variable speed-regulating energy-saving effects and high efficiency; the displacement-variable pump control motor closed type system reduces the overflow loss and the throttling loss, enhances the efficiency of the system and can also ensure a frequency variable speed-regulating range to exceed the limit of the limiting revolving speed of a pump; because the cutterhead has wide revolving speed range and large power variation range, the speed-regulating range of the cutterhead is widened through revolving speed-variable and displacement-variable compound control; the bi-directional pressure of the cutterhead can be regulated continuously through the combination of a one-way valve and a proportional overflow valve; and the impact shock of the oil liquid of the system can be absorbed through the installation of energy accumulators positioned on both ends of a variable pump, therefore the installed power of the system is reduced.

Owner:ZHEJIANG UNIV +2

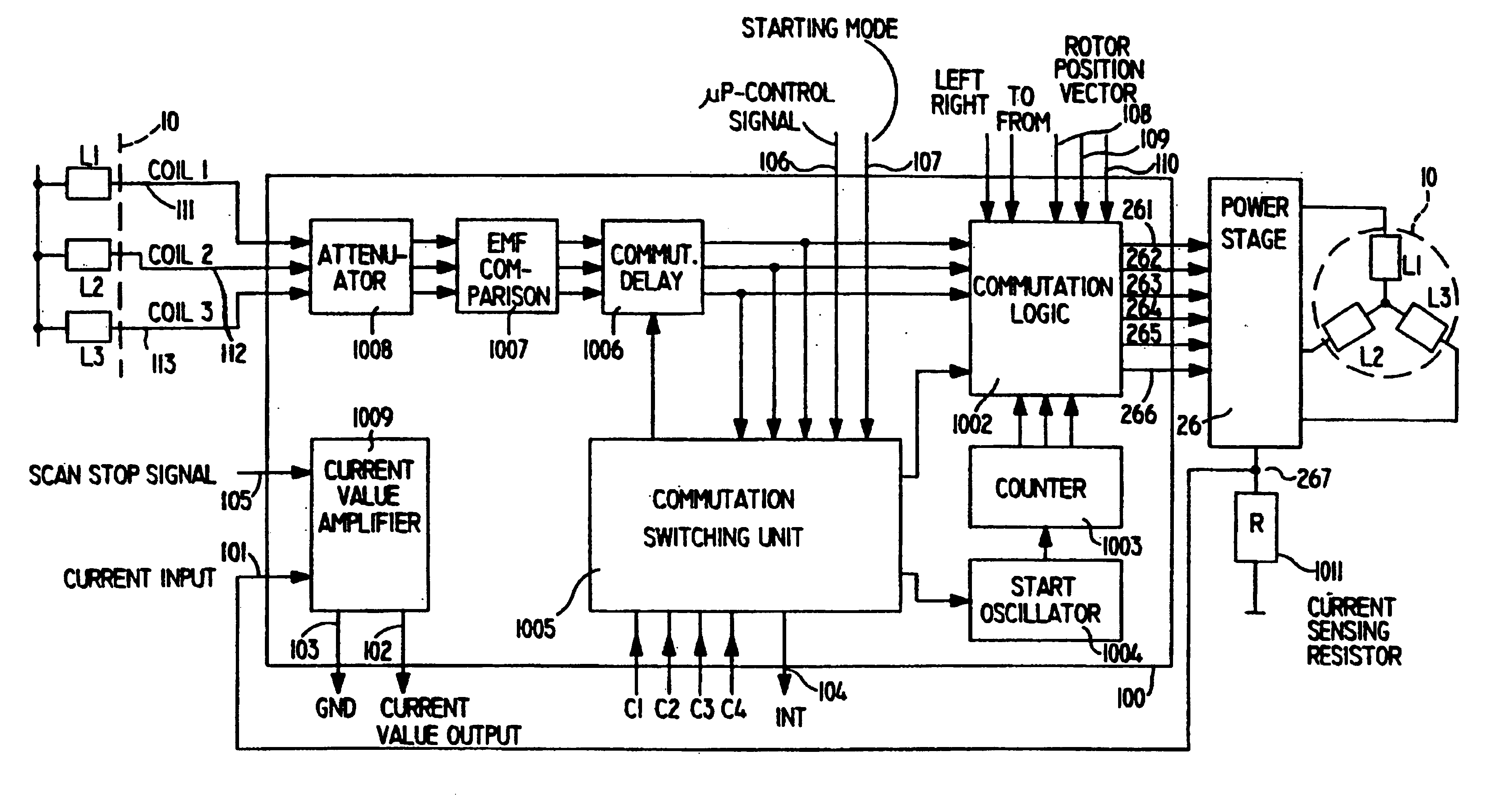

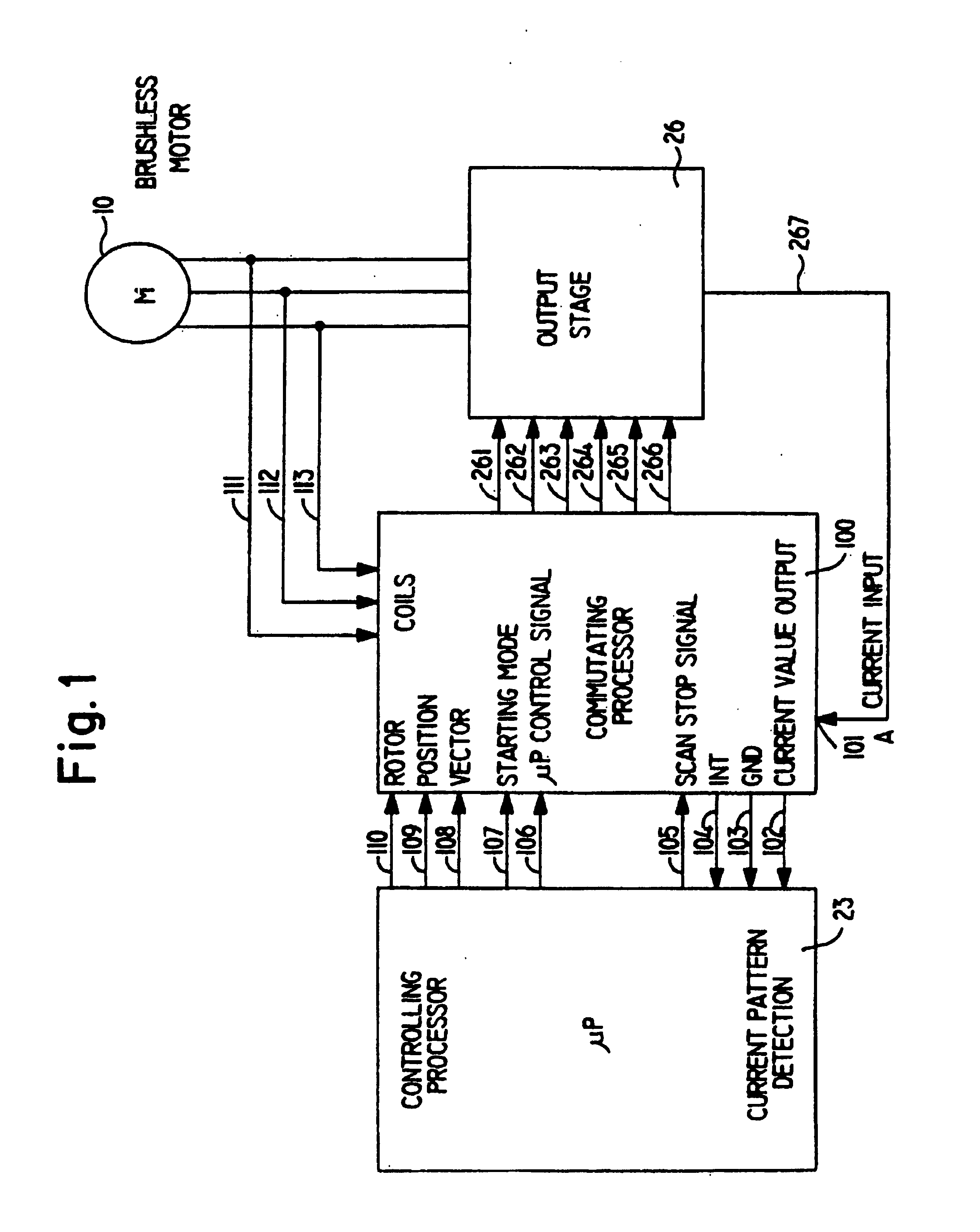

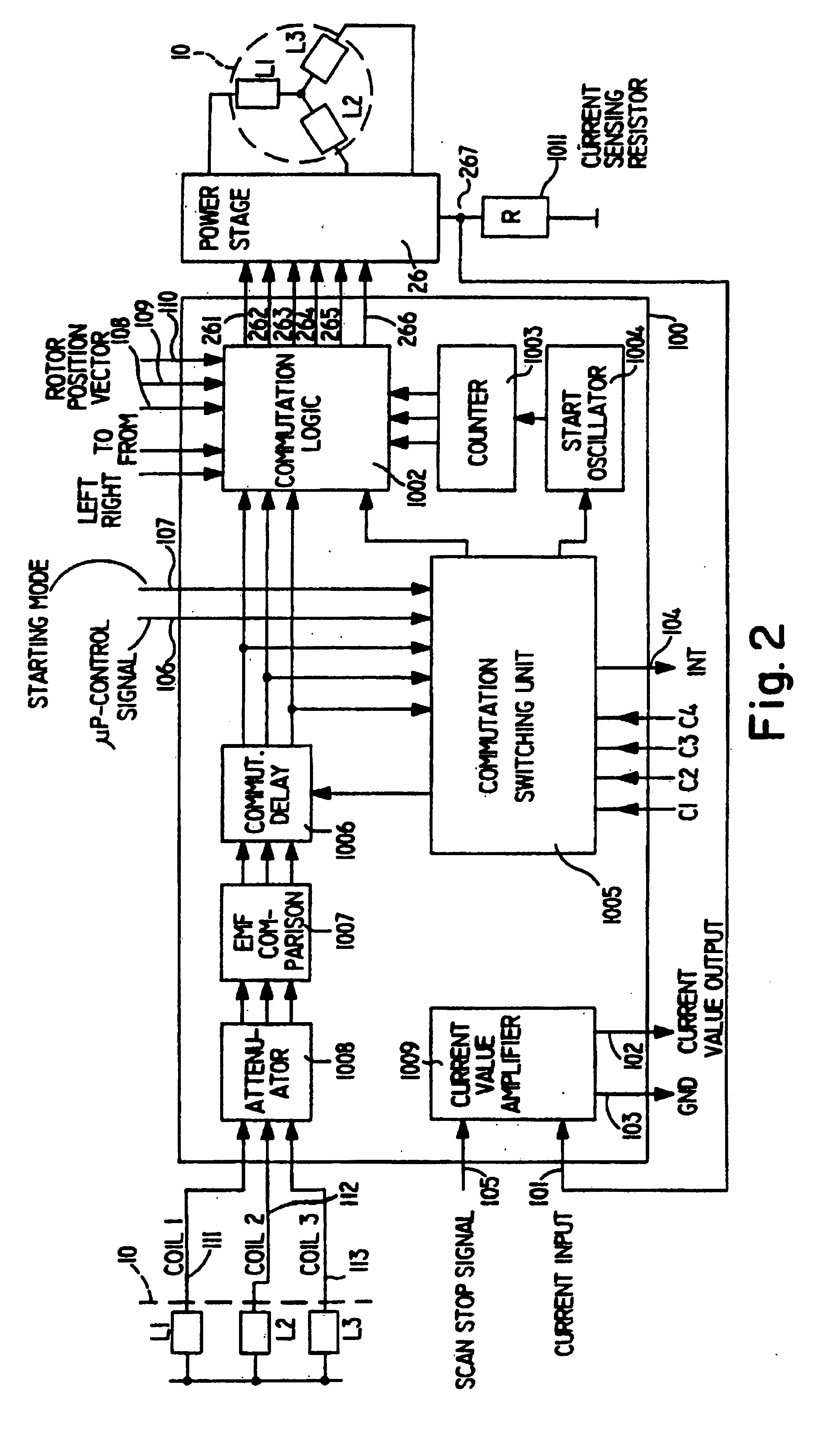

Apparatus and method for controlling brushless electric motors and position encoders and indicating position thereof

InactiveUSRE39076E1Increase usable speed rangeImprove accuracyMotor/generator/converter stoppersSynchronous motors startersEngineeringInductance

A brushless direct current motor is energized by a power stage. Switches of the power stage are selectively switched by an electronic control device. In order to determine the correct commutation pattern, without using rotor position indicators such as Hall effect devices, the control device is arranged to sample the power fed to the motor. The samples, each responsive to a test signal or normal energization pulses received by the motor, in a ordered sequence define an analogue function whose parameters can be determined by mathematical analysis. The analysis applied to the samples derives the necessary commutation information and the energization signals in a rapid manner by employing a vector or complex number addition based on functions dependent on variable inductance in the operation of the motor.

Owner:PAPST MOTOREN GMBH & CO KG

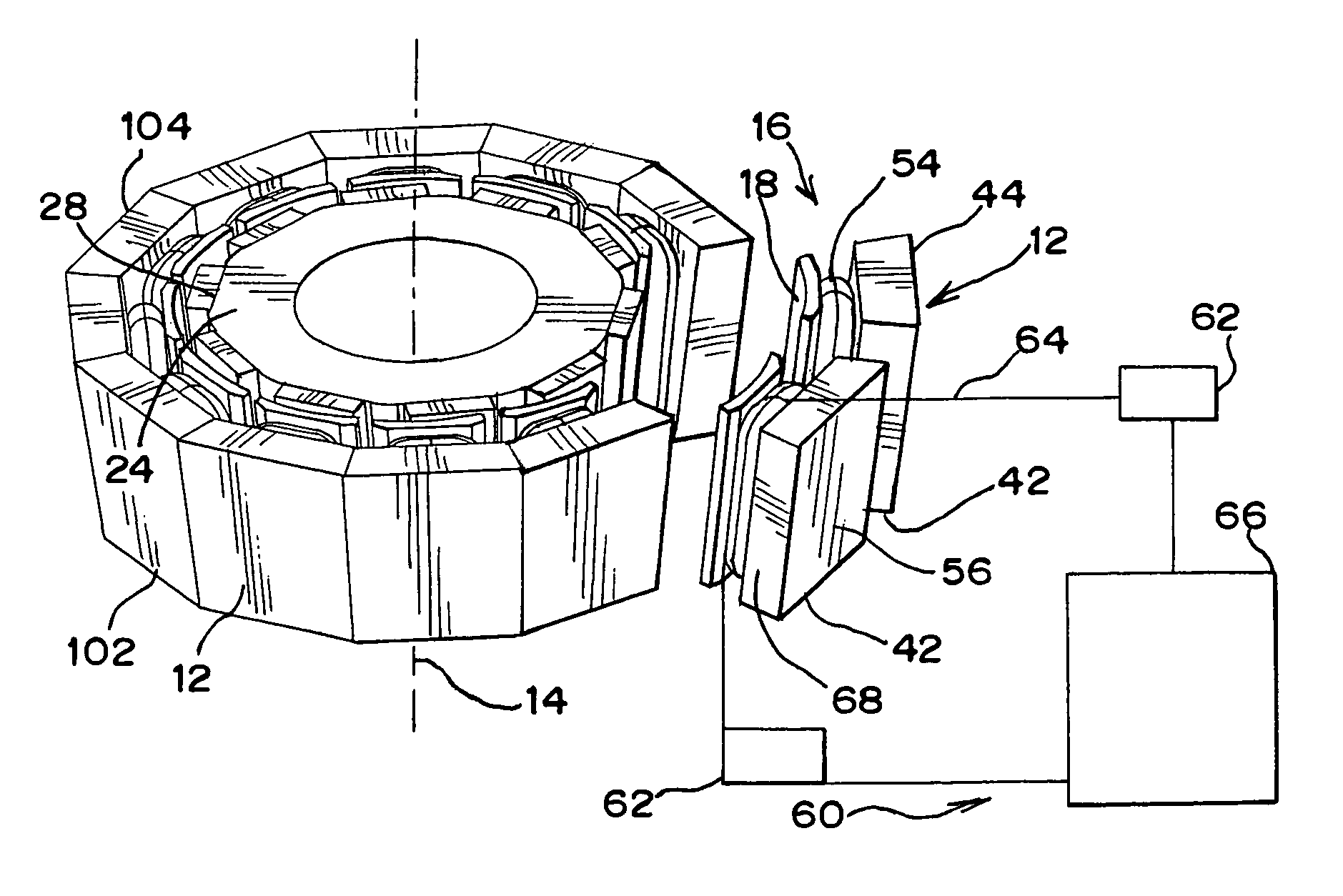

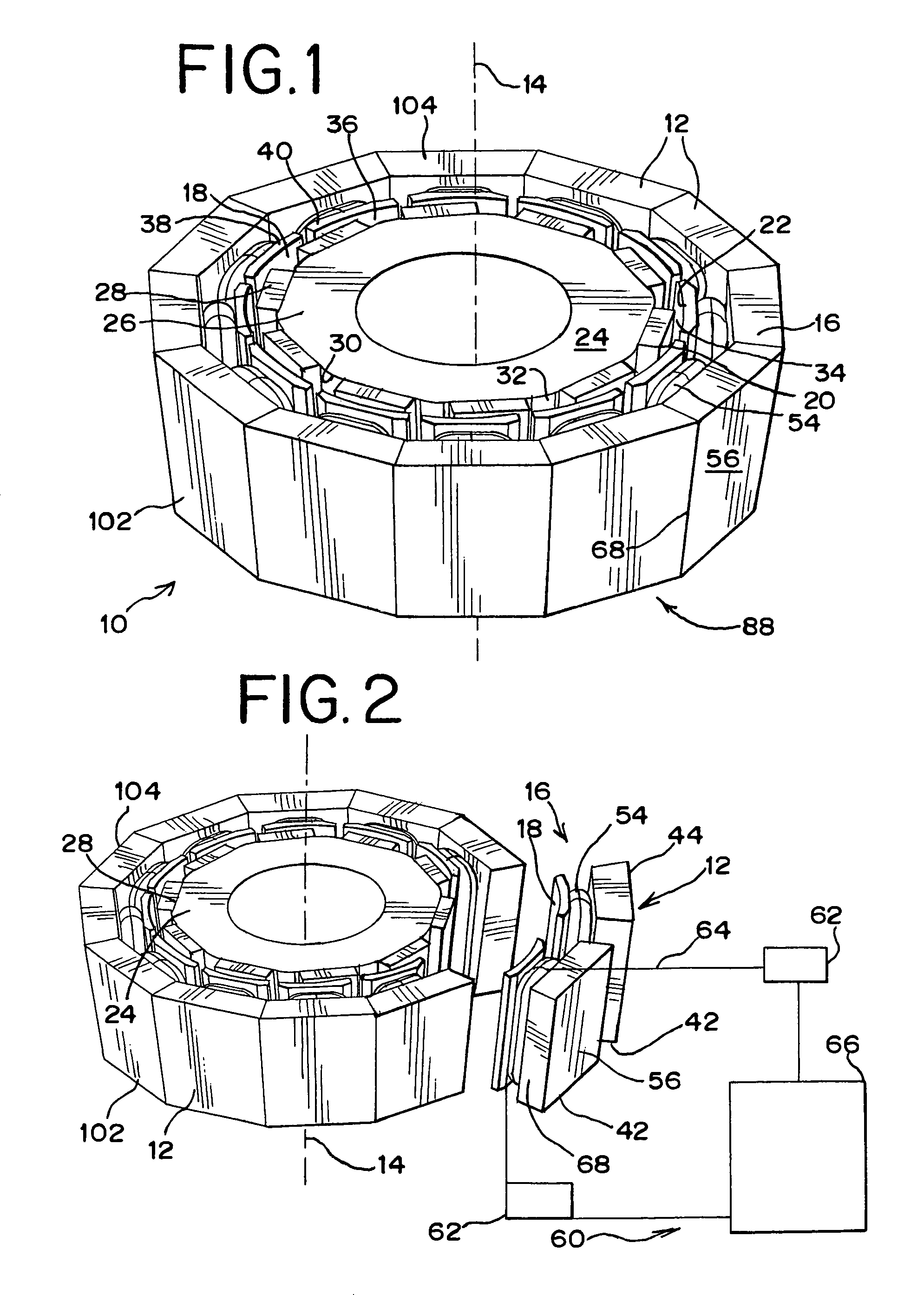

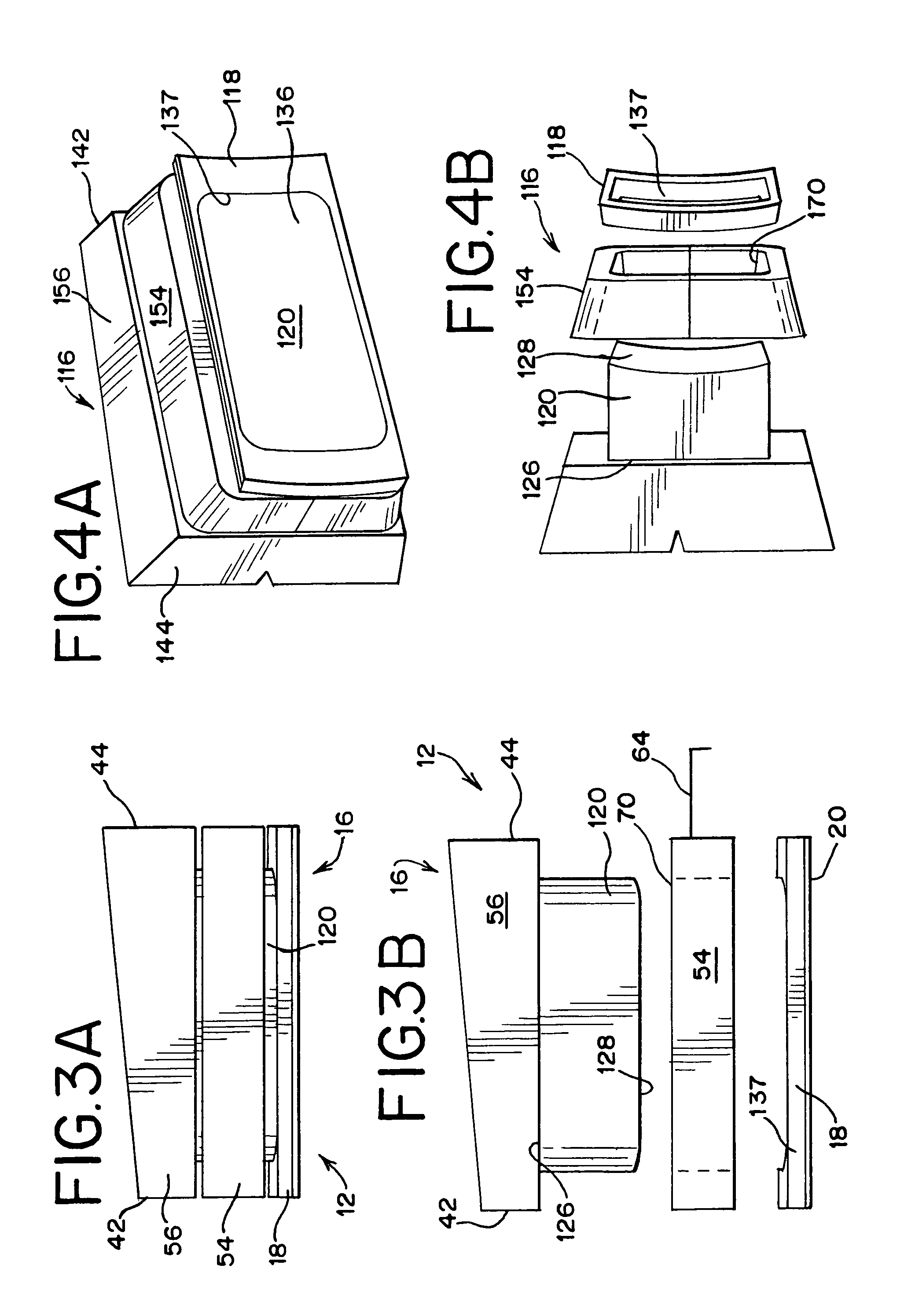

Manufacture of electric motor component

ActiveUS7847443B2Minimize disruptionAdd supportMagnetic circuit rotating partsSynchronous machinesElectric machineEngineering

The modular conical stator pole provides an improved conical stator assembly on electrical machines. The improved conical stator pole assembly comprises a plurality of stator poles, each pole comprising an assembly having a coil secured on a soft magnetic composites (SMC) stator pole tooth by inserting a winding support through the open core of the coil and attaching a back iron and a stator face to either end of the winding support. Each stator pole having a parallelogram shaped cross section for forming a conical shaped rotor space when the stator poles are assembled having the back irons bearing against each other to space the coils apart and form a conical shaped outside profile of the stator pole assembly. The conical stator having a small end and a big end. The tooth comprising a winding support integrally molded with either the back iron or the face.

Owner:BURGESS NORTON MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com