Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176 results about "Bearing stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The stiffness of a bearing is how the distance between the parts which are separated by the bearing varies with applied load. With rolling element bearings this is due to the strain of the ball and race.

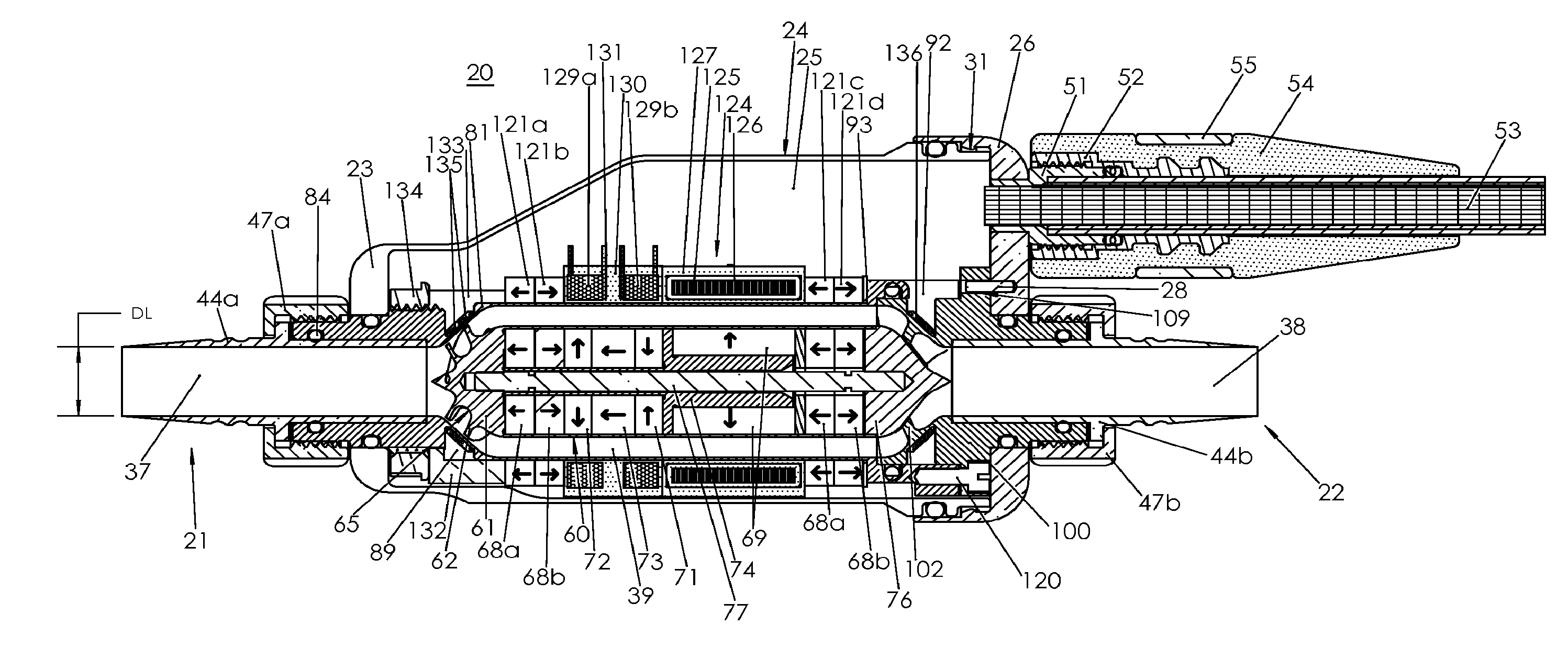

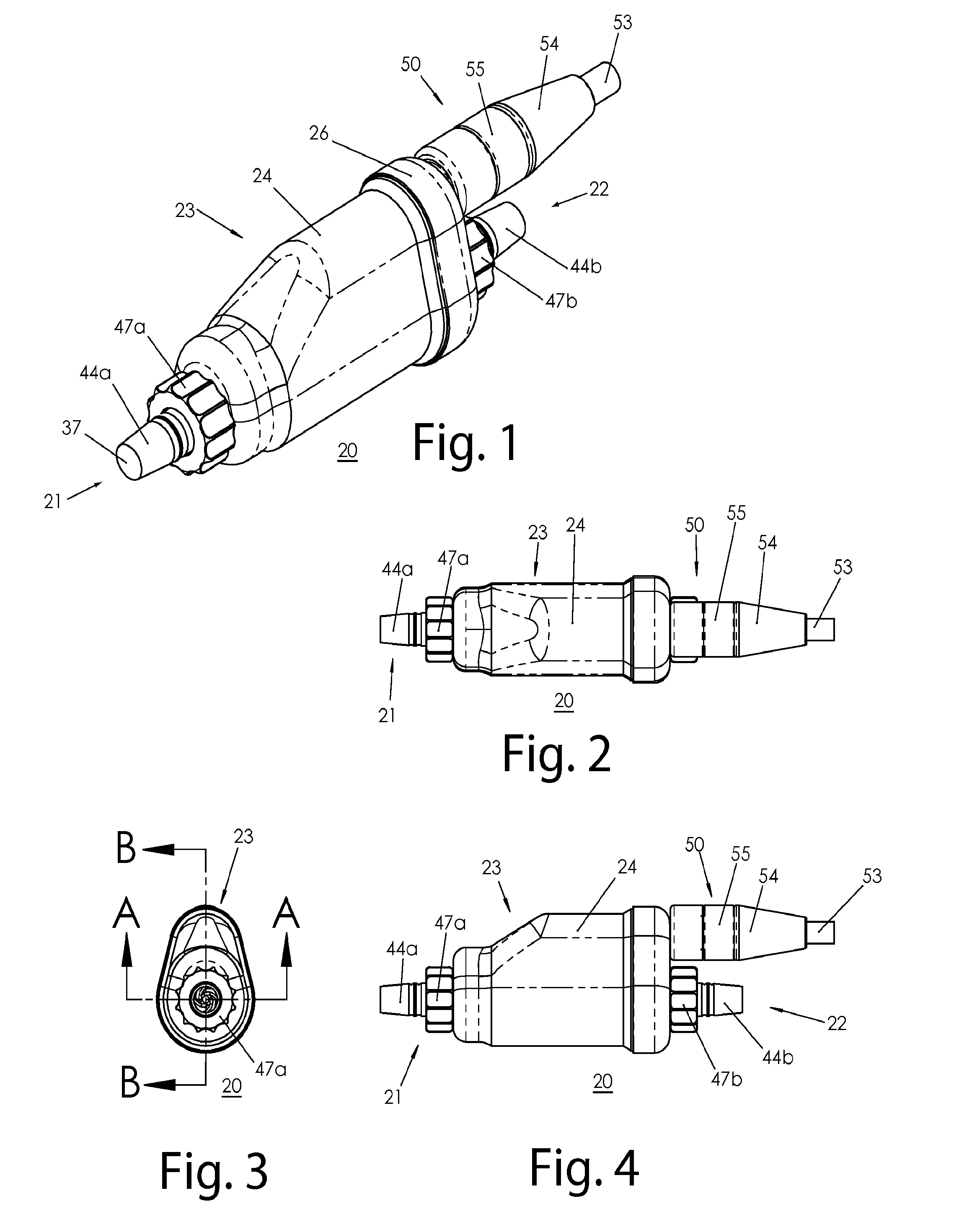

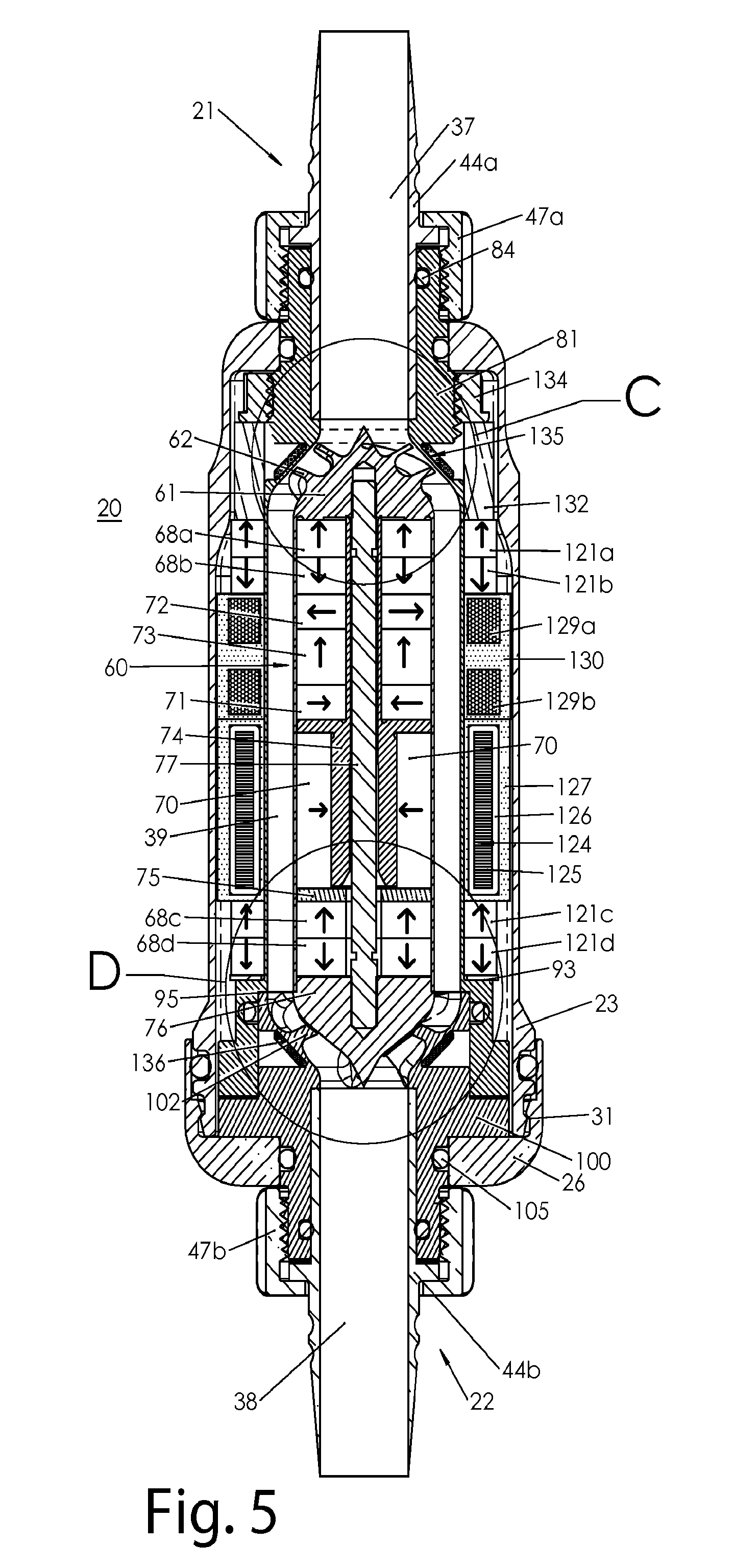

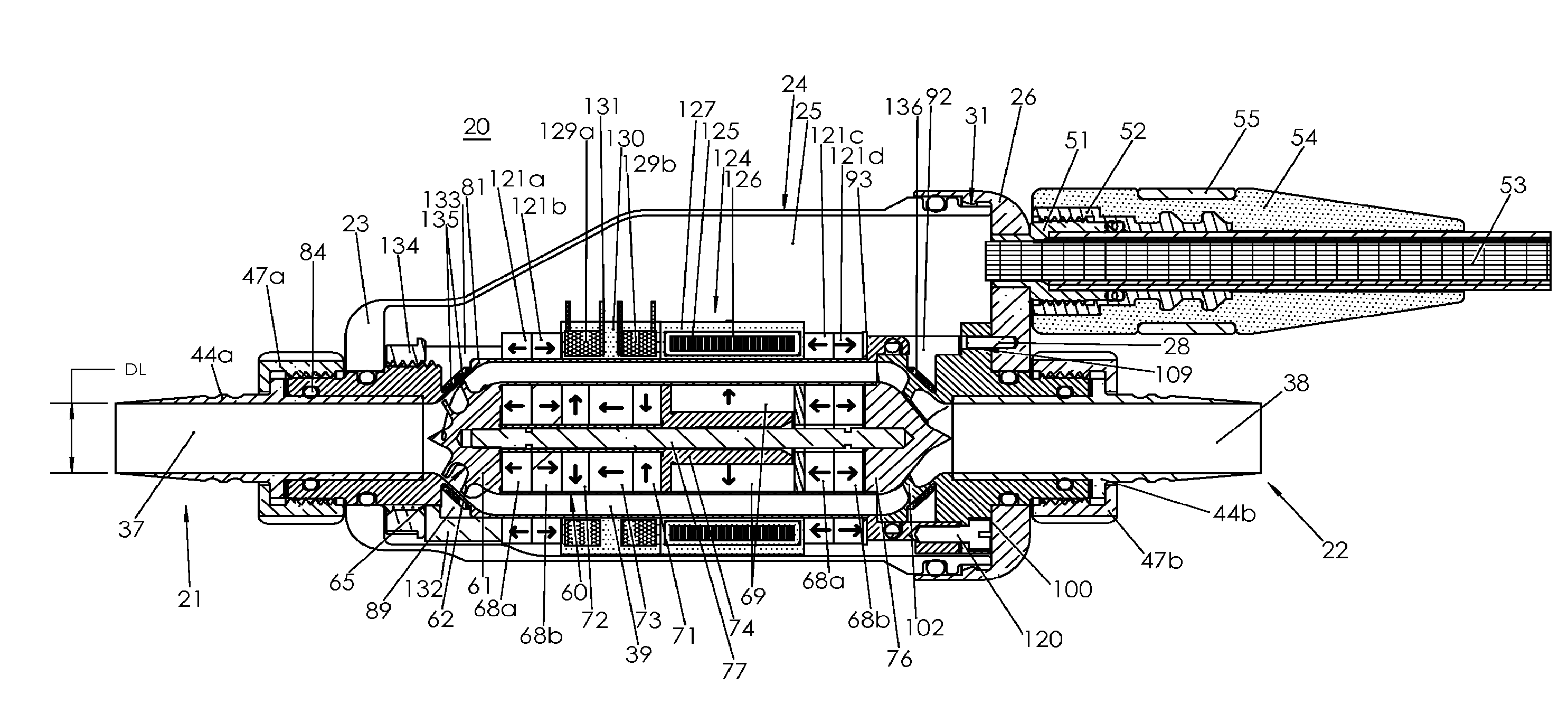

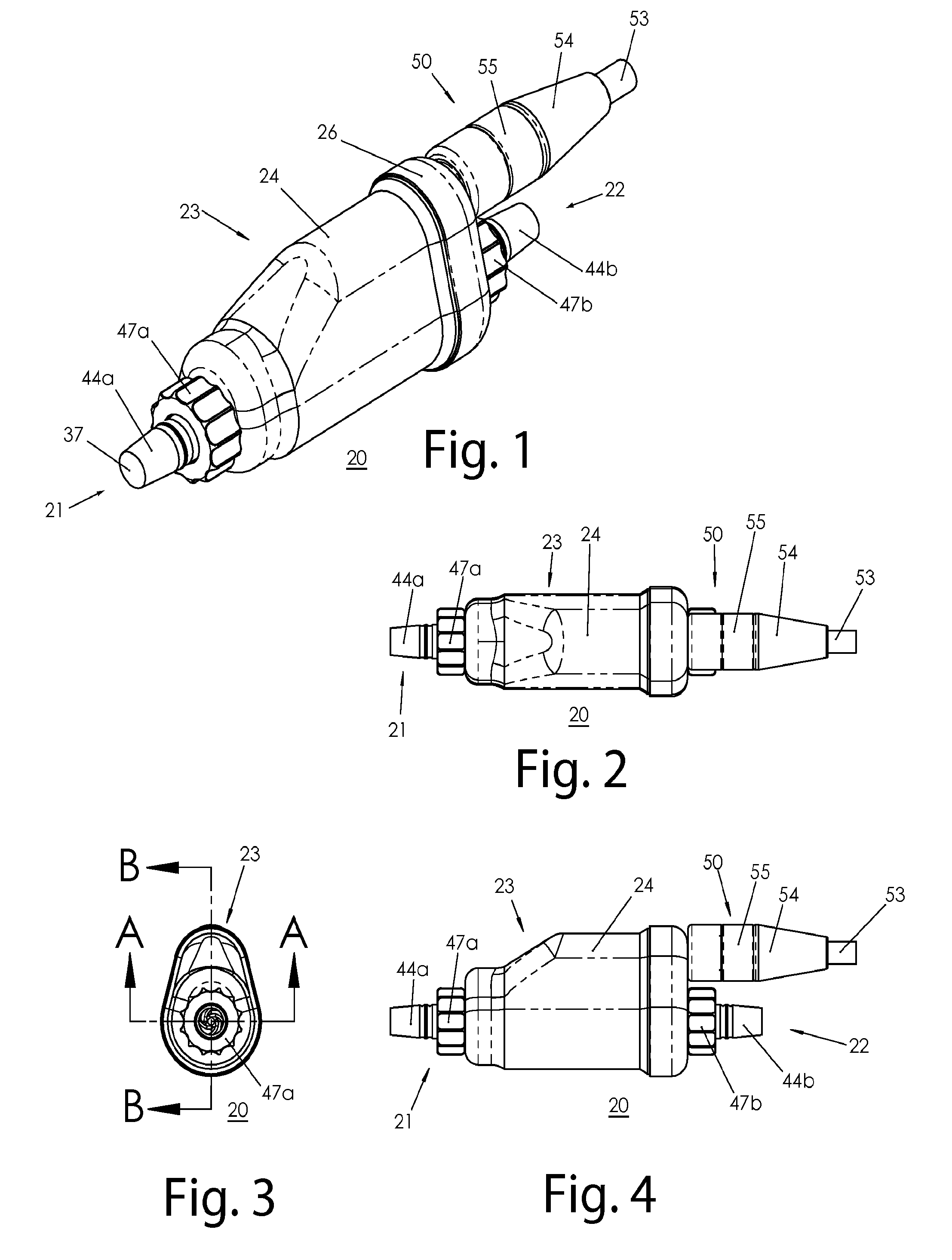

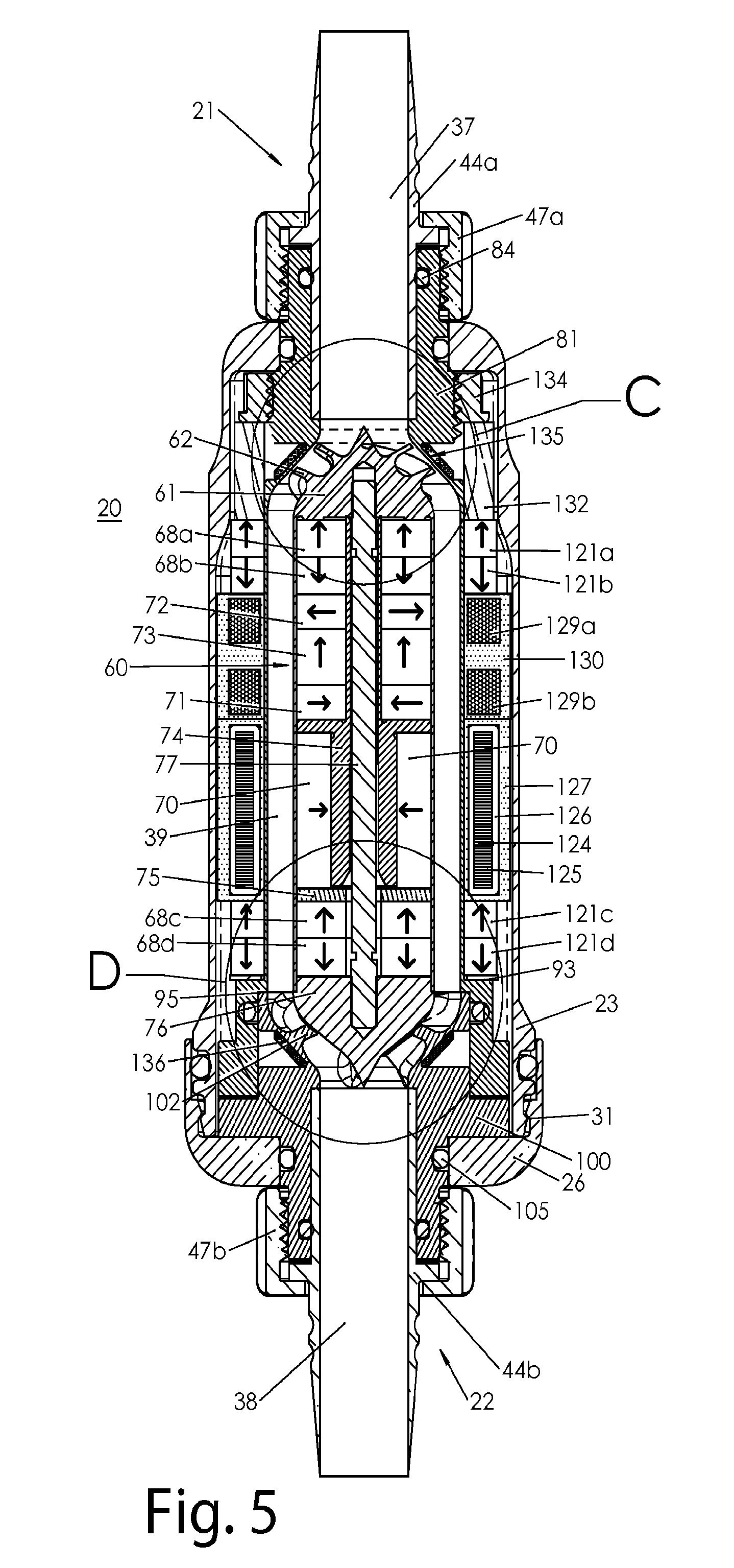

Magnetically-levitated blood pump with optimization method enabling miniaturization

ActiveUS20110237863A1Quality improvementReduce stiffnessControl devicesBlood pumpsBlood pumpMiniaturization

A magnetically-levitated blood pump with an optimization method that enables miniaturization and supercritical operation. The blood pump includes an optimized annular blood gap that increases blood flow and also provides a reduction in bearing stiffness among the permanent magnet bearings. Sensors are configured and placed optimally to provide space savings for the motor and magnet sections of the blood pump. Rotor mass is increased by providing permanent magnet placement deep within the rotor enabled by a draw rod configuration.

Owner:WORLD HEART +1

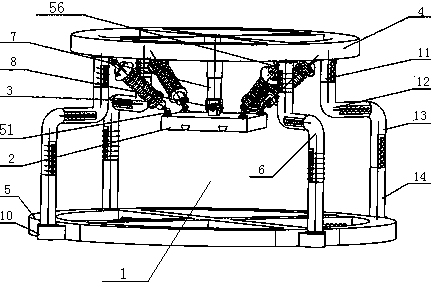

Parallel mechanism based multidimensional vibration platform

ActiveCN104154170AAchieving Nonlinear StiffnessSolve the problem of isolating low frequencySpringsShock absorbersEngineeringUltra low frequency

The invention discloses a parallel mechanism based multidimensional vibration platform. Standard zero stiffness of a vibration isolation platform at the equilibrium position and nonlinear stiffness nearby the equilibrium position can be realized by setting certain structural parameters, and the problem about difficulty in isolating low-frequency or ultra-low-frequency vibration for a traditional linear vibration isolation system; stiffness and damping can be easily and conveniently adjusted, vibration isolation of broad frequency domains are satisfied, and good engineering applicability is achieved; the multidimensional vibration platform is high in bearing stiffness, low in movement stiffness, small in static deflection, low in dynamic inherent frequency and good in vibration isolation effect; inherent contradictions restricting the traditional vibration isolation system, namely the contradictions of low-frequency vibration transmissibility and high-frequency vibration attenuation, can be solved by flexible adjustment of the stiffness and damping; the height and the static equilibrium position of the entire platform can be changed by adjusting a shock absorber spring base in height, and the multidimensional vibration platform is applicable to vibration isolation of objects of different weight.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Foil bearing assembly

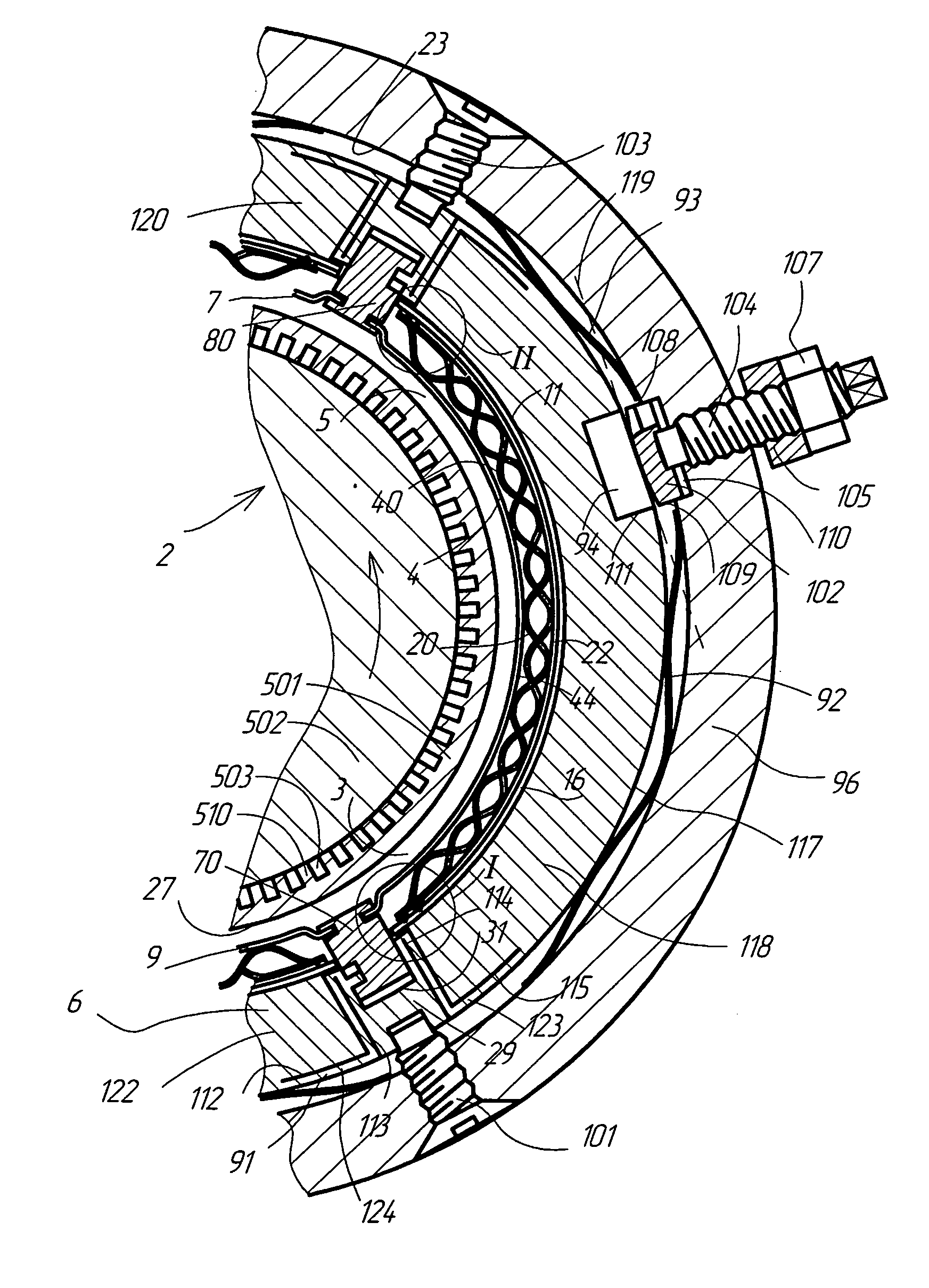

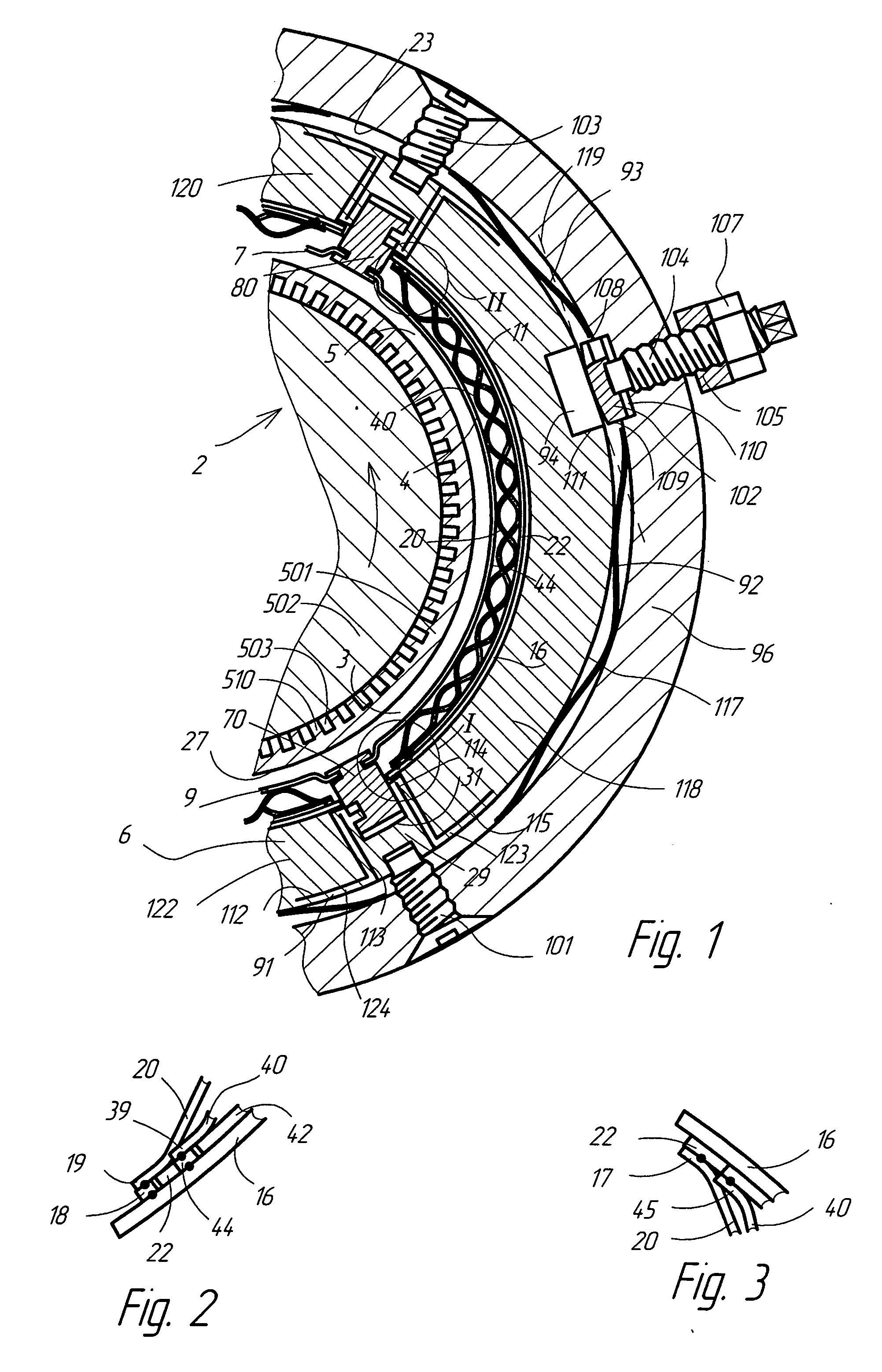

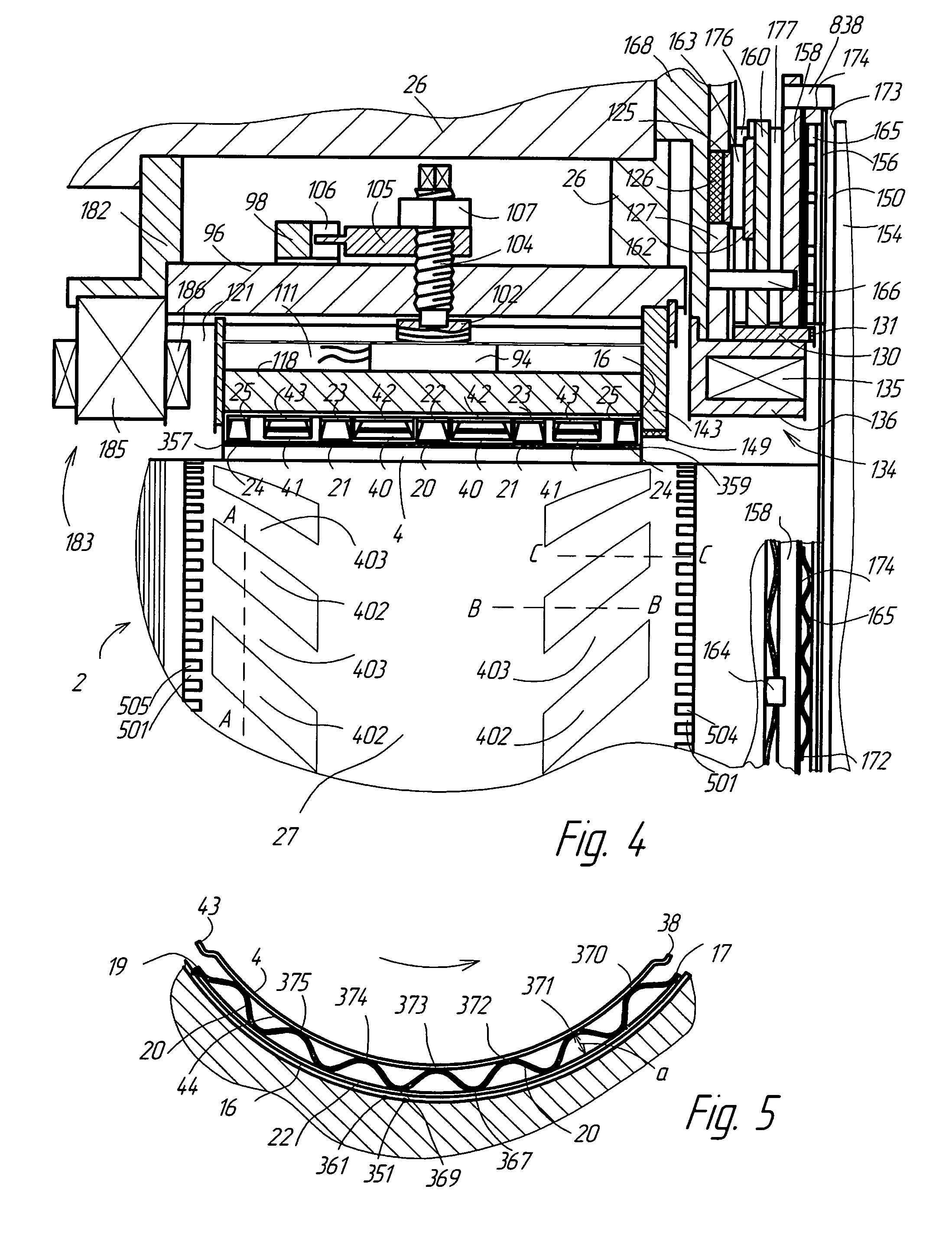

InactiveUS20150362012A1Reduce stiffnessConstant elastic member stiffnessRotary combination bearingsMagnetic bearingsEngineeringMechanical engineering

The bearing assembly comprises a radial foil bearing and an axial foil bearing, a control bearing preload device for controlling stiffness of the bearing under normal operating conditions, an electromagnetic unloading device for decreasing amplitude of rotor oscillations and an unloading means for increasing the ultimate bearing load without damaging bump foils. The radial foil bearing comprises a bushing 6 providing accommodating bearing misalignment with respect to the journal, an elastic member in the form of an elastic damping unit for increasing damping, which consists of a bump foil 20 and two smooth foils 16 and 22. The bump foils in the bearing have different heights and alternate in the axial direction to decrease wear under start / stop. A top foil 4 of the bearing is weldlessly retained within slots of mounting bars 70 and 80. The axial bearing has the bump foil with ridges circumferentially extended in order for the bearing to work in sealing mode. The top foils of the bearing are provided with circumferential slits in order to decrease thermal stress.

Owner:ERMILOV YURY IVANOVICH

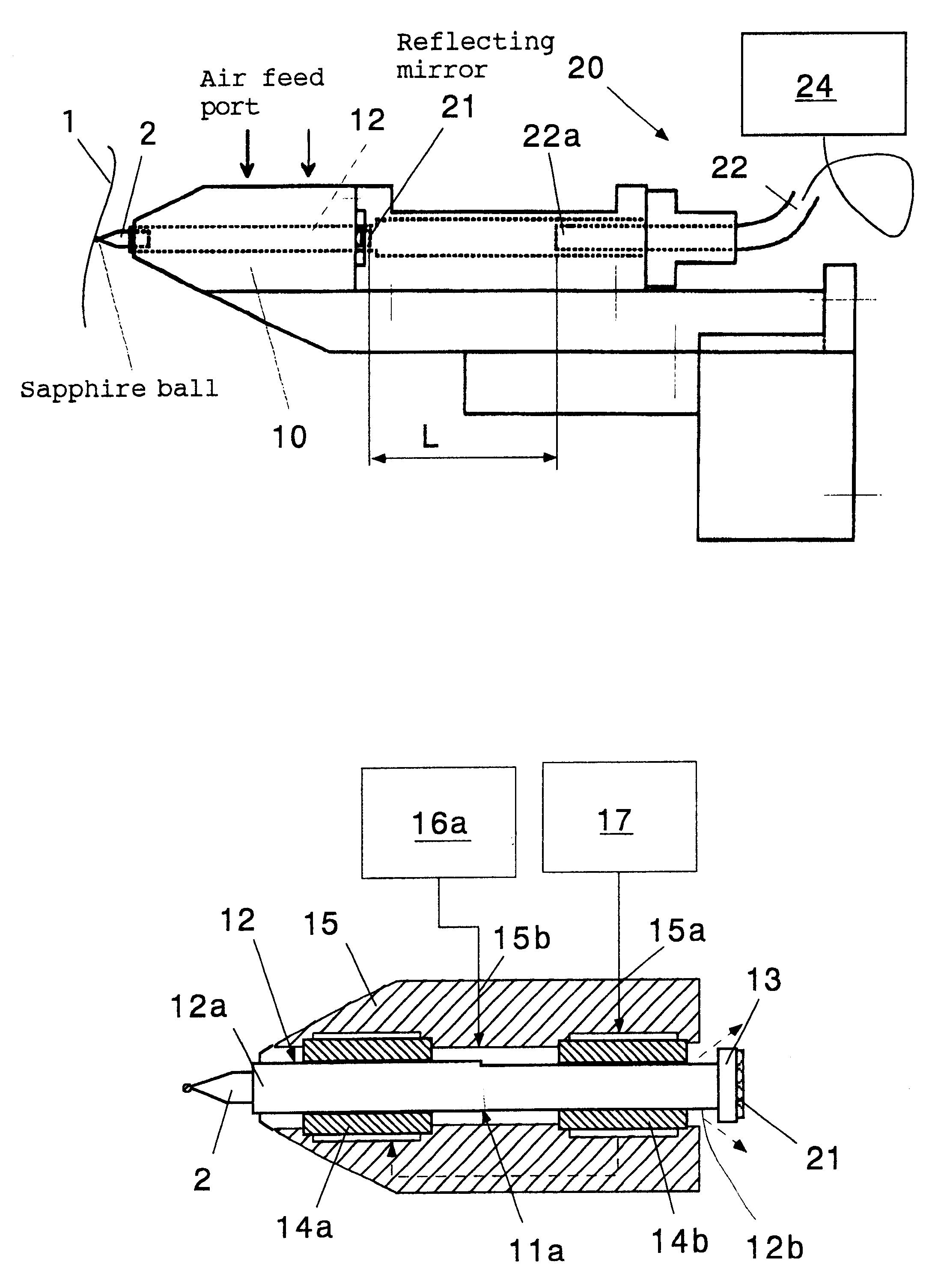

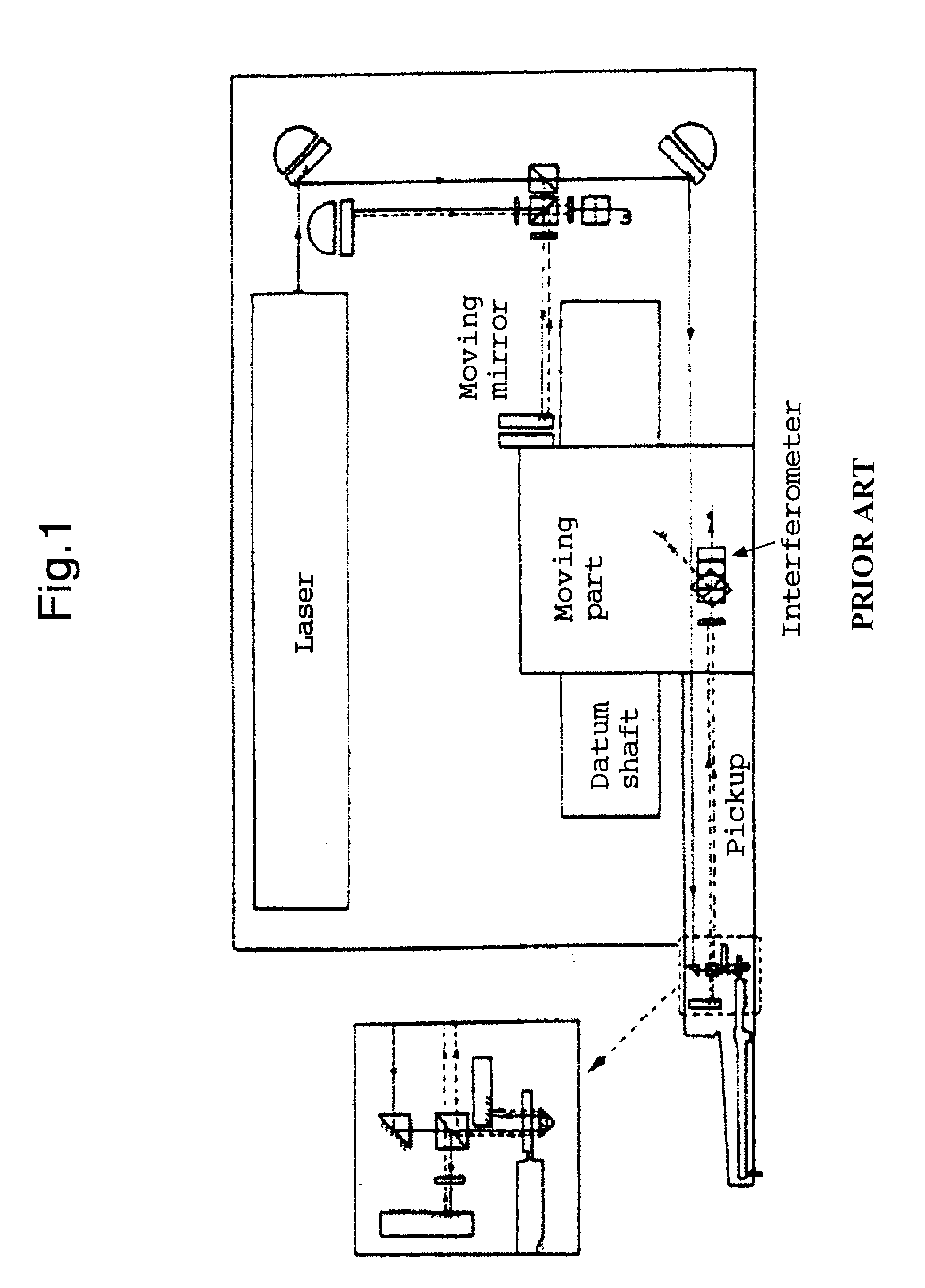

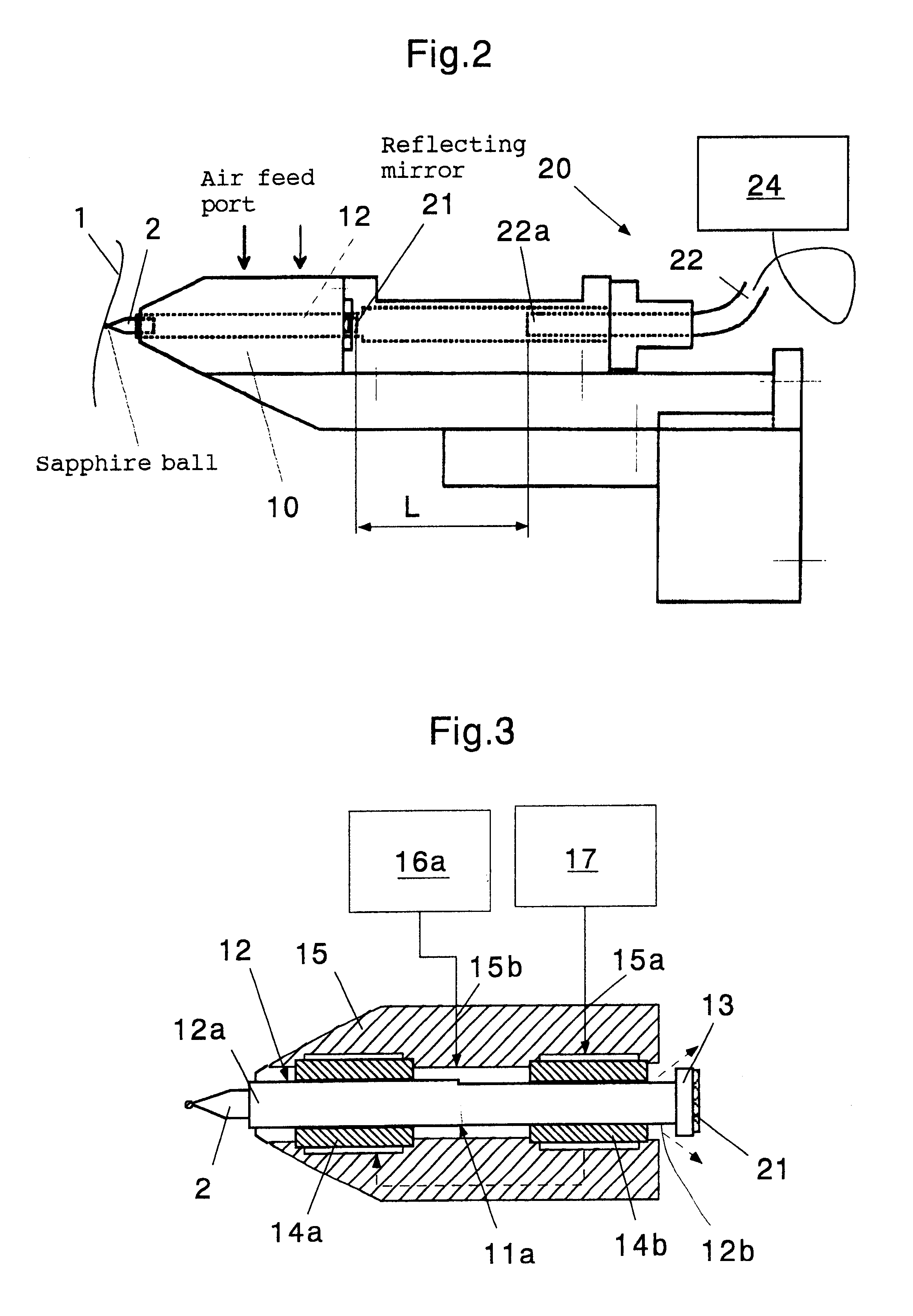

Probe type shape measuring sensor, and NC processing equipment and shape measuring method using the sensor

InactiveUS6539642B1Mechanical counters/curvatures measurementsUsing optical meansAir bearingHigh stiffness

A probe head 10 and a laser interferometric displacement meter 20 are provided. The probe head supports a probe 2 that is capable of contacting a workpiece 1, that is free to move in the direction of the workpiece, and drives the probe towards the workpiece. The displacement meter measures the displacement of the probe with a high accuracy without contact. The probe head 10 is also provided with a probe shaft 12 with steps 11a, 11b at intermediate portions thereof and air bearings 14a, 14b that support the probe shaft on each side of the steps. The air bearings have a high stiffness in the radial direction, and the probe shaft is made to float by using compressed air, thus the resistance of the shaft to sliding is reduced. In addition, another compressed air is supplied to the location of the step and produces a driving force in the direction of the workpiece due to the difference of cross sectional areas on each side of the step, that provides a very small load within a predetermined range. Thereby, the measuring pressure can be adjusted to a constant very small load without reducing the stiffness of the bearings of the probe, and the measuring pressures can be varied freely. Therefore, a sub-micron accuracy of about 0.1 mum can be obtained, and the equipment can be made compact and is easily applied to on-machine measurements.

Owner:RIKEN

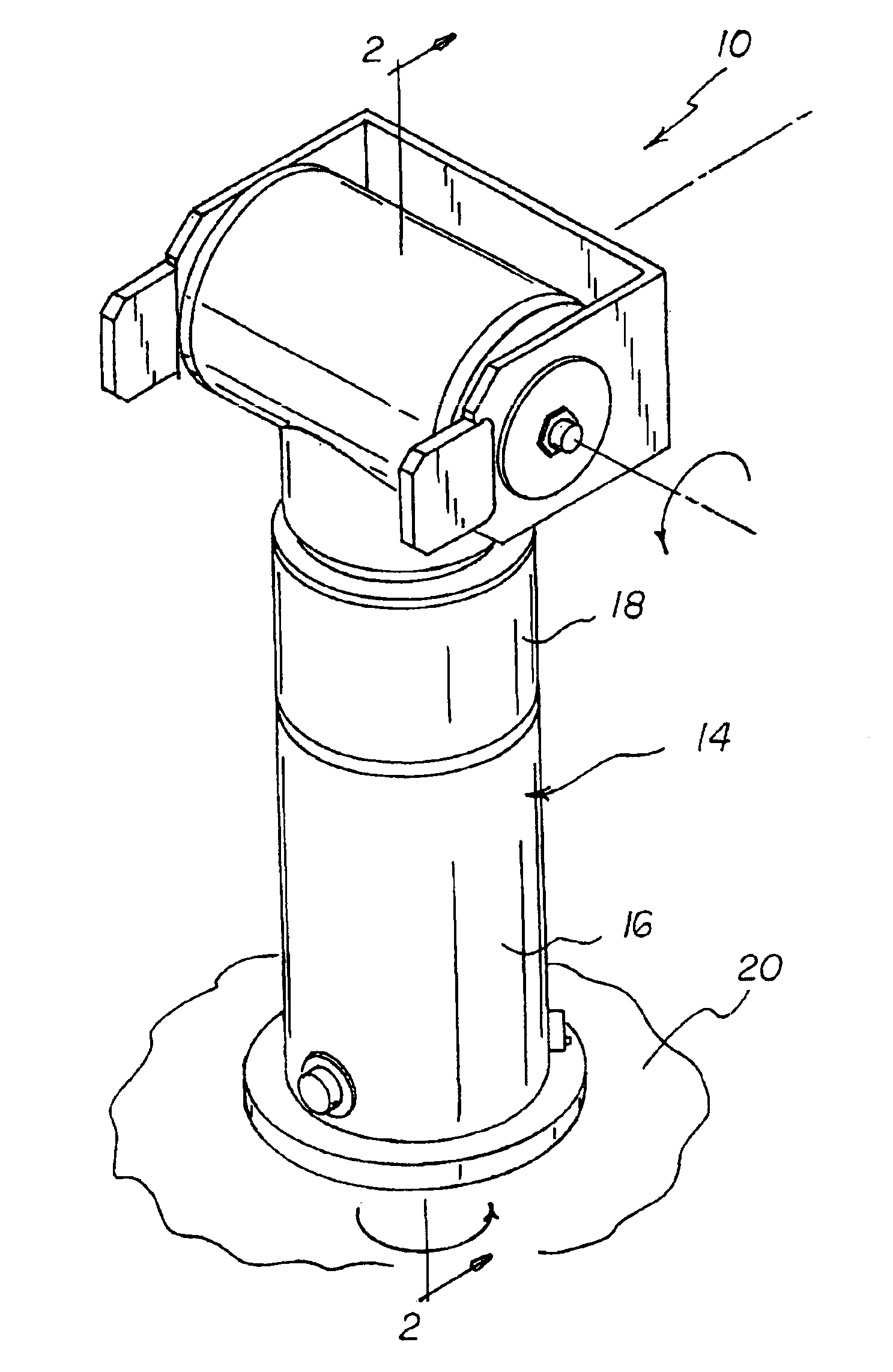

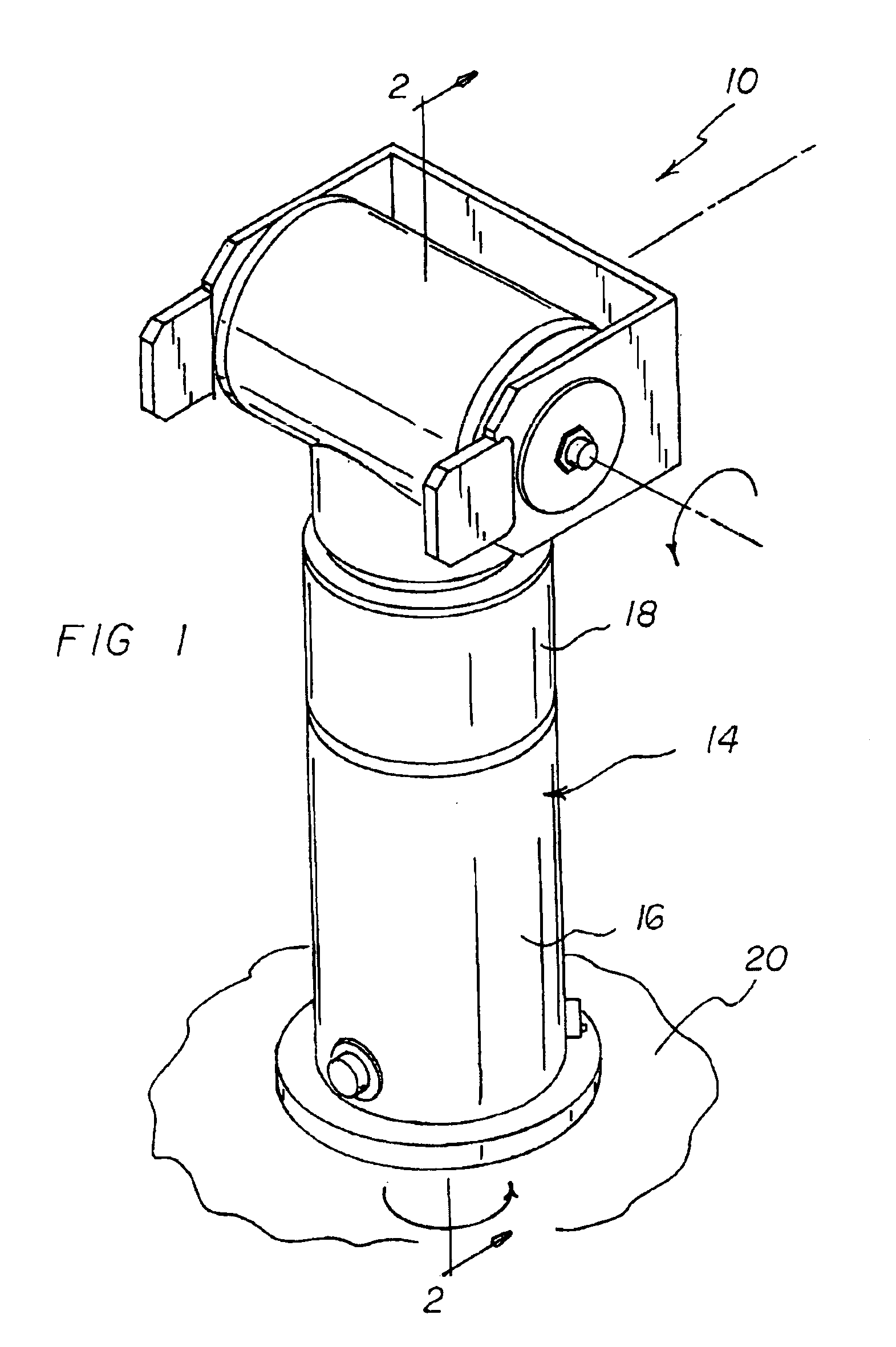

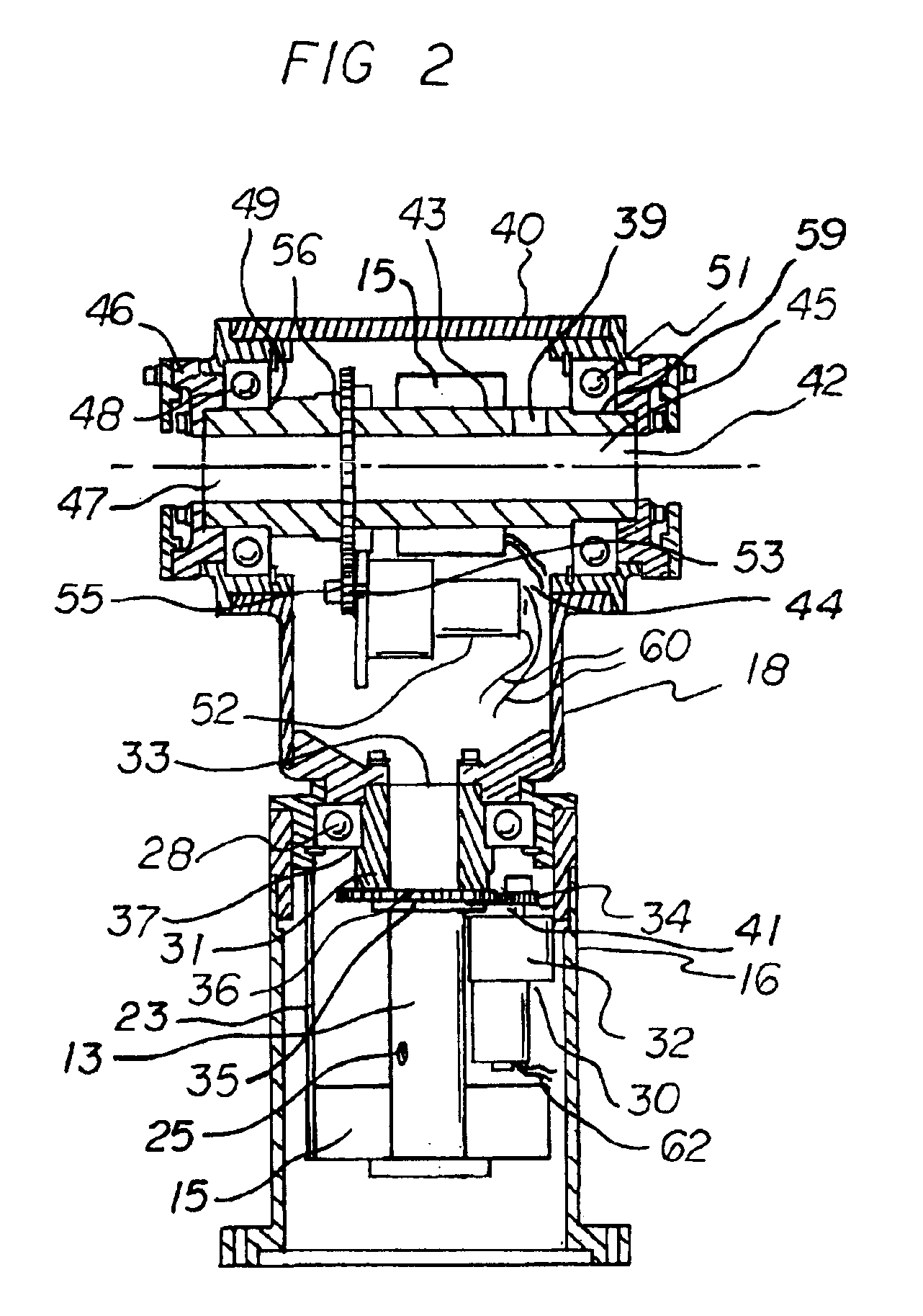

Pedestal system and method of controlling rotational and bearing stiffness

InactiveUS6914578B1Easy and efficient to manufactureDurable and reliable constructionAntenna supports/mountingsLower upperControl theory

A pedestal system comprises a base having a lower cylinder and an upper rotatably supported with respect to the lower vertical cylinder. A lower motor is coupled between the lower and upper cylinders to selectively cause rotational motion between the cylinders. Also provided is a top-most horizontal cylinder with a rotating shaft. The shaft has a bearing coupling the top-most horizontal shaft with respect to the upper vertical cylinder. Finally, an upper motor is provided. The upper motor is coupled between the top-most horizontal shaft and upper cylinder to selectively cause a rotational motion between the top-most horizontal shaft and the upper vertical cylinders.

Owner:MENAHEM ISRAEL

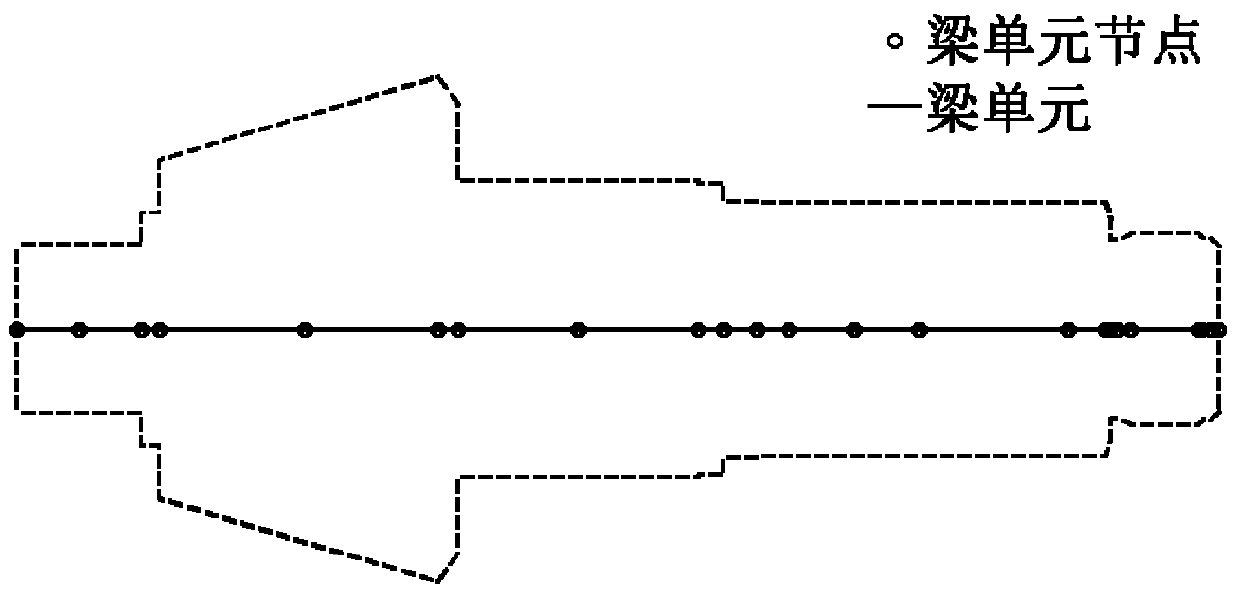

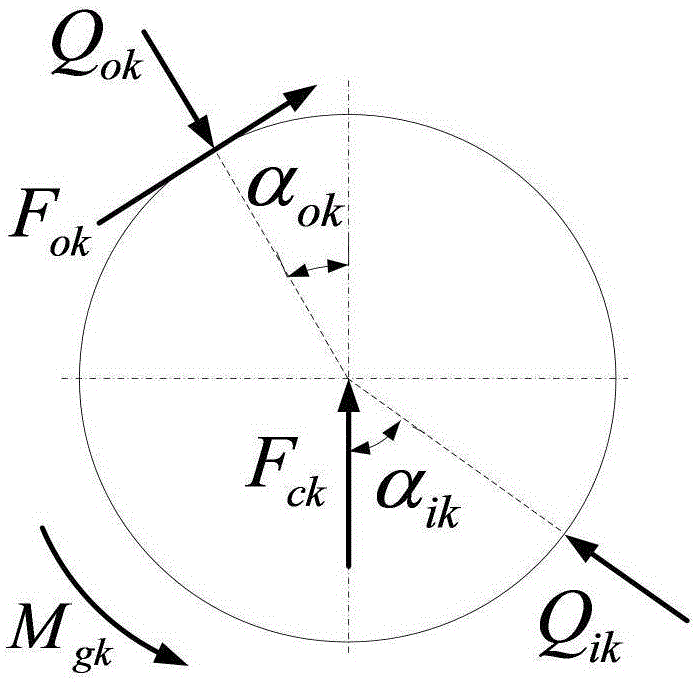

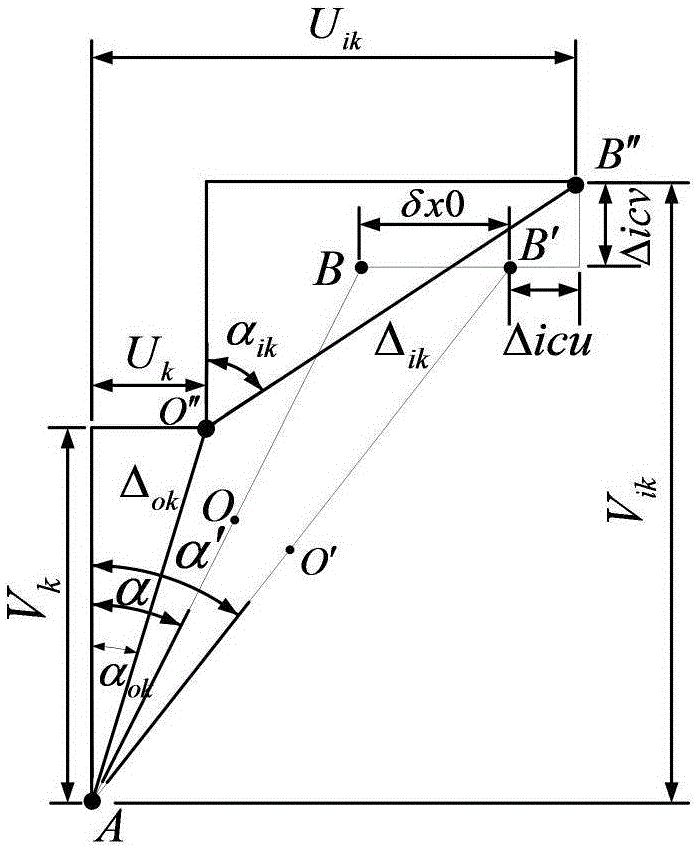

Multi-support shafting finite element method with bearing stiffness coupling nonlinearity considered

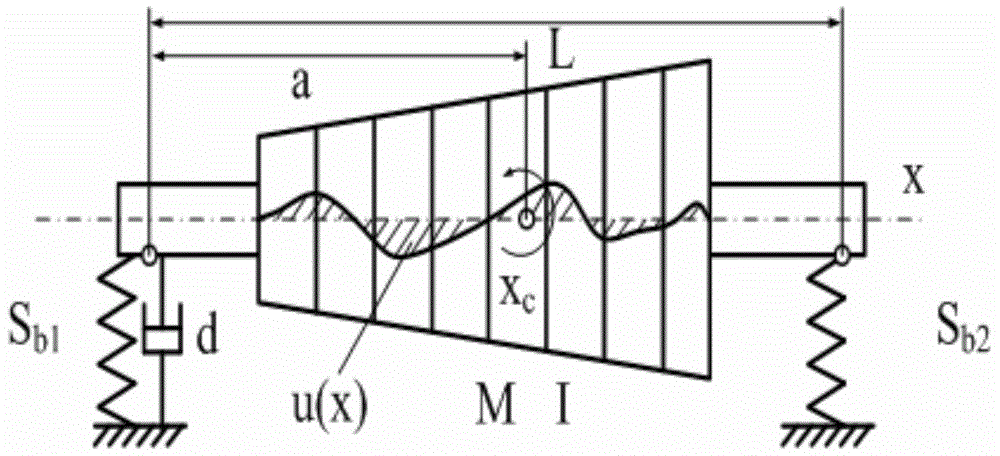

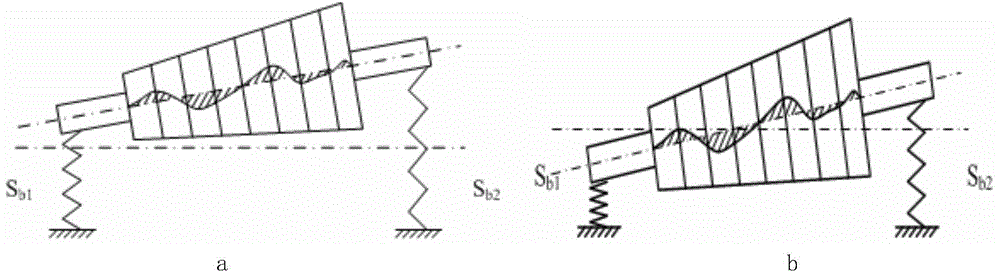

ActiveCN103530468AImprove computing efficiencyAccurate and efficient calculationSpecial data processing applicationsNODALElement model

The invention relates to a multi-support shafting finite element method with bearing stiffness coupling nonlinearity considered. The method comprises the steps of (1) establishing a local coordinate system of each bearing and obtaining a six-freedom-degree bearing stiffness matrix of each bearing under the corresponding local coordinate systems through calculating by means of the difference method with a corresponding bearing load calculation formula; (2) dividing a shaft into different shaft sections according to the difference of diameters, establishing nodes at the positions of bearing section starting positions, the bearing installation position and load action positions, then establishing finite element models of the shaft between the nodes, and obtaining a stiffness matrix of the whole shaft; (3) establishing a global coordinate system of a shafting, establishing another node at the bearing installation position to be used for simulating a fixed end, integrating the bearing stiffness matrix onto the installation node and the corresponding fixed end node on the shaft to obtain the overall stiffness matrix of the shafting, and establishing the stiffness equation of the shafting; (4) restraining the freedom degrees in six directions of the fixed end node, restraining the freedom degree, of rotating around the axis, of the node at the position of origin of the global coordinate system of the shafting, reducing the stiffness equation of the shafting according to restraining conditions, and solving the reduced stiffness equation of the shafting with the Newton-Raphson method in an iterative mode to obtain the displacement and load of each node.

Owner:TSINGHUA UNIV +1

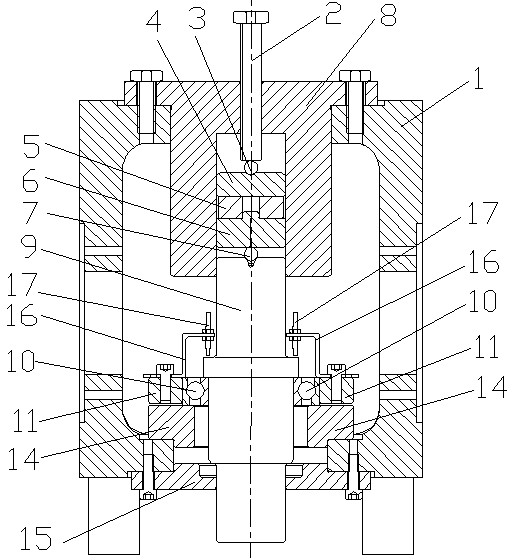

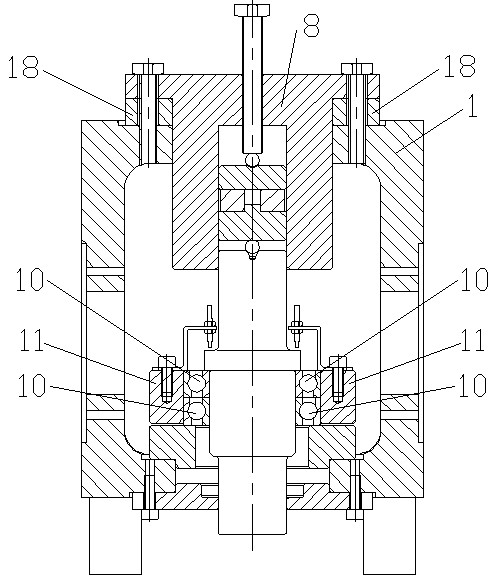

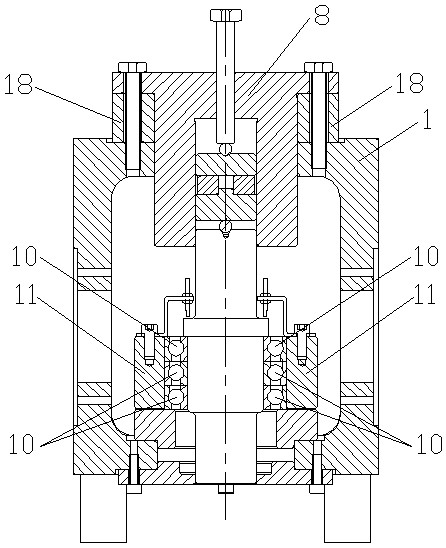

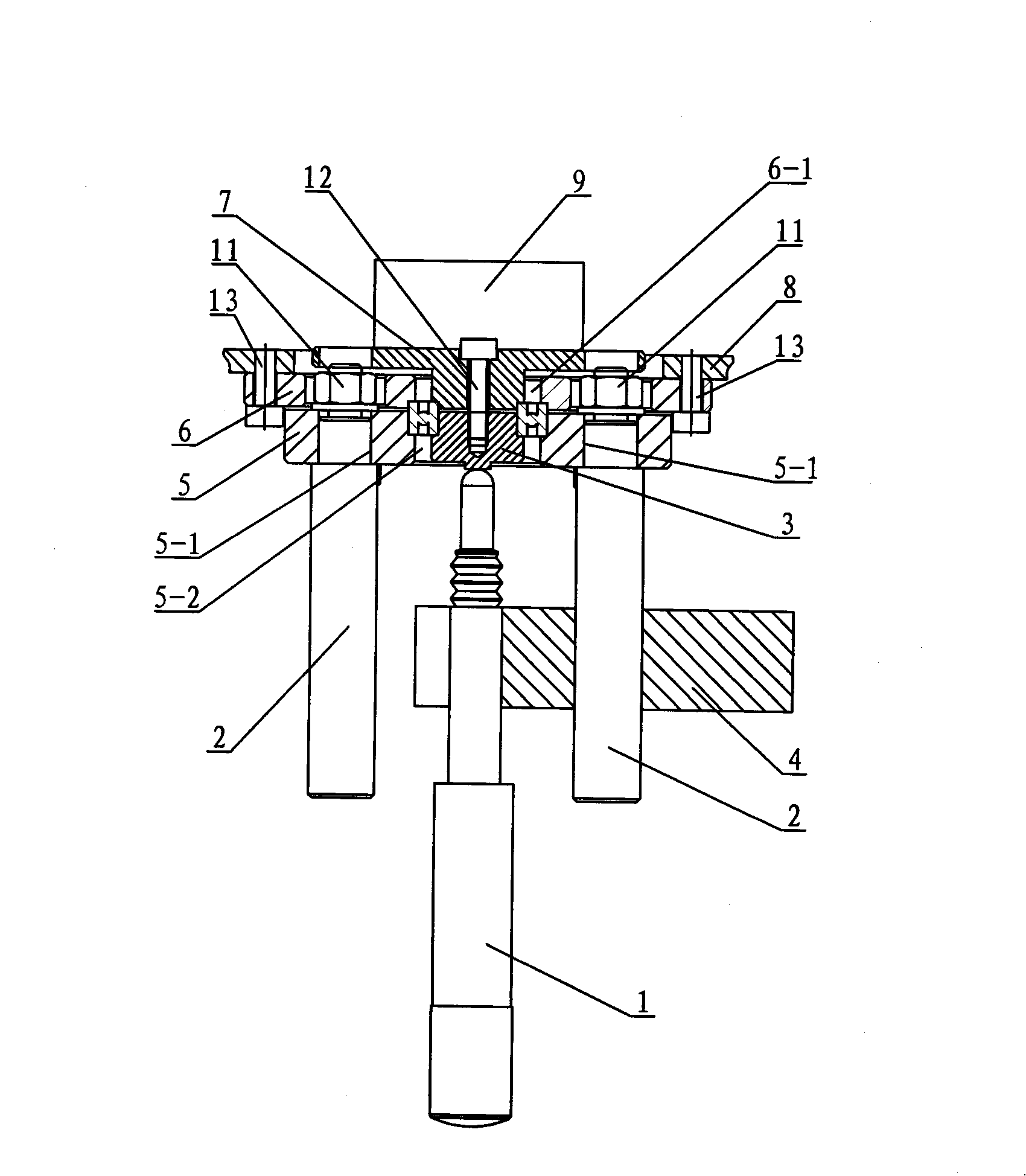

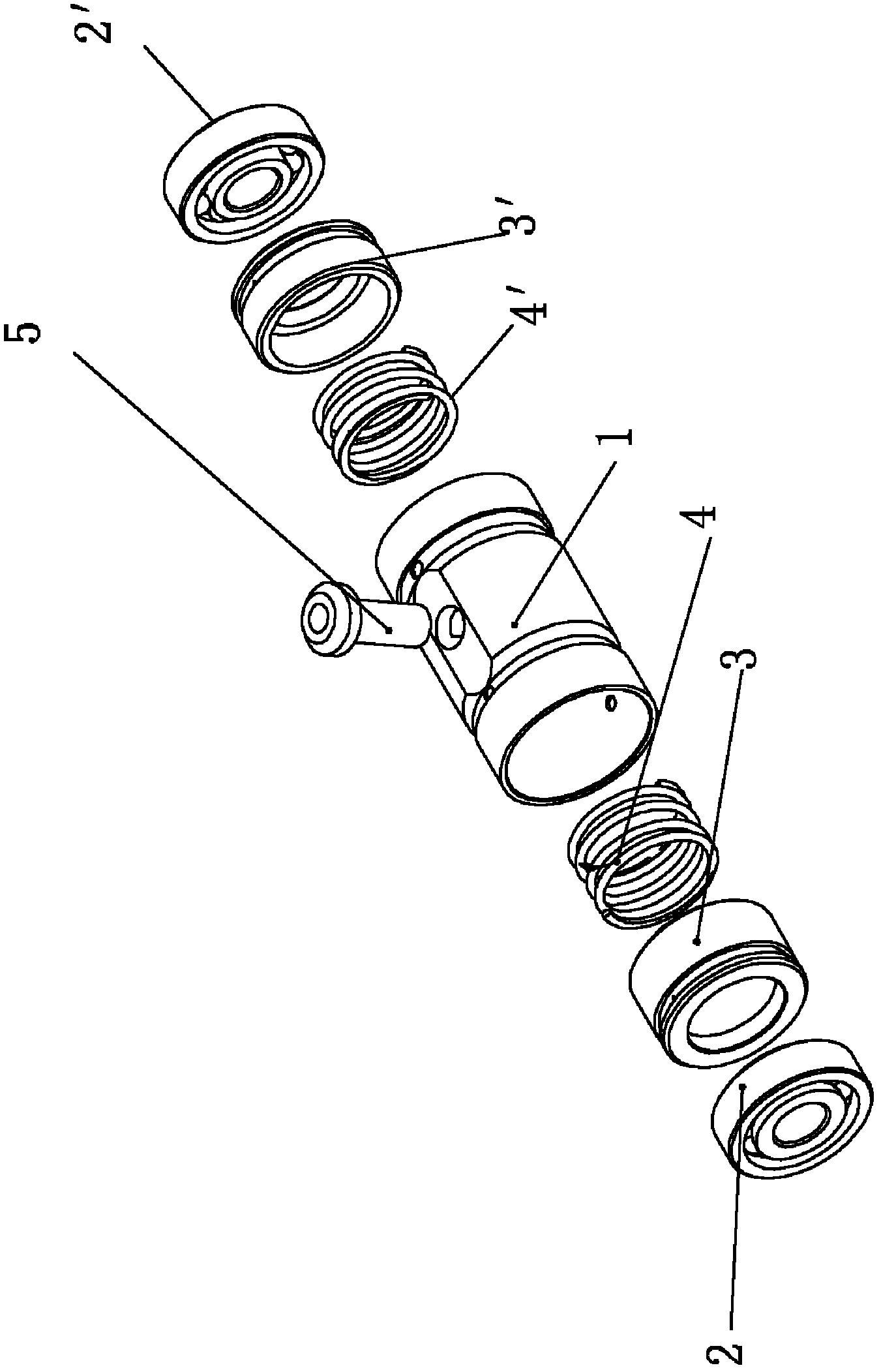

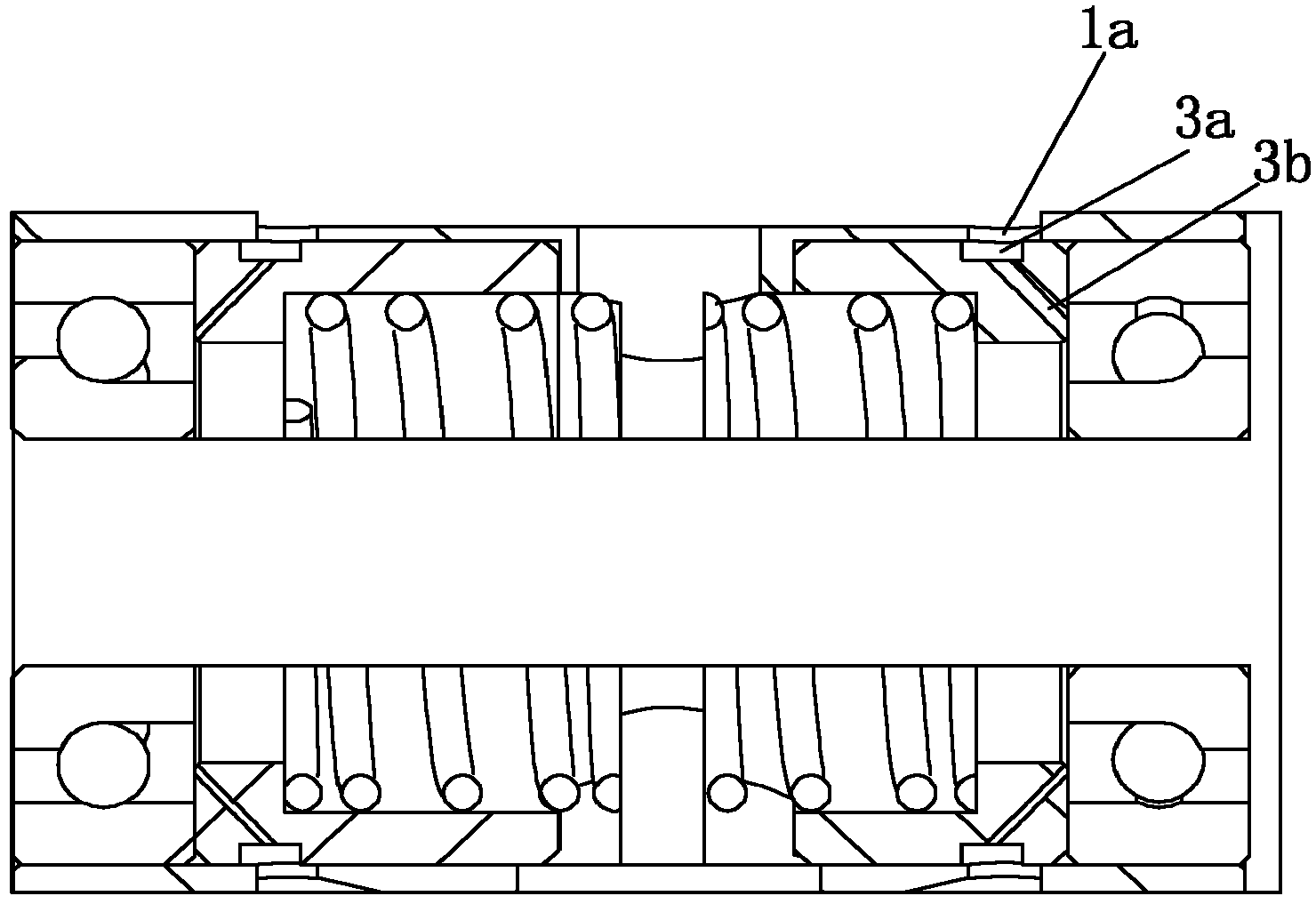

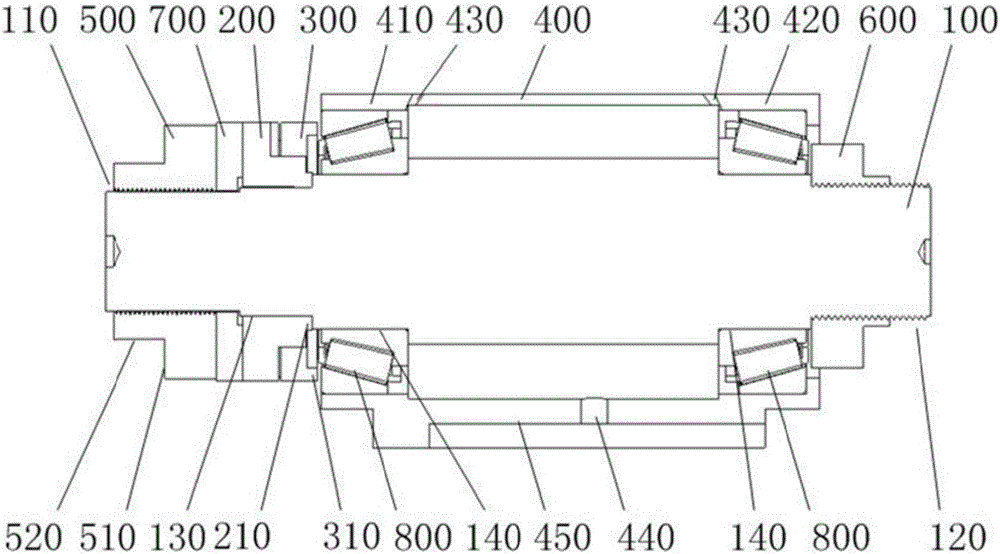

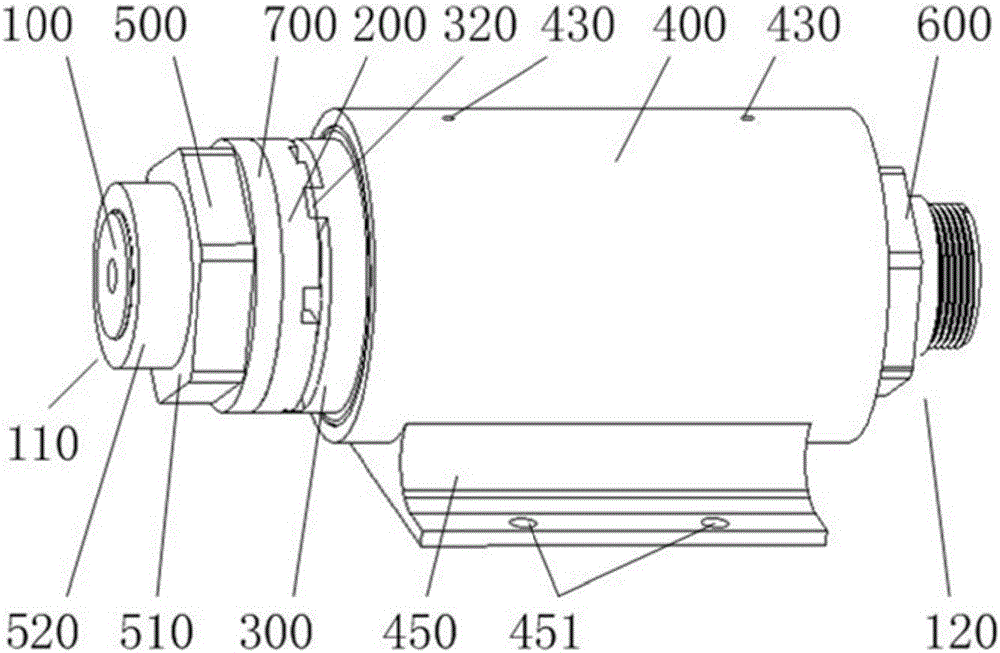

Modularized static stiffness testing device for angular contact ball bearings

InactiveCN101893512ATrue Stiffness ValueSimple structureMachine bearings testingAxial displacementBall bearing

The invention provides a modularized static stiffness testing device for angular contact ball bearings. The testing device comprises a square box for fixing the testing device, bearings supported by a simulating shaft, an outer ring sleeve sleeved outside the bearings, axial and radial loading devices and axial displacement and radial displacement measuring devices; the axial displacement measuring device can detect whether the bearings are deflected by adopting two sets of displacement sensors; the radial displacement measuring device can detect whether the radial loads borne by the two bearings are the same by adopting two sets of displacement sensors; and the simulating shaft is positioned through a positioning ring and a loading sleeve during axial stiffness test. By adopting the modularized structural design, the device can realize the static stiffness test of the angular contact ball bearings of different size series, and can test axial stiffness and radial stiffness at the same time. The device has the advantages of simple structure, multiple functions and wide application range, can acquire real stiffness values of the angular contact ball bearings, and has significance for searching the static performance of the angular contact ball bearings and determining reasonable pre-tensioning force of the bearings.

Owner:XIAN UNIV OF TECH

Calculation method for driving axle gear dynamic characteristics considering main speed reducer housing

ActiveCN103971006AGuaranteed accuracyAccurate and efficient calculationSpecial data processing applicationsElement modelReduction drive

The invention relates to a calculation method for driving axle gear dynamic characteristics considering a main speed reducer housing. The calculation method comprises the steps of (1) defining an overall coordinate system, (2) building an axis finite element model, (3) building a nonlinear bearing model, (4) building a gear mechanical model, (5) building a dimension reduction finite element model of the main speed reducer housing, (6) building a static model of a driving axle main speed reducer gear transmission system, (7) calculating bearing stiffness formed during static balance, (8) building a dynamic model of the driving axle main speed reducer gear transmission system, (9) calculating natural vibration characteristics of the driving axle main speed reducer gear transmission system, and (10) calculating the driving axle main speed reducer gear dynamic characteristics. According to the calculation method for the driving axle gear dynamic characteristics considering the main speed reducer housing, the gear transmission system dynamic model comprising the main speed reducer housing is built through a finite element method and a modal comprehensive method, the mutual effect of the main speed reducer housing and the transmission system is considered, the driving axle gear dynamic characteristics considering the effect of the main speed reducer housing can be accurately and efficiently calculated, and the calculation method can be widely applied to calculation and analysis of the dynamic characteristics of various gear transmission structures comprising housing bodies.

Owner:TSINGHUA UNIV +1

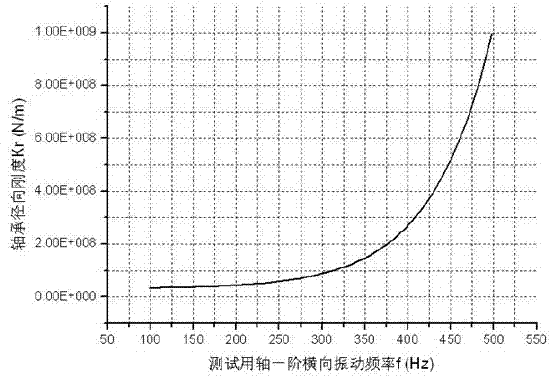

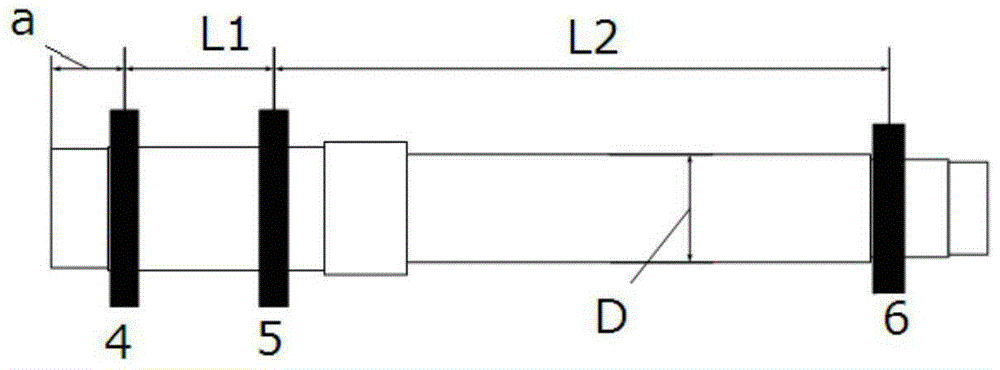

Dynamic measurement method for radial stiffness and axial stiffness of bearing

InactiveCN102889990AMeasuring Radial StiffnessMeasuring Axial StiffnessMachine bearings testingMeasurement testPhysical system

The invention belongs to the technical field of mechanical measurement and is applicable to measurement of radial stiffness and axial stiffness of bearings. The measurement principle is based on a relationship between the bearing stiffness and inherent vibration frequency of a shaft for test. The method comprises the following steps of: in the process of measuring the radial stiffness of the bearing, solving a function relationship between the radial stiffness of the bearing and the first-order transverse vibration frequency of a shaft for test, building a physical system among the shaft for test, a measured bearing and a rigid support, measuring the first-order radial vibration inherent frequency of the shaft for test, and finally, calculating the radial stiffness of the bearing according to a function relationship between the inherent vibration frequency and the radial stiffness of the bearing; and in the process of measuring the axial stiffness of the bearing, solving the mass of the shaft for test, building a physical system among the shaft for test, the measured bearing and the rigid support, measuring the first-order axial vibration inherent frequency of the shaft for test, and finally, calculating the axial stiffness of the bearing according to a relationship between the vibration inherent frequency and the axial stiffness of the bearing.

Owner:马会防

Fluid dynamic pressure bearing and spindle motor

ActiveUS7265467B2Interface stabilityWell formedShaftsRecord information storageEngineeringMechanical engineering

A fluid dynamic pressure bearing having a tapered seal part provided between a sleeve and a housing, from which lubricating liquid is injected and functions as a buffer of the lubricating liquid. An end part of a radial gap between the sleeve and a shaft body is a labyrinth filled with lubricating liquid. An opening periphery is covered with an oil repellent film to prevent outflow of the lubricating liquid. These features can make the size of the tapered seal part small in the axial direction. It enables a larger radial dynamic pressure bearing mechanism to be formed and, in particular, bearing rigidity in the radial direction can be increased.

Owner:NIDEC CORP

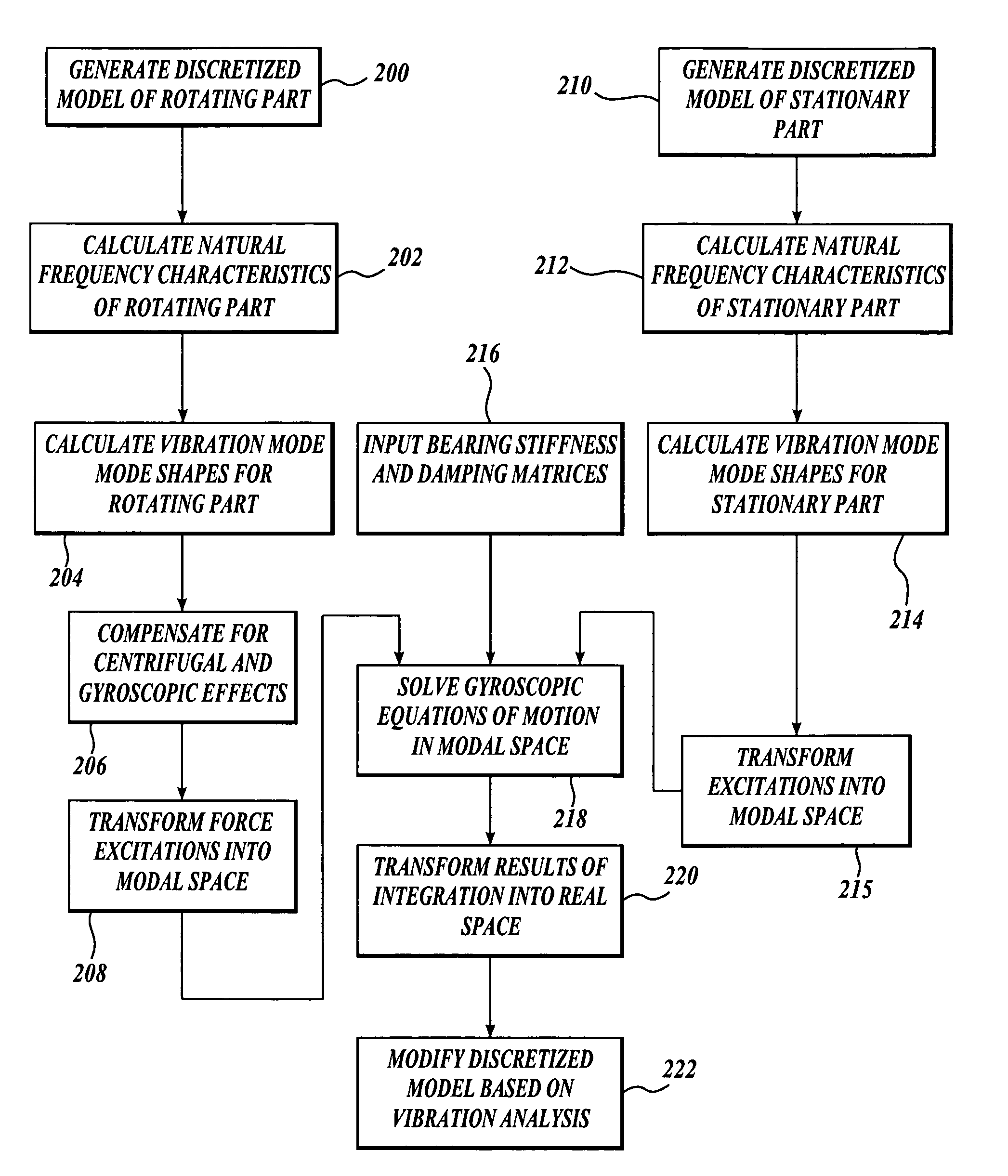

Method for predicting vibrational characteristics of rotating structures

InactiveUS7630869B2Improve featuresSimple designVibration measurement in solidsAnalogue computers for electric apparatusHard disc driveElement analysis

A method is disclosed for analyzing the vibrational characteristics of rotating devices, such as hard disk drives and jet engines, that are coupled through bearings to flexible supports. In the method, the rotating device is discretized, for example, using a mesh suitable for finite element analysis. The support is also discretized. The natural frequency of elastic vibration modes for the rotating device is calculated and the natural frequency of vibration modes for the support is calculated. The mode shapes are then calculated and a set of modal basis corresponding to the mode shapes is utilized. Bearing stiffness and damping matrices are input, and the Lagrangian equations of motion are integrated numerically in the modal space, to calculate the vibrational response of the rotating device and support. The modal space results are then transformed into ordinary space. The vibrational analysis may be used to design devices having desired vibrational characteristics.

Owner:UNIV OF WASHINGTON

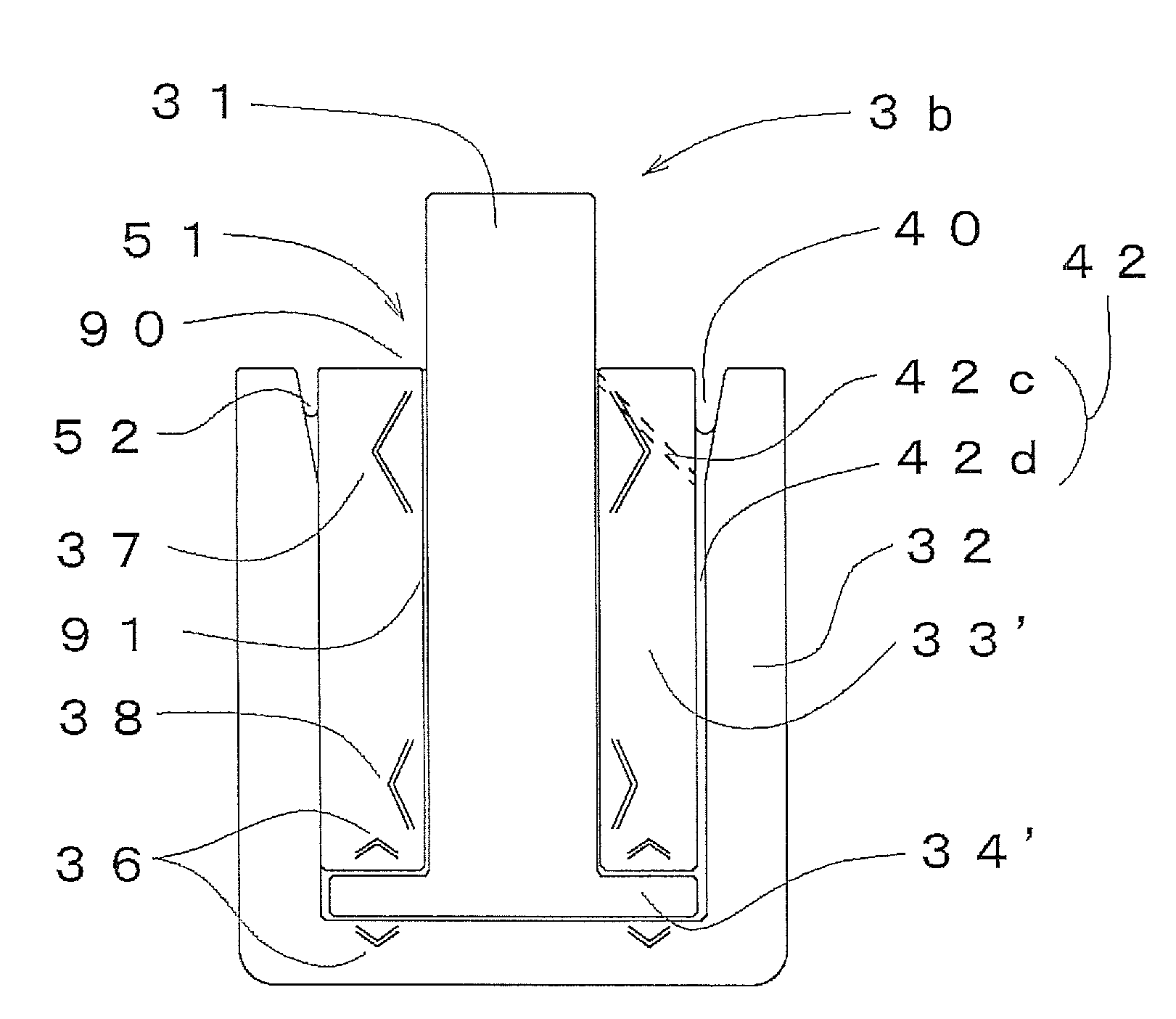

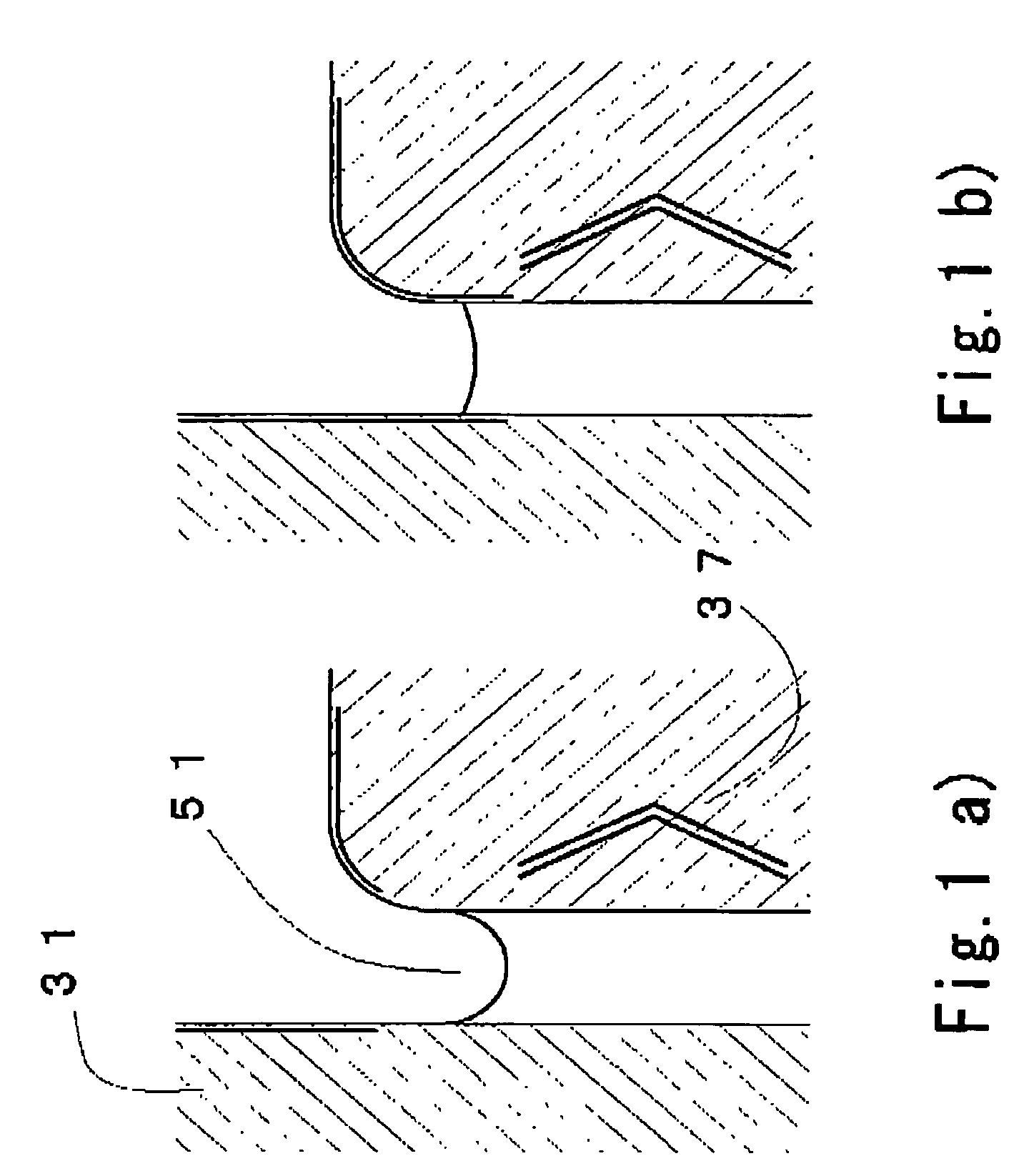

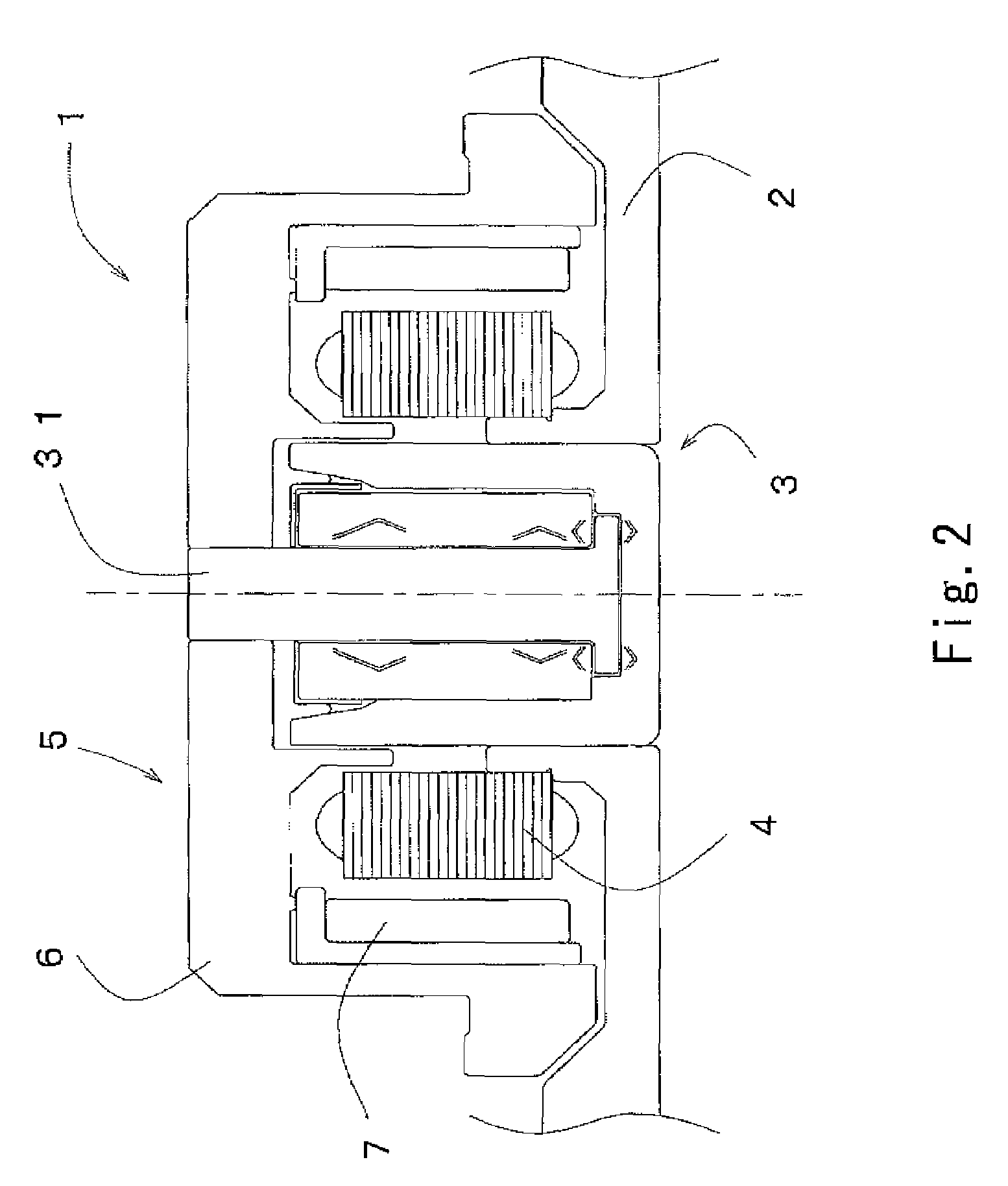

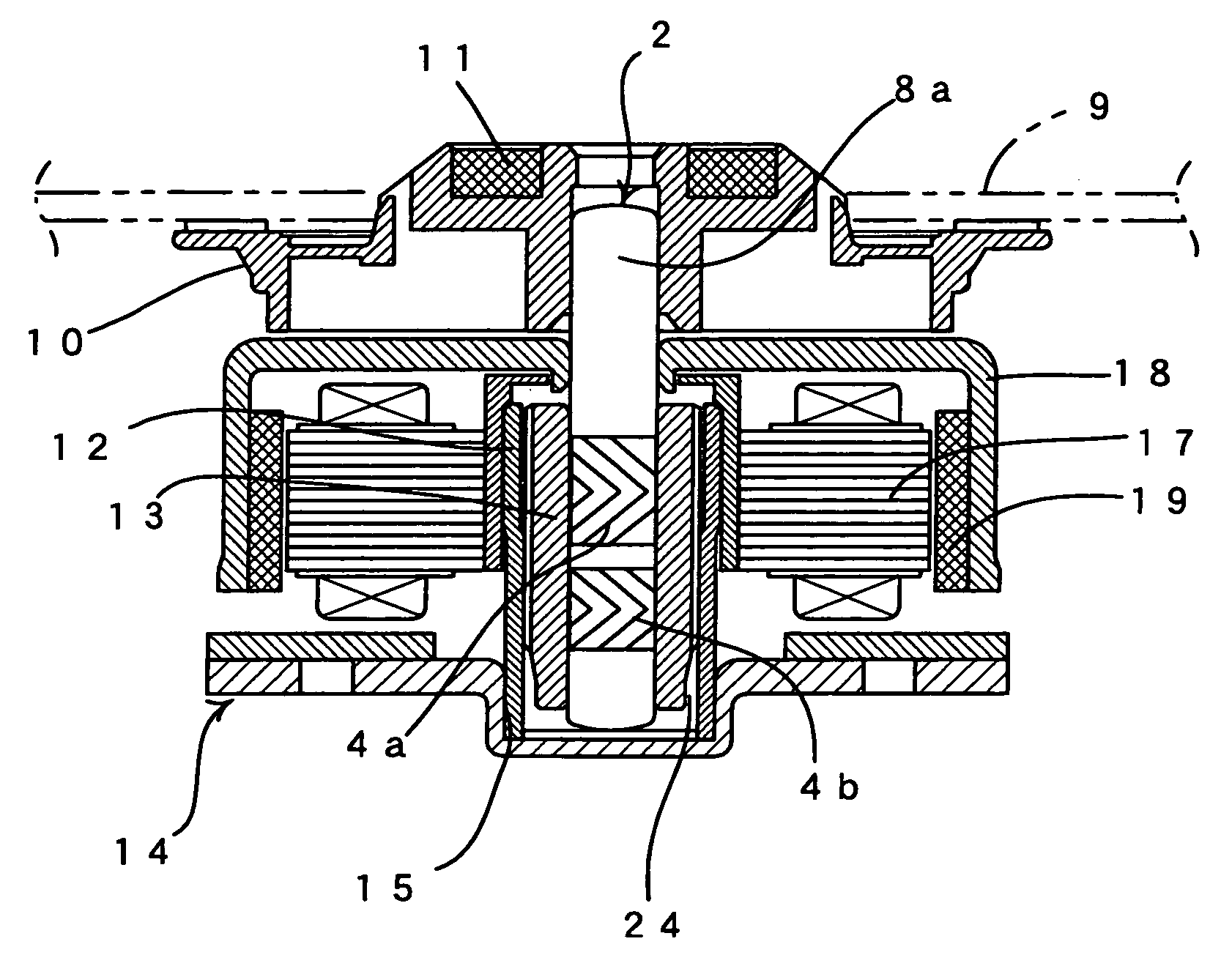

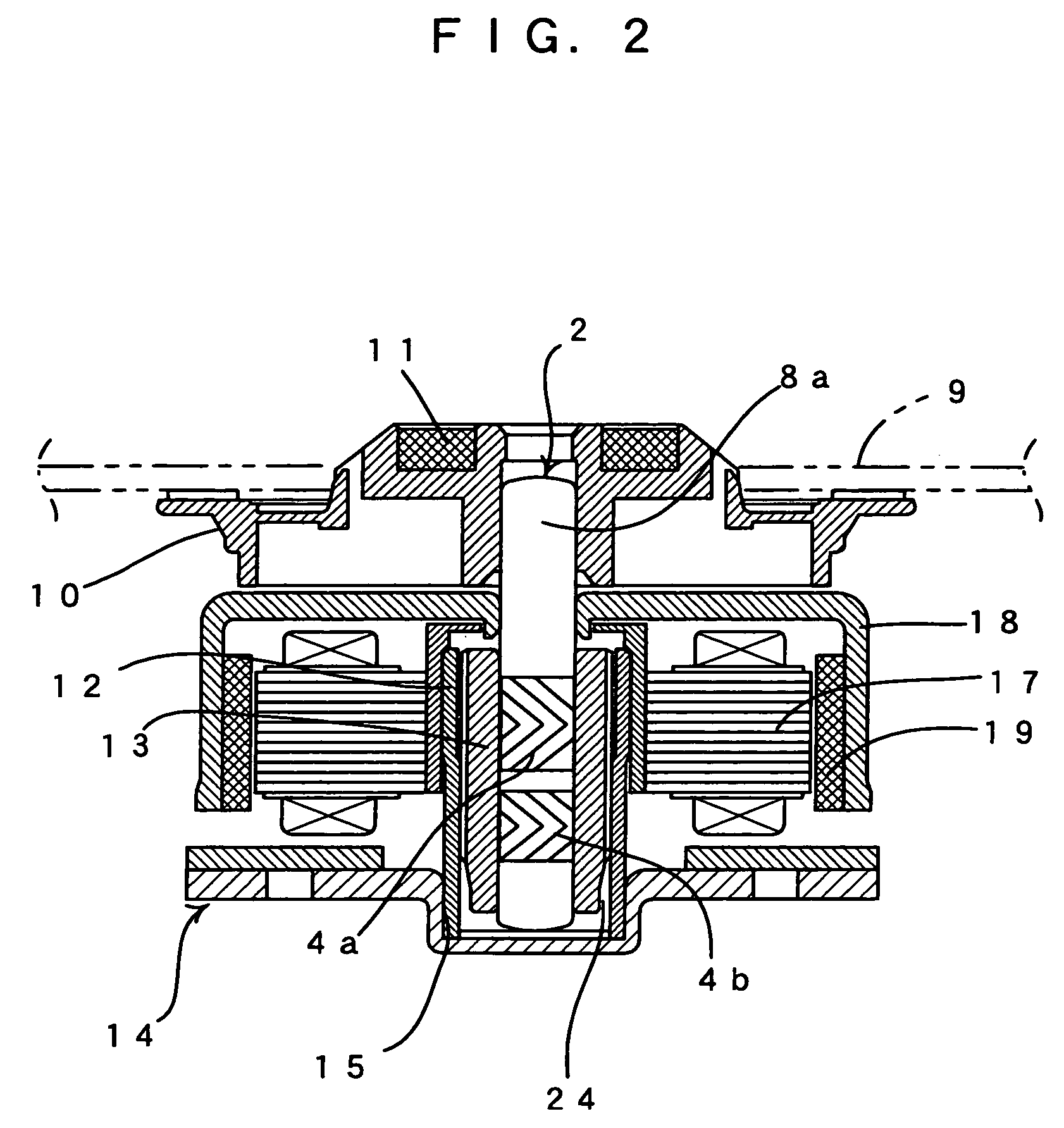

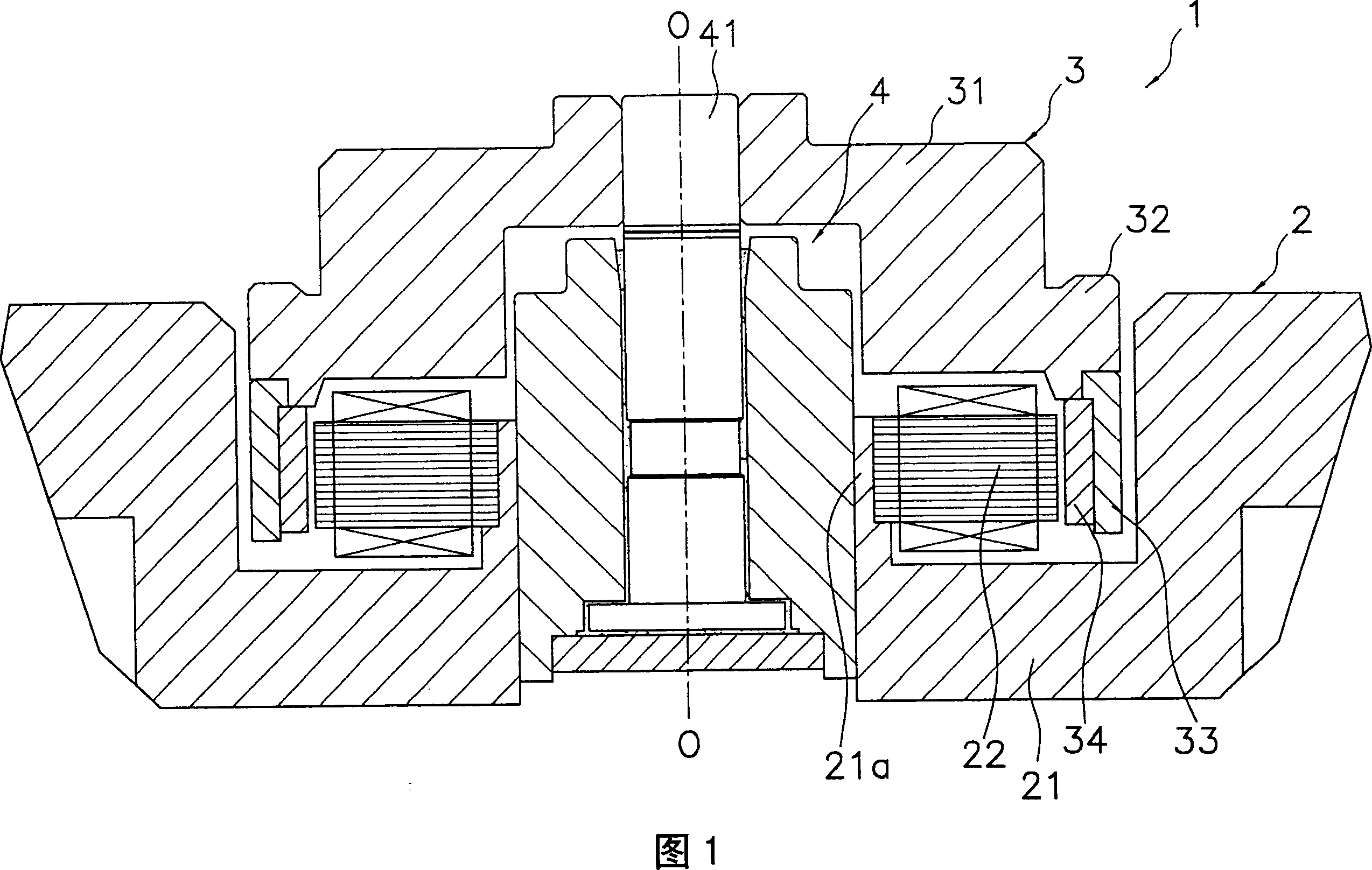

Brushless motor and method of manufacturing the same

InactiveUS20060087184A1Necessary bearing stiffnessSuppressing an increase in bearing lossSynchronous generatorsShaftsBrushless motorsEngineering

Fluid bearing mechanisms (6a and 6b) are formed between a shaft (2) and a central part (21) of an oil impregnated sintered sleeve (13). The oil impregnated sintered sleeve (13) has such an inner surface formed to be larger in aperture ratio at a thrust support end (23) and a loading end (22) than at a central part (21). With this configuration, it is possible to achieve a brushless motor which can suppress an increase in bearing loss while obtaining necessary bearing stiffness at high rpm.

Owner:MINEBEA MOTOR MFG

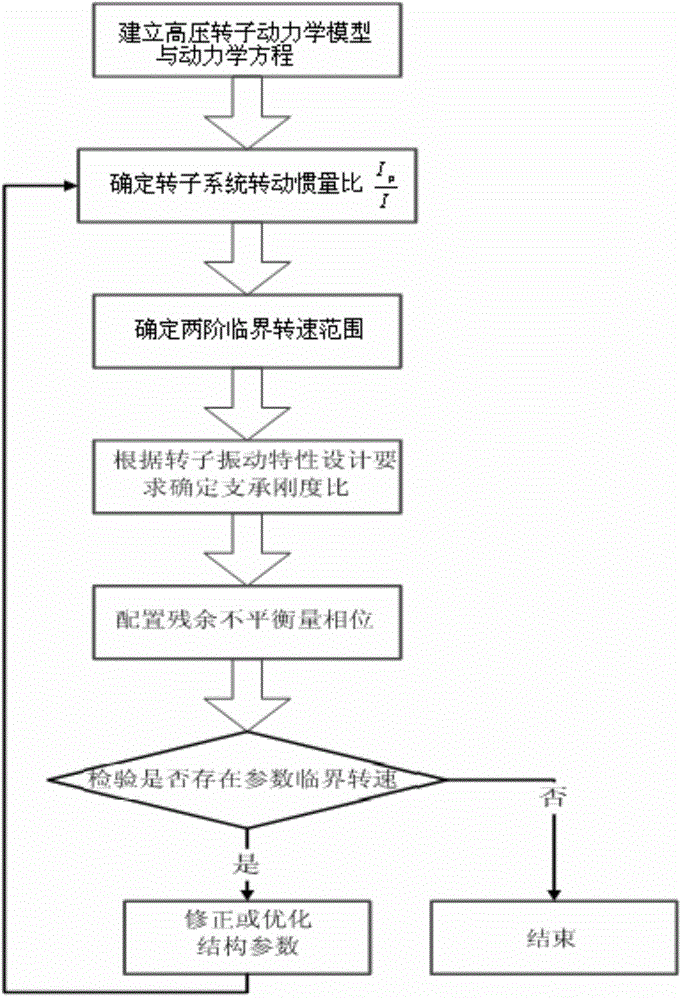

Structural dynamic design method for high-pressure rotor of aircraft engine

ActiveCN103821567AEnable Active DesignSimplify the design processBlade accessoriesMachines/enginesStructural dynamicsDynamic models

Disclosed is a structural dynamic design method for a high-pressure rotor of an aircraft engine. The relationship between high-pressure rotor model design parameters and rotor vibration characteristics is determined, so that the design method and criterions are provided for dynamic design of the high-pressure rotor, and the method is of great guiding significance to the design of the high-pressure rotor of the aircraft engine. The method includes: establishing a dynamic model and a dynamic equation of the high-pressure rotor to obtain a nondimensionalization characteristic equation; introducing an equivalent critical speed, and determining a two-order critical speed range of a high-pressure rotor system according to the equivalent critical speed; changing a conventional equilibrium amount configuration method by configuring residual disequilibrium amount phases; configuring a ratio of rotor pole rotation inertia to mass center rotation inertia in design according to a specific design objective; establishing configuration criterions for a rotor bearing stiffness ratio. A conventional design process is changed, structural dynamic active design of the high-pressure rotor is realized, the design process is optimized beneficially, design cycle is shortened, and the method has important construction value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

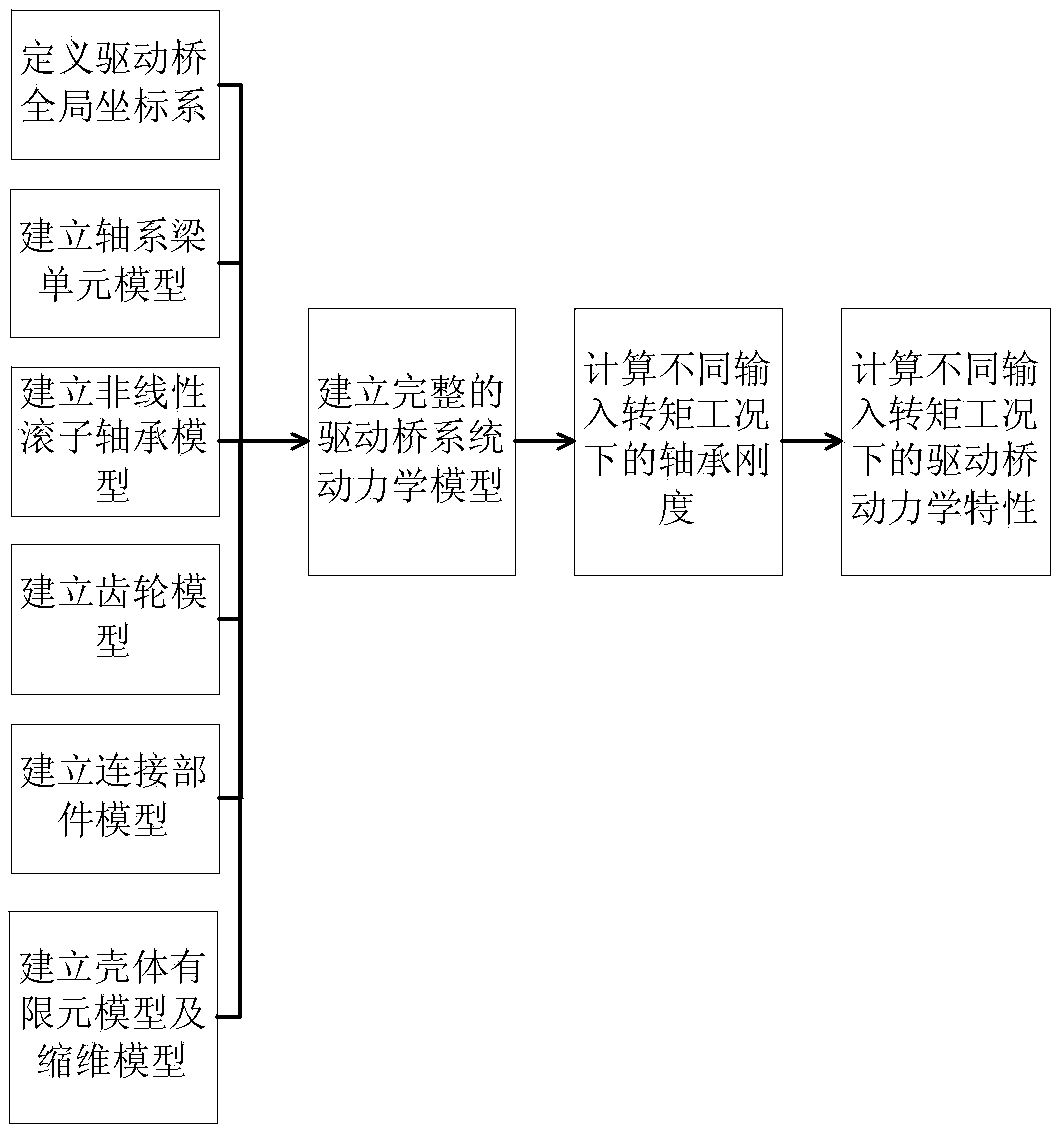

Drive axle dynamic characteristic computing method considering input torque changing

ActiveCN103995940AAccurate and efficient calculationImprove computing efficiencySpecial data processing applicationsReduced modelElement model

The invention relates to a drive axle dynamic characteristic computing method considering input torque changing. The method comprises the steps that (1) a drive axle global coordinate system is defined; (2) a shafting beam unit model is established; (3) a nonlinear roller bearing model is established; (4) a gear model is established; (5) a connecting part model is established; (6) a shell finite element model and a dimension-reducing model are established; (7) a complete drive axle system dynamics model is established; (8) bearing stiffness under different input torque working conditions is computed; and (9) the drive axle system dynamic characteristics under different input torque working conditions are computed. According to the method, a finite element method and a modality comprehensive method are used for establishing the complete drive axle system dynamics model which comprises a main speed reducing assembly, a differential mechanism assembly, a hub assembly, a shell and the like, and the dynamic characteristics of a drive axle system can be computed accurately and efficiently.

Owner:TSINGHUA UNIV +1

Magnetically-levitated blood pump with optimization method enabling miniaturization

Owner:WORLD HEART +1

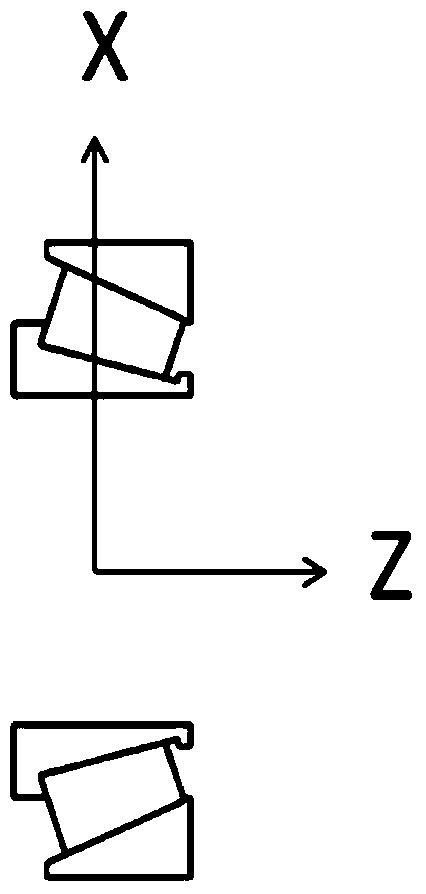

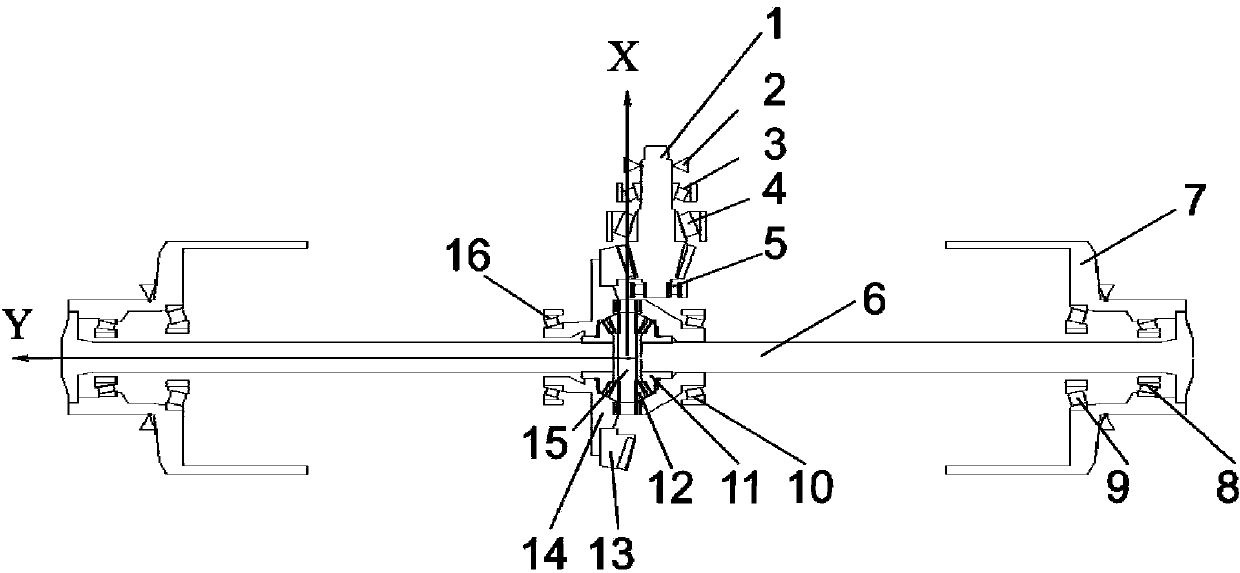

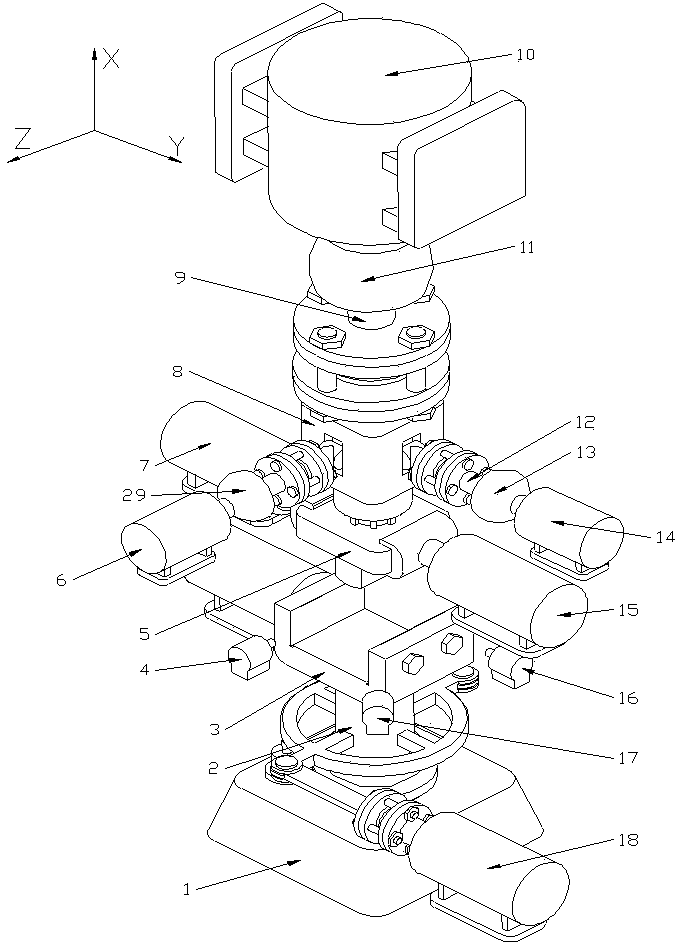

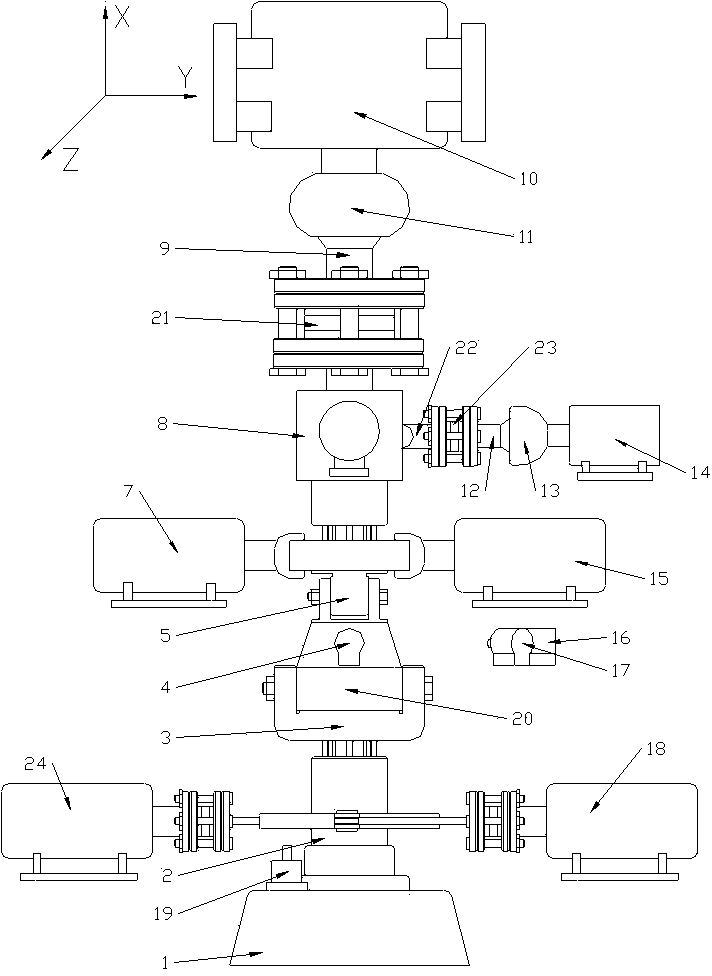

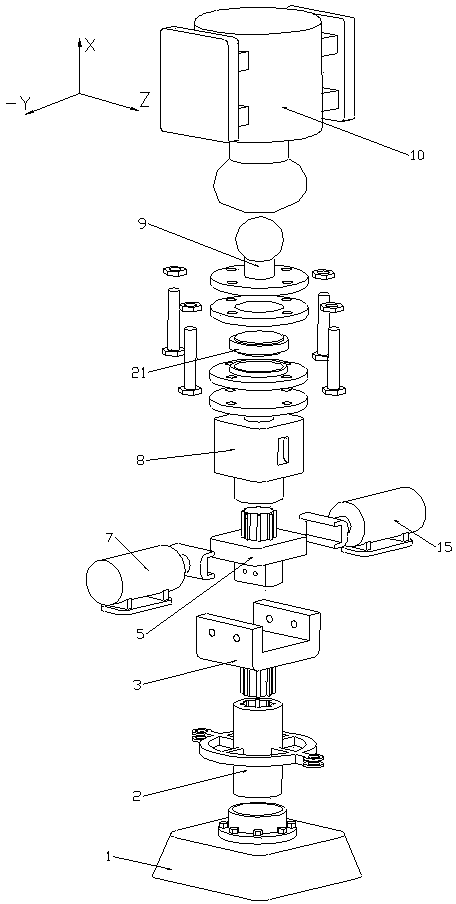

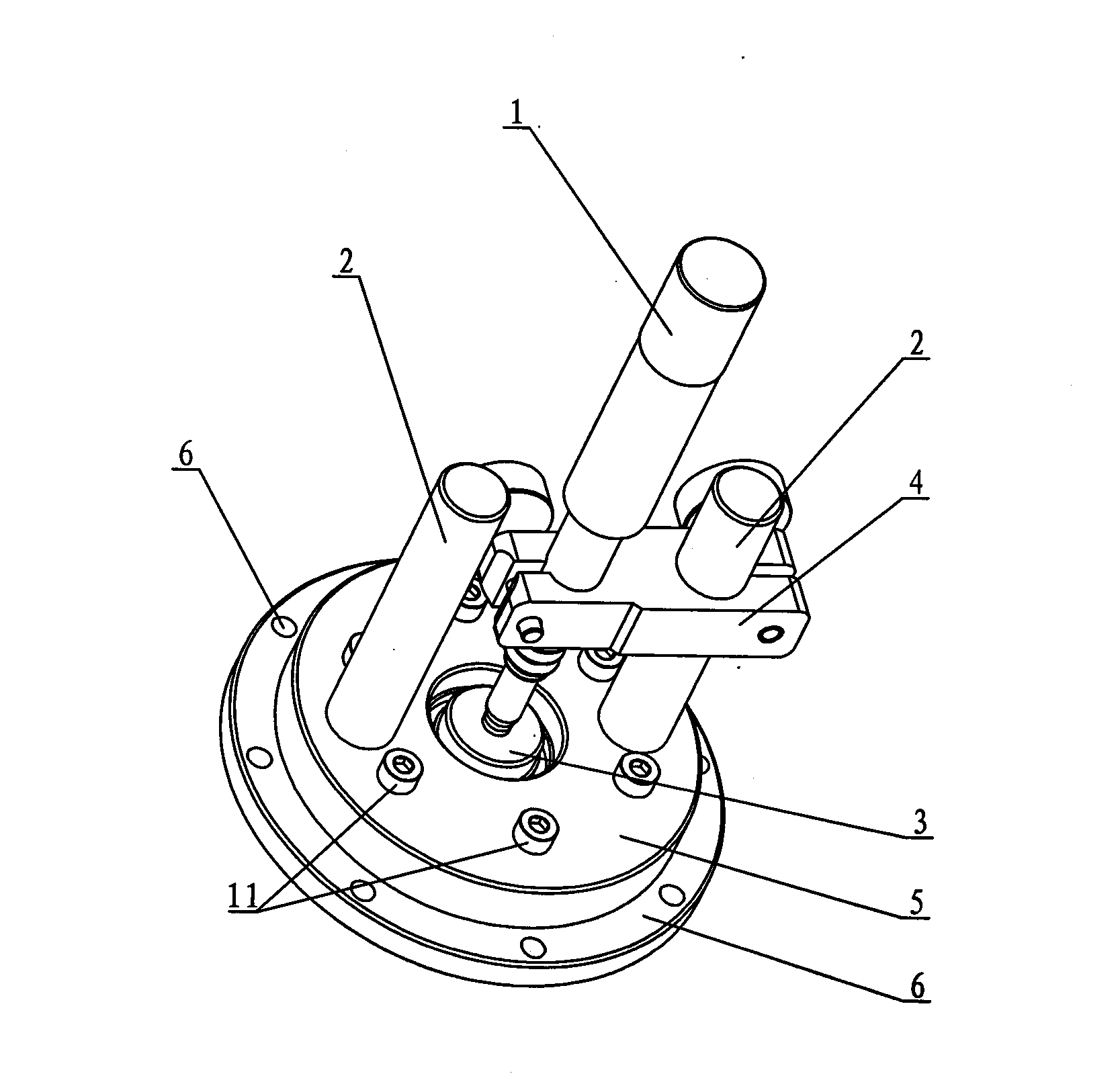

Helicopter rotor system elastic bearing load measuring device

InactiveCN104280241AEliminate degrees of freedomHigh precisionMachine bearings testingLocking mechanismEngineering

The invention relates to a helicopter rotor system elastic bearing load measuring device. The helicopter rotor system elastic bearing load measuring device comprises a measurement base, an X axis direction testing mechanism, a Y axis direction bending testing mechanism, a Z axis direction bending testing mechanism, an alignment locking mechanism and a torsion testing mechanism in the X axis direction. The measurement base is composed of a detecting platform base, a rotating shaft and a bearing large-end clamp and arranged at the bottom of the helicopter rotor system elastic bearing load measuring device. The X axis direction testing mechanism is arranged on the top of the helicopter rotor system elastic bearing load measuring device, and the torsion testing mechanism in the X axis direction, the alignment locking mechanism, the Y axis direction bending testing mechanism and the Z axis bending testing mechanism are correspondingly arranged on the lower layer, the middle layer and the upper layer of the helicopter rotor system elastic bearing load measuring device in sequence from bottom to top along the axis lead in the X direction. Through the helicopter rotor system elastic bearing load measuring device, the rigidity characteristic detection on different models of helicopter rotor system elastic bearings can be performed on one detecting platform, and university is good. The detecting efficiency and the safety of personnel in the detecting process are improved, the detecting strength is reduced, the elastic bearings can be clamped on one detecting platform at a time, and force (torque) in multi-dimensional directions can be loaded and measured.

Owner:HEFEI UNIV OF TECH

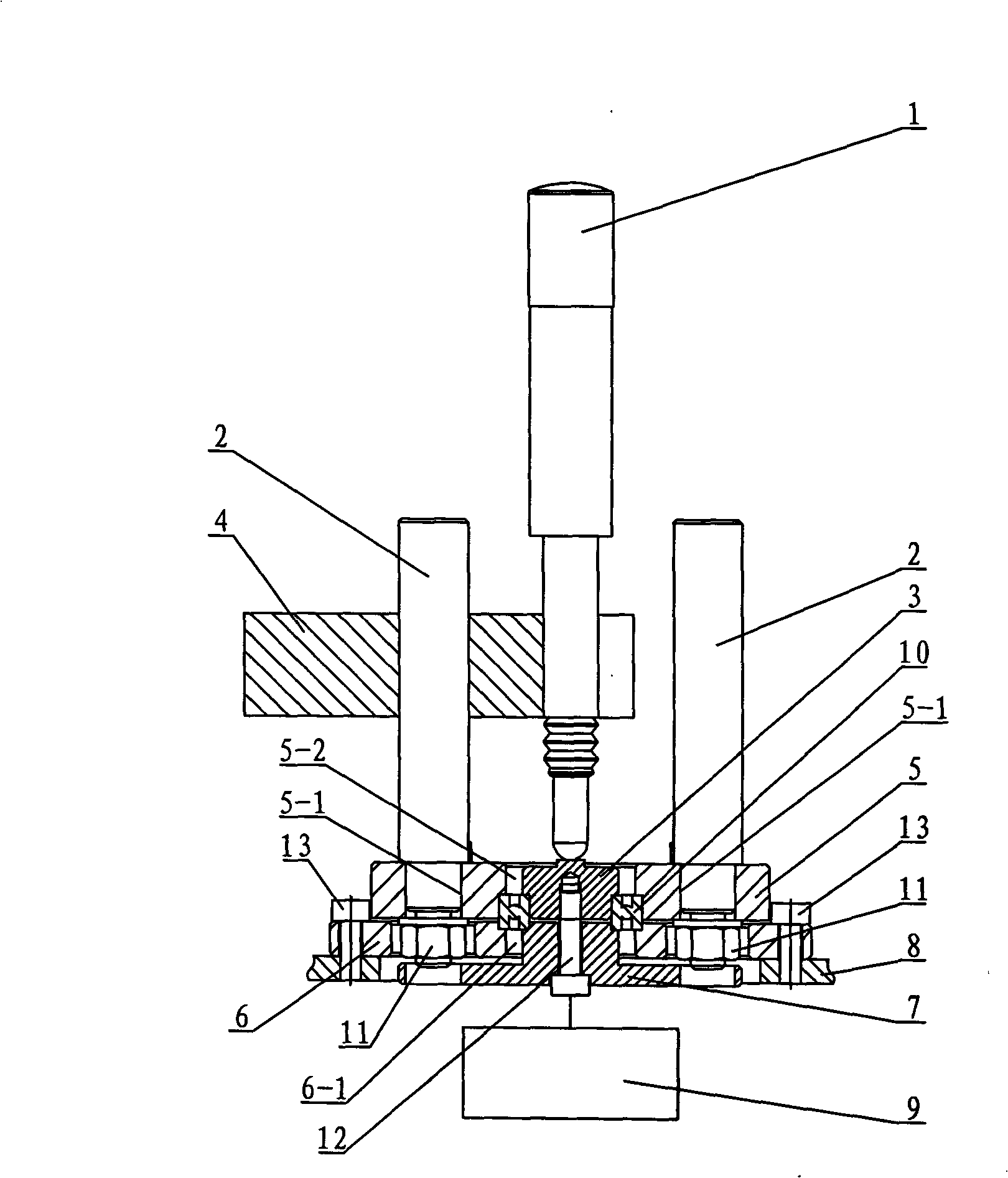

Bearing rigidity test device

InactiveCN101354314ASimple structureEasy to operateMachine bearings testingInsertion stentEngineering

The invention relates to a bearing stiffness testing device, aiming at solving the problems of complex structure, inconvenient operation and high requirements on the surrounding environment of the existing bearing stiffness testing device. Ends of two studdles of the invention are respectively arranged at two studdle holes; an inner ring briquette is arranged in a central hole; one end of a connecting stent is positioned at any one studdle and an inductance probe is installed at the other end of the connecting stent; the probe end of the inductance probe is pressed on the center of a contact surface corresponding to the inner ring briquette; a connecting plate is connected with a bearing seat in a detachable manner through a first connecting piece, a flange is positioned in the central hole of the connecting plate and connected with the inner ring briquette in a detachable manner through a second connecting piece and a weight is connected with the flange. The testing device of the invention fixes the inner ring and the outer ring of the bearing to be tested respectively, loads on the inner ring to obtain the position deviation of the inner ring and the outer ring of the bearing under different load, thereby obtaining bearing stiffness index; in addition, the testing device has simple structure, convenient operation and relatively low requirements on the surrounding environment.

Owner:HARBIN INST OF TECH

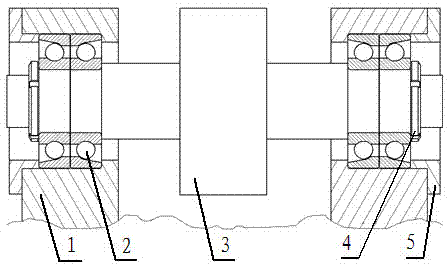

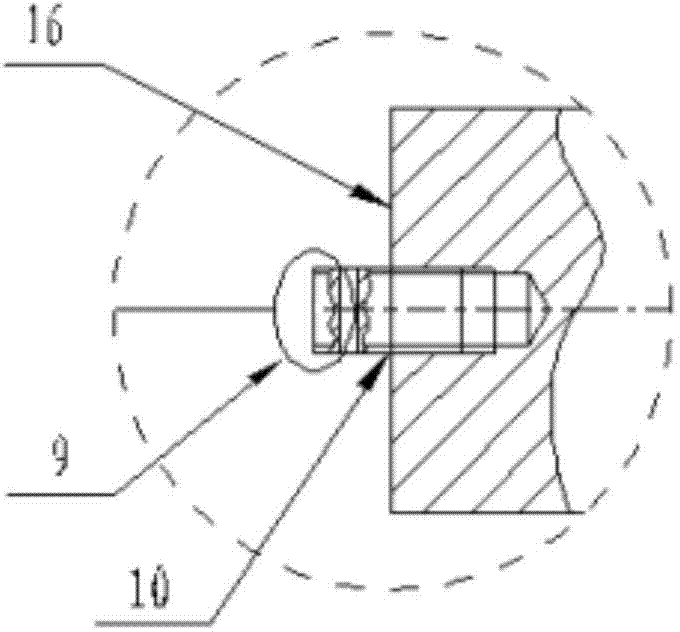

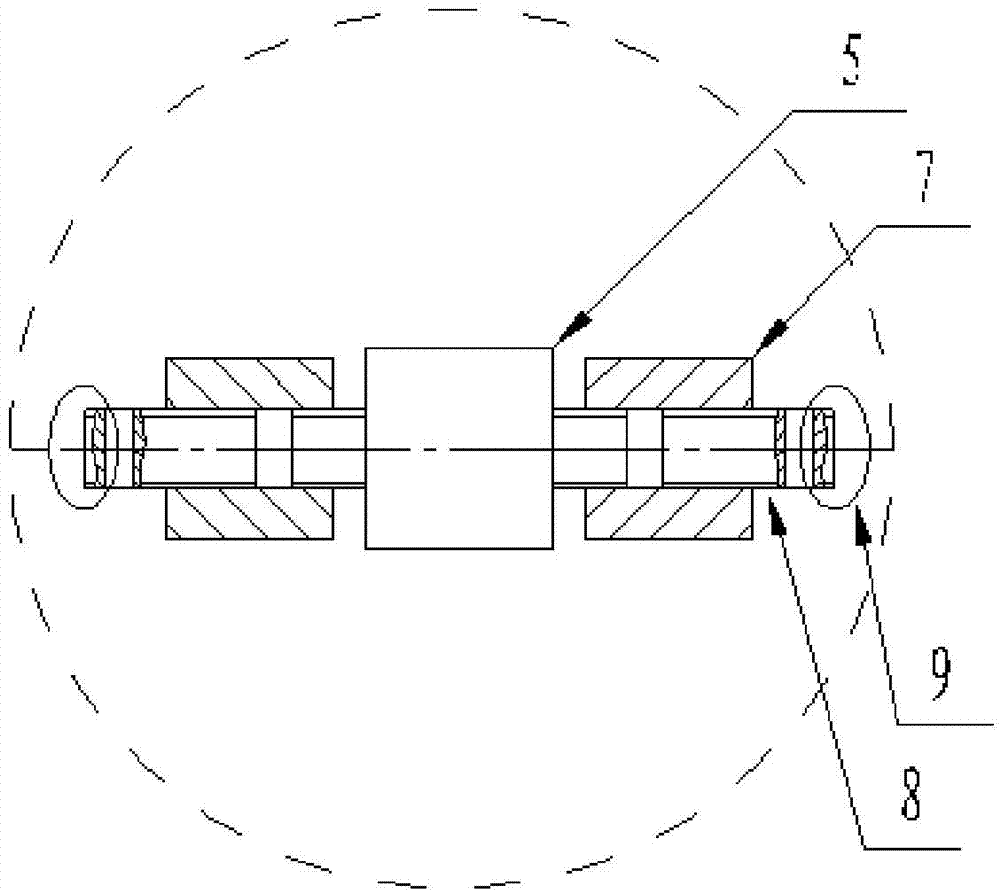

Rolling bearing stiffness testing experiment device and experiment method thereof

InactiveCN103543012AImprove accuracyEasy to pullMachine bearings testingHydraulic cylinderRolling-element bearing

The invention discloses a rolling bearing stiffness testing experiment device and an experiment method thereof. The experiment device comprises a hydraulic initial pre-tightening module, a piezoelectric actuator pre-tightening force adjustment module and a frequency response function testing module. The hydraulic initial pre-tightening module comprises a hydraulic system, a hydraulic cylinder, a tension sensor, a tension display and a spindle; the piezoelectric actuator pre-tightening force adjustment module comprises a plurality of first pressure sensors, a plurality of piezoelectric actuators, an actuator hole seat, a rolling bearing, an end cap and a bearing seat; the frequency response function testing module comprises a plurality of acceleration sensors, a plurality of second pressure sensors, a plurality of vibration exciters, a data acquisition instrument, a computer and a signal generator. According to the experiment method, a mode of implementing combined pre-tightening to the rolling bearing is adopted, and stiffness of the rolling bearing is calculated in the frequency response function testing module. By the rolling bearing stiffness testing experiment device, dynamic test on the stiffness of the rolling bearing is realized through accurate adjustment of pre-tightening force of the rolling bearing.

Owner:XI AN JIAOTONG UNIV

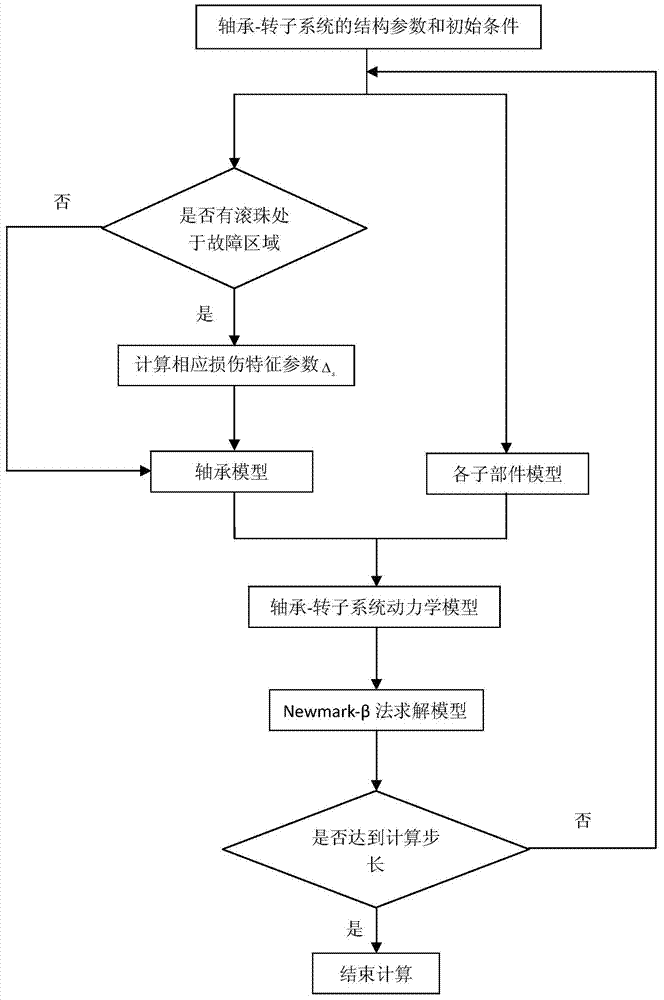

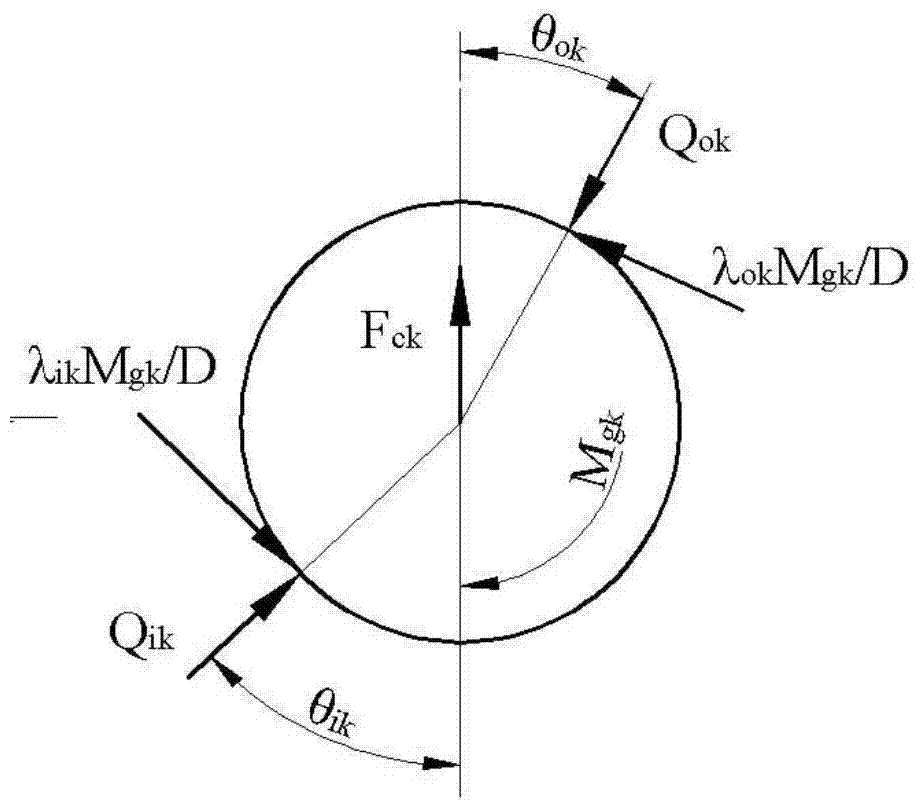

Rolling bearing-rotor system damage vibration response quantitative calculation method

ActiveCN103712785AThe calculation result is accurateMachine bearings testingElement modelDynamic models

The invention discloses a rolling bearing-rotor system damage vibration response quantitative calculation method. The method comprises the steps that the structure parameter and the initial parameter of a bearing-rotor system are acquired; according to the bearing parameters, a five freedom degree bearing model is established, and a bearing stiffness matrix of the bearing-rotor system is acquired; according to the geometric size and the material characteristic parameter of a subcomponent, a finite element model is established, and a rotor stiffness matrix, a rotor gyroscopic matrix, and an equivalent mass matrix caused by a centrifugal force are acquired; a dynamics model of the bearing-rotor system is established; a time-domain integral method is used to solve the bearing-rotor dynamics model, so as to acquire the displacement vibration response of the bearing-rotor system. According to the invention, based on the finite element dynamics model, quantitative calculation can be carried out on vibration response generated by single point or multi-point damage of inner and outer rings of a bearing, and a basis is provided for the analysis and the diagnosis of a fault mechanism of the rotor-bearing system.

Owner:XI AN JIAOTONG UNIV

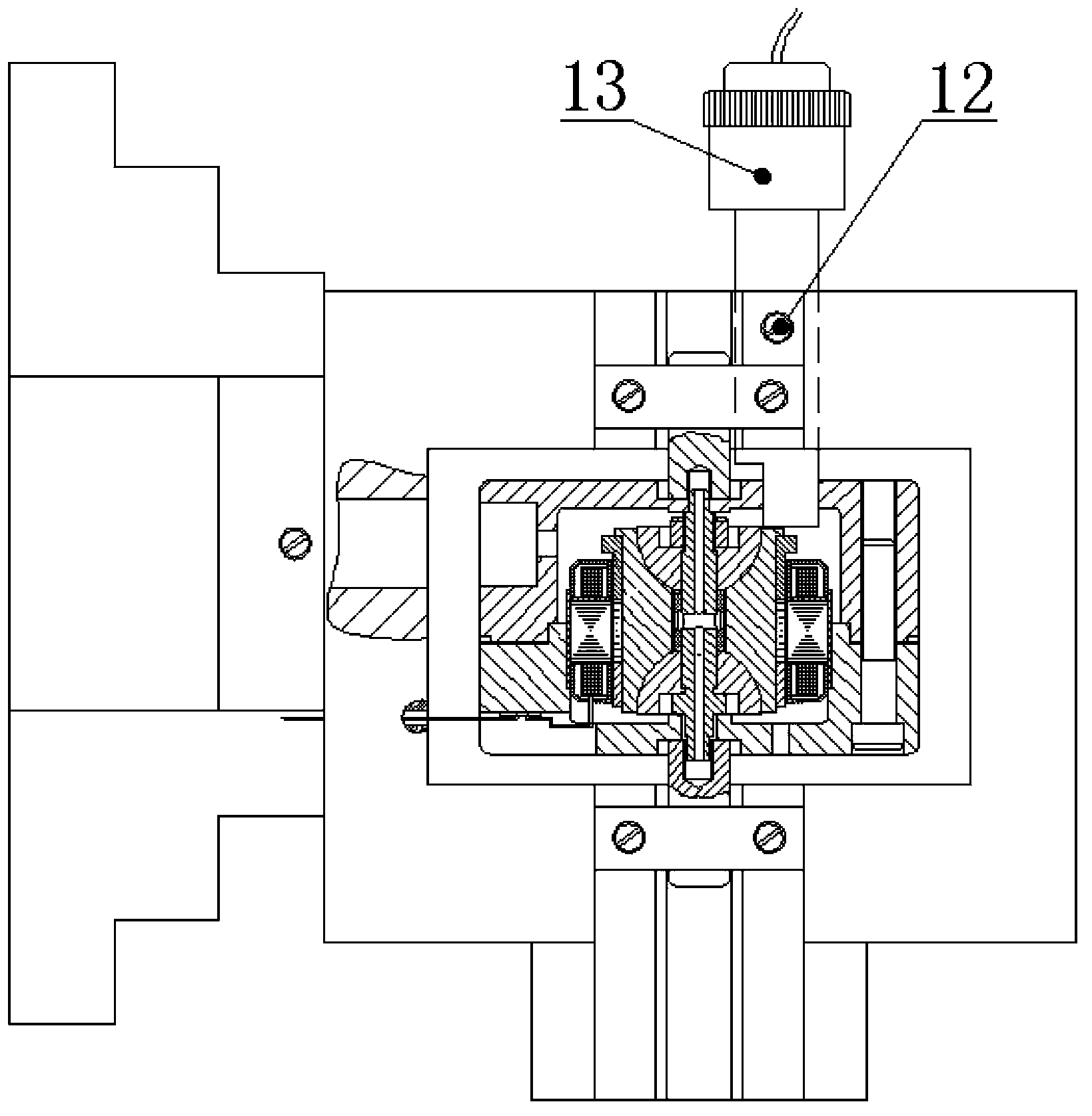

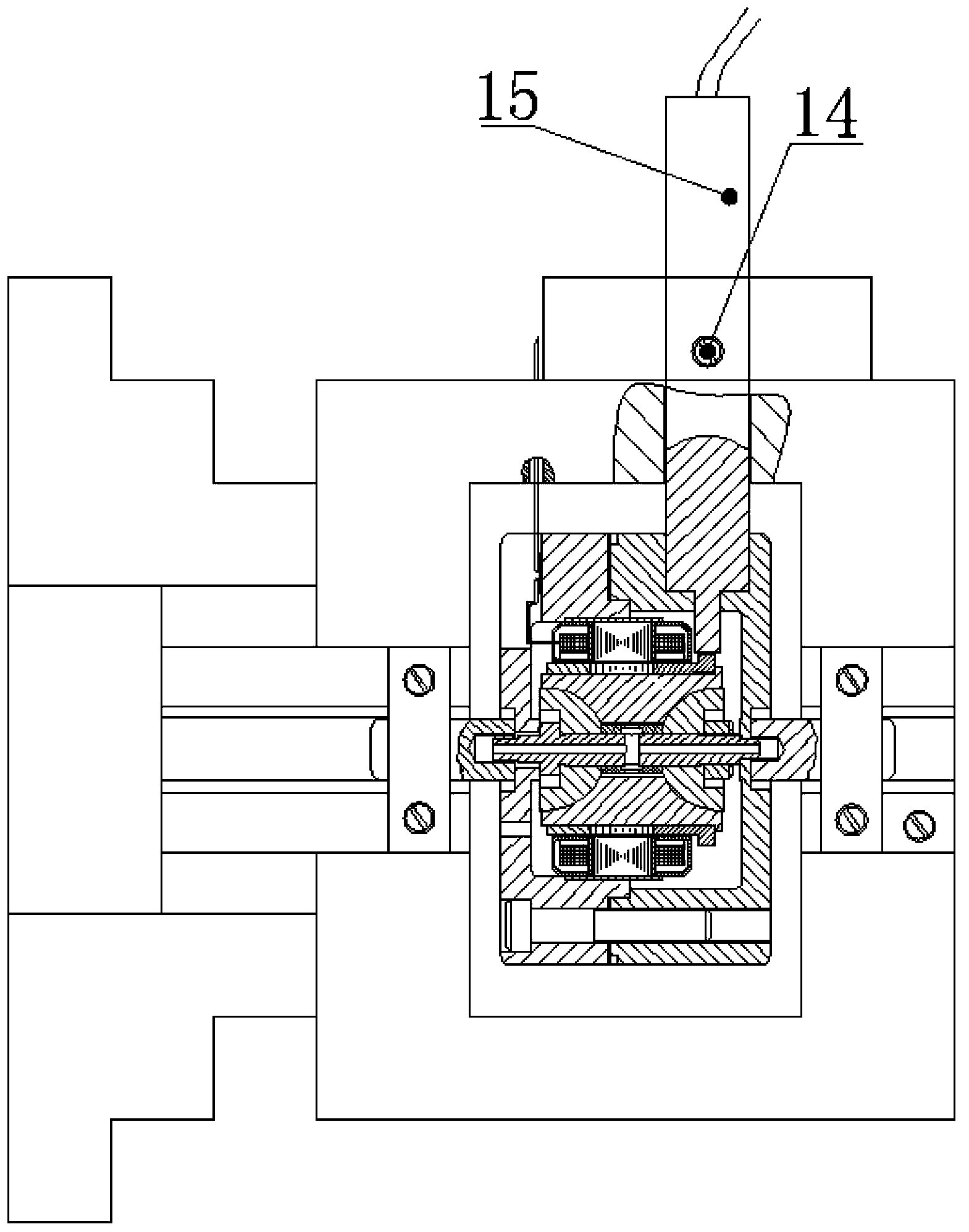

Dynamic stiffness testing device for joint part of main shaft bearing

InactiveCN106768749AMeasuring the Effect of StiffnessEasy to installMachine bearings testingVibration testingAxial displacementDynamic stiffness

The invention relates to the technical field of the dynamic behavior parameter testing of the bearing under the different working condition load, and in particular to a dynamic stiffness testing device for a joint part of a main shaft bearing. The dynamic stiffness testing device for the joint part of the main shaft bearing comprises a bottom plate, and a motor component, a revolution speed sensor, an accelerator, a support bearing component, a bearing component to be tested, an excitation device, a transmission shaft, an axial displacement sensor and a radial displacement sensor which are installed on the bottom plate. The bearing component to be tested and the excitation device are sheathed on the transmission shaft. Two ends of the transmission shaft are supported by the support bearing component, and one end is successively connected with the accelerator and the motor component. The revolution speed sensor, the axial displacement sensor and the radial displacement sensor are respectively used for measuring the revolving speed, the axial displacement and the radial displacement of the transmission shaft. The dynamic stiffness testing device for the joint part of the main shaft bearing has the characteristics of convenient measurement, clear structure and simple operation, and is capable of simulating the actual working conditions to obtain the bearing stiffness, and has the important function of researching the dynamic property of the joint part of the bearing and ensuring the rational pretension force.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Mixed type helical groove dynamical and static pressure gas composite thrust bearing

InactiveCN1632331AImprove carrying capacityIncrease stiffnessSliding contact bearingsGas cushion bearingsAir bearingHigh stiffness

The "hybrid spiral groove dynamic and static pressure gas composite thrust bearing" of the present invention relates to a high-speed, high rigidity, large load ultra-precision spiral groove dynamic and static pressure gas composite thrust bearing. There are herringbone dynamic pressure grooves on both sides of the air point distribution circle. Without increasing the air consumption of the air bearing, the bearing capacity is more than 30% higher than that of the traditional static pressure air bearing, and the bearing stiffness is higher than that of the traditional static pressure air bearing. The bearing is improved by more than 15%.

Owner:HARBIN INST OF TECH

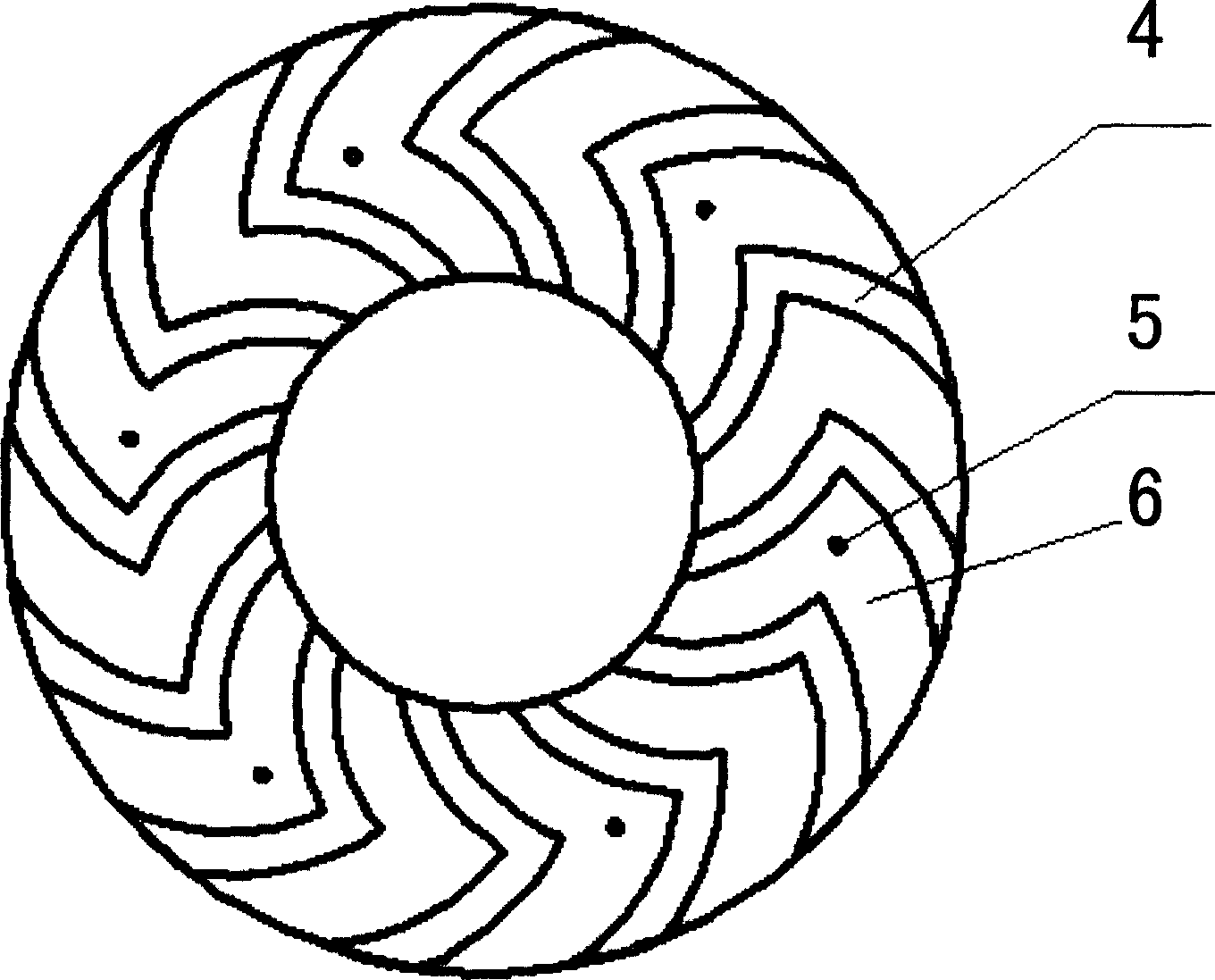

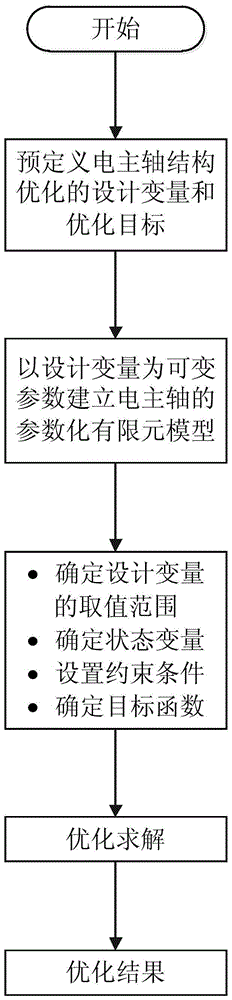

Motorized spindle structure optimization method based on parametric finite element model

ActiveCN105243215AImprove rigidityImprove convenienceSpecial data processing applicationsElement modelHigh stiffness

The invention discloses a motorized spindle structure optimization method based on parametric finite element model. The method is characterized by comprising the following steps of: according to a to-be-optimized motorized spindle, initially defining a design variable and an optimization goal of an optimization problem; 2) taking the design variable as a variable parameter, and establishing a motorized spindle parametric finite element model; 3) according to a motorized spindle design principle and related theories, determining value range of the design variable and determining a state variable, establishing a constraint condition, and then establishing an objective function; 4) selecting an intelligent optimization algorithm to perform optimization solving, and obtaining an optimization result. The method optimization based on the motorized spindle parametric finite element model, nonlinear bearing stiffness is considered, the established model is more close to practice, the model is flexible, the optimization effect is good, and thus, the method is particularly suitable for dual-goal optimization of high stiffness and light weight of the motorized spindle. The method can effectively improve stiffness of the motorized spindle and reduce mass of the motorized spindle, and provides effective guidance for design of the motorized spindle.

Owner:无锡鸣山机电科技有限公司

Inner rotor type gyro motor testing device

ActiveCN103411764ASolve the problem that cannot be installedSolve space problemsMachine part testingMotor testingVibration acceleration

The invention discloses an inner rotor type gyro motor testing device. A locknut (2) and a locknut (10) are in threaded connection with the big shaft end and the small shaft end of a gyro motor rotor (9). A testing support (8) and nut lock blocks (11) are matched to form a cylindrical cavity used for accommodating the locknuts. The locknuts are fixed to the testing support (8) through the two nut lock blocks (11). A gyro motor stator (6) is installed inside an upper stator installation seat (5). The gyro motor rotor (9) is installed inside the gyro motor stator (6), and the end face of the big shaft end of the gyro motor rotor (9) is matched with the bottom surface of the upper stator installation seat (5) for positioning. The end face of the small shaft end of the gyro motor rotor (9) is matched with the bottom surface of a lower stator installation seat (7) for positioning. The lower stator installation seat (7) and the upper stator installation seat (5) are locked through a connecting bolt (14). The inner rotor type gyro motor testing device can test the vibration acceleration and the bearing stiffness, and a testing method is simple and accurate.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

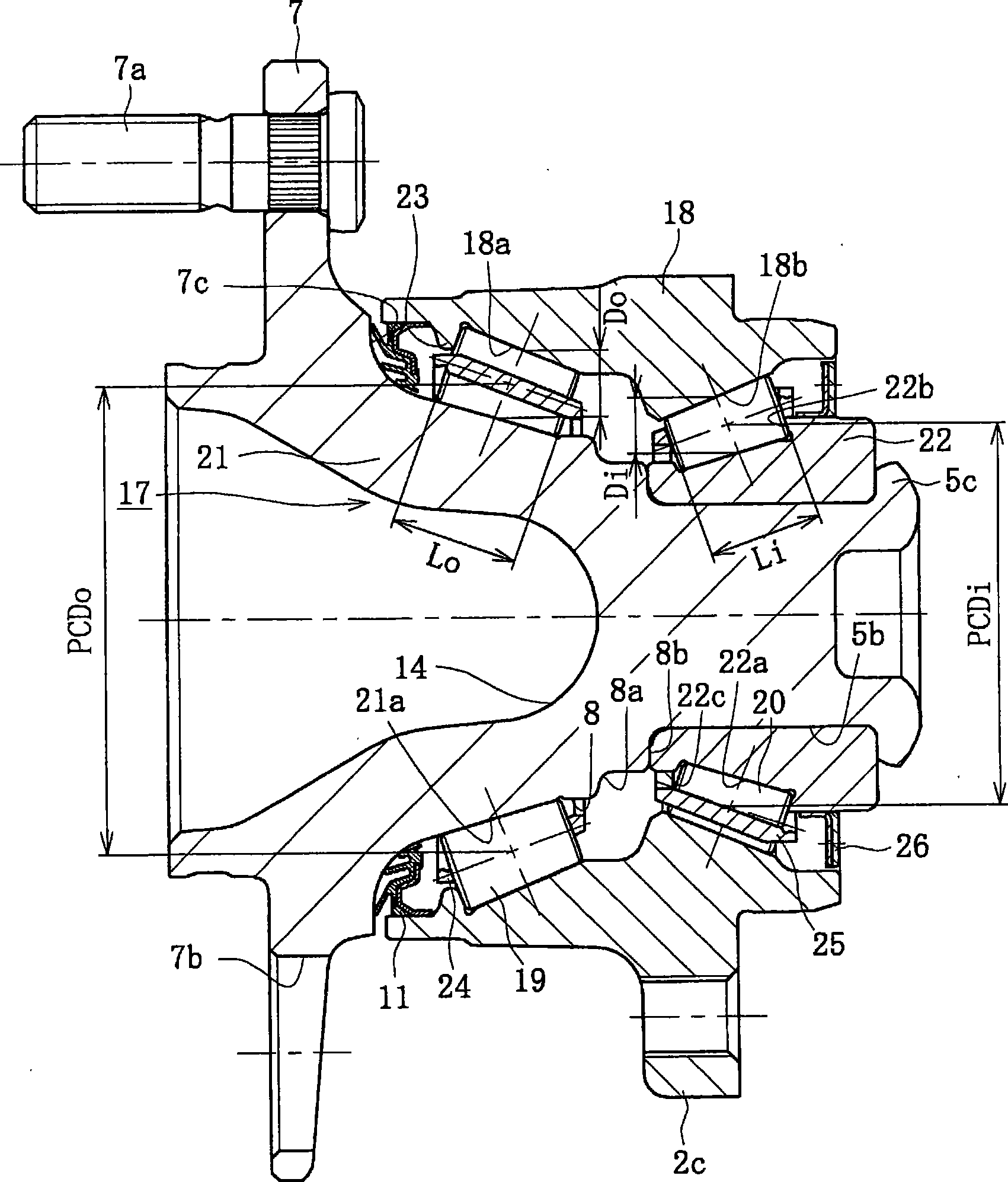

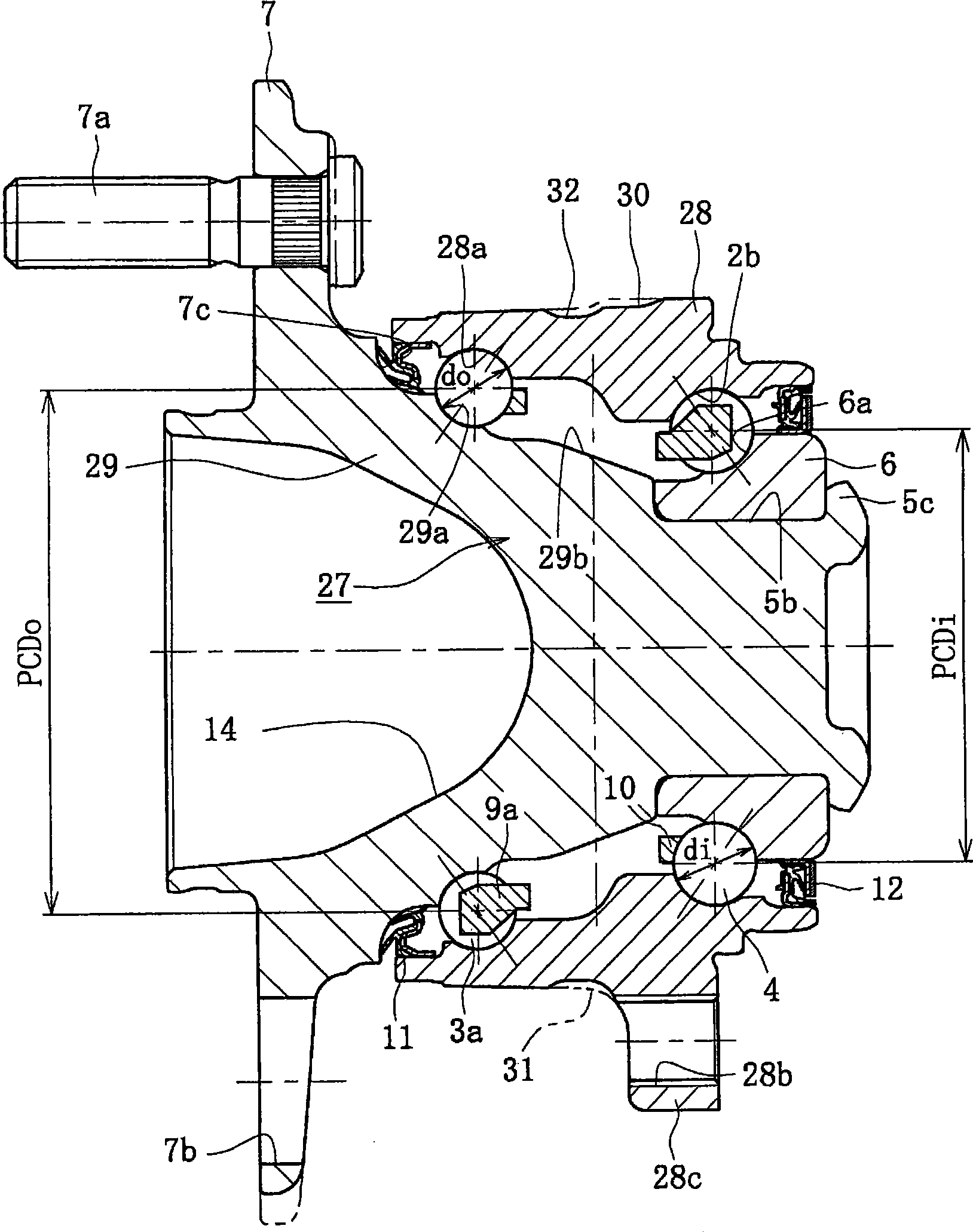

Bearing device for wheel

ActiveCN101512170AIncrease stiffnessReduce weightRoller bearingsBearing componentsBall diameterFlange

To provide a wheel bearing device which is made light and compact while increasing the rigidity of a bearing. In the wheel bearing device, a pitch circle diameter PCDo of a ball group 3 located close to a wheel mounting flange 7, out of double row ball groups 3, 4, is set to be larger than a pitch circle diameter PCDi of the ball group 4 located far from the wheel mounting flange 7. A ball diameter do of the ball group 3 located close to the wheel mounting flange 7 is set to be larger than a ball diameter di of the ball group 4 located far from the wheel mounting flange 7, the ball number of the former is set to be more than that of the latter. A mortary recessed portion 14 is formed in the end on the outer side of a hub ring 5. The depth of the mortary recessed portion 14 reaches the vicinity of at least shaft portion 8, and the shell of the hub ring 5 is shaped with its thickness approximately uniform. This solves conflicting problems on the device which is lighter / compacter as well as highly rigid.

Owner:NTN CORP

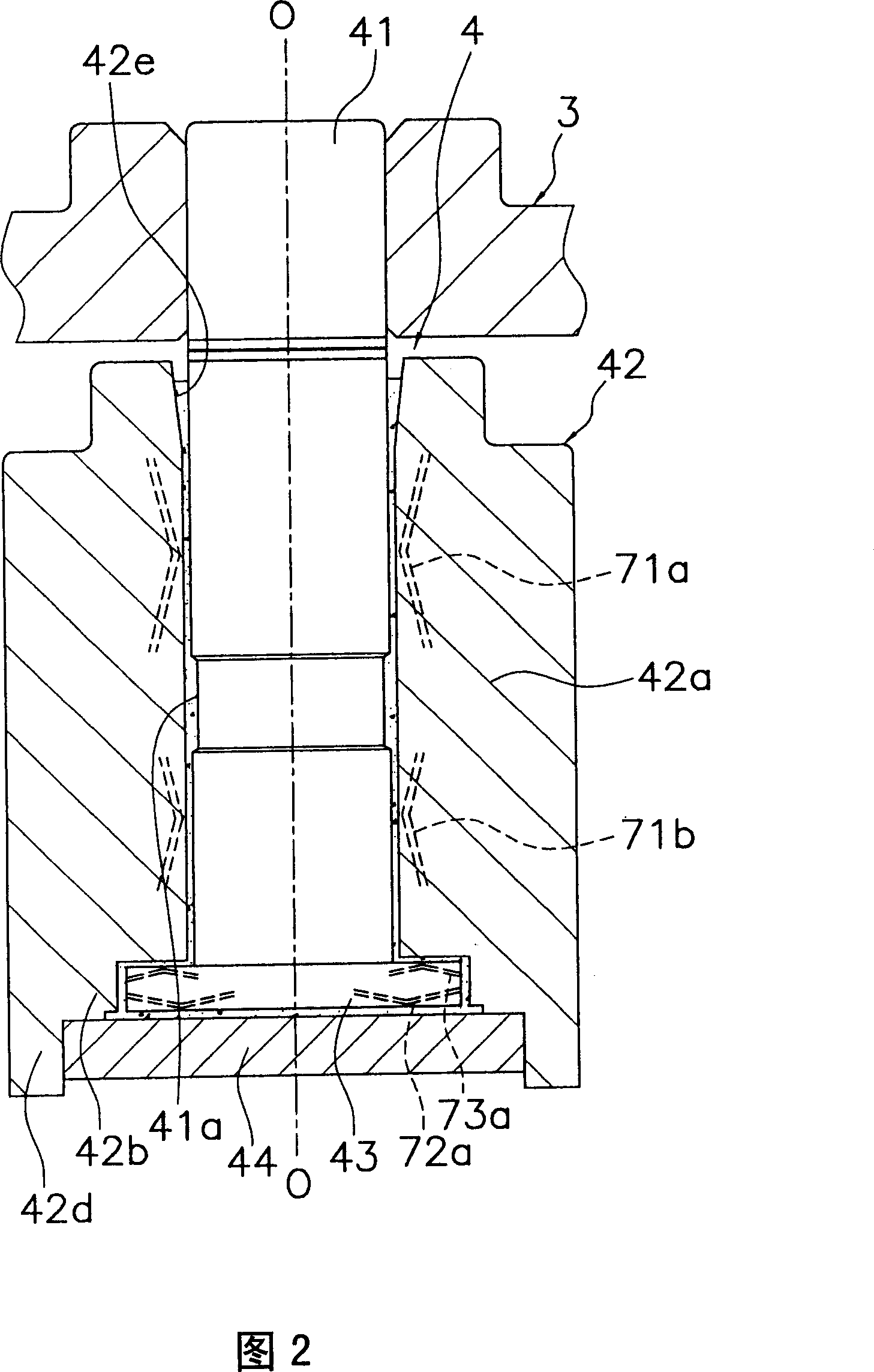

Flexible dynamic-pressure gas thrust bearing and assembling method thereof

ActiveCN106438676AAvoid local severe wear and tearExtended service lifeSliding contact bearingsThrust bearingEngineering

The invention discloses a flexible dynamic-pressure gas thrust bearing and an assembling method thereof. The flexible dynamic-pressure gas thrust bearing comprises a bearing block, an elastic support connected to the bearing block and top-layer flat foil connected to the elastic support. The top-layer flat foil comprises a plurality of flat foil pieces fixedly connected to the elastic support to form a bearing working plane. The flexible dynamic-pressure gas thrust bearing has the advantages that the thrust bearing does not have an inlet slope structure machined in advance, the inlet slope structure of the thrust bearing is formed through self-acting during bearing work, the bearing does not limit the rotation direction of a rotor thrust collar, that is to say, the rotor thrust collar can rotate along different directions, the bearing can work normally, and a traditional flexible dynamic-pressure gas bearing only allows the rotor thrust collar to rotate along one direction; the flexible feature of the dynamic-pressure gas thrust bearing can be regulated simply, and the rigidity feature of the bearing can be regulated conveniently by changing the elasticity of the elastic support so as to adapt to the rigidity requirements on the bearing under different application conditions.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Sleeve for hydrodynamic bearing device, hydrodynamic bearing device and spindle motor using the same, and method for manufacturing sleeve

A bearing stiffness of a sintered metal sleeve is prevented from lowering. A sleeve includes an inner section formed of metal powder for sintering and a resin for impregnation, and a surface deformation section which covers a surface of the inner section and is formed by shot blast process. Since the surface deformation section is formed by the shot blast process, the number of pores formed between the metal powder for sintering near the surface can be reduced. In this way, a supporting pressure at a bearing portion can be prevented from being released out through the pores, and the bearing stiffness can be prevented from lowering. In this way, the bearing stiffness can be prevented from lowering during sintering metal sleeve.

Owner:NIPPON DENSAN CORP

Rotor Support Mechanism of Rolling Bearing Turbocharger

InactiveCN102278154ASolve Vibration ProblemsImprove support rigidityRolling contact bearingsInternal combustion piston enginesTurbochargerThrust bearing

The invention belongs to the field of turbochargers for internal combustion engines, in particular to a rotor supporting mechanism of a rolling bearing turbocharger. It includes a bearing sleeve and two springs, two thrust sleeves and two bearings in the bearing sleeve. The two springs are symmetrically arranged in the bearing sleeve and connected to each other. Put the spring into the thrust sleeve and apply pre-tightening force. Two bearings are respectively arranged on the end face of the thrust sleeve. Both bearings are angular contact rolling bearings. The advantage of the present invention is that ceramic rolling bearings are used instead of ordinary floating bearings, which improves the mechanical efficiency and transient response capability of the turbocharger, solves the vibration problem of the rolling bearing turbocharger, and improves the steady-state performance and performance of the turbocharger. The service life of the rolling bearing is improved, the support rigidity of the rolling bearing is improved, the limit speed of the rolling bearing is increased, the requirement of high-speed operation of the turbocharger is met, the lubrication problem of the turbocharger is solved, the reliability of the rolling bearing supercharger is improved, and the balanced transmission The force system meets the requirements for the normal operation of the rolling bearing turbocharger.

Owner:CHANGZHOU E&E TURBO POWER

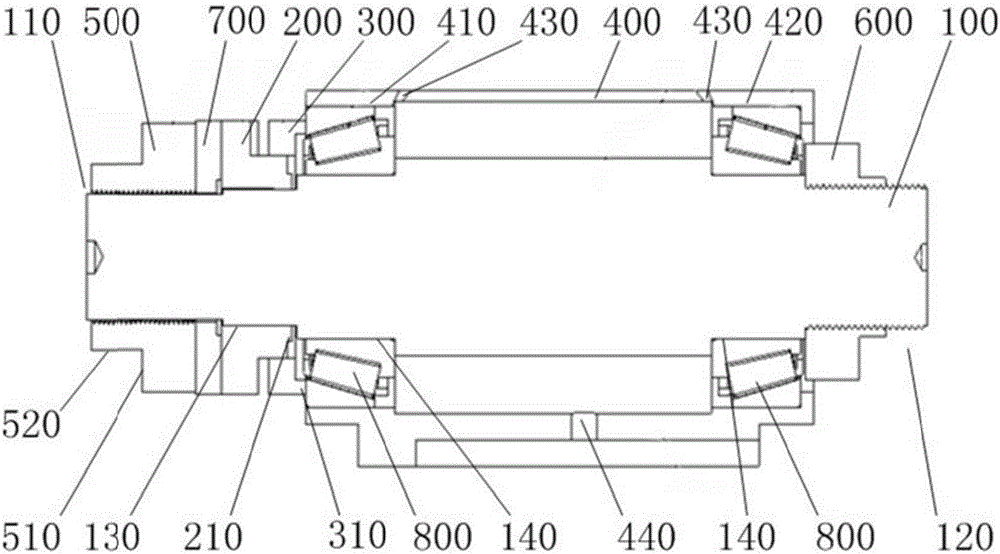

Mixed preloaded bearing rigidity calculation method considering main shaft-bearing coupling

InactiveCN105069213AAccurate calculation of stiffnessSpecial data processing applicationsCouplingEngineering

The invention provides a mixed preloaded bearing rigidity calculation method considering a main shaft-bearing coupling relation. The method comprises the steps as follows: firstly establishing iterative equations for a location preloaded bearing and a constant pressure preloaded bearing, and a main shaft kinetic equation; then coupling the main shaft and the bearing by using bearing rigidity and main shaft support node displacement (bearing inner race displacement) as coupling amount, and finally using Matlab to compile a calculation program to obtain the rigidity of the mixed preloaded bearing based on a finite iteration method. The method considers the influence of mixed preloaded and the main shaft-bearing coupling relation to the rigidity of the bearing, and could use different preloaded manners to perform accurate calculation to dynamic rigidity of the bearing under a working condition of bearing and high-speed cutting. The method provides guidance for designing and using an electric main shaft.

Owner:BEIJING UNIV OF TECH

Comprehensive measurement device and method for bearing rigidity and starting friction torque

ActiveCN106525424AAchieve stiffnessAchieve frictionMachine bearings testingForce sensorsFriction torqueMeasurement device

The invention discloses a comprehensive measurement device for bearing rigidity and starting friction torque, including a driving shaft, an inner axial pressure conduction block, an outer axial pressure conduction block, a pressure sensor and locking nuts. The driving shaft comprises a first step, a second step which is used for clamping a bearing, a testing end and a fastening end, and the testing end and the fastening end are provided with outer threads. The inner axial pressure conduction block is sleeved on the first step and is provided with a groove. The outer axial pressure conduction block is provided with a projection cooperated with the groove. The pressure sensor is sleeved on the driving shaft, and the end surface of the pressure sensor is adhered to the end surface of the inner axial pressure conduction block. The locking nuts are fixedly connected at two ends of the driving shaft respectively. The comprehensive measurement device for bearing rigidity and starting friction torque obtains the pretightening force, rigidity and starting friction torque of a single bearing or bearings in pair with one measurement device.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

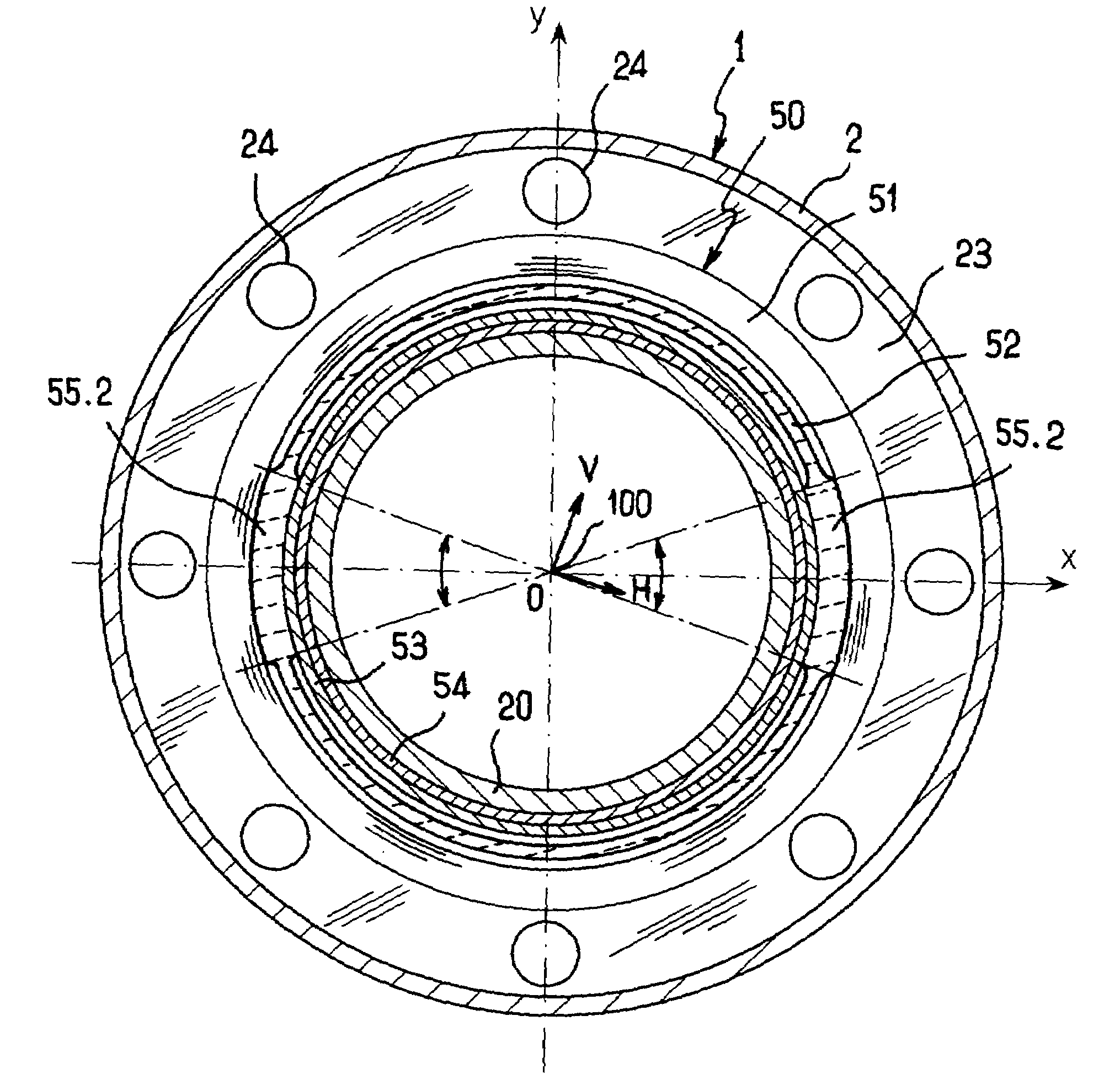

Brake system for braking aircraft wheels

InactiveUS7124860B2Better withstandNoise/vibration controlAxially engaging brakesShaft collarBraking system

The invention relates to a brake system for braking aircraft wheels, the brake system being of the type which, for each wheel, comprises a stator central portion coaxially surrounding a wheel axle on which a rotor annular portion is mounted to rotate, and a succession of brake disks disposed between the stator central portion and the rotor annular portion with alternate disks being constrained to rotate with one and the other of said portions, said stator central portion being provided with a brake collar equipped with a plurality of sets of pistons and, rigidly secured to said collar, a torsion tube internally provided with a transverse annular web, a centering bearing being interposed between the annular web and the axle. According to the invention the centering bearing has structural characteristics that vary circumferentially in a distribution configuration suitable for generating different bearing stiffnesses along two orthogonal axes contained in a plane that is perpendicular to the axis of the axle.

Owner:SAFRAN LANDING SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com