Bearing rigidity test device

A testing device and stiffness technology, applied in the field of bearing stiffness testing devices, can solve the problems of high requirements on the surrounding environment, inconvenient operation, complex structure, etc., and achieve the effects of low requirements on the surrounding environment, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

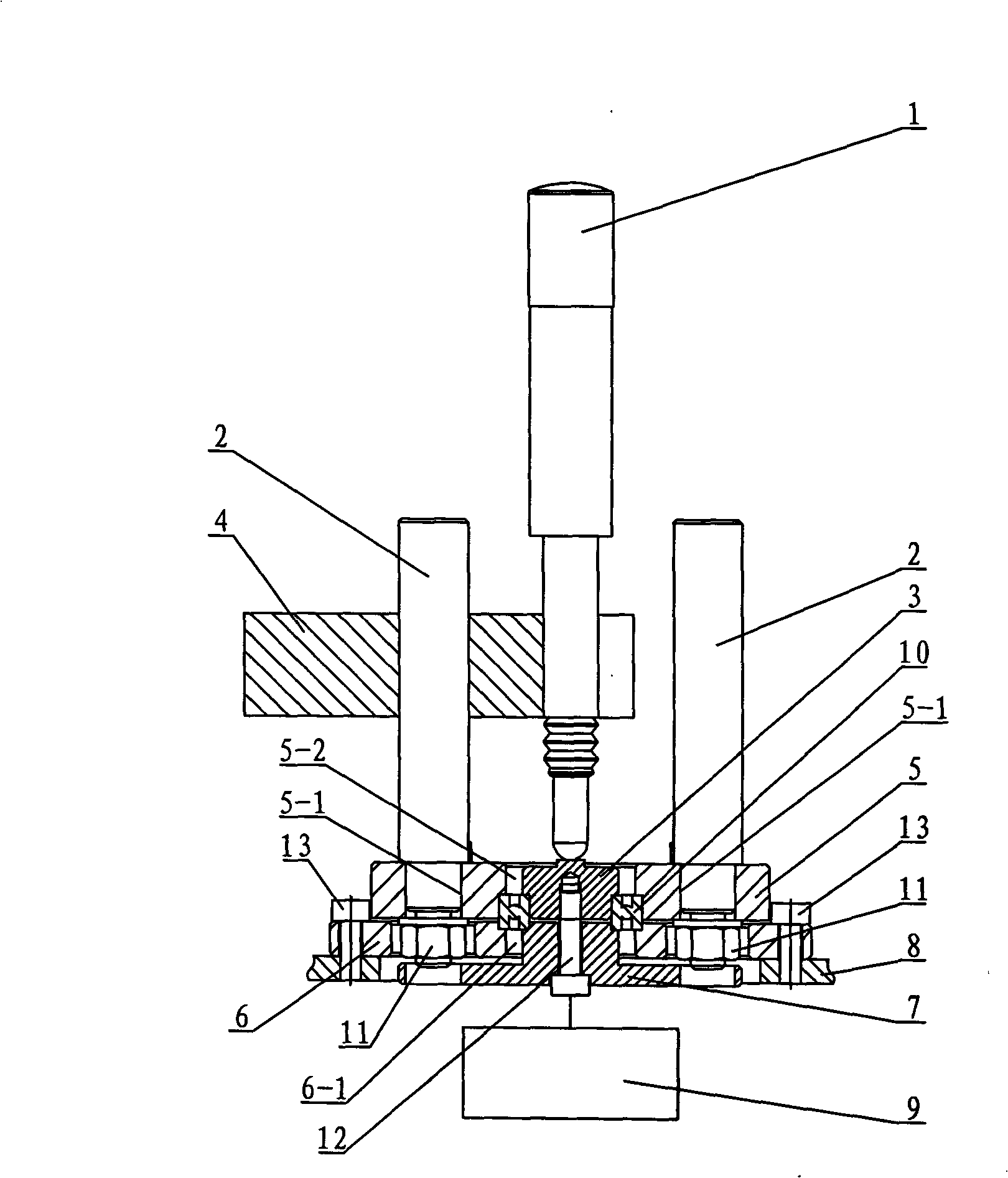

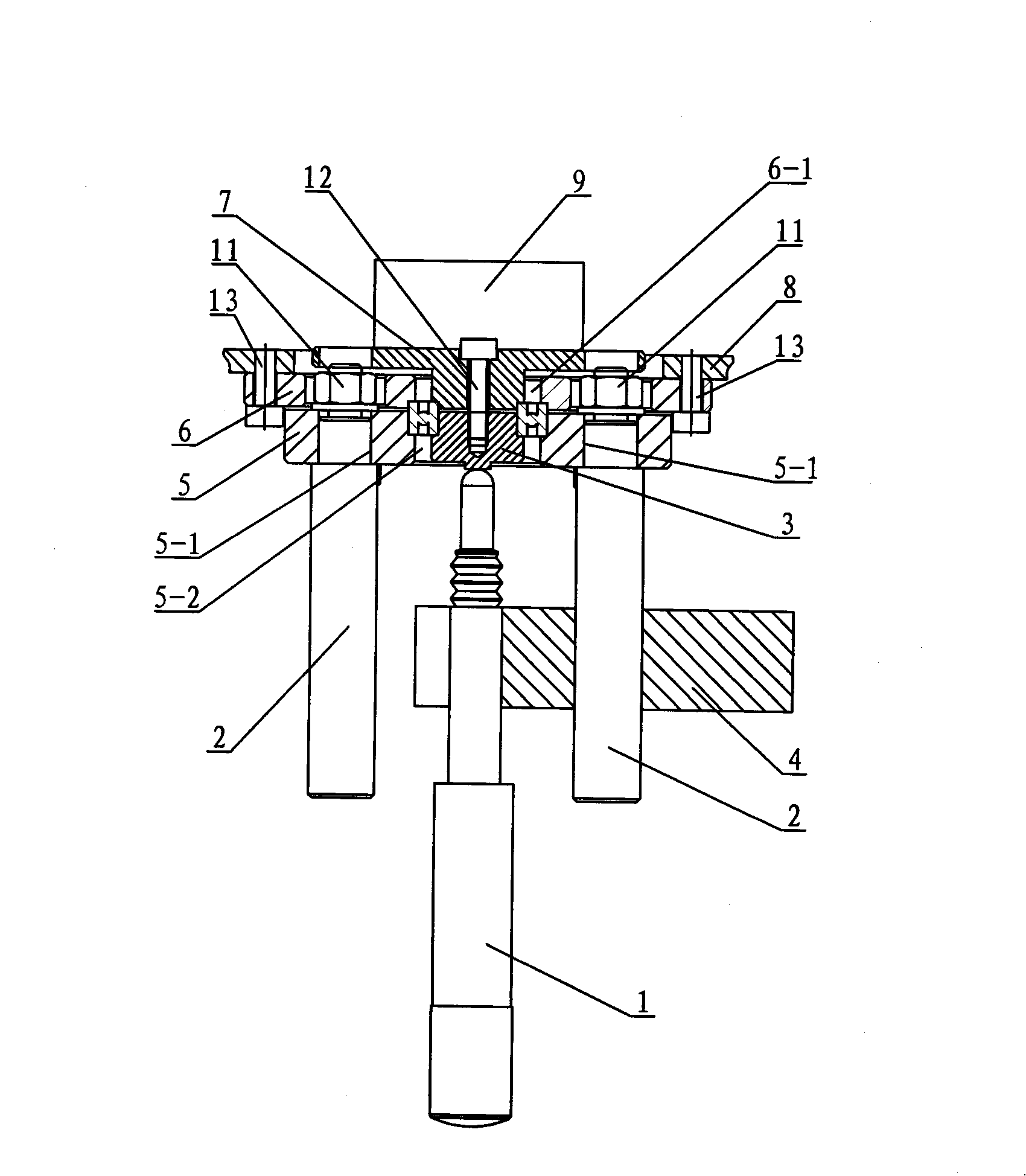

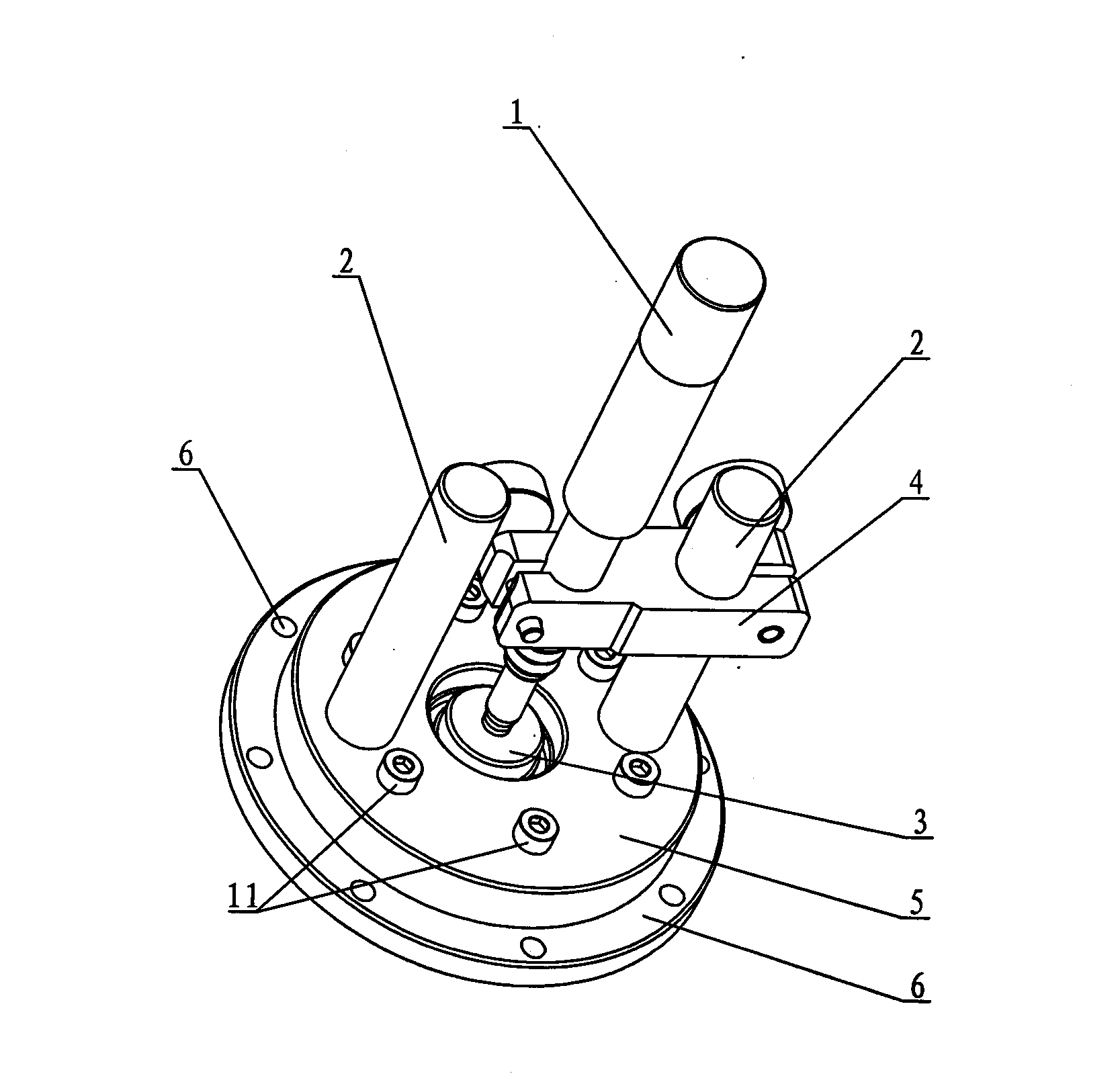

[0007] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment. This embodiment includes an inductive probe 1, two support rods 2, an inner ring pressure block 3, a connecting frame 4, a bearing seat 5, a connecting plate 6, a flange 7, a weight 9, and a first connecting piece 11 and the second connecting piece 12, one end of the two support rods 2 is respectively installed in the two support rod holes 5-1 on the bearing seat 5, and the inner ring pressure block 3 is installed in the center hole 5-2 on the bearing seat 5 Inside, one end of the connecting frame 4 is mounted on any one of the two supporting rods 2, the electric probe 1 is mounted on the other end of the connecting frame 4, and the probe end of the electric probe 1 is pressed against the inner ring pressure block 3 Corresponding to the central position of the contact surface, the connecting plate 6 is provided with a flange hole 6-1, the connecting plate 6 is detachably connected...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment. The difference between this embodiment and the first embodiment is that it also adds a support plate 8 and a third connecting piece 13. The support plate 8 is adjacent to the connection plate 6, and the connection plate 6 is located on the bearing seat 5. Between the support plate 8 , the large flange on the flange 7 is installed in the center hole of the support plate 8 , and the support plate 8 and the connecting plate 6 are detachably connected through the third connecting piece 13 . Design like this is to increase the intensity of connecting plate 6. Other components and connections are the same as those in the first embodiment.

[0009] Working principle: The outer ring of the tested bearing 10 is clamped by the bearing seat 5 and the connecting plate 6, and the inner ring of the tested bearing 10 is clamped by the inner ring pressure block 3 and the flange 7, and the outer ring of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com