Mixed preloaded bearing rigidity calculation method considering main shaft-bearing coupling

A technology for preloading bearings and stiffness calculation, which is used in calculations, special data processing applications, instruments, etc., and can solve problems such as not considering the influence of mixed preloading methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

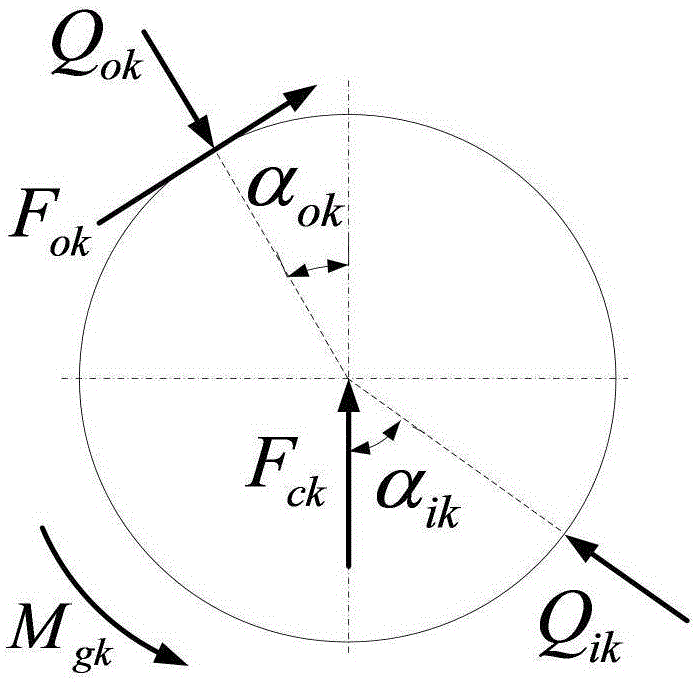

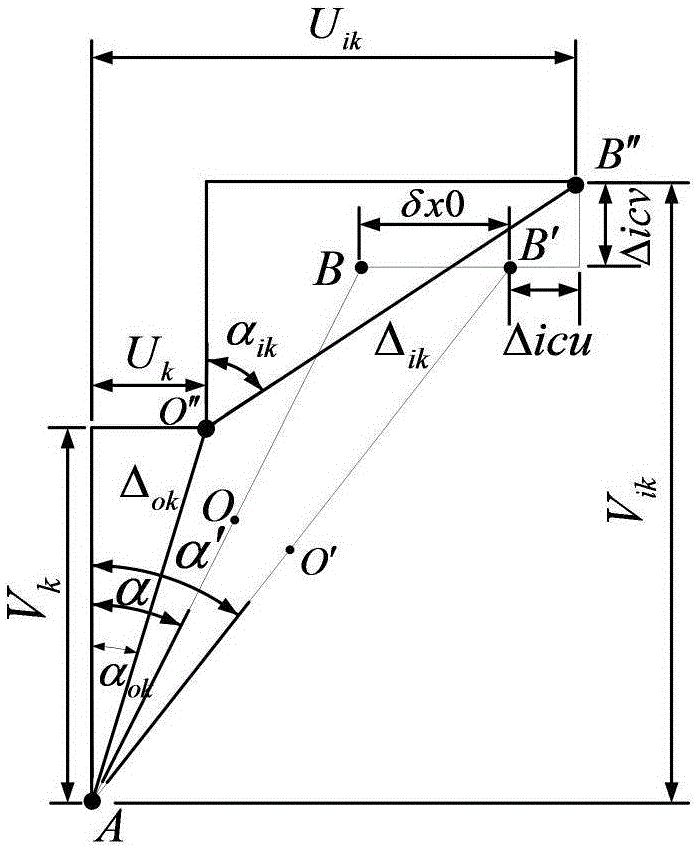

[0020] The present invention implements a hybrid preloaded bearing stiffness calculation method considering the spindle-bearing coupling relationship. The implementation of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0021] figure 1 It is a schematic diagram of the working state of the spindle-bearing system. As shown in the figure, the front end bearing of the main shaft adopts positioning preload, and the rear end bearing adopts constant pressure preload. The dotted line represents the static state, and the solid line represents the working state. The spindle produces dynamic displacement under the action of high speed and cutting load, and the displacements of the spindle support node and the inner ring of the bearing are {qi}, {qj}, {qk}. The outer ring of the positioning preload bearing is regarded as fixed, and the outer ring of the constant pressure preload bearing can slide along the axial direction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com