Apparatus for separating plastic chips

A screening device and technology for plastics, used in plastic recycling, mechanical material recycling, electrostatic effect separation, etc., can solve problems such as inability to screen with high purity and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

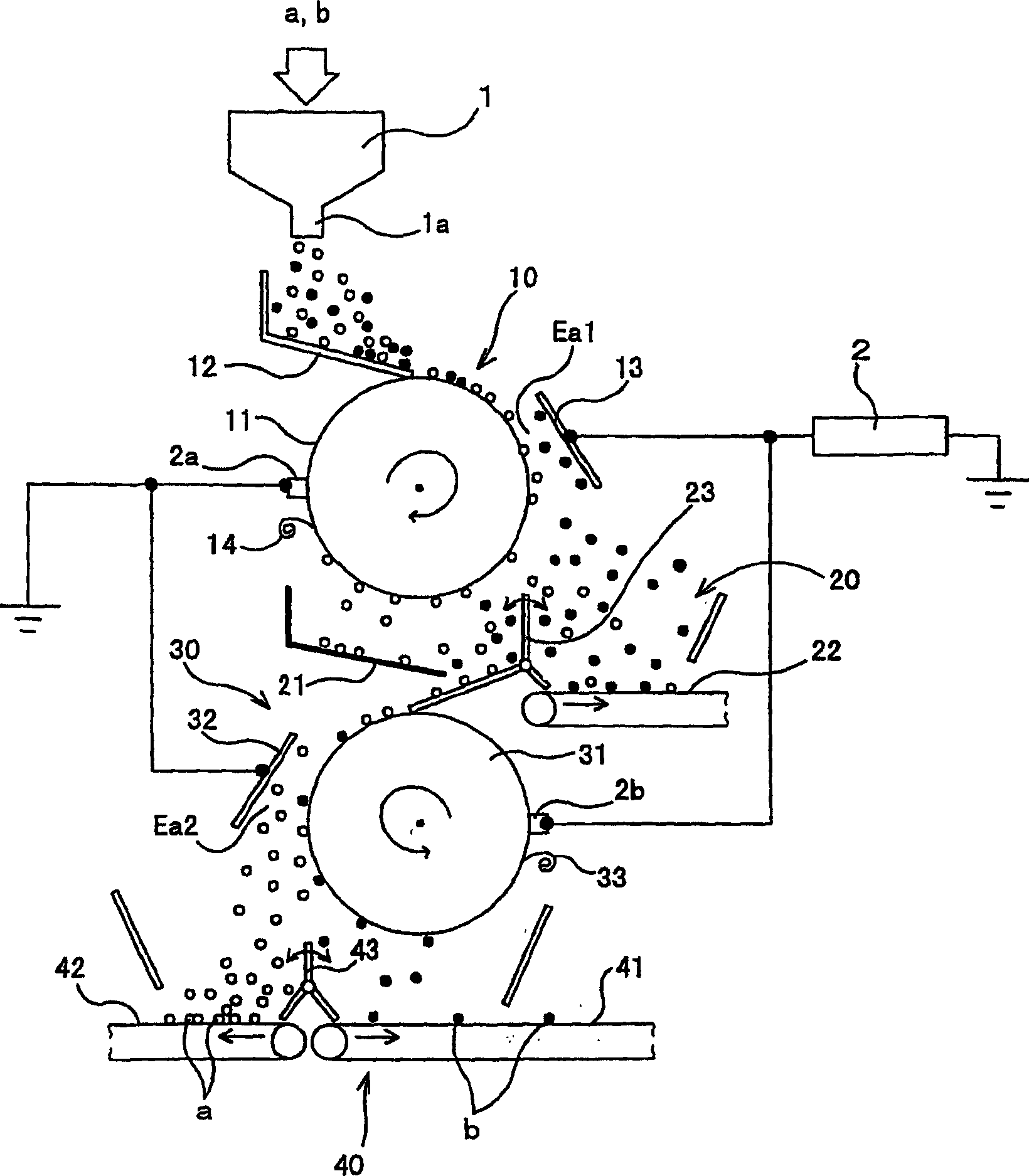

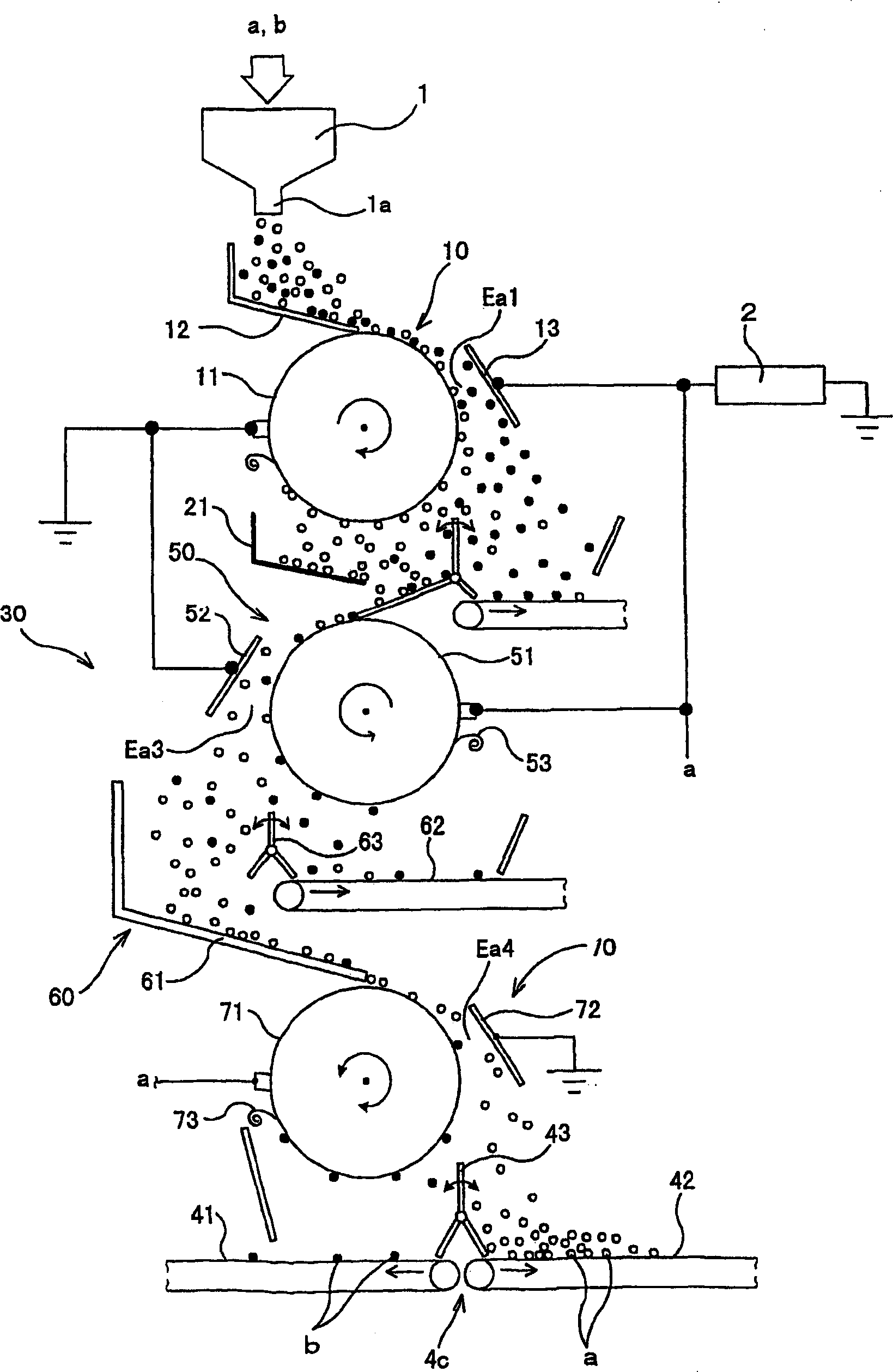

[0027] In order to illustrate the present invention in more detail, we illustrate according to accompanying drawing.

[0028] First, we refer to figure 1 and figure 2 The first embodiment of the plastic screening device related to the present invention will be described.

[0029] This type of plastic screening device has a part that mixes at least two or more different types (materials) of plastic chips (such as shredded plastic waste for screening) a, b in a state of mixing, and makes the different types of plastics Sheets a and b are frictionally contacted to make them triboelectrically electrified with the polarity and charge amount corresponding to the order of the charging sequence; it is arranged below the outlet 1a of the triboelectric device 1 and electrostatically separates various The upper electrostatic separation part 10 of the plastic sheets a and b; the lower electrostatic separation part 30 of the plastic sheets a and b that is further electrostatically sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com