Modified microcrystal graphite cathode material of lithium ion battery as well as preparation method and application thereof

A technology of negative electrode material and microcrystalline graphite, applied in the field of modified microcrystalline graphite negative electrode material for lithium ion battery and its preparation field, can solve the problems of low initial charge and discharge efficiency, short cycle life and the like, and achieve high rate charge and discharge performance. , improved cycle life, good isotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

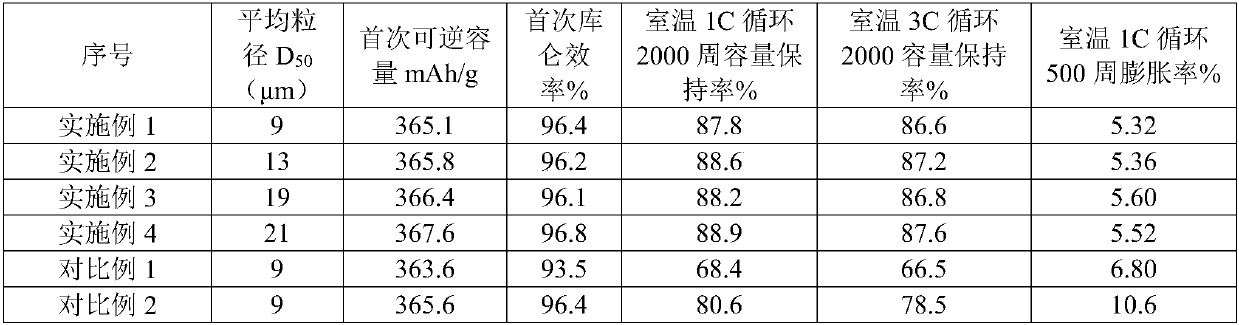

Examples

Embodiment 1

[0051] (1) Coarsely pulverize microcrystalline graphite with a carbon content of 85% to 100 mesh, and then use H at 95°C 2 SO 4 :HF:HCl (1:2:1.5) mixed acid aqueous solution purification, microcrystalline graphite purity increased to 99.0%;

[0052] (2) The material in step (1) is first crushed with a low-speed impact ball mill, then shaped with a jet mill, and finally classified by air flow to obtain D 50 8μm material;

[0053] (3) Pack the material obtained in step (2) into a flexible packaging bag and seal it, put the packaging bag into a dipping tank, vacuumize, and heat the dipping tank to make its vacuum degree reach 0.07MPa and the temperature reach 300°C.

[0054] (4) inject the pitch in the melting tank (350° C.) into the impregnation tank of step (3) at 30 MPa, and when the pitch liquid exceeds the height of the packaging bag in the dip tank, stop vacuuming and keep warm for 1 hour at 40 MPa;

[0055] (5) After the step (4) heat preservation is completed, the asph...

Embodiment 2

[0059] (1) Coarsely pulverize microcrystalline graphite with a carbon content of 90% to 100 mesh, and then use H at 90°C 2 SO 4 :HF:HCl (1:1.5:1) mixed acid aqueous solution purification, microcrystalline graphite purity increased to 99.2%;

[0060] (2) The material in step (1) is first pulverized with an air flow vortex micro-powder machine, then shaped with a high-pressure mill, and finally a jet classifier is used to obtain D 50 12μm material;

[0061] (3) Pack the material obtained in step (2) into a soft packaging bag and seal it, put the packaging bag into a dipping tank, vacuumize, and heat the dipping tank so that its vacuum reaches 0.08MPa and the temperature reaches 300°C.

[0062] (4) inject the asphalt in the melting tank (300 DEG C) into the impregnation tank of step (3) at 50MPa, and when the asphalt liquid exceeds the height of the packaging bag in the impregnation tank, stop vacuuming and keep warm for 2 hours at 50MPa;

[0063] (5) After the step (4) heat p...

Embodiment 3

[0067] (1) Coarsely pulverize microcrystalline graphite with 80% carbon content to 100 mesh, and then use H at 95°C 2 SO 4 :HF:HCl (1:2.5:2) mixed acid aqueous solution purification, microcrystalline graphite purity increased to 99.4%;

[0068] (2) the material of step (1) is first pulverized with an ultrafine pulverizer, then with a rod mechanical pulverizer, and finally adopts an ultramicron airflow classifier to obtain D 50 16μm material;

[0069] (3) Pack the material obtained in step (2) into a soft packaging bag and seal it, put the packaging bag into a dipping tank, vacuumize, and heat the dipping tank so that its vacuum degree reaches 0.09MPa and the temperature reaches 330°C.

[0070] (4) inject the pitch in the melting tank (330° C.) into the impregnation tank of step (3) at 50 MPa, and when the pitch liquid exceeds the height of the packaging bag in the dip tank, stop vacuuming and keep warm for 3 hours at 50 MPa;

[0071] (5) After step (4) heat preservation is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com