Gold plated ZnO nano-bar array electrode and method for making same

A nanorod array and nanorod technology, applied in the field of electrochemistry, can solve the problems of difficult electrochemical electrodes, dissolution and corrosion, and no conductivity, etc., and achieve high sensitivity, extended service life, and stable chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

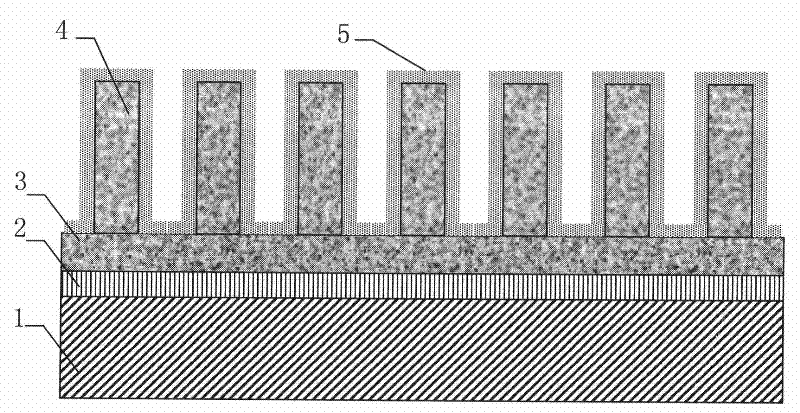

[0017] Such as figure 1 , 4 As shown, the structure of the gold-plated ZnO nanorod array electrode is a silicon substrate 1, a silicon dioxide dielectric layer 2, a ZnO seed layer 3 and a ZnO nanorod array layer from bottom to top. The silicon dioxide dielectric layer 2 is located on the silicon substrate 1 , the ZnO seed layer 3 is located on the silicon dioxide dielectric layer 2 , and the ZnO nanorod array layer is located on the ZnO seed layer 3 . A gold layer 5 with the same thickness is plated on the surface of each ZnO nanorod 4 and the surface of the ZnO seed layer 3 in the ZnO nanorod array layer, the thickness of which is 150 nm.

[0018] The preparation method of the gold-plated ZnO nanorod array electrode mainly includes two steps, firstly the preparation of the ZnO nanorod 4 array, and finally the gold plating of the ZnO nanorod 4 array. The specific process is as follows. In the first step of the preparation of the ZnO seed layer 3, a p-type or n-type single cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com