Microcrystal graphite used for negative electrode material of lithium battery, and preparation method of microcrystal graphite

A technology of microcrystalline graphite and negative electrode materials, which is applied in the direction of battery electrodes, secondary batteries, hybrid capacitor electrodes, etc., can solve the problems of poor electrical properties of natural microcrystalline graphite, reduce usage, increase specific surface area, and reduce ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing microcrystalline graphite for negative electrode materials of lithium batteries, comprising the following steps:

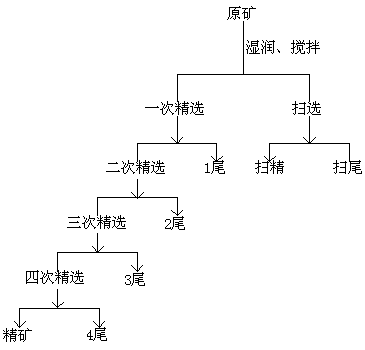

[0055] S1. Raw ore treatment: crush Lutang aphanitic graphite, and then conduct deep grinding on the microcrystalline graphite raw ore, and obtain materials with a fineness of -0.074mm through grinding, and increase the content of materials with a fineness of -0.074mm 90% of the raw ore samples are subjected to flotation, specifically as figure 1 As shown, a roughing process is adopted for four times of selection and one sweeping process, followed by drying and magnetic separation to obtain microcrystalline graphite with a fixed carbon content of 90%;

[0056] Wherein, the properties of Lutang aphanitic graphite described in step S1 are as follows: moisture 2.4%, volatile matter 2.99%, ash content 18.37%, carbon content 78.64%, specific surface area 12.8㎡ / g.

[0057] S2. acid leaching purification: the microc...

Embodiment 2

[0061] The implementation is basically the same as in Example 1, except that the process conditions are different in step S2, as follows:

[0062] S2. acid leaching purification: the microcrystalline graphite obtained in step S1 is mixed with a mixed acid, the mixed acid is a mixed acid of HF and HCL, the liquid-solid ratio of the mixed acid to graphite is 2ml / g, the volume content of HF is 30%, and that of HCL The volume content is 10%, and then carry out acid leaching under normal pressure under the conditions of temperature 60°C and reaction time 1h. The leaching residue is washed with distilled water or deionized water until the graphite precipitates when the washing solution is neutral, and then filtered. Dry at ~150°C for 2-3 hours to obtain purified microcrystalline graphite with a fixed carbon content of 99.12%.

Embodiment 3

[0064] The implementation is basically the same as in Example 1, except that the process conditions are different in step S2, as follows:

[0065] S2. acid leaching purification: the microcrystalline graphite obtained in step S1 is mixed with a mixed acid, the mixed acid is a mixed acid of HF and HCL, the liquid-solid ratio of the mixed acid to graphite is 3.5ml / g, the volume content of HF is 60%, and the HCL The volume content is 20%, and then carry out normal pressure acid leaching at a temperature of 80°C and a reaction time of 4 hours. The leaching residue is washed with distilled water or deionized water until the graphite precipitates when the washing solution is neutral, and then filtered, and heated at a temperature of Dry at 80-150° C. for 2-3 hours to obtain purified microcrystalline graphite with a fixed carbon content of 99.56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com