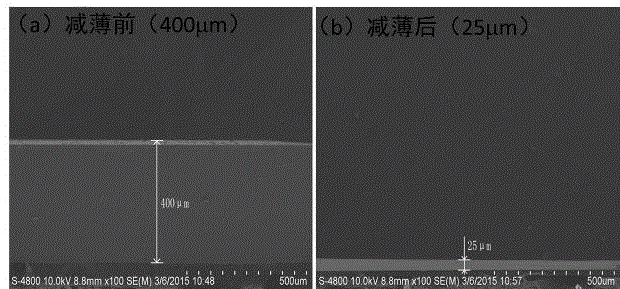

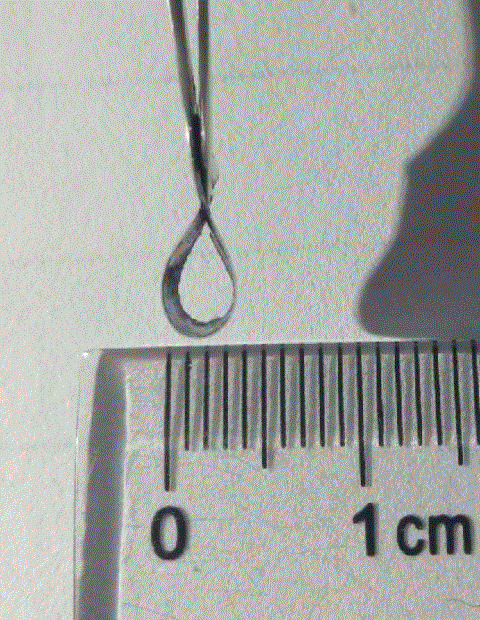

Wet chemical etching method for preparing large-area and flexible ultra-thin monocrystalline silicon wafers

A single crystal silicon wafer, wet chemical technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high equipment requirements, easy cracking and damage, brittleness and instability, and achieve high quality and size of finished products. Unlimited, thickness-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Use N (100) double-sided polished single-crystal silicon wafers with a resistivity of 1~5W?cm, and ultrasonically clean them in acetone, absolute ethanol, and deionized water for 5 minutes each; rinse with deionized water after each ultrasonic wave 2 minutes; then soak in hydrofluoric acid with a mass percentage concentration of 5% for 5 minutes at room temperature; rinse with deionized water with a resistivity above 18W?cm for 2 minutes, and vacuum dry;

[0024] 2. Use solid potassium hydroxide, isopropanol and deionized water with a resistivity above 18W?cm to prepare a mixed solution (hereinafter referred to as thinning solution) with the following concentration characteristics: the mass percentage concentration of potassium hydroxide is 45% , the mass percentage concentration of isopropanol is 12%; stir on a magnetic stirrer for 10-20 minutes to promote the full dissolution of potassium hydroxide and make the solution evenly mixed; then put it into a water bath at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com