Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

752results about How to "Unlimited size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Messaging service in a wireless communications network

ActiveUS20110039584A1Increase speedUnlimited sizeInformation formatNetwork topologiesComputer hardwareMobile device

This invention concerns a messaging service in a wireless communications network. In a first aspect, the invention is a method for providing a messaging service on a wireless device in a wireless communications network; the method comprising the steps of: Retrieving the destination address of an outgoing message on the device. Verifying whether the destination address is capable of receiving the message via a packet-switched bearer. If verification is affirmative, then automatically sending the message to the destination address via a packet-switched bearer, but otherwise, automatically sending the message to the destination address via an SMS bearer. In another aspect, the invention is a mobile device programmed to perform the method. In a further aspect, the invention is a software program to implement the method.

Owner:REMBRANDT MESSAGING TECH II LP

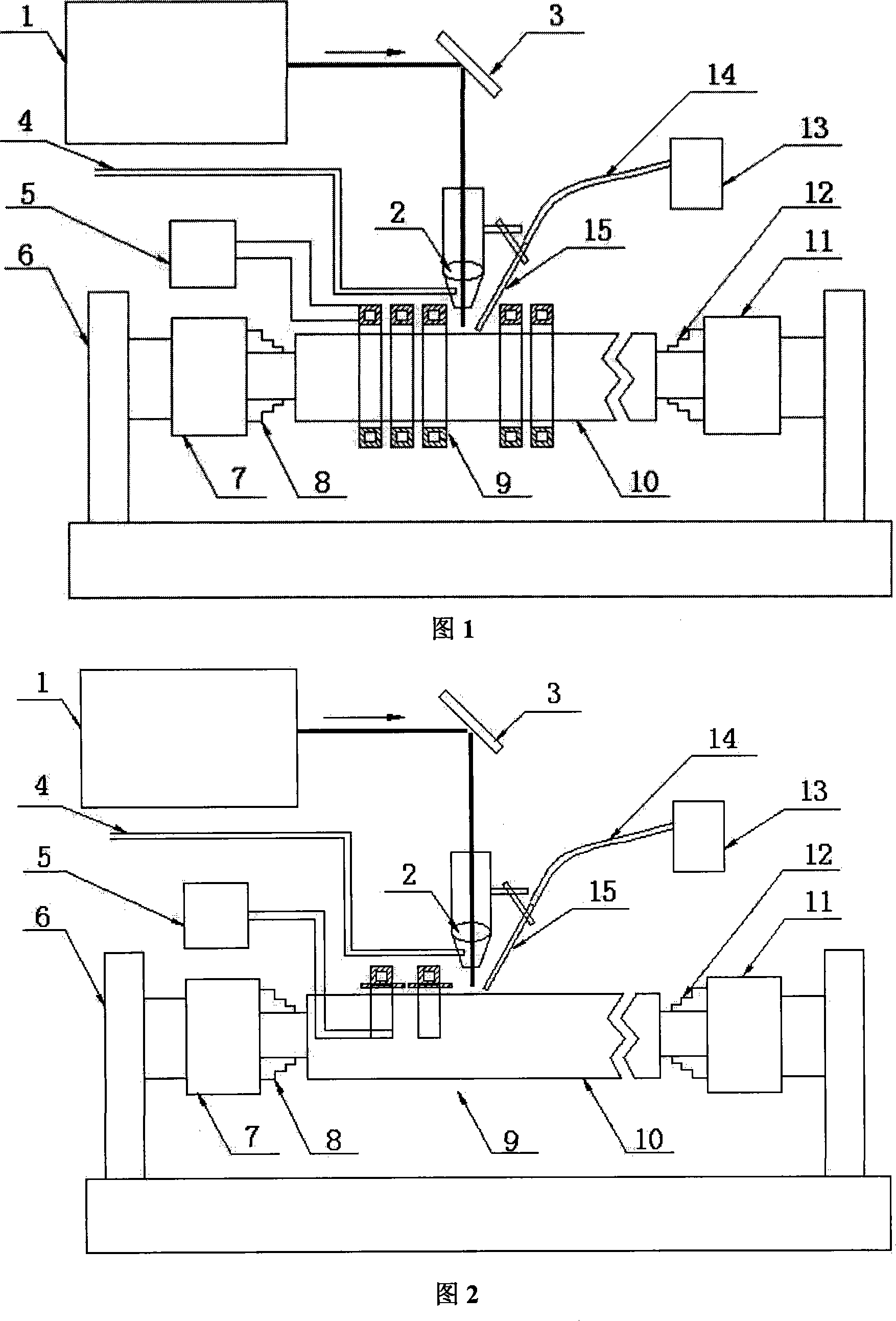

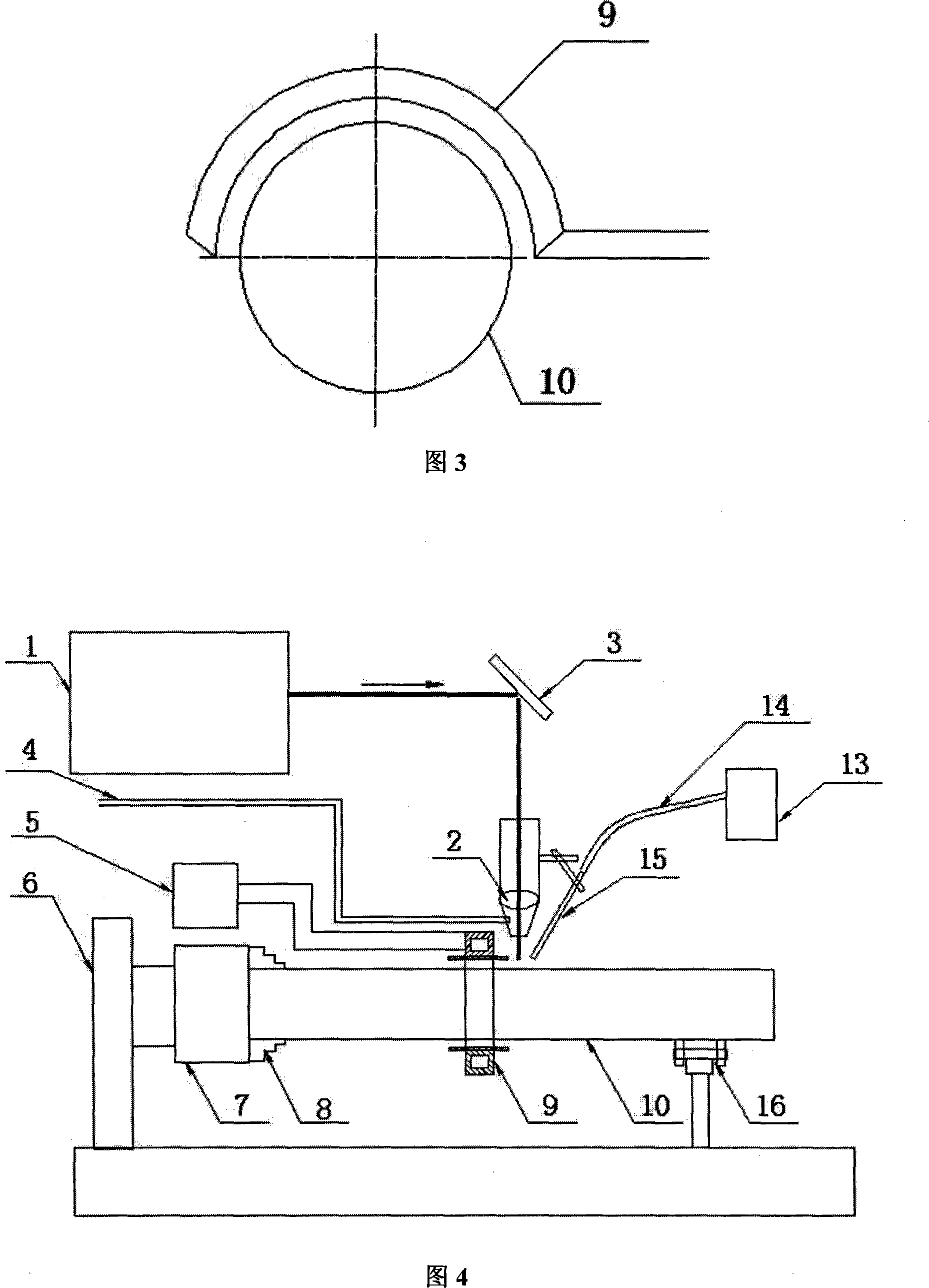

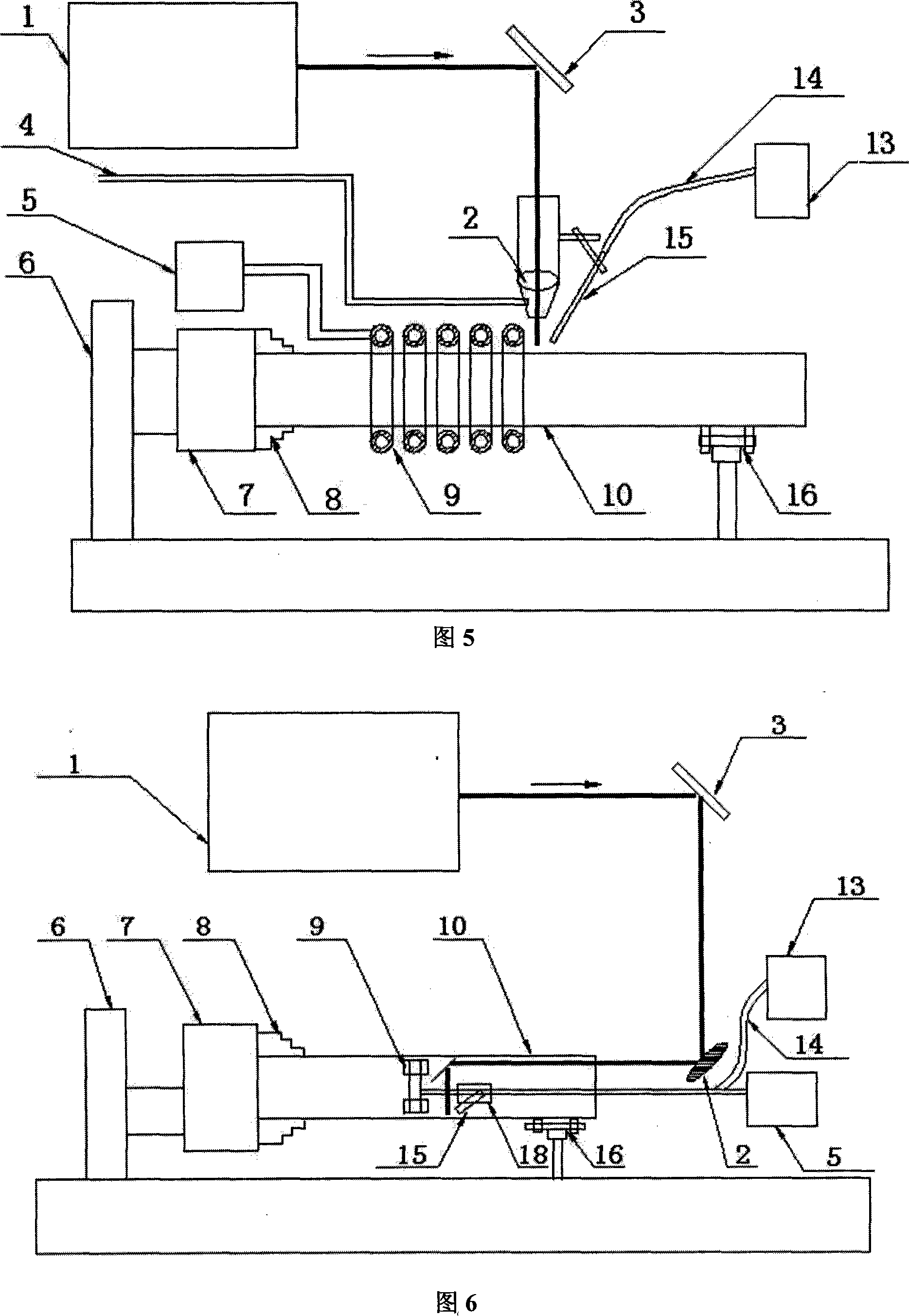

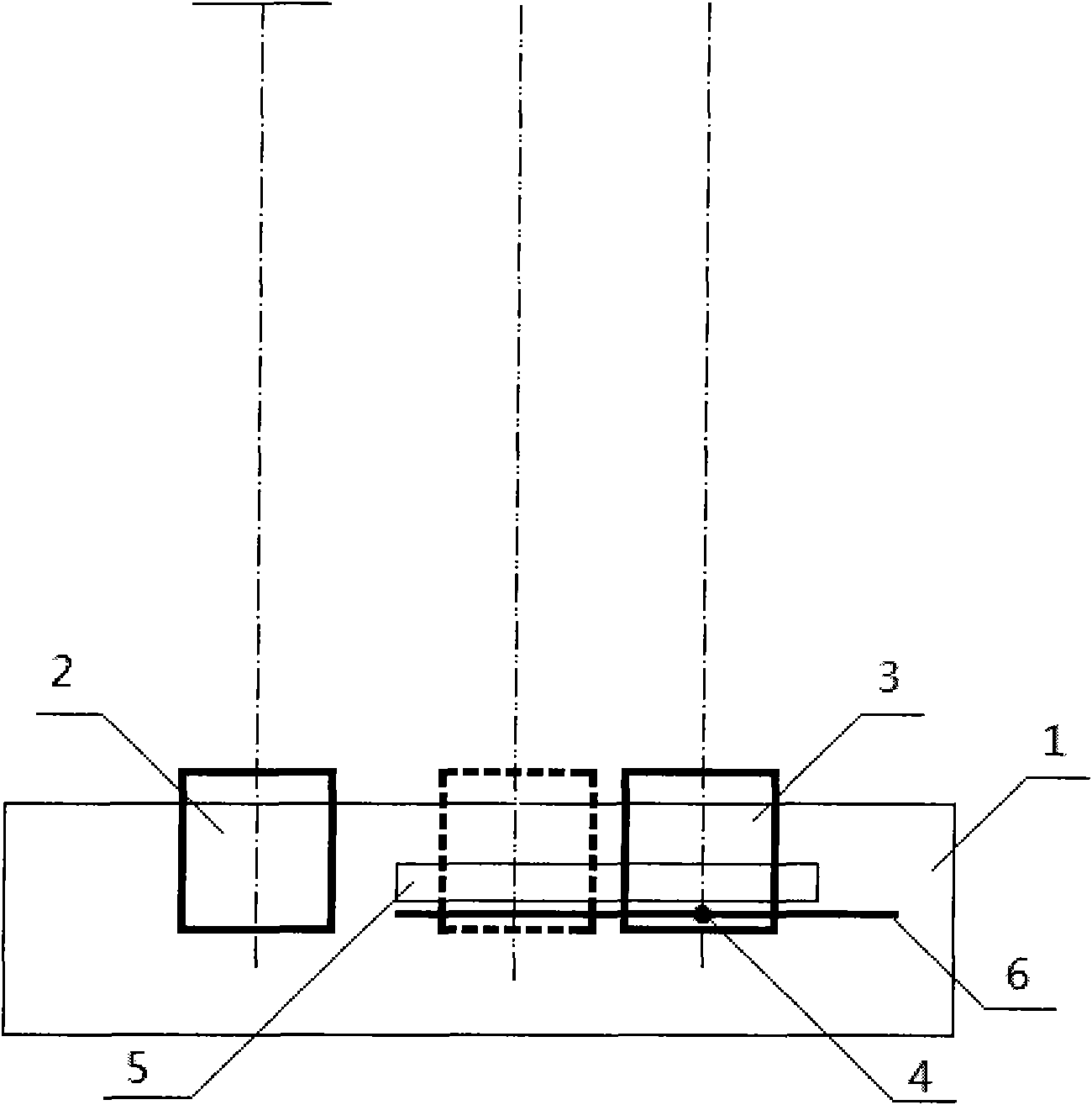

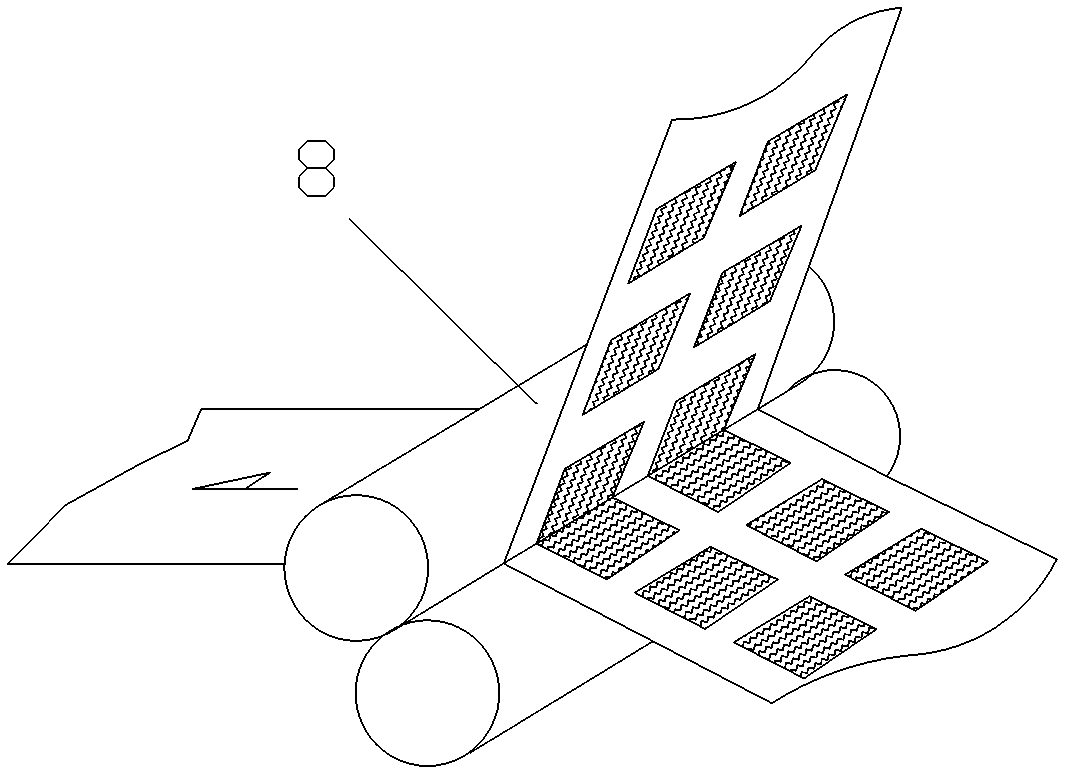

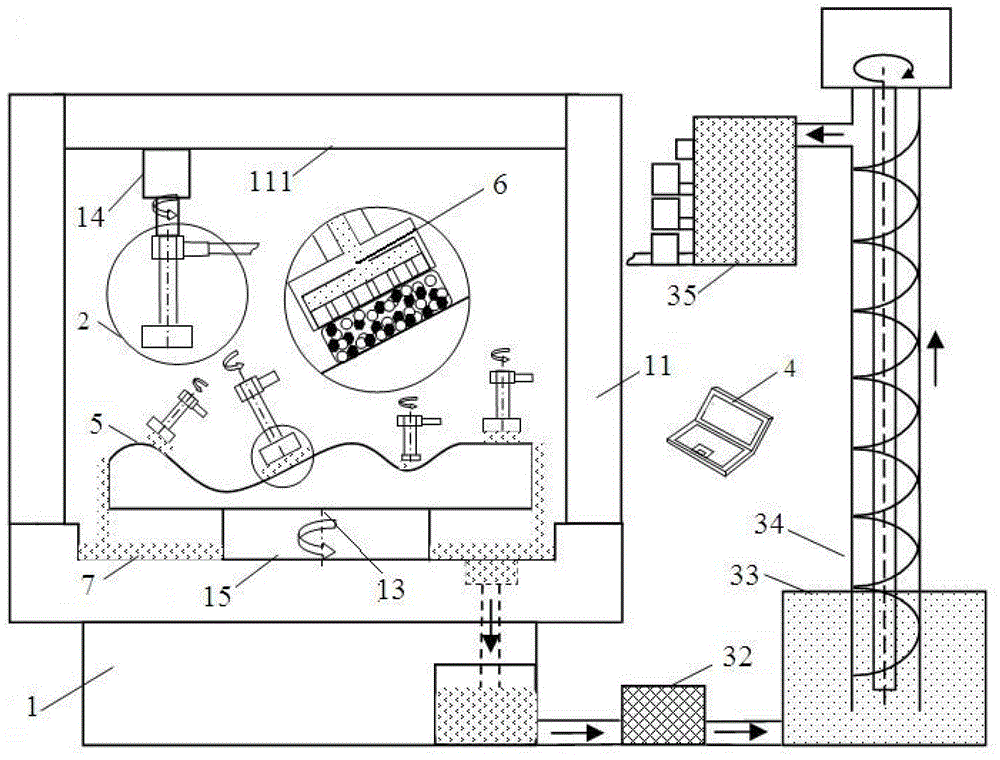

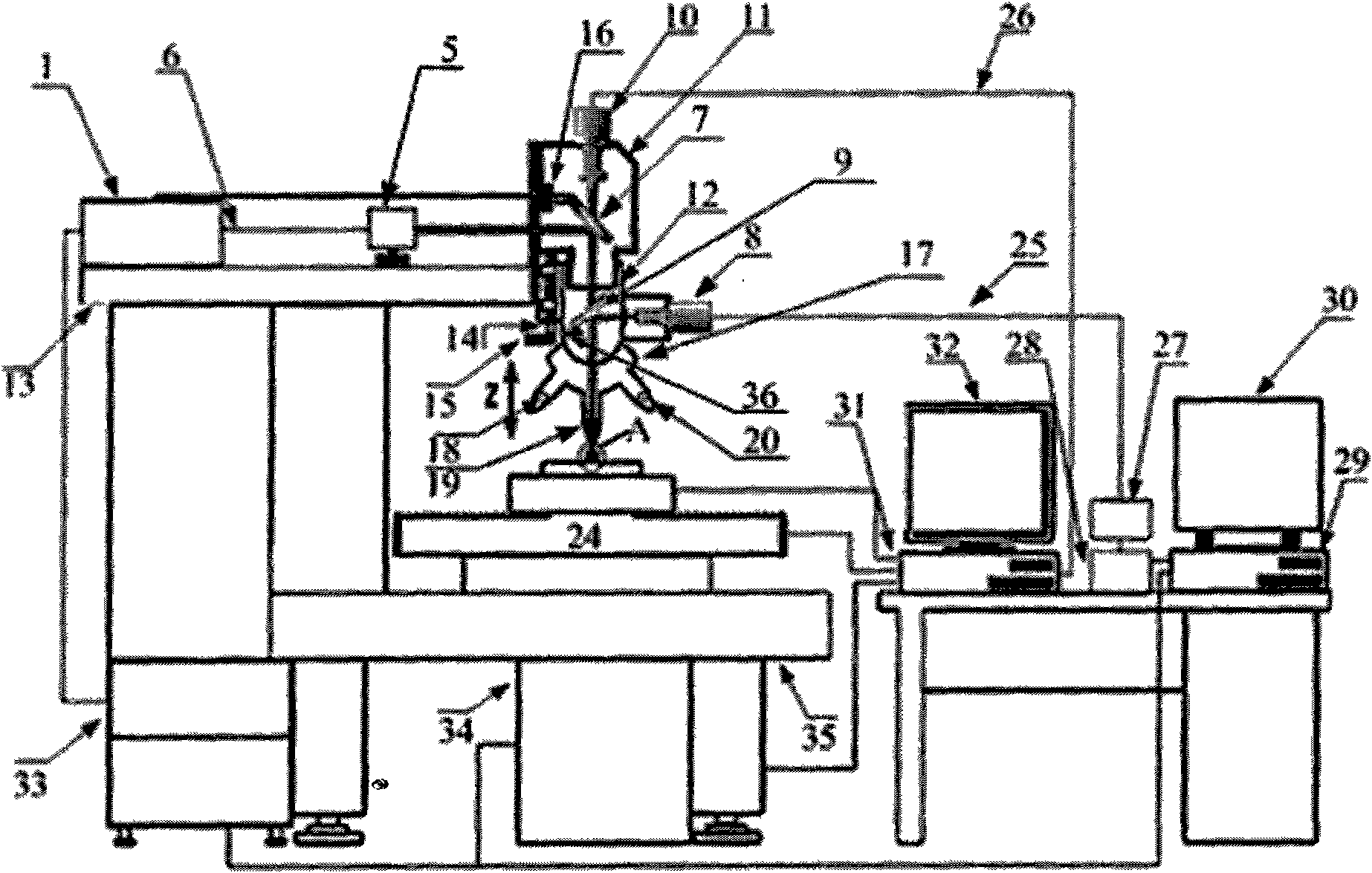

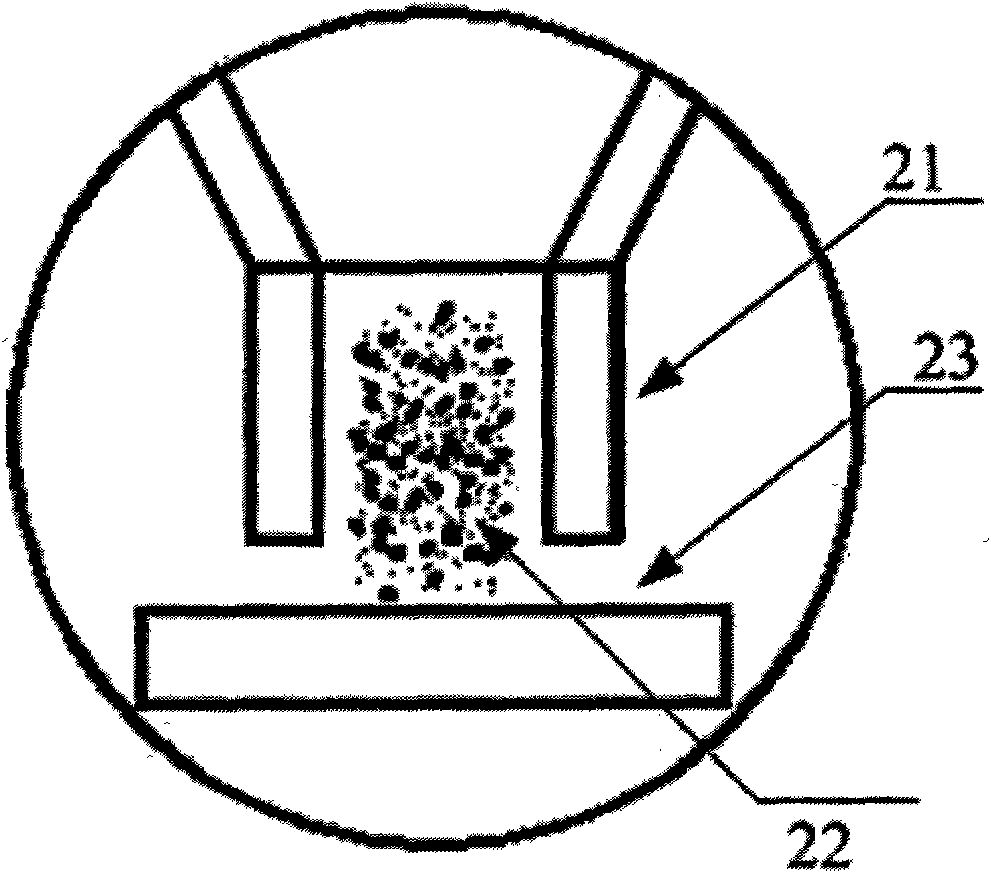

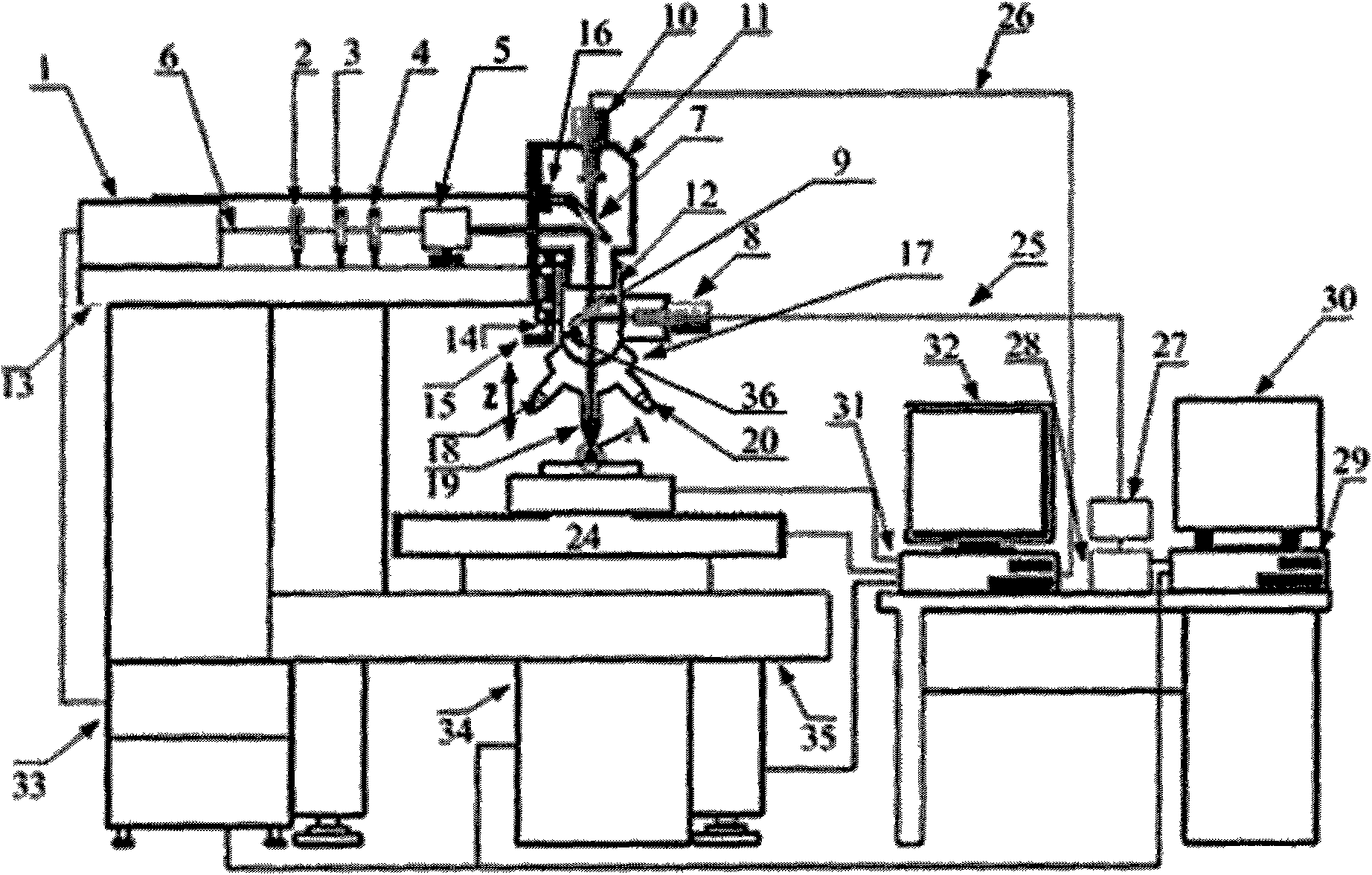

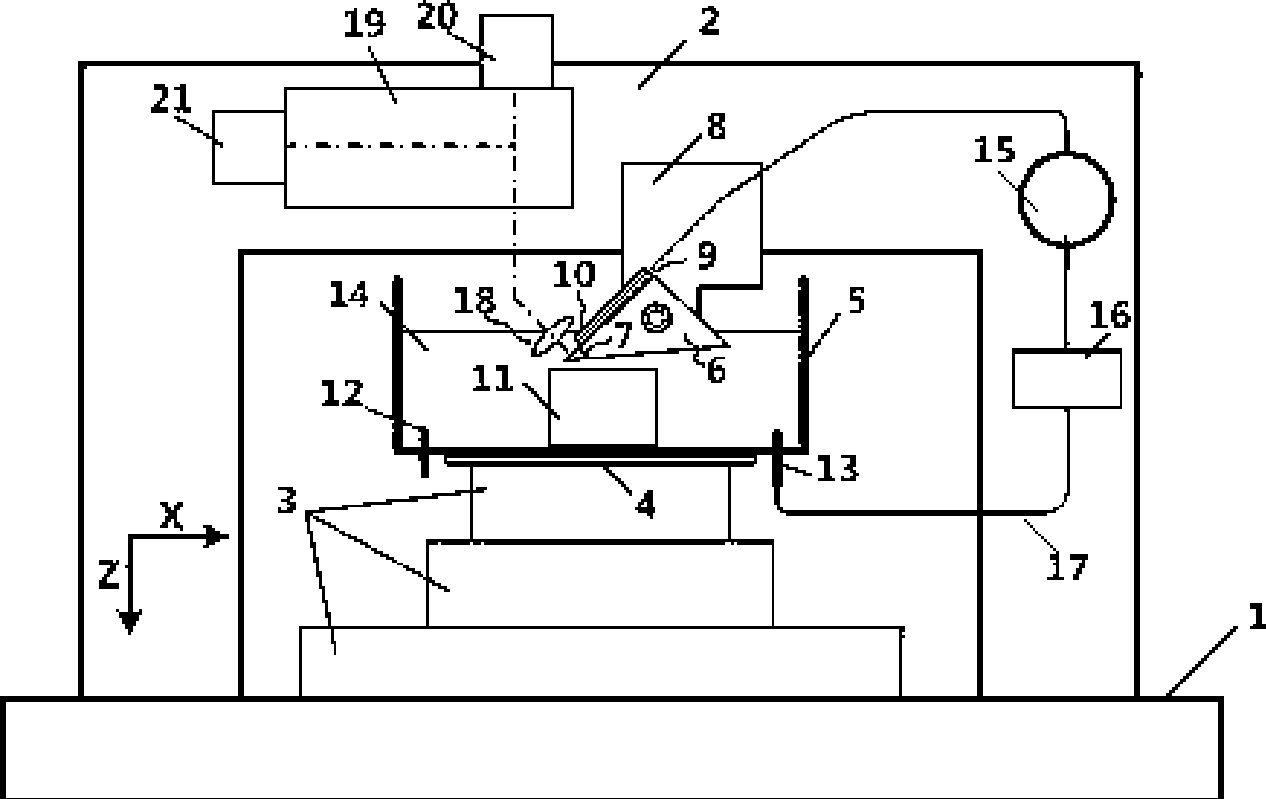

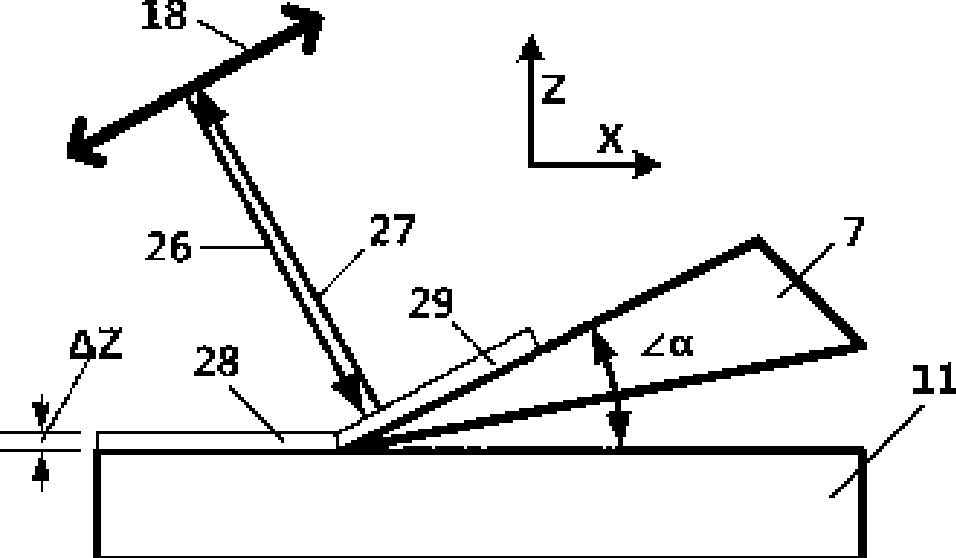

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

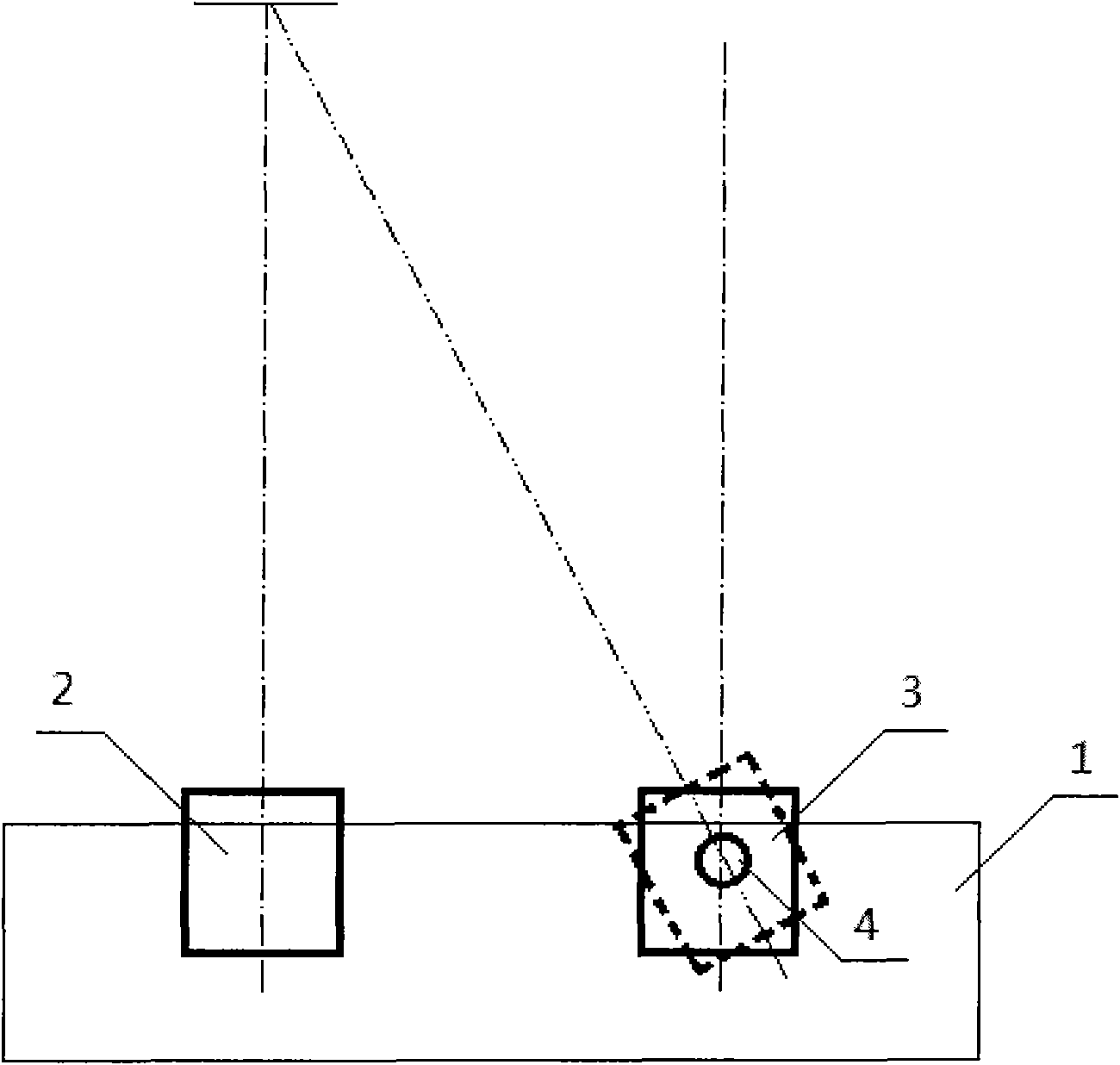

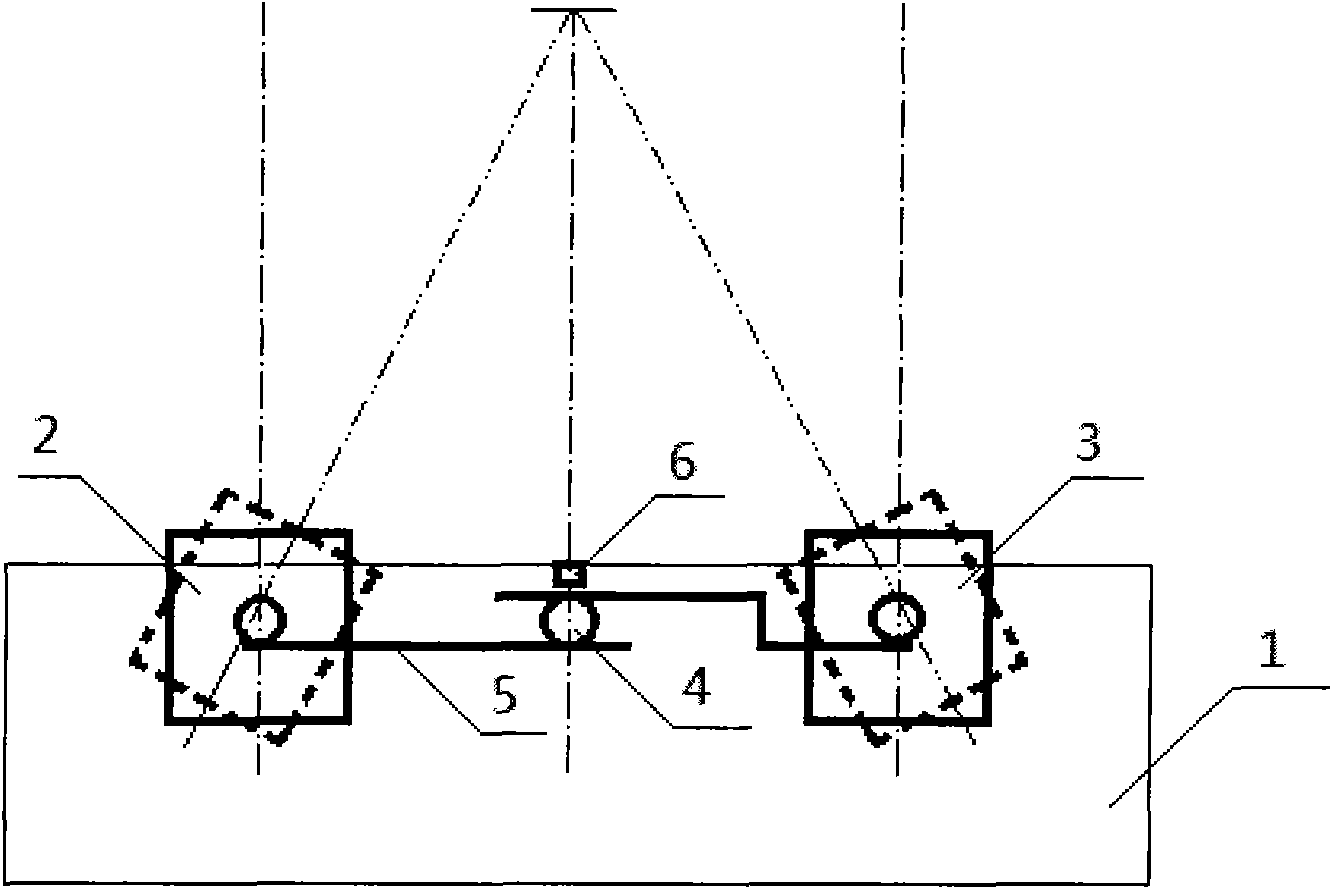

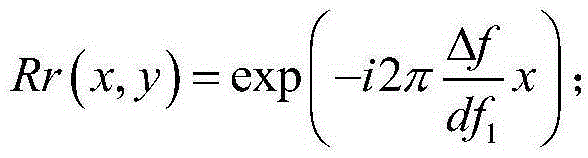

Method and device for shooting stereo images by automatically correcting parallax error

InactiveCN101840146AParallax guaranteeEliminate discomfortTelevision system detailsColor television detailsCamera lensStereo cameras

The invention relates to a method and a device for shooting stereo images by automatically correcting a parallax error. The method comprises the following steps of: acquiring scenery distance information; calculating parallax error correcting data; automatically adjusting space or an angle of a camera lens; completing automatic focus and shooting; and synthesizing the stereo images. The method and the device make shooting equipment shoot high-quality stereo images in various situations by automatically correcting the parallax error during shooting, and avoid the defects that unreasonable parallax errors exist in the shot stereo images because of over short scenery distance or overlarge lens focus of the conventional stereo image shooting technology so as to generate feelings of dizziness and eye discomfort. The invention particularly provides the following three kinds of schemes for correcting the parallax error: automatically adjusting space, automatically adjusting angle by using single lenses, and automatically adjusting the angle by using double lenses. The device for implementing the scheme can be arranged in stereo shooting mobile phones, stereo cameras and stereo video cameras to shoot the stereo images by automatically correcting the parallax error.

Owner:夏佳梁

Method and device for monitoring memory

InactiveCN101561775ARealize real-time accurate monitoringUnlimited sizeMemory adressing/allocation/relocationHardware monitoringData operationsMassage

The invention discloses a method and a device for monitoring a memory. The memory monitoring method comprises the following steps: setting memory management unit access protection for the memory needing to be monitored, recording a memory allocating massage by aiming at the application and release operations of a program packet to the memory, and triggering an abnormity processing operation based on the memory management unit access protection when the program packet executes data reading or writing operation to the memory; acquiring a reading or writing data destination address, and judging whether the memory access operation of the reading or writing data exceeds the limit according to the destination address and the memory allocating message, if so, recording a site message of the memory access operation exceeding the limit, and permitting the program packet to continuously carry out the following flow according to a contained program code; otherwise, permitting the program packet to continuously carry out the following flow according to the contained program code. The technical proposal can monitor the site message that the memory reading and writing data exceeds the limit in real time and achieve real-time monitoring of the memory; and the size of a monitored storage area is not restricted.

Owner:HUAWEI TECH CO LTD

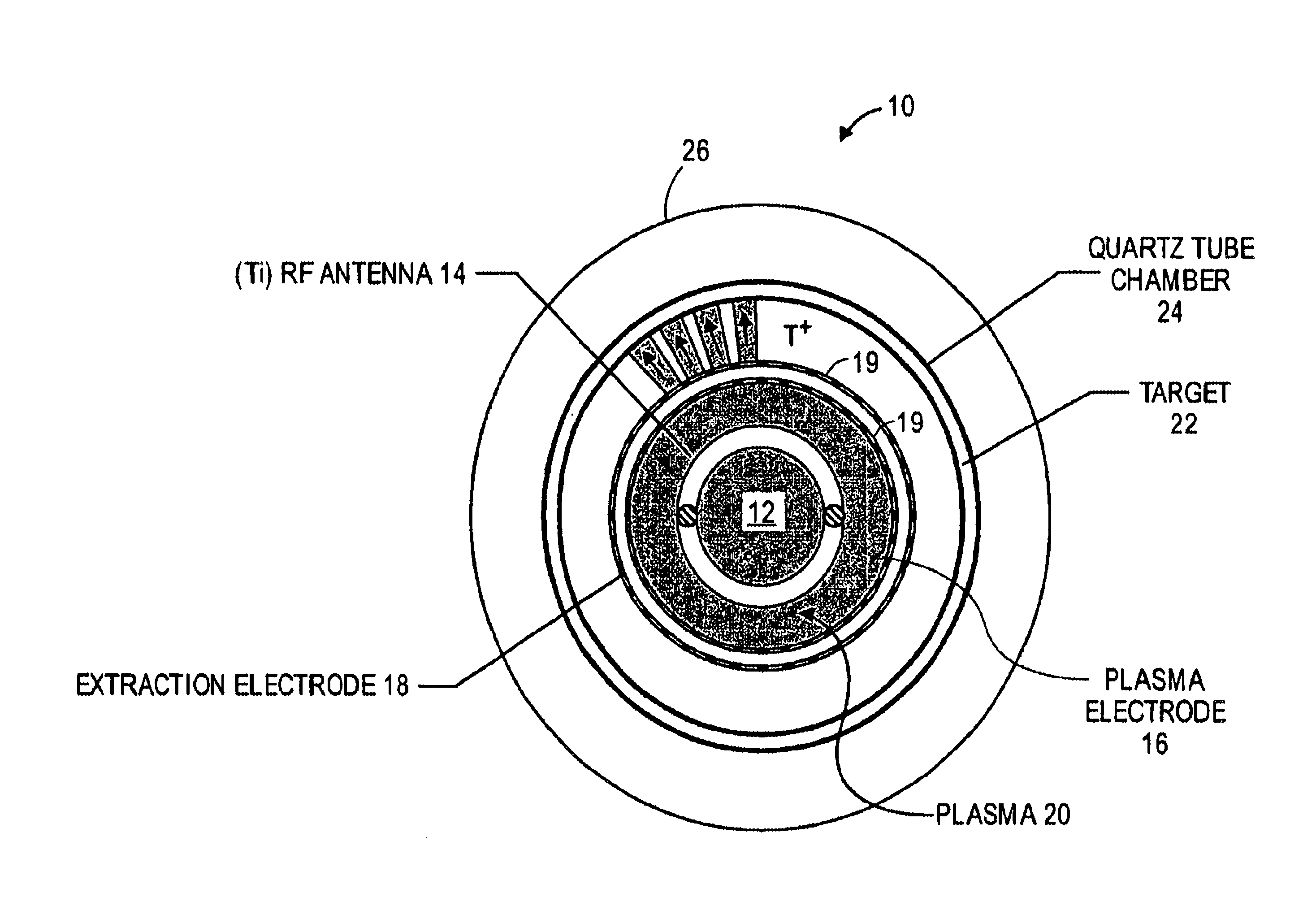

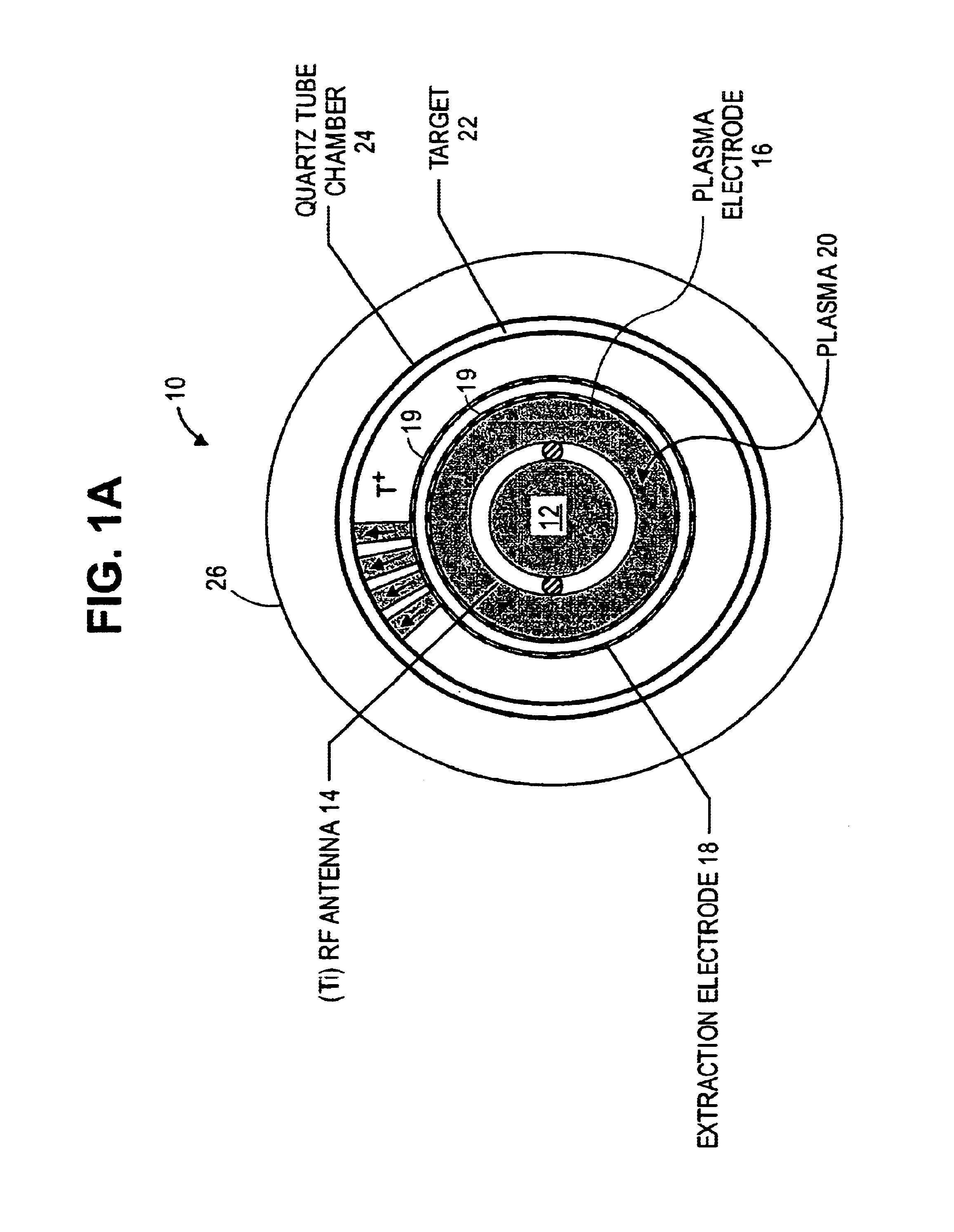

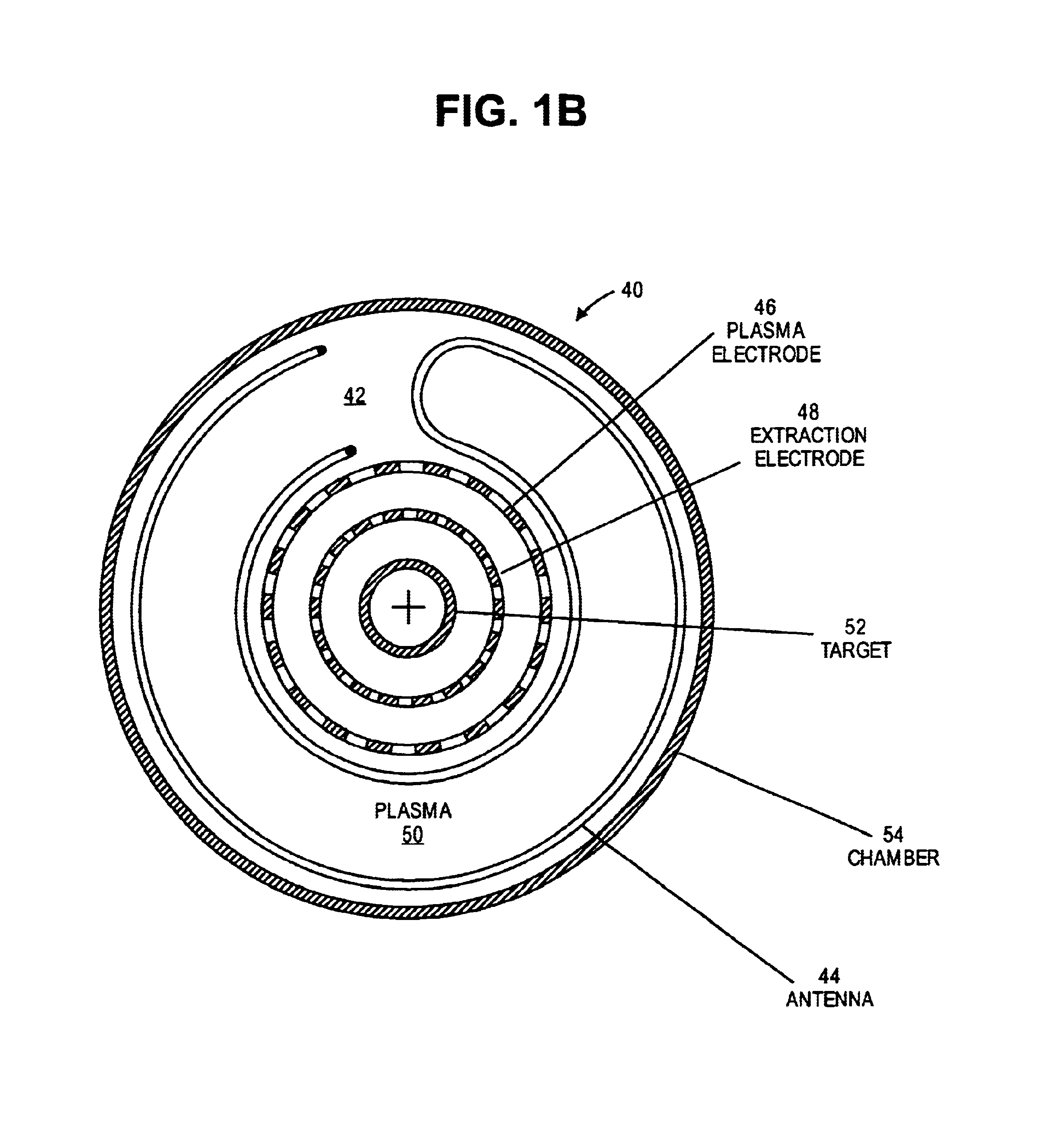

Cylindrical neutron generator

InactiveUS6907097B2Increase neutron fluxHigh densityConversion outside reactor/acceleratorsNuclear energy generationPlasma generatorNeutron flux

A cylindrical neutron generator is formed with a coaxial RF-driven plasma ion source and target. A deuterium (or deuterium and tritium) plasma is produced by RF excitation in a cylindrical plasma ion generator using an RF antenna. A cylindrical neutron generating target is coaxial with the ion generator, separated by plasma and extraction electrodes which contain many slots. The plasma generator emanates ions radially over 360° and the cylindrical target is thus irradiated by ions over its entire circumference. The plasma generator and target may be as long as desired. The plasma generator may be in the center and the neutron target on the outside, or the plasma generator may be on the outside and the target on the inside. In a nested configuration, several concentric targets and plasma generating regions are nested to increase the neutron flux.

Owner:RGT UNIV OF CALIFORNIA

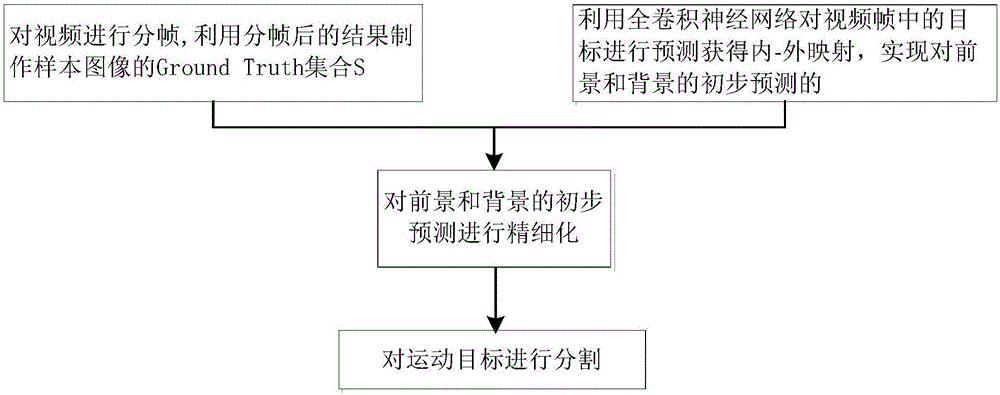

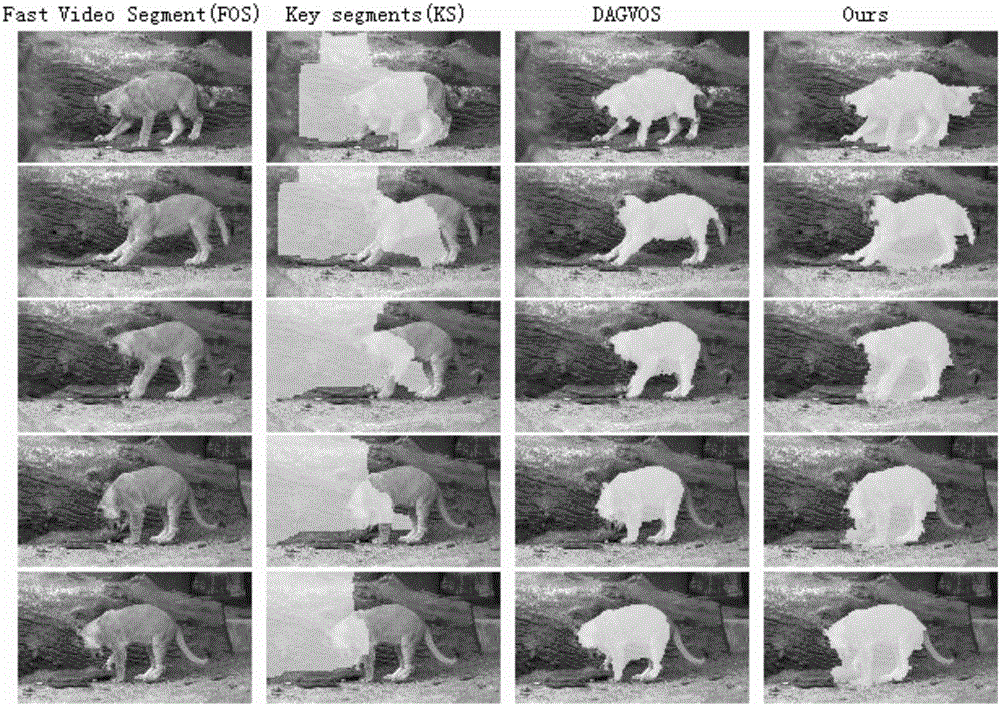

Method of quickly segmenting moving target in non-restrictive scene based on full convolution network

ActiveCN106296728AOvercoming the disadvantages of incomplete target segmentationUnlimited sizeImage enhancementImage analysisGround truthSample image

The invention relates to a method of quickly segmenting a moving target in a non-restrictive scene based on a full convolution network, which belongs to the technical field of video object segmentation. The method comprises steps: firstly, framing is carried out on the video, and a result after framing is used for making a Ground Truth set S for a sample image; a full convolution neural network trained through a PASCAL VOC standard library is adopted to predict a target in each frame of the video, a deep feature estimator for an image foreground target is acquired, target maximum intra-class likelihood mapping information in all frames is obtained hereby, and initial prediction on the foreground and the background in the video frames is realized; and then, through a Markov random field, deep feature estimators for the foreground and the background are refined, and thus, segmentation on the video foreground moving target in the non-restrictive scene video can be realized. The information of the moving target can be effectively acquired, high-efficiency and accurate segmentation on the moving target can be realized, and the analysis precision of the video foreground-background information is improved.

Owner:KUNMING UNIV OF SCI & TECH

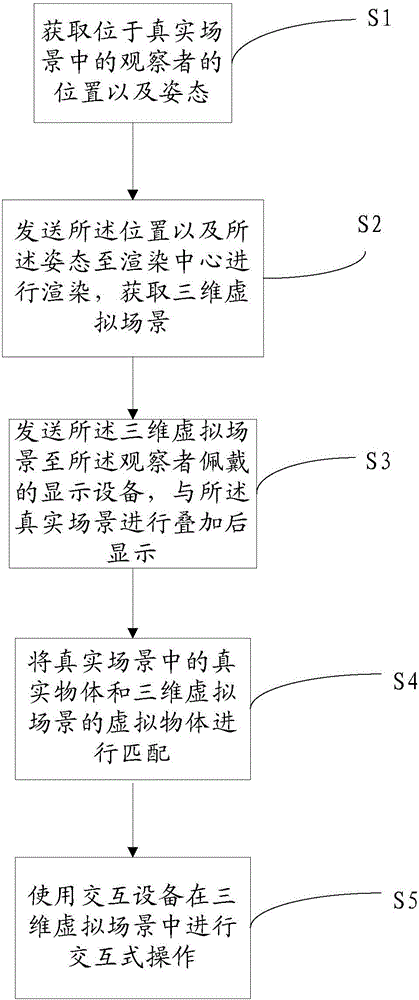

AR implementation method and system based on positioning of visual angle of observer

InactiveCN106710002ARealize Fusion DisplayUnlimited sizeImage data processingDigital output to display deviceSimulationObserver based

The invention relates to an AR implementation method and system based on the positioning of a visual angle of an observer, and the method comprises the steps: obtaining the position and posture of the observer located in a real scene, and giving the position and posture to a virtual camera; transmitting and the position and posture to a rendering center for rendering, and obtaining a three-dimensional virtual scene; transmitting the three-dimensional virtual scene to display equipment worn by the observer, carrying out the superposing of the three-dimensional virtual scene and the real scene, and displaying the superposed scene; and carrying out the matching of a real object in the real scene and a virtual object in the three-dimensional virtual scene. The method achieves the fusion and display of the real world and a virtual world, employs the rendering center in a server for rendering, enables the rendering process to be integrated in the server, achieves no constraint on the size of the real scene and the complexity, is strong in rendering capability, is high in applicability, and is wide in application range.

Owner:SHENZHEN DLP DIGITAL TECH

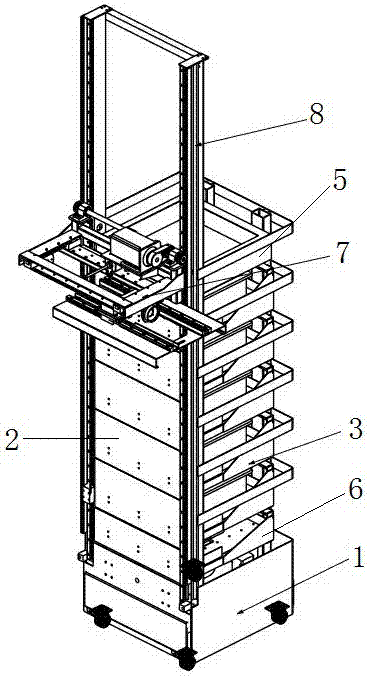

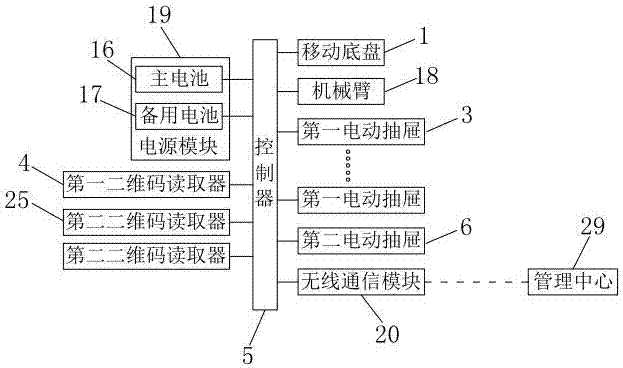

Intelligent warehousing robot, system, control method and charge method

ActiveCN106927179AUnlimited sizeImprove the efficiency of picking goodsIndicating/monitoring circuitsCharging managementElectricityComputer module

The invention discloses an intelligent warehousing robot, a system, a control method and a charge method. The intelligent warehousing robot comprises a robot body, and a control device and a mechanical arm arranged on the robot body; the robot body comprises a mobile chassis, and a robot shelf arranged on the mobile chassis; the robot shelf is provided with multiple first electric drawers; a first two-dimensional code reader is arranged at the bottom of the mobile chassis; the control device comprises a controller, a power supply module and a wireless communication module; and the controller is electrically connected with the mobile chassis, the mechanical arm, the first electric drawers, the first two-dimensional code reader, the power supply module and the wireless communication module. The intelligent warehousing robot has no need to carry the whole shelf during goods taking and placing, is lower in cost, is free of limiting the size of the shelf, and improves the efficiency of staff picking goods.

Owner:喻祥祥

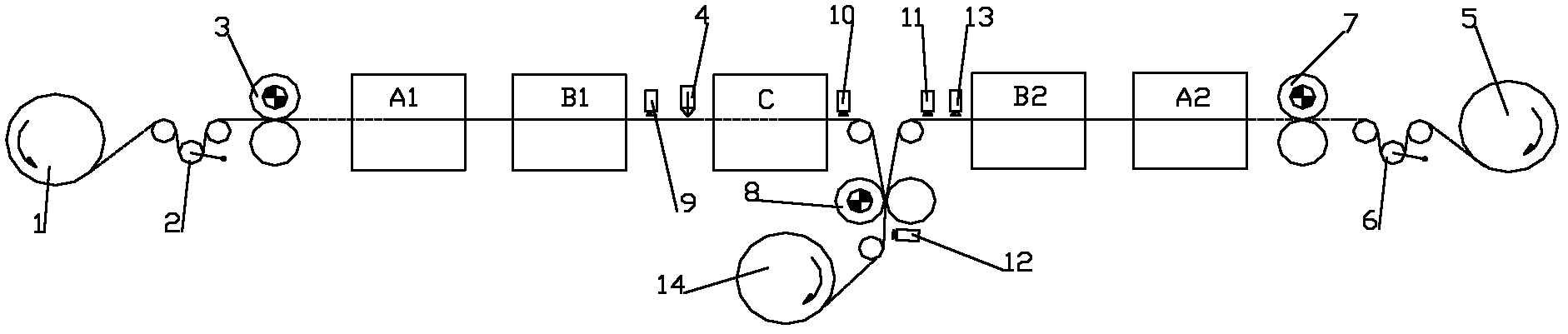

Method for manufacturing flexible touch screen and equipment for manufacturing touch electrode coil

ActiveCN102662522AEasy to processLow costInput/output processes for data processingLithography processEngineering

The invention provides a method for manufacturing a flexible touch screen and equipment for manufacturing a touch electrode coil for the flexible touch screen. A transparent conductive electrode pattern and an electrode lead of the touch screen are directly printed on the surface of a transparent insulated plastic substrate in a coil-to-coil manner. Compared with a traditional lithography process and dry-wet method etching manufacturing process for the touch screen, the method disclosed by the invention has the advantages that processing procedures of the touch screen are greatly simplified, the cost is reduced and the yield is increased; and in addition, the bottleneck that the processing size is limited is overcome and the flexible touch screen with large size can be manufactured, so that the touch screen can be applied to and popularized in the novel fields in a wide range.

Owner:姜洪波

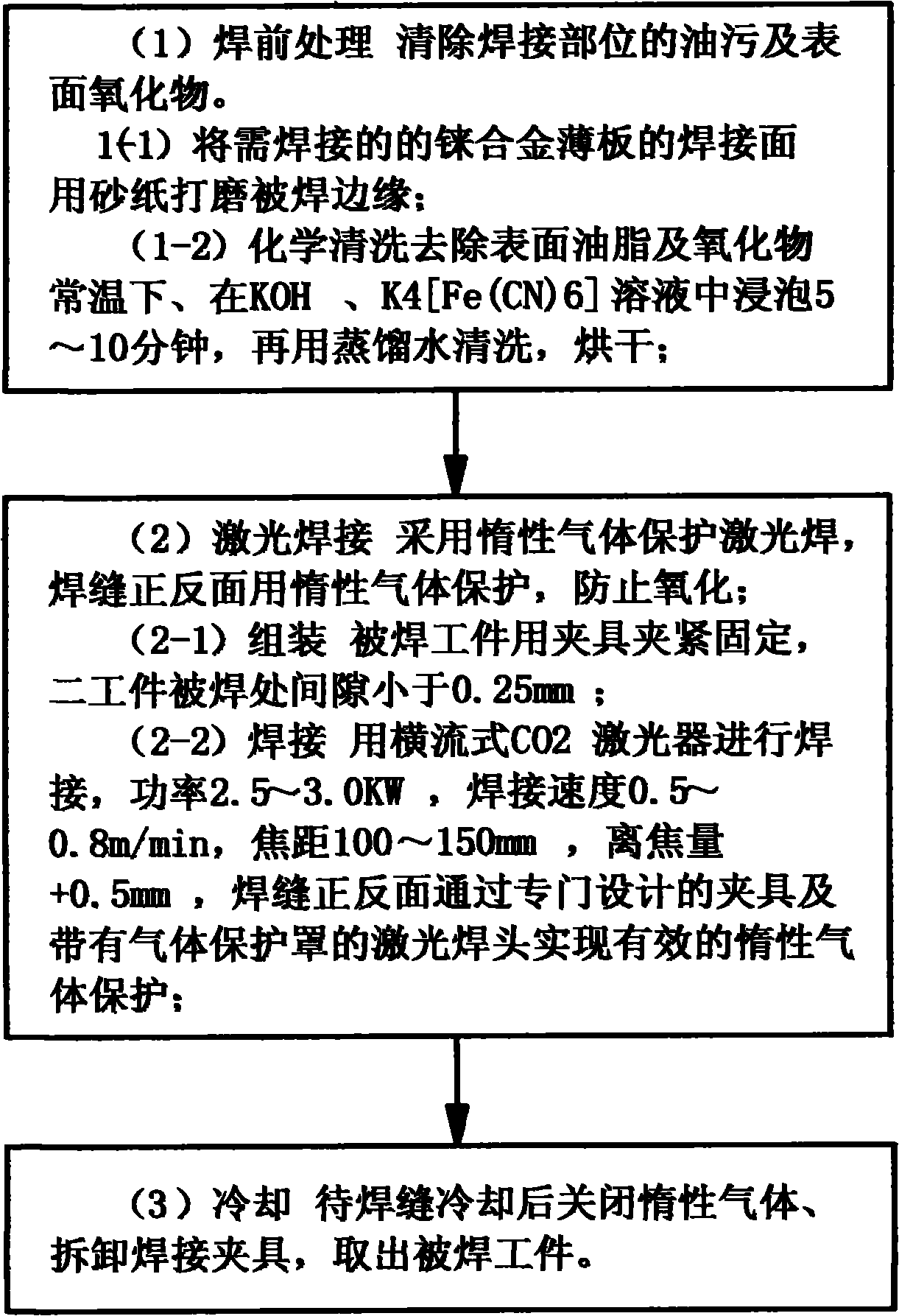

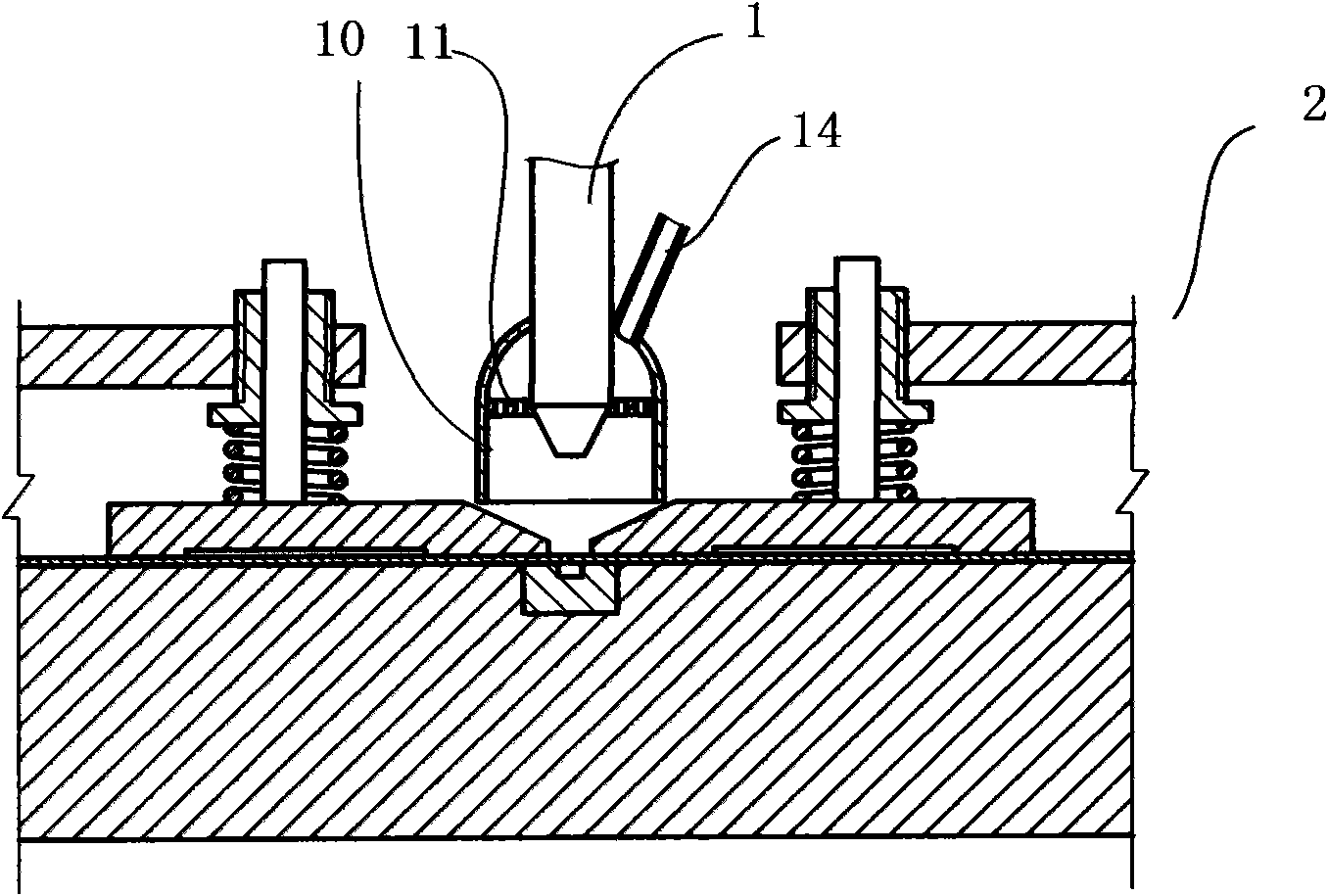

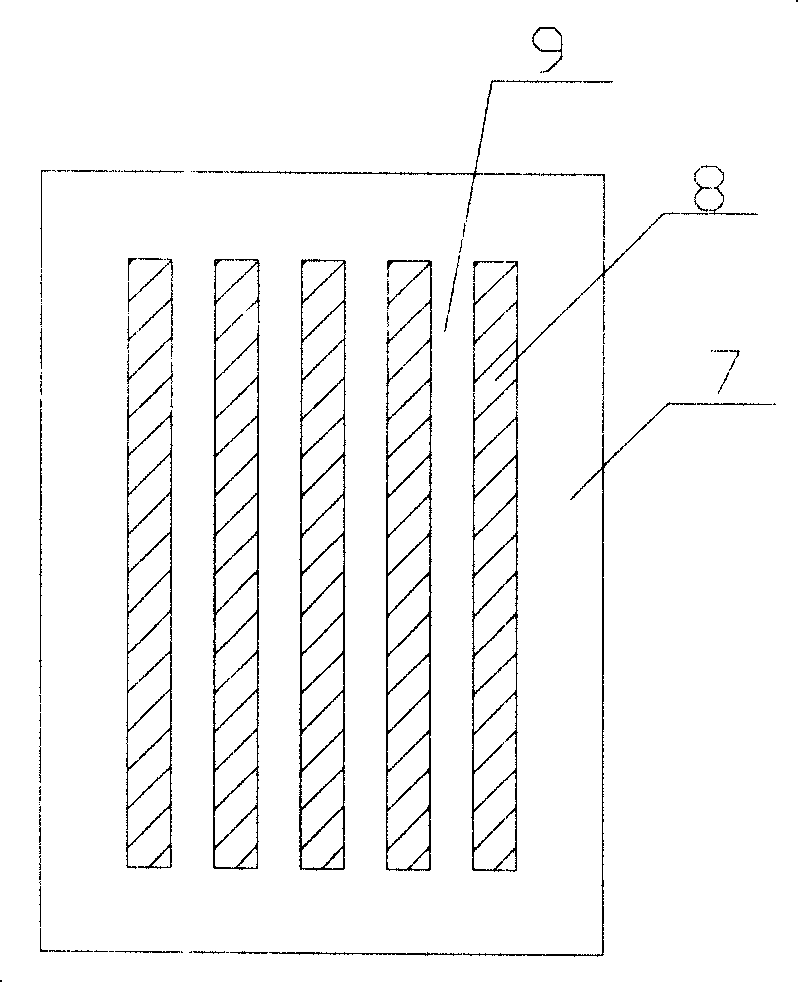

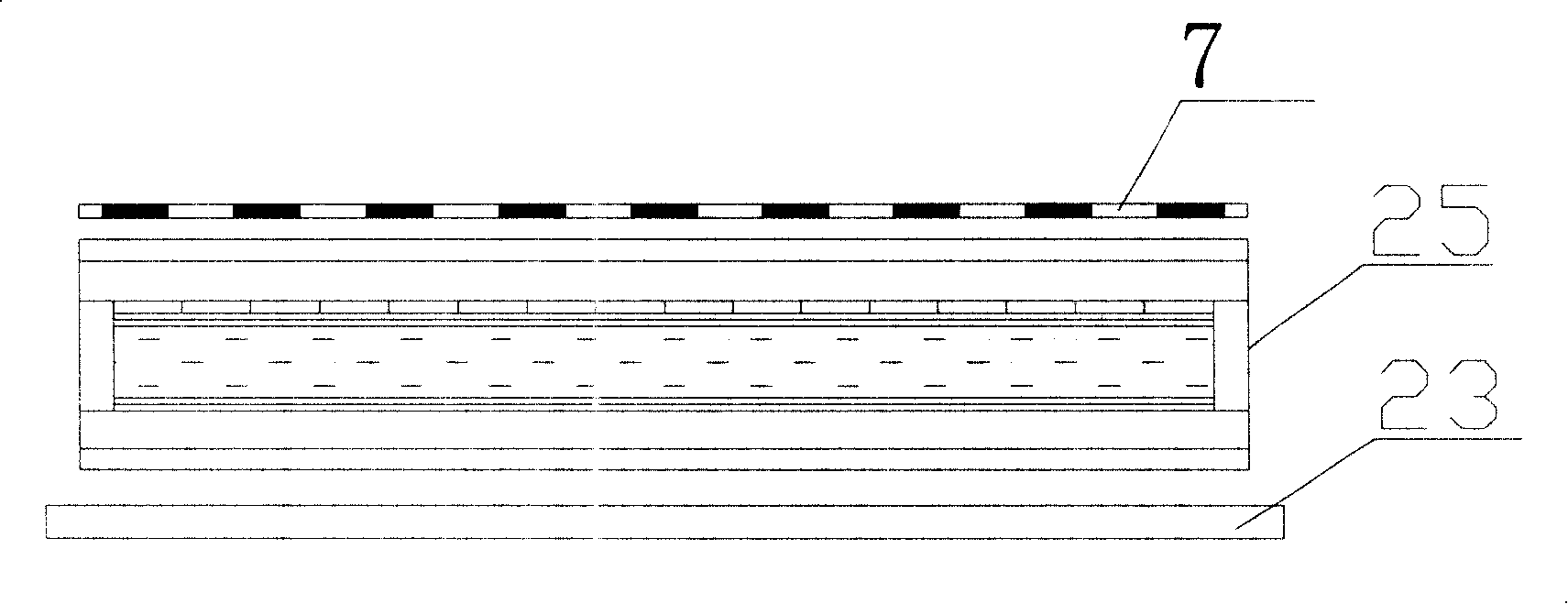

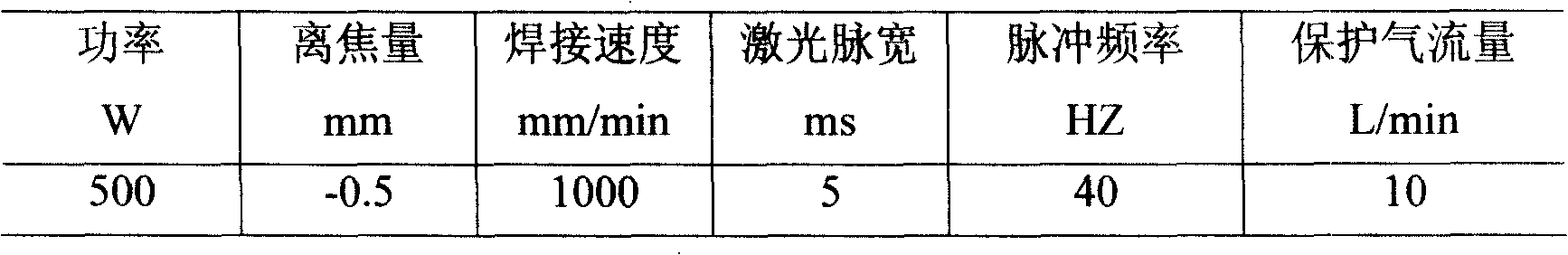

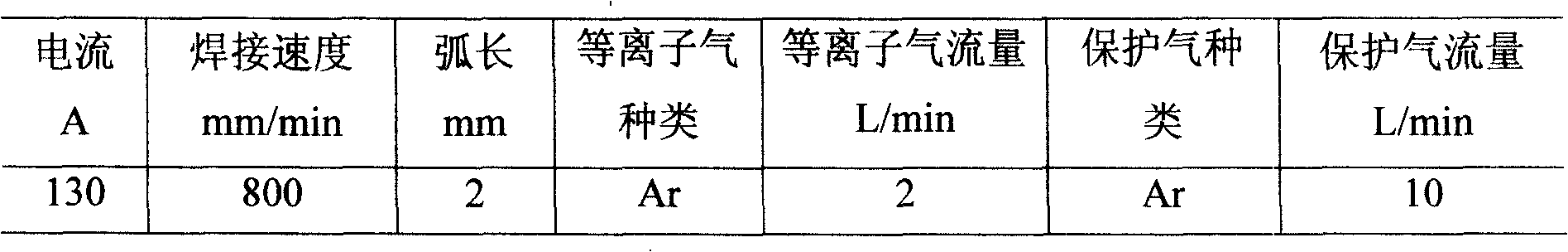

Laser welding method of rhenium alloy thin sheet

ActiveCN101817119APrevent oxidationSimple and efficient operationWelding/soldering/cutting articlesMetal working apparatusWeld seamSurface oxide

The invention relates to a special metal welding method, in particular to a laser welding method of a rhenium alloy thin sheet, which comprises the following steps: (1) treatment before welding: cleaning oil stains and surface oxides at the welding part; (2) laser welding: adopting inert gas for protecting laser welding, using the inert gas for protecting the front surfaces and the back surfaces of weld seams and further preventing oxidation; and (3) cooling: closing the inert gas after cooling the weld seams, detaching a welding clamp and taking out a welded workpiece. Compared with the vacuum electron beam welding, the volume of the welded workpiece is not limited, and the operation is simple, thereby being applicable to the rhenium alloy thin sheet with the sheet thickness of 0.5-4mm, optimizing the welding parameters, realizing the one-sided welding with back formation of the rhenium alloy thin sheet, eliminating the welding defects of air holes and the like and leading the weld seam quality to achieve the I-level weld seam standard.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Material and method for preparing aluminum alloy structural member by using laser 3D (Three-Dimensional) printing technology

InactiveCN104759625AImprove performanceIncrease profitAdditive manufacturing apparatusComputer Aided DesignMaterial synthesis

The invention discloses a material and method for preparing an aluminum alloy structural member by using a laser 3D (Three-Dimensional) printing technology. Technologies such as a CAD (Computer Aided Design) three-dimensional entity model slicing technology, a digital programming technology and a laser quick forming technology and a material synthesis technology are combined integrally; under the condition that no any special mold or tool is used, multi-layer cladding accumulation is performed through quick melting and solidification of a laser beam on an aluminum alloy substrate by taking the powder of Al, Fe, Cu, Si, Ti, B, Mn, C and Ce according to the mass percentage of 80.0, 3.0, 2.0, 3.0, 4.0, 3.0, 1.5, 2.0 and 1.5 as a raw material; an aluminum alloy structural member with good comprehensive performance such as high performance, full compactness and high fatigue life is directly finished from a part digital model in one step. The method has the characteristics of low cost, short period and high material utilization rate, and is suitable for integrated quick forming manufacturing of large-sized and complex aluminum alloy structural members; the shapes and the sizes of the prepared parts are not limited, and the requirement on structural integration can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Machining device based on non-Newtonian fluid shear thickening mechanism polishing method

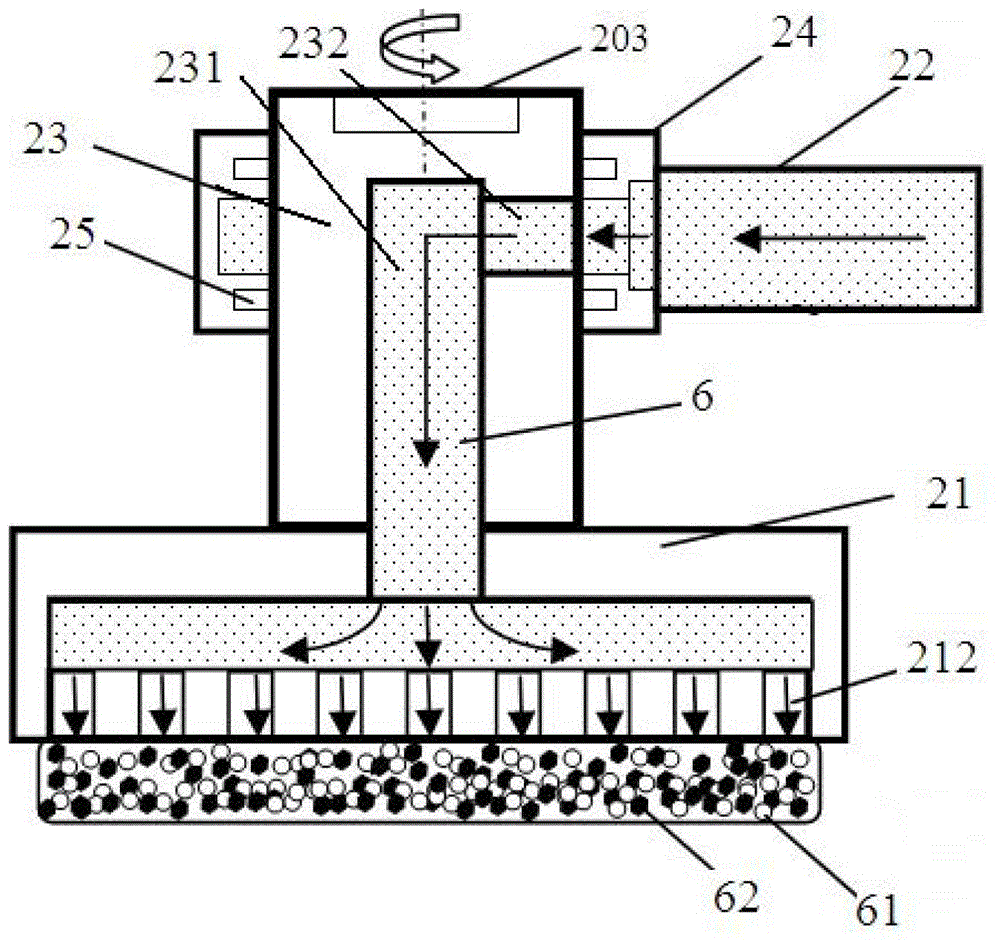

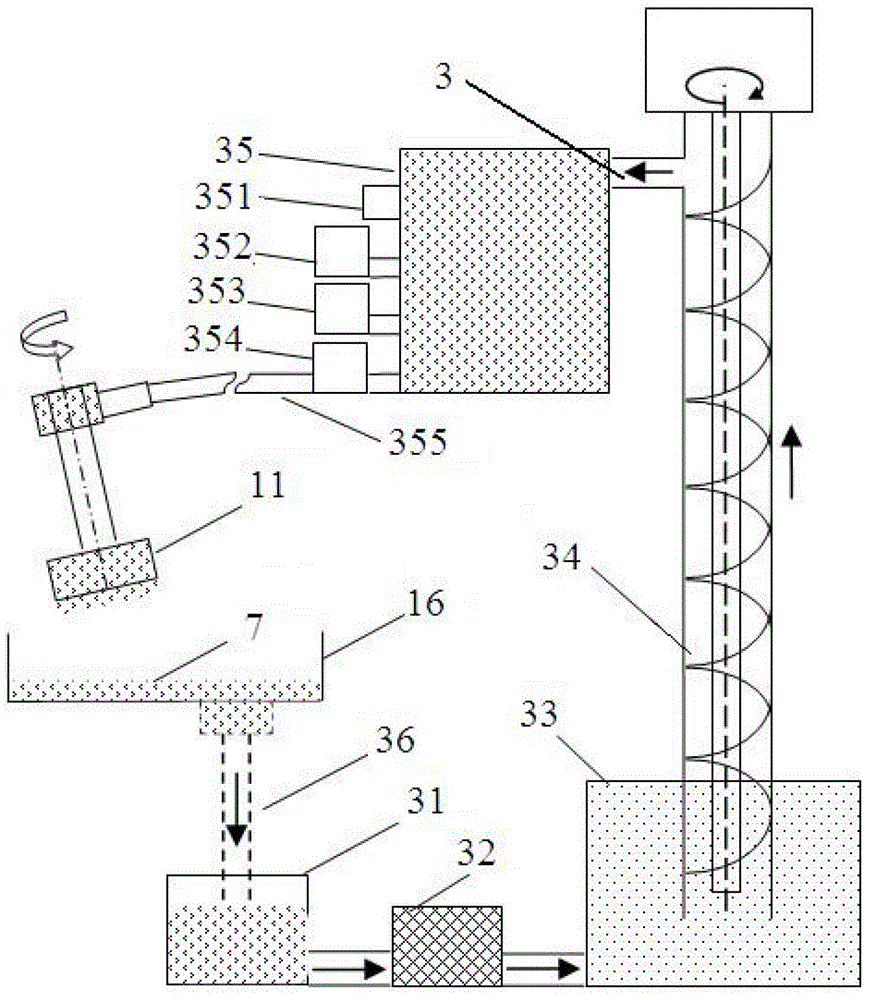

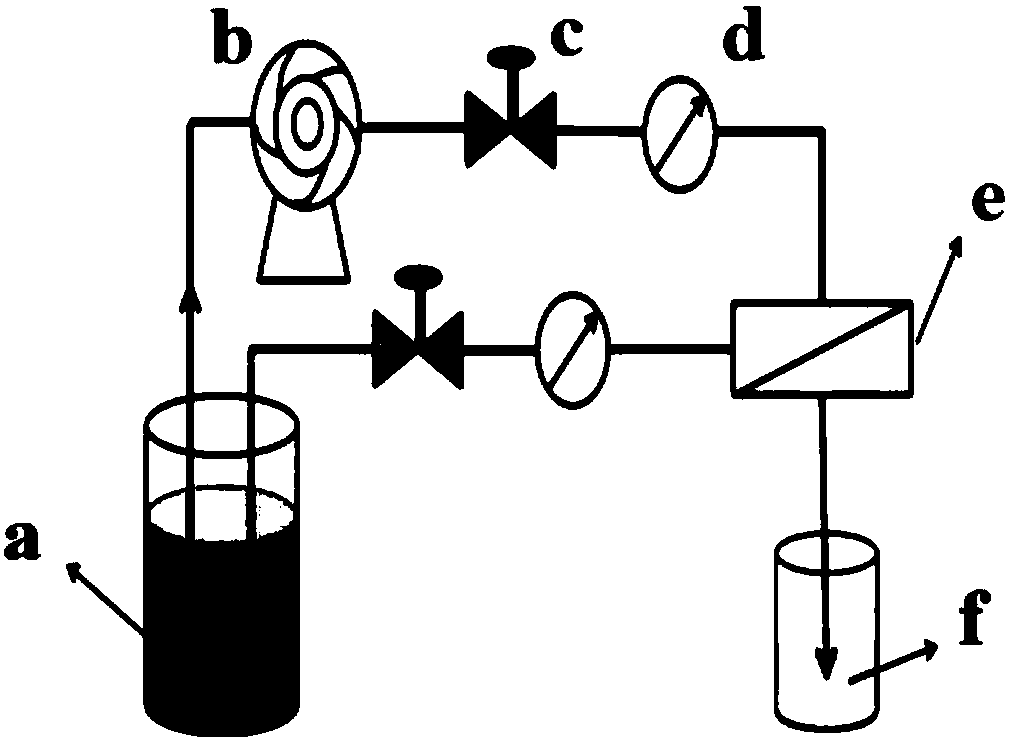

ActiveCN103331685ARealize multi-pose transformationRemovablePolishing machinesEngineeringPortal frame

A machining device based on a non-Newtonian fluid shear thickening mechanism polishing method comprises a workbench, a polishing tool system, an abrasive fluid circulation device and a computer control module, wherein the polishing tool system is installed on a portal frame of the workbench, an inlet of the abrasive fluid circulation device is communicated with an abrasive backflow opening in the workbench, and the workbench, the polishing tool system and the abrasive fluid circulation device are respectively connected with the computer control module. The machining device has the advantages that the application range is wide, the size of machined workpieces is not limited, the structure of the device is simple, the device is controlled easily, a computer controls the operation track of the device, the polishing process of non-Newtonian fluid abrasive fluid and the surfaces of the workpieces can be controlled effectively, a non-Newtonian fluid abrasive fluid circulation system is adopted, and the functions of removing abrasive dust, purifying, recycling, transporting and storing the abrasive fluid, and adjusting performance are achieved.

Owner:ZHEJIANG UNIV OF TECH

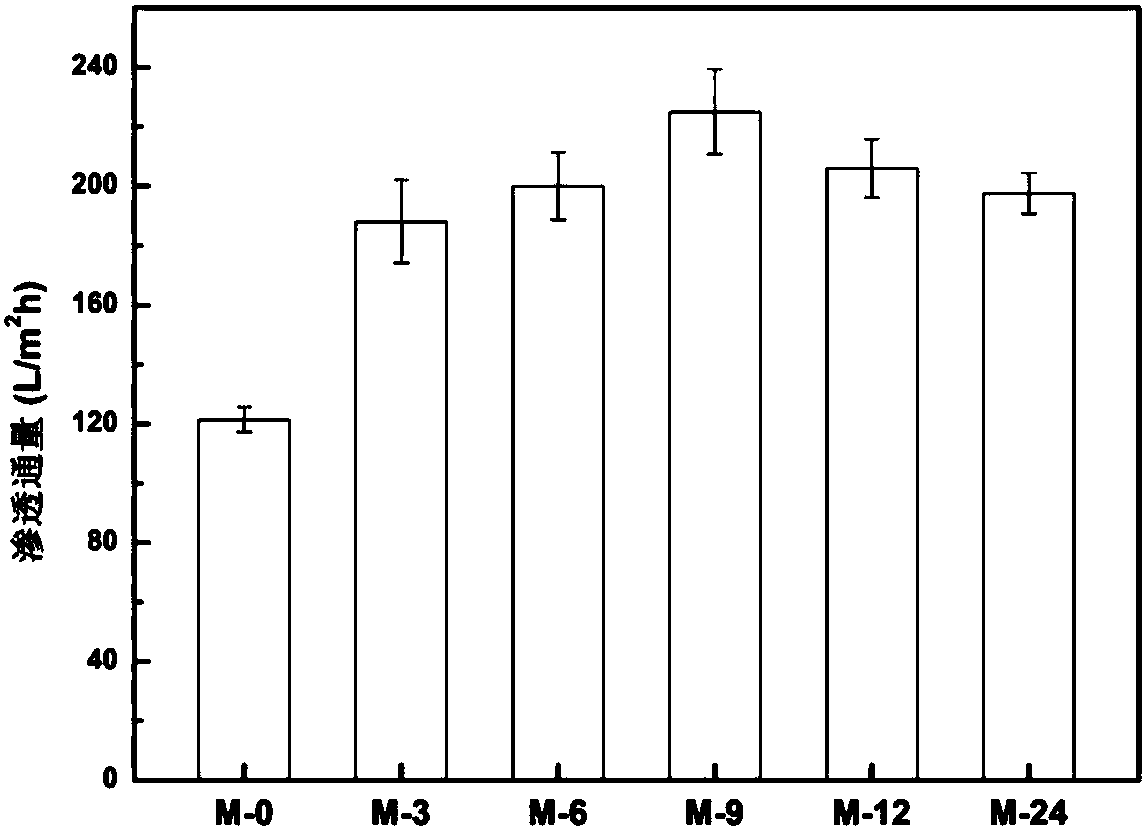

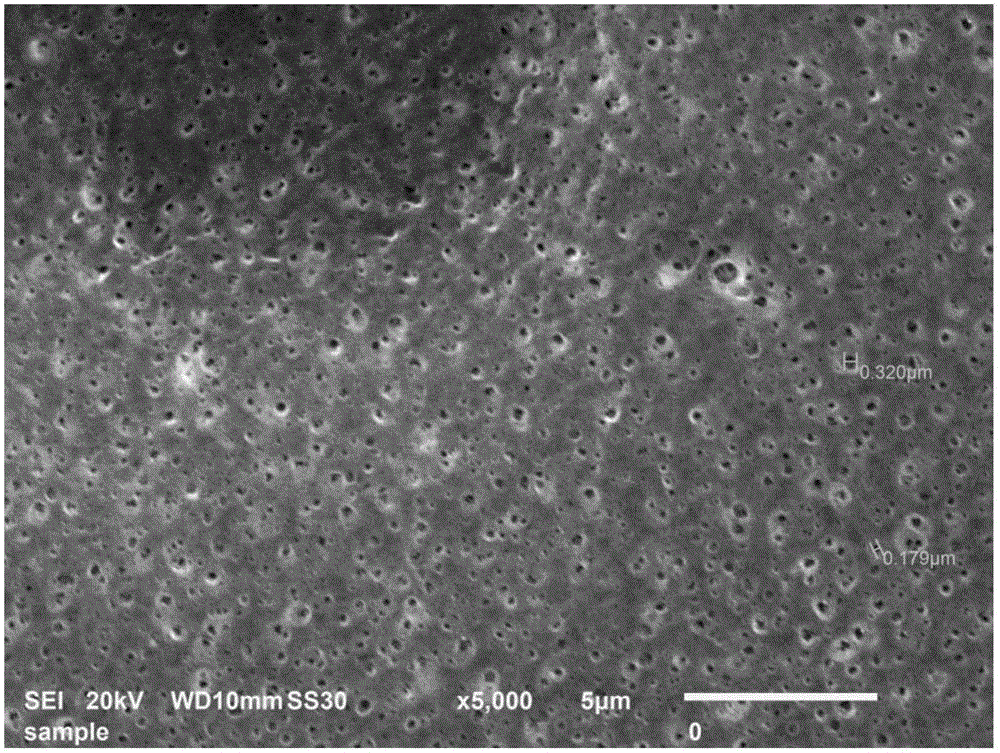

Plant polyphenol modified polymer membrane as well as preparation method and application thereof

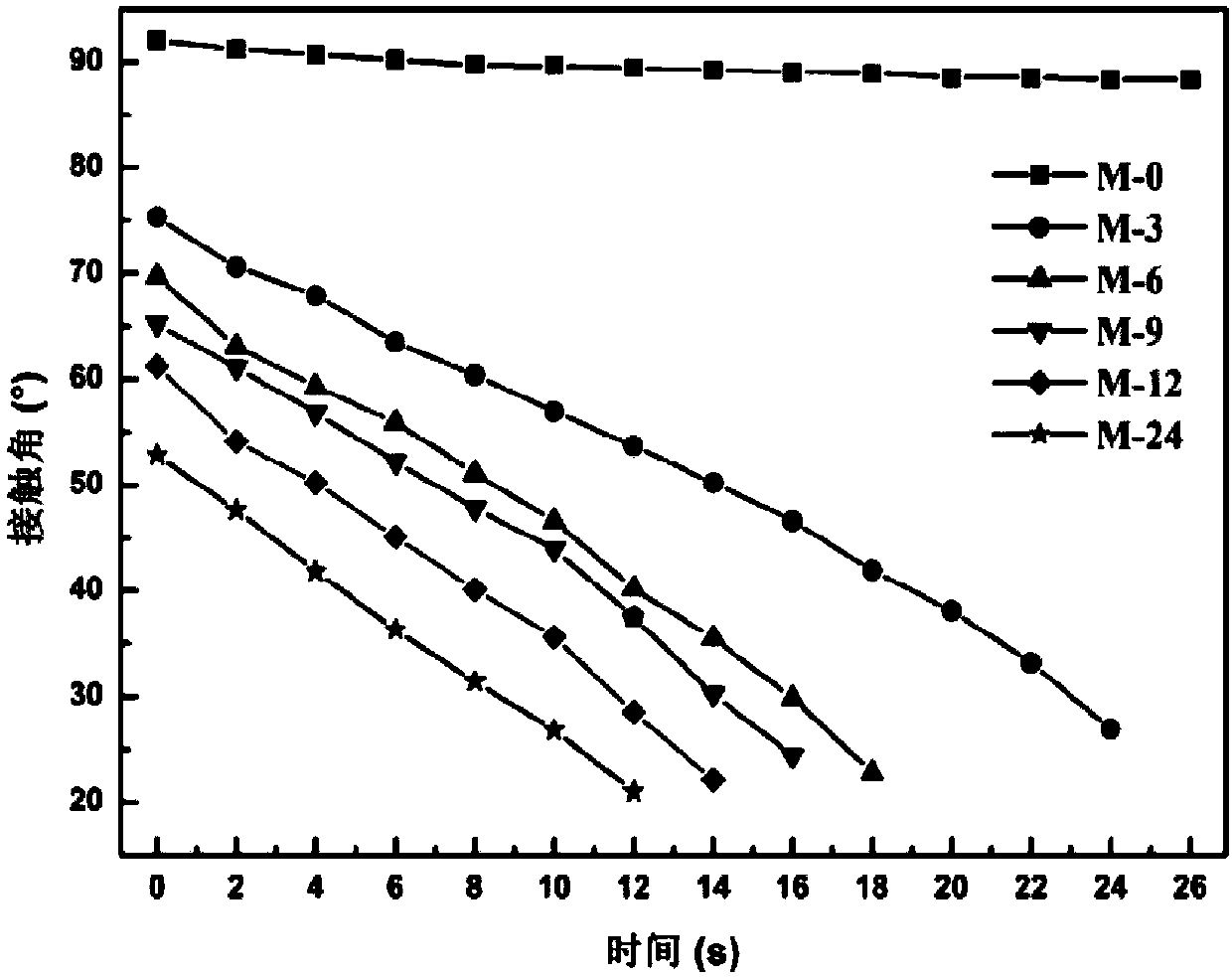

ActiveCN107670513AAvoid performance damageAvoid pollutionMembranesSemi-permeable membranesHydrophilic coatingPolymer science

The present invention discloses a plant polyphenol modified polymer membrane as well as a preparation method and application thereof, in particular relates to the field of modified polymer membranes with anti-fouling properties. In the prior art, due to low surface energy of the polymer membrane, the polymer membrane is susceptible to contamination with proteins, oils and the like and causes a series of temporary or permanent pollution problems. The polymer membrane provided by the invention utilizes the super-strong adhesive ability of plant polyphenols and the coordination of polyphenols andmetal ions to build a hydrophilic coating on the surface of a hydrophobic polymer membrane. The polymer membrane provided by the invention has the advantages of simplicity, high efficiency, mild reaction condition and strong practicability. The controllable hydrophilic modification of a hydrophobic polymer can be realized by changing the conditions of the dip-coating time, the concentration of aplant polyphenol mixed solution, the pH, the temperature and the like, and a high permeation flux can be maintained in the course of cross-flow continuous work, so that the polymer membrane has a verygood application prospect in the field of water treatment. The invention also opens up an effective way, which is simple and easy to operate and has strong universality, for modification of polymer membranes under mild conditions.

Owner:TIANJIN POLYTECHNIC UNIV

Super-scalable, continuous flow instant logic™ binary circuitry actively structured by code-generated pass transistor interconnects

InactiveUS20080082786A1Few solutionsAvoid collisionGeneral purpose stored program computerComputer programmed simultaneously with data introductionInformation processingTransistor array

A processing space contains an array of operational transistors interconnected by circuit and signal pass transistors that when supplied with selected enable bits will structure a variety of circuits that will carry out any desired information processing. The Babbage / von Neumann Paradigm in which data are provided to circuitry that would operate on those data is reversed by structuring the desired circuits at the site(s) of the data, thereby to eliminate the von Neumann bottleneck and substantially increase the computing power of the device, with the apparatus conducting only non-stop Information Processing on a steady stream of data and code, with no repetitious Instruction and data transfers as in the normal computer being required. A code is defined that will identify the physical locations of every transistor in the processing space, which code will then enable only selected ones of the pass transistors therein so as to structure the circuits needed for any algorithm sought to be executed. The circuits so structured, operating independently of and in parallel with every other circuit so structured, are then restructured after each step into another group of circuits, so that almost no transistor will ever “sit idle,” but all of the processing space can be devoted entirely to information processing, thereby again to increase enormously the computing power of the device. The apparatus is also super-scalable, meaning that an Instant Logic Apparatus built around that processing space could be built to have any size, speed, and level of computer power desired.

Owner:WEND

Component analyzer for laser probe micro-area

ActiveCN101587074AHigh absolute analytical precisionBig room for expansionFluorescence/phosphorescenceMountingsLaser probeTrace element

The invention belongs to the technical field of laser detection, specifically relates to a component analyzer for laser probe micro-area. The structure thereof comprises that: a laser, a beam expanding lens and a first total reflector are sequentially positioned on the same horizontal optical path; an included angle between the reflection plane of the first total reflector and the horizontal optical path is 45 degrees; an industrial CCD is positioned above the first total reflector, the industrial CCD and a first focusing object lens are sequentially arranged from top to bottom and optical axes thereof are superposed; the surface of a three-dimensional workbench is positioned below the first focusing object lens; the total reflector is movably mounted on the reflection optical path of a sample, an optical cable probe is positioned the reflection optical path of the total reflector; the industrial CCD is connected via the optical cable with a computer having a display, the optical cable probe is connected with a grating spectrograph, an enhanced CCD and the computer. The laser probe instrument can probe micro-area elements of substances losslessly, can satisfy rapid qualitative analysis for element components of devices having various materials and sizes, and can also implement high-accuracy quantitative analysis on micro elements and trace elements in the micro area of the sample.

Owner:HUAZHONG UNIV OF SCI & TECH

Flexible transparent touch membrane

InactiveCN103383617AEasy to processLow costInput/output processes for data processingTouchscreenTouch function

The invention provides a flexible transparent touch membrane which can be mounted or pasted on any display interfaces, the display interface can be planar and curved, can be used as a display wall, and can realize interactive touch function. Compared with the traditional touch screen, the flexible transparent touch membrane provided by the invention is light in weight and low in cost, can be mounted and exchanged at ease, can be bent due to the flexibility of the membrane, is not confined by processing size, while being combined with a future flexible display, a wide touch application space is provided, and the touch membrane can be applied in a new field and can be used on a large scale.

Owner:姜洪波

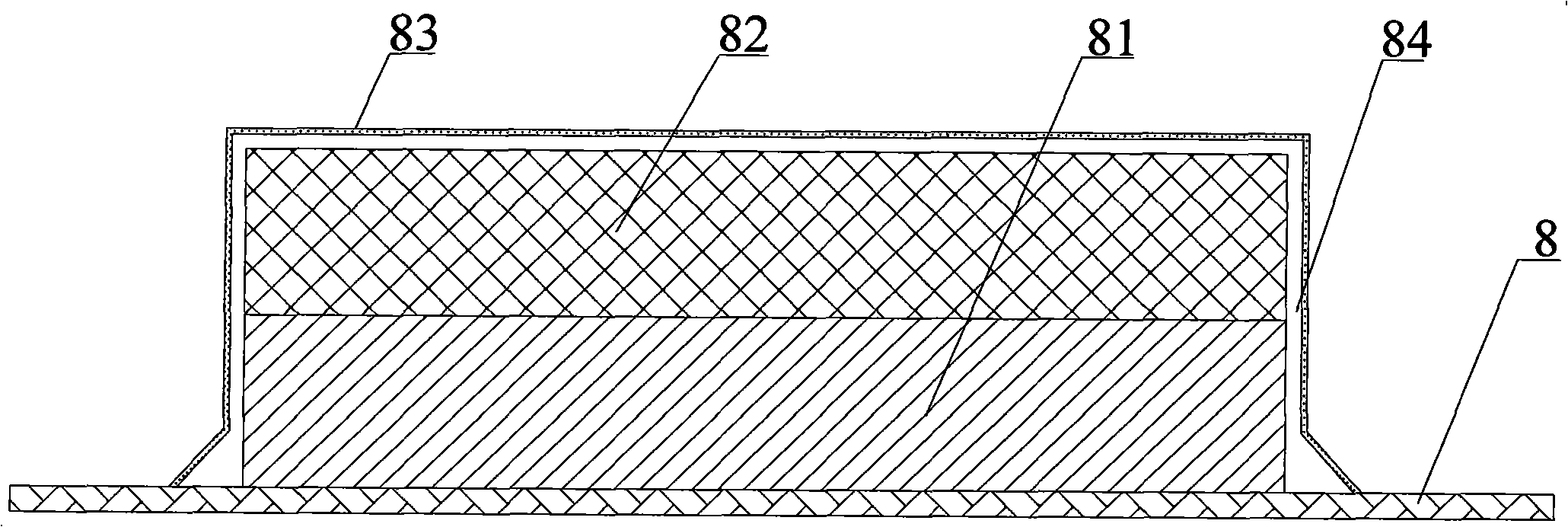

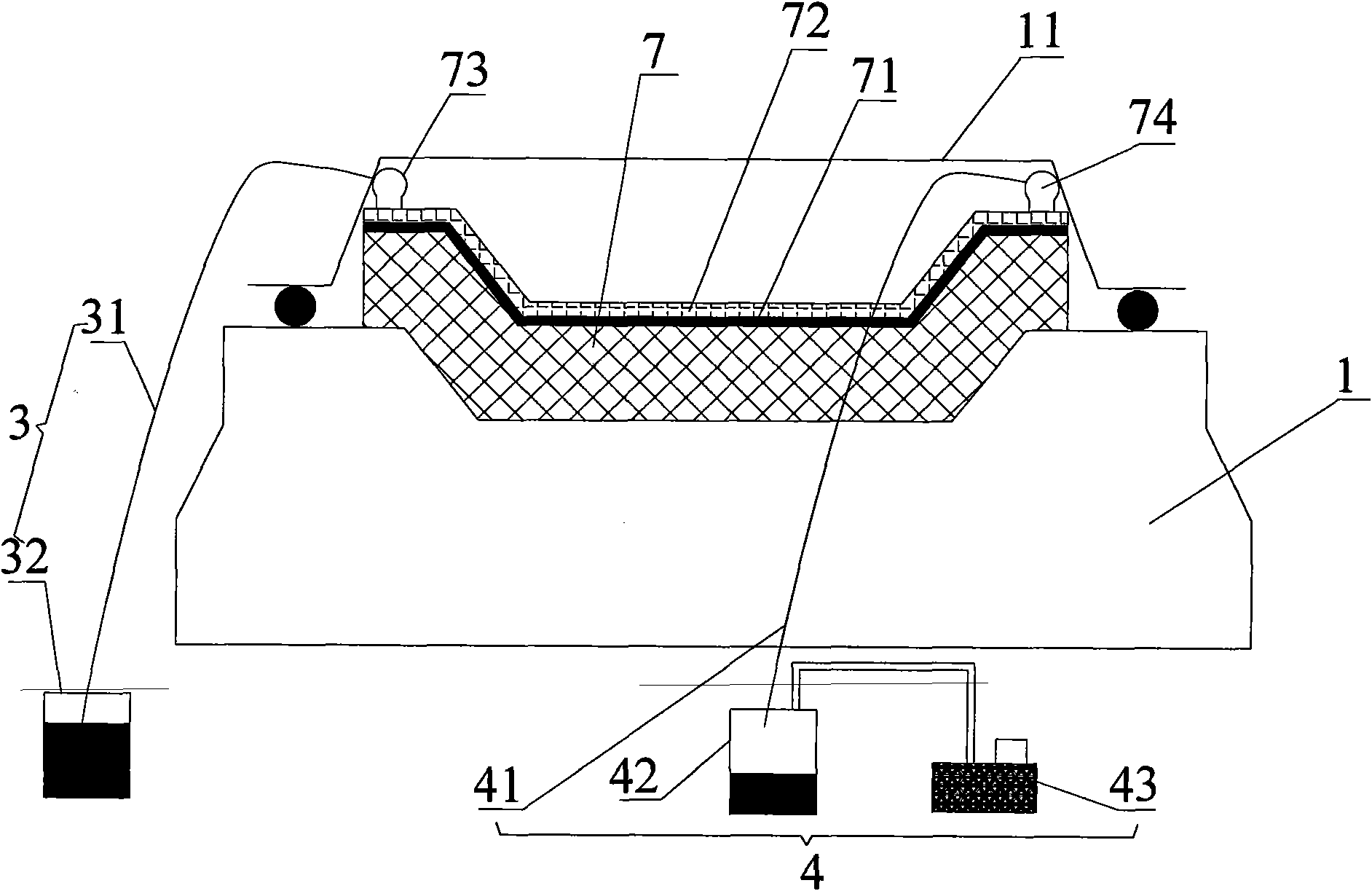

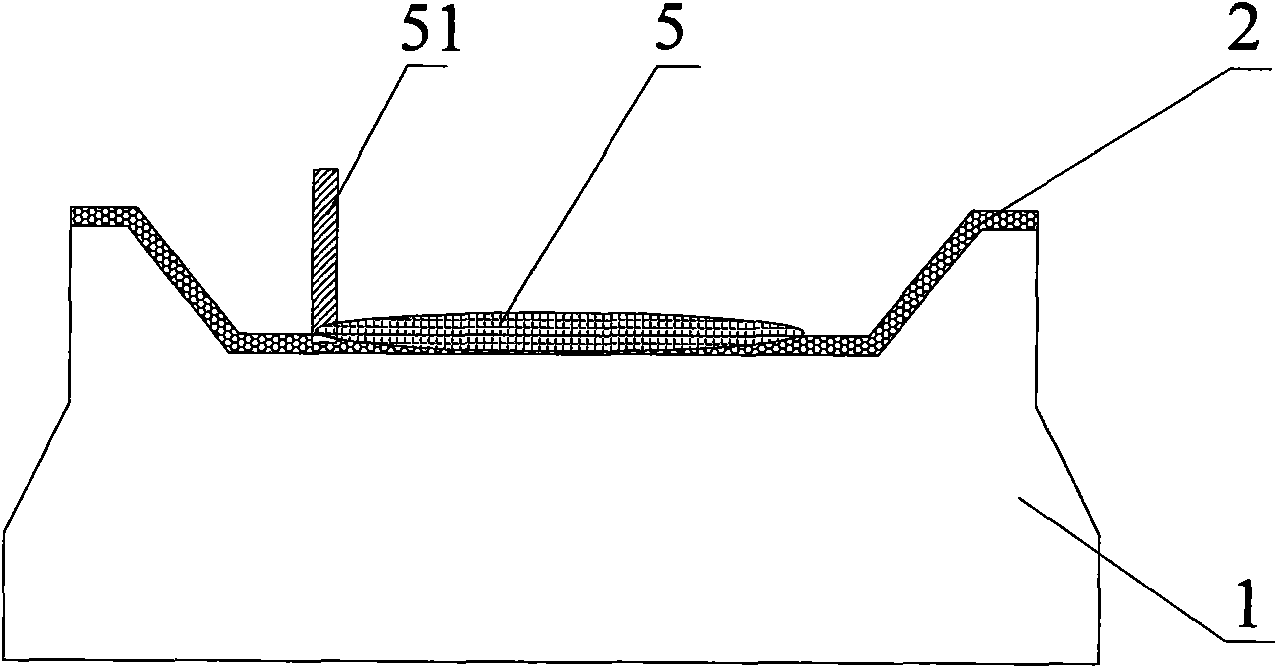

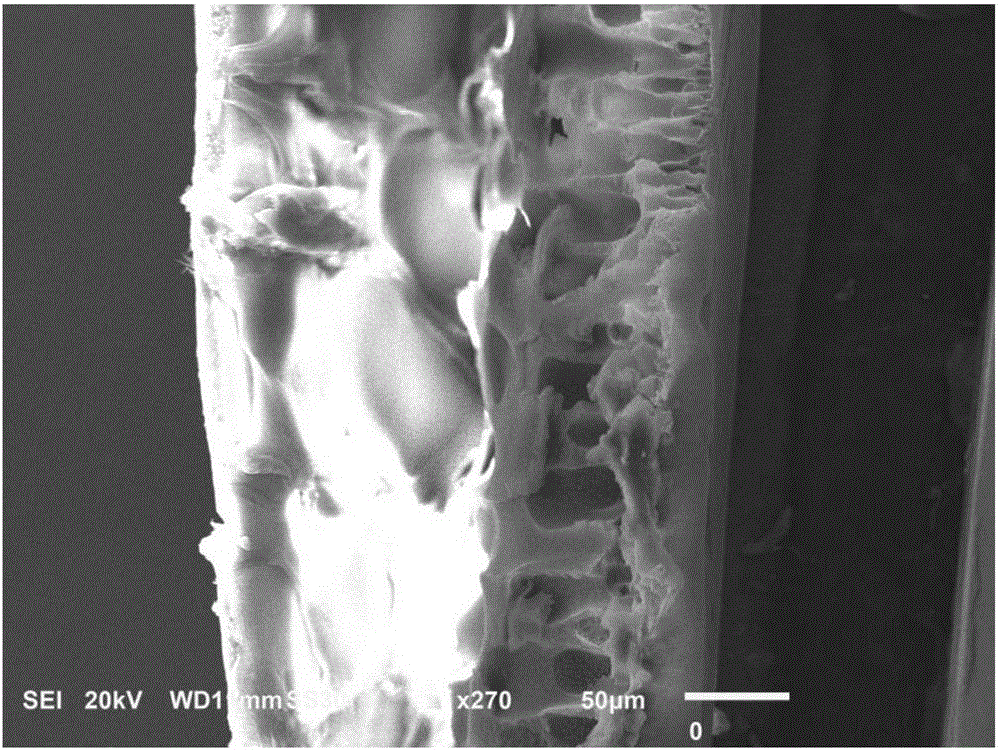

Composite material member with surface function layer and VIMP preparation method thereof

InactiveCN101830095AFast impregnationGood surface qualitySynthetic resin layered productsSurface functionMaterial system

The invention belongs to the technical field of a multilayer structural composite material member and a preparation method thereof and specifically discloses the composite material member with a surface function layer and a VIMP preparation method thereof. The composite material member comprises an outer surface layer and a main body layer, wherein, the outer surface layer and the main body layer are respectively a first composite material system and a second composite material system; and the first composite material system takes epoxy resin, phenolic resin and the like as a matrix, the second composite material system takes unsaturated polyester resin as a matrix, and the two systems take fiber cloth of carbon fiber or glass fiber as reinforcement. The VIMP preparation method comprises the following steps: firstly preparing a reinforced resin film on a die surface for vacuum dip molding by a resin film infiltration process, and then preparing the composite material member with a molding die covered with the reinforced resin film through the vacuum dip molding process. The VIMP process of the invention combines the double advantages of an RFI process and the VIMP process; and the obtained composite material member has better surface quality, better integrity and excellent comprehensive performances.

Owner:NAT UNIV OF DEFENSE TECH

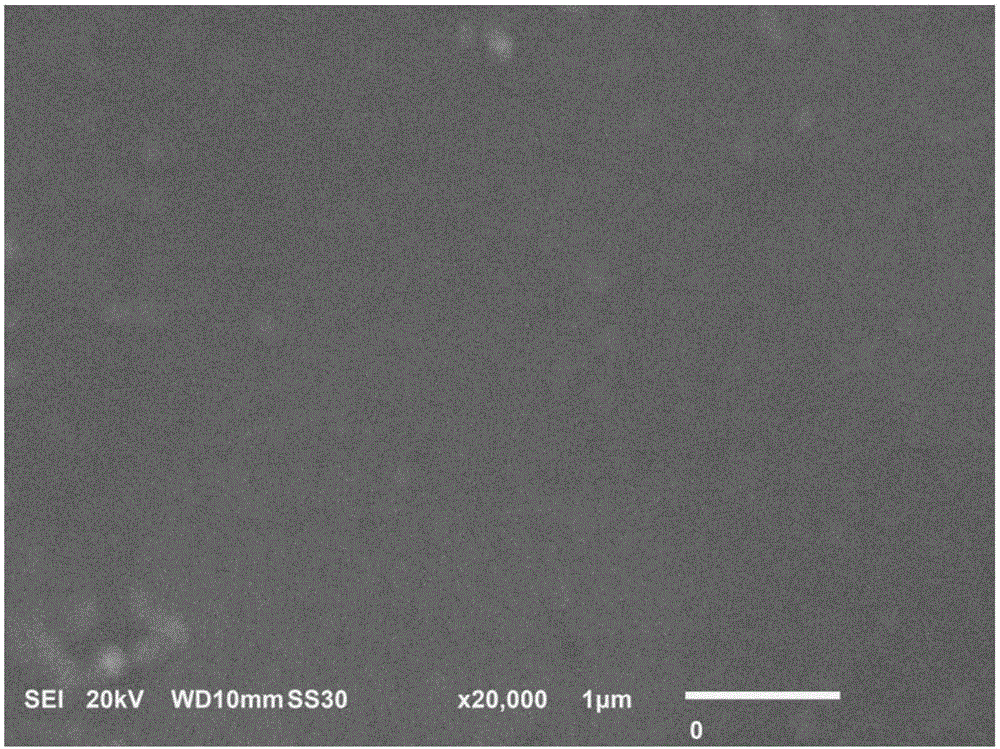

Surface modification method for polymer separation membrane

ActiveCN103041721AModification equipment is simpleShorten the production cycleSemi-permeable membranesPolymer scienceAgglutination

The invention discloses a surface modification method for a polymer separation membrane. Under the water solution condition, a dopa compound is easily oxidized by dissolved oxygen in water to generate auto-agglutination-composite reaction in order to generate a firmly attached dopa compound composite layer on the surface of the polymer separation membrane; the dopa compound composite layer contains rich catechol radicals which can form the multi-point hydrogen bonding effect with lactam radicals in polyvinylpyrrolidone, and the polyvinylpyrrolidone is firmly complexed on the surface of the separation membrane; and the polymer separation membrane immobilized with povidone-iodine on the surface can be prepared through the complexation between the polyvinylpyrrolidone and iodine. The method has simple technique, and is suitable for the polymer separation membranes with different materials and shapes; and the modified polymer separation membrane has excellent hydrophily, blood compatibility, contamination resistance and bacterial resistance, so that the important significance is given to improve the comprehensive performance of the polymer separation membrane.

Owner:ZHEJIANG UNIV

Micro-optical scanning tomography device

The invention relates to a three-dimensional micro-optical imaging device and aims to provide an imaging method of micro-optical scanning chromatography. The method comprise that: a large sample is sliced up layer by layer through precise mechanical processing technique; and the slice is scanned and imaged while performing the mechanical processing so as to acquire a complete faultage image data set of the sample. The system comprises a mechanical processing module, an imaging module and a data acquiring module, wherein the mechanical processing module is used for realizing scanning type slicing on the sample; the imaging module is used for imaging the sample near a cutter edge; and the data acquiring module is used for scanning and recording the imaging of the sample. The three modules coordinate to realize the functions of a micro-optical scanning chromatography imaging device. The imaging device adopts a synchronous mode of slicing and imaging, the automation degree of the whole process is extremely high, the problem that pictures between different layers are difficult to match does not exist, and the acquisition efficiency of the whole data is high.

Owner:WUHAN OE BIO CO LTD

Pervaporation separation membrane and preparation method thereof

InactiveCN106110910AImprove hydrophilicityEasy to separateSemi-permeable membranesMembranesPervaporationEthyl ester

The invention discloses a pervaporation separation membrane and a preparation method thereof. The pervaporation separation membrane is prepared by stably polymerizing dopa or dopamine on the surface of a base membrane, and performing grafting and cross-linking. According to the pervaporation separation membrane and the preparation method thereof, a polydopa or polydopamine composite layer which can be firmly combined with the base membrane on the basis of a biological bonding principle is obtained; the composite layer is directly cross-linked with hydroxyls in a long-chain molecule, so that the pervaporation separation membrane which is high in hydrophility, permeation flux, separation performance and membrane stability is prepared. The preparation process is simple and convenient; raw materials are easy to obtain; the condition is mild; the prepared pervaporation membrane is used for separating ethyl acetate from water, and has relatively high permeation flux and membrane stability.

Owner:JIANGSU SOPO GRP +2

Conductive type polyaniline composite film, prepn. method and use thereof

InactiveCN1831033AImprove self-cleaning abilityNot affectedPlastic/resin/waxes insulatorsOther chemical processesFiberJet aeroplane

The invention relates to the current conducting ployaniline composite membrane having the framework of the lotus leaf genus. It is the cancellated film composed by the nm fibre with microsphere and has the tuber on the surface of the fibre and the microsphere. The producing process of the composite includes the below steps: the eigenstate polyaniline is dissolved into the solvent; the insoluble substance is rejected, the adulterating acid is added; then, the polystyrene is added; the current conducting polyaniline mixed liquor is gained; finally, the petrified urrent conducting ployaniline composite membrance is gained one the receiving system using the electrostatic spinning technique. The composite membrane is indicative of the contact angle of 160 degree and the roll angle of below 5 degree to the pure water, the acid and the alkaline solution in the range of the entirely PH value and express the sky high ability of self purging; at the same time, the conductivity of the conducting macromolecule composite membrane don't change with the acid and alkaline solution. The conducting composite membrane can be used for producing the resisting electromagnetic shielding material, the antistatic stuff, the anticorrosion stuff, the anti fouling stuff of the shipping and the airplane, the latent stuff, the liquid transmission without the loss and the micro-flow stuff.

Owner:INST OF CHEM CHINESE ACAD OF SCI

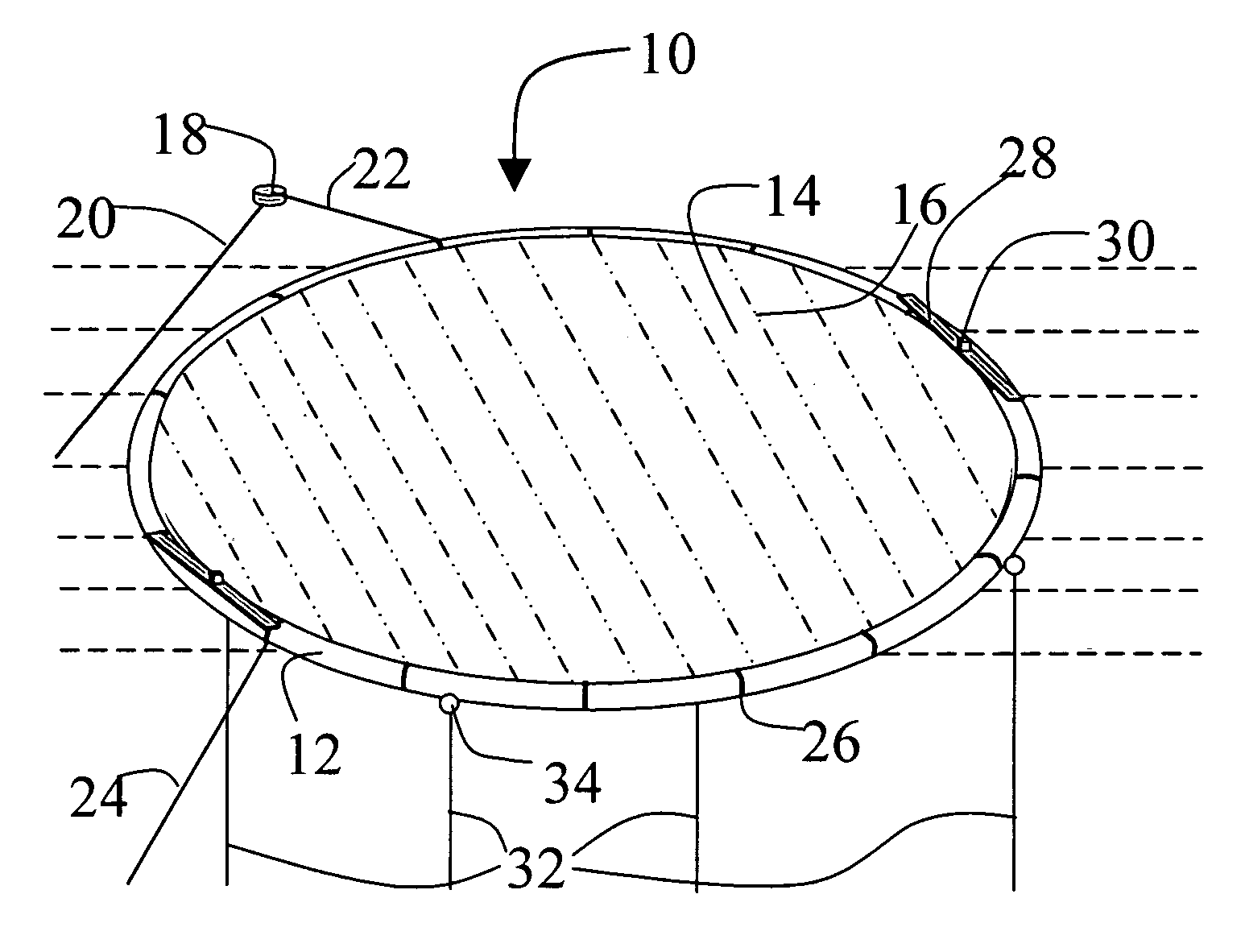

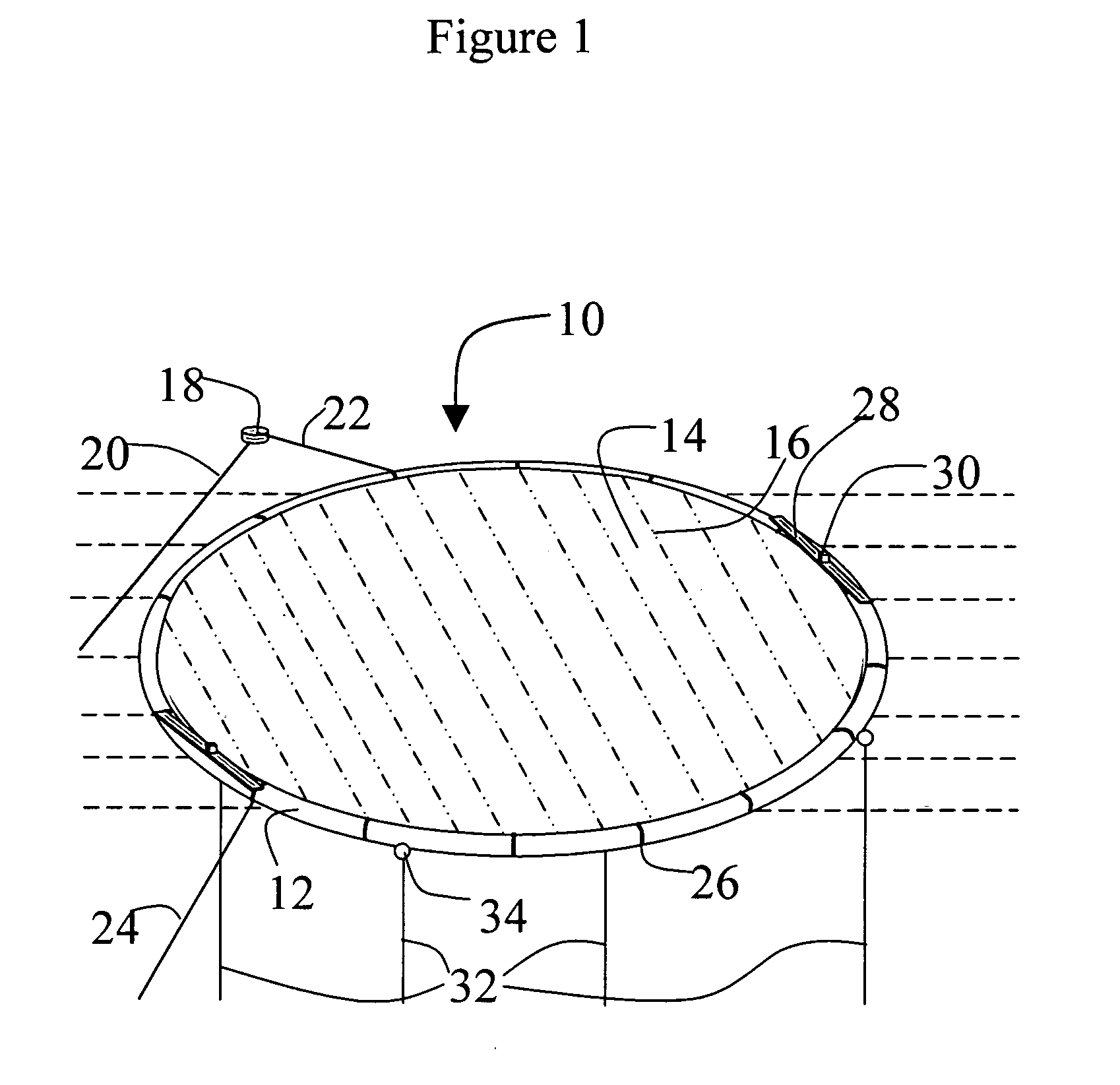

Submersible aquatic algae cultivation system

ActiveUS20100287829A1Quick upgradeReduces contributing costAlgae productsClimate change adaptationMooring systemFishery

Floating ponds for the cultivation of algae are disclosed. The floating ponds consist of a buoyant framework, a liner, a culture, and a mooring system. Submersible floating ponds are disclosed with a buoyant framework built from tubes that may be filled or partially filled with, for example, air, or water, or the surrounding water, or the culture, and thereby the present invention provides a framework in which the buoyancy may be modulated. Use of submerging lines and spools are disclosed to control the orientation and depth of the floating pond during submersion.

Owner:BUSSELL STUART

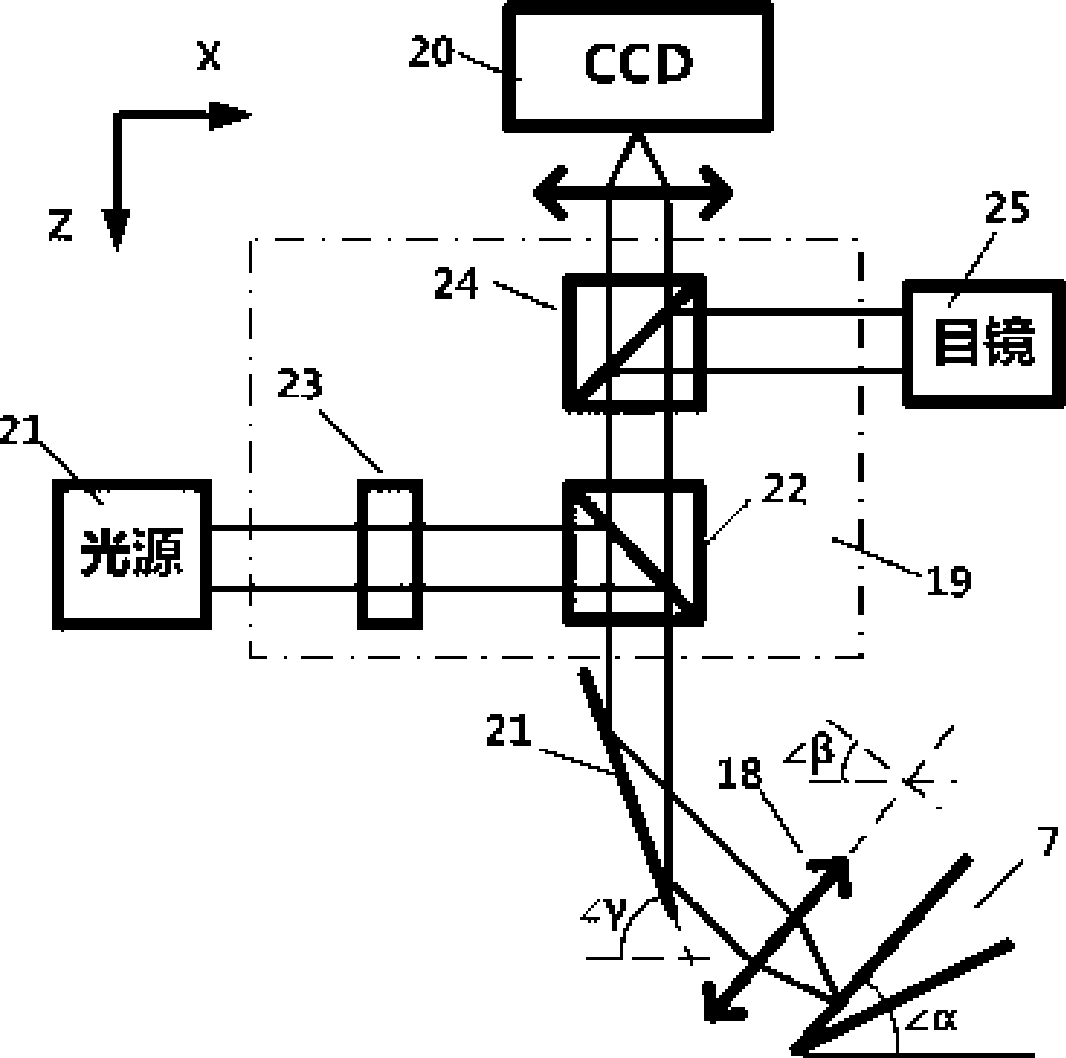

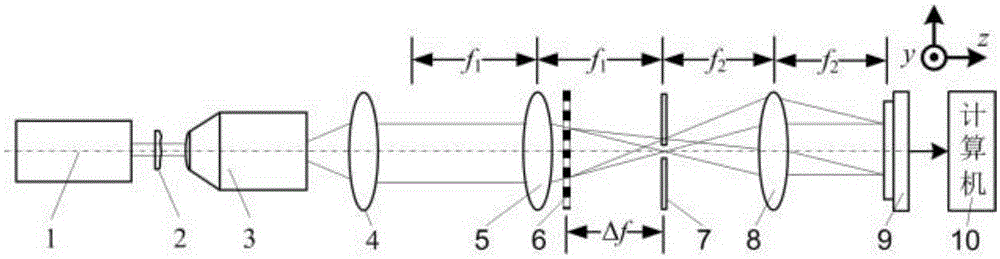

Common-path digital holographic microscopic device and method based on optical grating defocusing

ActiveCN105423911ASimple structureLow positioning complexity requirementsUsing optical meansGratingLight beam

The invention discloses a common-path digital holographic microscopic device and method based on optical grating defocusing. The device comprises a light source, a to-be-detected object, a microscopic object lens, a correction object lens, a first lens, a second lens, an image sensor, and a computer. The device also comprises a one-dimensional periodic optical grating and a hole array. Light emitted by the light source passes through the to-be-detected object, the microscopic object lens and the correction object lens to come to the first lens. An outgoing beam, formed after the first lens converges the light, passes through the one-dimensional periodic optical grating to be divided into zero-level diffracted light and +1-level diffracted light, and is filtered by the hole array to form reference light and object light. The reference light and object light pass through the second lens to be converged into a light beam, and the light beam is received by a light receiving surface of the image sensor. An image signal output end of the image sensor is connected with an image signal input end of the computer. The device is simple and practicable, and is convenient to adjust. Moreover, the size of a to-be-detected object is not limited, and the view field of a detection window is used fully. The device can greatly reduce the complexity in determining a system carrier frequency, and improves the phase recovery algorithm efficiency.

Owner:HARBIN ENG UNIV

Sulfur transfer catalyst and and the preparation thereof

InactiveCN1485132AAdvantages of preparation methodEase of industrial productionCatalyst carriersCatalytic crackingRare-earth elementActive component

A sulfur-transferring catalyst comprises a cerium oxide of 2í½30úÑ by weight as the active component and a spinel compound of 70í½98úÑ by weight containing magnetium and aluminum as the carrier. The spinel compound containing magnetium and aluminum comprises MgO of 5í½70úÑ, Al2O3 of 30í½ 95%, an oxide of a rare earth element of 0í½15 úÑ except cerium, V2O5 of 0í½10úÑ,relative to the total weight of the compound. Moreover, the invention provides a method of producing the catalyst. The sulfur-transferring catalyst has a high efficiency of absorbing and desorbing SO x.

Owner:CHINA PETROLEUM & CHEM CORP +1

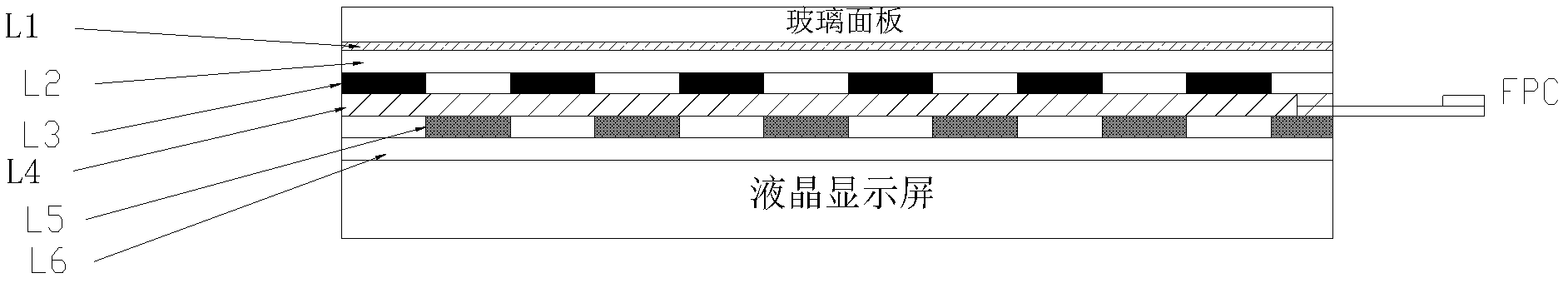

Stereo liquid crystal display device and method for making the same

ActiveCN101162311AUnlimited sizeHigh precisionDiffraction gratingsNon-linear opticsGratingLiquid-crystal display

The invention discloses a stereo liquid crystal displayer structure and a method for manufacturing the same, wherein, when the liquid crystal displayer is made, a raster layer is integrated between an upper plaroid and an upper glass plate of the displayer, forming a stereo liquid crystal displayer which has the advantages of high precision and accurate para position and is based on the parallax barrier technique. The invention can be widely applied to a plurality of liquid crystal displayers with different screen sizes; moreover, the invention has the advantages of easy technological transformation, low manufacturing cost and preferable stereo displaying effect.

Owner:BYD CO LTD

Activator for magnesium alloy welding

InactiveCN101244497AWell formed weldImprove joint qualityArc welding apparatusWelding/cutting media/materialsAlcoholActive agent

The invention relates to an active agent applying to magnesium alloy welding, belonging to the material engineering technical field, which is characterized in that: the active agent is composed of TiO2, Cr2O3, MgO, MnO2, and CaO and the weight proportion is TiO2: 40 to 70%, Cr2O3: 5 to 20%, MgO: 2 to 20%, MnO2: 5 to 20%, CaO: 5 to 20%. Firstly, the active agent is grinded to powder, then is dried and cooled; secondly, the active agent is mixed with acetone or alcohol and then is equally coated or sprayed on the surface of the welding bead; finally, after the acetone or the alcohol is volatilized, welding can be implemented. The active agent has the advantages that: the weld penetration can increase at least twice; the weld joint of magnesium alloy is well moulded; the joint is of high quality and the intensity can be above the 95% of the intensity of the parent metal; the deformation due to welding is reduced; the invention is of easy operation and high productivity.

Owner:DALIAN UNIV OF TECH

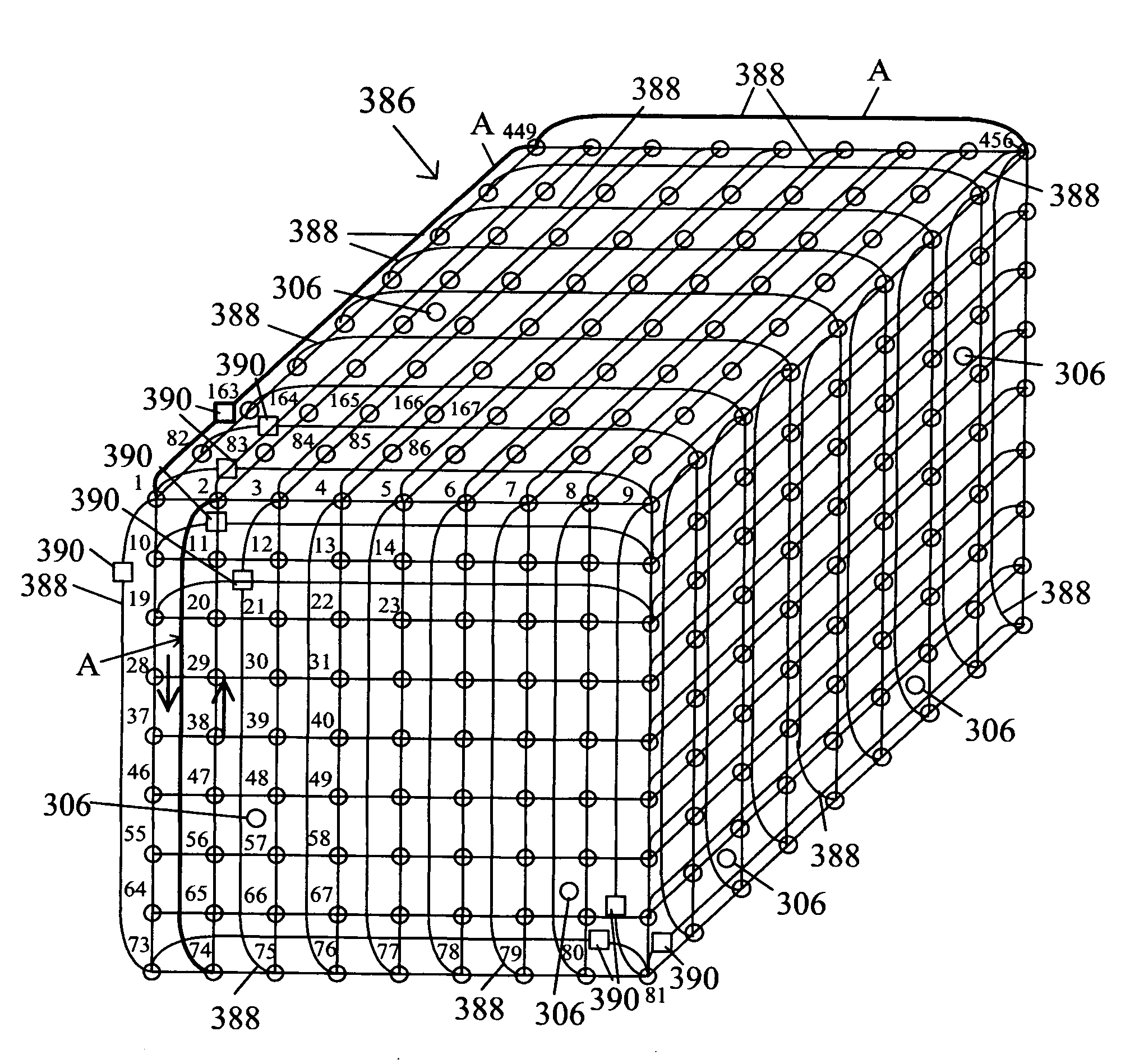

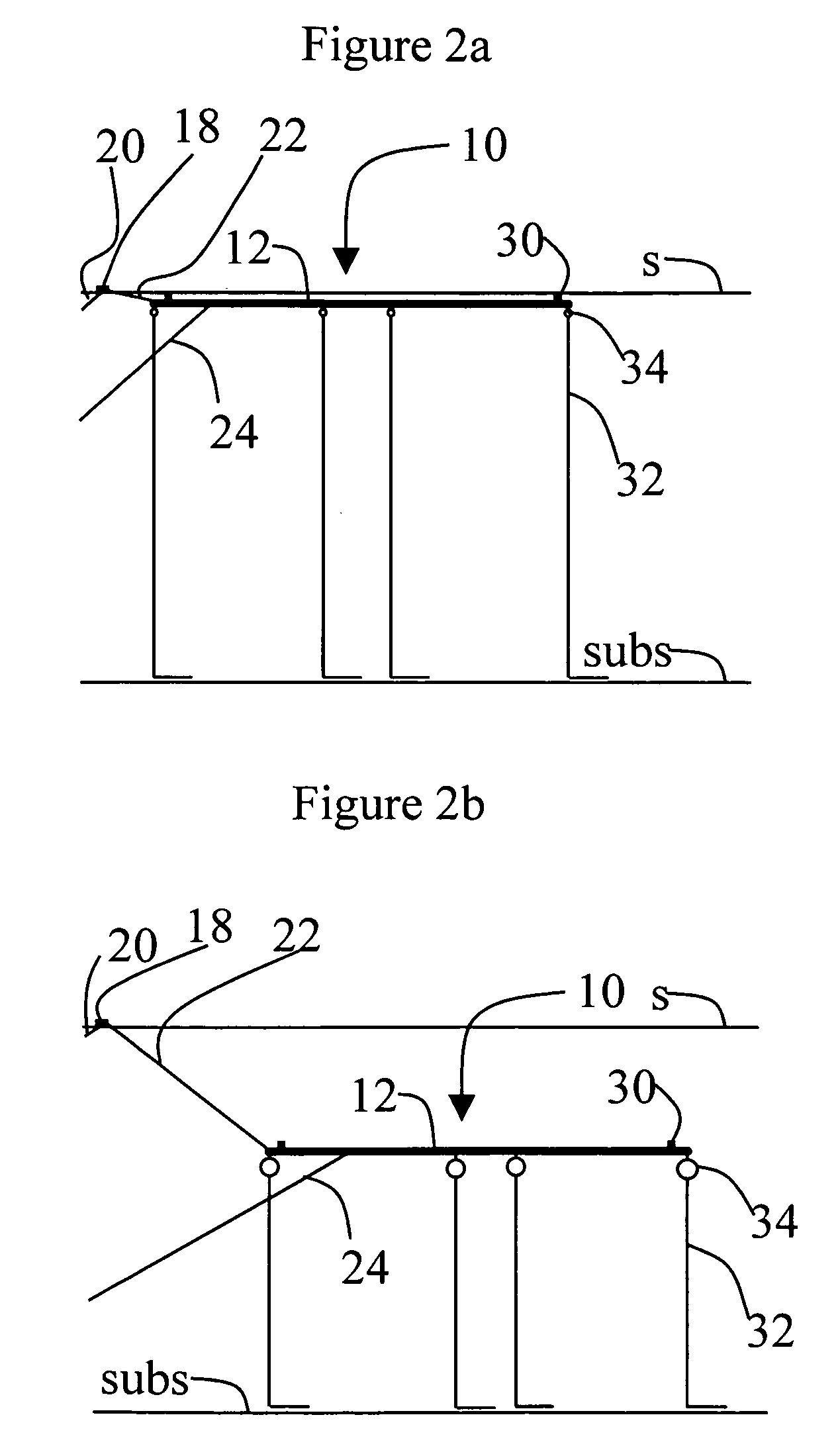

Continuous flow instant logic binary circuitry actively structured by code-generated pass transistor interconnects

InactiveUS7895560B2Few solutionsAvoid collisionGeneral purpose stored program computerComputer programmed simultaneously with data introductionInformation processingTransistor array

A processing space contains an array of operational transistors interconnected by circuit and signal pass transistors that when supplied with selected enable bits will structure a variety of circuits that will carry out any desired information processing. The Babbage / von Neumann Paradigm in which data are provided to circuitry that would operate on those data is reversed by structuring the desired circuits at the site(s) of the data, thereby to eliminate the von Neumann bottleneck and substantially increase the computing power of the device, with the apparatus conducting only non-stop Information Processing on a steady stream of data and code, with no repetitious Instruction and data transfers as in the normal computer being required. A code is defined that will identify the physical locations of every transistor in the processing space, which code will then enable only selected ones of the pass transistors therein so as to structure the circuits needed for any algorithm sought to be executed. The circuits so structured, operating independently of and in parallel with every other circuit so structured, are then restructured after each step into another group of circuits, so that almost no transistor will ever “sit idle,” but all of the processing space can be devoted entirely to information processing, thereby again to increase enormously the computing power of the device. The apparatus is also super-scalable, meaning that an Instant Logic Apparatus built around that processing space could be built to have any size, speed, and level of computer power desired.

Owner:WEND

Method for silane reinforcing magnesium alloy cathode electrophoretic corrosion-proof layer

InactiveCN1936101AGood adhesionImprove corrosion resistanceElectrophoretic coatingsMetallic material coating processesSilanesLacquer

The invention relates to a method of silence enhancing magnesium alloy cathode electrophoresis corrosion resistant coating layer. It takes silence enhancing process to the surface of magnesium alloy after cleaning. The silence solution adopts aqueous solution of 2-3 ethoxy, silicone base propyl tetrasulfide, propenyl-3-ethoxy silicane, gama- glycidol ether oxygen propyl-3-methoxyl silence or 2, 3 ethoxy silicone base ethane, and pH value is acidity. The method need not special device to heat, and combining with cathode electrophoresis, the binding power of cathode electrophoresis lacquer and magnesium alloy basal body would be enhanced.

Owner:重庆工学院

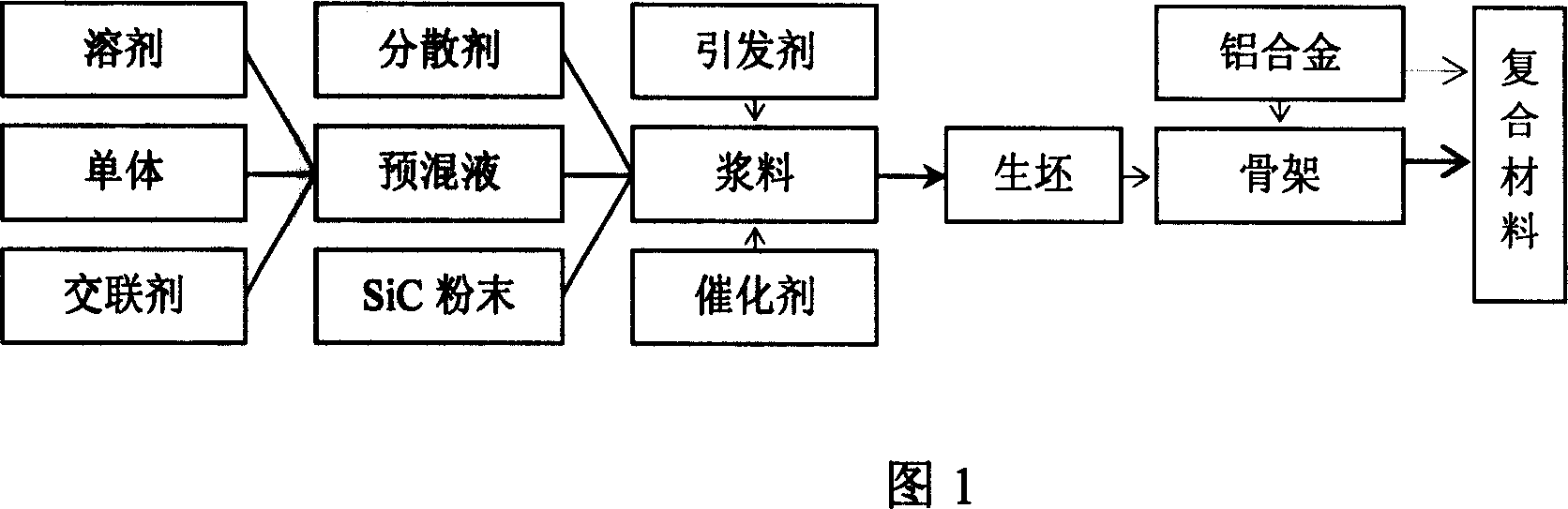

Method of preparing SiCp/Al composite material with complicated shape and high volume percent ratio

The invention discloses a preparing method of SiCp / Al composite with complete shape and high analytic in metal base composite material researching domain, which comprises the following steps: allocating pre-mixing liquid with monomer, cross linker and disperser; adding into SiC powder; balling; getting stable suspension with SiC volume content at 50-70%; adding into trigger and activator; stirring evenly; injecting into unapertured mold; solidifying and shaping in incubator with temperature at 50-70 deg.c; getting green compact; drying; discharging glue; presintering; getting SiC bone; placing Al alloy of 4-8% Mg, 6-12% Si on the adaptive position of bone; putting into heater; heating-up at 900-1200 deg.c under the protection of inert gas; inflating high pure nitrogen; keeping the temperature at 1-6 h; cooling; getting the product. This invention possesses the merit of cheap cost.

Owner:UNIV OF SCI & TECH BEIJING

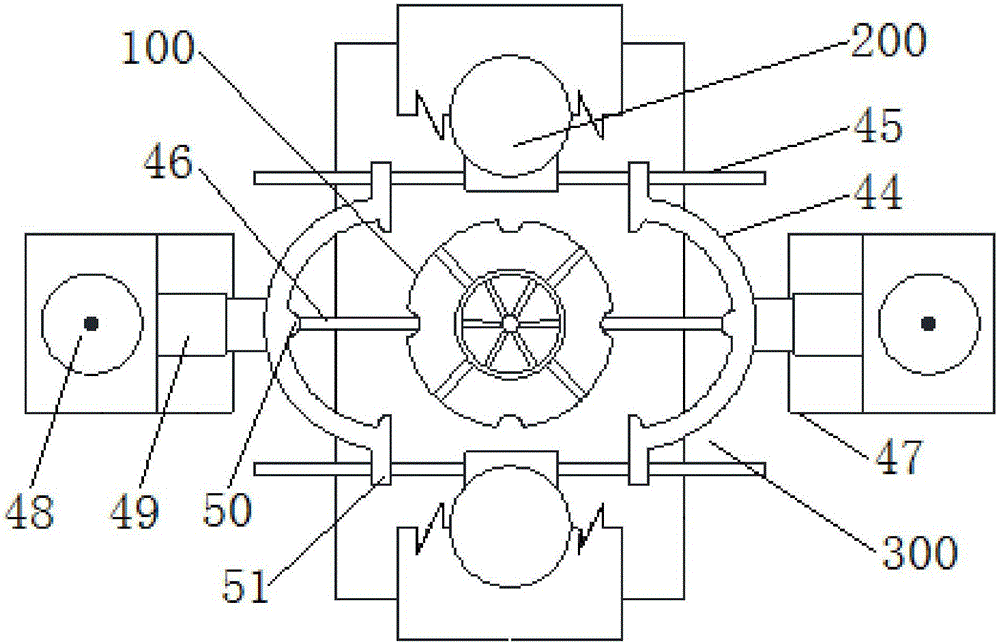

Device suitable for ring shear test and soil sample preparation of vertical shearing surface

ActiveCN106840810AAvoid breaking unevennessUniform stressPreparing sample for investigationMaterial strength using steady shearing forcesLift systemEngineering

The invention relates to a device suitable for ring shear test and soil sample preparation of a vertical shearing surface. The device comprises a shearing box, a lifting system, a power rotating system, a monitoring control system, a soil sample preparation system and a frame, wherein shearing plates are uniformly fixed on an annular base plate along the radial direction of the annular base plate; an outer cover of the shearing box is covered on the annular base plate and the shearing plates and is assembled and fixed with the annular base plate through a guide strip and a guide slot; the outer cover of the shearing box is connected with a rotating force arm of the power rotating system and is used for transmitting torque; a coupling pressing plate is aligned and embedded into a central hole of a top plate of the outer cover of the shearing box and is driven by the lifting system to load normal force; the annular base plate is aligned and embedded into a cylindrical support platform; and under the effect of driving torque, an inner cylindrical side wall generated by the circling motion of the annular base plate under the driving of the shearing plates is the vertical shearing surface. According to the invention, the shearing displacement and the uniform distribution of the shearing stress on the shearing surface can be guaranteed, the thickness of the vertical shearing surface is not limited and the device has the functions of sample preparation and vertical shearing test.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com