Multiple layer hydrogen infiltration -resistant compound film preparation method

A composite membrane and hydrogen-resistance technology, applied in the field of materials, to achieve controllable thickness, improve hydrogen permeation resistance and corrosion resistance, and improve high-temperature oxidation resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

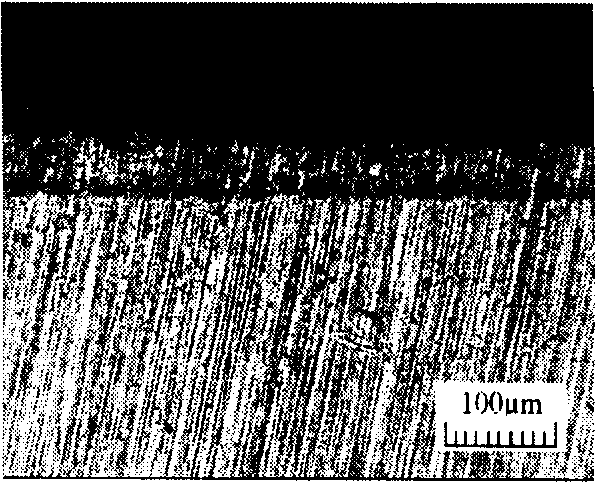

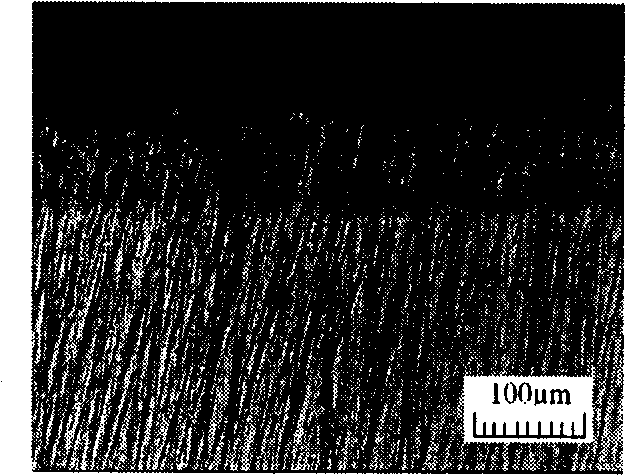

[0024] The stainless steel that has been thermally sprayed with aluminum is subjected to micro-arc oxidation, and the electrolyte is 8g / L Na 2 SiO 3 solution, the constant current method is adopted in the reaction process, and the current density is 10A / dm2 , the micro-arc oxidation time is 20 minutes, figure 1 and figure 2 The cross-sectional metallography and surface morphology of the prepared hydrogen permeable barrier composite membrane, respectively.

Embodiment 2

[0026] The stainless steel alloyed with aluminum is subjected to micro-arc oxidation, and the electrolyte is 10g / L Na 2 SiO 3 solution with a current density of 20A / dm 2 , the cross-sectional metallography of the obtained multilayer hydrogen permeable barrier composite membrane is as follows image 3 shown.

Embodiment 3

[0028] Perform micro-arc oxidation on stainless steel that has undergone magnetron sputtering aluminum, and the electrolyte is 8g / L Na 2 SiO 3 +2g / L Na 2 B 4 o 7 The mixed solution, the surface morphology of the obtained multilayer hydrogen permeation barrier composite membrane is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com