Full-inorganic high-temperature-resistant insulating bonding method for iron-based metal soft magnetic composite material

A soft magnetic composite material, inorganic high-temperature-resistant technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low bonding strength and uneven coating of the insulating coating layer, and achieve excellent magnetic properties Performance and mechanical properties, the effect of improving mechanical properties and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

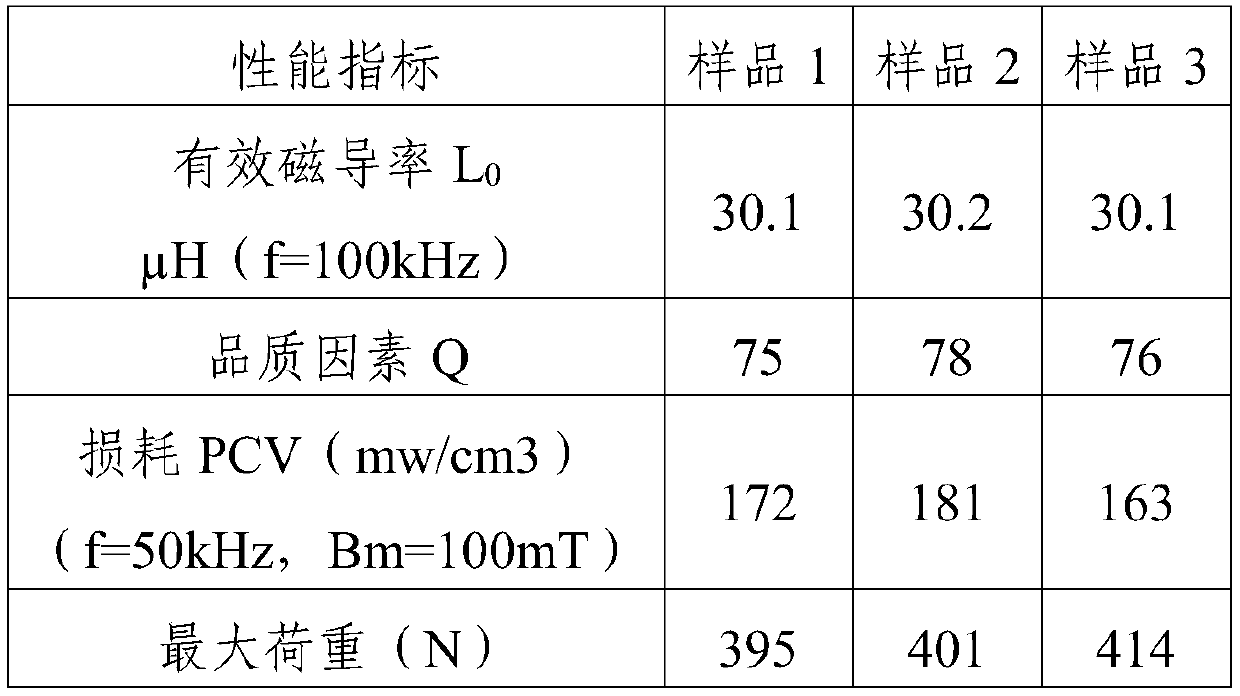

Embodiment 1

[0022] An all-inorganic high-temperature-resistant insulation bonding method for iron-based metal soft magnetic composite materials, comprising the following steps:

[0023] (1) The sendust magnetic powder is mixed according to the weight ratio of 150-200 mesh: 200-300 mesh: 300-400 mesh: 400 mesh or more: 1:3:3:2.5;

[0024] (2) Coating treatment: mix acidic (pH 3-5) silica sol and acidic (pH 3-5) aluminum sol at a volume ratio of 4:1, and add 0.1% dichromic acid of magnetic powder mass Potassium, add sendust magnetic powder into the mixed solution, stir evenly at 70°C and dry to obtain insulating powder;

[0025] (3) Bonding treatment: adding 1.0% water glass binder of magnetic powder weight and 0.15% solidifying agent silicon tripolyphosphate of magnetic powder weight and 1% magnetic powder weight to the above-mentioned dry insulating powder is silicon micropowder of 5 microns Filler, stir evenly at 120°C and dry, add lubricating powder to the dried magnetic powder and sti...

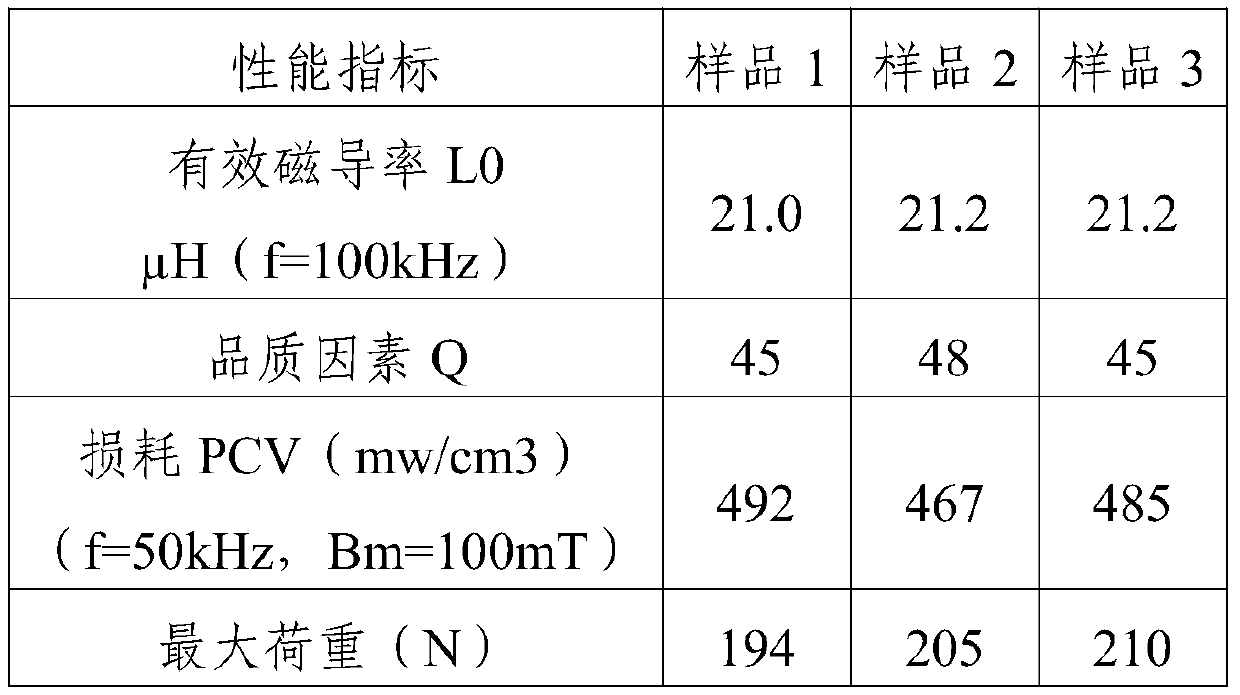

Embodiment 2

[0030] An all-inorganic high-temperature-resistant insulation bonding method for iron-based metal soft magnetic composite materials, comprising the following steps:

[0031] (1) The iron-silicon magnetic powder is mixed according to the weight ratio of 150-200 mesh: 200-300 mesh: 300-400 mesh: 400 mesh or more in a weight ratio of 1:3:3:3;

[0032] (2) Coating treatment: mix alkaline (pH 8-10) silica sol and alkaline (pH 7-9) aluminum sol at a volume ratio of 1:1, and add 0.3% of the mass of magnetic powder Potassium chromate, adding magnetic powder into the mixed solution, stirring evenly at 120°C and drying to obtain insulating powder;

[0033] (3) adding the water glass binder of magnetic powder weight 1.0% and the curing agent silicon tripolyphosphate of magnetic powder weight 0.1% to the insulating powder of above-mentioned drying and the particle diameter of magnetic powder weight 0.8% is the alumina filler of 3 microns, at 100 Stir evenly at ℃ and dry, add lubricating ...

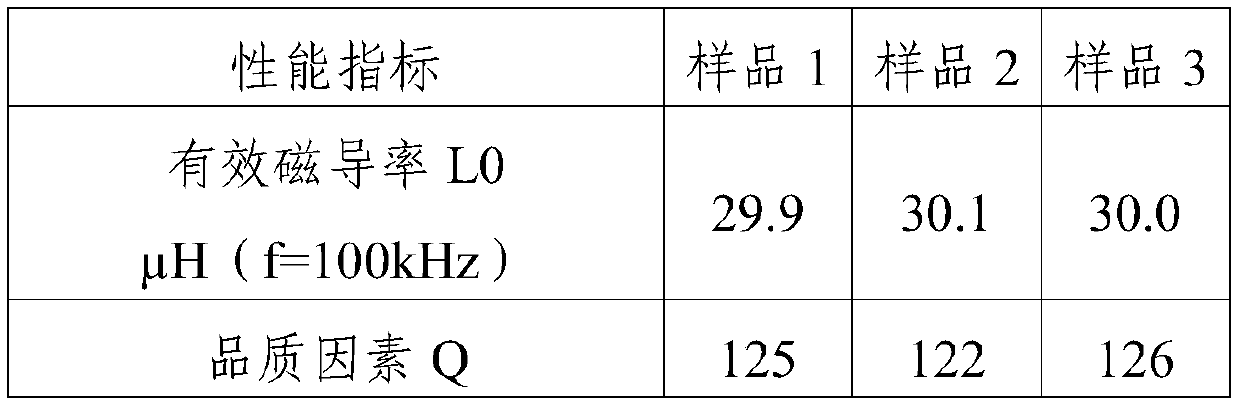

Embodiment 3

[0038] An all-inorganic high-temperature-resistant insulation bonding method for iron-based metal soft magnetic composite materials, comprising the following steps:

[0039] (1) The iron-nickel magnetic powder is mixed according to the weight ratio of 150-200 mesh: 200-300 mesh: 300-400 mesh: 400 mesh or more is 1.5:3:3:2.5;

[0040] (2) Coating treatment: mix alkaline (pH 8-10) silica sol and alkaline (pH 7-9) aluminum sol at a volume ratio of 3:1, and add 0.1% of the mass of magnetic powder Potassium chromate, adding magnetic powder into the mixed solution, stirring evenly at 100°C and drying to obtain insulating powder;

[0041] (3) Bonding treatment: adding 0.5% of the water glass binder of the magnetic powder weight and 0.05% of the magnetic powder weight of the solidifying agent silicon tripolyphosphate and 0.5% of the magnetic powder weight to the above-mentioned dry insulating powder is silicon micropowder of 2.6 microns filler. Stir evenly and dry at 120°C, add lubr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com