Method for effectively preparing high-orientation and high-compactness two-dimensional material thin film

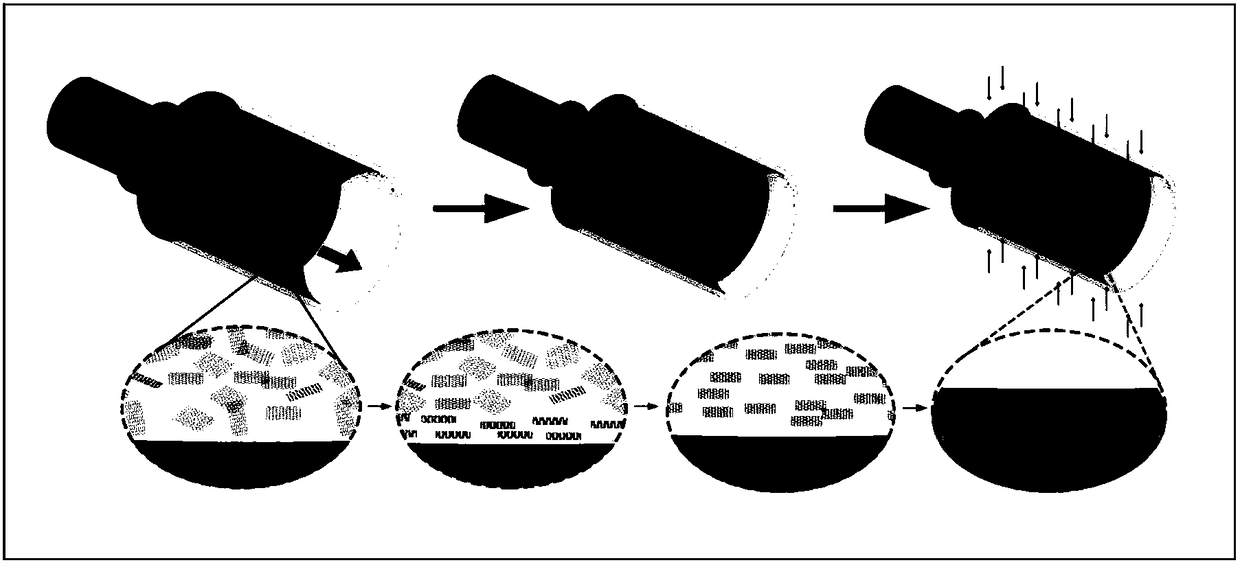

A technology of two-dimensional materials and material thin films, which is applied in the preparation and application of two-dimensional materials, can solve the problems of unsuitable large-area and thick film preparation, small driving force, and difficulty in self-assembly and orientation of two-dimensional materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a quartz glass tube with an inner diameter of 110 mm is used as the casting mold, the rotation speed of the mold is set at 500 r / min, and the auxiliary heating temperature is set at 80° C. A graphene oxide aqueous solution (average sheet size of about 1 micron, concentration of 2 mg / ml) is continuously added to the casting mold, and the solution is evaporated to dryness to obtain a film with a film thickness of 3 μm to 20 μm. Cut the film along the axis and peel it off from the mold to obtain a graphene oxide film with a strength of about 90 MPa.

Embodiment 2

[0039] The difference from Example 1 is:

[0040] In this embodiment, a quartz glass tube with an inner diameter of 110 mm is used as the casting mold, the rotation speed of the mold is set at 1000 r / min, and the auxiliary heating temperature is set at 80° C. A graphene oxide aqueous solution (average sheet size of about 1 micron, concentration of 2 mg / ml) is continuously added to the casting mold, and the solution is evaporated to dryness to obtain a film with a film thickness of 3 μm to 20 μm. After the film is cut along the axis, it is peeled off from the mold to obtain a graphene oxide film whose strength is increased to 125MPa.

Embodiment 3

[0042] The difference from Example 1 is:

[0043] In this embodiment, a quartz glass tube with an inner diameter of 110 mm is used as the casting mold, the rotation speed of the mold is set at 1500 r / min, and the auxiliary heating temperature is set at 80° C. A graphene oxide aqueous solution (average sheet size of about 1 micron, concentration of 2 mg / ml) is continuously added to the casting mold, and the solution is evaporated to dryness to obtain a film with a film thickness of 3 μm to 20 μm. After the film is cut along the axis and peeled off from the mold, a highly oriented and dense graphene oxide film is obtained, and its strength is further increased to 145MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com