Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206 results about "2-butanone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Butanone is often found dissolved in water or as a gas in the air. 2-Butanone is also a natural product made by some trees and is found in some fruits and vegetables. The exhausts of cars and trucks release 2-butanone into the air.

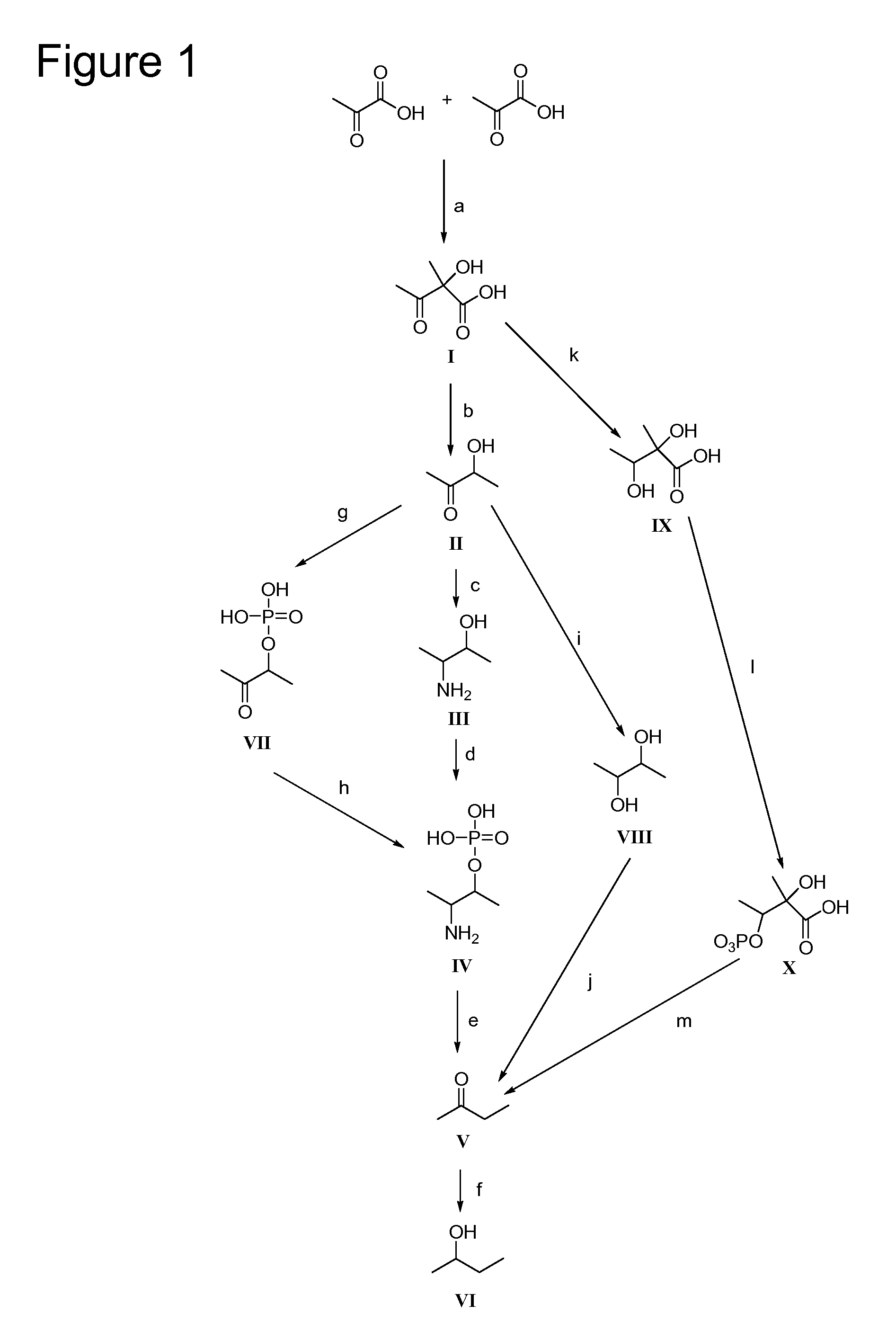

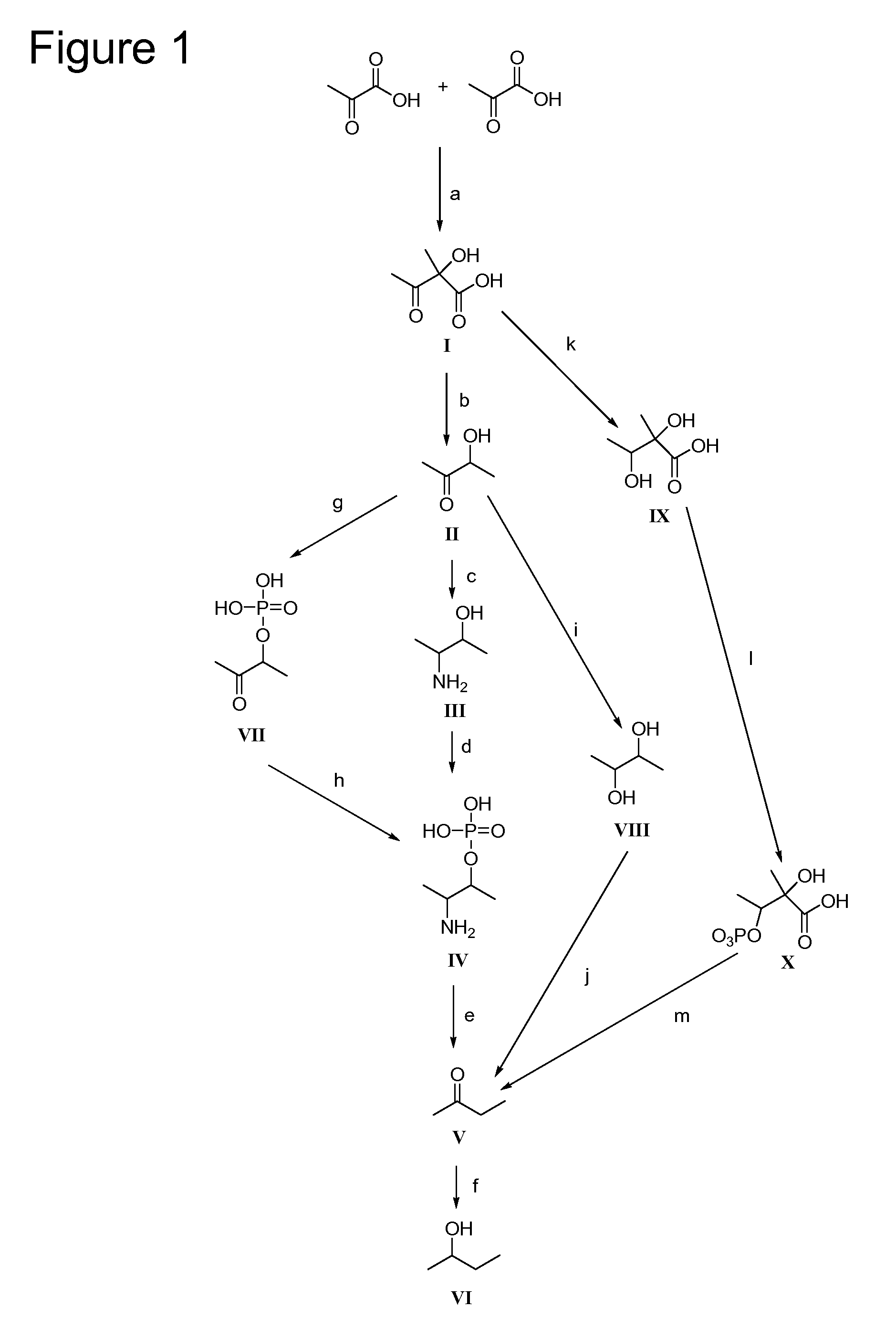

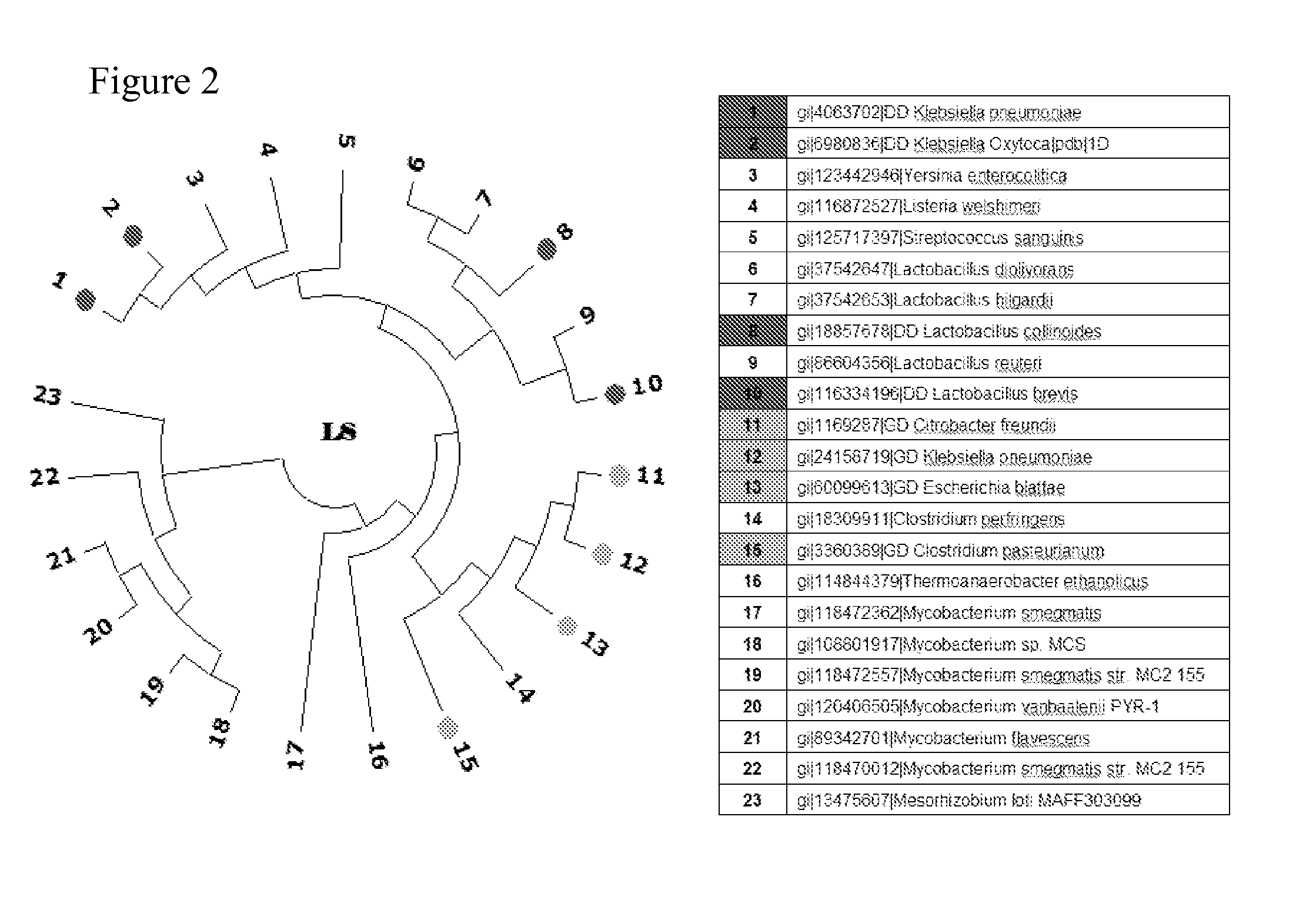

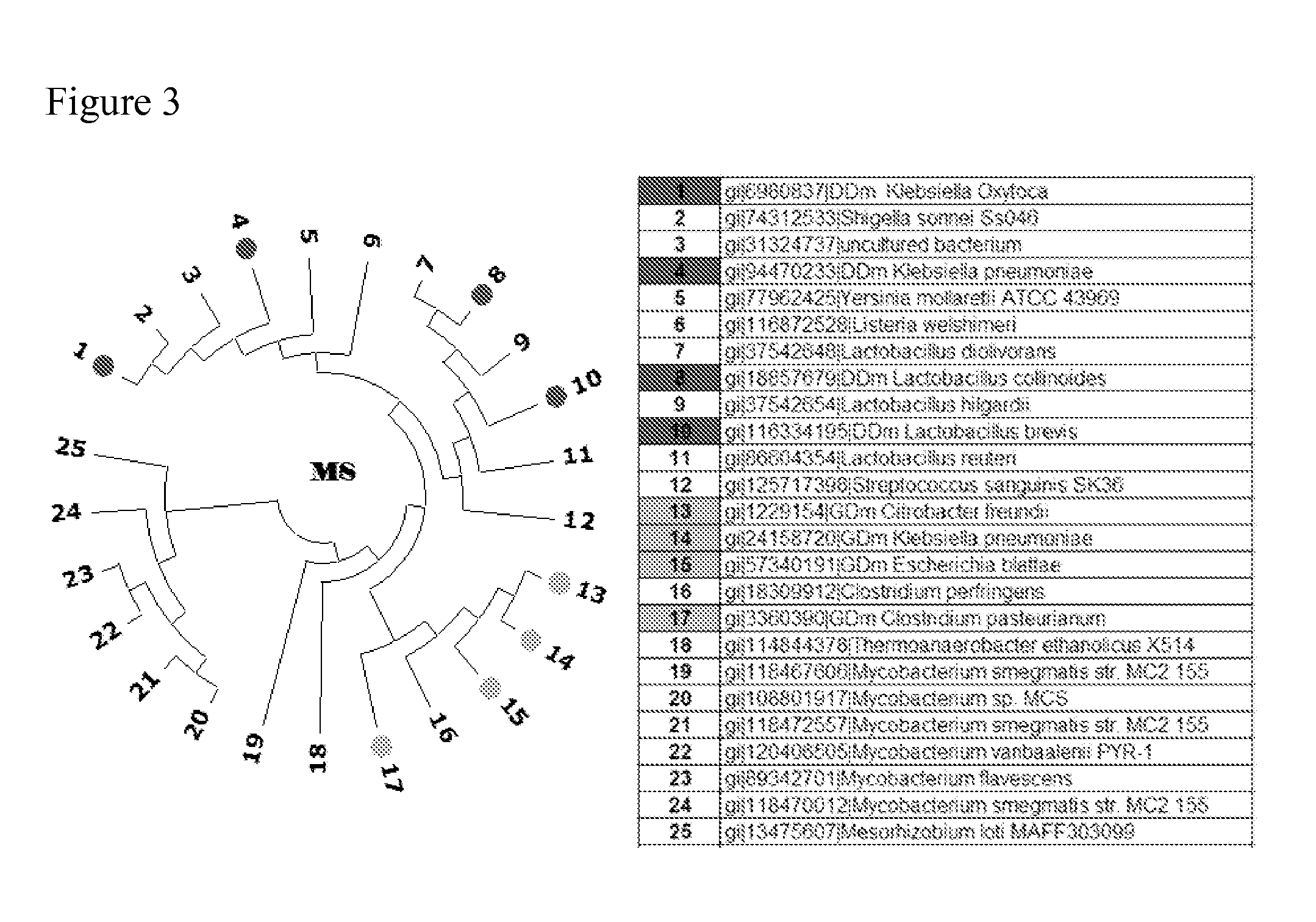

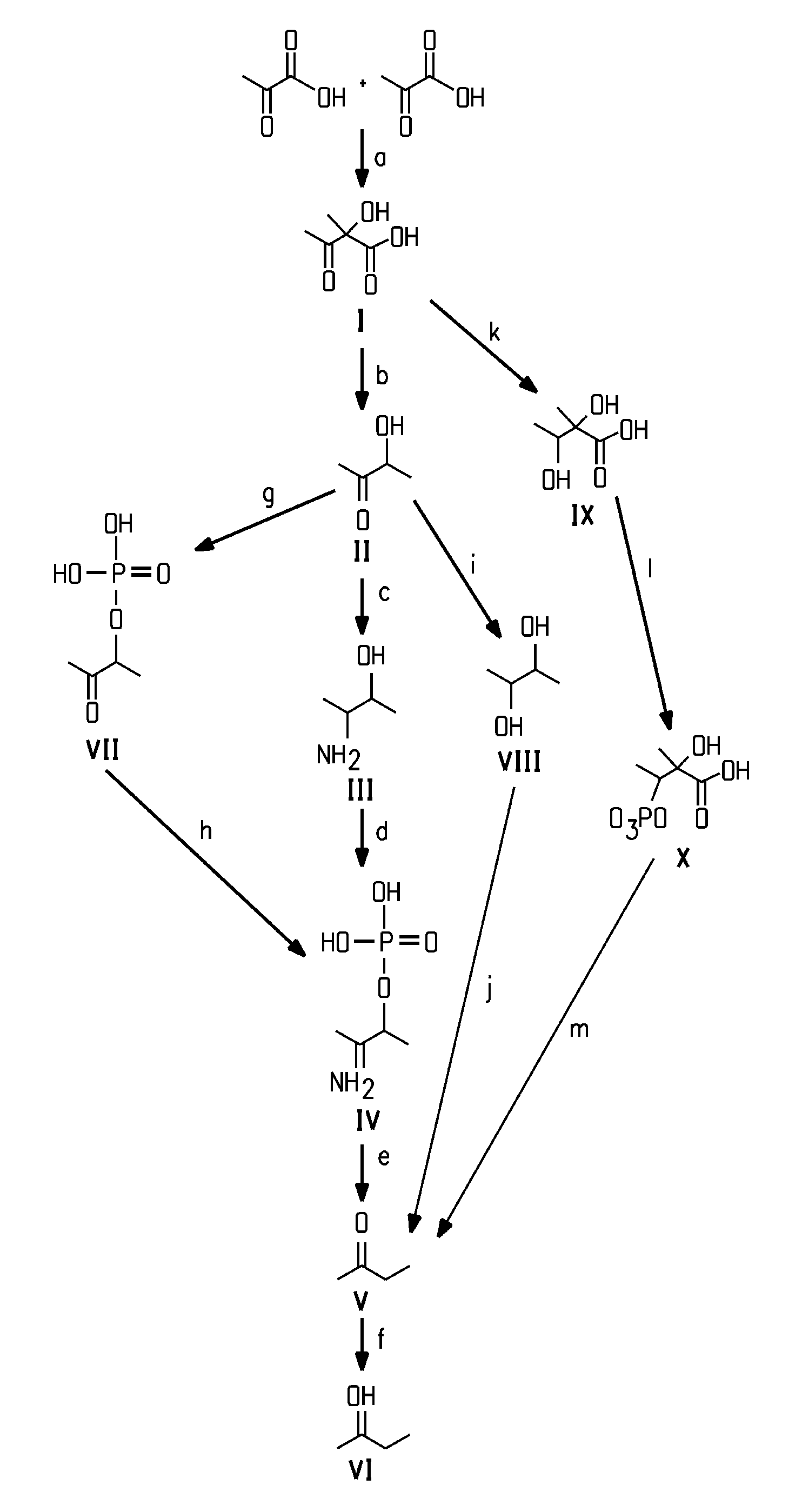

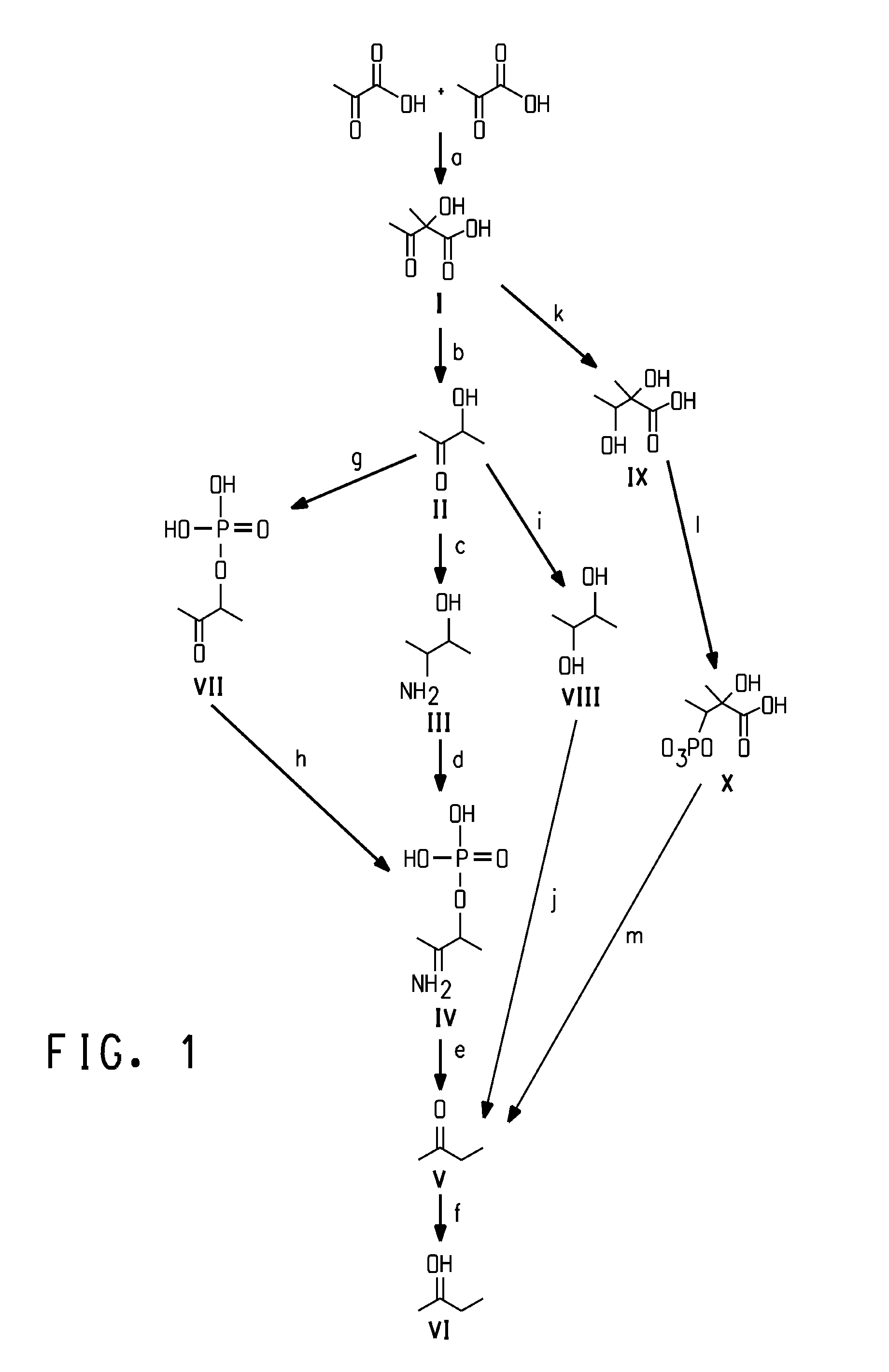

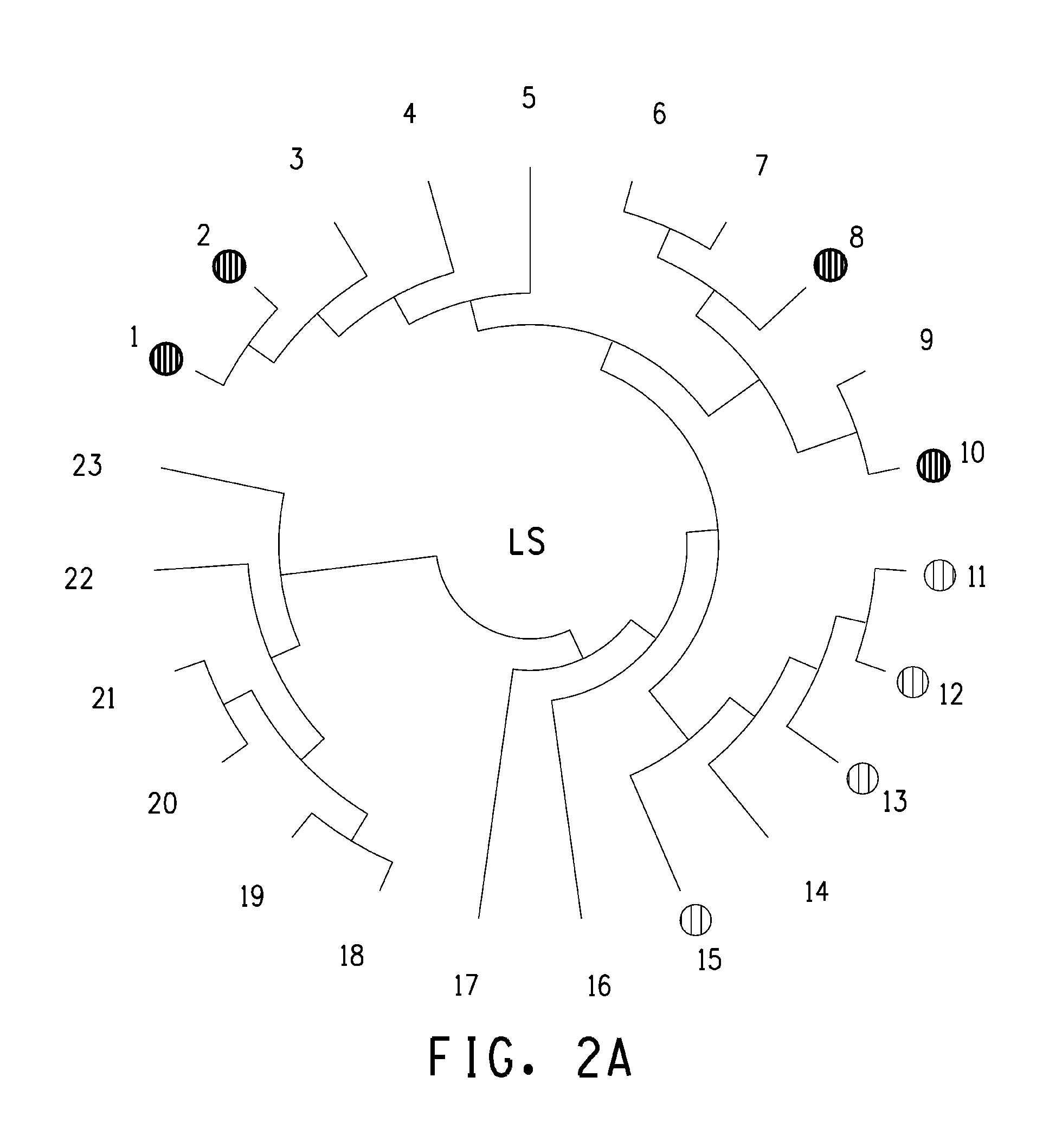

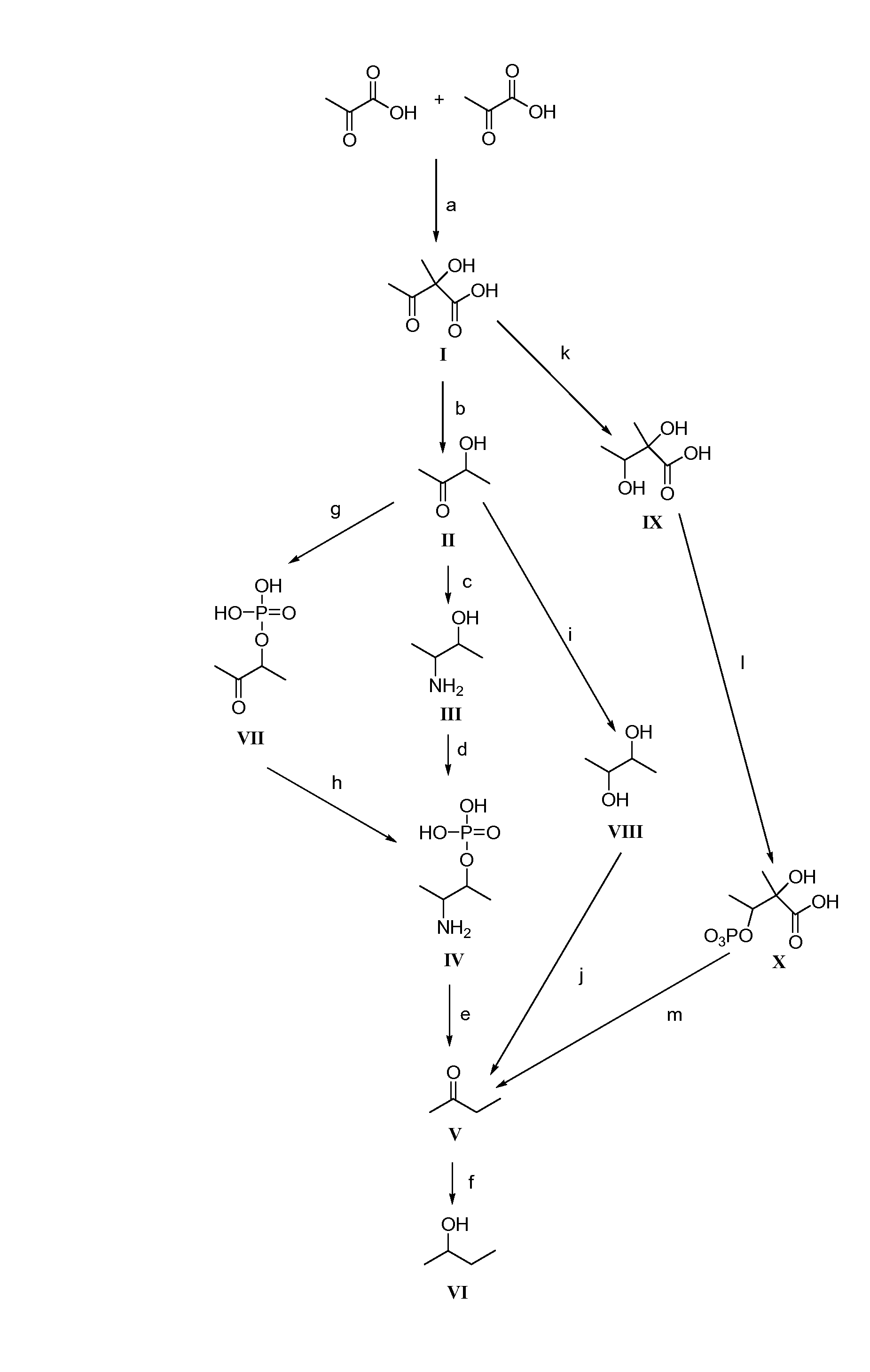

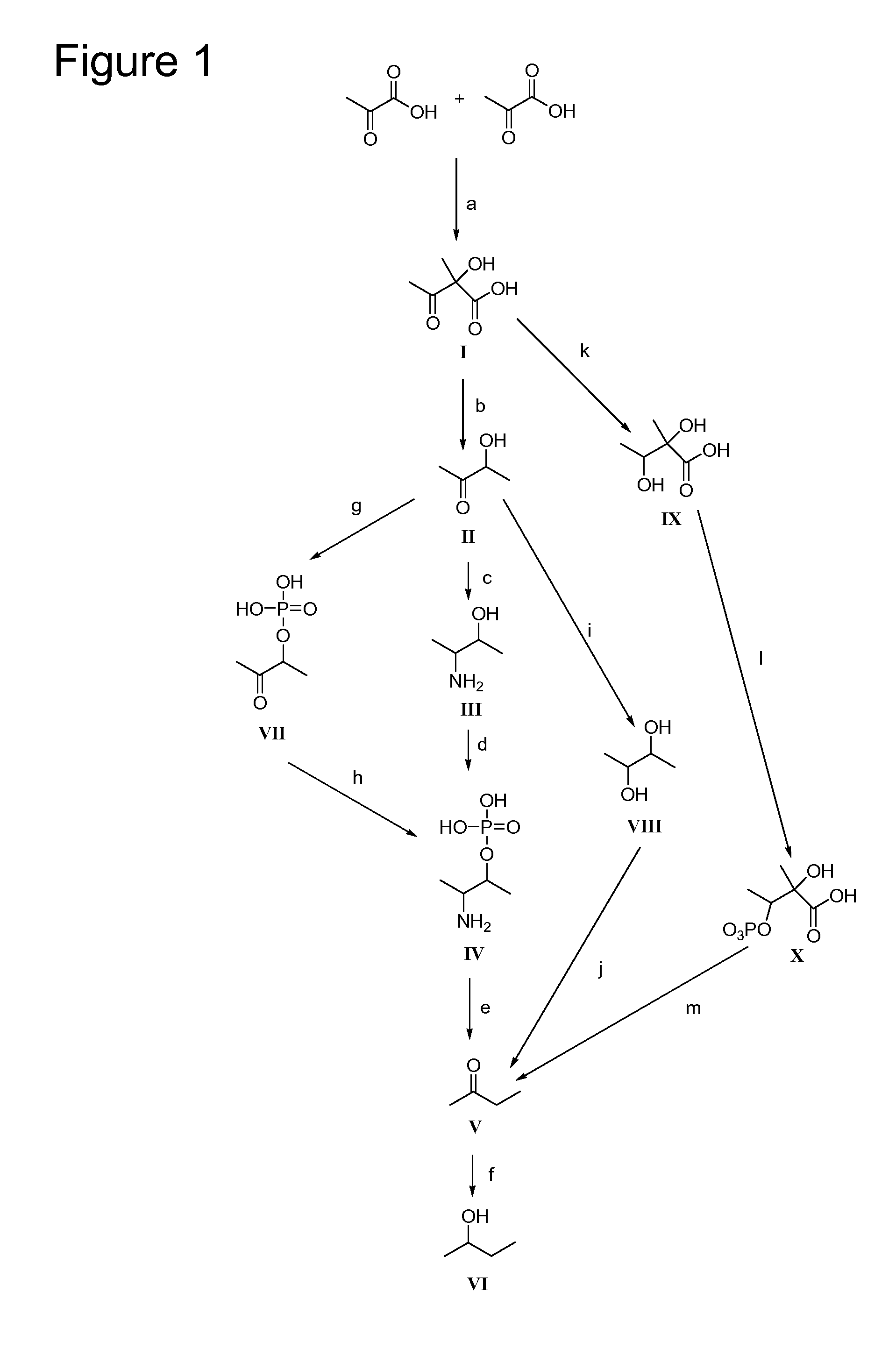

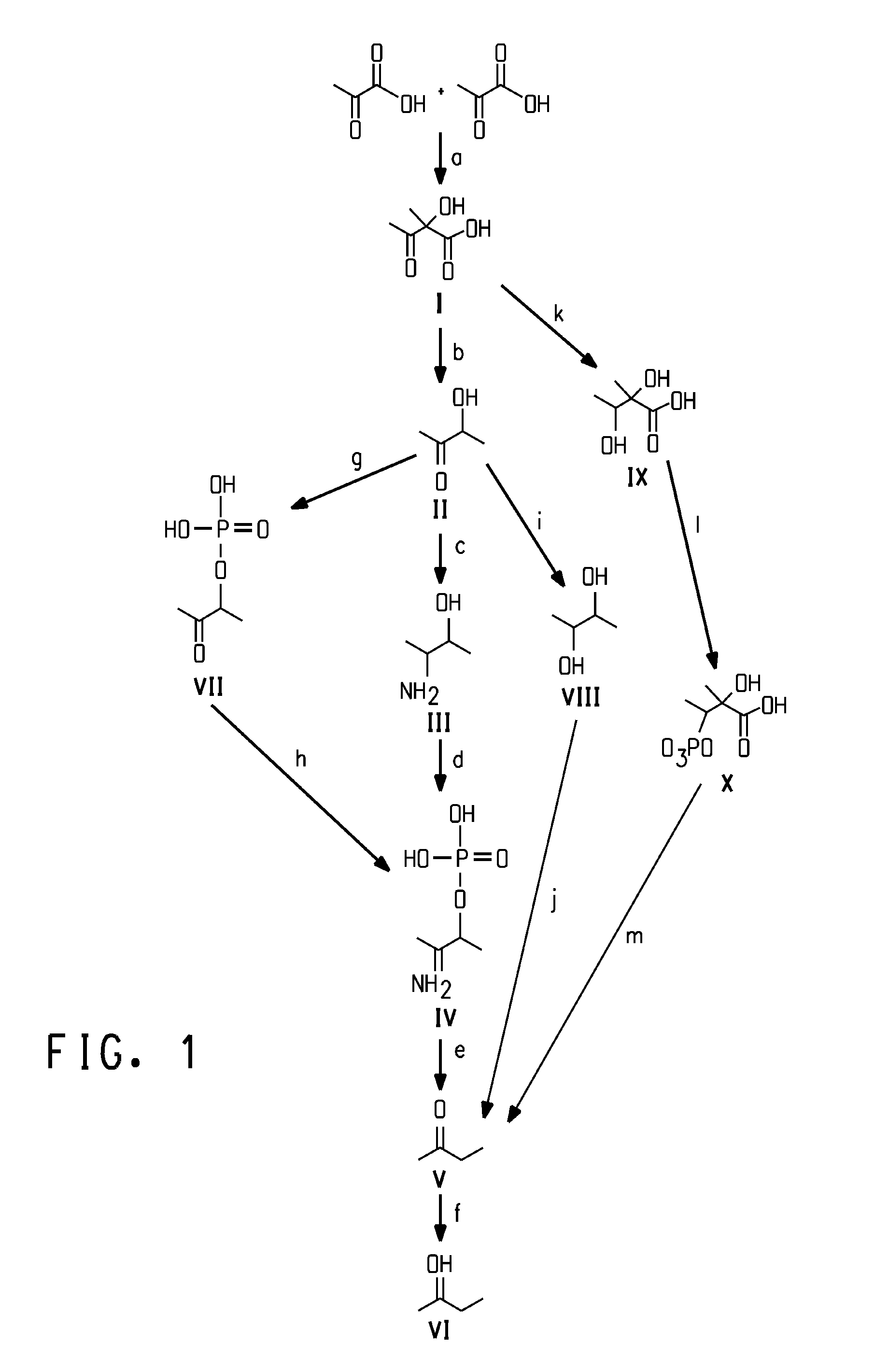

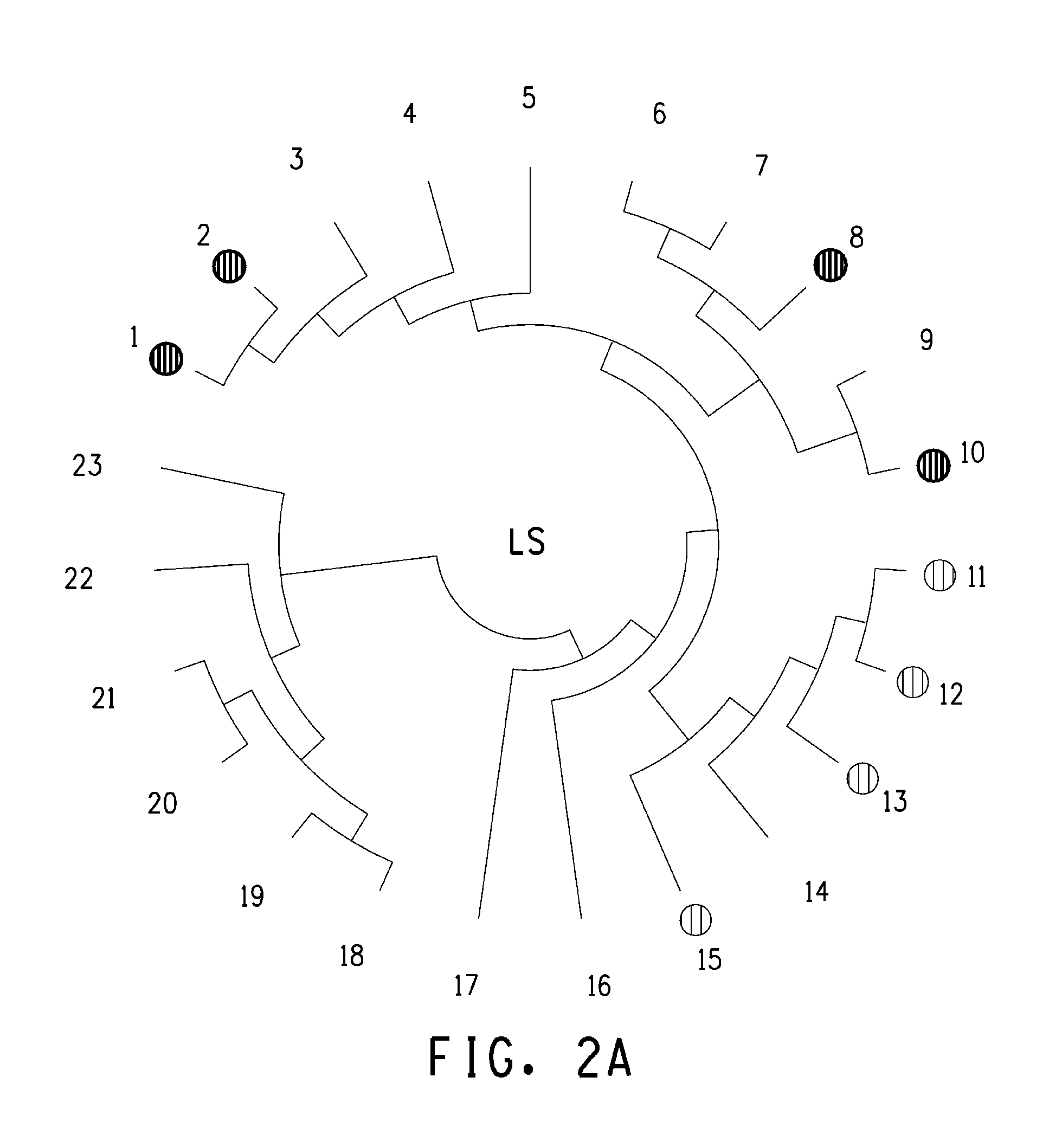

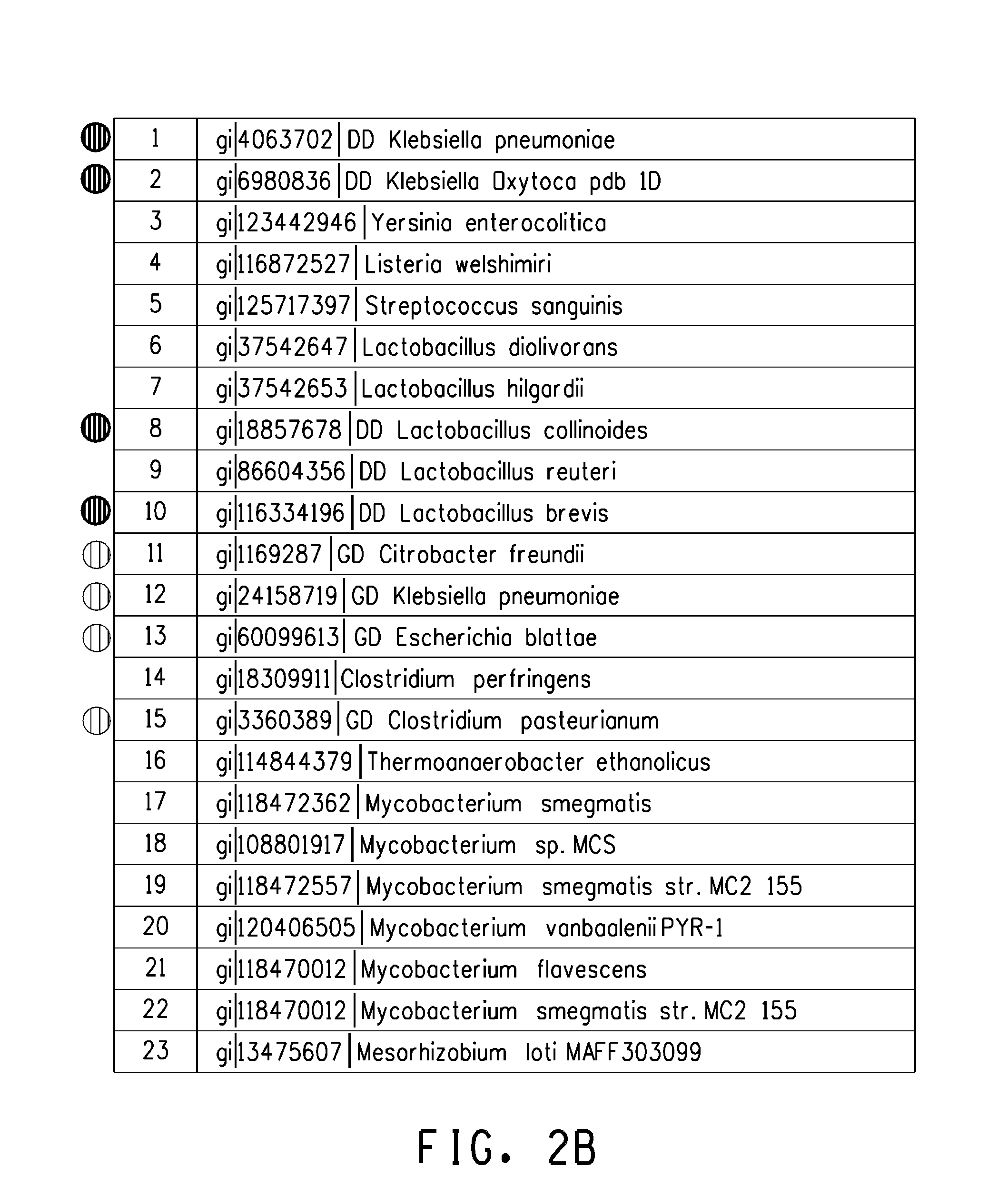

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein.

Owner:GEVO INC

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein.

Owner:GEVO INC

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

Method for the production of 2-butanone

InactiveUS20080274522A1Reduce the temperatureRobust toleranceBiofuelsFermentationBiotechnologyButanone

A method for the production of 2-butanone by fermentation using a microbial production host is disclosed. The method employs a reduction in temperature during the fermentation process that results in a more robust tolerance of the production host to the butanone product.

Owner:EI DU PONT DE NEMOURS & CO

Production of four carbon alcohols using improved strain

Owner:GEVO INC

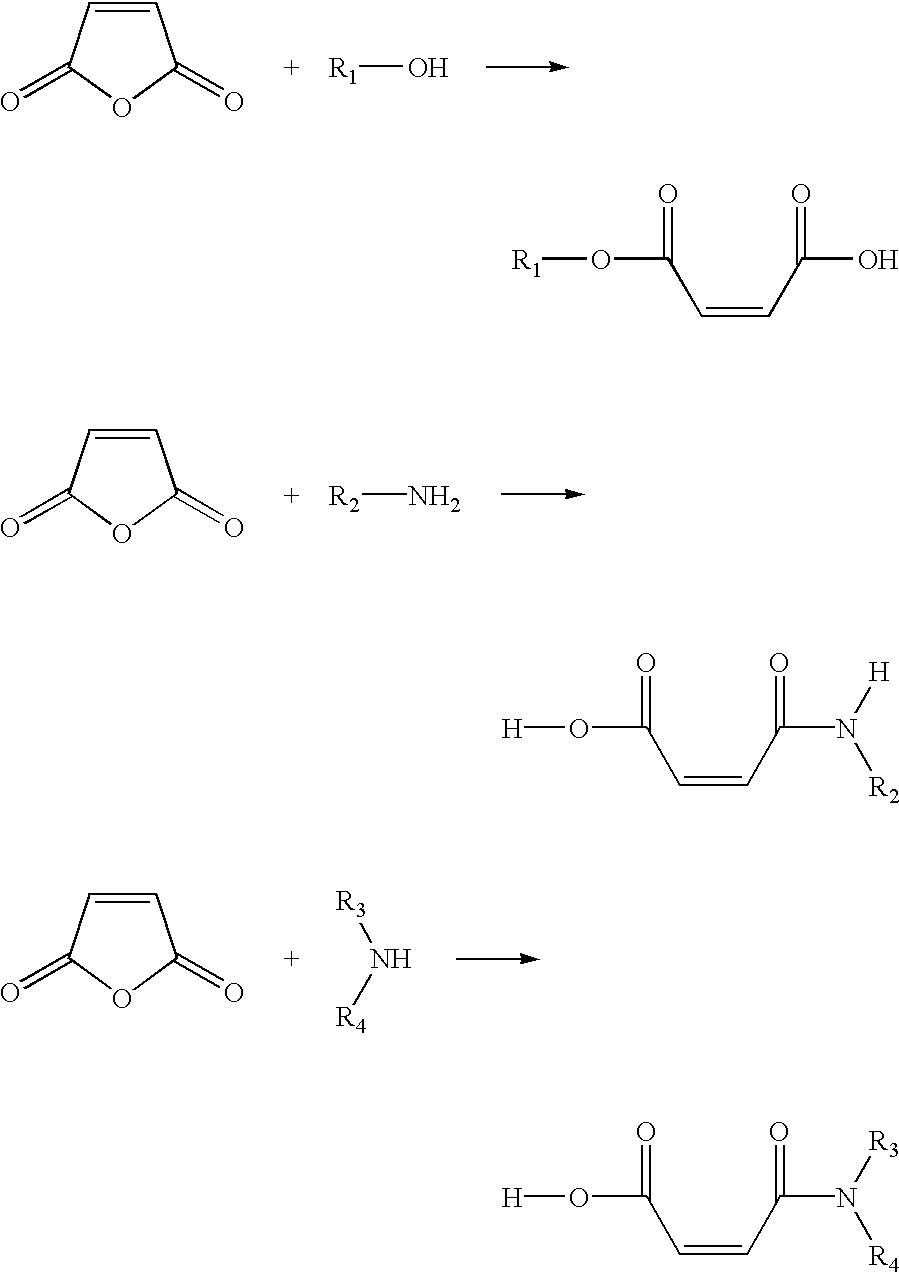

Cationically polymerizable adhesive composition containing an acidic component and methods and materials employing same

An adhesive composition that includes a mixture of a cationically polymerizable component, an acidic component, and an initiator is provided. Preferably, the initiator comprises an iodonium salt, a visible light sensitizer, and an electron donor compound, wherein the initiator has a photoinduced potential greater than or equal to that of N,N-dimethylaniline in a standard solution of 2.9x10-5 moles / g diphenyl iodonium hexafluoroantimonate and 1.5x10-5 moles / g camphorquinone in 2-butanone. This adhesive composition is cationically polymerizable and is able to bond to hard tissue and cationic restorative materials upon curing.

Owner:3M INNOVATIVE PROPERTIES CO +1

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

Optical film, anti-reflection film, polarizing plate and image display device

InactiveUS20070207298A1Improve surface uniformityDecreasing drying unevennessLayered productsOptical filters2-butanoneViscosity

An optical film, which comprises: a transparent support; and an optical layer on or above the transparent support, wherein the optical layer contains a thickening agent which shows a viscosity of 10 mPa·sec or more when added to 2-butanone in a content of 3% by mass, and the optical layer has a thickness of 5 μm or more.

Owner:FUJIFILM CORP

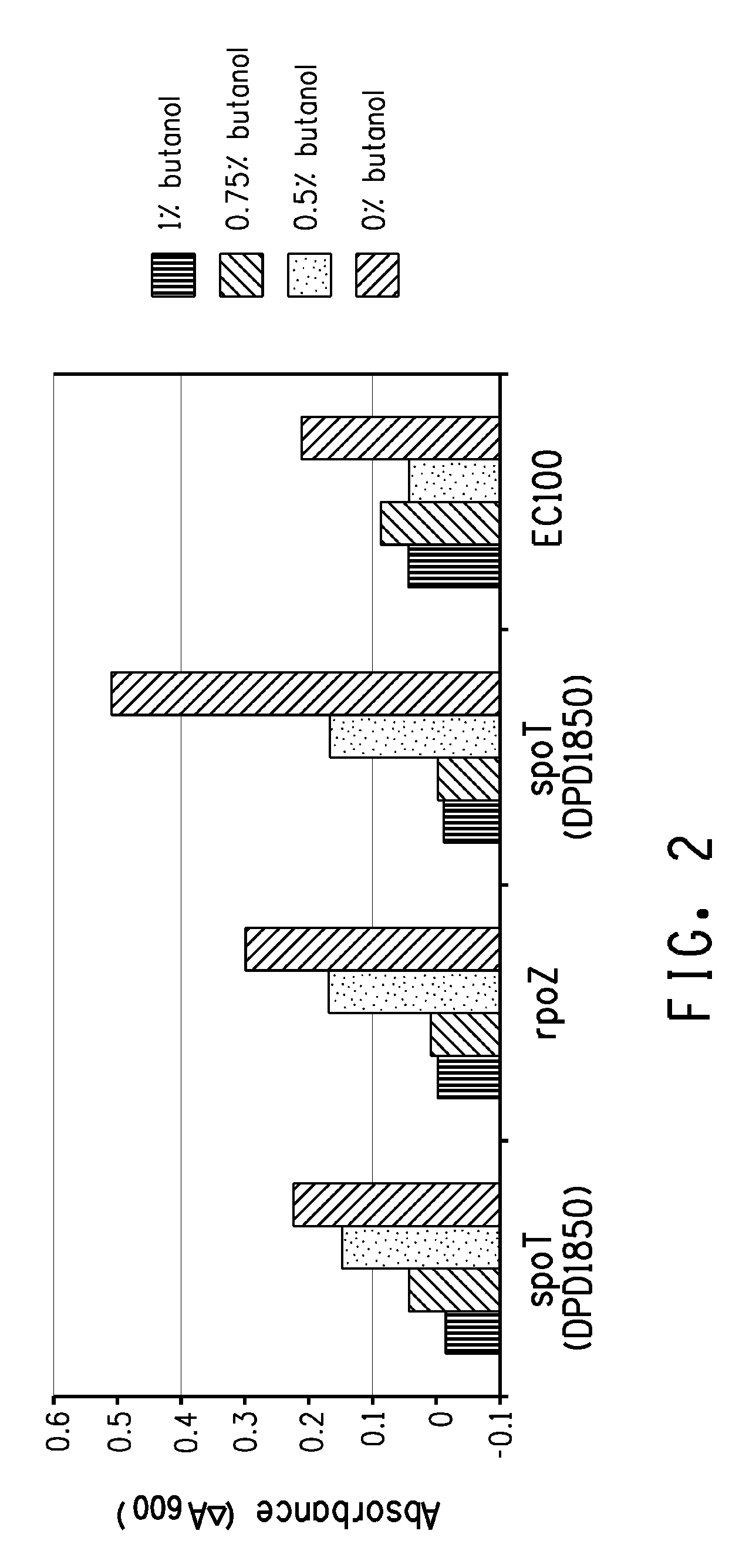

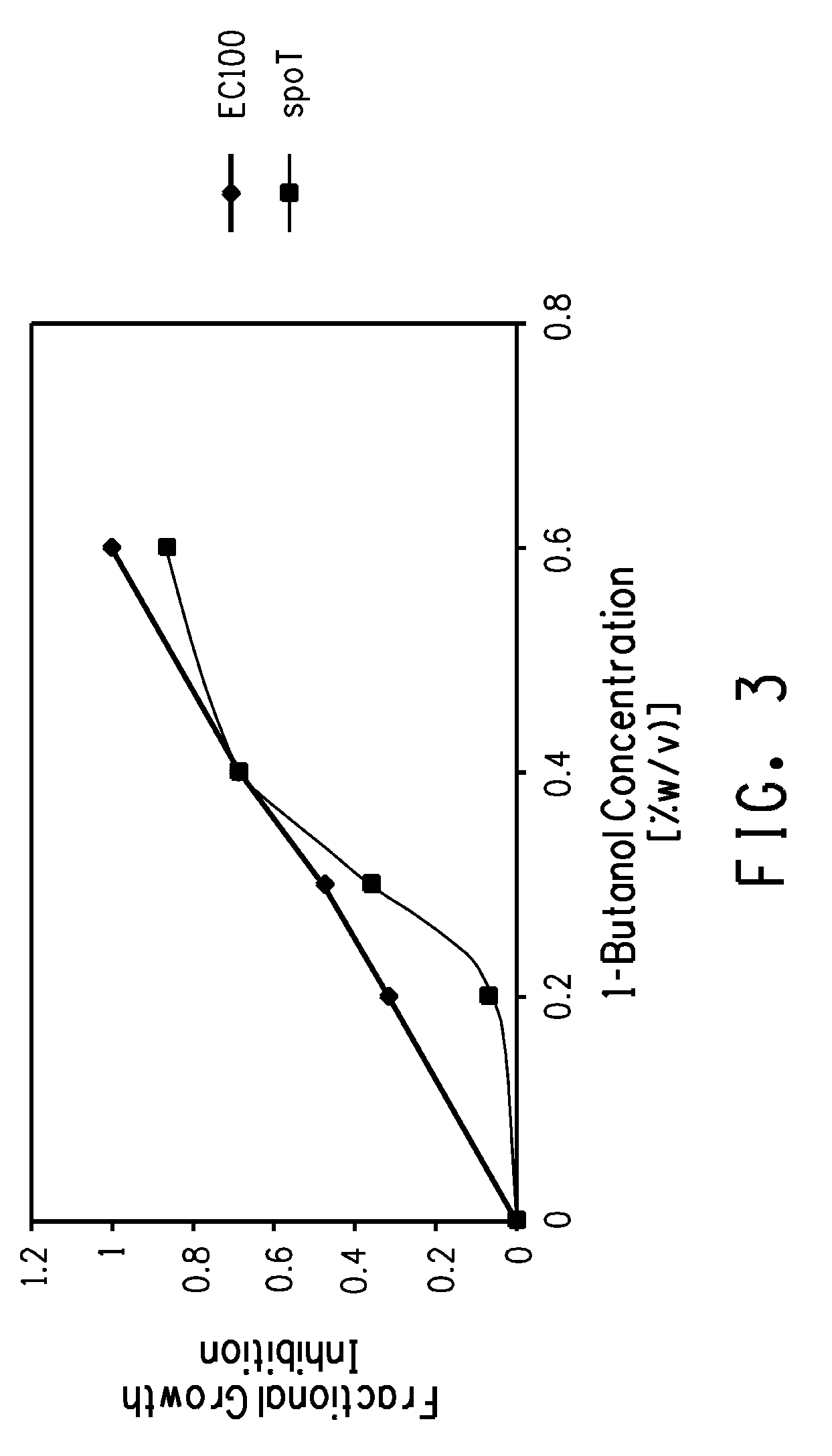

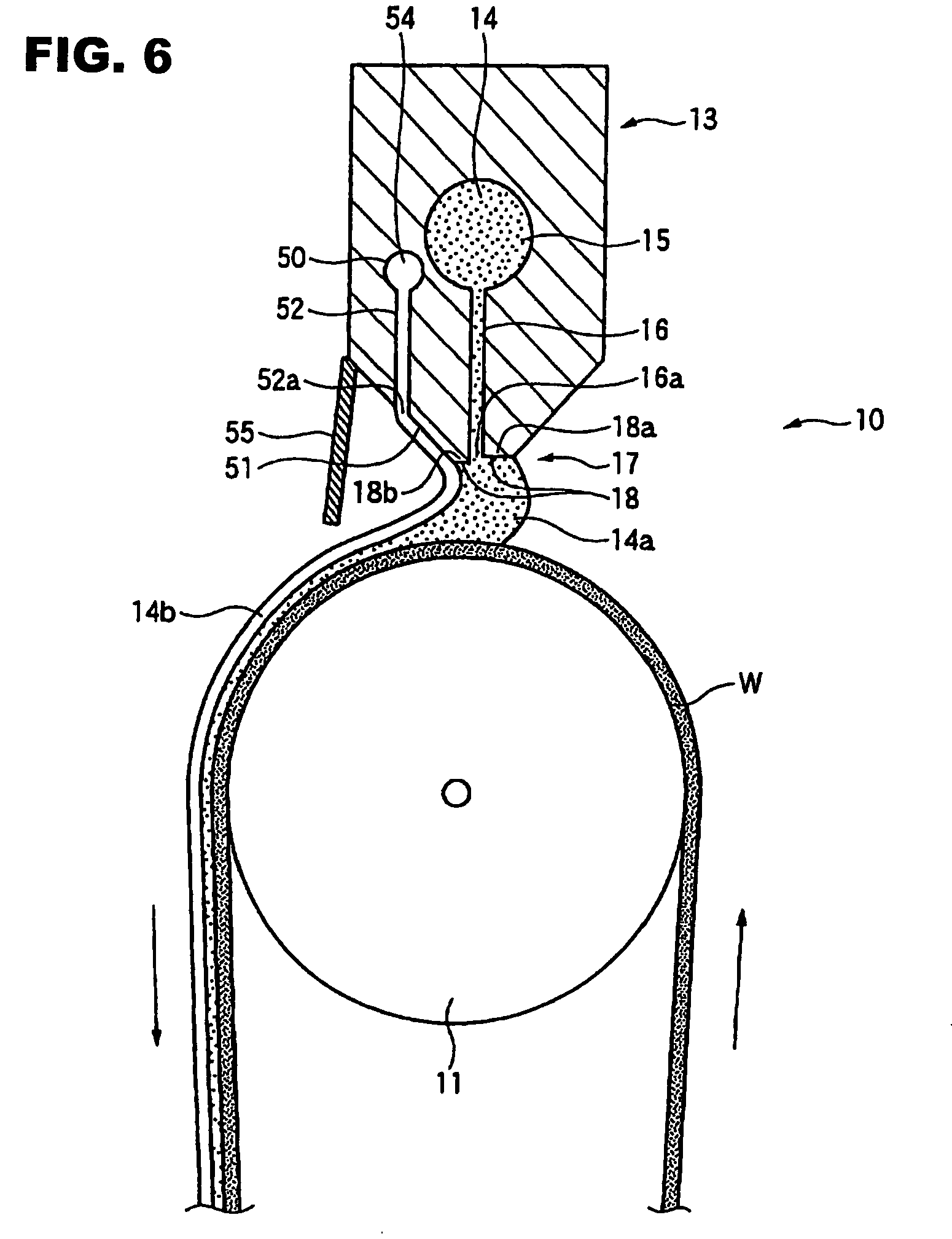

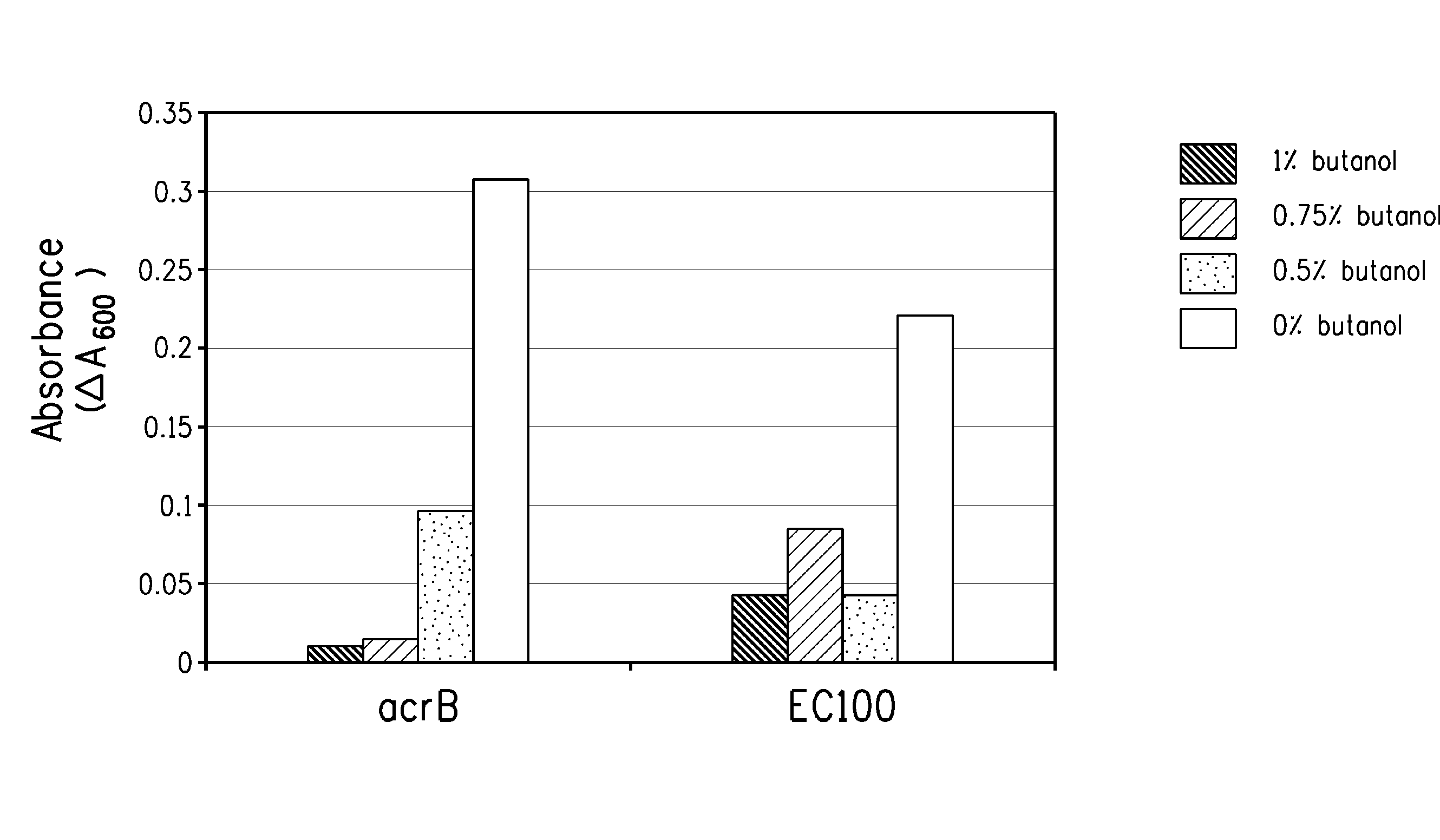

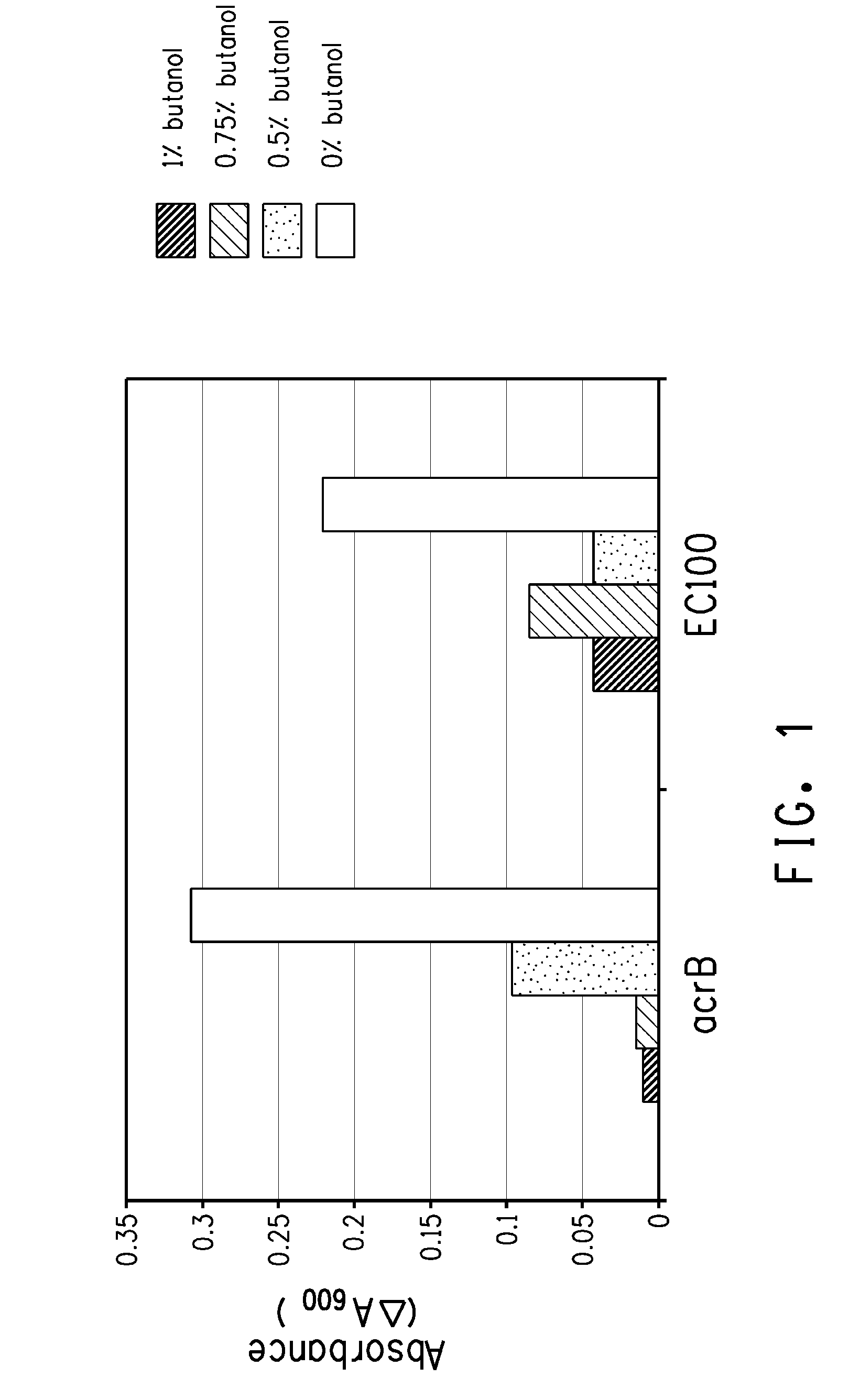

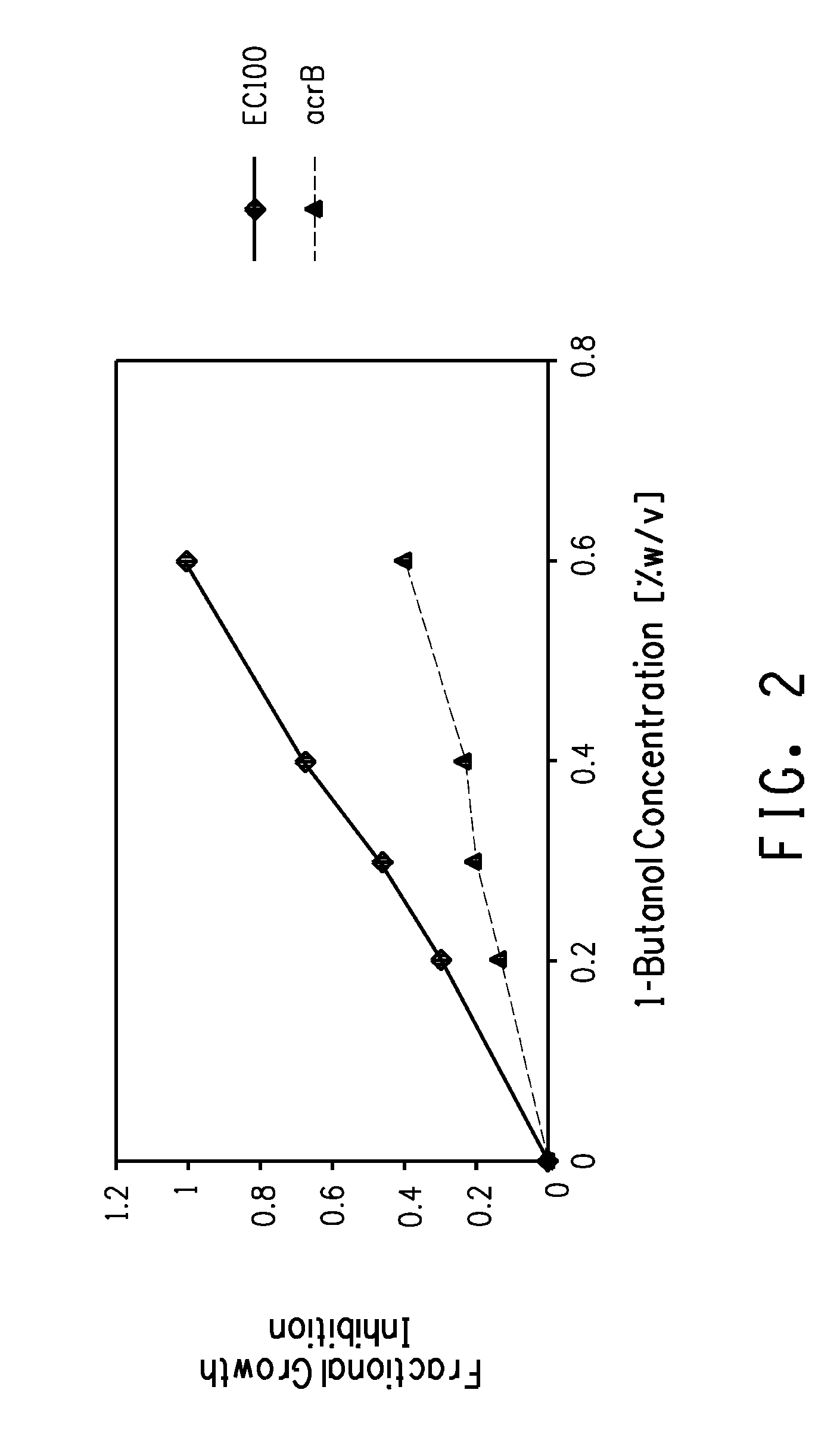

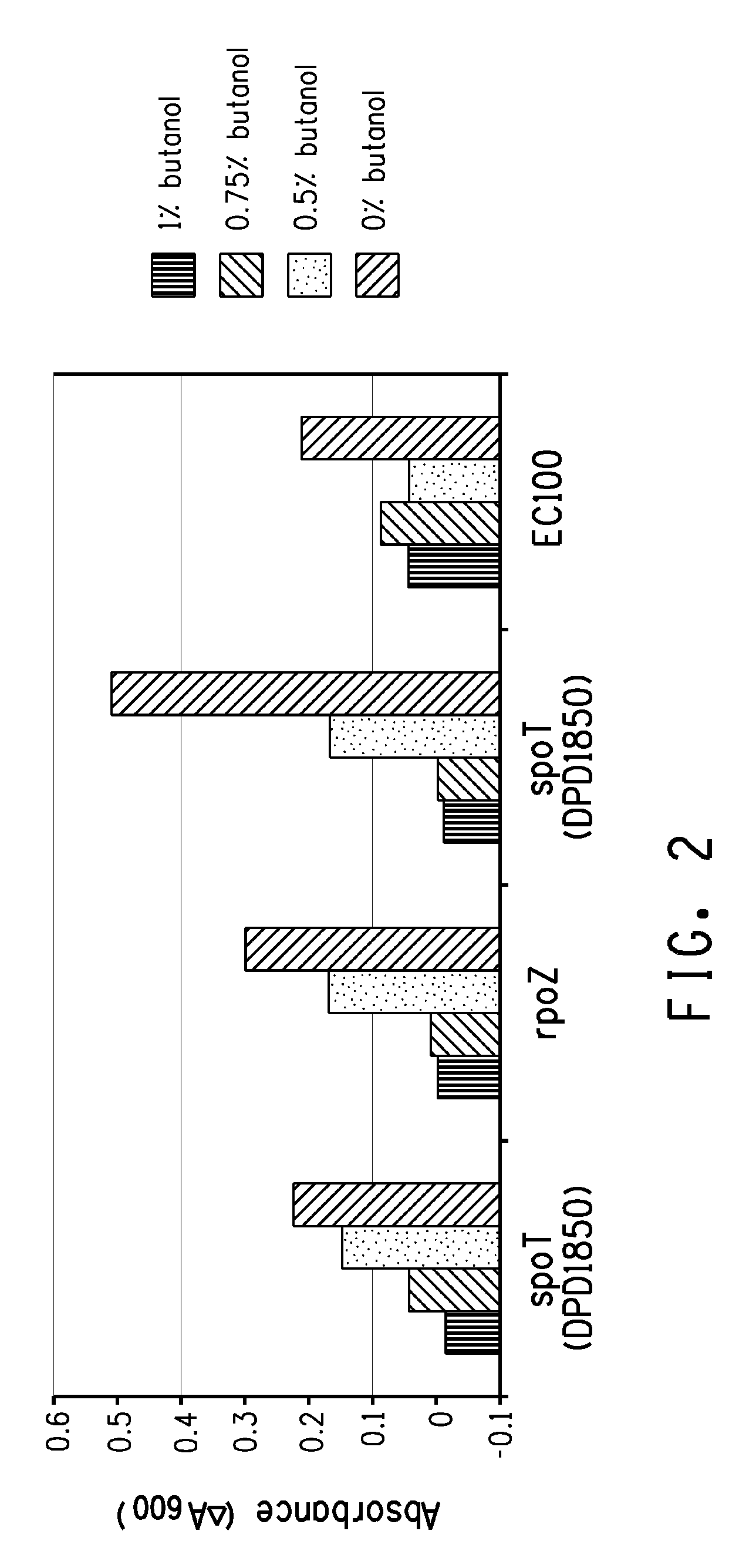

Strain for butanol production

Using screening of transposon random insertion mutants, genes involved in a complex that is a three-component proton motive force-dependent multidrug efflux system were found to be involved in E. coli cell response to butanol. Reduced production of the AcrA and / or AcrB proteins of the complex confers increased butanol tolerance. E. coli strains with reduced AcrA or AcrB production and having a butanol or 2-butanone biosynthetic pathway are useful for production of butanol or 2-butanone.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Optical film, Anti-reflection film, polarizing plate and image display device

InactiveUS20110256312A1Improve surface uniformityDecreasing drying unevenness and wind unevennessOptical filtersPolarising elementsDisplay deviceViscosity

Owner:FUJIFILM CORP

Germicide composition

A bactericide composition comprises difenoconazole (A) and at least one bactericide (B) selected from 1-(4-chlorophenoxy)-3, 3-dimethyl-1-(1H-1, 2, 4-triazole-1-methyl)-2-butanone, 1-(4-chlorophenoxy)-3, 3-dimethyl-1-(1H-1, 2, 4triazole-1methyl)butyl-2-alcohol, bi-(4-fluorophenyl)methyl(1H-1, 2, 4-triazole-1-kya methylene)silicane, and 2-(4-chlorphenyl)-2-(1H, 1, 2, 4-triazole-1-methyl) capronitrile. The composition can be used for preventing and treating rice sheath blight disease and wheat powdery mildew.

Owner:ANHUI HUAXING CHEM IND CO LTD

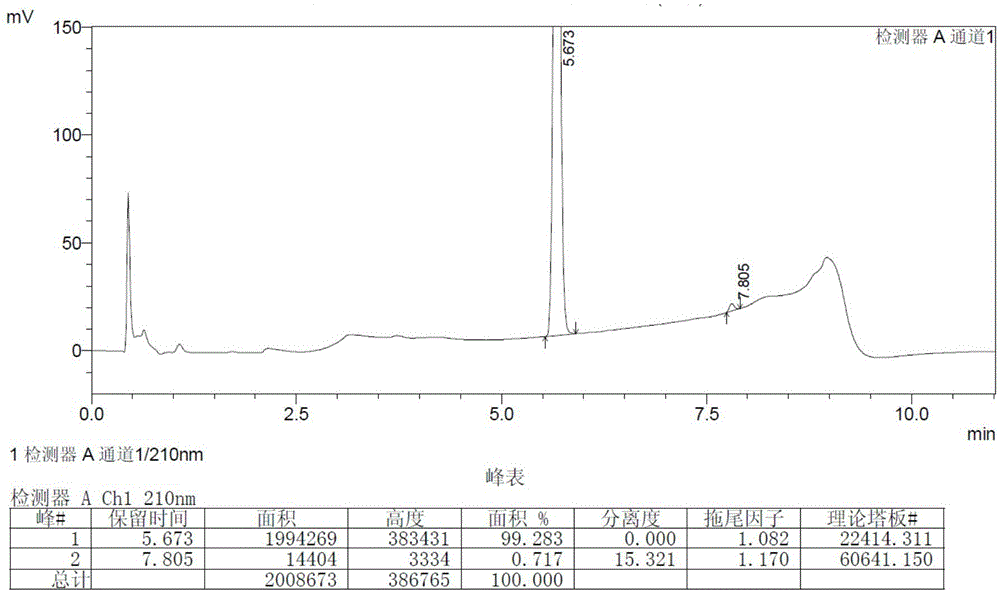

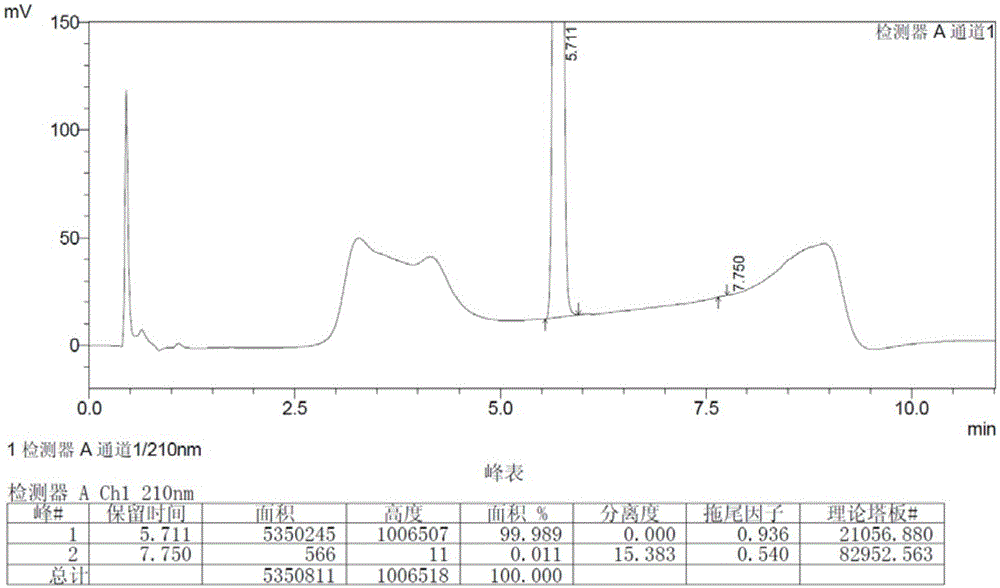

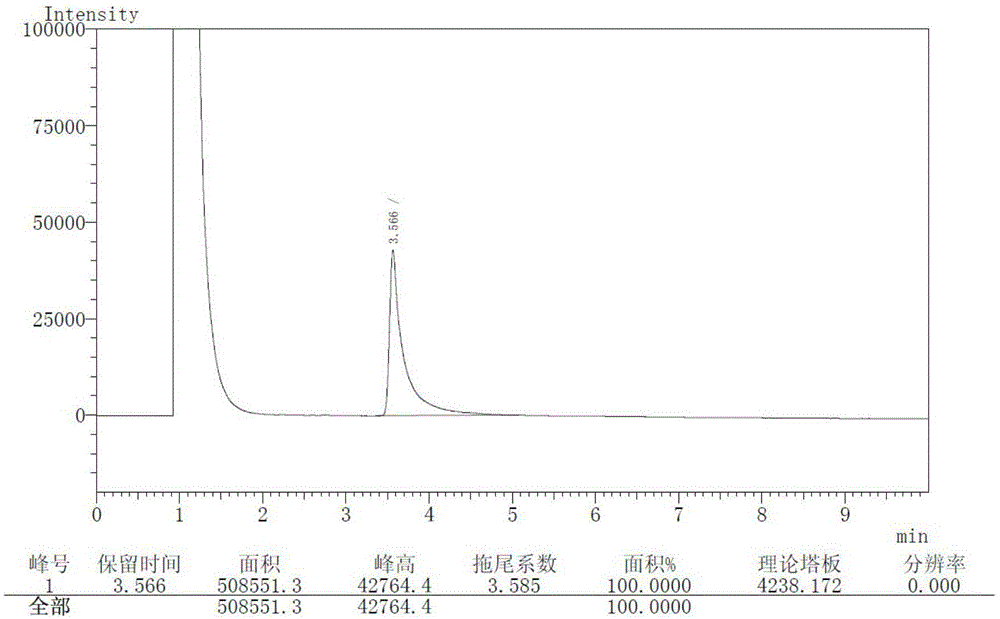

Preparation method of high-purity vildagliptin

InactiveCN105085360AReduce contentImprove technical effectOrganic chemistrySynthesis methodsPotassium iodine

The invention discloses a preparation method of high-purity vildagliptin, which comprises the following steps: carrying out nucleophilic substitution reaction on an intermediate (2S)-1-(2-chloracetyl)-2-pyrrolidine formonitrile and 3-amino-1-adamantanol in a certain reaction solvent by using potassium iodide as a catalyst and potassium carbonate as an acid-binding agent, carrying out after-treatment to obtain grease, and carrying out solvent crystallization to obtain a vildagliptin crude product; and refining the vildagliptin crude product by using a purified solvent to obtain the refined product. The synthesis method by controlling the vildagliptin crude product obtains favorable technical effects, and can obviously lower the impurity content in the vildagliptin crude product. A refinement technique different from the documents is adopted, and isopropanol and 2-butanone impurity removal is performed to obtain favorable technical effects, thereby obviously lowering the content of the main impurity 3-amino-1-adamantanol and vildagliptin bis-substituted impurity in the vildagliptin crude product. The vildagliptin purity detected by HPLC (high performance liquid chromatography) and GC (gas chromatography) is up to 99.8% or above, and the contents of the two impurities are respectively lower than 0.1%.

Owner:NANJING UNIV OF SCI & TECH

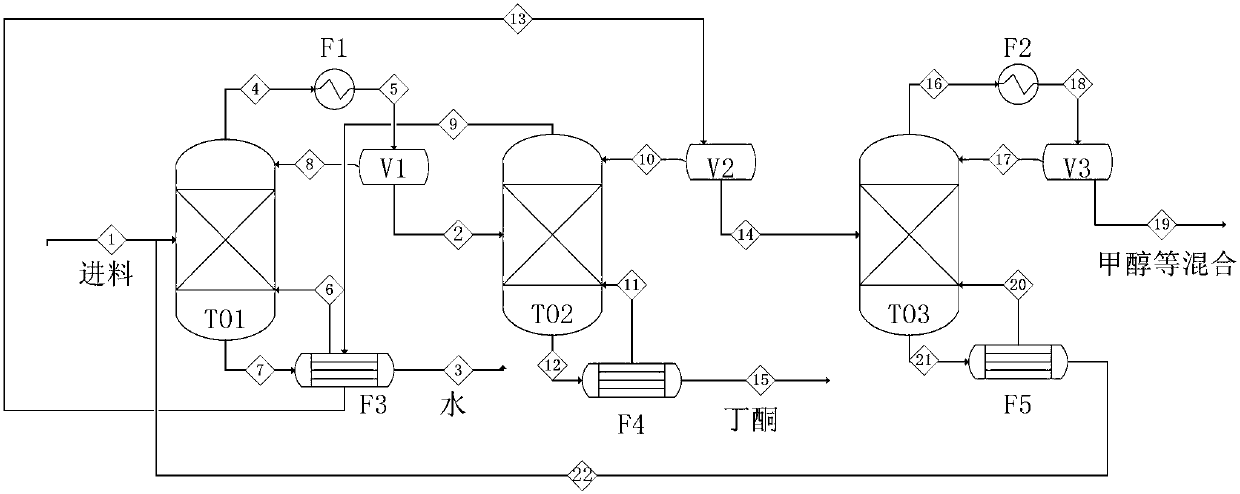

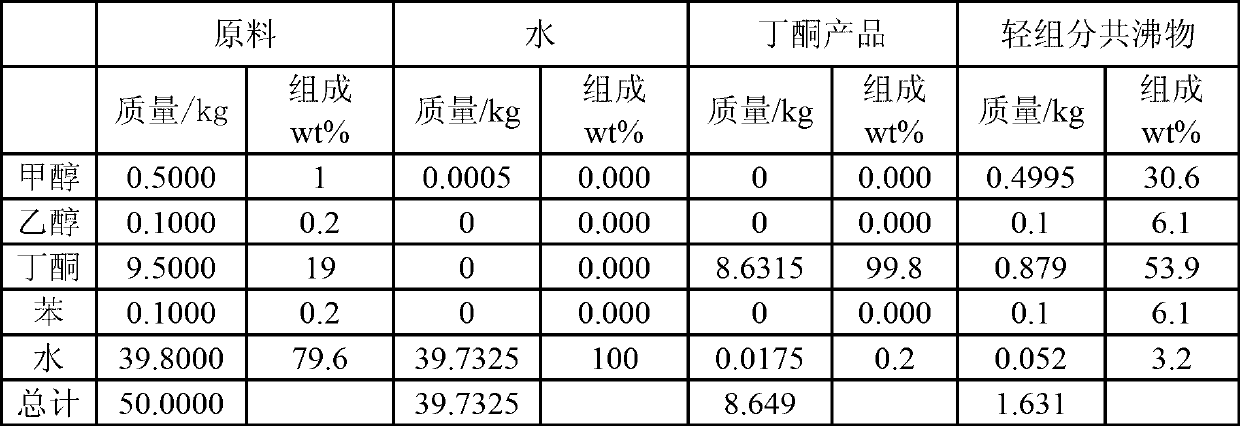

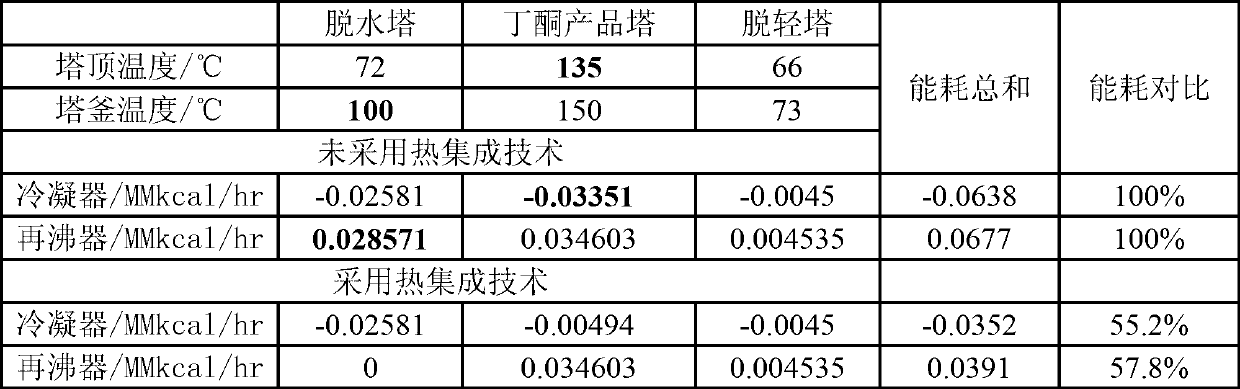

Method and device for separating and recycling butanone by three-tower pressure-variable rectification and heat integration

InactiveCN102992985ASolve the problem of separation and recovery of butanoneHigh purityChemical industryCarbonyl compound separation/purificationHigh pressure2-butanone

The invention relates to a method and a device for separating and recycling butanone by three-tower pressure-variable rectification and heat integration. The method comprises the steps of: enabling raw materials to enter a dehydrating tower, obtaining water containing a small amount of organic matters from the tower bottom of the dehydrating tower, and extracting a normal-pressure azeotrope from the tower top; pressurizing the normal-pressure azeotrope and enabling the normal-pressure azeotrope to enter a butanone product tower, wherein the pressure boost increases the content of water in an azeotropic system of butanone-water, and methanol, ethanol, benzene and the like generate a minimum-boiling-point azeotrope with butanone and water; extracting a high-pressure azeotrope from the tower top, and extracting a butanone product with higher purity from the bottom of the butanone product tower; adopting a hot material stream entering from the tower top of the butanone product tower as the hot source of the dehydrating tower; and enabling the high-pressure azeotrope to enter a light component removing tower, extracting a light-component azeotrope from the tower top of the light component removing tower, obtaining a circulating material stream from the tower bottom, and enabling the circulating material stream to enter the dehydrating tower for cyclic operation. By using the method, the difficulty that butanone is separated and recycled from a complex system is solved, butanone with higher purity is obtained, the quality purity of butanone is more than or equal to 99.5%, and the energy consumption is reduced to the largest extent as a heat integration process is adopted.

Owner:TIANJIN UNIV +1

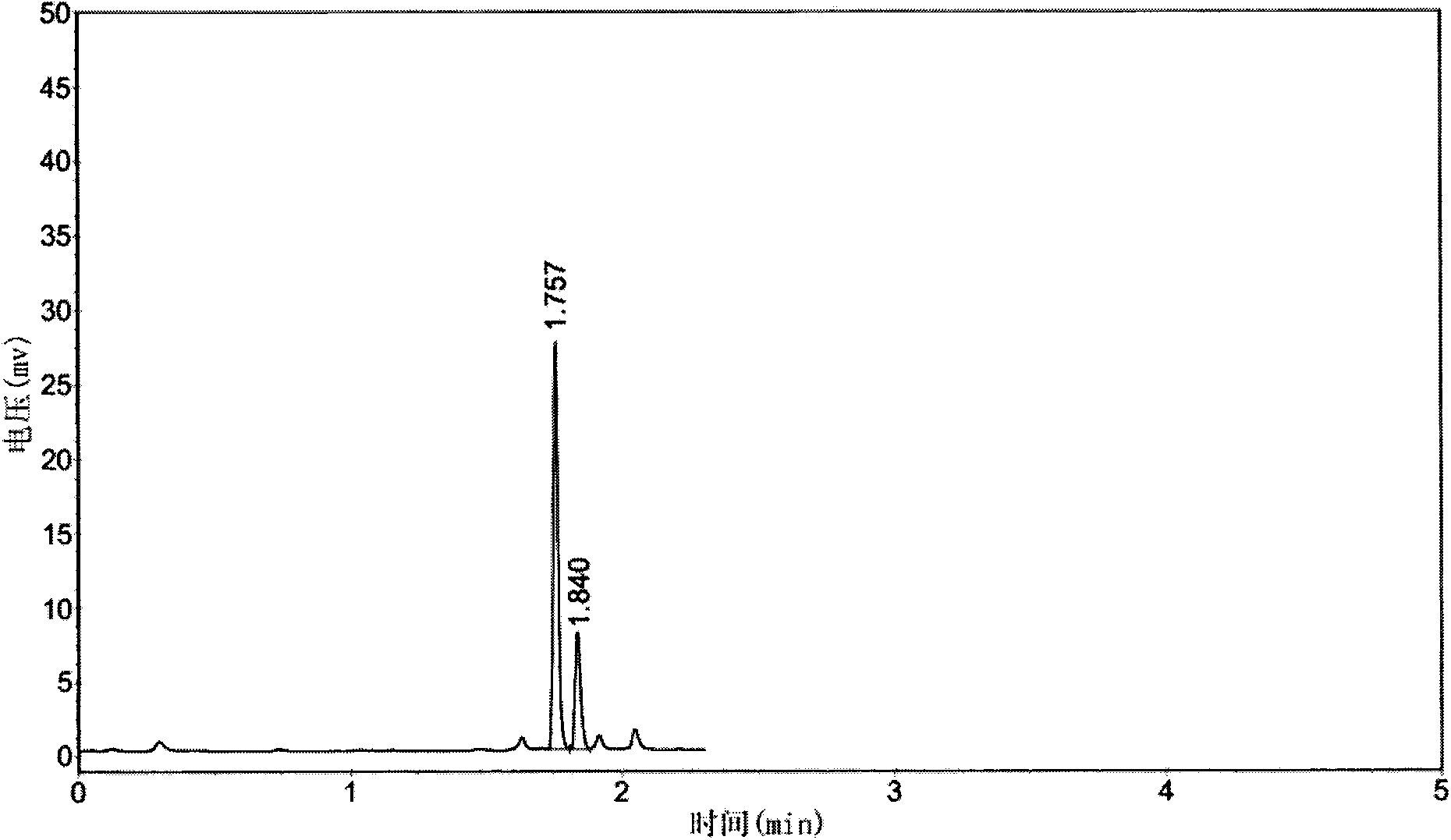

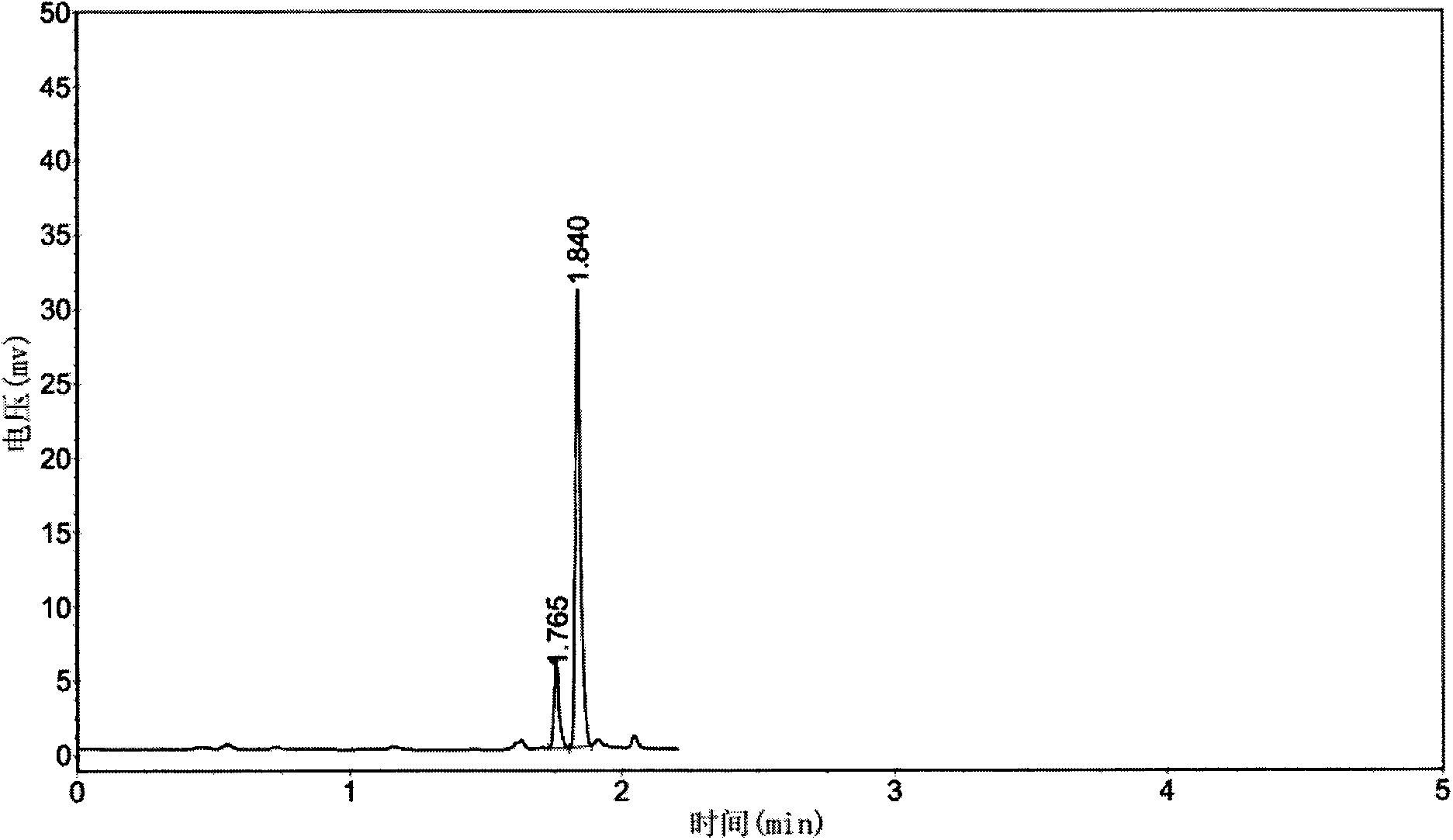

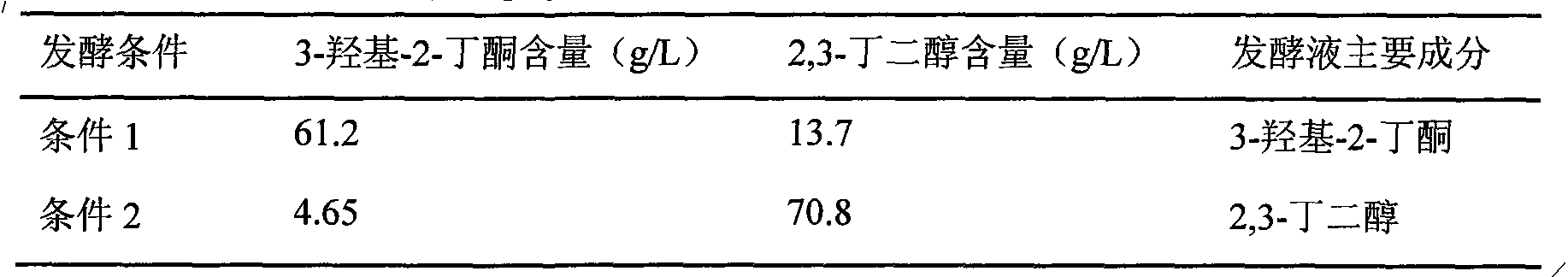

Method for selectively producing 3-hydroxyl-2-butanone and 2, 3-butanediol through microbial fermentation

ActiveCN103525877ALow costMeet the requirements of safe productionMicroorganism based processesFermentation2,3-ButanediolBacterial strain

The invention discloses a method for selectively producing 3-hydroxyl-2-butanone and 2, 3-butanediol by using an environmental safety bacterial strain Bacillus amyloliquefaciens with the CCTCC NO. M2012349 and changing the content of corn steep liquor in a medium, the stirring speed and the ventilation capacity, and belongs to the field of a fermentation technology in biological engineering. The method is characterized in that when the 3-hydroxyl-2-butanone is mainly synthesized, the concentration of the corn steep liquor in the fermentation medium can be reduced to be more than or equal to 5g / L, and the relatively high dissolved oxygen level (the air mass flow is 240m<3> / h.m<3> medium, and the stirring rotating speed is 450r / min) is maintained in a fermentation process; and when the 2, 3-butanediol is synthesized, the concentration of the corn steep liquor in the fermentation medium can be increased to be more than or equal to 40g / l, the relatively low dissolved oxygen level (the air mass flow is 120m<3> / h.m<3> medium, and the stirring rotating speed is 350r / min) is maintained in a fermentation process.

Owner:JIANGNAN UNIV

Method for preparing tetramethyl pyrazine

InactiveCN1935794AThorough responseResidue reductionOrganic chemistryTetramethyl pyrazineNitrogen gas

The invention relates to a Chuanxiongzine preparing method, comprising the steps of: using 3-hydrox-2-butanone and ammonium acetate as raw materials, adding in alcohol, charging nitrogen gas, and blending in hot bath for 5-8 h; on air or oxygen condition, blending for 12 h; adding in oxidant, and blending for 1-2 h, where the weight ratio of oxidant to 3-hydrox-2-butanone = (0.5-1):1; and filtering out the remaining oxidant; vacuum-distilling to make it. And the method has high yield. And the organic solvent utilization in the preparing course is less, beneficial to environmental protection. And the invention has advantages of low cost and simple operation.

Owner:张锋

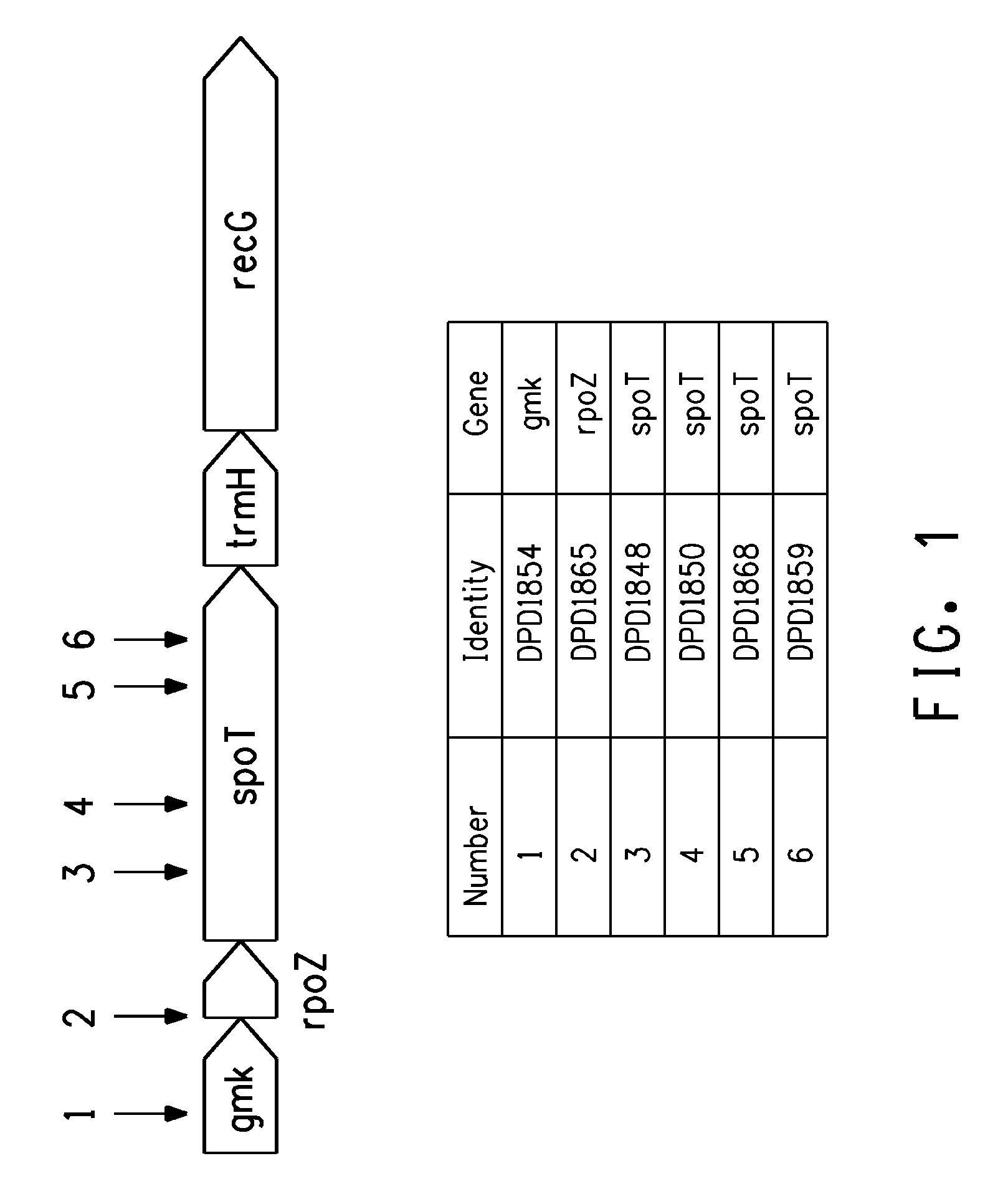

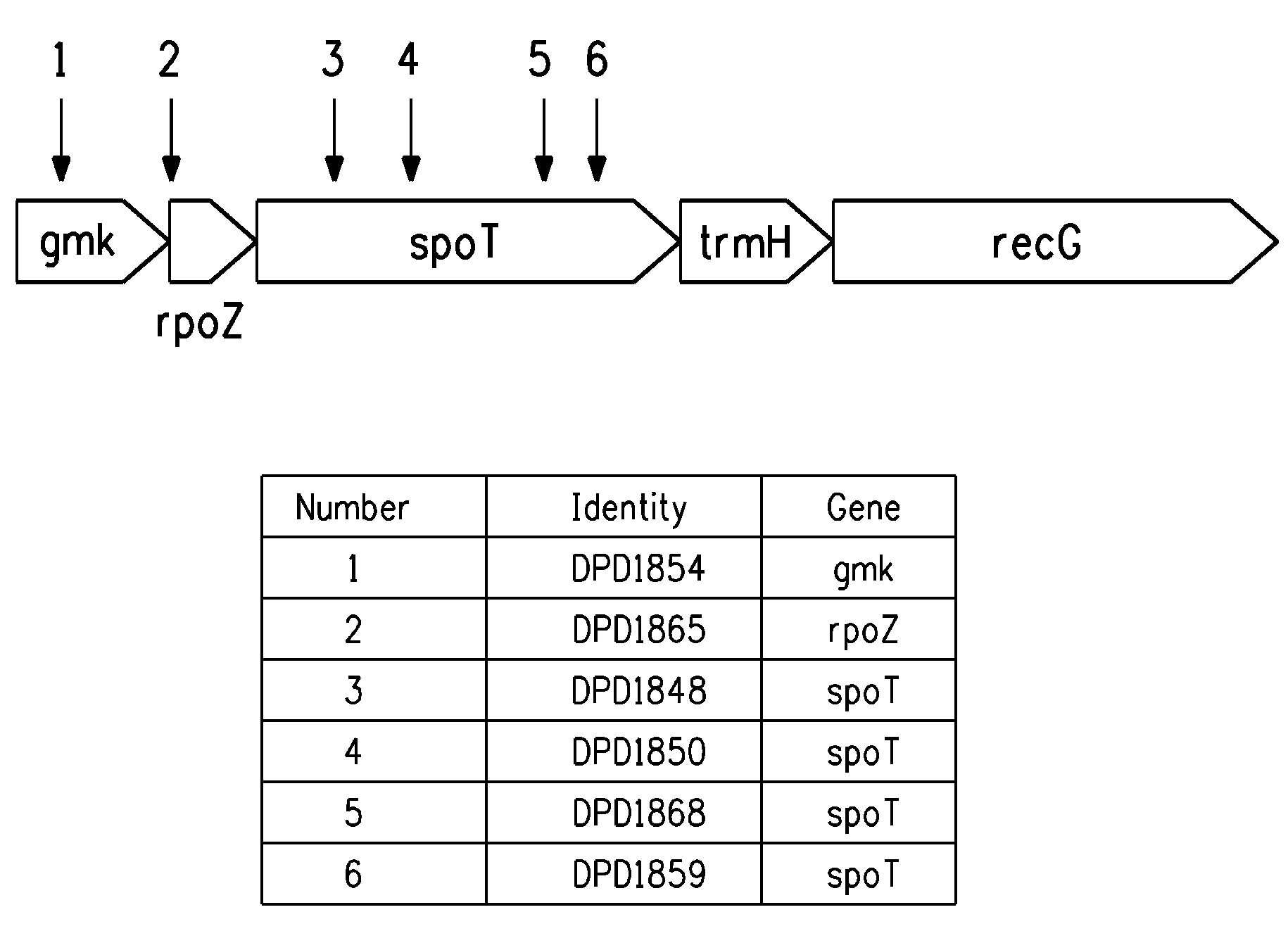

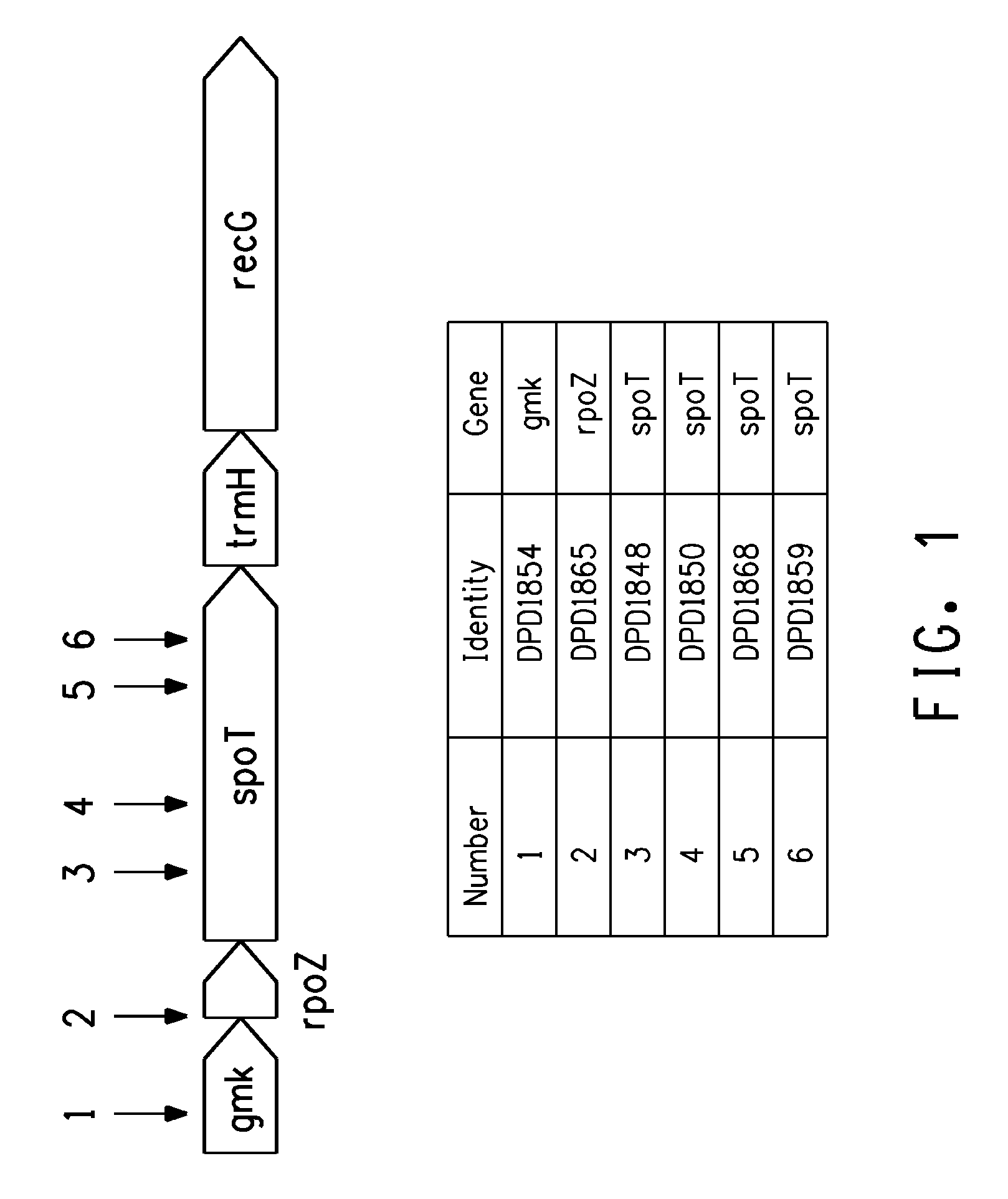

Production of four carbon alcohols using improved strain

Using screening of transposon random insertion mutants, genes involved in accumulation of (p)ppGpp were found to be involved in bacterial cell response to butanol. Reduced production of proteins with enzymatic activity for (p)ppGpp biosynthesis confers increased butanol tolerance. Bacterial strains with reduced (p)ppGpp accumulation and having a butanol or 2-butanone biosynthetic pathway are useful for production of butanol or 2-butanone.

Owner:GEVO INC

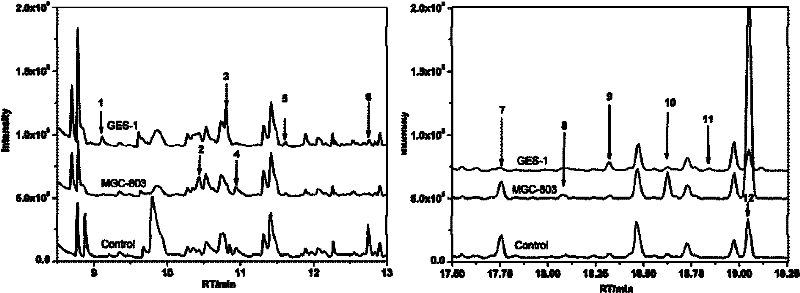

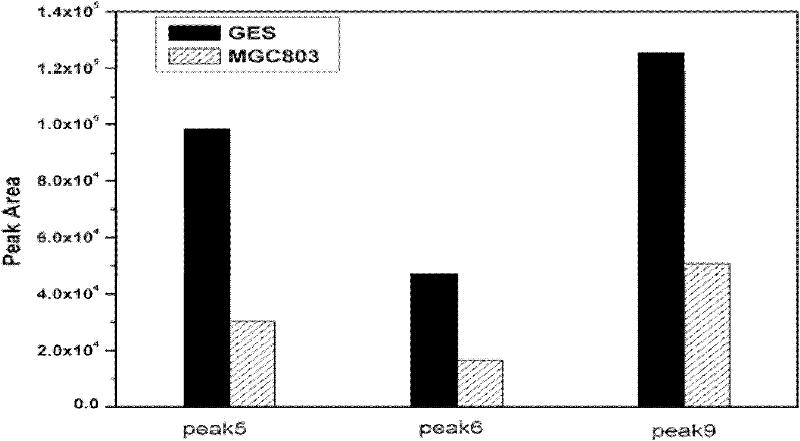

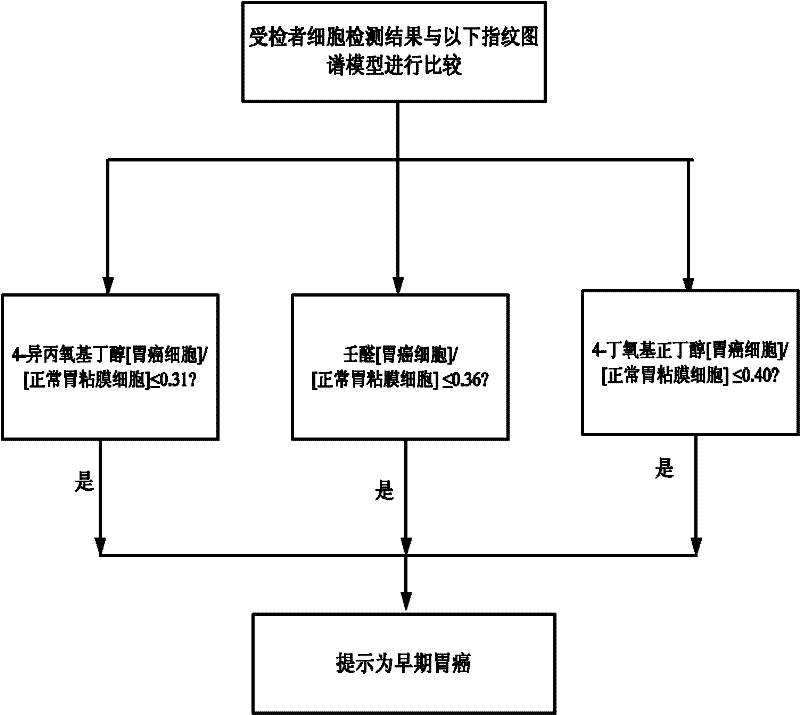

Compound fingerprint atlas model used in early-stage gastric cancer diagnosis/early warning, and establishing method thereof

ActiveCN102495146AThe source is painless and non-invasiveAbundant resourcesComponent separationSystems biologyCancers diagnosis2-butanone

The invention discloses a compound fingerprint atlas model used in early-stage gastric cancer diagnosis / early warning, and an establishing method thereof. According to the invention, the concentration of a trace amount of volatile organic compound in a gastric cancer cell metabolic product is separated and detected by using a gas chromatograph-mass spectrometer, and the atlas model is drawn. A mass volume concentration ratio of 4-isopropoxy butanol to nonanal to 4-butoxyl n-butanol is represented by that: 4-isopropoxy butanol [gastric cancer cell] / [normal gastric mucosa cell] is no higher than 0.31, nonanal [gastric cancer cell] / [normal gastric mucosa cell] is no higher than 0.36, and 4-butoxyl n-butanol [gastric cancer cell] / [normal gastric mucosa cell] is no higher than 0.40. The gastric cancer cell metabolic product has characteristic peaks of 3-octanone and 2-butanone. Volatile organics in a cell metabolic product requiring detection are compared with the fingerprint atlas model provided by the invention, such that the fingerprint atlas model can be used in early-stage gastric cancer diagnosis and early warning.

Owner:SHANGHAI JIAOTONG UNIV

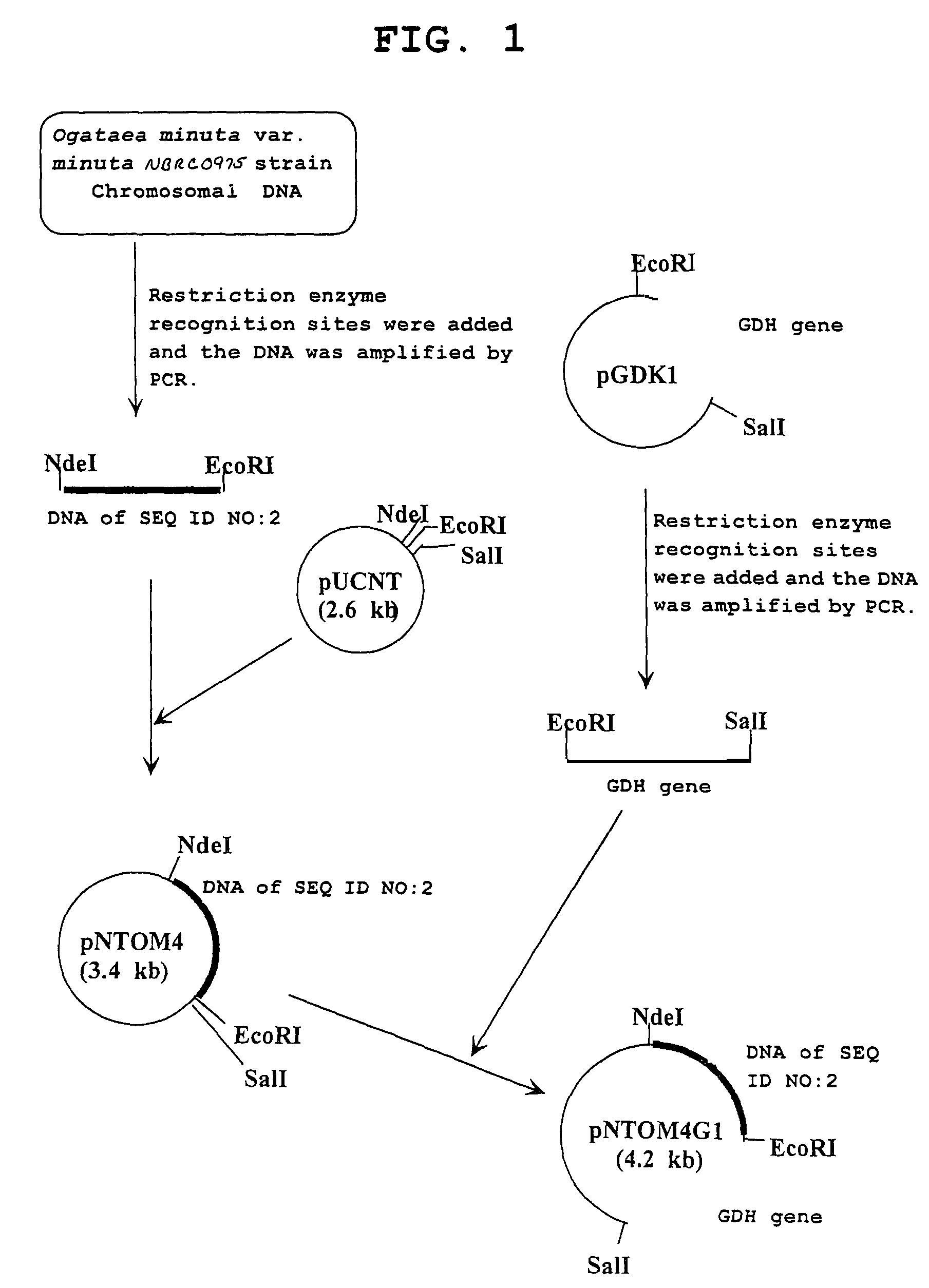

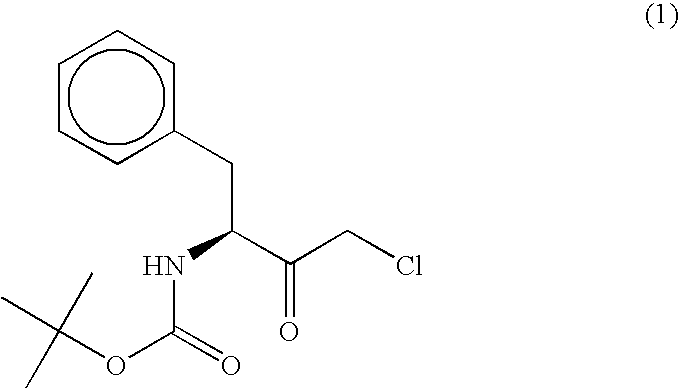

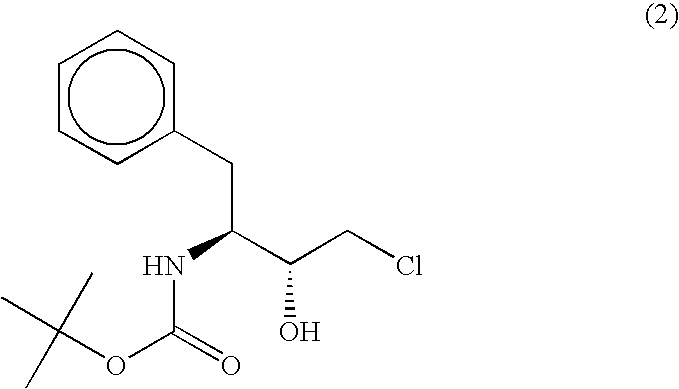

Carbonyl reductase, gene thereof and method of using the same

The present invention relates to a polypeptide having an activity to asymmetrically reduce (3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanone to produce (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol isolated from a microorganism belonging to the genus Ogataea, a DNA encoding the polypeptide and a transformant that produces the polypeptide. The present invention moreover relates to a method of producing (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol utilizing the polypeptide or the transformant. Using the polypeptide or transformant of the present invention, optically active alcohols such as (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol and the like can be produced efficiently.

Owner:KANEKA CORP

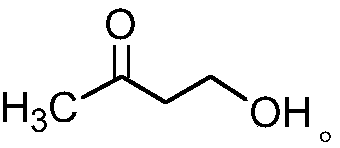

Leifsonia xyli HSO904-based short chain dehydrogenase, and encoding gene, carrier, engineering bacteria and application thereof

The invention discloses a leifsonia xyli HSO904-based short chain dehydrogenase, and an encoding gene, a carrier, engineering bacteria and application thereof. A gene of the leifsonia xyli HSO904-based short chain dehydrogenase has more than 90% of homology of a nucleotide sequence shown in SEQ ID NO. 1. A colon bacillus BL21 / pET28a (+)-SDR prepared by the recombination of the short chain dehydrogenase is used as an enzyme source, 3, 5-bis-trifluoro methyl acetophenone, trifluoromethyl acetophenone, 4-hydroxyl-2-butanone, acetoacetic ester, 4-chloro ethyl acetoacetate, acetoacetic acid tert-butyl acetate and the like are used as substrates to prepare corresponding chiral compounds such as (R)-3, 5-bis-trifluoromethyl phenethyl alcohol, trifluoromethyl benzaldehyde ethanol, 2-hydroxyl-butyl alcohol, 3-hydroxy ethyl butyrate, 4-chloro-3-hydroxy ethyl butyrate and 3-hydroxy butyric acid tert-butyl acetate through a catalytic asymmetric reduction reaction.

Owner:艾吉泰康(嘉兴)生物科技有限公司

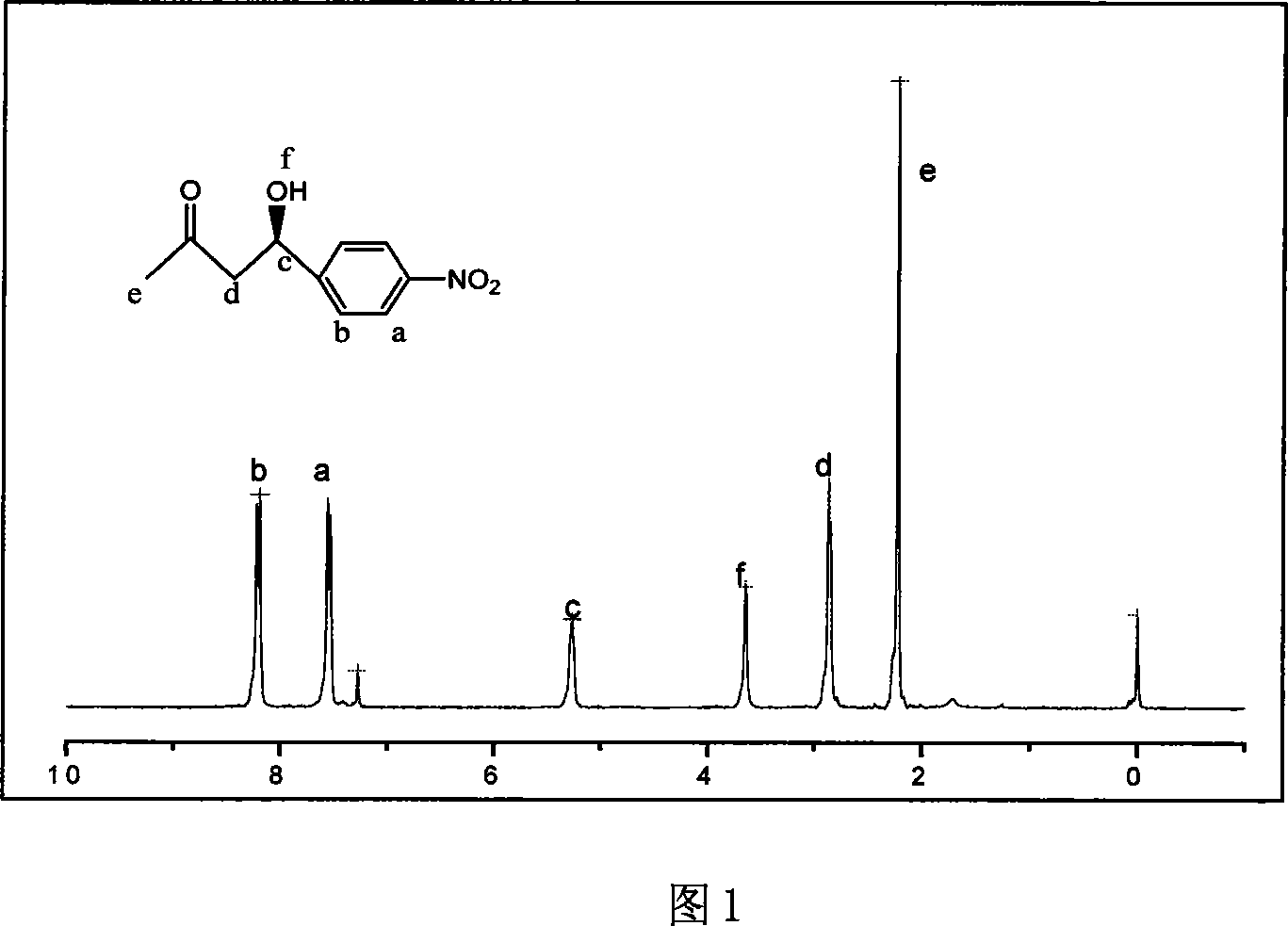

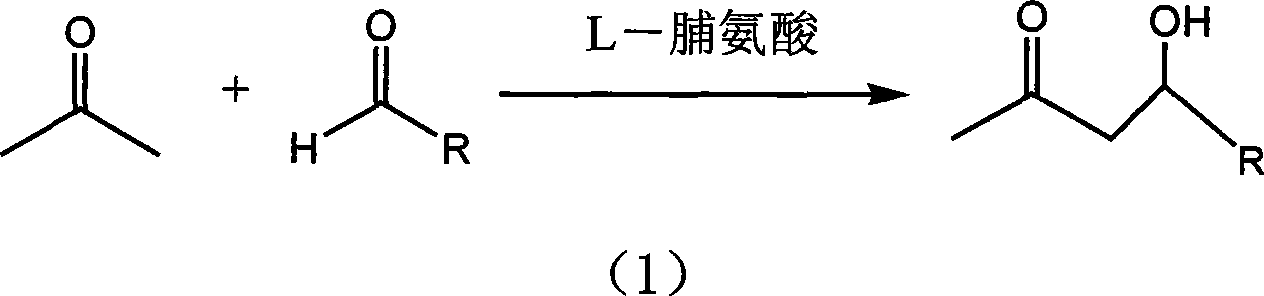

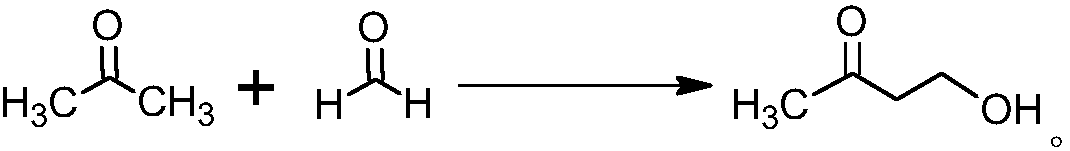

Method for prepring compound of beta hydroxyketone in supercritical liquid of carbon dioxide

InactiveCN101092338AOvercoming pollutionOvercoming complexityOrganic compound preparationCarbonyl compound preparationKetoneProton NMR

This invention discloses a method for preparing beta-hydroxy ketones in supercritical CO2 fluid. The method comprises: preparing crude beta-hydroxy ketone compounds, separating and purifying. The method performs asymmetric aldol condensation reaction on acetone and different aldehyde compounds catalyzed by L-proline in supercritical CO2 fluid. The method solves the problems serious environmental pollution and complex post treatment faced by traditional organic solvent method. The method has such advantages as no need for organic solvent, little environmental pollution, high productivity and high enantio selectivity of the catalyst. The proton NMR spectrum of the product is identical to that of 4-(4-nitrophenyl)-4-hydroxyl-2-butanone. The method has such advantages as reasonable design, simple process, little pollution, high yield, and high enantio selectivity of the catalyst.

Owner:SHAANXI NORMAL UNIV

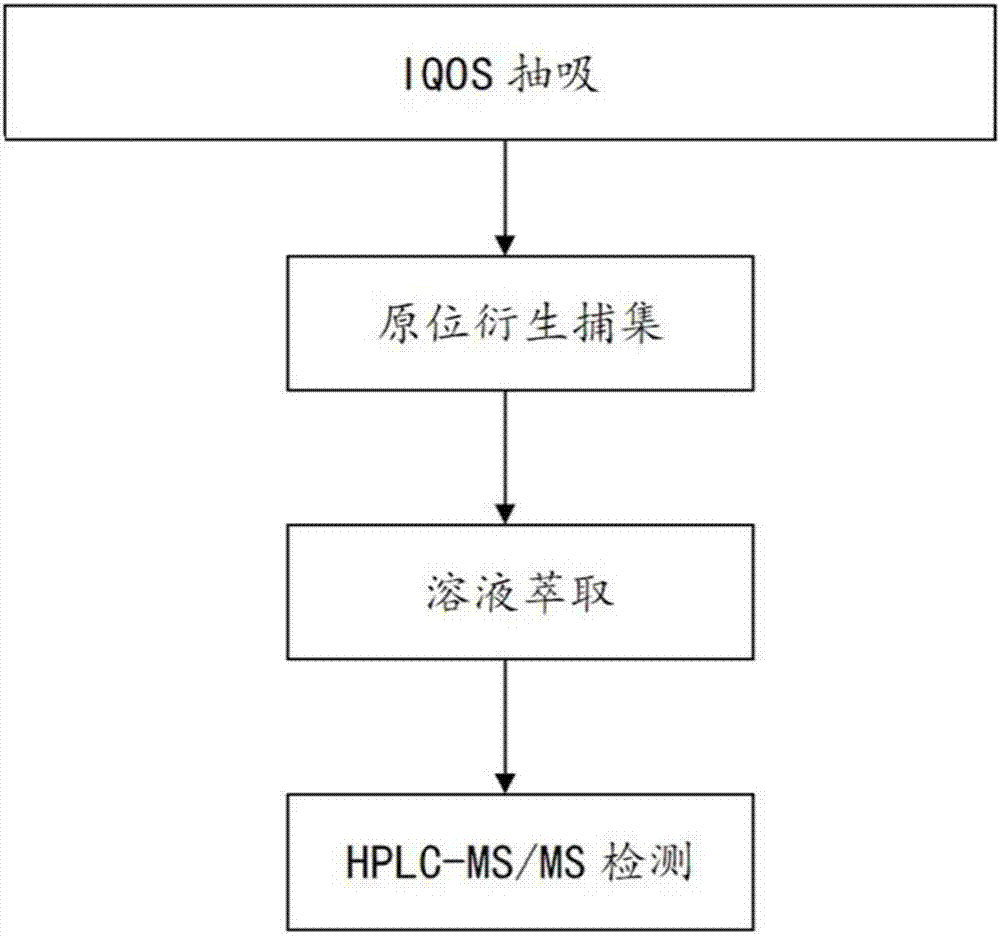

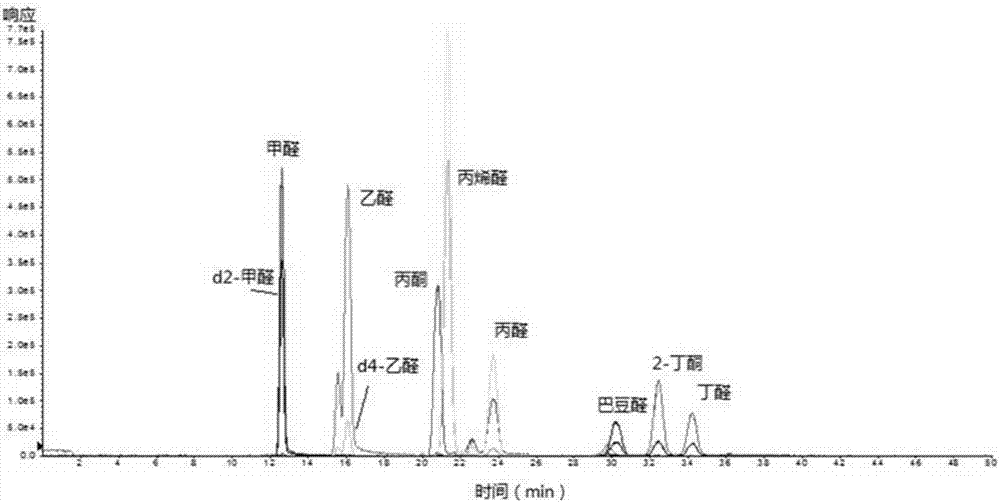

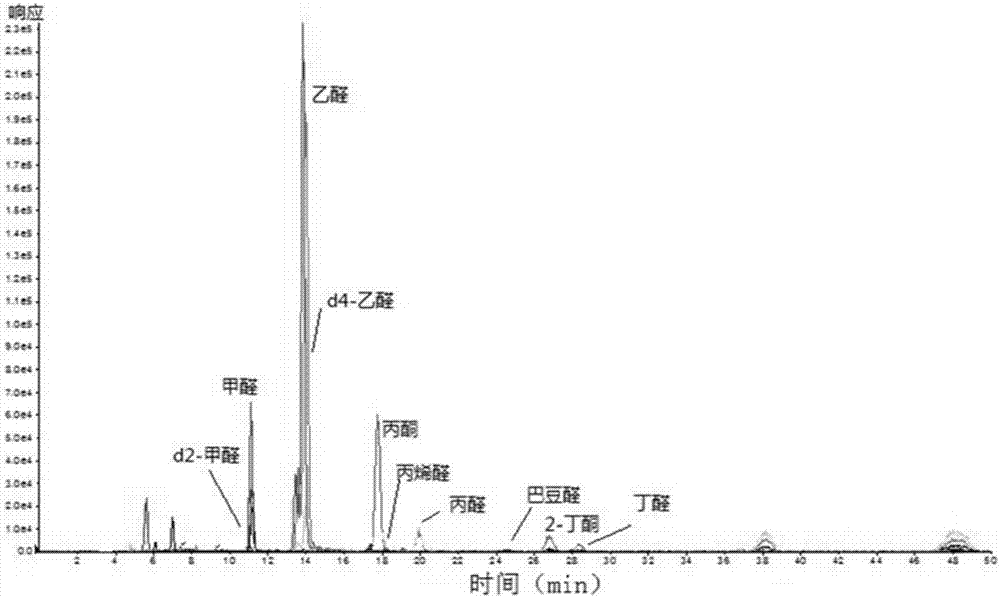

Method for determining eight carbonyl compounds in heating non-combustible cigarette main flue gas

ActiveCN107490636AThe assay method is fast and efficientHigh sensitivityComponent separationCrotonaldehydeRelative standard deviation

The invention relates to a method for determining eight carbonyl compounds in heating non-combustible cigarette main flue gas, which belongs to the technical field of physical and chemical examination of cigarette main flue gas. The method comprises the following steps: extracting a filter disc used for capturing eight carbonyl compounds in the heating non-combustible cigarette main flue gas by employing a pyridine acetonitrile solution to obtain an extract, using high performance liquid chromatography-tandem mass spectrum for determination, and performing quantification by an internal standard method; wherein the carbonyl compounds are formaldehyde, acetaldehyde, acetone, acrolein, propionaldehyde, crotonaldehyde, 2-butanone, and butyraldehyde. The determination method is rapid and effective, and has the advantages of high sensitivity and low detection limit, average relative standard deviation is less than 6.7%, and the average recovery rate of the index is between 83.5% and 90.5%.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

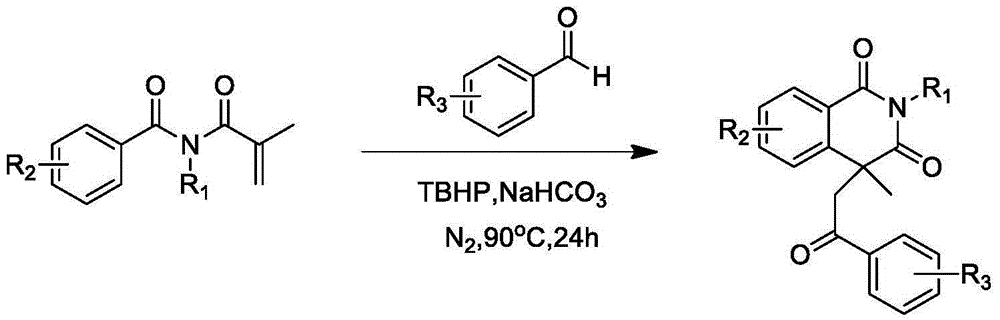

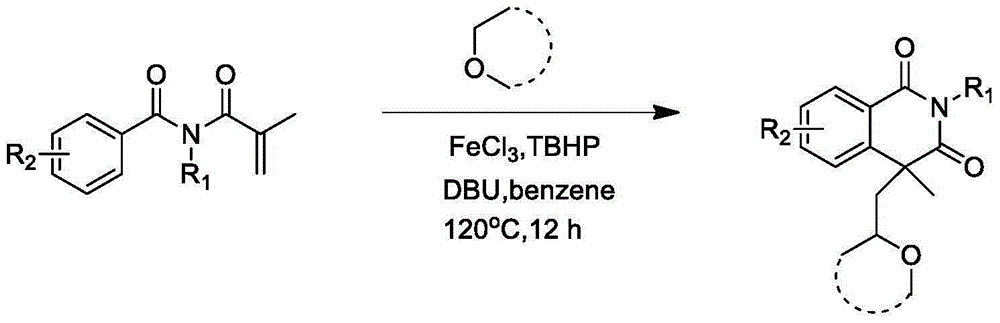

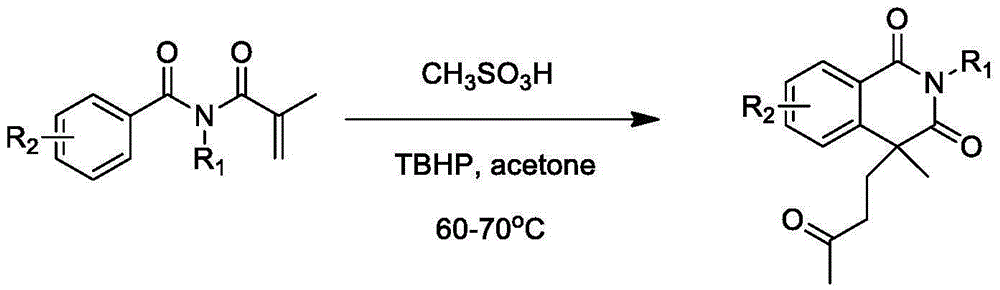

Preparation of 1,3-isoquinoline dione derivative

ActiveCN105198811AMild reaction conditionsSimple and fast operationOrganic chemistryEthyl acetateMethyl group

The invention discloses a preparation method of a 1,3-isoquinoline dione derivative. The preparation method is characterized by comprising steps as follows: (1), N-methyl-N-isobutylene acyl benzamide and methane sulfonic acid are added to acetone, 2-butanone or 3-pentanone respectively, TBHP (tert-butyl hydroperoxide) is added while stirring is performed at the room temperature, and a mixed system reacts for 2 hours at certain temperature; (2), after a reaction ends, water is added for quenching, the mixture is extracted with 20 mL of ethyl acetate twice and washed with a saturated salt solution once, and ethyl acetate is removed through spin-drying under reduced pressure; (3), the mixture is subjected to column chromatography, and a target product is obtained.

Owner:JIANGNAN UNIV

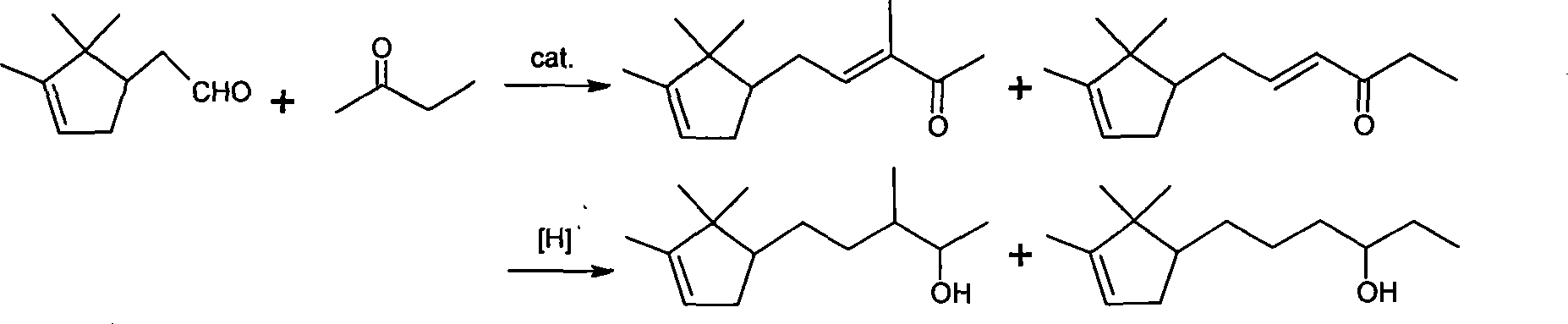

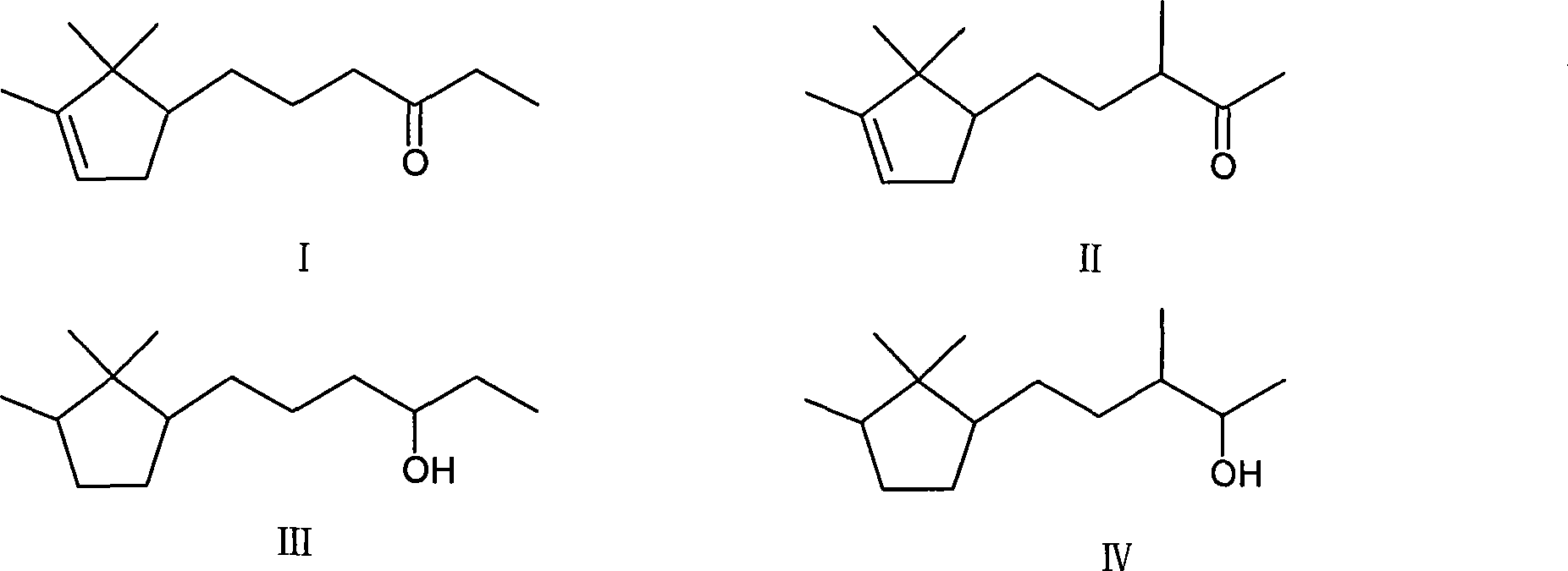

Method for preparing 3- bornylene

ActiveCN101125798AEasy to controlMild reaction conditionsOrganic compound preparationHydroxy compound preparationSynthesis methodsFatty alcohol

The invention discloses a synthesis method of organic chemical industry field, in particular to the preparation method of 3-Campholenyl-2-Butanol. 3-campholenyl-2-Butanol is prepared by three continuous reaction steps: firstly, campholenic aldehyde is used as raw material to do an aldol condensation with butanone; secondly, 3-Subcampholenyl-2-Butanone, fatty alcohols with 2 to 4 carbon atoms, solid base and copper / chromium catalyst are reacted with each other; finally crude 3-Campholenyl-2-Butanol is added with solvent and reductant, and the finished product is prepared. The invention has the advantages of mild reaction condition, safe operation, and complete reaction, easy control of reaction endpoint as well as colorless and good fragrance of obtained sandalwood 210, etc. The invention avoids a technical obstacle of incomplete reaction or over-reduction which is existed in other technologies. The product of the invention can be widely used in makeup essence, soap essence, detergent essence and household essence.

Owner:格林生物科技股份有限公司

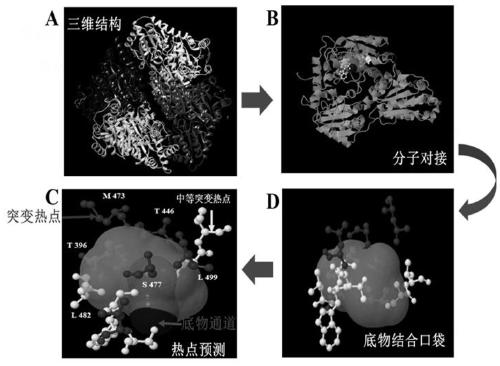

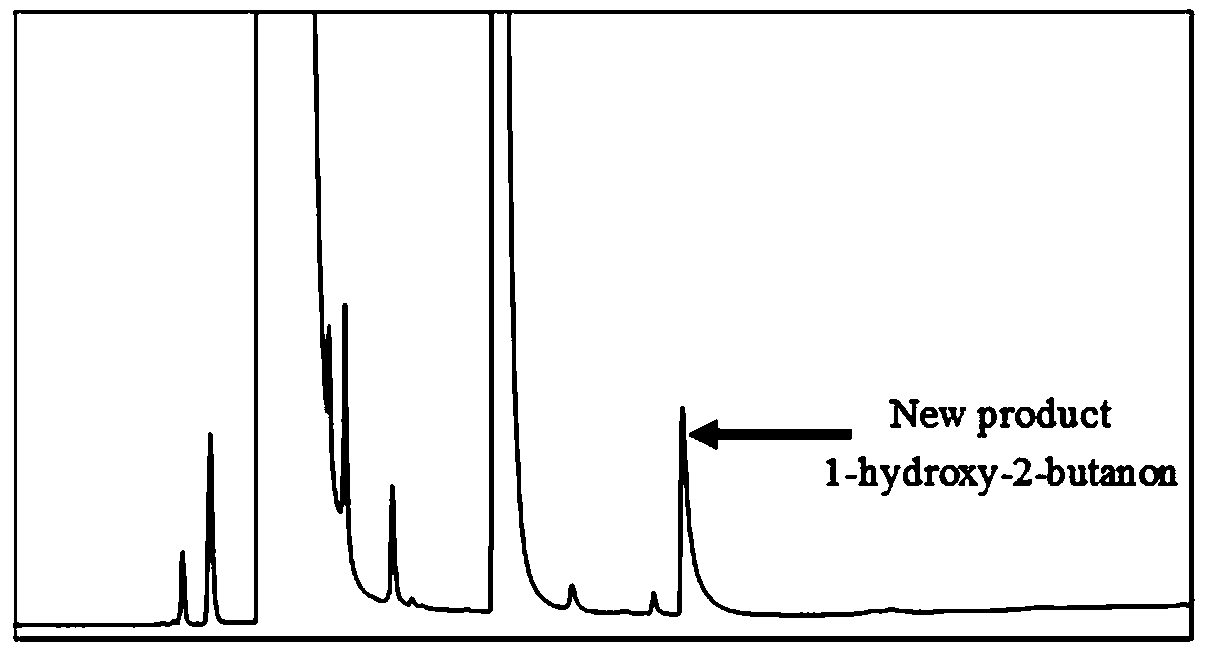

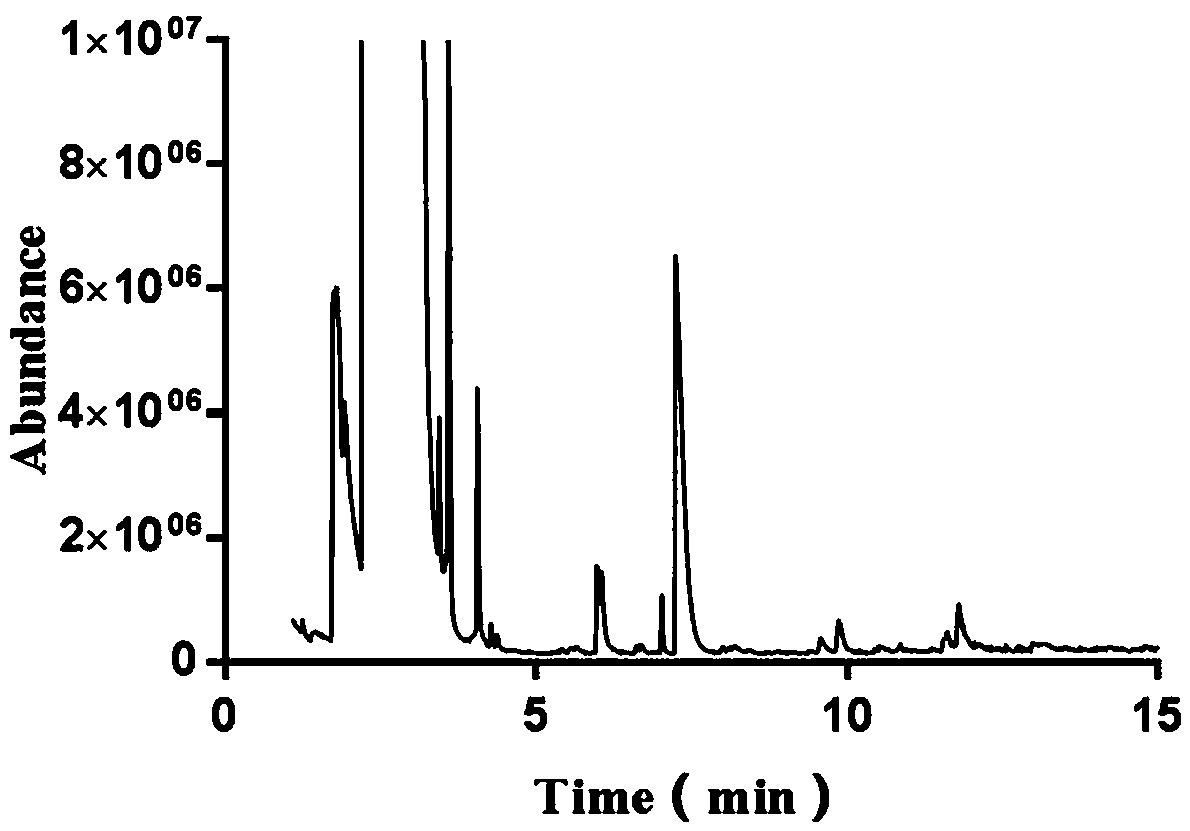

Method for whole-cell catalytic synthesis of 1-hydroxy-2-butanone

The invention provides a method for whole-cell catalytic synthesis of 1-hydroxy-2-butanone and belongs to the technical field of bioengineering. A mutant library is constructed by fixed-point saturated mutation of formaldehyde lyase 482 amino acid, and an engineering strain containing formaldehyde lyase (FLS) is obtained by screening. Whole-cell catalytic synthesis of the 1-hydroxy-2-butanone is realized with the strain as whole cells and formaldehyde and n-propanal as raw materials. The strain can produce the 1-hydroxy-2-butanone from one molecule of formaldehyde and one molecule of propionaldehyde under the action of the FLS. The method can finish synthesis of the 1-hydroxy-2-butanone in only one step, the reaction condition is mild, the raw materials are wide and easy to obtain, and thecost is low.

Owner:FUJIAN AGRI & FORESTRY UNIV

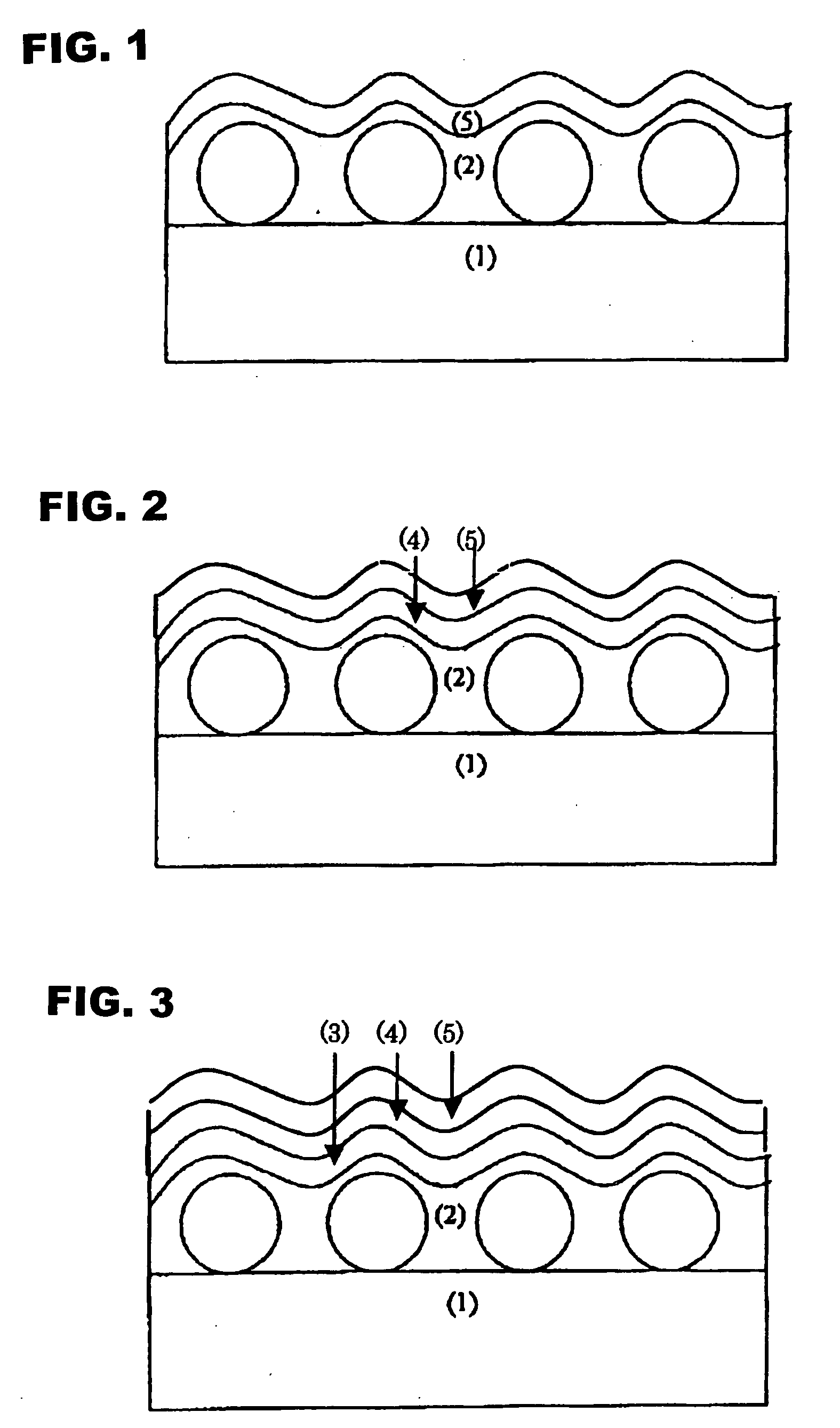

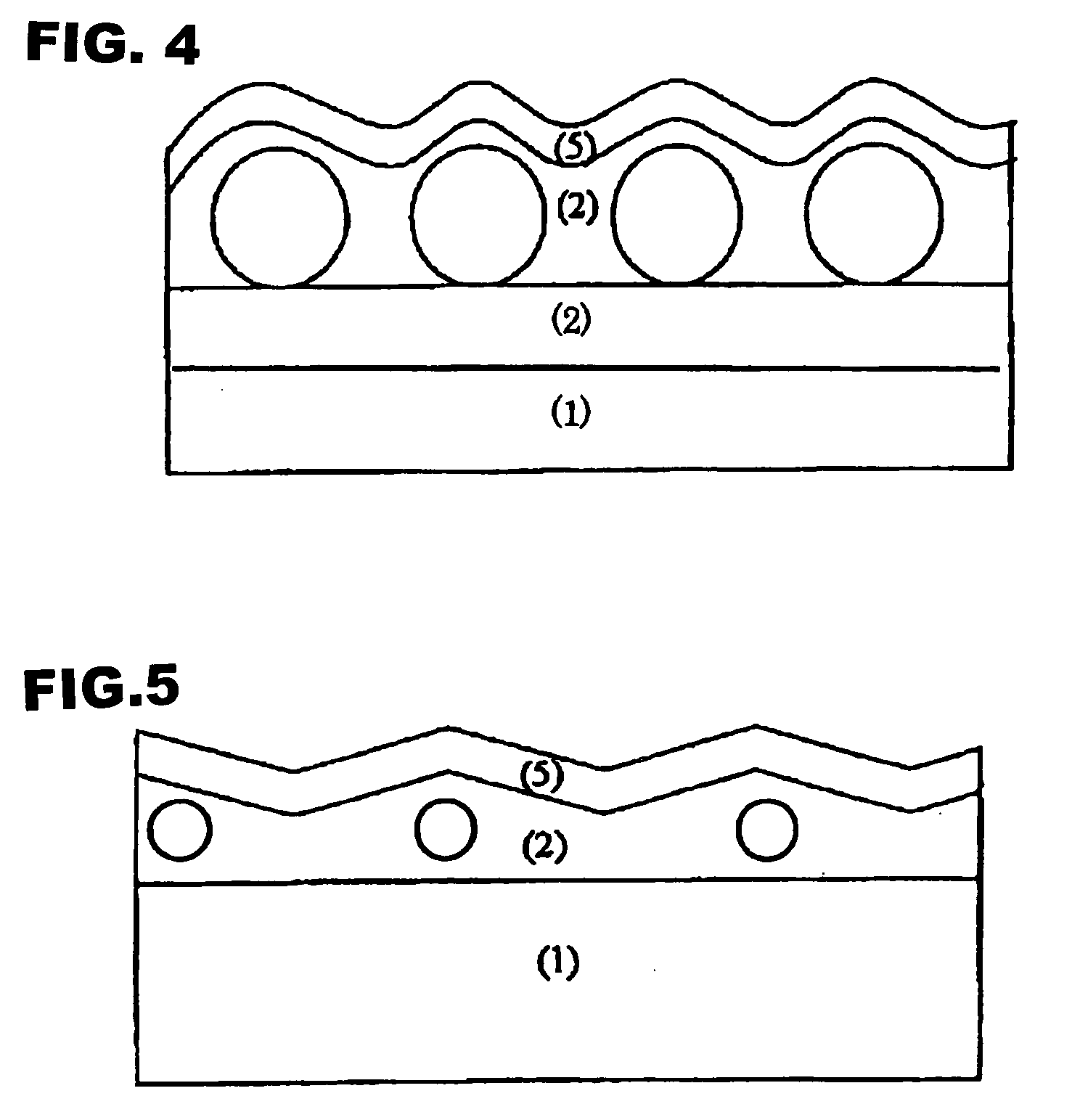

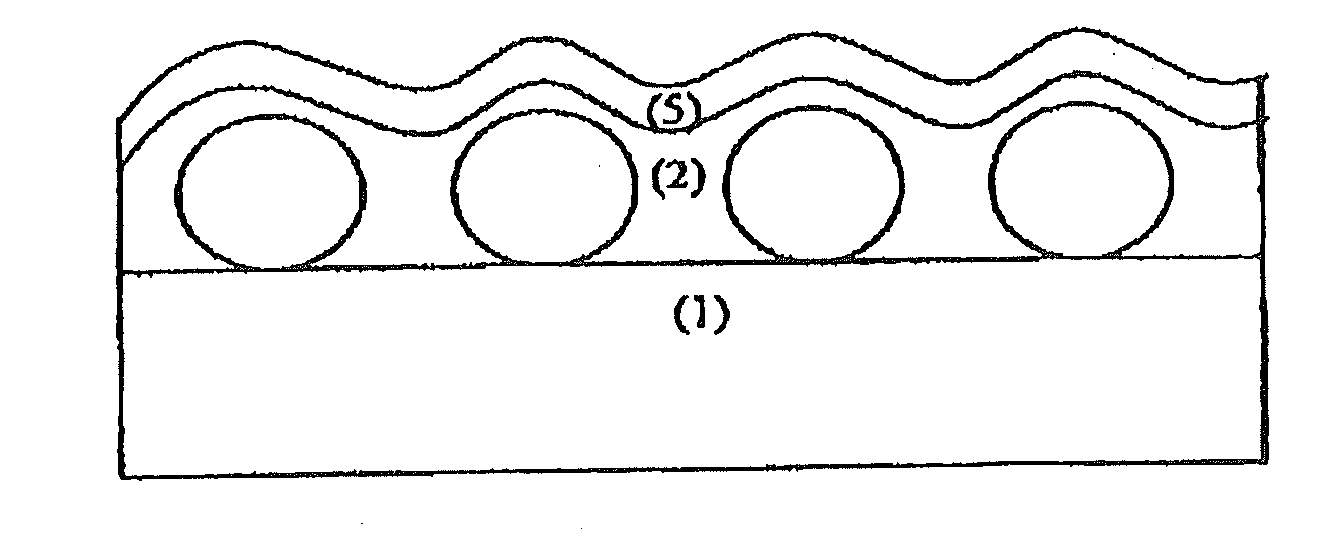

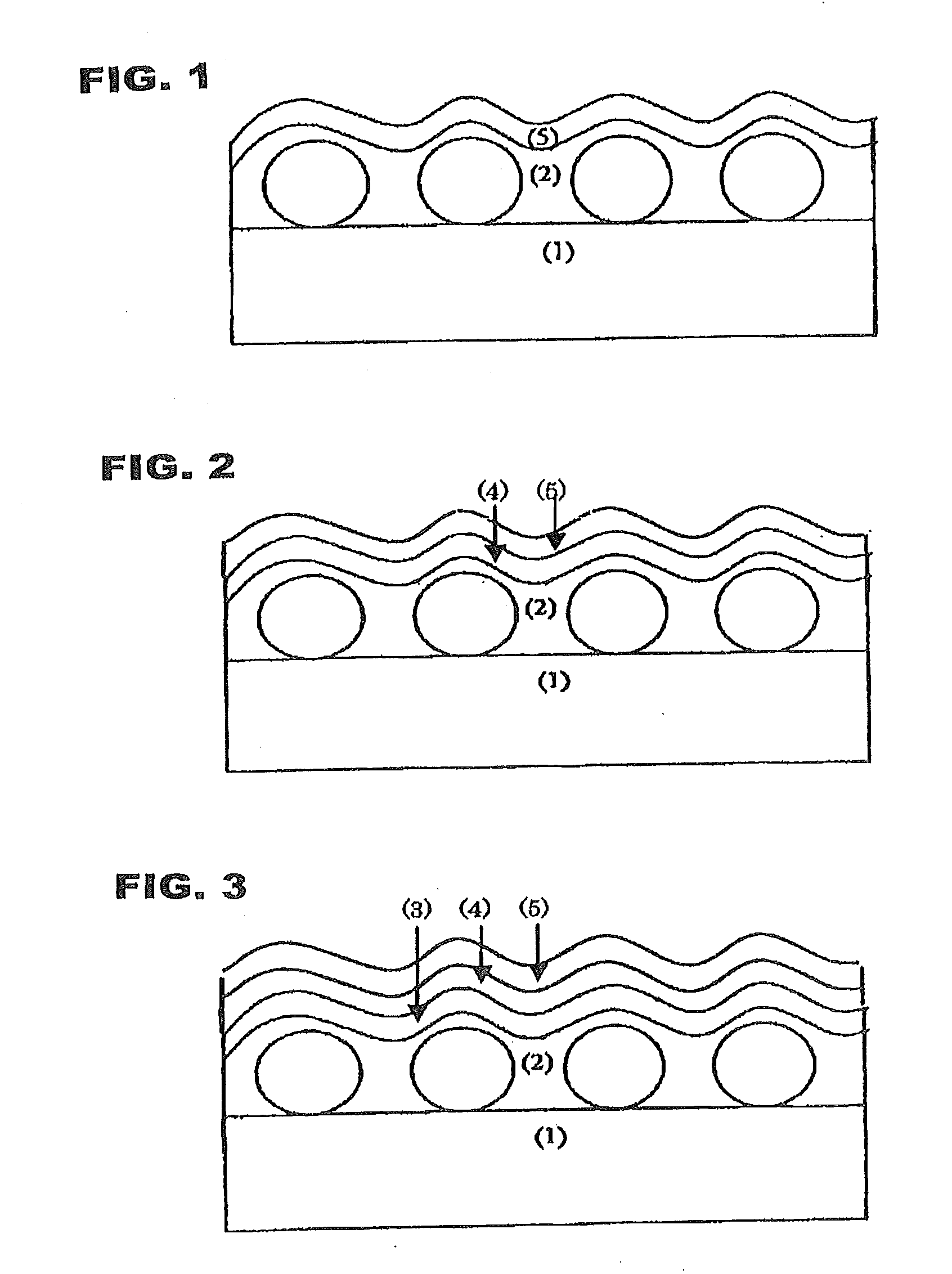

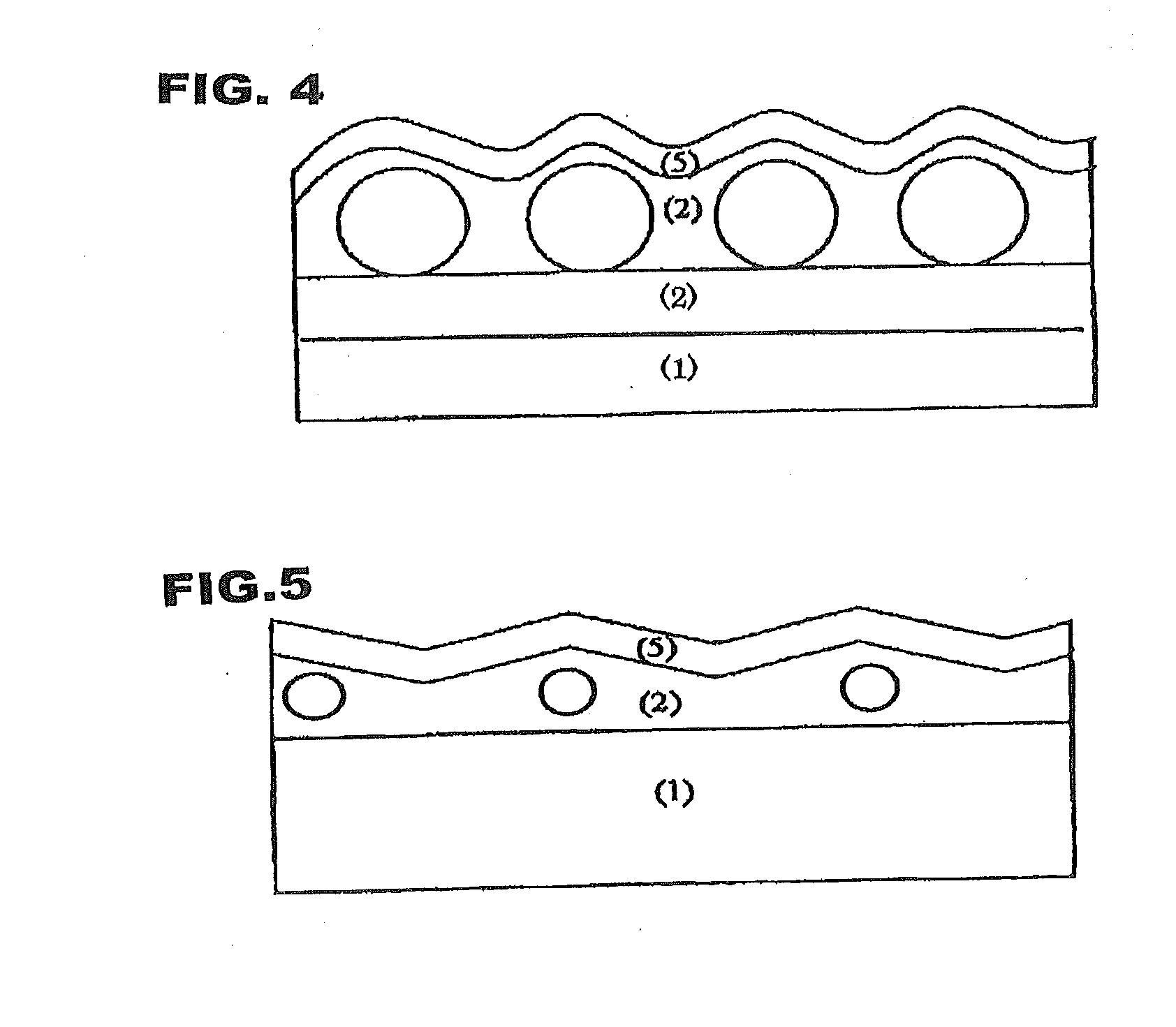

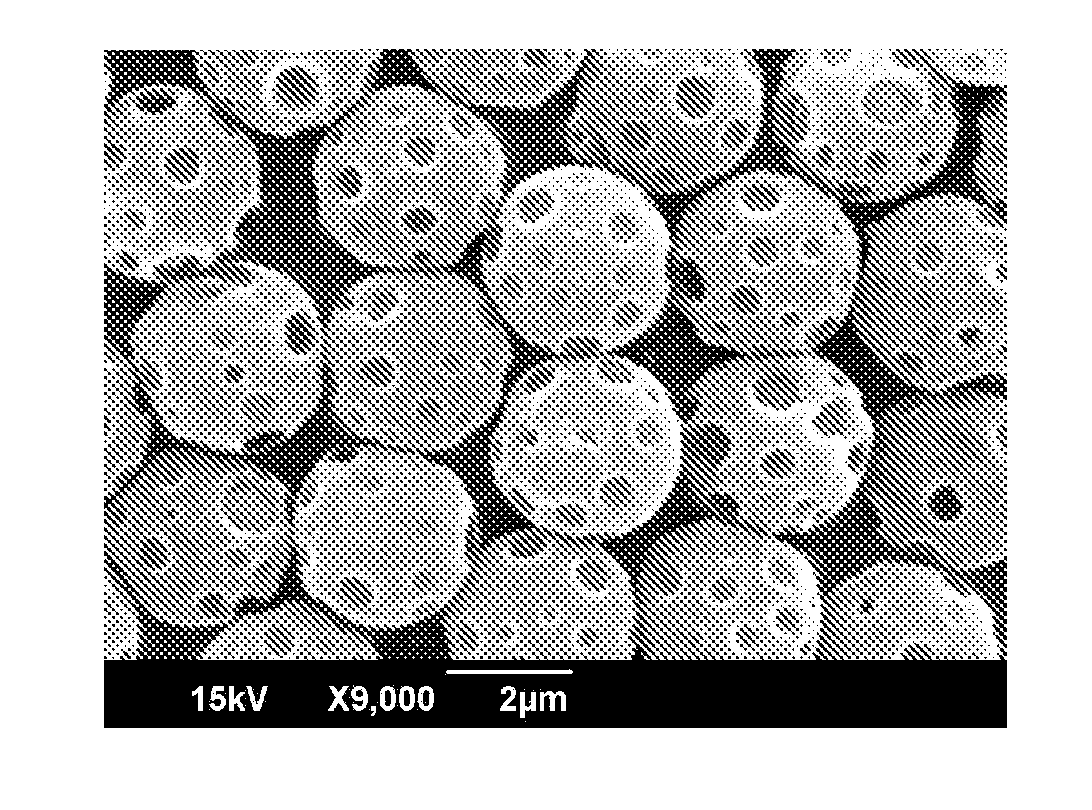

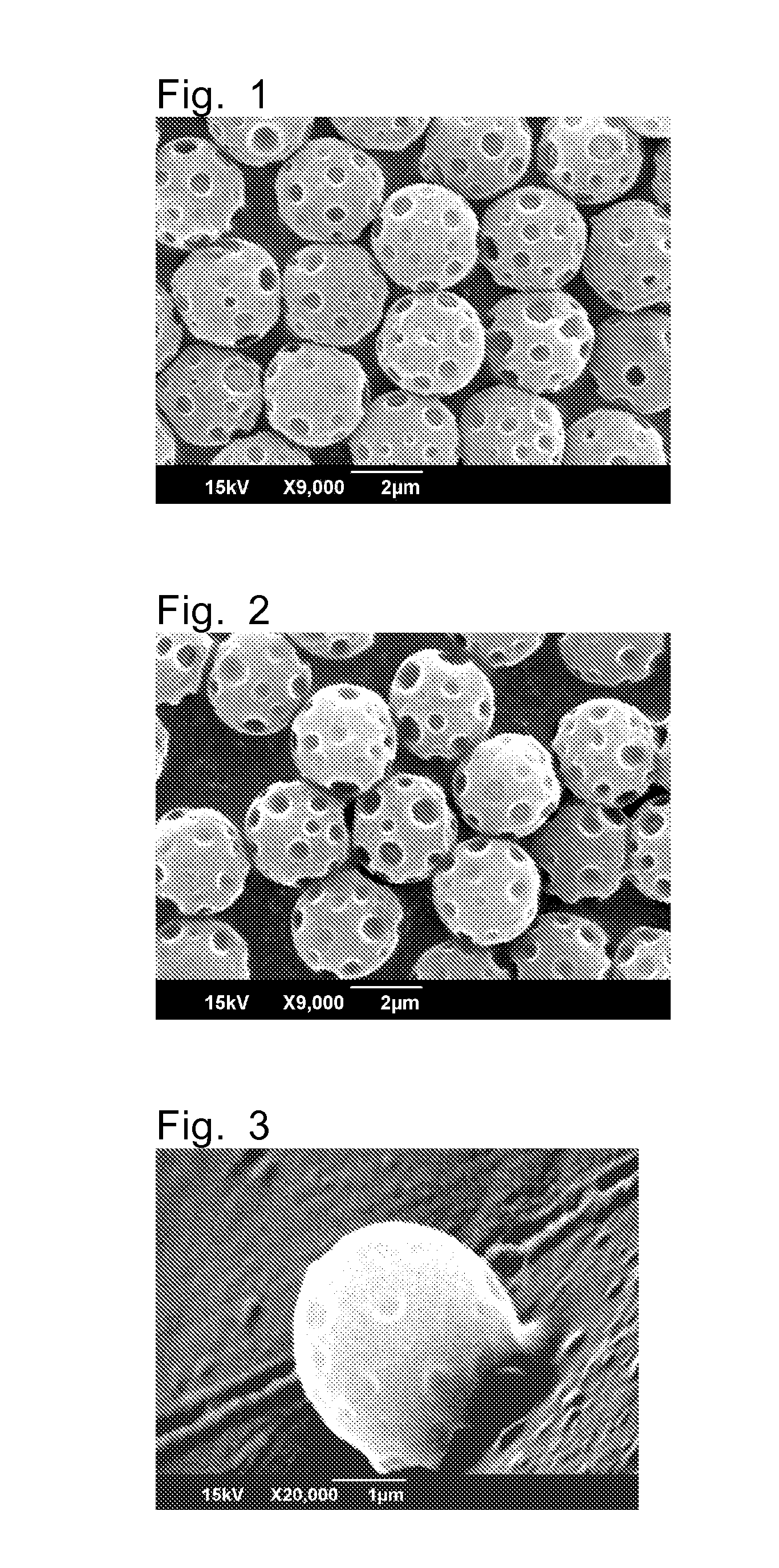

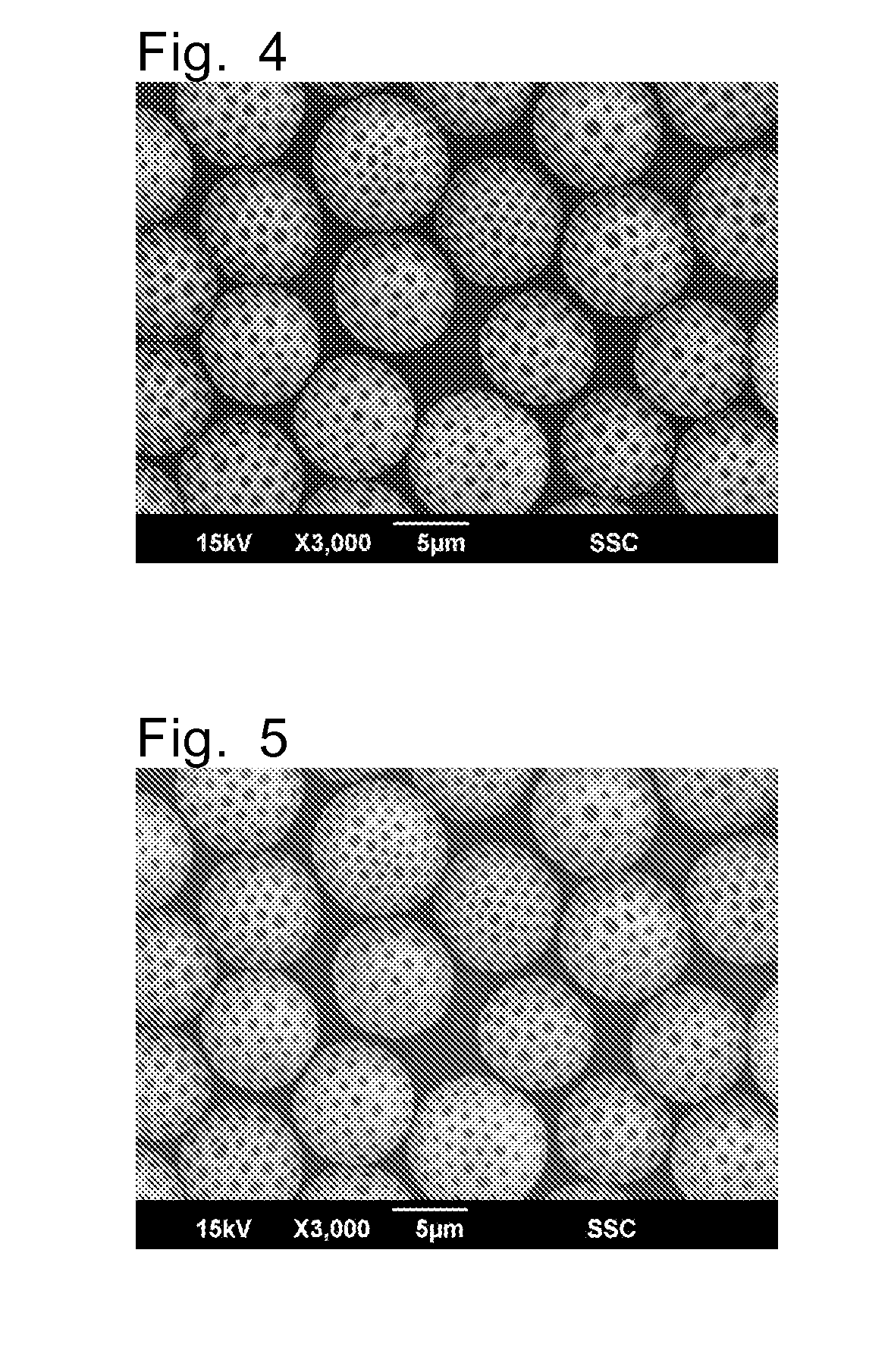

Resin particle having many recesses on the surface thereof

The present invantion provides a resin particle having many recesses on the surface thereof, which has solvent resistance and heat resistance. More specifically, the present invantion provides a resin particle having many recesses on the surface thereof which is obtained by using a seed particle, wherein a seed particle component in the resin particle has a crosslinked structure. Since the resin particle having many recesses on the surface thereof of the present invention is excellent in solvent resistance and heat resistance in addition to light diffusing properties, the resin particle is appropriate for use, for example, in not only cosmetics containing silicone oil and the like in a preparation, a light diffusing film and a light diffusing sheet prepared by dispersing resin particles as a light diffusing agent in an organic solvent such as 2-butanone and the like in a production process, and a light diffusing plate prepared by kneading at a high shear force the resin patticles as a light diffusing agent with polystyrene or polymethyl methacrylate and the like which melts at a high temperature of approximately 300° C. in a production process.

Owner:SUMITOMO SEIKA CHEM CO LTD

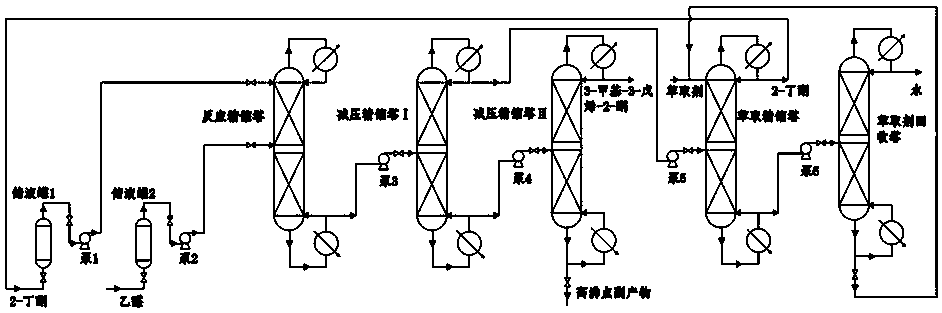

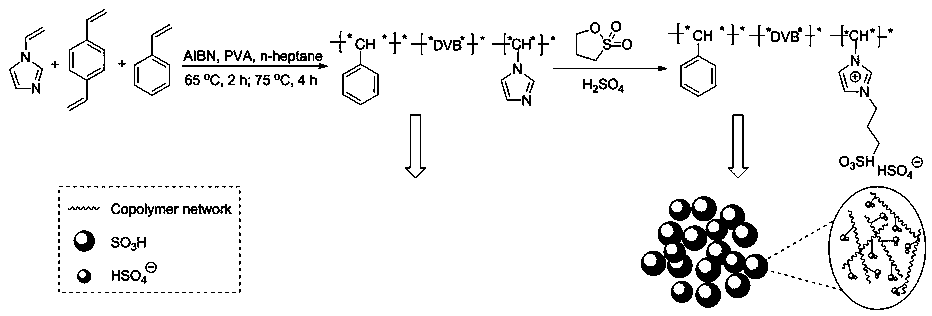

Method for continuously producing 3-methyl-3-pentene-2-one by reactive distillation

ActiveCN109867596AImprove conversion rateHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsStrong acidsMethyl group

The invention discloses a method for continuously producing 3-methyl-3-pentene-2-one by reactive distillation. 2-butanone and acetaldehyde are used as raw materials, a novel microspherical polymer ionic liquid P(VB-VS)HSO4 is adopted as a catalyst, acetaldehyde and 2-butanone are subjected to an aldol condensation reaction in a reactive distillation column to generate 3-methyl-3-pentene-2-one, andthen, a reaction solution is delivered into a reduced-pressure distillation column and is subjected to reactant and product separation to obtain high-purity 3-methyl-3-pentene-2-one. According to themethod, the novel microspherical polymer ionic liquid is used as a reaction catalyst instead of traditional strong acid / alkali, so that the reaction condition is mild, the conversion rate and selectivity of acetaldehyde are high, side reactions are reduced, meanwhile, an acid-base neutralization process in a traditional process is further omitted, the energy loss and wastewater treatment are greatly reduced, and the method is capable of saving energy and environment-friendly; and the superfluous 2-butanone can be further used as a reaction raw material after being separated, so that the resource loss is reduced.

Owner:FUZHOU UNIV

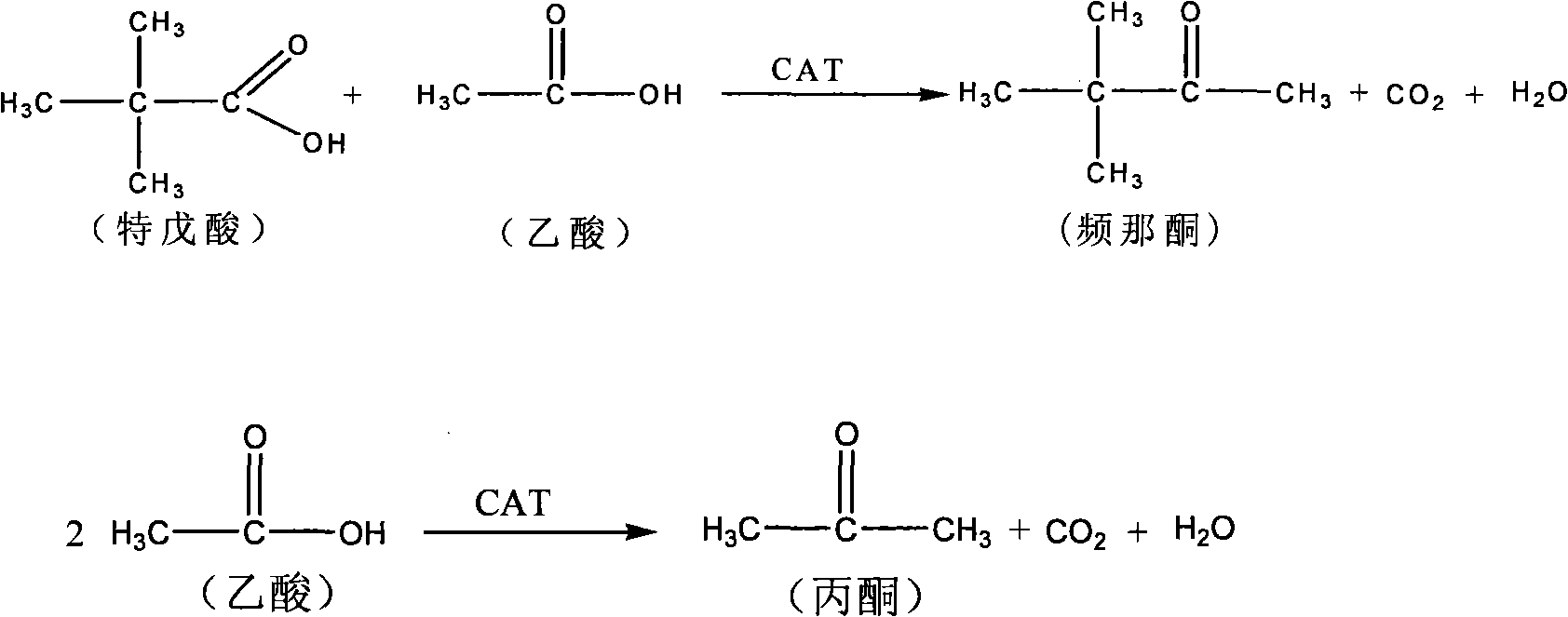

Process for synthesizing 3,3-dimethyl-2-butanone

ActiveCN101289376ASimple processEasy to operateCarbonyl compound preparation by condensationPivalic acidGas phase

The invention relates to a synthesis method of 3, 3-dimethyl-2-butanone by using pivalic acid and glacial acetic acid as raw materials which are catalyzed to react by gas phase under the conditions of normal pressure. The pivalic acid and the glacial acetic acid and water are uniformly mixed up under the normal temperature according to the molar ratio of 1:1:3 to 1:1.4:3; after vaporization, the pivalic acid and the glacial acetic acid and the water are catalyzed to have a decarboxylation reaction and then pinacolone is produced under the normal pressure with the temperature of 380 to 400 DEG C in a fixed bed reactor; the carrier of the catalyst is A12O3; active components are one or two compounds of rare earth metals Ce, Nd, La or oxides thereof; the active component content which is calculated according to the weight of metal oxides takes up 20-30 percent of the weight of the carrier A12O3; the bulk density of the catalyst is 0.47 to 0.5; after analysis, the selectivity of the pinacolone is above 95 percent and then the 3, 3-dimethyl-2-butanone product with the purity of 99 percent can be obtained after the pinacolone is purified by rectification under the normal pressure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

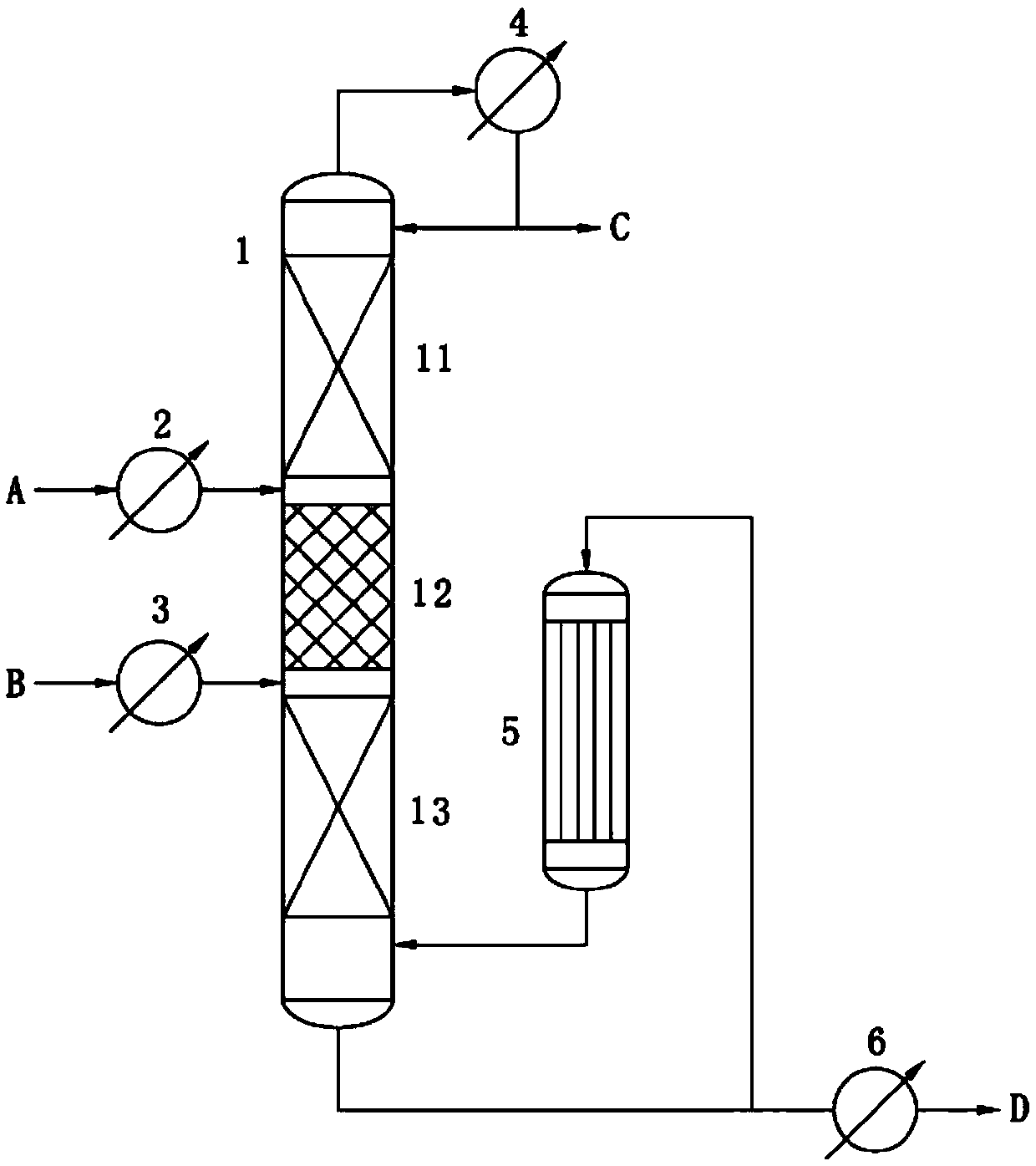

Method and device for synthetizing 4-hydroxy-2-butanone through catalytic reaction rectification

ActiveCN109516906AReduce lossHigh reaction yieldOrganic compound preparationChemical industryTower2-butanone

The invention belongs to the field of compound preparation, and concretely discloses a method and device for synthetizing 4-hydroxy-2-butanone through catalytic reaction rectification. The method forsynthetizing 4-hydroxy-2-butanone through catalytic reaction rectification is performed in the device for synthetizing 4-hydroxy-2-butanone through catalytic reaction rectification. The device comprises a catalytic reaction rectification tower (1), wherein the catalytic reaction rectification tower (1) comprises a rectification section (11), a catalysis section (12) and a stripping section (13) from top to bottom; formaldehyde and acetone are subjected to catalytic reaction in the catalysis section (12) to generate the 4-hydroxy-2-butanone; light ingredients in catalytic reaction products ascend to the rectification section (11) for separation and purification so as to obtain unreacted acetone; heavy ingredients in the catalytic reaction products sink to the stripping section (13) for separation and rectification so as to obtain the 4-hydroxy-2-butanone. When the method and device provided by the invention are used for synthetizing the 4-hydroxy-2-butanone, the reaction yield can be improved; the acetone loss is reduced; the reaction heat of catalytic reaction can be fully utilized; the subsequent separation energy consumption is low; the technological process is simplified; the production cost is reduced.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

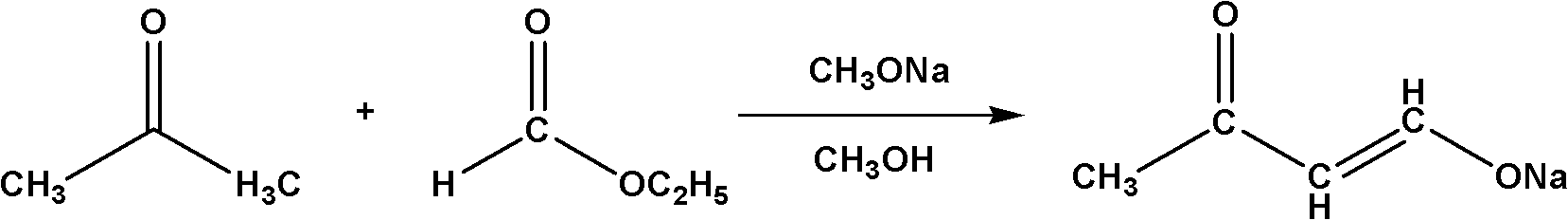

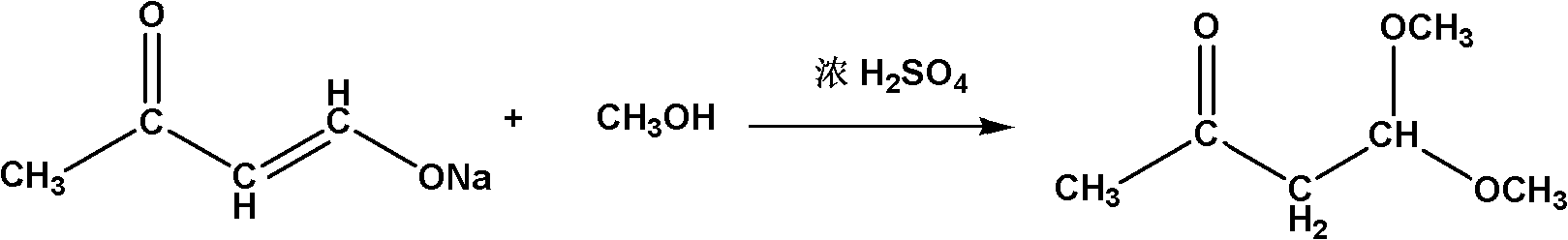

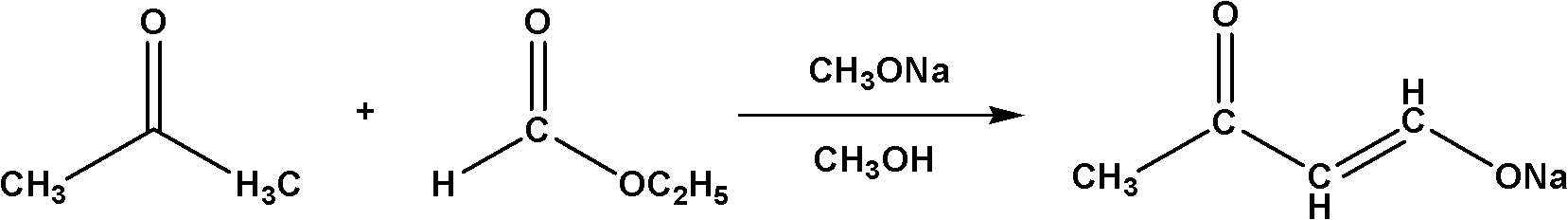

Method for synthesizing 4,4-dimethoxy-2-butanone

InactiveCN102010311AHigh boiling pointEasy to storeOrganic compound preparationCarbonyl compound preparationSodium methoxideClaisen condensation

The invention relates to a method for synthesizing a 4,4-dimethoxy-2-butanone fine chemical engineering raw material. The method comprises the following steps of: performing a Claisen condensation reaction of ethyl formate, liquid sodium methoxide, acetone and concentrated sulfuric acid, which serve as raw materials, to prepare butanone sodium enolate, dripping solution of the treated butanone sodium enolate into solution of methanol containing the concentrated sulfuric acid and reacting to obtain a crude product of the 4,4-dimethoxy-2-butanone, and distilling under normal pressure and reduced pressure to obtain the 4,4-dimethoxy-2-butanone. In the invention, the raw materials are cheap, and the method and process are simple, convenient to operate and suitable for large-scale industrial production and have a high industrial application value.

Owner:SOUTHEAST UNIV

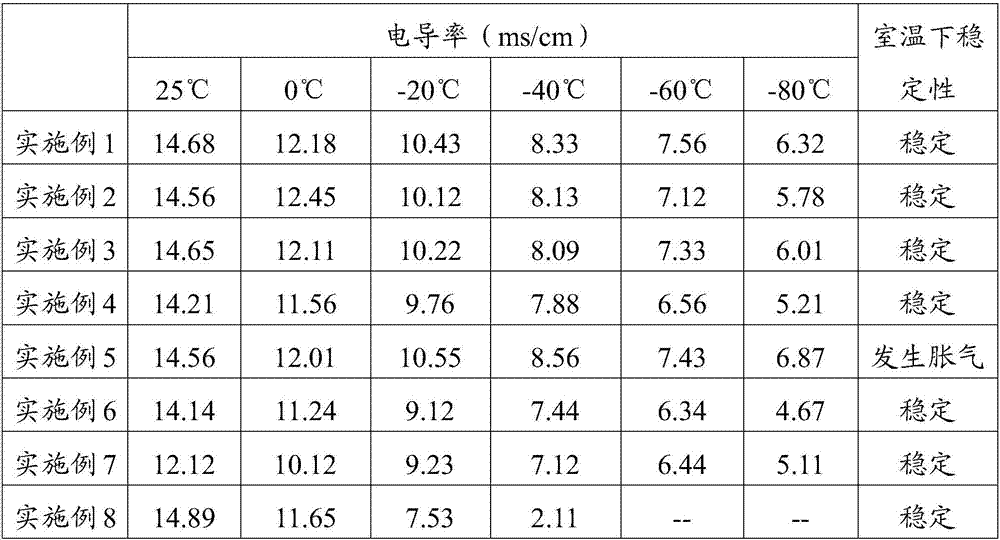

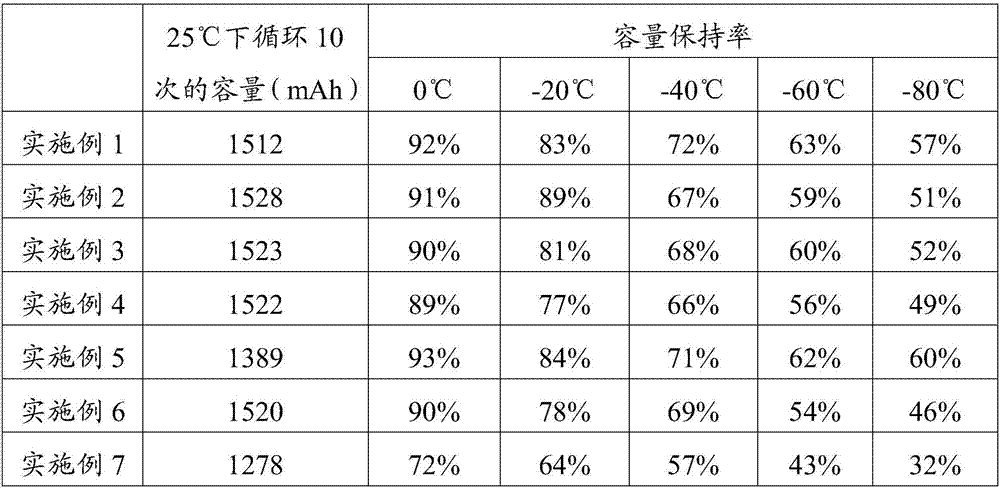

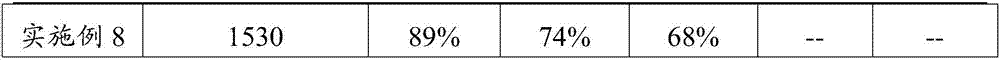

Lithium ion battery electrolyte and lithium ion battery

ActiveCN107154510AImprove electrochemical performanceImprove stabilitySecondary cellsSolubilityElectrochemistry

The invention relates to a lithium ion battery electrolyte and a lithium ion battery. The lithium ion battery electrolyte comprises solvents and lithium salt, and the solvents include ethylene carbonate, 2-butanone and dichloromethane according to a mass ratio of 1-2:1-7:1-7. Ethylene carbonate, 2-butanone and dichloromethane are used as the solvents, ethylene carbonate can form a stable SEI film during use, and 2-butanone and dichloromethane have low melting point, has high chemical stability at normal temperature and low temperature and can still present high solubility at low temperature. The above solvents are matched in use and reasonably proportioned, so that the lithium ion battery electrolyte and the lithium ion battery have good electrochemical performance and stability at low temperature.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com