Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191 results about "Sec-Butanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Butanol, or sec-butanol, is an organic compound with formula CH3CH(OH)CH2CH3. This secondary alcohol is a flammable, colorless liquid that is soluble in 3 parts water and completely miscible with polar organic solvents such as ethers and other alcohols.

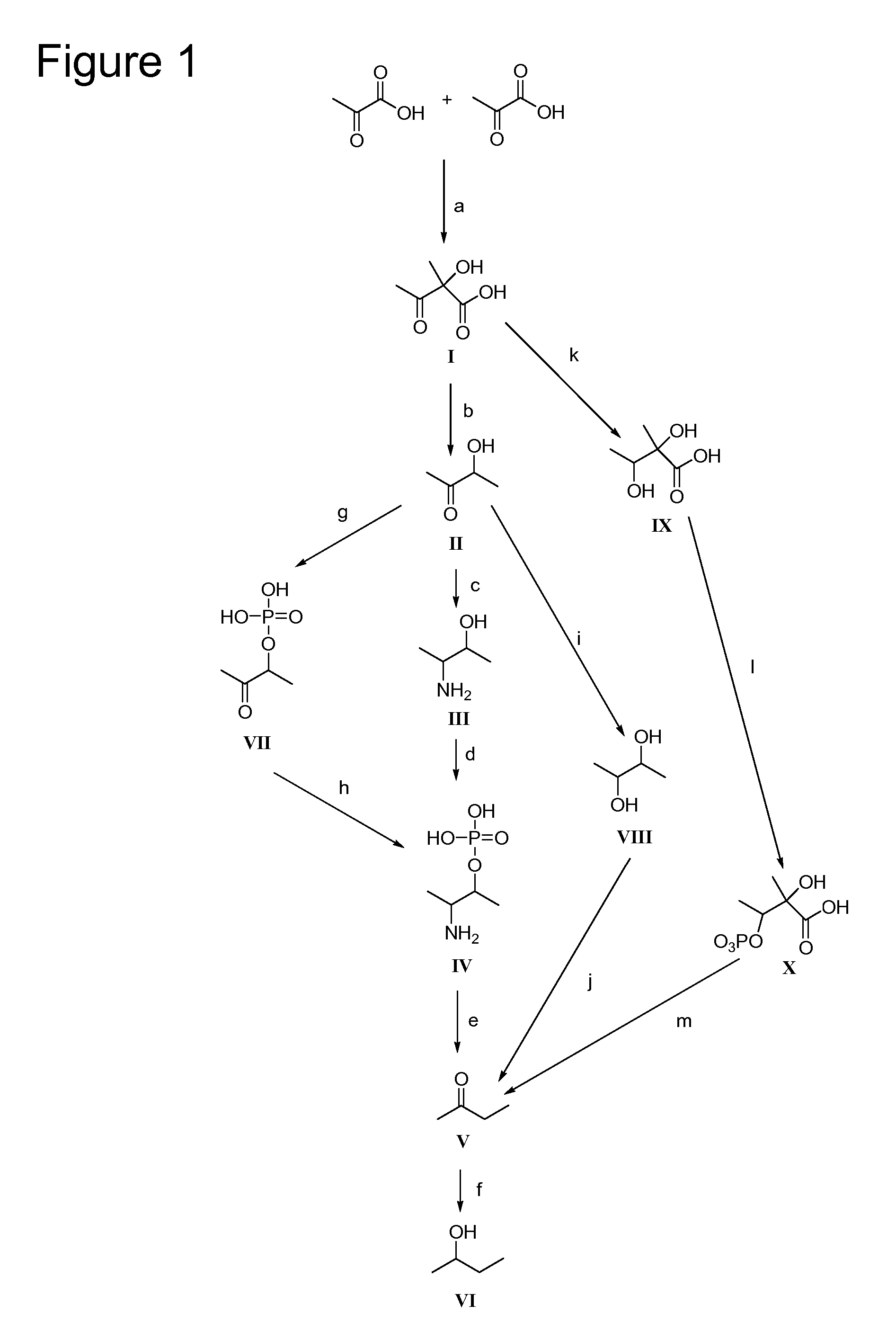

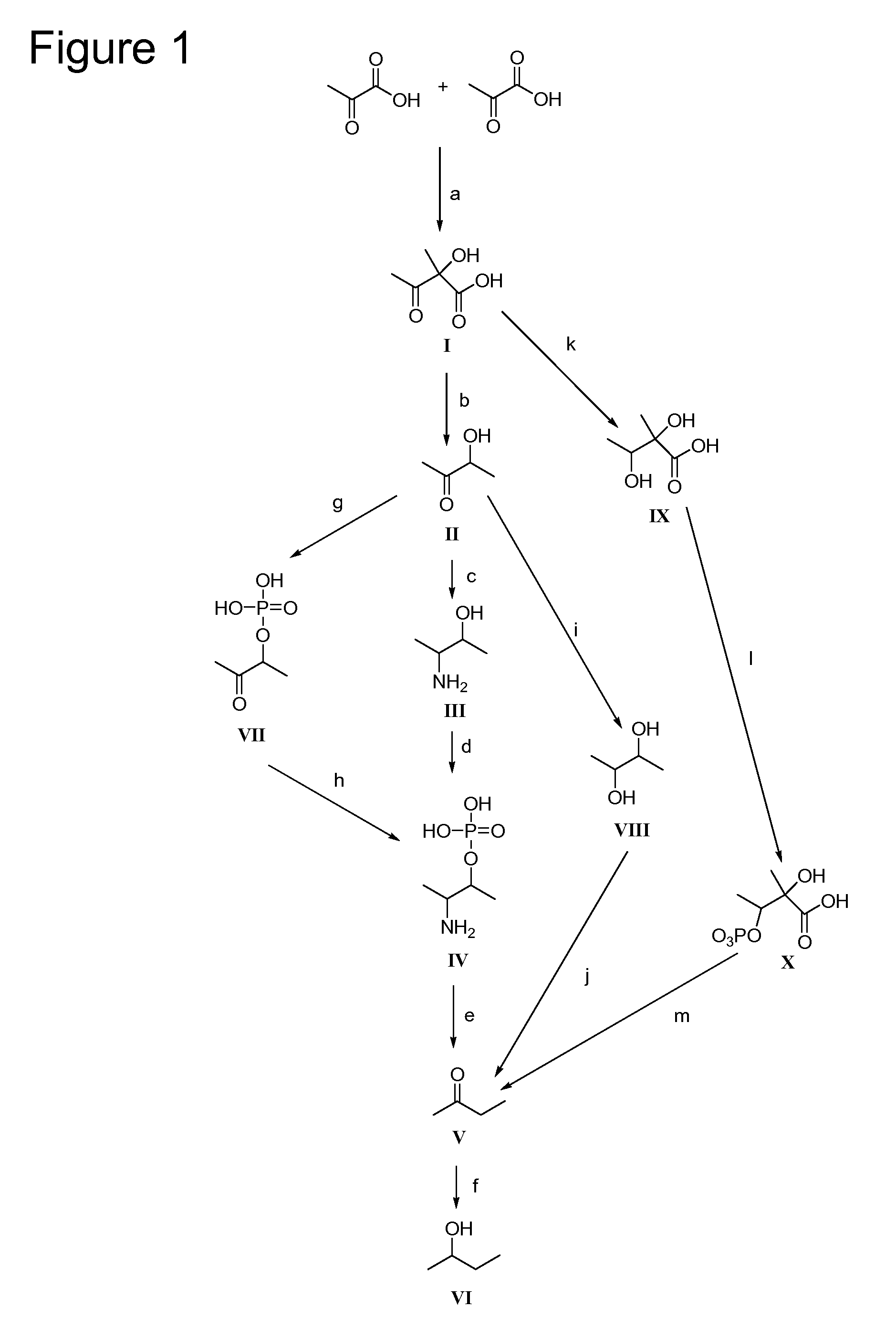

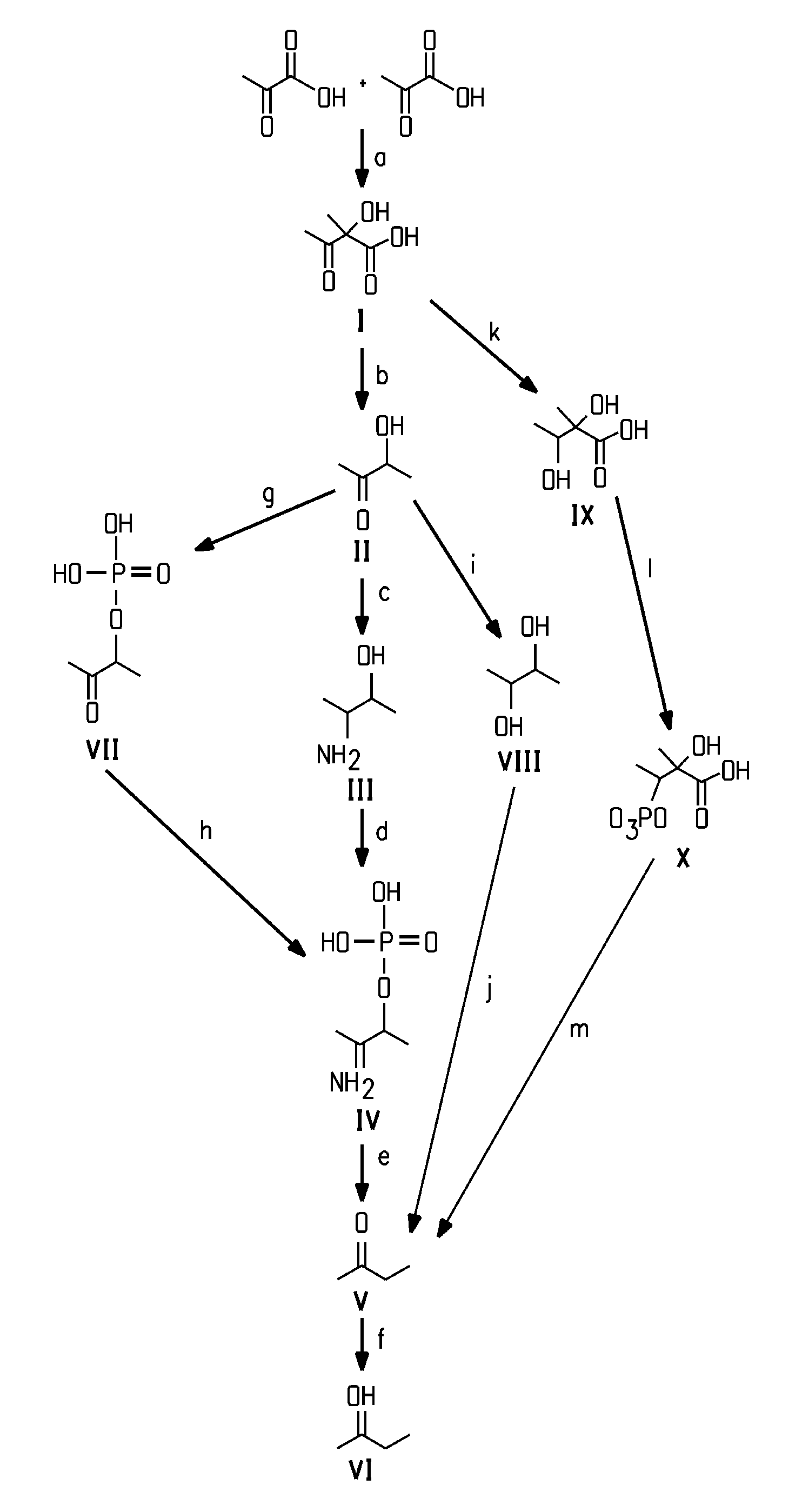

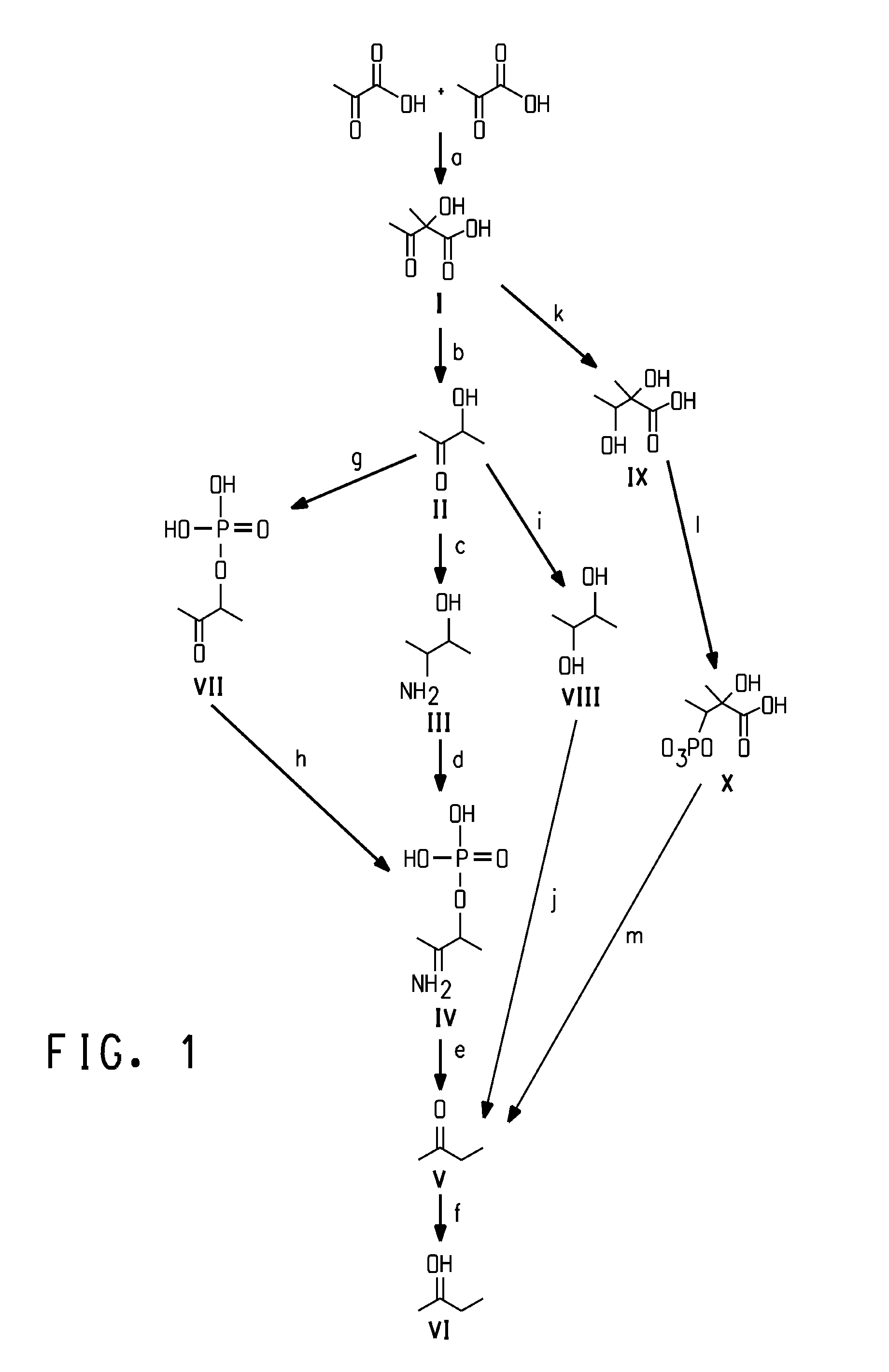

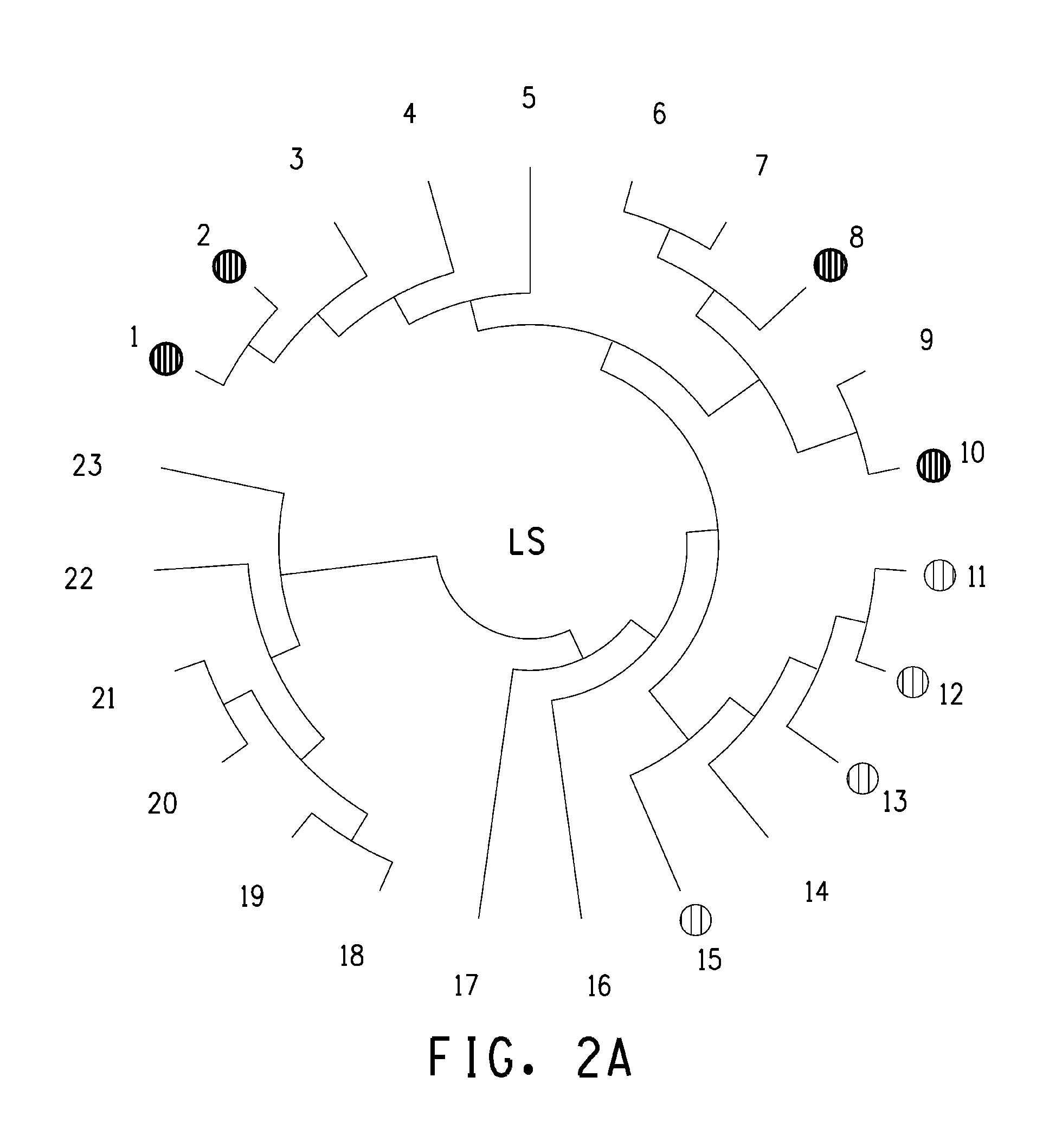

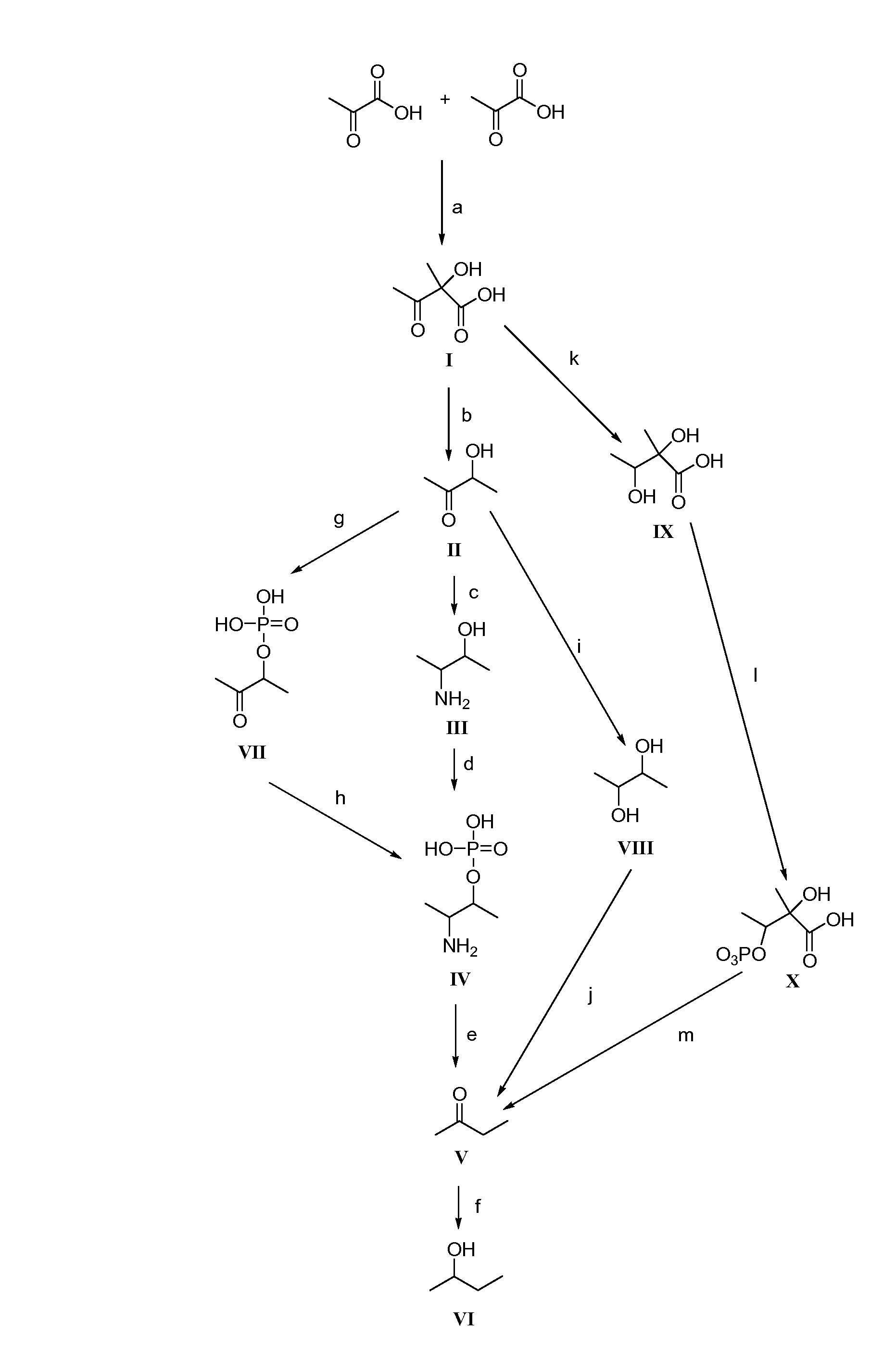

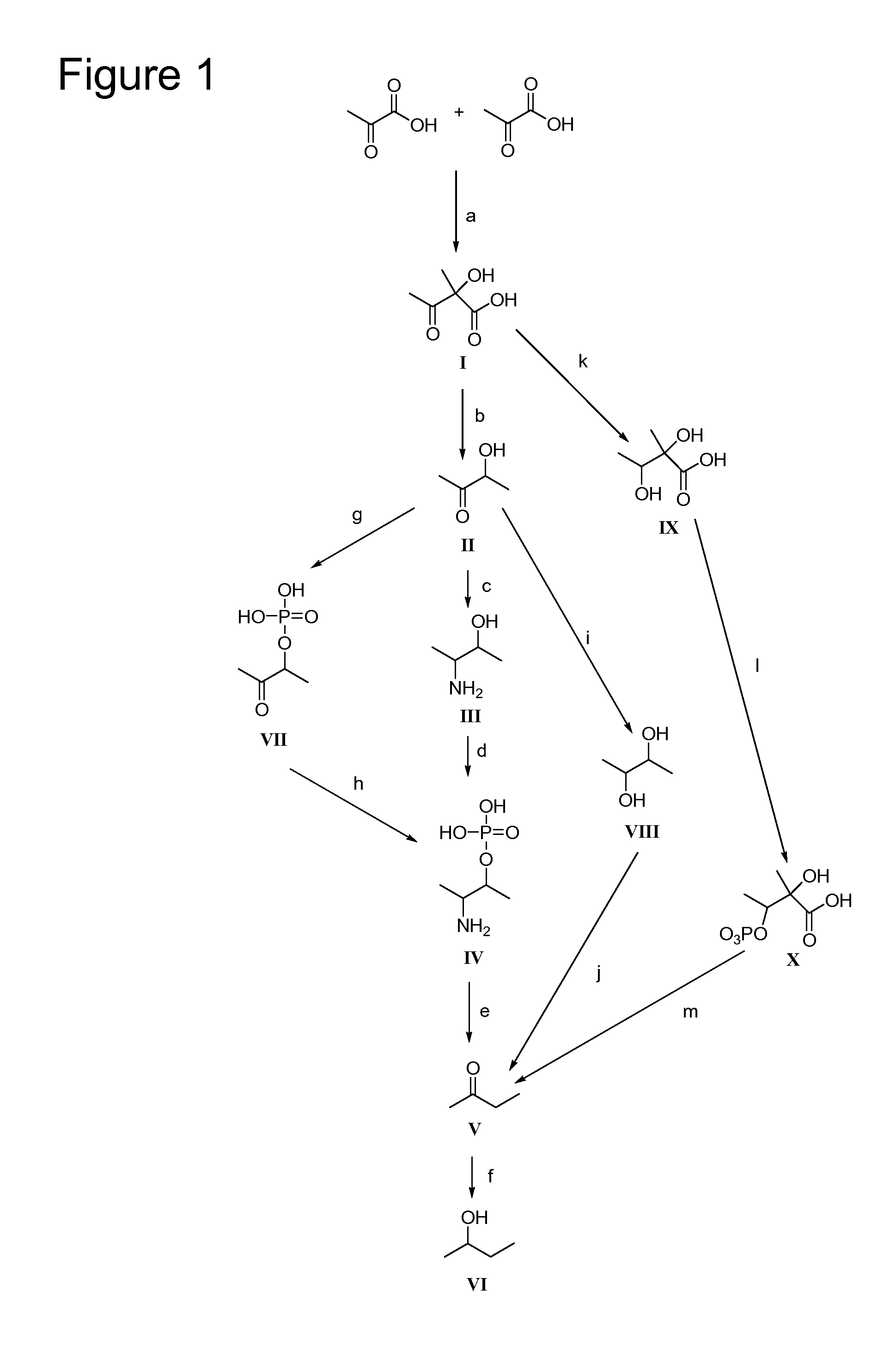

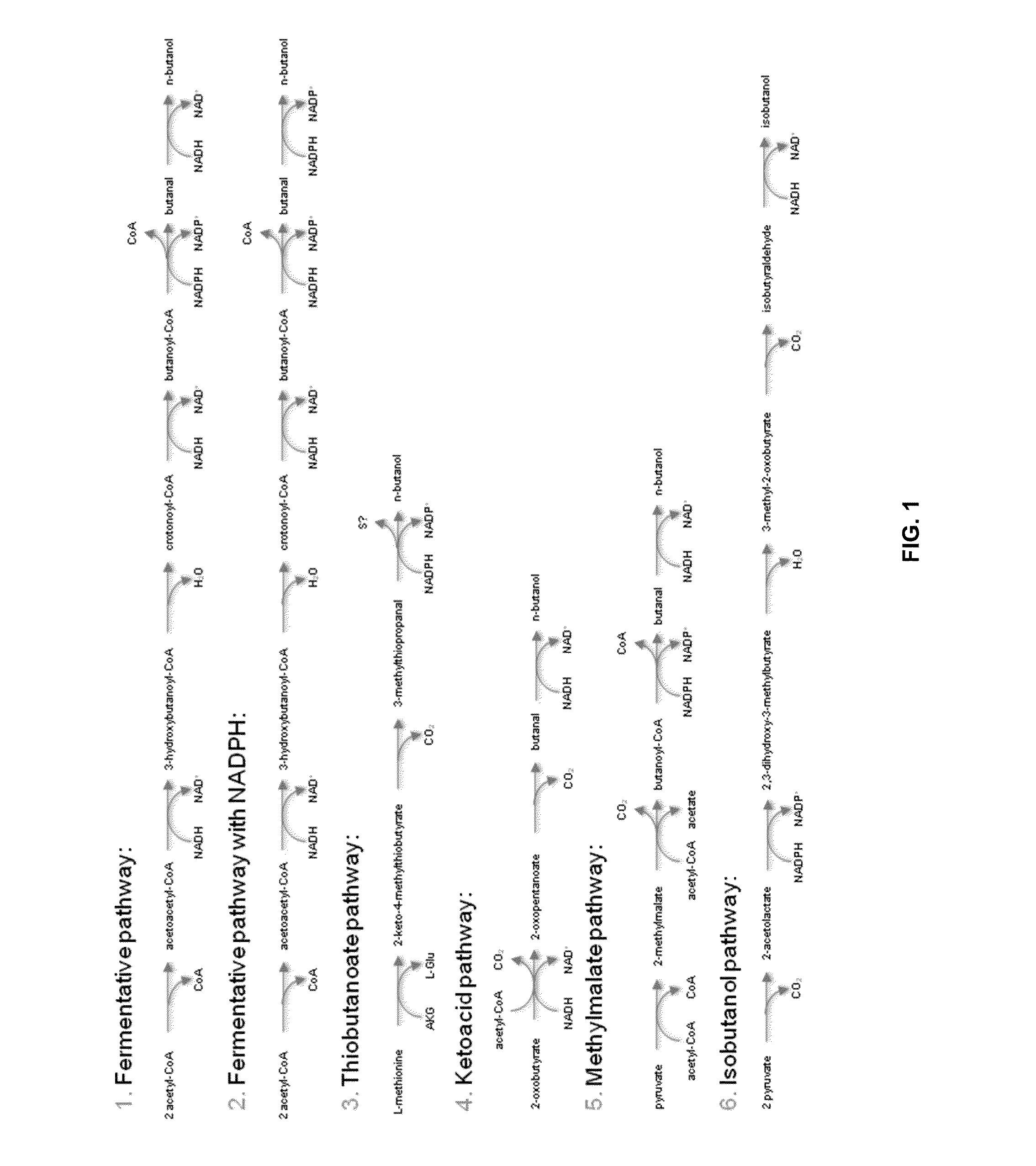

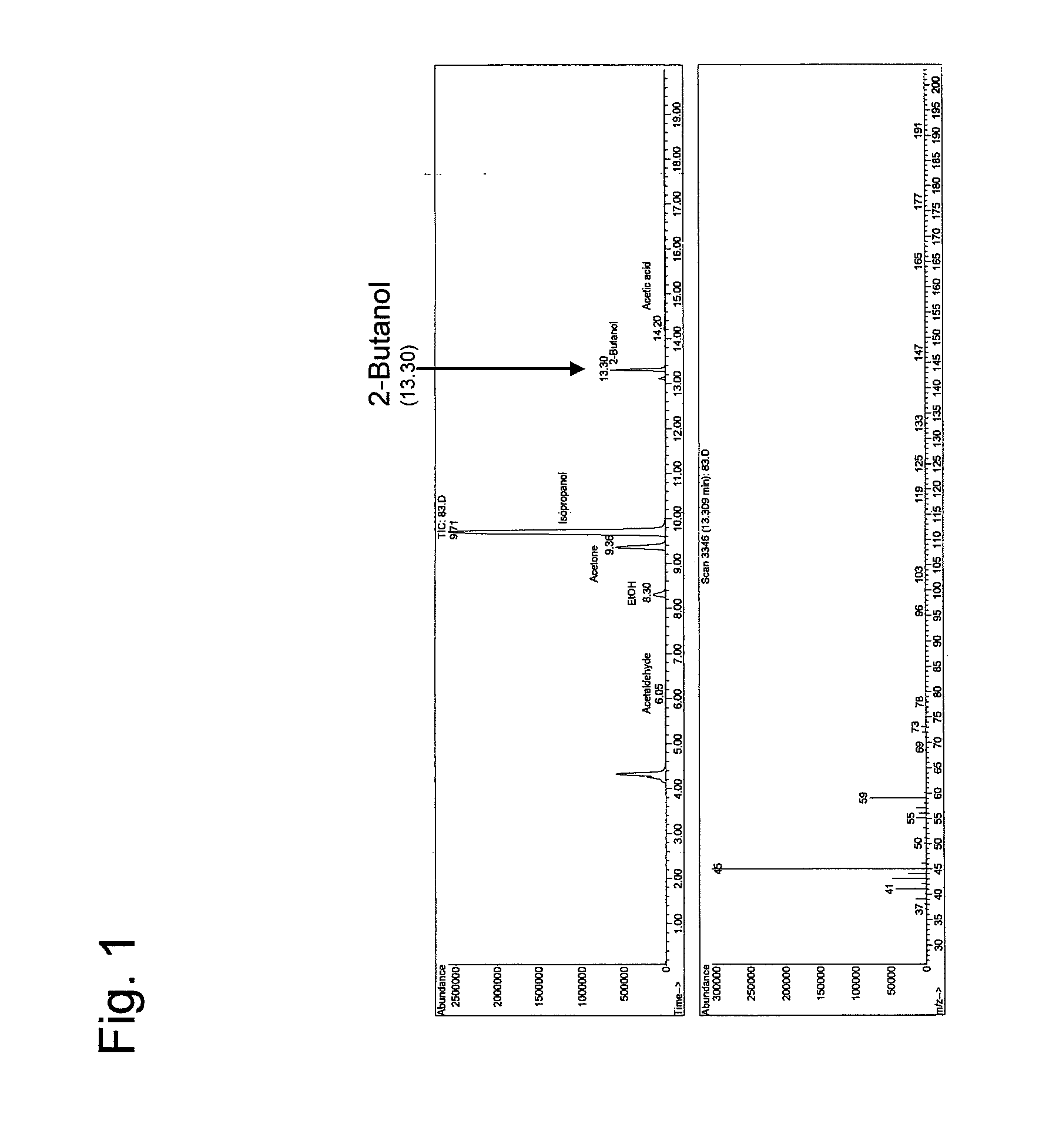

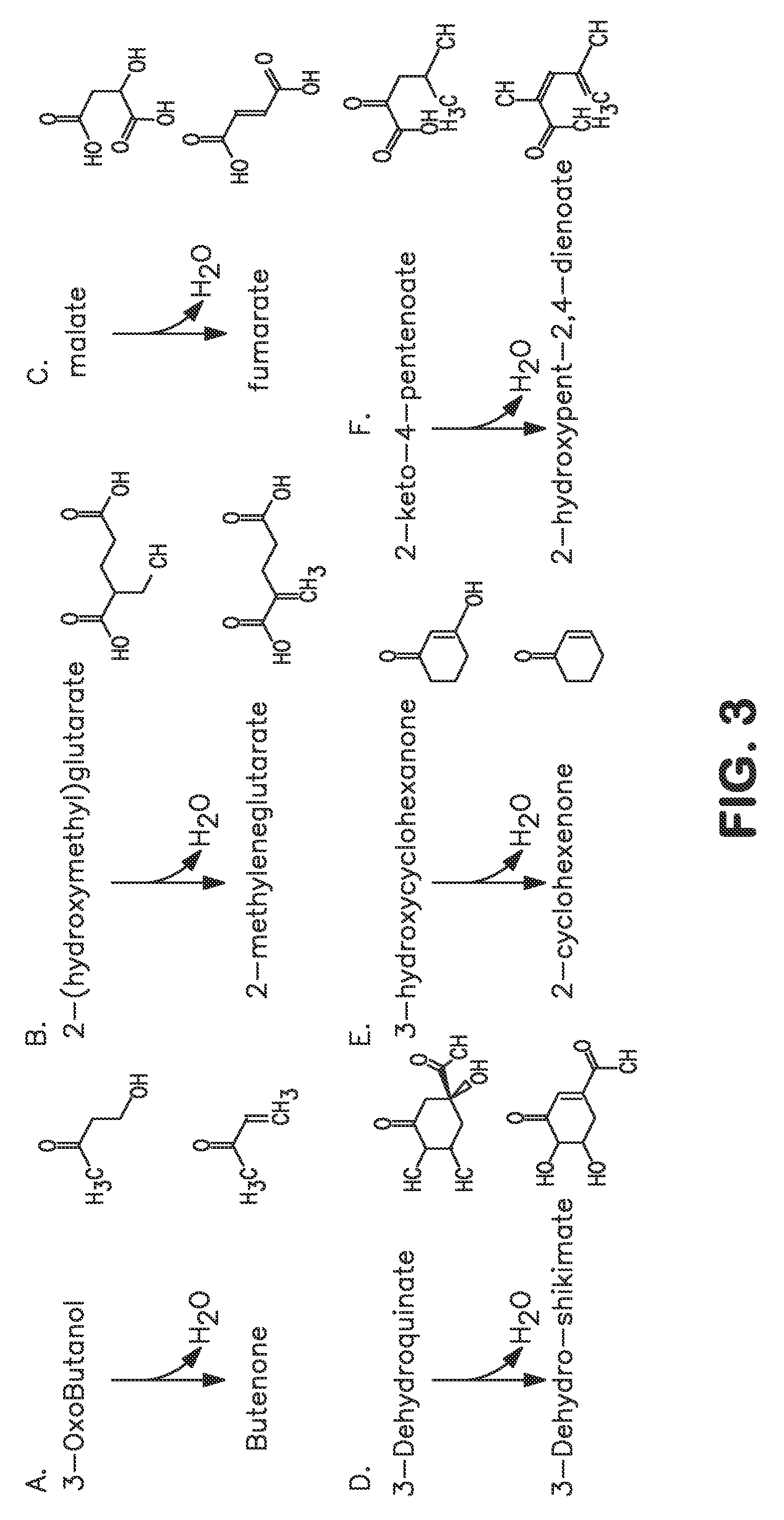

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein.

Owner:GEVO INC

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein.

Owner:GEVO INC

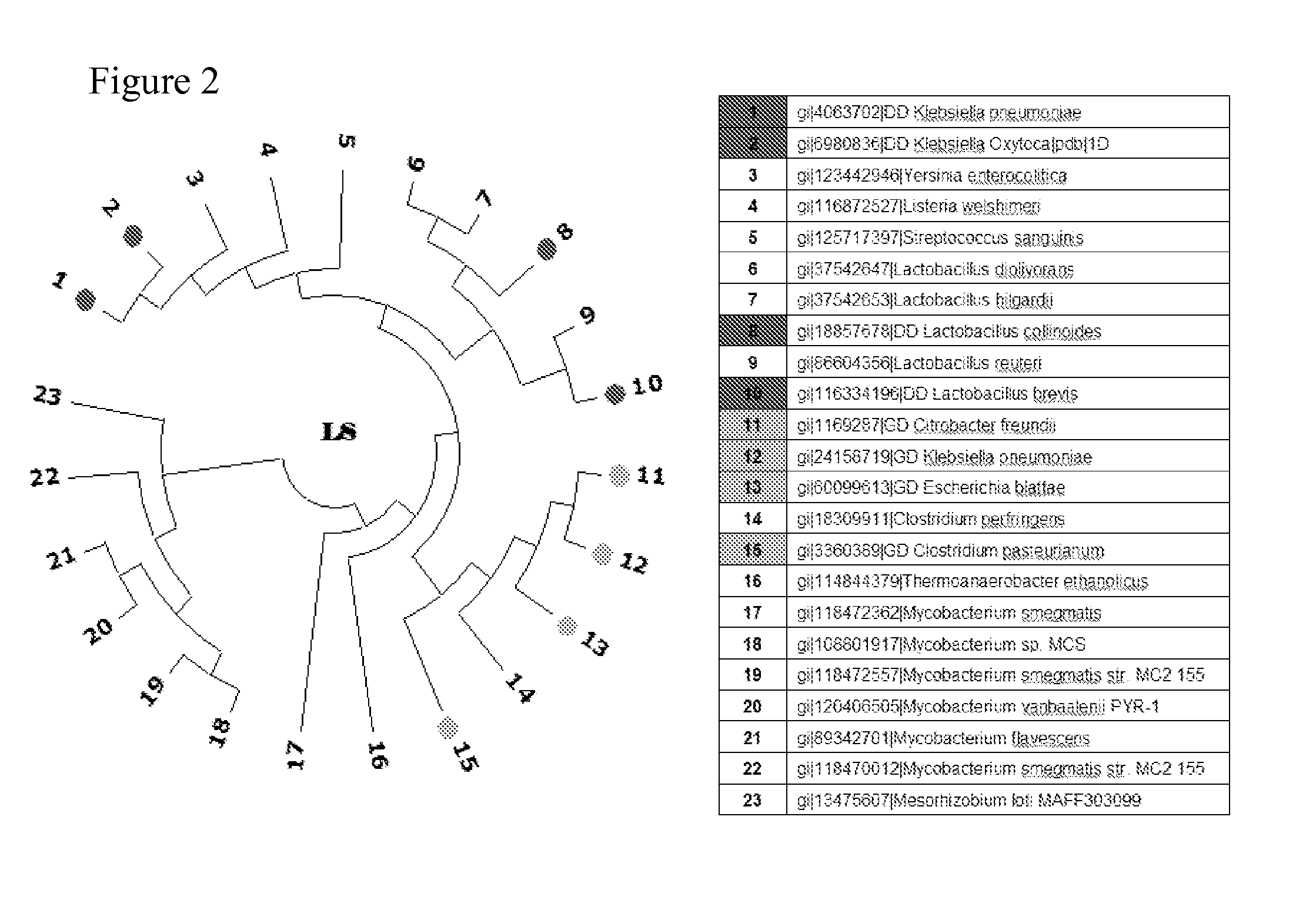

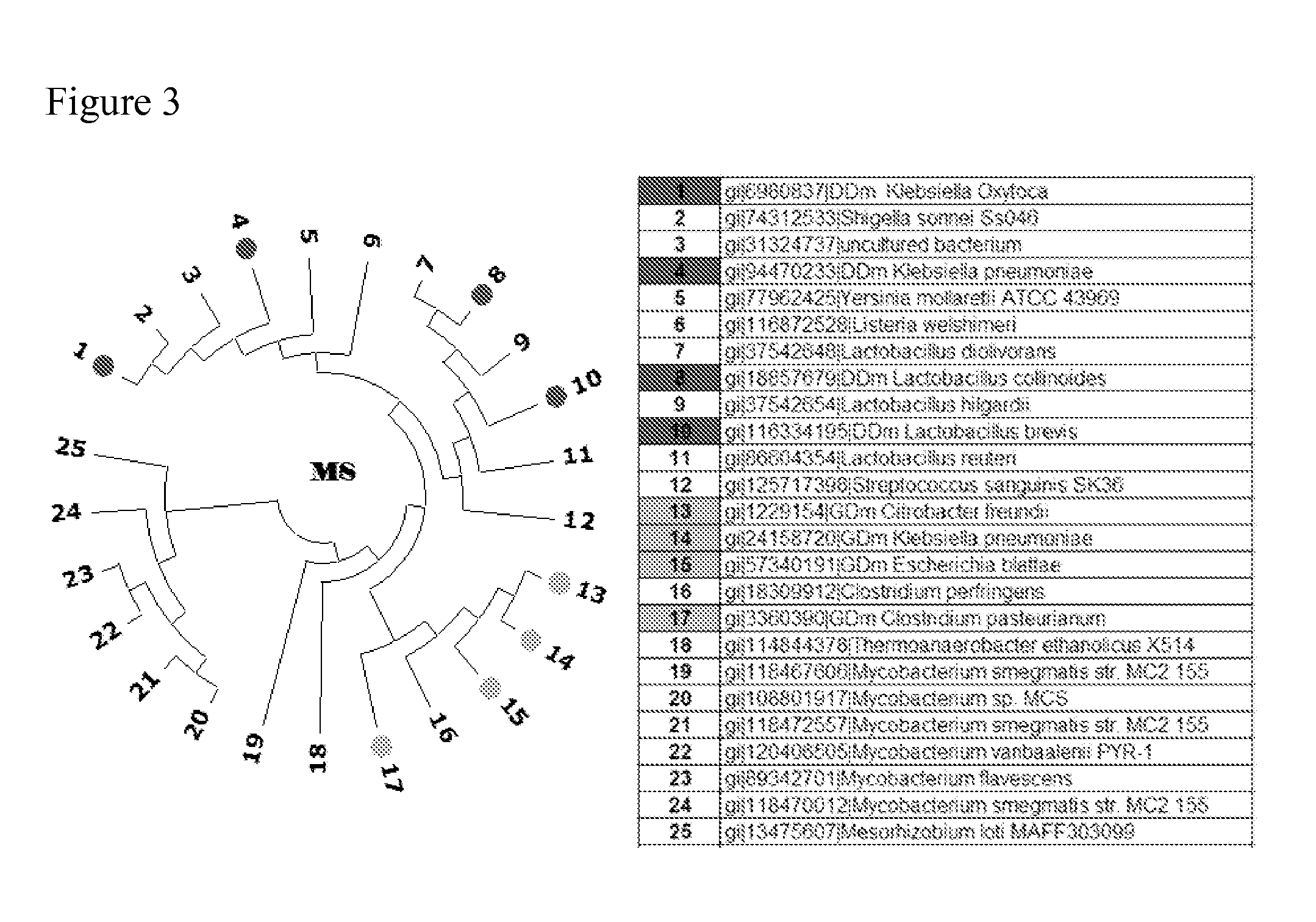

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein. Specifically disclosed herein are the use of coenzyme B12-independent butanediol dehydratases that catalyzes the substrate to product conversion of 2,3-butanediol to 2-butanone in the process of producing 2-butanol and 2-butanone.

Owner:GEVO INC

Method for the production of 2-butanol

ActiveUS20080274525A1Reduce the temperatureRobust toleranceMicrobiological testing/measurementBiofuelsSec-ButanolFermentation

A method for the production of 2-butanol by fermentation using a microbial production host is disclosed. The method employs a reduction in temperature during the fermentation process that results in a more robust tolerance of the production host to the butanol product.

Owner:GEVO INC

Method for preparing N-long chain acyl neutral amino acid

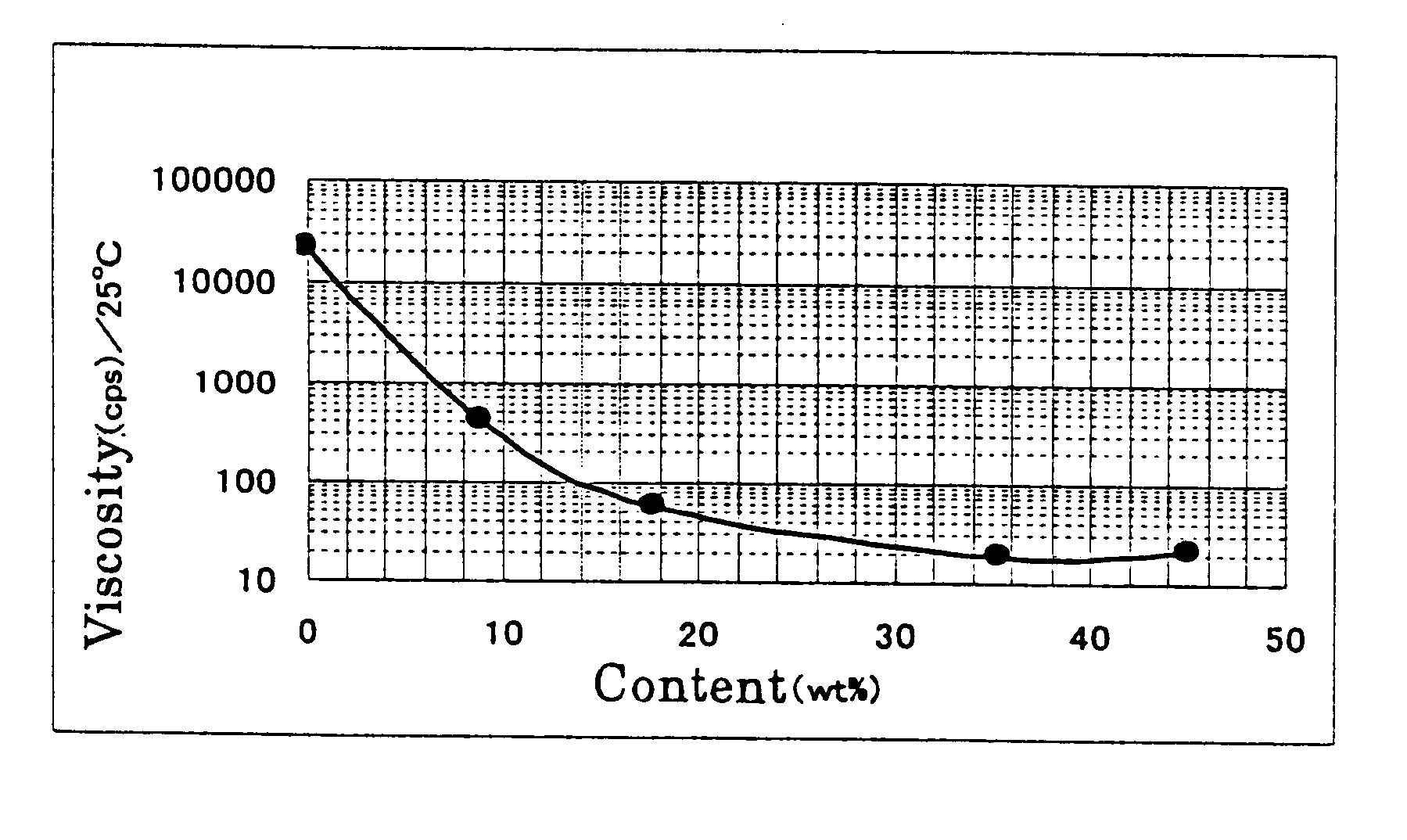

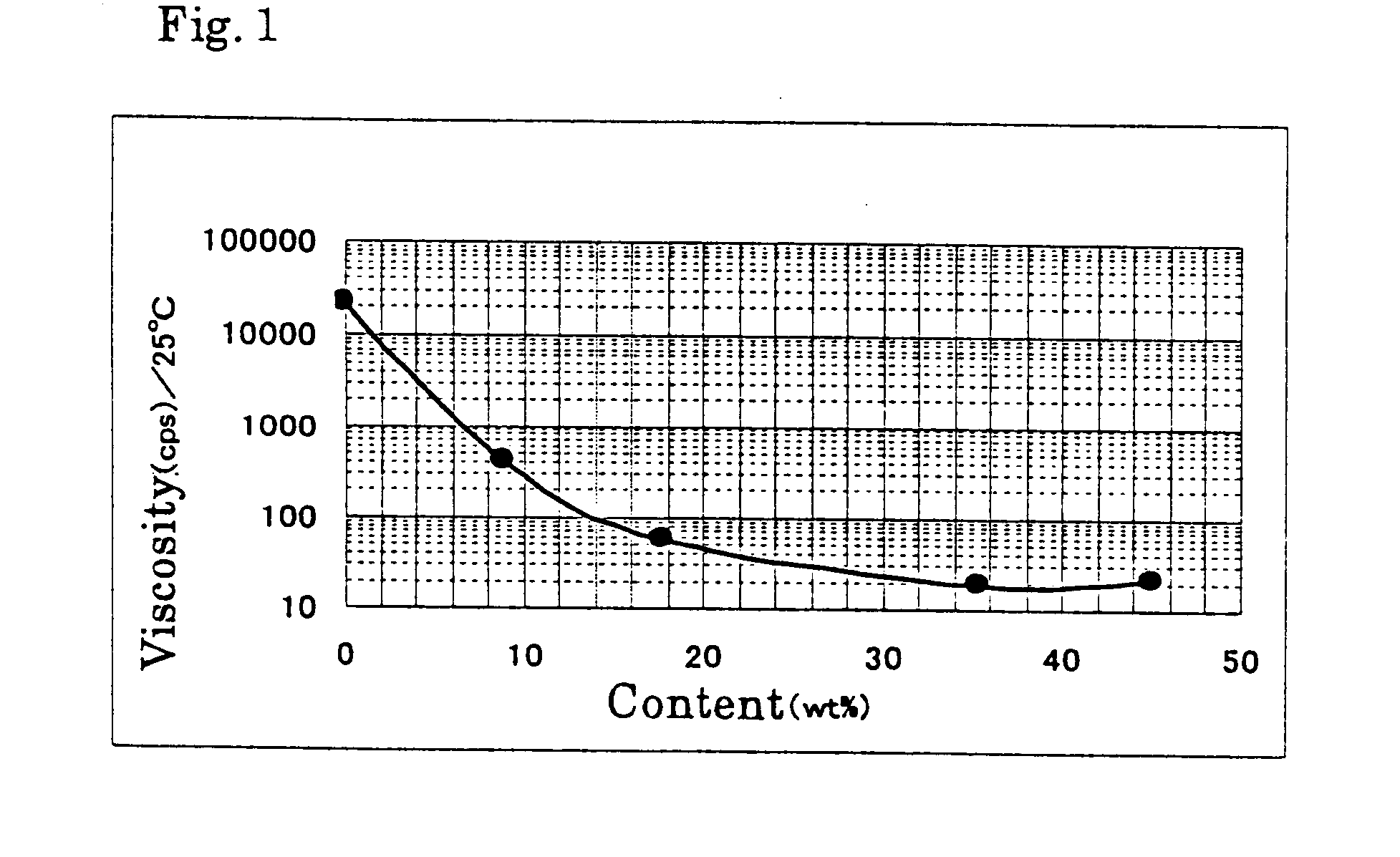

InactiveUS6703517B2Efficient conductionLow viscosityCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlanine

A method for preparing a highly purified N-long chain acyl neutral amino acid for use of a detergent and the like in a simple and convenient manner and in a high yield by reacting a neutral amino acid such as glycine, gamma-aminobutyric acid, and alanine, with a saturated or unsaturated fatty acid halide having 8 to 22 carbon atoms, wherein the reaction is performed in a mixture of water and one or more kinds of hydrophilic organic solvents selected from the group consisting of acetone, acetonitrile, a secondary alcohol having 3 or 4 carbon atoms, and a tertiary alcohol having 4 carbon atoms such as isopropanol, sec-butanol, and tert-butanol in the presence of a base.

Owner:AJINOMOTO CO INC

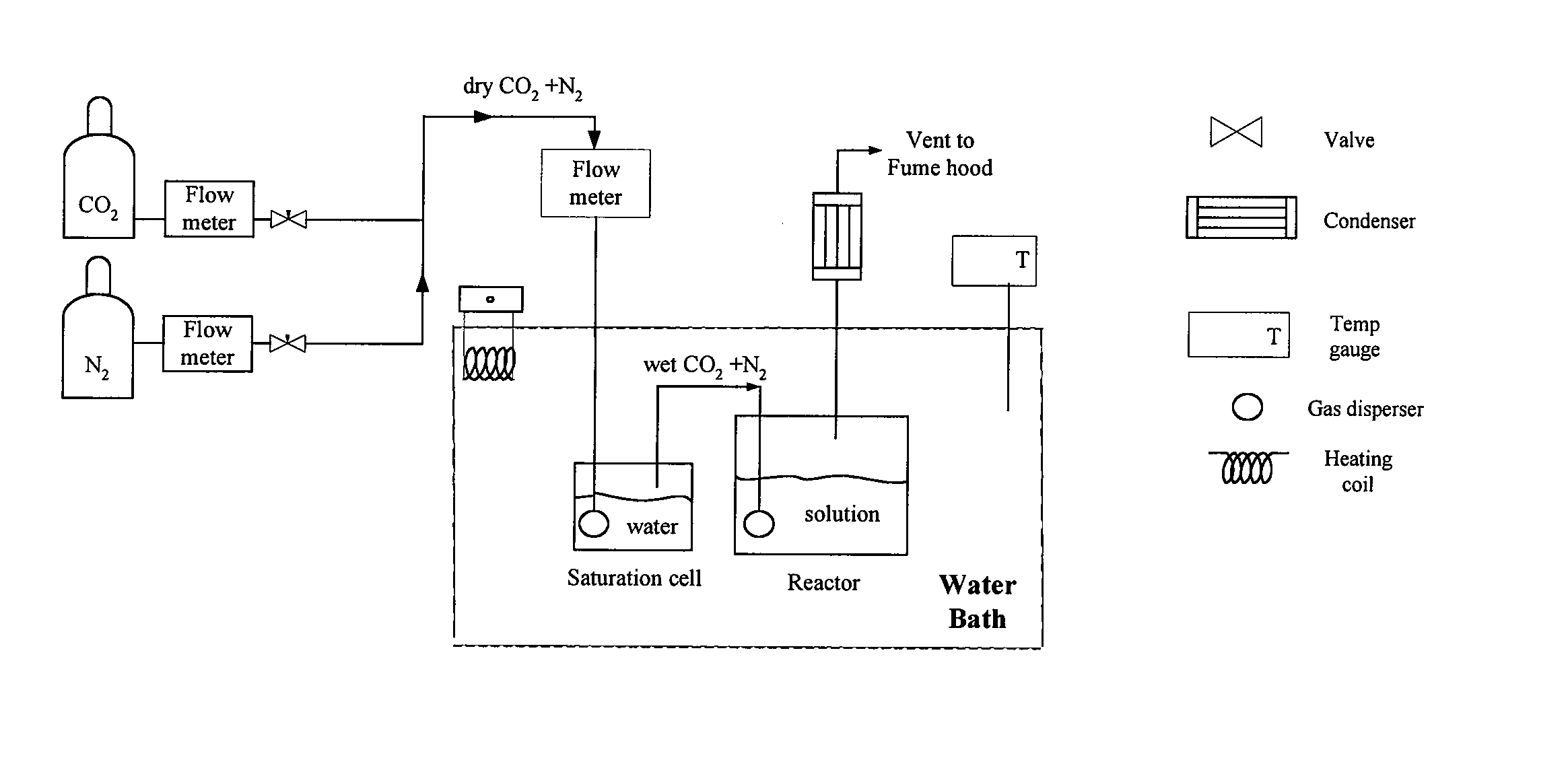

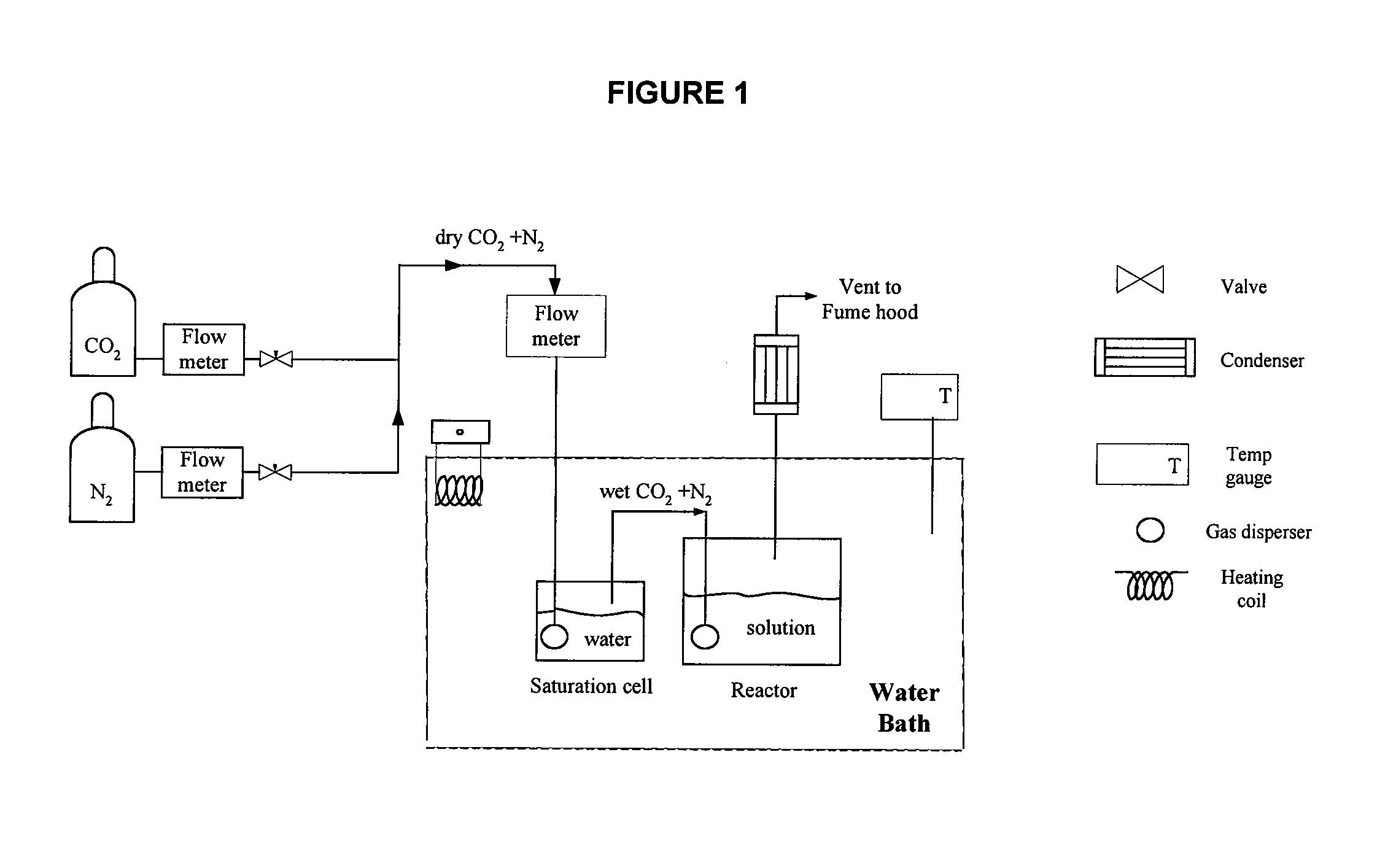

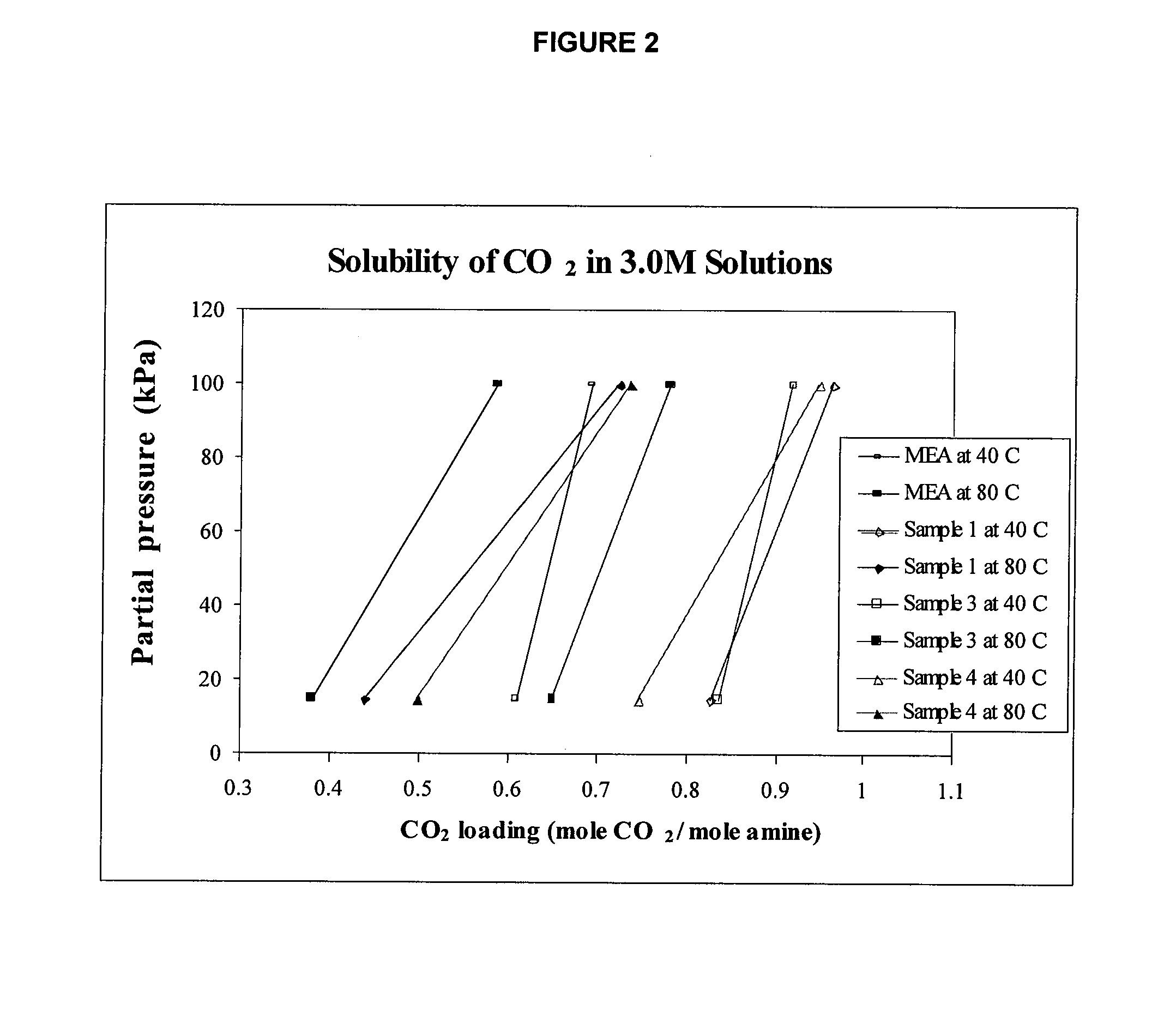

Method of capturing carbon dioxide from gas streams

The present invention relates to a method for removing carbon dioxide (CO2) from a gas stream. Particularly, the present invention relates to a method for removing CO2 from a gas stream by a liquid absorbent having an amino alcohol derived from 4-amino-2-butanol. In comparison to conventional amines, the amino alcohols of the present invention have been found to provide a higher CO2 absorption capacity and a higher cyclic capacity for CO2 removal.

Owner:UNIVERSITY OF REGINA

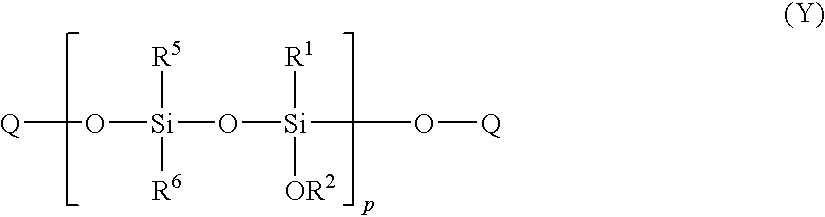

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

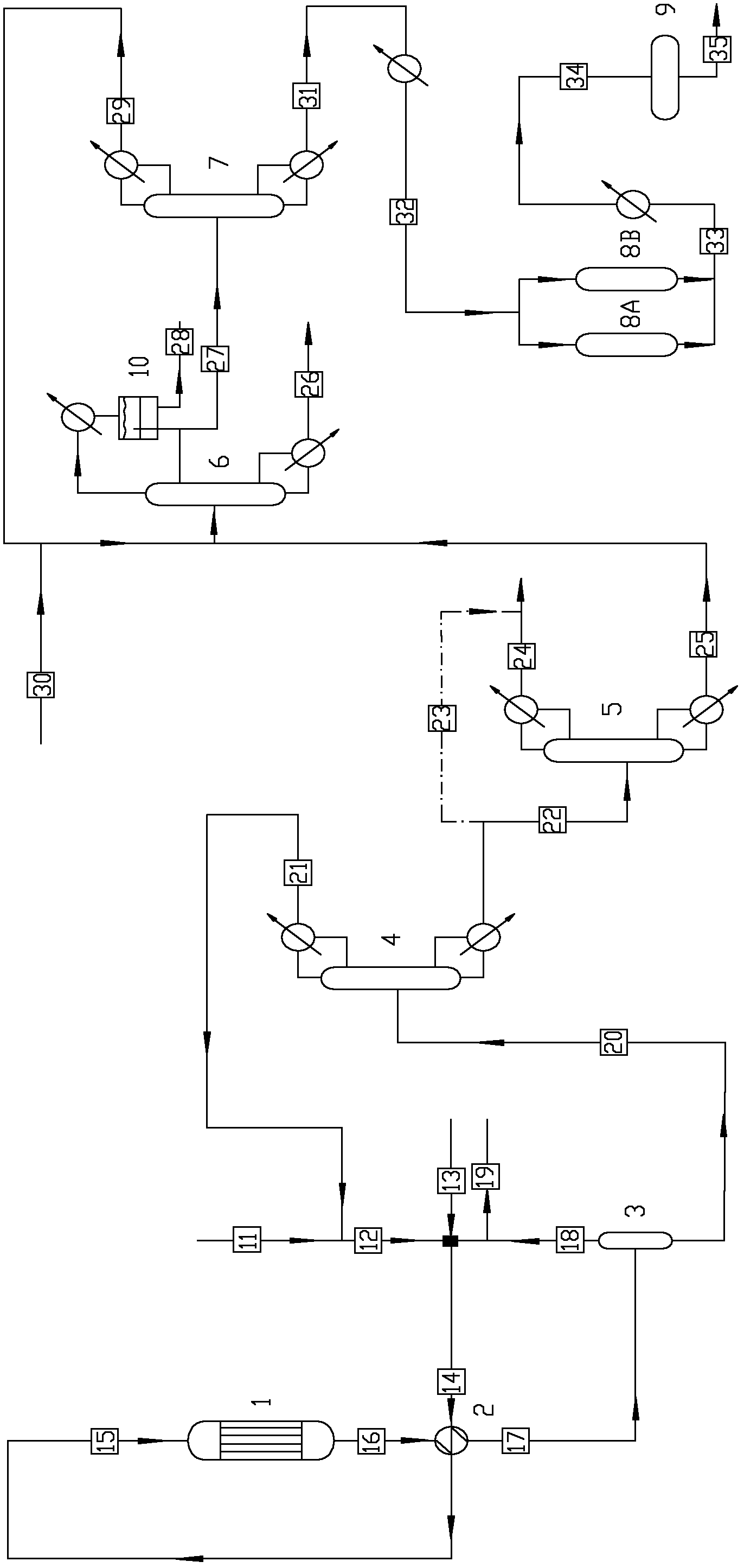

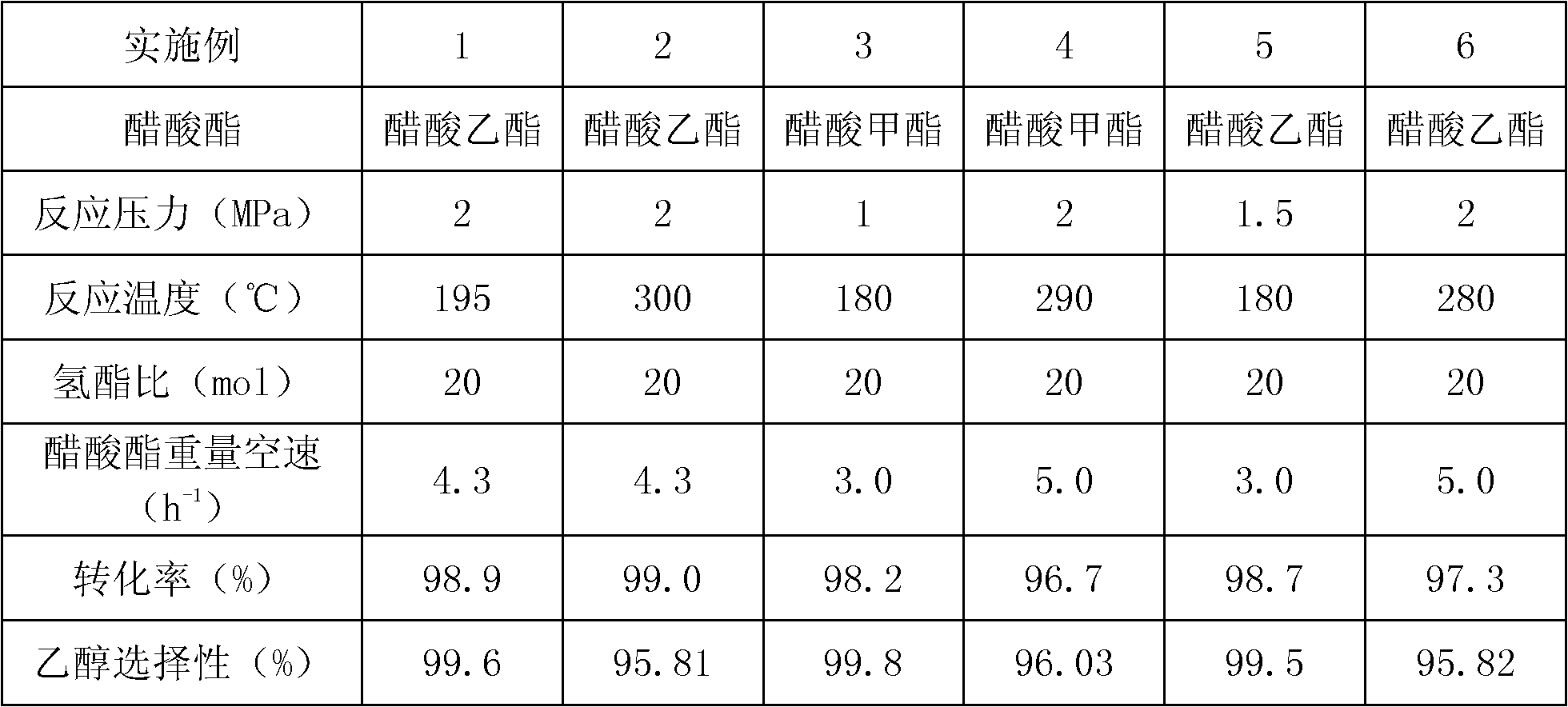

Process for producing alcohol and selectively co-producing 2-butanol by utilizing acetate and matching process system thereof

ActiveCN102659513AHigh selectivityHigh activityOrganic compound preparationHydroxy compound separation/purificationProcess systemsSec-Butanol

The invention relates to a process for producing alcohol and selectively co-producing 2-butanol by hydrogenising acetate and a matching process system thereof. After industrial acetate is hydrogenised and purified, a product is rectified, purified and dehydrated, thereby obtaining alcohol and co-producing 2-butanol. Cu-Zn-M is taken as an active component of a catalyst adopted in the process, wherein M is selected from the compound of one and more of Ir, Mn, W, Ru and Zr. 2-butanol is selectively co-produced by adjusting the reaction temperature. The catalyst, process and device adopted by the invention have the characteristics of high activity, high selectivity, high yield, strong market adaptability, less equipment investment, environmental protection, simpleness in preparing process, economical and practical properties, and the like. Meanwhile, conversion per pass is high and reaction heat is effectively utilized, so that the load for separating rough products is greatly relieved, the production flow is shortened and the energy consumption of production is also greatly reduced.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

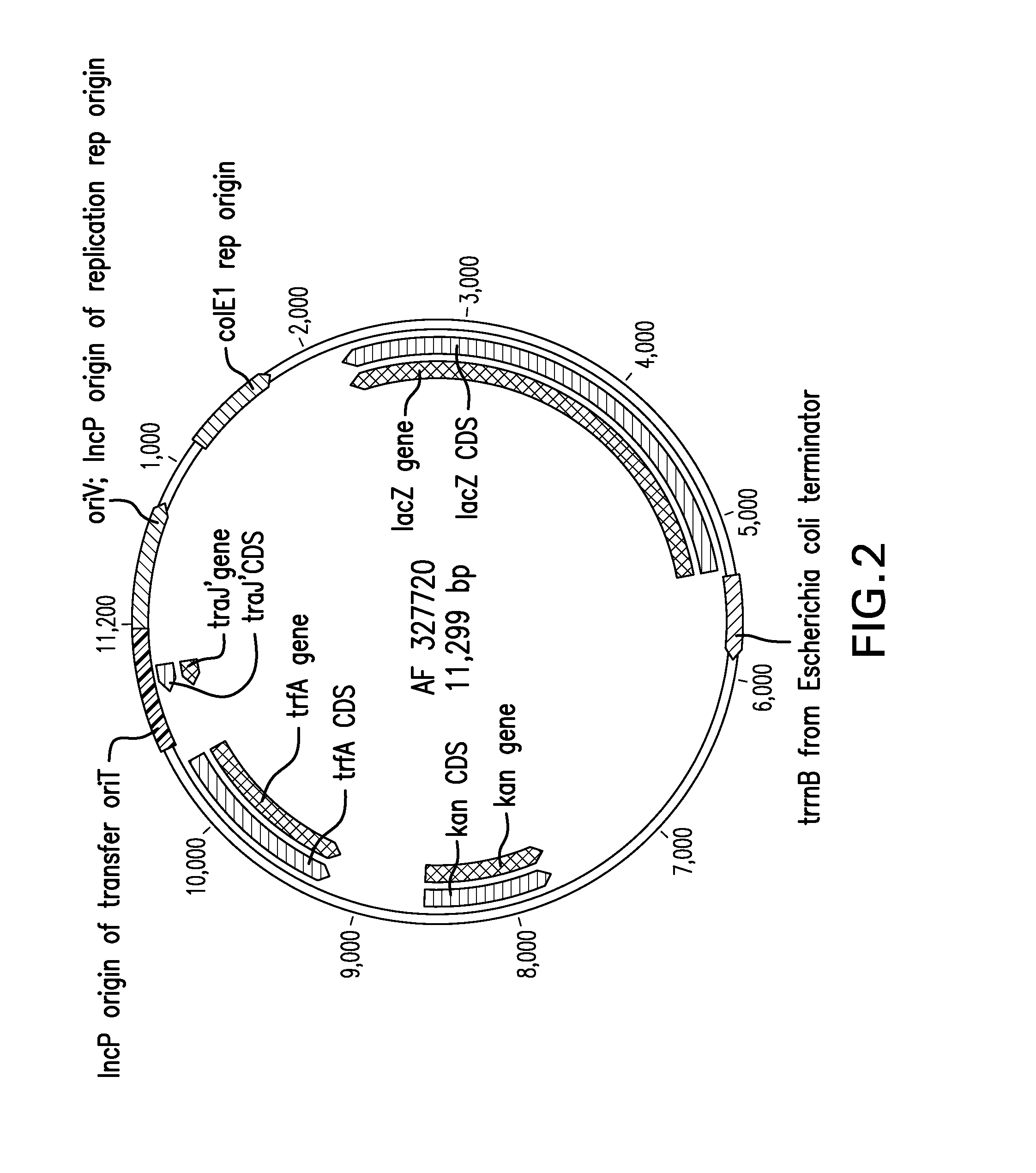

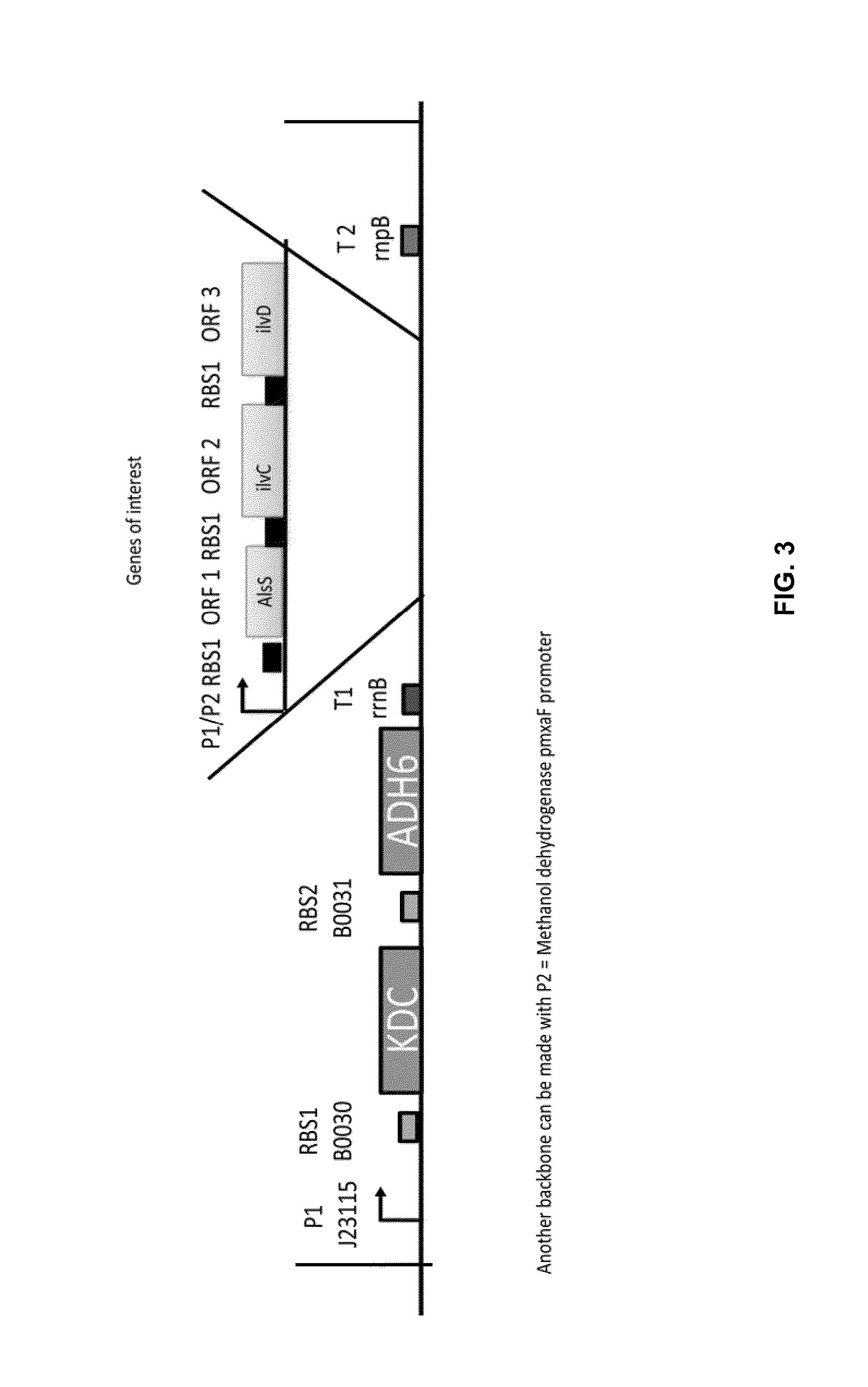

Biological Conversion of Multi-Carbon Compounds from Methane

Multi-carbon compounds such as ethanol, n-butanol, sec-butanol, isobutanol, tert-butanol, fatty (or aliphatic long chain) alcohols, fatty acid methyl esters, 2,3-butanediol and the like, are important industrial commodity chemicals with a variety of applications. The present invention provides metabolically engineered host microorganisms which metabolize methane (CH4) as their sole carbon source to produce multi-carbon compounds for use in fuels (e.g., bio-fuel, bio-diesel) and bio-based chemicals. Furthermore, use of the metabolically engineered host microorganisms of the invention (which utilize methane as the sole carbon source) mitigate current industry practices and methods of producing multi-carbon compounds from petroleum or petroleum-derived feedstocks, and ameliorate much of the ongoing depletion of arable food source “farmland” currently being diverted to grow bio-fuel feedstocks, and as such, improve the environmental footprint of future bio-fuel, bio-diesel and bio-based chemical compositions.

Owner:PRECIGEN INC

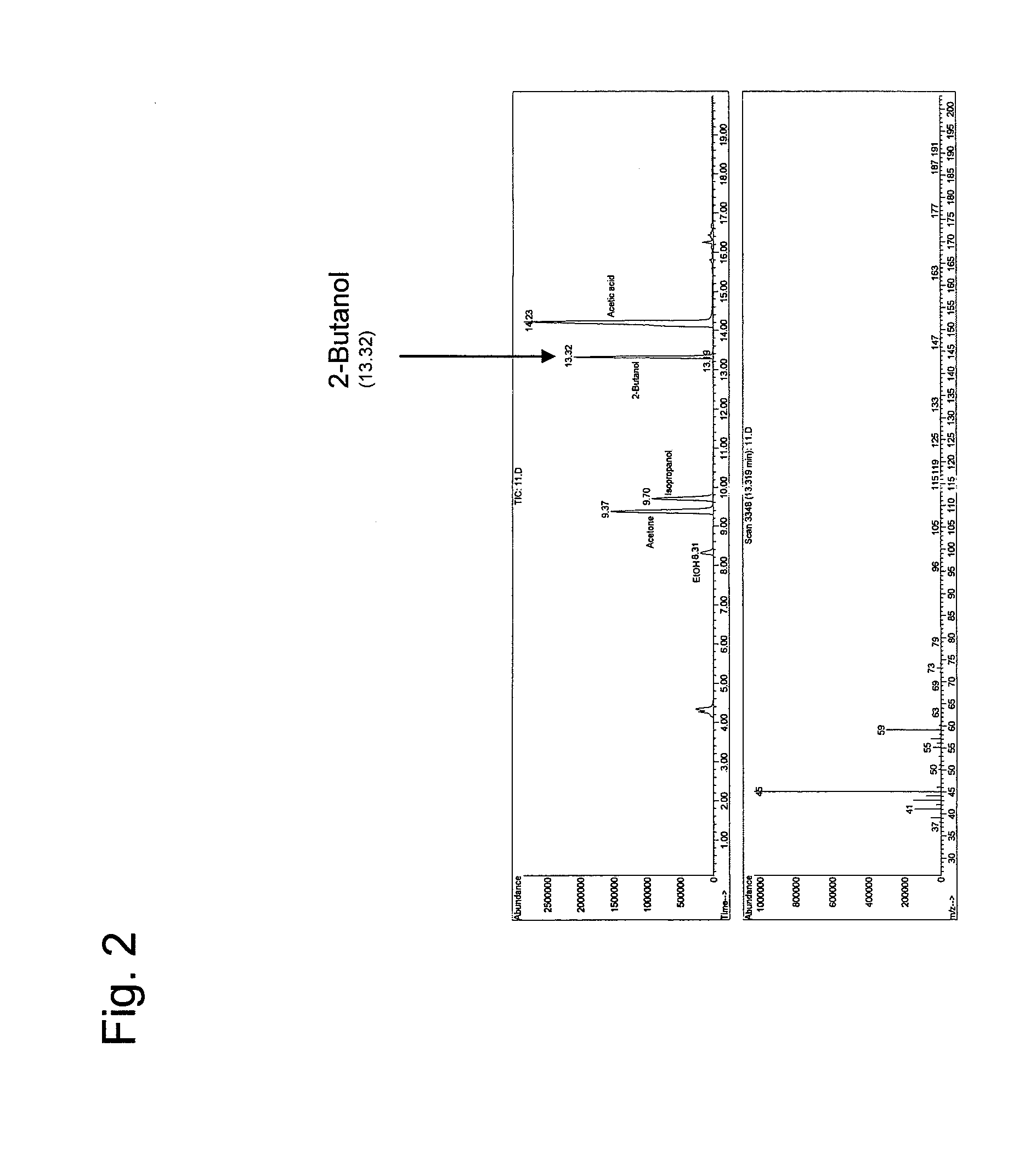

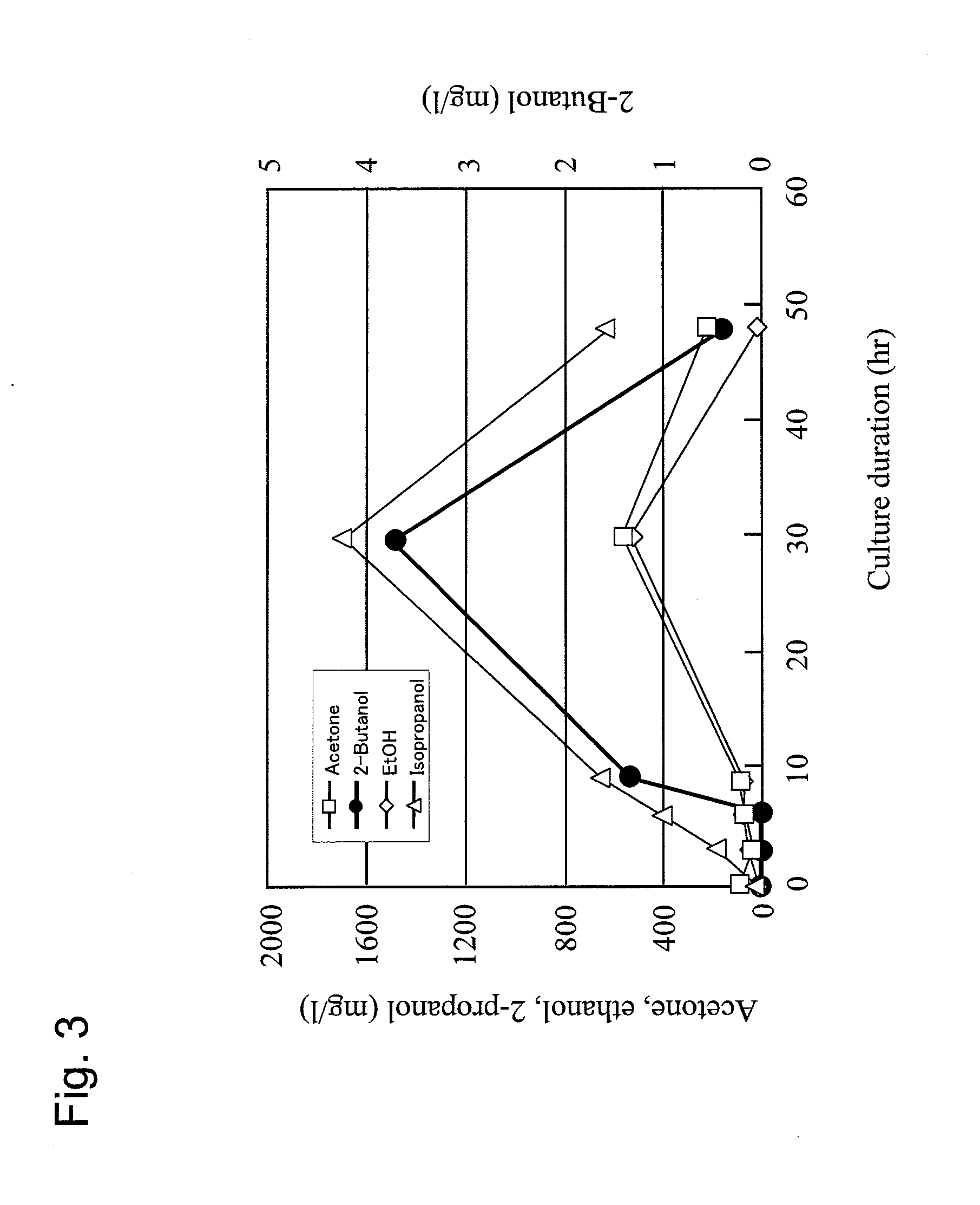

Method for producing 2-butanol and recombinant microorganism having 2-butanol production capacity

ActiveUS20110281315A1Increase production capacitySimple materialBacteriaSugar derivativesPropanolMicroorganism

This invention is intended to produce 2-butanol with excellent productivity via a fermentation process. Recombinant microorganisms into which the acetoacetyl-CoA synthase gene and a group of genes (i.e., genes involved in 2-propanol synthesis) encoding a set of enzymes synthesizing 2-propanol from acetoacetyl-CoA have been introduced are cultured, so that, in addition to 2-propanol, 2-butanol is produced at a high level in a medium.

Owner:TOYOTA JIDOSHA KK

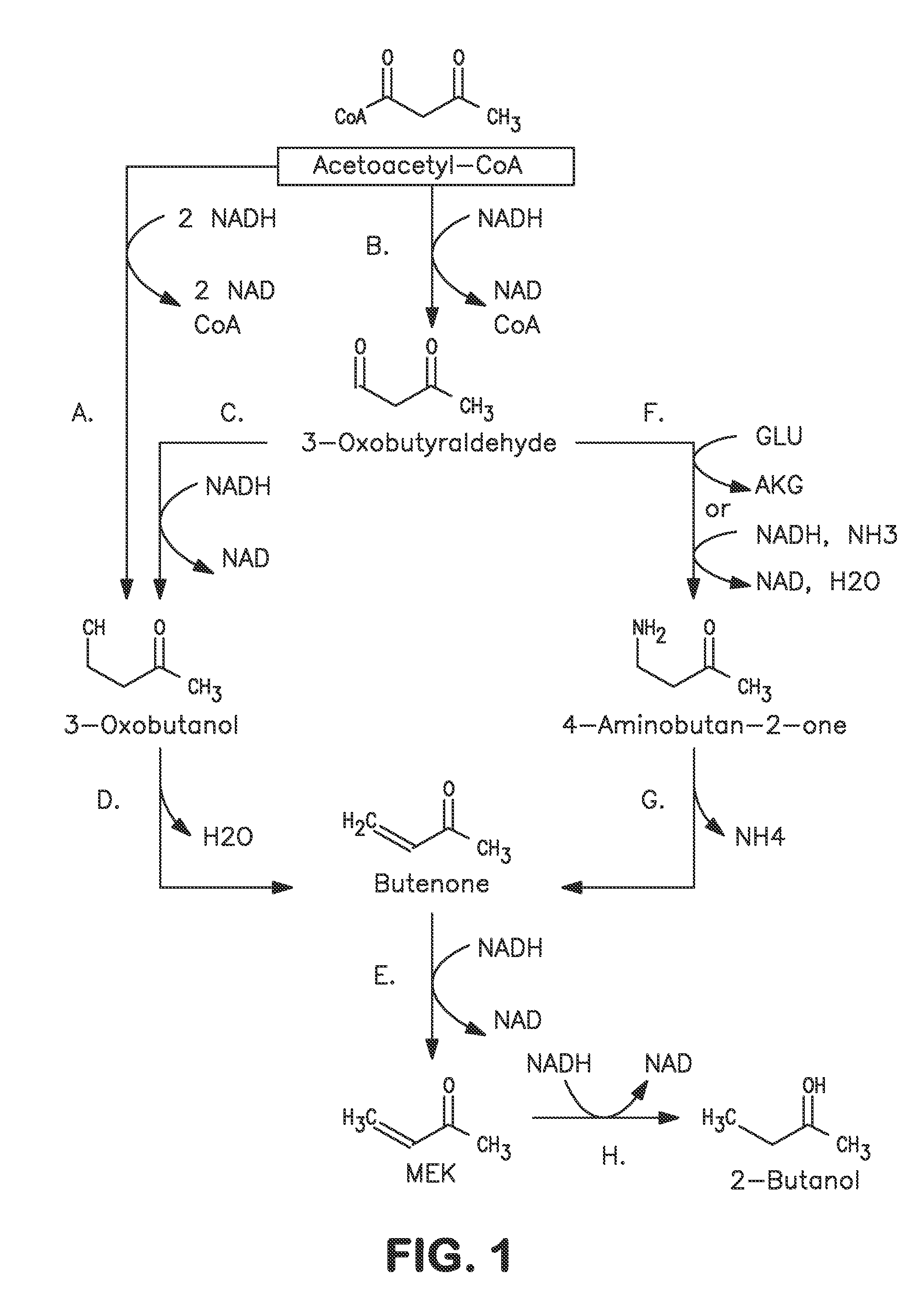

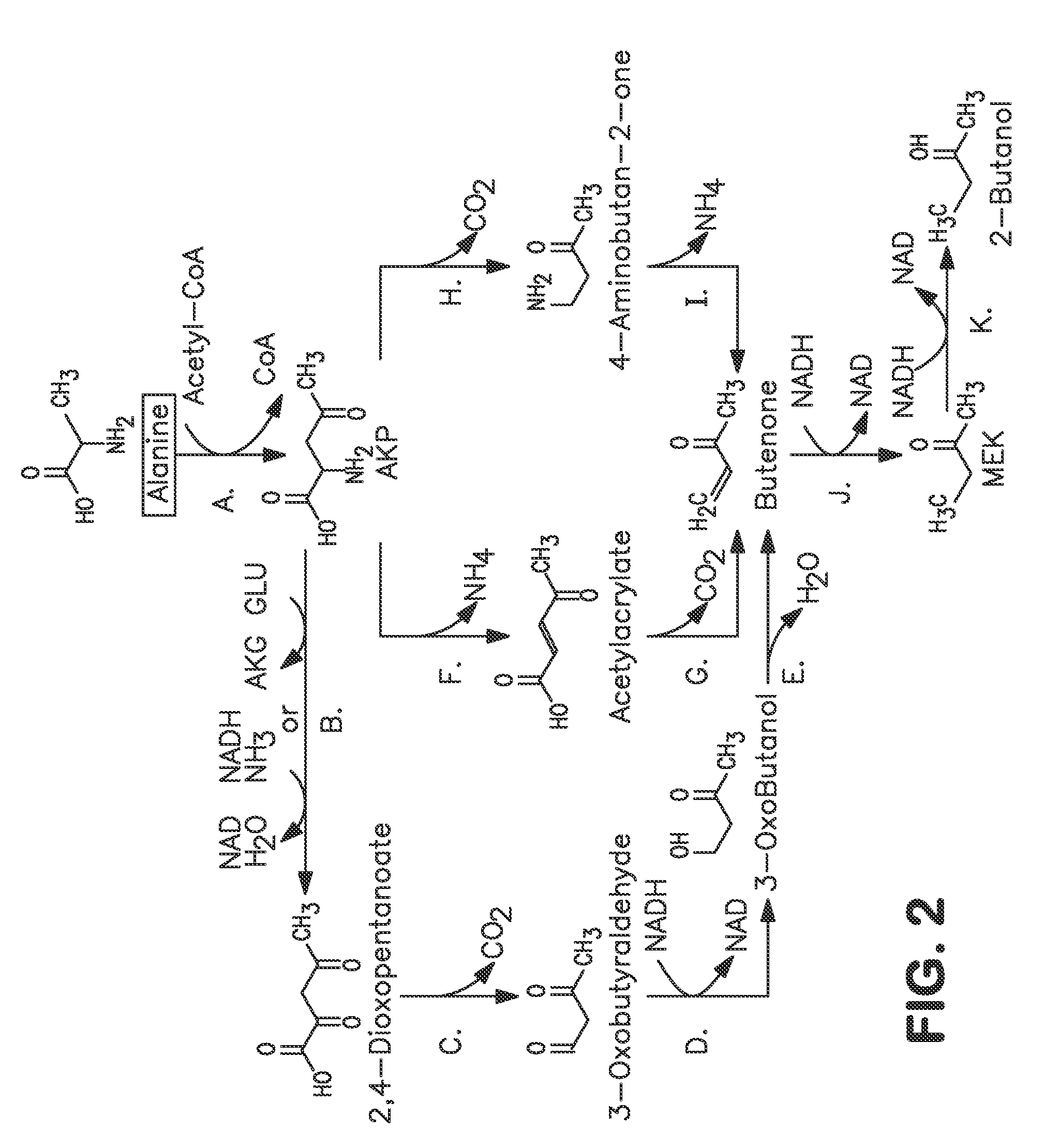

Microorganisms and methods for carbon-efficient biosynthesis of MEK and 2-butanol

A non-naturally occurring microbial organism has at least one exogenous nucleic acid encoding a MEK pathway enzyme expressed in a sufficient amount to produce MEK. The MEK pathway includes an enzyme selected from an acetoacetyl-CoA dehydrogenase (bifunctional), an acetoacetyl-CoA aldehyde dehydrogenase, a 3-oxobutyraldehyde reductase, a 3-oxobutanol dehydratase, an MEK oxidoreductase, a 3-oxobutyraldehyde aminotransferase, a 4-aminobutan-2-one deaminase, a 2-amino-4-ketopentanoate (AKP) thiolase, an AKP aminotransferase, a 2,4-dioxopentanoate decarboxylase, an AKP deaminase, an acetylacrylate decarboxylase, an AKP decarboxylase, a glutamate dehydrogenase, a 3-oxobutyraldehyde oxidoreductase (aminating) and an AKP oxidoreductase (aminating). A 2-butanol pathway further includes an MEK reductase. A method for producing MEK or 2-butanol includes culturing these organisms under conditions and for a sufficient period of time to produce MEK or 2-butanol.

Owner:GENOMATICA INC

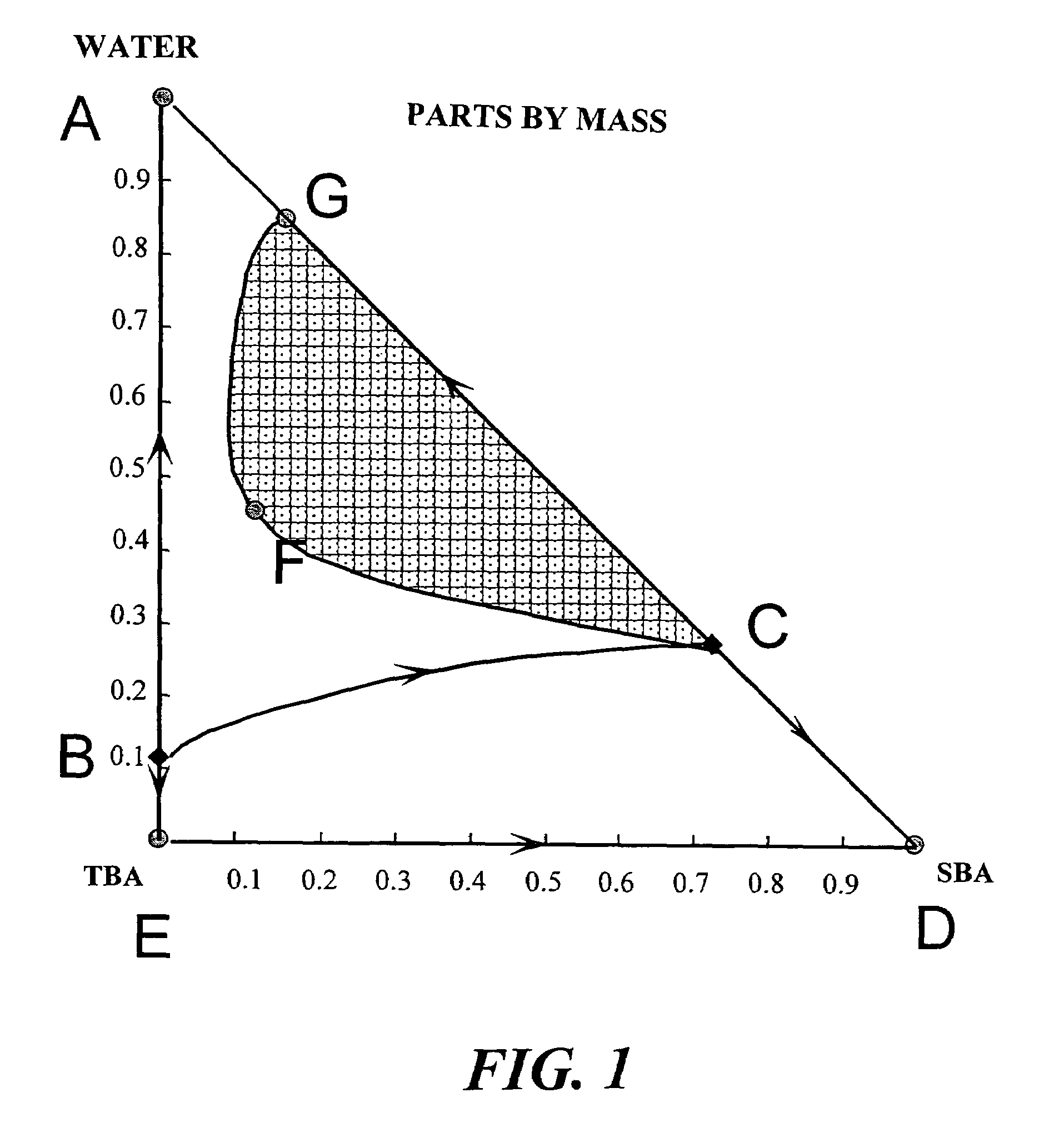

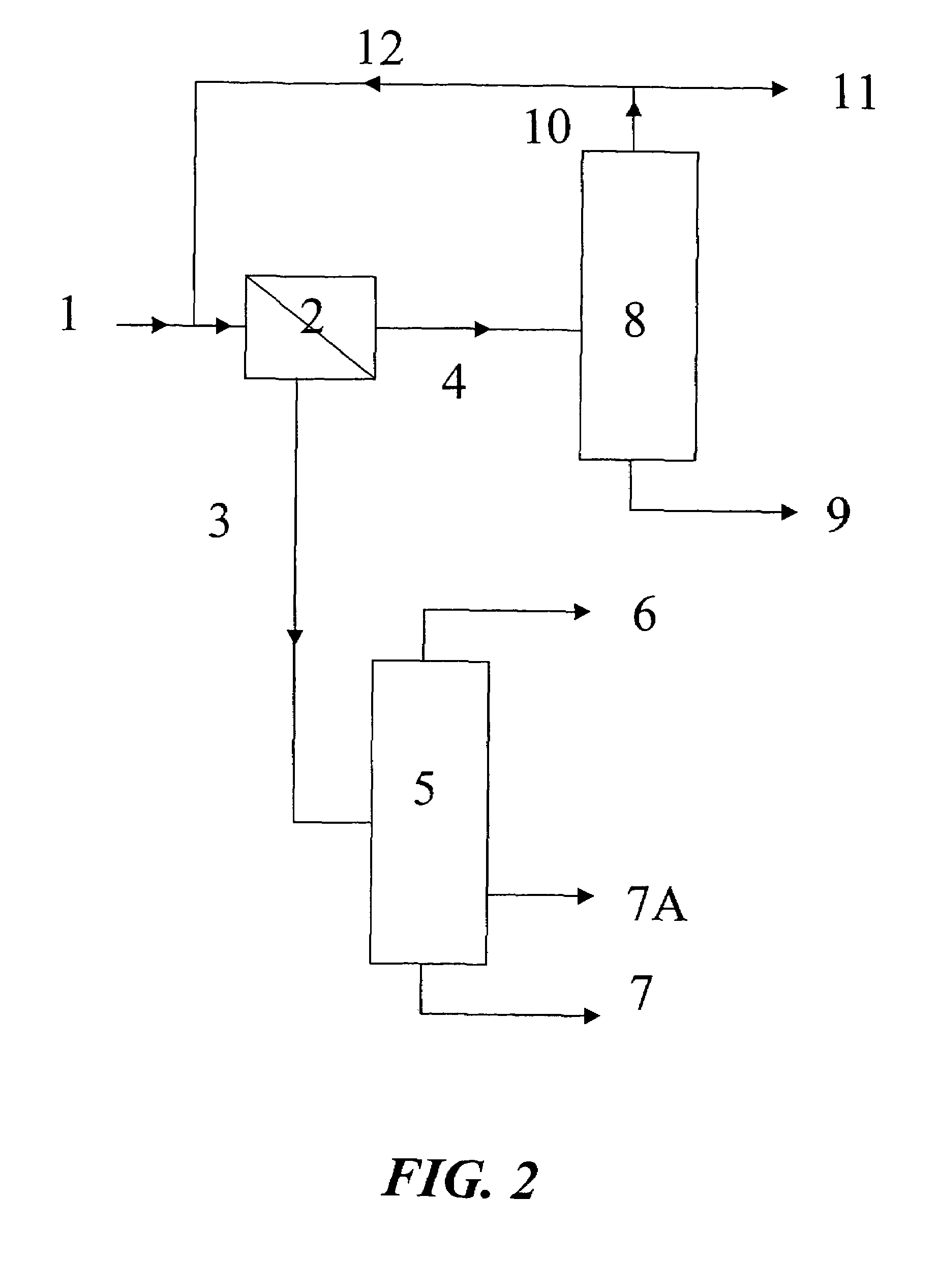

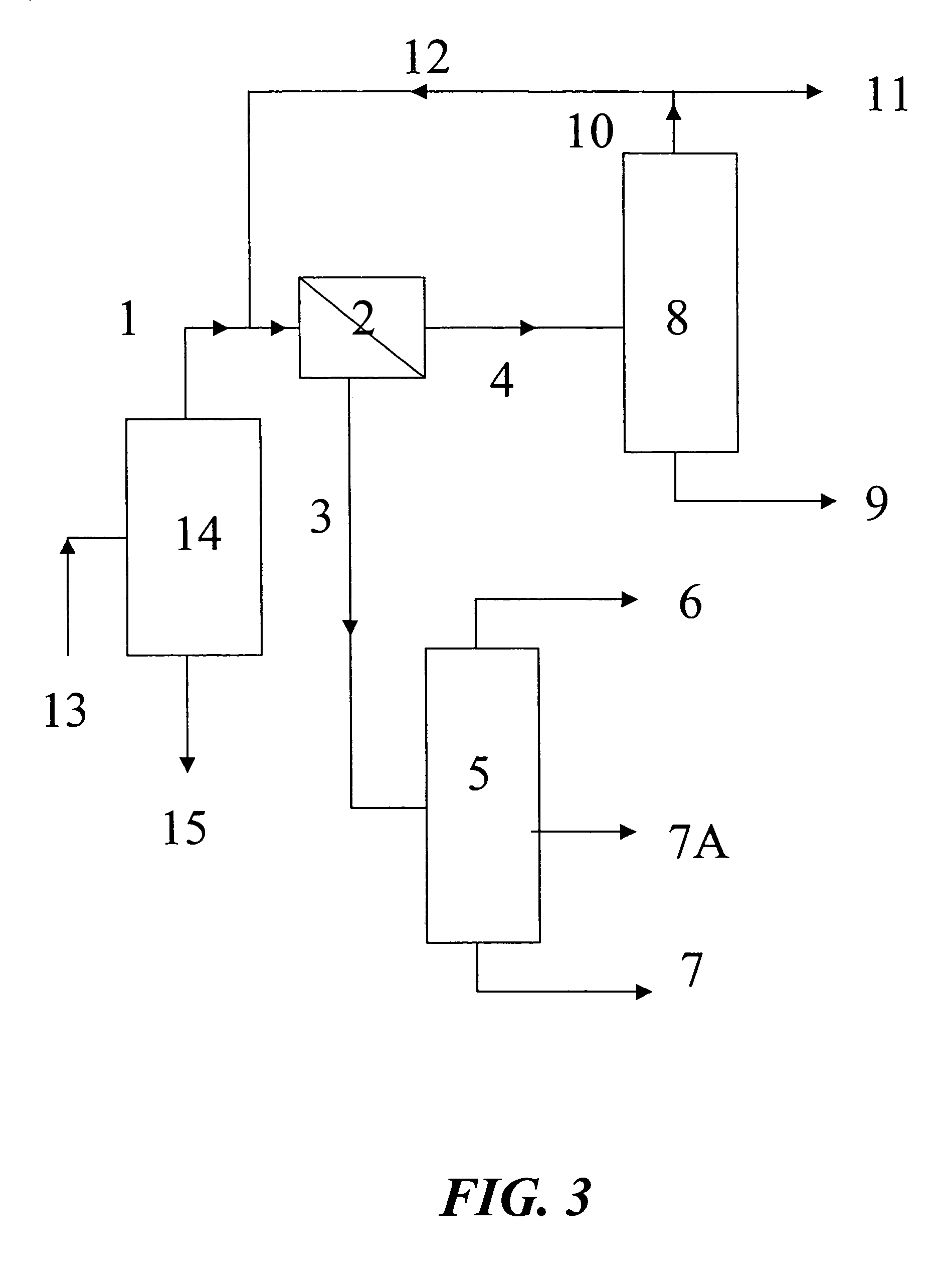

Process for separating 2-butanol from tert-butanol/water mixtures

The present invention relates to a process for separating 2-butanol from tert-butanol / water mixtures using a membrane to reduce a water concentration to less than the limit concentration of the distillation boundary line connecting the two azeotropes TBA / water and SBA / water and is subsequently worked up by distillation.

Owner:EVONIK DEGUSSA GMBH

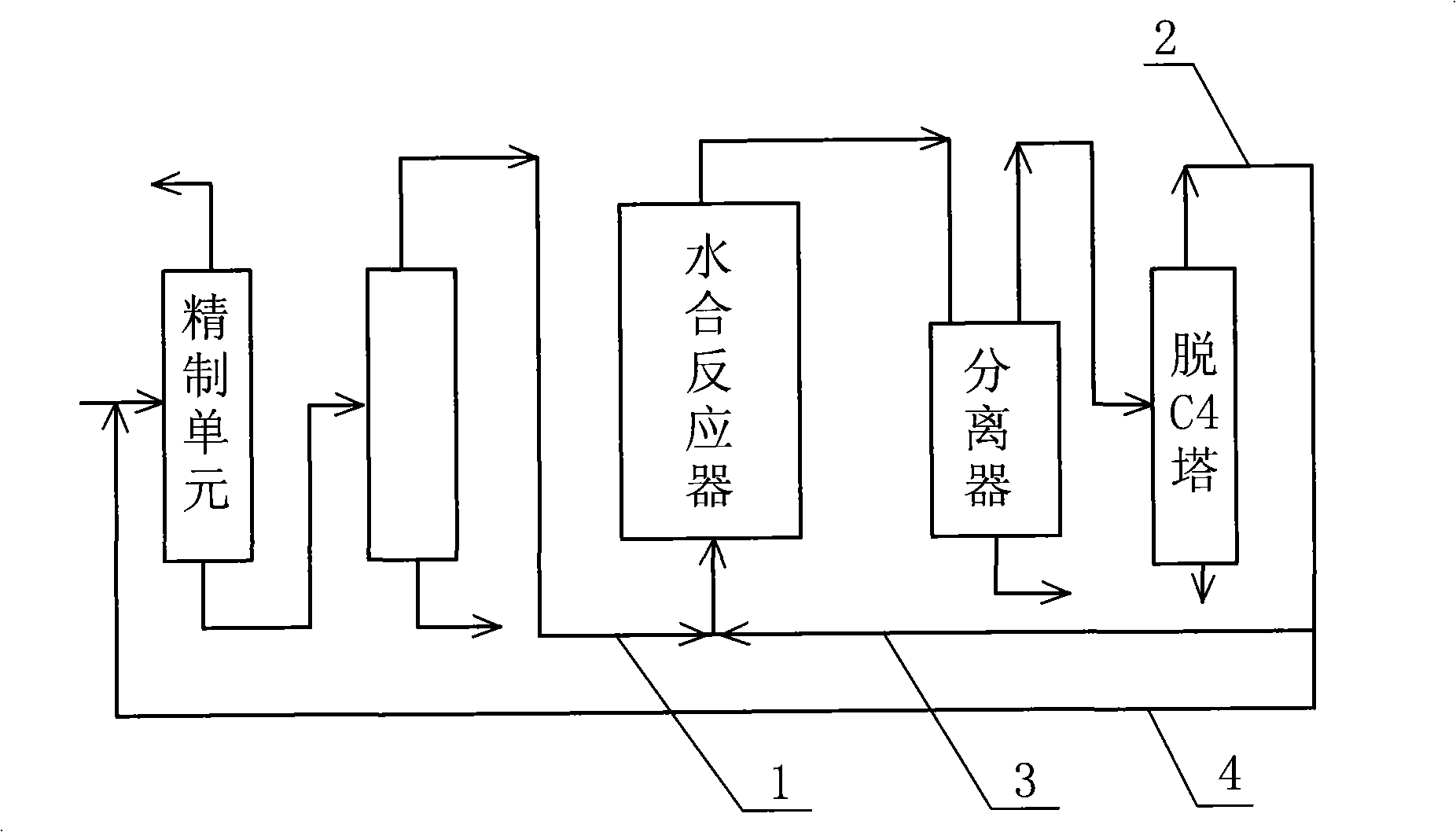

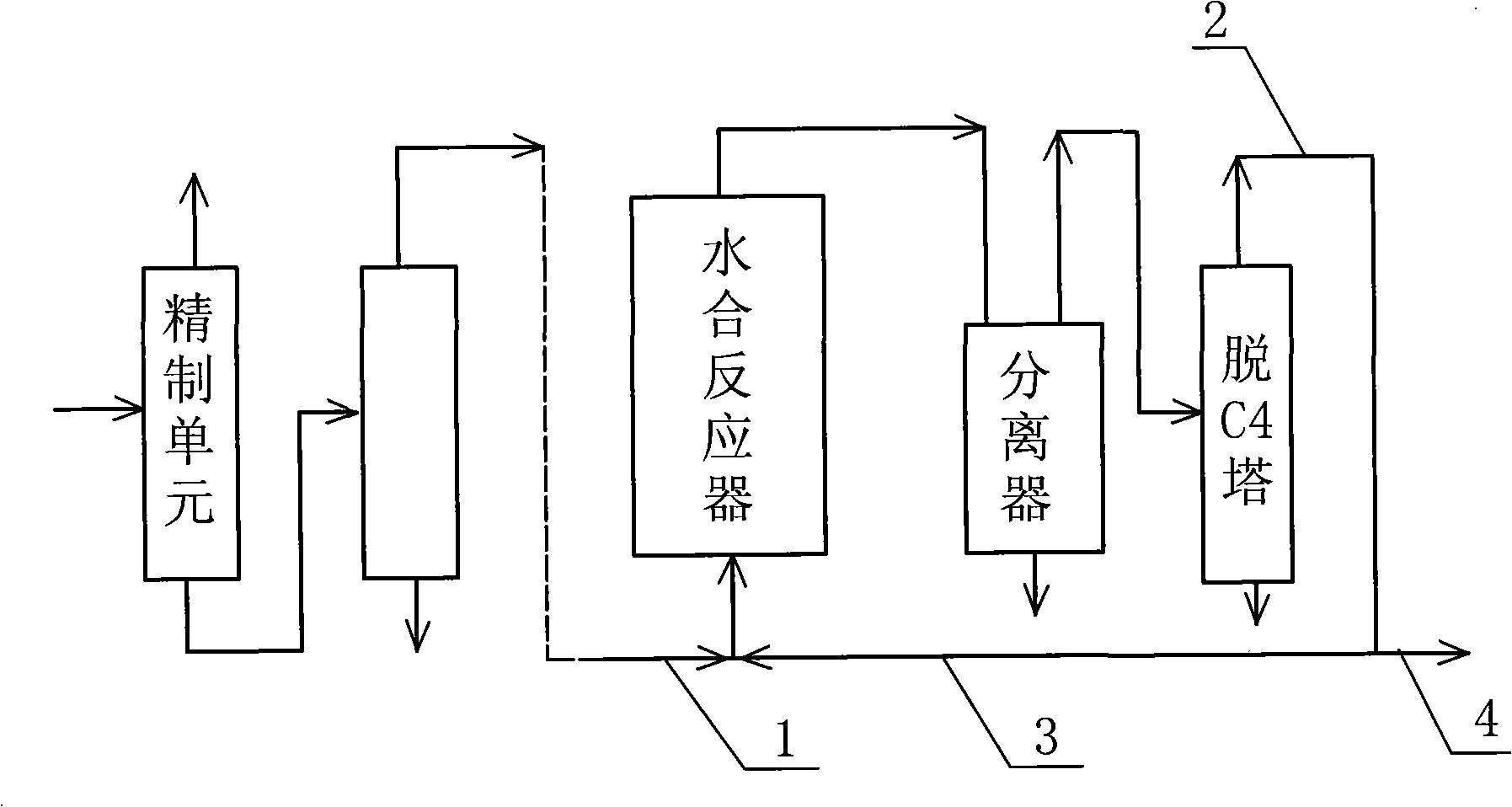

Technological process for continuously producing sec-butyl alcohol by direct hydration of n-butene

InactiveCN101289368AIncrease productionImprove volumetric efficiencyPreparation by hydroxy group additionBulk chemical productionHydration reactionStrong acids

The invention relates to a technique method of the continuous production of 2-butanol by the direct hydration of n-butene, belonging to the technical field of petrochemical industry. The invention comprises the steps that under the existence of the catalyst of strong acid ion exchange resin, fresh raw material of the n-butene and a cycling n-butene are mixed up and enter a hydration reactor for a hydration reaction, and then enter a separation unit of crude products for separation; a refining unit of the n-butene is additionally arranged; one part of the unreacted n-butene which is separated from the separation unit of crude products is used as the cycling n-butene and is returned to the hydration reactor for further hydration reaction and the other part is sent to the refining unit of the n-butene for the rectification and n-butene is recycled after the removal of butane to be used as the fresh raw material of the n-butene continually. The method has the advantages of improving recycling, improving the volumetric efficiency of the hydration reactor, improving the yield of 2-butanol greatly, reducing ineffective circulation and reducing the consumption of energy, thus realizing the zero discharge of the n-butene with high yield and low energy consumption.

Owner:ZIBO QIXIANG TENGDA CHEM

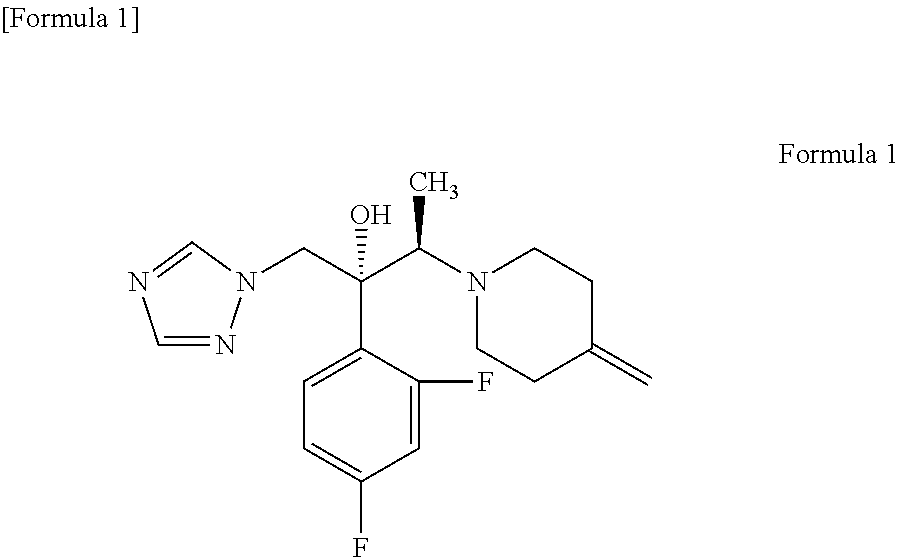

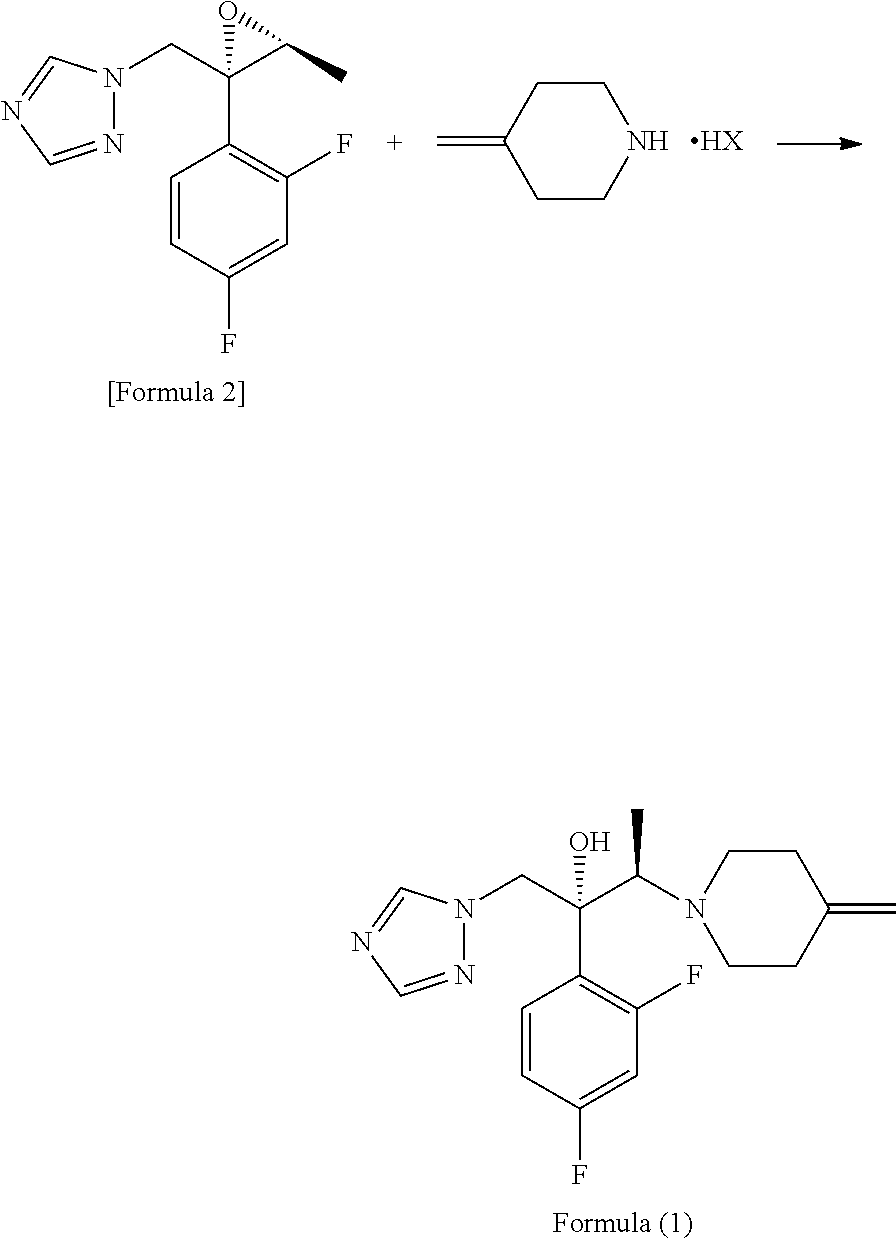

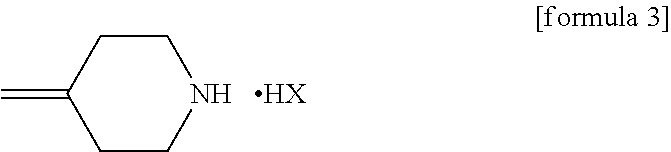

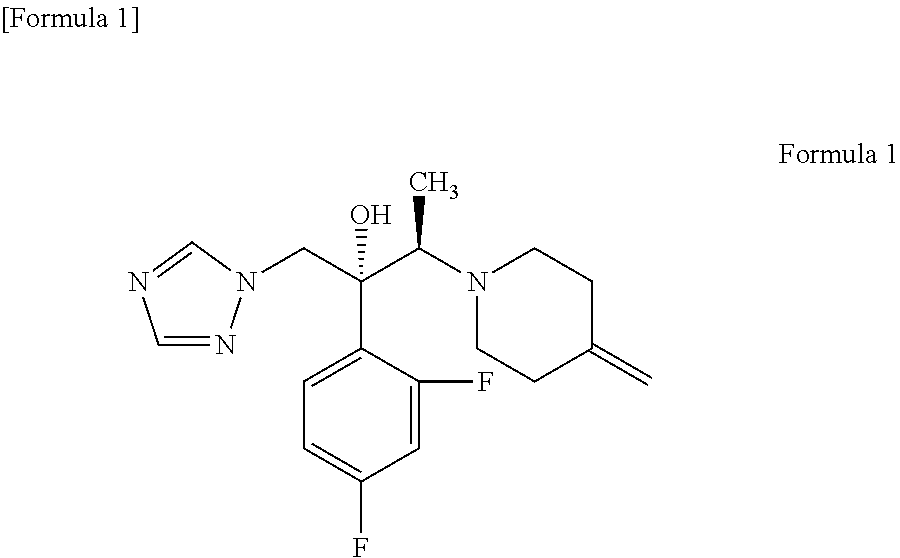

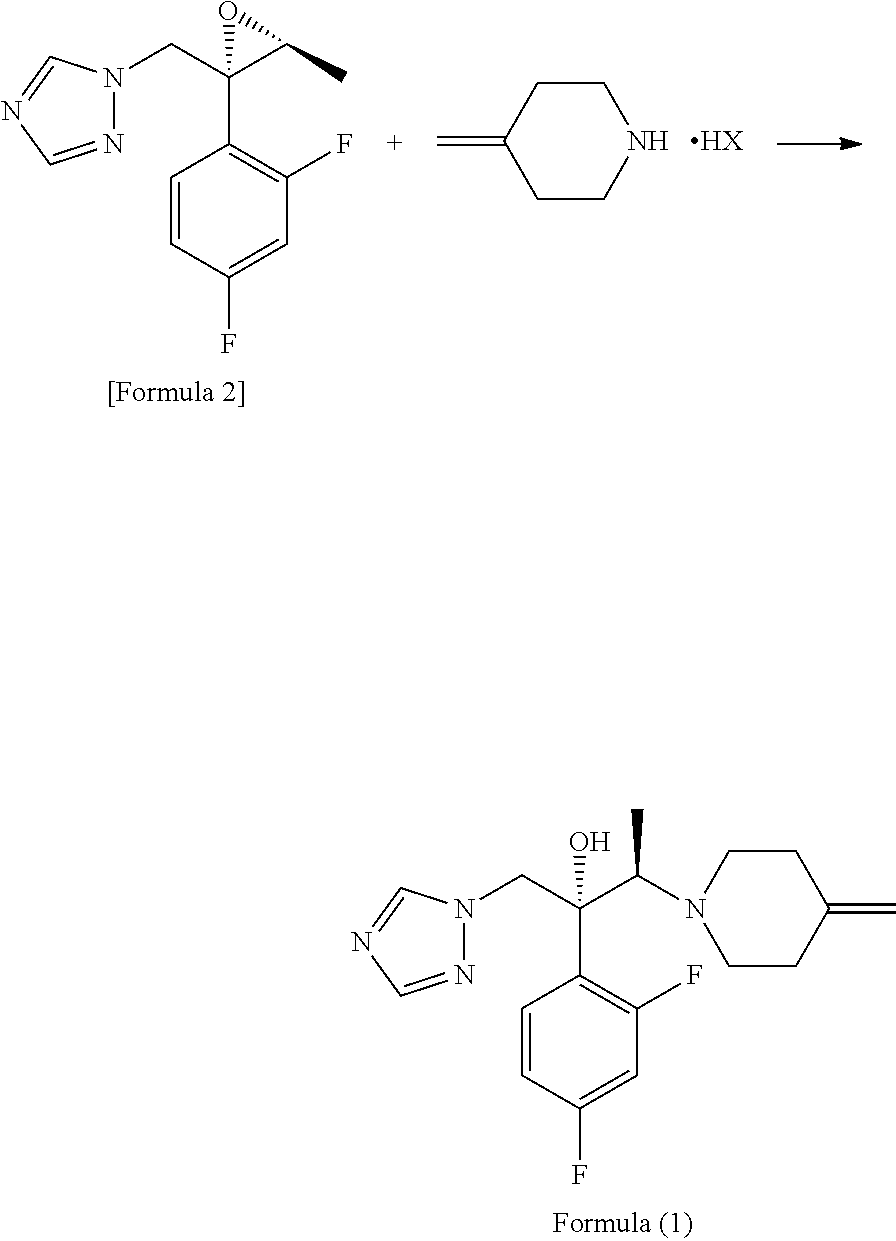

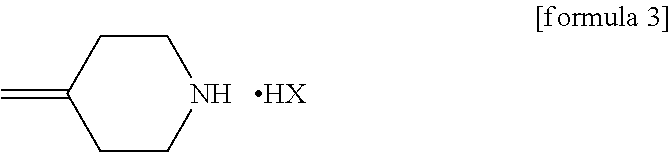

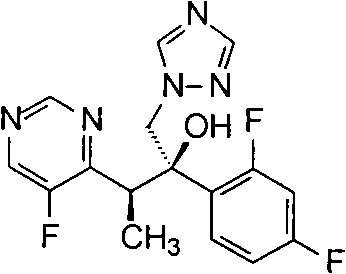

Process for producing 1-triazole-2-butanol derivatives

ActiveUS20130150586A1High yieldReduce generationAntimycoticsOrganic chemistryAlkaline earth metalCycloaddition

An object is to provide a process for producing the compound of formula 1 in higher yield by the ring-opening addition reaction of epoxytriazole with amine under mild conditions without using a large excess of 4-methylenepiperidine. The process for producing (2R,3R)-2-(2,4-difluorophenyl)-3-(4-methylenepiperidin-1-yl)-1-(1H-1,2,4-triazol-1-yl)butan-2-ol or an acid addition salt thereof comprises reacting (2R,3S)-2-(2,4-difluorophenyl)-3-methyl-2-[(1H-1,2,4-triazol-1-yl)methyl]oxirane with an acid addition salt of 4-methylenepiperidine in a reaction solvent in the presence of a hydroxide of an alkali metal or an alkaline earth metal selected from the group consisting of lithium, sodium, calcium, and strontium, or a hydrate thereof.

Owner:KAKEN PHARMA CO LTD

Ketone catalyst fabricated by dehydrogenating alcohol, and preparation method

ActiveCN1872412ASimple preparation processEasy to operateCatalyst activation/preparationCarbonyl compound preparation by oxidationAlcoholPtru catalyst

A catalyst for preparing ketone by dehydrogenating alcohol is prepared from Cu as active component, Zn, Cr, or K as active assistant and alumina as carrier through co-depositing, coating alkali metal by immersing or spraying, drying, and calcining. It has high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing 1-triazole-2-butanol derivatives

ActiveUS8871942B2Reduce generationHigh yieldAntimycoticsOrganic chemistryAlkaline earth metalCycloaddition

An object is to provide a process for producing the compound of formula 1 in higher yield by the ring-opening addition reaction of epoxytriazole with amine under mild conditions without using a large excess of 4-methylenepiperidine. The process for producing (2R,3R)-2-(2,4-difluorophenyl)-3-(4-methylenepiperidin-1-yl)-1-(1H-1,2,4-triazol-1-yl)butan-2-ol or an acid addition salt thereof comprises reacting (2R,3S)-2-(2,4-difluorophenyl)-3-methyl-2-[(1H-1,2,4-triazol-1-yl)methyl]oxirane with an acid addition salt of 4-methylenepiperidine in a reaction solvent in the presence of a hydroxide of an alkali metal or an alkaline earth metal selected from the group consisting of lithium, sodium, calcium, and strontium, or a hydrate thereof.

Owner:KAKEN PHARMA CO LTD

Preparation method of butoconazole nitrate intermediate suitable for industrial production

ActiveCN103880596AHigh yieldReduce bumpsPreparation by OH and halogen introductionMagnesium organic compoundsGrignard reactionEthyl Chloride

The invention provides a method for industrial production of a butoconazole nitrate intermediate, that is 1-chloro-4-p-chlorophenyl-2-butanol (a compound in formula II). The method of the invention comprises: 1. a Grignard reaction, that is, adopting p-chlorobenzyl chloride as a raw material, and performing a Grignard reaction with magnesium powder in a mixed solvent of methyl tertiary butyl ether and tetrahydrofuran; 2. a condensation reaction, that is, continuing reaction by adding epichlorohydrin to obtain the compound II which is an important intermediate for preparing butoconazole nitrate. According to the method, the raw materials are cheap and easily available, the reaction solvent is safer, and the method is suitable for industrial production.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Method for synthesizing diatomic alcohol ether acid ester

InactiveCN101475469ALow toxicityEasy to useOrganic compound preparationCarboxylic acid esters preparationSolubilityReaction temperature

The invention relates to a method for synthesizing glycol ether ester. The method comprises the following steps that: glycol ether and fatty acid as raw materials are directly esterified and synthesized into glycol ether acetic ester at a temperature of between 80 and 180 DEG C in the presence of an acidic catalyst and an azeotropic dehydrating agent; and the acidic catalyst is paratoluenesulfonic acid or methanesulfonic acid, and dosage of the catalyst is 0.05 to 1 percent of total weight of reaction materials. The method is characterized in that the mol ratio of the fatty acid to the glycol ether is 1.0:0.8-1.5; and the azeotropic dehydrating agent is isobutyl acetate or 2-butanol acetate, and dosage of the azeotropic dehydrating agent is 5 to 30 percent of the total weight of the reaction materials. The method has the advantages that compared with butyl acetate, the azeotropic dehydrating agent used in the reaction has a lower boiling point and a lower azeotropic point, smaller solubility and lower hydrolysis speed, so that energy consumption during reacting and reclaiming the azeotropic dehydrating agent can be reduced, the reaction speed is improved, and water entrainment of a side product is reduced.

Owner:NANJING FORESTRY UNIV +1

Corn fermentation partly substituted method for producing acetone-butanol

InactiveCN101161818ALow costImprove use valueMicroorganism based processesFermentationFiltrationDistillation

The invention discloses a method partly replacing corn fermentation in acetone butanol production, including the following steps: raw material is prepared and boiled down for sterilization; when boiled mash is cooled down within a certain temperature range, strain is inoculated; after fermentation for a certain time, the mash is made into final acetone, butanol and ethanol products after filtration and distillation. The invention reduces the raw material cost in producing acetone butanol through adopting zymotechnics and eases the problem of high grain consumption; meanwhile, the invention increases the use value of B starch or B starch slurry in processors processing wheat flour, etc.

Owner:上海天之冠可再生能源有限公司

Ketone catalyst fabricated by dehydrogenating alcohol, and preparation method

ActiveCN100360228CSimple preparation processEasy to operateCatalyst activation/preparationCarbonyl compound preparation by oxidationAlcoholPtru catalyst

A catalyst for preparing ketone by dehydrogenating alcohol is prepared from Cu as active component, Zn, Cr, or K as active assistant and alumina as carrier through co-depositing, coating alkali metal by immersing or spraying, drying, and calcining. It has high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurization of sulfurized rubber

This invention is based upon the unexpected discovery that the surface of reclaimed rubber crumb particles can be devulcanized by heating the crumb particles to a temperature of at least about 150 DEG C. under a pressure of at least about 3.4x10<6 >Pascals in the presence of 2-butanol. It is further based upon the unexpected discovery that such surface devulcanized rubber crumb particles having a particle size within the range of about 325 mesh to about 20 mesh can be recompounded and recured into high performance rubber products; such as, tires, hoses and power transmission belts. This invention more specifically discloses a process for devulcanizing the surface of reclaimed rubber crumb into surface devulcanized reclaimed rubber crumb that is suitable for being recompounded and recured into high performance rubber products, said process comprising the steps of (1) heating the reclaimed rubber crumb to a temperature which is within the range of about 150 DEG C. to about 300 DEG C. under a pressure of at least about 3.4x10<6 >Pascals in the presence of 2-butanol to devulcanize the surface of the rubber crumb thereby producing a slurry of the surface devulcanized reclaimed rubber crumb in the 2-butanol, wherein the reclaimed rubber crumb has a particle size which is within the range of about 325 mesh to about 20 mesh, and (2) separating the surface devulcanized reclaimed rubber crumb from the 2-butanol.

Owner:THE GOODYEAR TIRE & RUBBER CO

Combustible Mixed Butanol Fuels

InactiveUS20110023355A1Increase ratingsEmission reductionLiquid carbonaceous fuelsFuel additivesHeating oilSec-Butanol

A fuel composition including mixed butanols, such as for example, 2-butanol, iso-butanol and tert-butanol, preferably 2-butanol and tert-butanol is provided. Methods of preparing and using the mixed butanols composition as combustible neat fuels and / or oxygenate fuel constituents in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, and the like are also provided.

Owner:SAUDI ARABIAN OIL CO

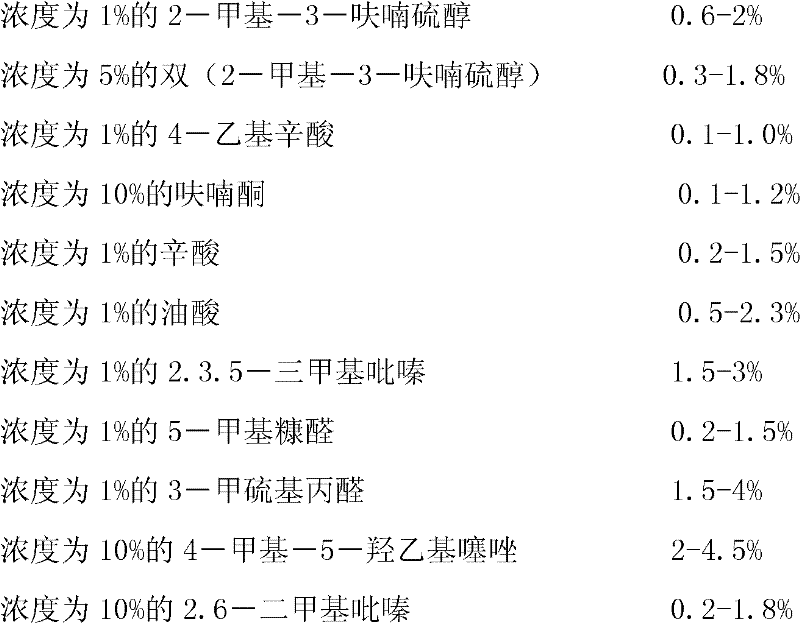

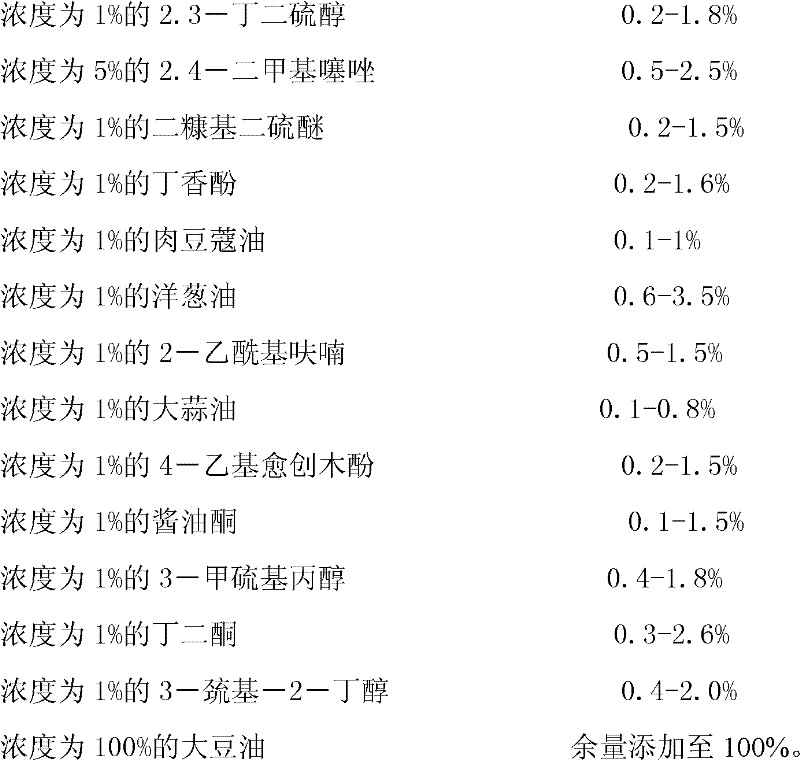

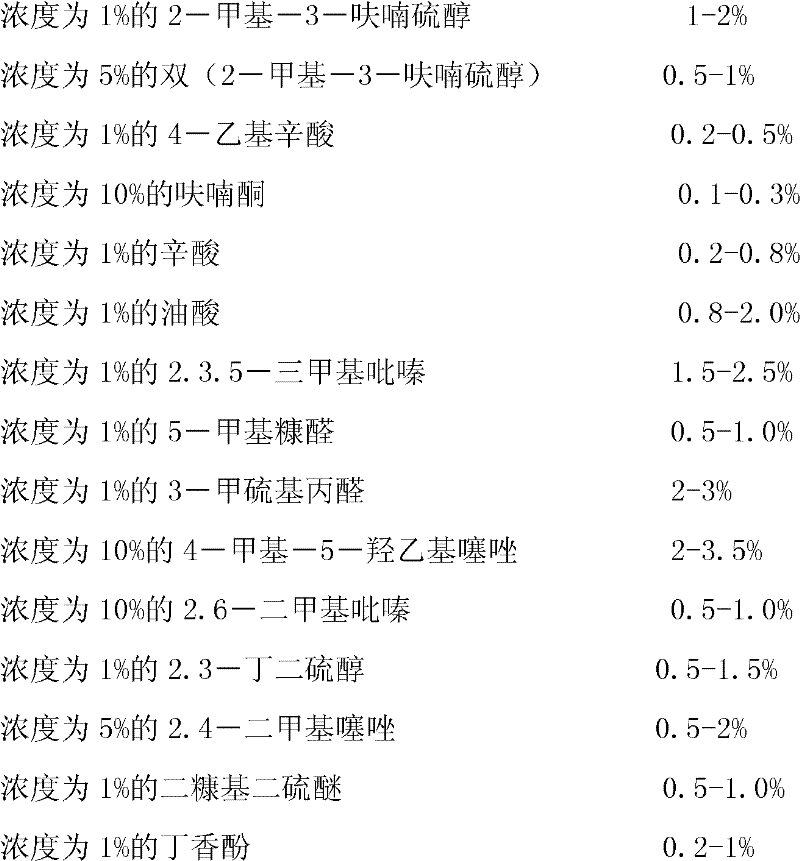

Formulated beef oily essence and preparation method thereof

InactiveCN102362658AGood aroma effectIncrease aromaFood preparation2-methyl-3-furanthiol4-methyl-5-thiazoleethanol

The invention relates to a formulated beef oily essence and a preparation method thereof. The essence comprises the following raw materials: 2-methyl-3-furanethiol, bis (2-methyl-3-furanethiol), 4-ethyloctanoic acid, furanone, octanoic acid, oleic acid, 2,3,5-trimethyl pyrazine, 5-methylfurfural, 3-(methylthio) propionaldehyde, 4-methyl-5-thiazoleethanol, 2, 6-dimethylpyrazine, 2, 3-butanedithiol, 2, 4-dimethyl thiazole, difurfuryl disulfide, eugenol, mace oil, onion oil, 2-acetylfuran, garlic oil, 4-ethylguaiacol, soy fouranone, 3-methylthiopropanol, butanedione, 3-sulfydryl-2-butanol and soybean oil. The prepared essence has an intense beef flavor, the flavoring effect in spicy and hot small foods is good, the stability of the fragrance and the flavor is very good and the fragrance and the flavor of the spicy and hot small foods can be kept to be very good within the quality guarantee period.

Owner:TIANJIN CHUNFA BIO TECH GRP

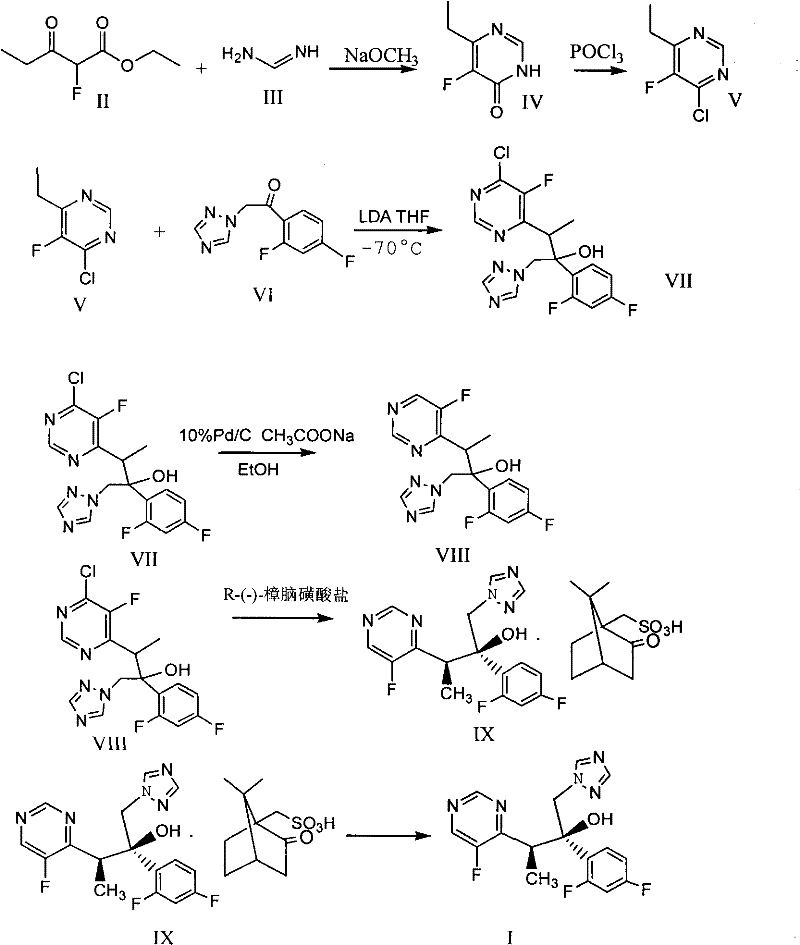

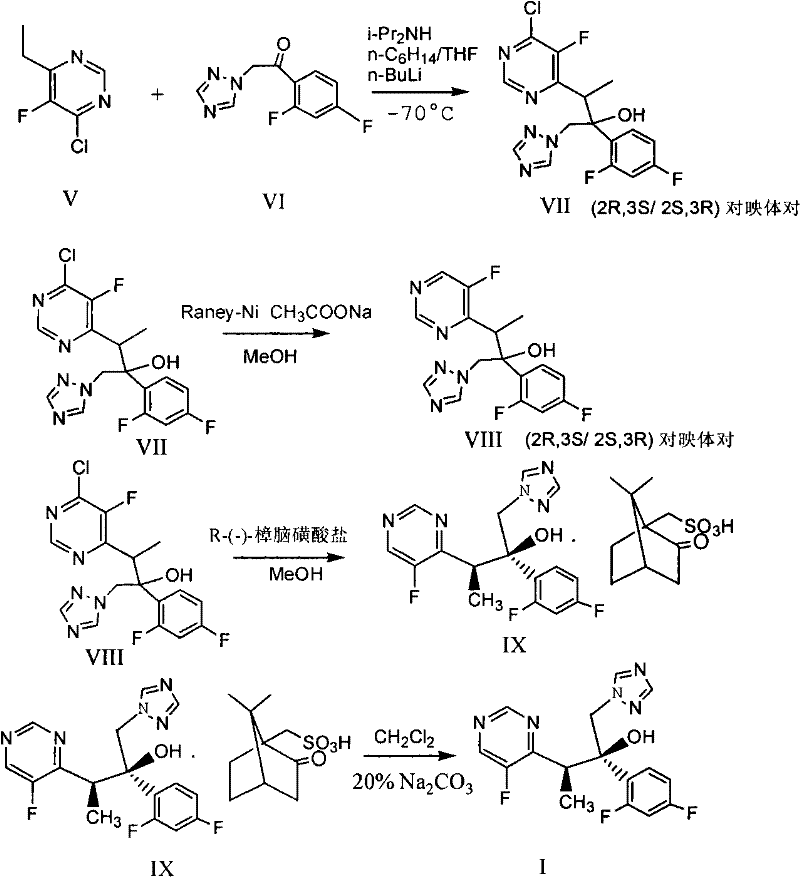

Novel method for producing voriconazole

The invention provides an improved preparation method of (2R,3S)-3-(5-fluoropyrimidine-4-yl)-2-(2,4-difluorophenyl)-1-(1H-1,2,4-triazole-1-yl)-2-butanol(voriconazole), comprising the following steps: preparing a mixture of four enantiomers by using Reformatsky coupling reaction, then in the presence of residual zinc dust after the reaction, directly adding proper amount of acid to carry out hydrogenolysis dechlorination; splitting by directly using chiral acid to obtain chiral acid addition salts of a target compound with (2R,3S) configuration, and dissociating under alkaline conditions to obtain high-yield high-optical purity voriconazole. The method is safe, convenient and efficient, can fully utilize the residual zinc dust of the coupling reaction, and can save the steps of separating the enantiomers through hydrochloride production, alkalization, palladium-carbon catalytic hydrogenation dechlorination, thus the production process is greatly simplified, the product yield and production safety are raised, and simultaneously the production cost is greatly reduced.

Owner:北京联本医药化学技术有限公司 +2

Production of alcohol blend usable in flexible fuel vehicles via fischer-tropsch synthesis field of the invention

InactiveUS20100005709A1Effective controlMaximize formationLiquid carbonaceous fuelsWater useAlternative fuels

Alternative fuel compositions, blends of the alternative fuel compositions and gasoline, and methods for their preparation and use are disclosed. The alternative fuel compositions ideally include ethanol, isopropyl alcohol, and one or more of sec-butanol and t-butanol, and ideally include no more than 3% methanol, and no more than 15% C5 or higher alcohols. The fuel compositions can be prepared using Fischer-Tropsch synthesis to convert syngas to a product stream comprising C2-4 olefins, and hydrolyzing these olefins. The process facilitates isolation of C2-4 alkanes, because the boiling point difference of these alkanes is significantly lower than that of the C2-4 alcohols. Ideally, the compositions provide more energy per unit volume than E85, even without the addition of gasoline, although the compositions can be blended with gasoline in any desired ratio. The resulting alternative fuel can be derived, at least in part, from renewable resources, in that the syngas can be derived from renewable resources, and a significant portion of the molecule is derived from the water used to hydrolyze the olefins. The alternative fuel compositions, and blends thereof with gasoline, can help reduce U.S. dependence on foreign crude oil.

Owner:BRADIN DAVID

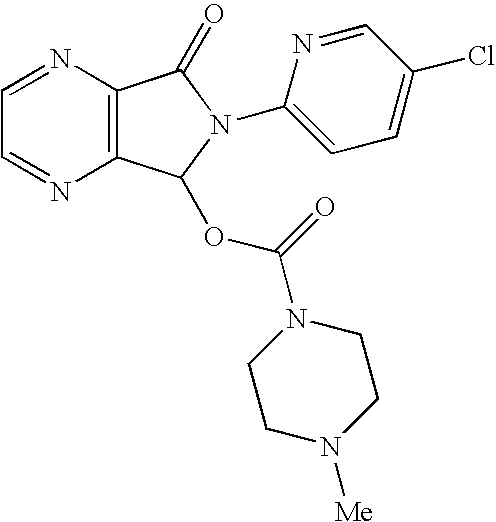

Methods for preparing eszopiclone crystalline form a, substantially pure eszopiclone and optically enriched eszopiclone

The present invention provides methods for preparing eszopiclone Form A, substantially chemically pure eszopiclone, or eszopiclone with low level(s) of residual solvent(s). The present invention also provides eszopiclone with low level(s) of residual solvent(s). The present invention also provides a process for optical enrichment of eszopiclone free base. For instance, one of the embodiments of the invention is directed to a method of preparing eszopiclone Form A, wherein the method comprises crystallizing eszopiclone free base from a solvent selected from the group consisting of isopropanol (IPA), methyl isobutyl ketone (MIBK), acetone, n-butanol, i-butanolisobutanol, 2-butanol, tetrahydrofuran (THF), dimethyl carbonate, methanol, ethanol, ethyl lactate, dimethylformamide (DMF), carbon tetrachloride, toluene, iso-butyl acetate and mixtures thereof.

Owner:TEVA PHARM USA INC

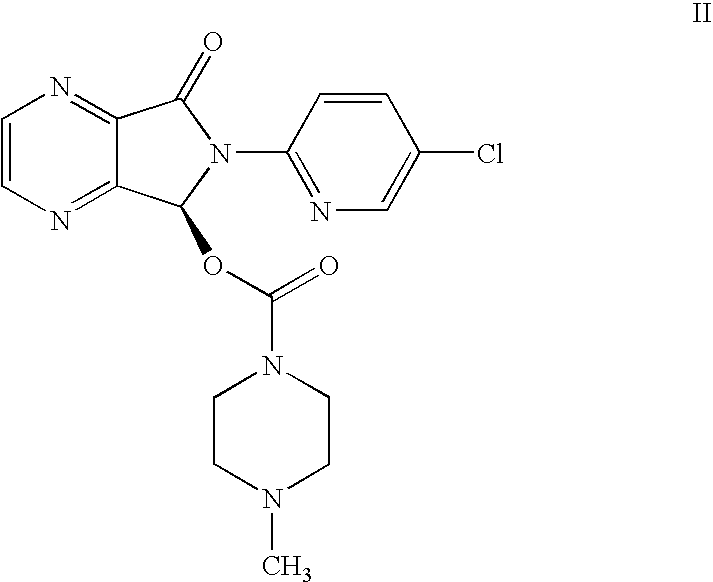

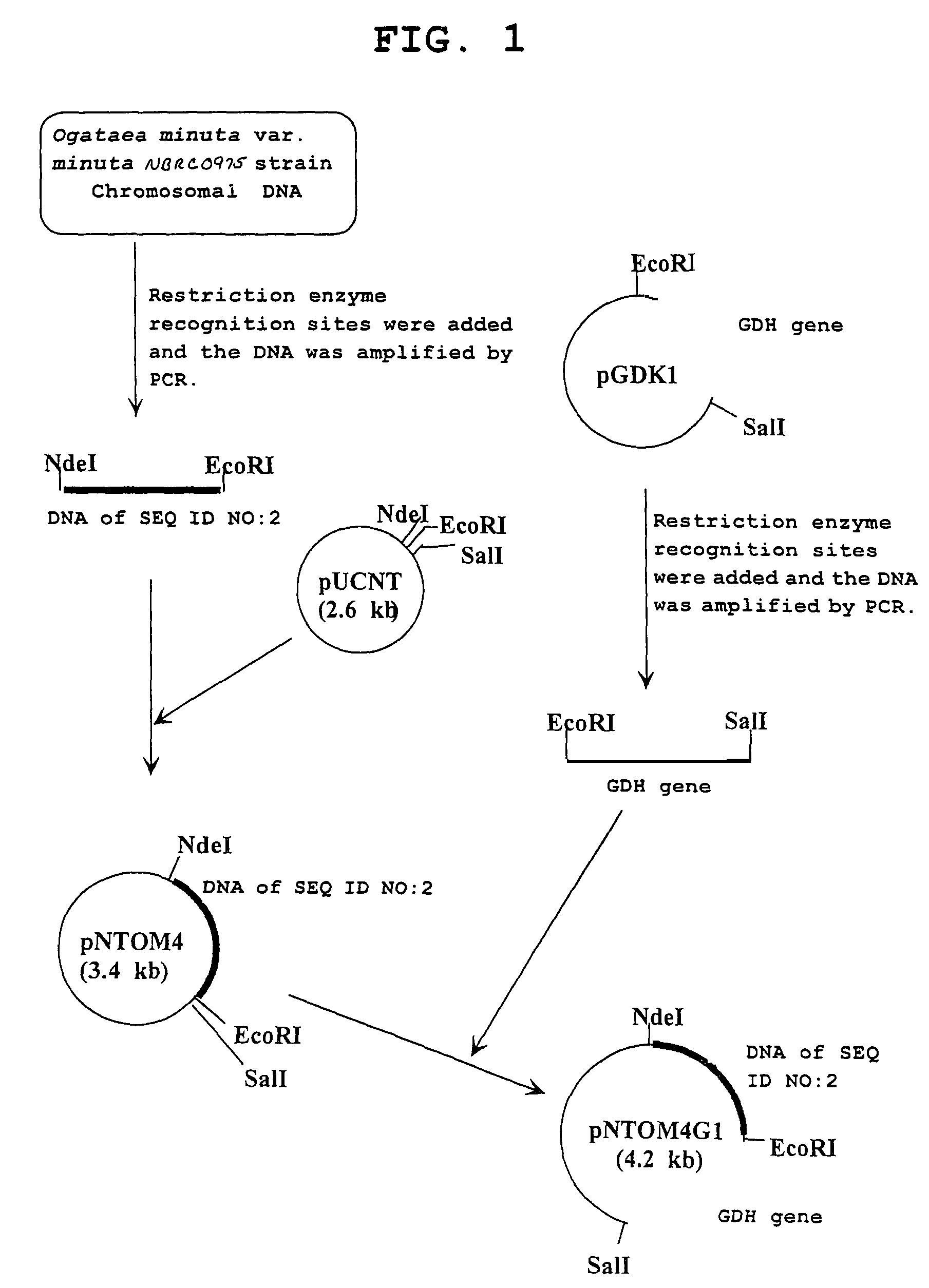

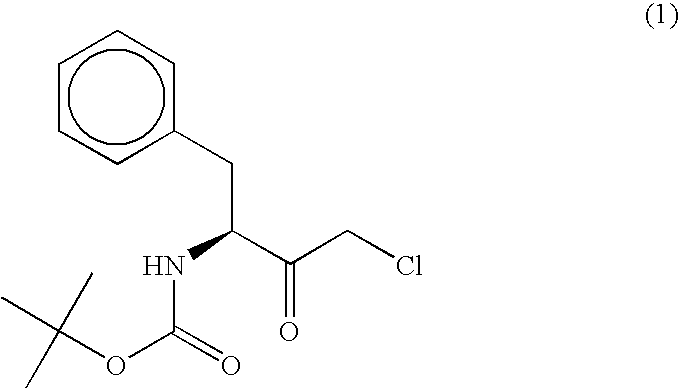

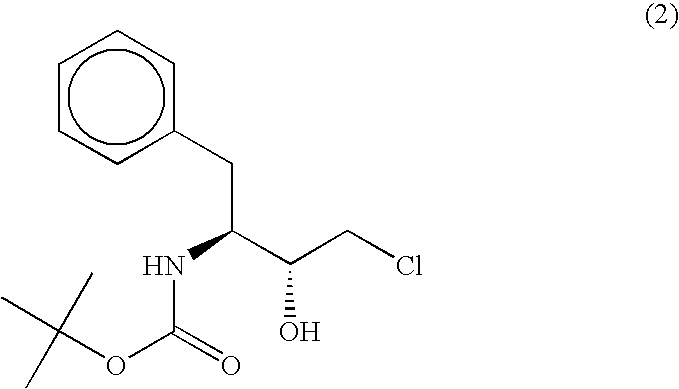

Carbonyl reductase, gene thereof and method of using the same

The present invention relates to a polypeptide having an activity to asymmetrically reduce (3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanone to produce (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol isolated from a microorganism belonging to the genus Ogataea, a DNA encoding the polypeptide and a transformant that produces the polypeptide. The present invention moreover relates to a method of producing (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol utilizing the polypeptide or the transformant. Using the polypeptide or transformant of the present invention, optically active alcohols such as (2R,3S)-1-chloro-3-tert-butoxycarbonylamino-4-phenyl-2-butanol and the like can be produced efficiently.

Owner:KANEKA CORP

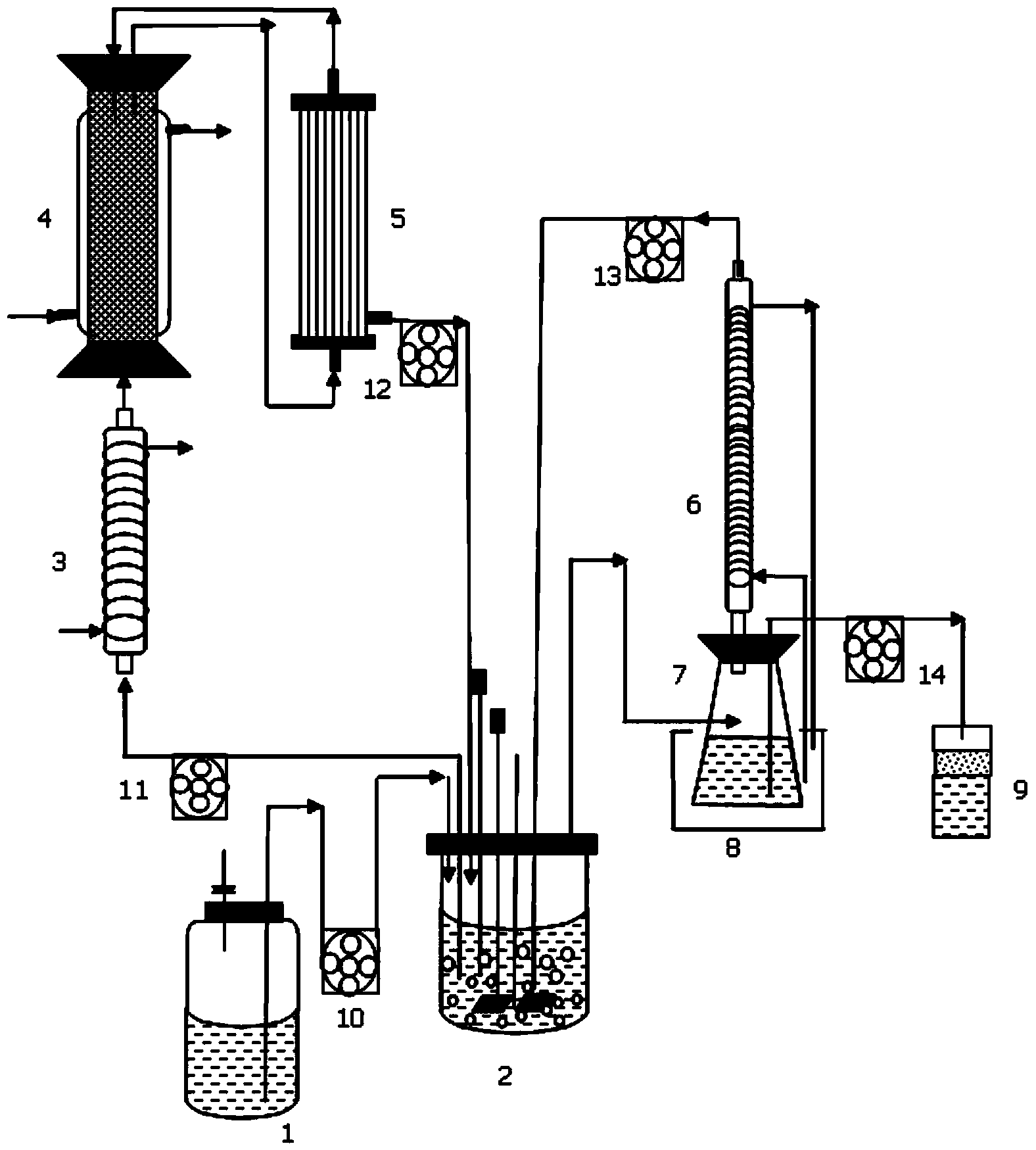

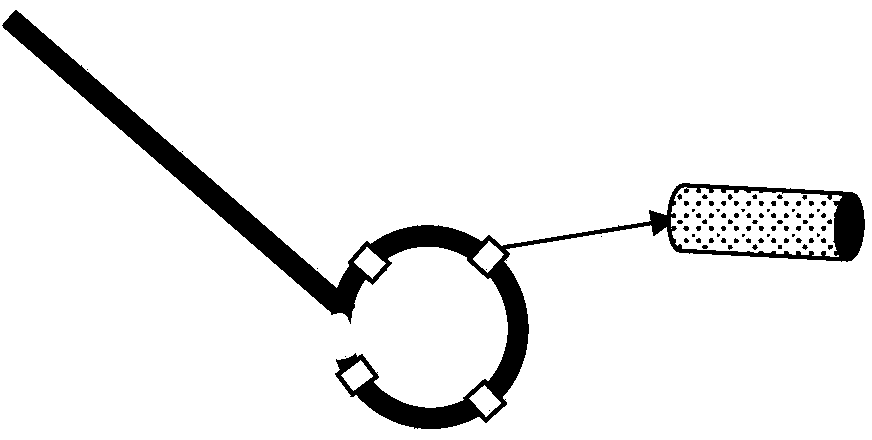

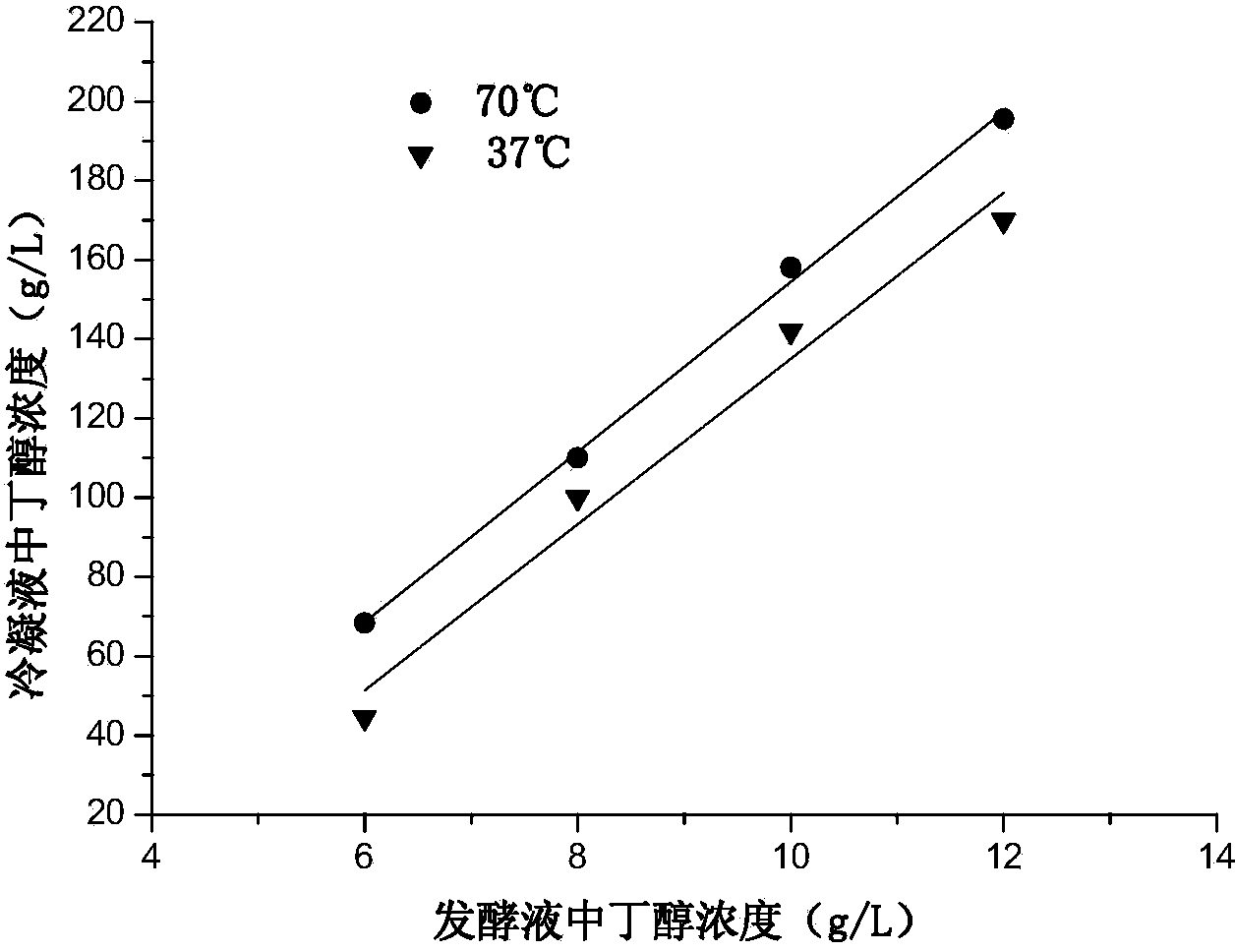

Device and method for preparing butanol through fermentation, coupling, separation and purification of acetone-butanol

ActiveCN103555560AIncrease production capacityImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsSec-ButanolDistributor

The invention discloses a device for preparing butanol through the fermentation, coupling, separation and purification of acetone-butanol. A stirred bioreactor is communicated with a seed cultivating pot through a pipeline; a gas distributor is arranged in the bottom of the stirred bioreactor; the stirred bioreactor, a cooling device, an immobilization device and a bacteria liquid separation device are sequentially communicated so as to form a circulation loop; the stirred bioreactor is sequentially communicated with an air stripping condenser pipe and a storage tank, the storage tank is arranged in a low-temperature circulating constant-temperature bath, and the storage tank is communicated with a condensed fluid collector through a pipeline. The invention also discloses a method for preparing butanol through the fermentation, coupling, separation and purification of acetone-butanol by using the device. According to the invention, besides the inhibition effect of sugar and acetone-butanol fermentation products is effectively eliminated, and the yield of acetone-butanol fermentation products and the utilization efficiency of raw materials are improved, the production energy consumption and the cost also can be reduced, therefore, the device and method disclosed by the invention provide a new technical support for the separation and purification of butanol and acetone and products thereof produced by using a biological method currently.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

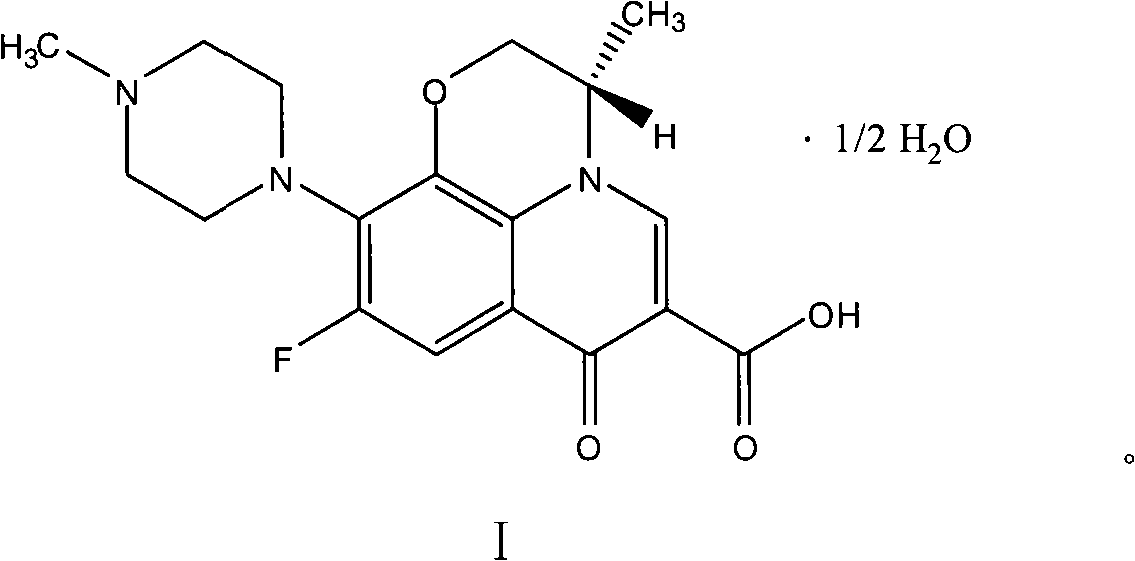

Process for preparing hemihydrate of levofloxacin

InactiveCN101307060AInhibitory NoneNo poisoning effectAntibacterial agentsOrganic chemistrySec-ButanolOrganic solvent

The invention discloses a process for preparing a levofloxacin hemihydrate. The prior method which uses an organic solvent with stronger polarity or weaker polarity to purify a levofloxacin crude product is disadvantageous to the quality and the yield of a levofloxacin hemihydrate finished product; the organic solvent with a higher boiling point not only consumes large energy, but also is difficult to reclaim, when the organic solvent is reclaimed. The method comprises the following steps of: dissolving the levofloxacin crude product into a dissolvent system consisting of water and an organic solvent, wherein the organic solvent selects any composition or multiple compositions of normal butanol, isobutyl alcohol, 2-butanol and tertiary butanol; and discoloring, filtering, crystallizing, crystal-growing, pumping filtering, rinsing and drying the mixed solution to produce an acicular levofloxacin hemihydrate crystal. The hydrous composite solvent adopted by the method has the advantages of suitable polarity, low boiling point, easy reclaiming and small energy consumption; and the product has high purity, and high bioavailability after a preparation which is prepared by the product is taken by a human body.

Owner:ZHEJIANG JINGXIN PHARMA +1

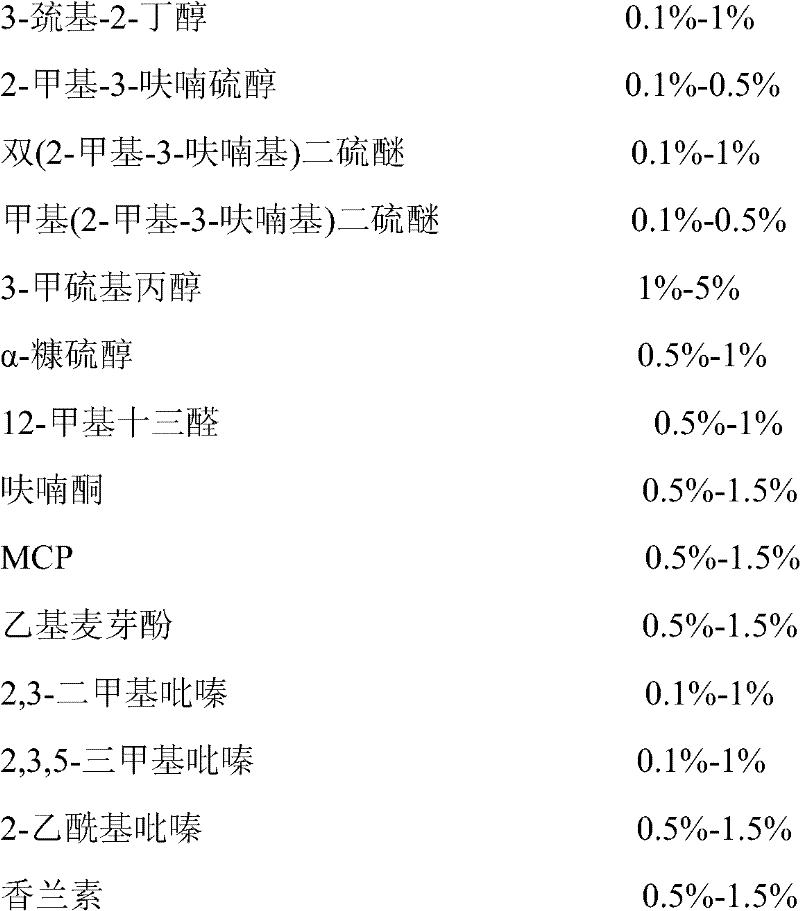

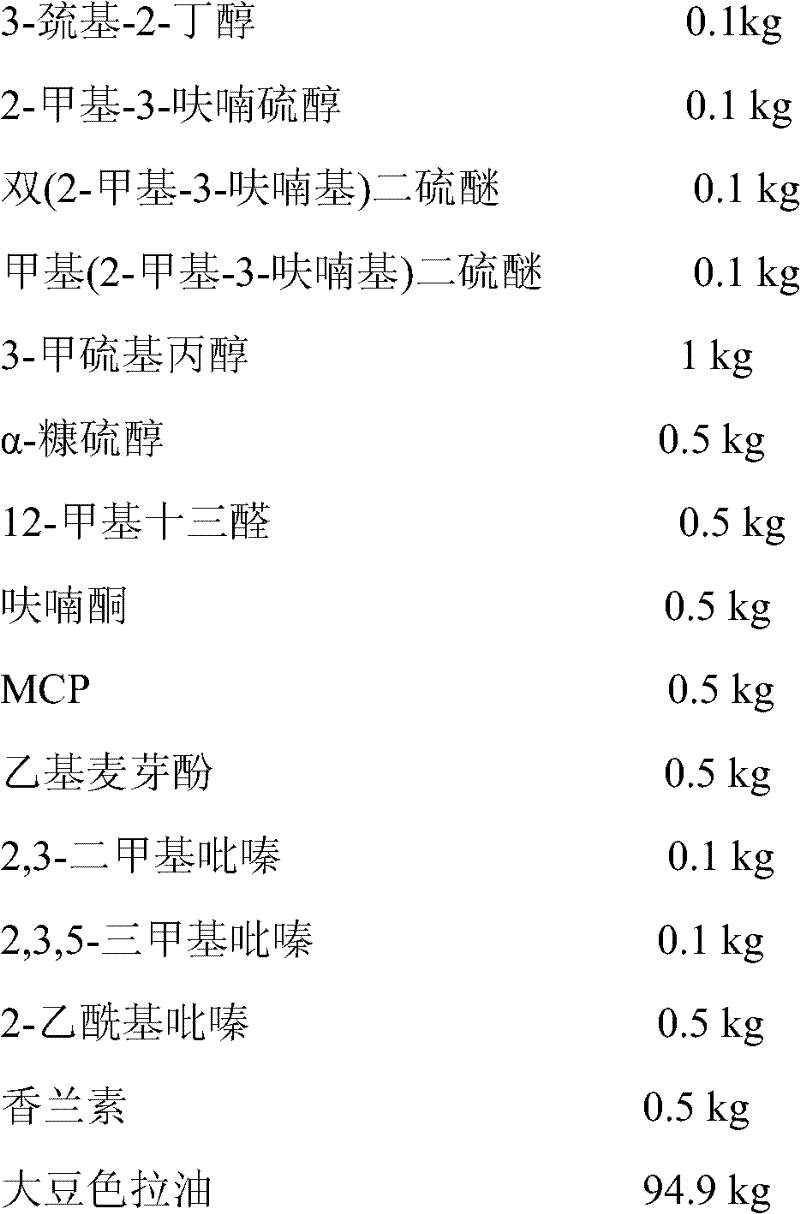

Beef oily essence and preparation method thereof

The invention relates to beef oily essence and a preparation method thereof. The essence is prepared from the following raw materials: 3-sulfydryl-2-butanol, 2-methyl-3-furanthiol, bis(2-methyl-3-furyl) disulfide, methyl(2-methyl-3-furyl) disulfide, 3-methylmercapto-propyl alcohol, alpha-furfurylmercaptan, 12-methyl tridecylic aldehyde, furanone, methylcyclopentadienyl pregnenolone (MCP), ethyl maltol, 2,3-dimethylpyrazine, 2,3,5-trimethylpyrazine, 2-acetyl pyrazine, vanillin and soybean salad oil. The invention also provides a preparation method for the essence. In an essence product prepared by the method, flavor volatile substances contained in roast beef are adopted, and a formula is formulated in a reasonable ratio, so the beef oil essence has the flavor of natural roast beef, vivid and natural fragrance, long fragrance retention and high heat stability. The beef oily essence has an irreplaceable effect in fields of seasonings and instant noodles.

Owner:TIANJIN CHUNFA BIO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com