Device and method for preparing butanol through fermentation, coupling, separation and purification of acetone-butanol

A technology for the fermentation, separation and purification of acetone butanol, which is applied in the field of biochemical industry to achieve the effects of saving energy consumption, increasing equipment investment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

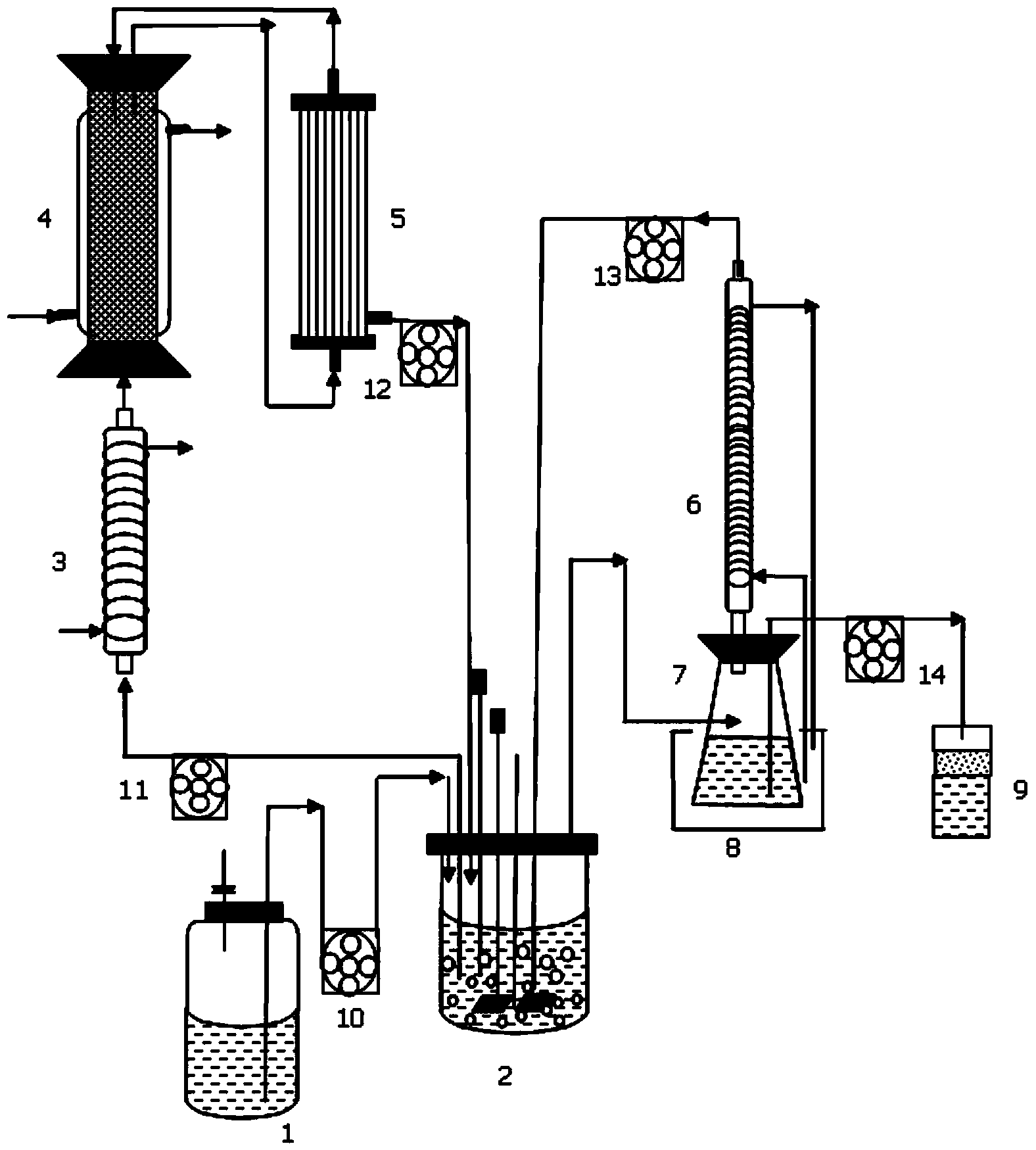

[0025] figure 1 It is a schematic diagram of the device of the present invention. Depend on figure 1 As can be seen, the acetone-butanol fermentation coupling separation and purification device of the present invention prepares butanol, which comprises a seed culture tank 1, a stirred bioreactor 2, a cooling device 3, an immobilization device 4, a bacterial liquid separation device 5, an air stripping Condensation pipe 6, storage tank 7, low-temperature circulation constant temperature tank 8 and condensate collector 9; wherein, the stirred bioreactor 2 is communicated with the seed cultivation tank 1 through a pipeline; the built-in gas distributor at the bottom of the stirred bioreactor 2; stirring Type bioreactor 2, cooling device 3, immobilization device 4, and bacterial liquid separation device 5 are sequentially connected to form a circulation loop; and stirred bioreactor 2 is sequentially connected to stripping condenser pipe 6 and storage tank 7 , the storage tank 7 ...

Embodiment 2

[0031] Inoculate the butanol-producing bacteria into the seed culture tank 1 for seed cultivation; then pump it into the stirred bioreactor 2 for fermentation through the pump 10, and pump the fermented liquid out of the stirred bioreactor 2 through the pump 11 during the fermentation process Enter the cooling device 3 to reduce the temperature of the fermented liquid, continue to pump into the immobilization device 4 to realize the immobilization of the bacterial strain, then pump into the bacterial liquid separation device 5, and the entrapped liquid of the bacterial liquid separation device 5 returns to the immobilization device 4, and the bacterial liquid separation device The effluent of 5 is pumped back into the stirred bioreactor 2 through the pump 12, so as to realize the immobilization of the bacterial strain cells. The effects of cell immobilization are as follows: ① most of the cells are adsorbed by the adsorption and immobilization material, and a small part of the ...

Embodiment 3

[0044] Acetobutanol-producing bacteria: Clostridium acetobutylicum strain (Clostridium acetobutylicum strain), purchased from China General Microbiology Collection Center (CGMCC5234)

[0045] Seed medium: yeast powder 3g / L, peptone 5g / L, glucose 10g / L (usually glucose has a molecule of crystal water, which is actually 10% more), ammonium acetate 2g / L, sodium chloride 2g / L, seven Magnesium sulfate hydrate 3g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L, ferrous sulfate heptahydrate 0.1g / L.

[0046] Fermentation medium: carbon source (glucose 60g / L), phosphate buffer (potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L), ammonium acetate 2.2g / L, vitamins (p-aminobenzoic acid 1mg / L, thiamine 1mg / L, biotin 0.01mg / L), mineral salt (manganese sulfate monohydrate 0.01g / L, sodium chloride 0.01g / L, magnesium sulfate heptahydrate 0.2g / L, sulfuric acid heptahydrate ferrous iron 0.01g / L).

[0047] Cultivation and fermentation of bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com