Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Pinacolone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pinacolone (3,3-dimethyl-2-butanone) is an important ketone in organic chemistry. It is a colorless liquid and has a slight peppermint- or camphor- odor. It is a precursor to triazolylpinacolone in the synthesis of the fungicide triadimefon and in synthesis of the herbicide metribuzin. The molecule is an unsymmetrical ketone. The α-methyl group can participate in condensation reactions. The carbonyl group can undergo the usual reactions (hydrogenation, reductive amination, etc.). It is a Schedule 3 compound under the Chemical Weapons Convention 1993, due to being related to pinacolyl alcohol, which is used in the production of soman. It is also a controlled export in Australia Group member states.

Preparation method of tebuconazole

ActiveCN103435564AReduce generationIncrease contentOrganic chemistryEthylene oxideHydrogenation reaction

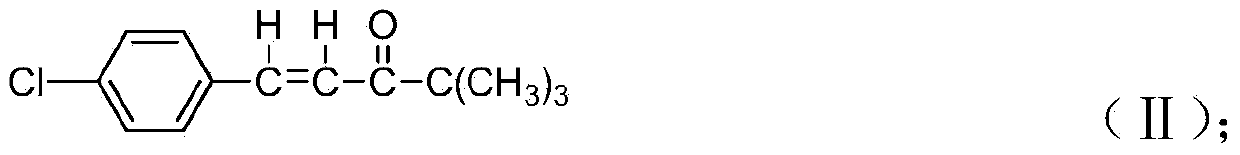

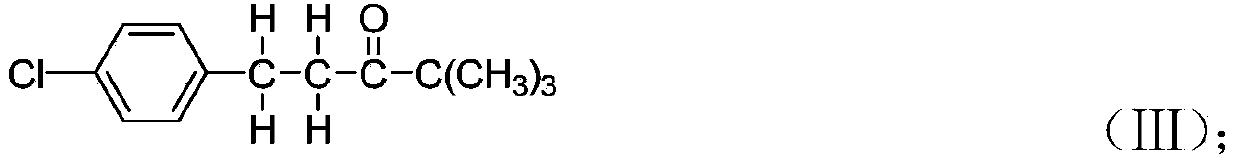

The invention discloses a preparation method of tebuconazole. The preparation method using p-chlorobenzaldehyde and pinacolone as initial raw materials comprises the following steps of: obtaining 2-(4-chlorobenzene ethyl)-2-tertiary butyl ethylene oxide through condensation reaction, hydrogenation reaction and epoxidation reaction in sequence; obtaining tebuconazole through ring-opening reaction of 2-(4-chlorobenzene ethyl)-2-tertiary butyl ethylene oxide and triazole under the co-catalysis of organic amine and crown ether. A catalysis technology of a composite catalyst which is composed of organic amine and crown ether is adopted, so that the isomer byproducts in the ring-opening reaction are greatly reduced, the ring-opening yield is improved to 92.8% from 80% of the conventional process, the product quality is improved to 98.5% or higher from 95%, and the total yield (in terms of p-chlorobenzaldehyde) is improved to 82% or higher from 65% of the conventional process.

Owner:SHANGYU NUTRICHEM +1

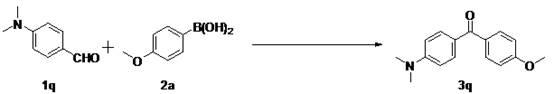

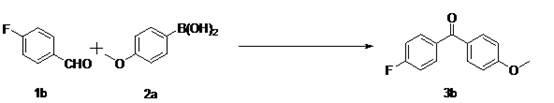

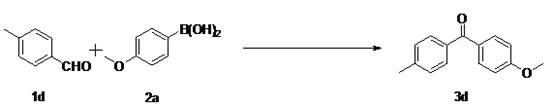

Method for preparing aryl ketone

ActiveCN102153434AMild reaction conditionsReduce usageCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystRuthenium Compounds

The invention relates to the field of catalysis, in particular to a method for preparing aryl ketone through reacting aldehyde with aryl boric acid under the catalysis of a ruthenium catalyst. In the method, an organic phosphide is used as a ligand, potassium phosphate is used as alkali, pinacolone or acetone is used as an additive, toluene or / and water is (are) used as a solvent(s), aldehyde and aryl boric acid which are used as reaction substrates react at 95-100 DEG C for 10-24h in the presence of a ruthenium compound used as a catalyst to prepare aryl ketone, wherein the catalyst is one of [Ru(cymene)Cl2]2, [Ru(CO)3Cl2]2, RuH2(CO)PPh3, Ru2(OAc)4, [Ru(benzene)Cl2]2, Ru(S-BINAP)Cl2 or Ru3(CO)12. In the invention, the used catalyst has relatively low price and low toxicity, thereby reducing the preparation cost and being more environmentally friendly.

Owner:铜陵市官作文化有限公司

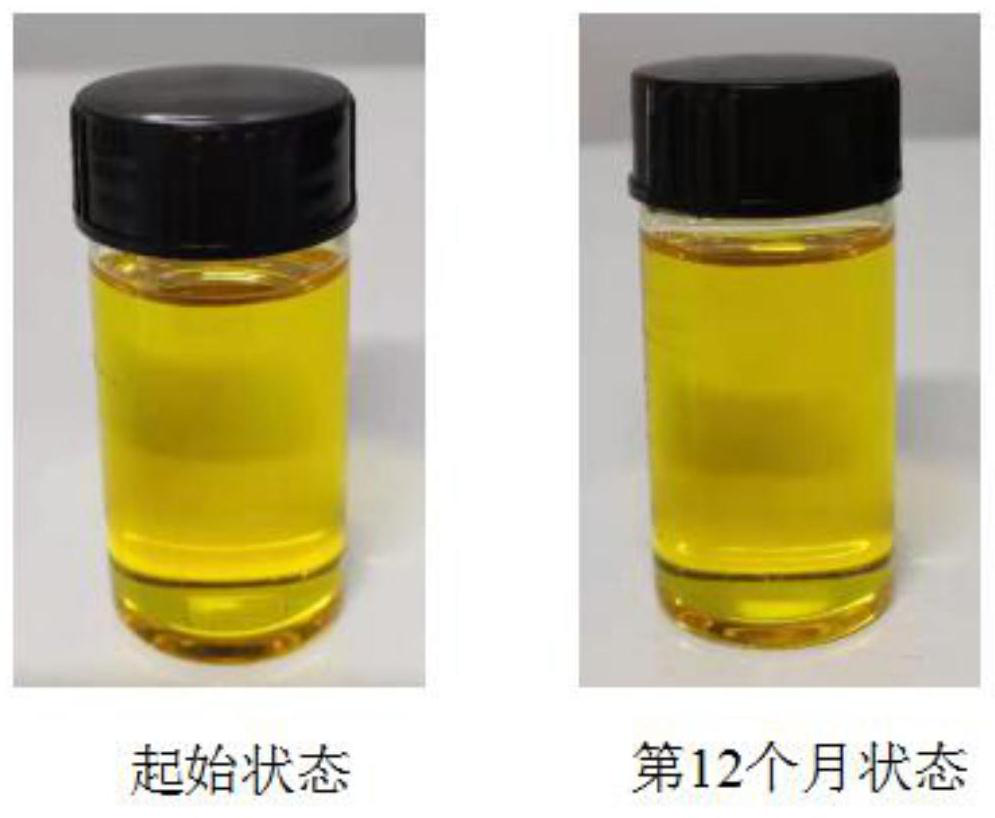

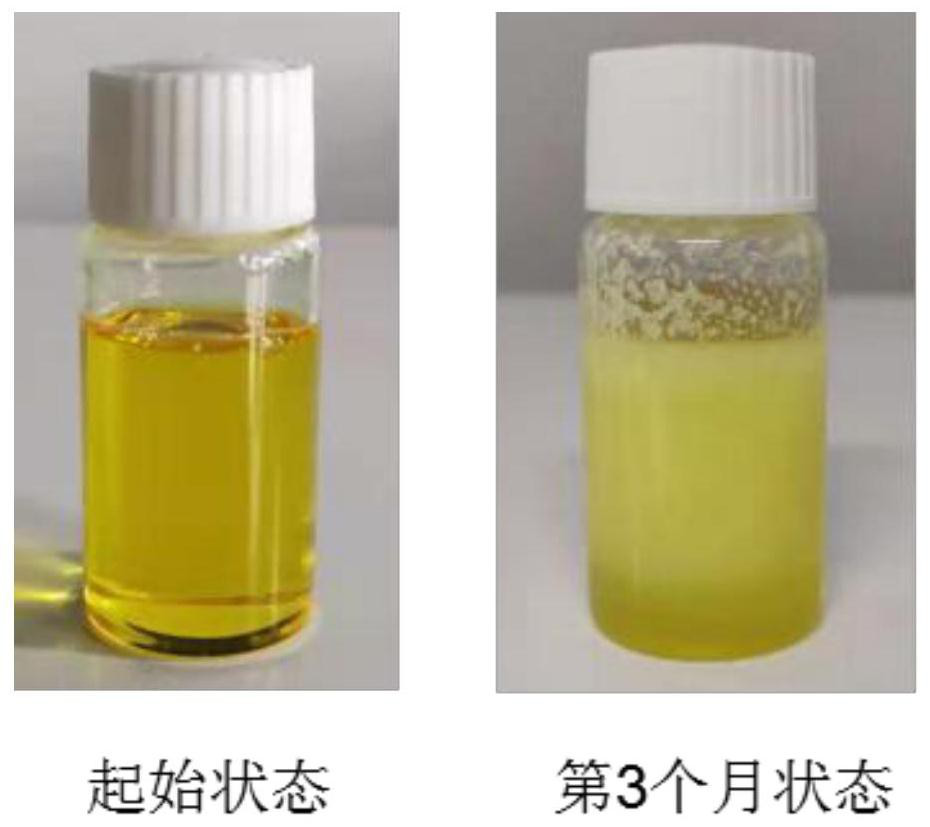

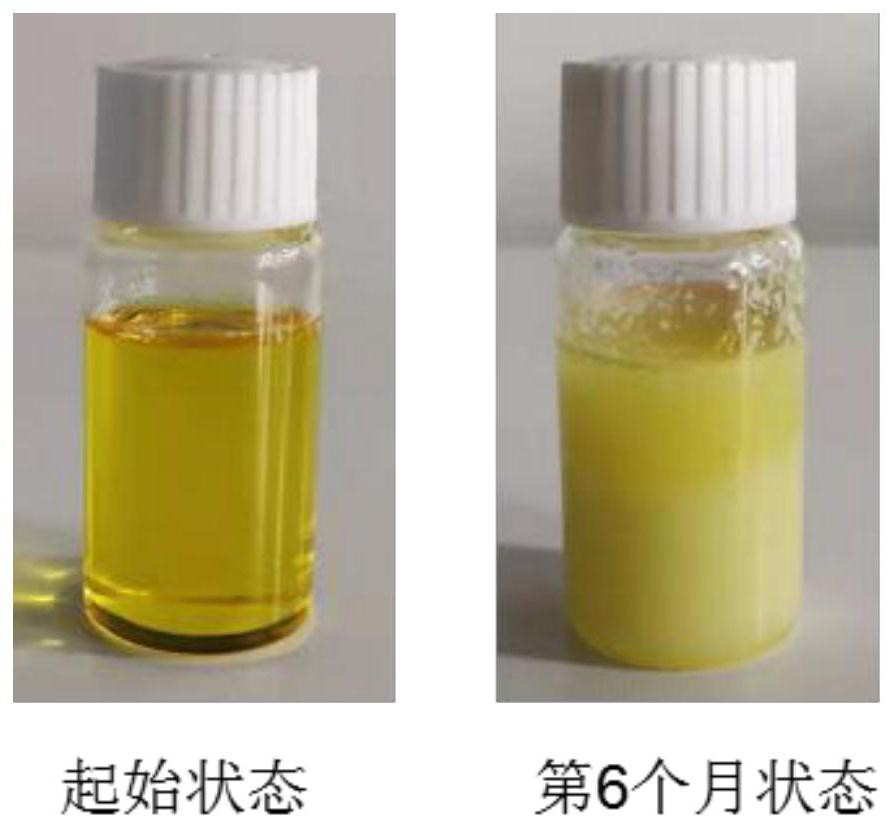

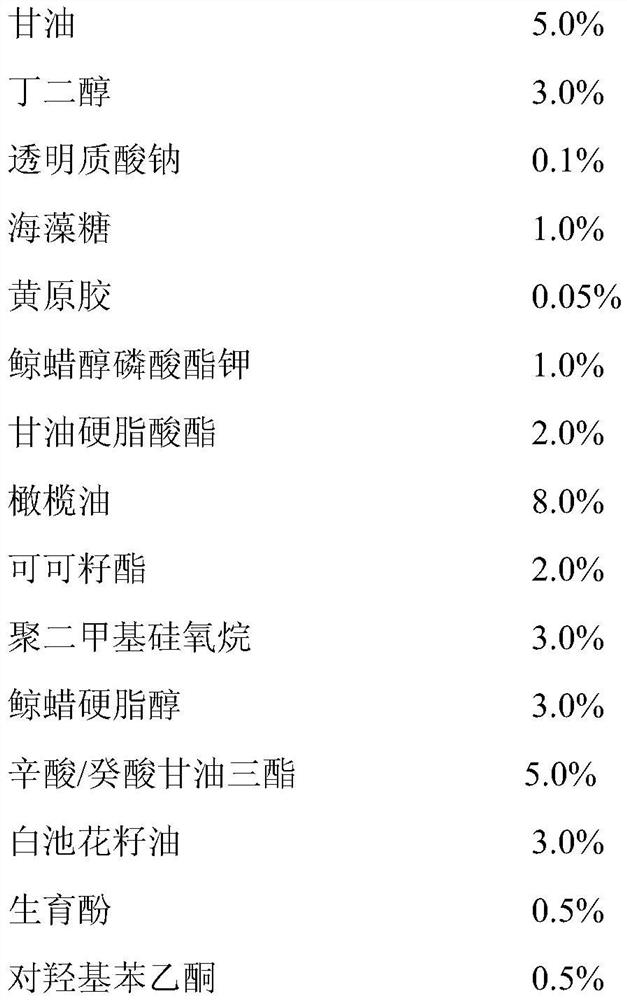

Multi-effect hydroxyl pinacolone retinoate nano composition as well as preparation method and application thereof

ActiveCN112957276ASmall particle sizeLarge specific surface areaCosmetic preparationsToilet preparationsPinacoloneBiology

The invention relates to the field of cosmetics, in particular to a multi-effect hydroxyl pinacolone retinoate nano composition which comprises hydroxyl pinacolone retinoate, nicotinamide, glycyrrhizic acid, an emulsifying agent, a co-emulsifying agent and polyhydric alcohol. The hydroxyl pinacolone retinoate accounts for 0.1-10% of of the total mass of the nano composition; the nicotinamide accounts for 0.1-10% of the total mass of the nano composition; and the glycyrrhizic acid accounts for 0.1-10% of the total mass of the nano composition. According to the nano composition disclosed by the invention, the hydroxyl pinacolone retinoate, the nicotinamide and the glycyrrhizic acid are wrapped in the nano composition, so that the stability of functional components is effectively improved. The three functional components of the nano composition are reasonably matched and synergistically interacted, penetrate through a skin barrier and enter deep skin tissues, the bioavailability is improved, the anti-aging, acne-removing and whitening effects are improved, and the nano composition is mild and non-irritant to skin and can be widely applied to cosmetics.

Owner:WUHAN BEST CARRIER NANO TECH

Process for preparing beta-diketone compound and process for preparing metal complex thereof

InactiveCN1636422AGroup 4/14 element organic compoundsOrganic compound preparationPivalic acidDiketone

The invention discloses a method for preparing 2,2,6,6-tetramethyl-3,5-heptanedione, which comprises the process of using alkyl pivalate as a solvent without using other solvents Alkyl pivalate and pinacolone are reacted in the presence of an alkali metal alkoxide catalyst, or they are reacted in an amide type solvent or a urea type solvent in the presence of an alkali metal alkoxide catalyst. Also disclosed is a method for preparing 2,2,6,6-tetramethyl-3,5-heptanedione metal using 2,2,6,6-tetramethyl-3,5-heptanedione complex method. The method for preparing 2,2,6,6-tetramethyl-3,5-heptanedione is an industrialized method, wherein alkali metal alkoxides are easy to handle and can be used as Catalyst for the preparation of 2,2,6,6-tetramethyl-3,5-heptanedione from esters and pinacolones.

Owner:SHOWA DENKO KK

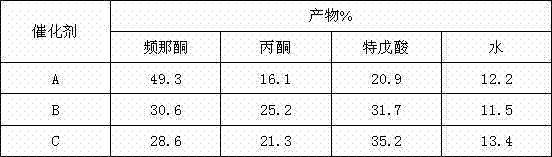

Process for preparing pinacolone and compound catalyst

InactiveCN103240094AThe process steps are simpleEasy to operateCarbonyl compound preparation by condensationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureEconomic benefits

The invention discloses a process for preparing pinacolone. The process is characterized by comprising the following steps of: performing condensation reaction of chloro tertpentane and formaldehyde under an acidic condition, and catalyzing by a Zn / Co / Sb compound catalyst, wherein the reaction temperature is 60-95 DEG C and the reaction time is 4-5 hours; the molar ratio of the components in the Zn / Co / Sb compound catalyst is 1:1:1. The process disclosed by the invention has the beneficial effects that the Zn / Co / Sb compound catalyst catalyzes condensation reaction of chloro tertpentane and formaldehyde, so that not only is the process step concise and the process is easy to operate and realize, but also the conversion ratio is high and the reaction time is short. The yield can be improved by 8-15%, and the condensation time can be shortened by over 1 / 3, so that the production cost is effectively lowered, and the economic benefit is considerable.

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

Synthesizing method for pinacolone

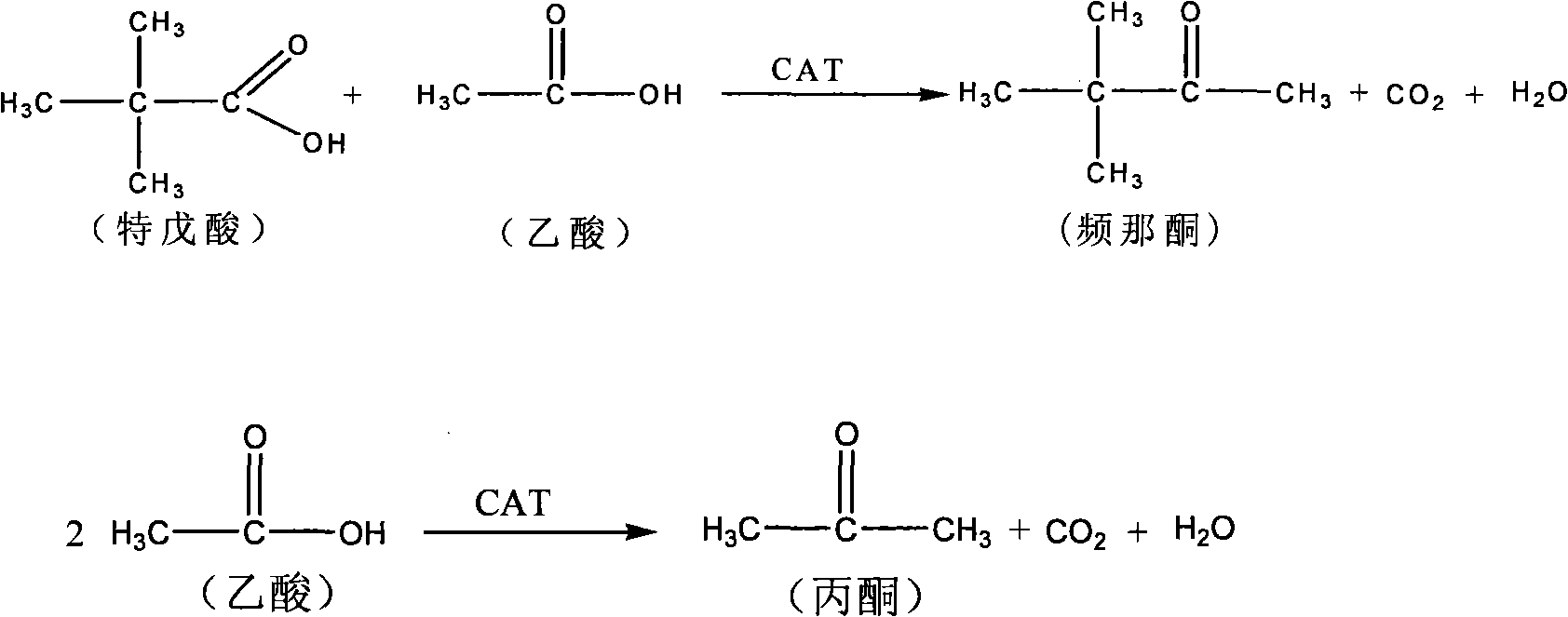

InactiveCN101148401ASolve environmental problemsShort production processOrganic compound preparationCarbonyl compound preparationAcetic acidPivalic acid

The pinacoline synthesizing process features that in the presence of composite alumina and titania carrier supported RE oxide catalyst, pivalic acid and acetic acid / acetone in the molar ratio of 0.8-1.2 to 0.5-1.5 are reacted at 300-500 deg.c to synthesize pinacoline, with the feeding rate being 0.5-1.0 g / g.hr.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ruthenium complex and process for producing tert-alkyl alcohol therewith

InactiveUS7378560B2Effectively hydrogenatedRuthenium organic compoundsOrganic compound preparationHydrogenSec-Butanol

Owner:KANTO CHEM CO INC +1

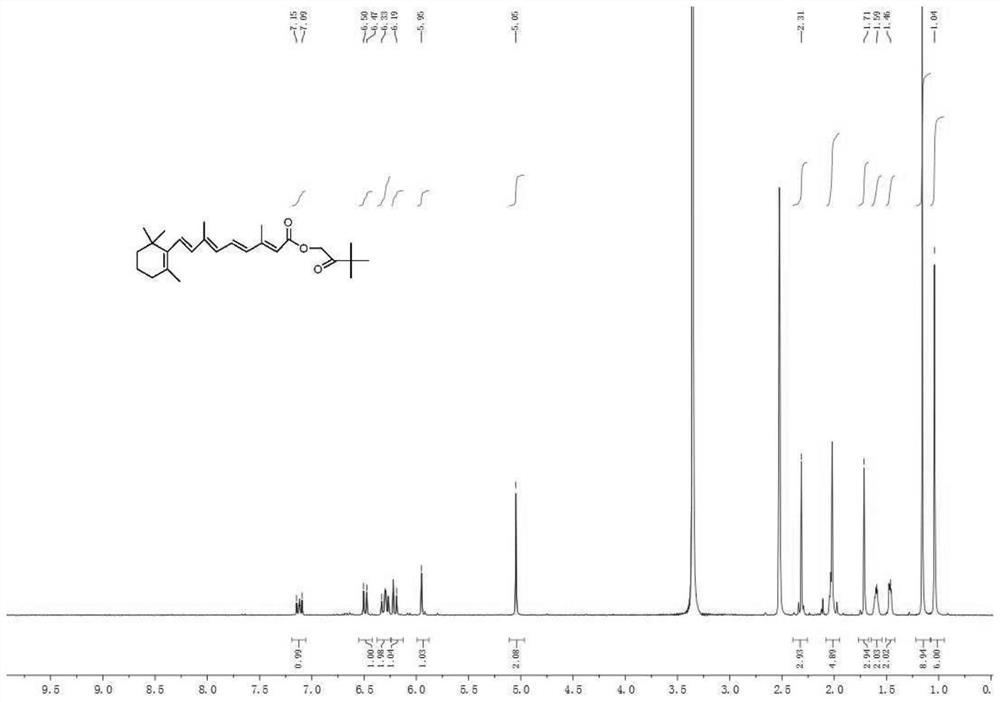

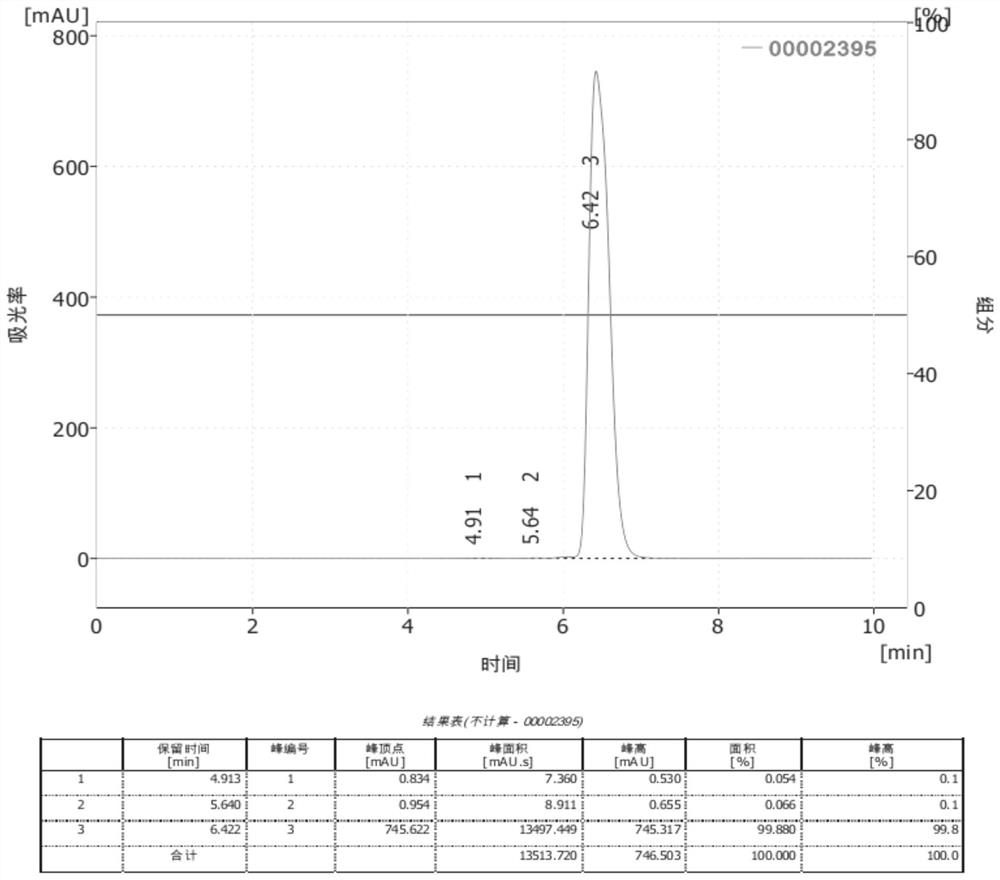

Synthesis process of hydroxyl pinacolone retinoate

ActiveCN113880797AFast absorptionStable esterification reactionOrganic chemistryChemical recyclingPtru catalystTretinoin

The invention belongs to the field of synthesis, and particularly relates to a synthesis process of hydroxyl pinacolone retinoate, the synthesis process comprises the following steps: carrying out condensation reaction on tretinoin and hydroxyl pinacolone under the action of a water absorption catalyst to obtain hydroxyl pinacolone retinoate, wherein the water absorption catalyst adopts a shell-core catalyst, vermiculite is used as an inner core, and titanium aluminum oxide is used as a mesoporous shell layer. According to the synthesis process, the defects in the prior art are overcome, distilled water generated in the reaction process is rapidly absorbed by utilizing the water absorption catalyst, and stable esterification reaction is formed under the catalytic action of titanium oxide.

Owner:南京先达医药科技有限公司

Process for synthesizing 3,3-dimethyl-2-butanone

ActiveCN101289376ASimple processEasy to operateCarbonyl compound preparation by condensationPivalic acidGas phase

The invention relates to a synthesis method of 3, 3-dimethyl-2-butanone by using pivalic acid and glacial acetic acid as raw materials which are catalyzed to react by gas phase under the conditions of normal pressure. The pivalic acid and the glacial acetic acid and water are uniformly mixed up under the normal temperature according to the molar ratio of 1:1:3 to 1:1.4:3; after vaporization, the pivalic acid and the glacial acetic acid and the water are catalyzed to have a decarboxylation reaction and then pinacolone is produced under the normal pressure with the temperature of 380 to 400 DEG C in a fixed bed reactor; the carrier of the catalyst is A12O3; active components are one or two compounds of rare earth metals Ce, Nd, La or oxides thereof; the active component content which is calculated according to the weight of metal oxides takes up 20-30 percent of the weight of the carrier A12O3; the bulk density of the catalyst is 0.47 to 0.5; after analysis, the selectivity of the pinacolone is above 95 percent and then the 3, 3-dimethyl-2-butanone product with the purity of 99 percent can be obtained after the pinacolone is purified by rectification under the normal pressure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

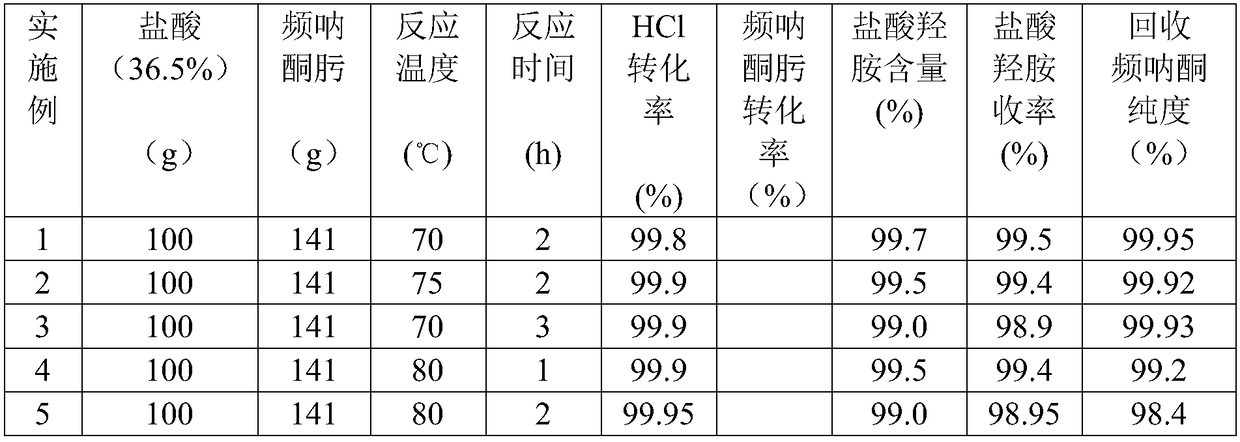

Hydroxylamine hydrochloride synthesis method

ActiveCN108584893ALess waste waterHigh yieldHydroxylamineSynthesis methodsHydroxylamine Hydrochloride

The invention discloses a hydroxylamine hydrochloride synthesis method which comprises the following steps: putting pinacolone oxime and a concentrated hydrochloric acid solution into a kettle in a mole ratio of 1.2-1.5 to 1, intensely stirring, heating to 70-80 DEG C, and carrying out hydrolysis; cooling, leaving to stand and layer, collecting an upper layer, namely pinacolone, and a lower layer,namely a hydroxylamine hydrochloride solution, carrying out vacuum distillation on a water layer, separating a white crystal in the kettle, adding ethanol, cooling, crystallizing, and filtering, so as to obtain hydroxylamine hydrochloride of high purity and high yield. By adopting the hydroxylamine hydrochloride synthesis method, side reactions in a hydrolysis process can be avoided, the purity of hydroxylamine hydrochloride can be improved, the yield of the hydroxylamine hydrochloride can be increased, in addition, the method has the characteristics of being simple in step, easy in raw material obtaining, small in wastewater amount, good in environmental-friendliness, and the like.

Owner:CHINA CATALYST HLDG CO LTD

Method for treating high concentration phenolic wastewater

ActiveCN104129827ALow boiling pointEnergy saving during recycling phaseWater contaminantsWater/sewage treatment by extractionHigh concentrationWastewater

The invention relates to a method for treating high concentration phenolic wastewater. The treating method comprises extracting the high concentration phenolic wastewater with a dephenolization extractant to obtain an extraction phase and a raffinate phase, wherein the dephenolization extractant contains pinacolone, and the high concentration phenolic wastewater contains not less than 2000mg / L of total phenolic contents of phenol. Compared with the prior art, the treating method in the invention is more energy-saving in the solvent recovery stage, and energy consumption of water tower is reduced greatly; and pinacolone has excellent extraction effect, so that the treating method can effectively reduce the content of phenols in the high concentration phenolic wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Cleaning agent for cleaning 3D-type sand printing head and preparation method of cleaning agent

InactiveCN105039025AOvercoming toxicityOvercome the disadvantages of strong pungent smellOrganic non-surface-active detergent compositionsEngineeringCleansing Agents

The invention relates to a cleaning agent for cleaning a 3D type sand printing head and a preparation method of the cleaning agent. The cleaning agent for cleaning the 3D type sand printing head comprises the following components in percentage by weight: 30-40% of sec-amyl alcohol, 18-26% of tetramethylurea, 18-22% of dipropyl ether, 6-14% of pinacolone, 9-15% of valerone and 0.6-1.4% of a stabilizing agent, wherein the stabilizer is propylene glycol methyl ether. The cleaning agent has the beneficial effects that raw materials relatively mild to human bodies and production environments are selected to reduce harms to the bodies and the environments to the utmost extent; the cleaning agent is small in surface tension and viscosity and strong in osmotic force, and can quickly dissolve resin crystals in the 3D-type sand printing head to ensure that the patency rate of an ore canal in the printing head is not less than 98.5%; the cleaning agent is stable in chemical property and cannot cause swelling and corroding actions on other parts of the printing head; the cleaning agent can reduce the production cost and prolong the service life of the 3D type sand printing head.

Owner:GANSU KOCEL CHEM

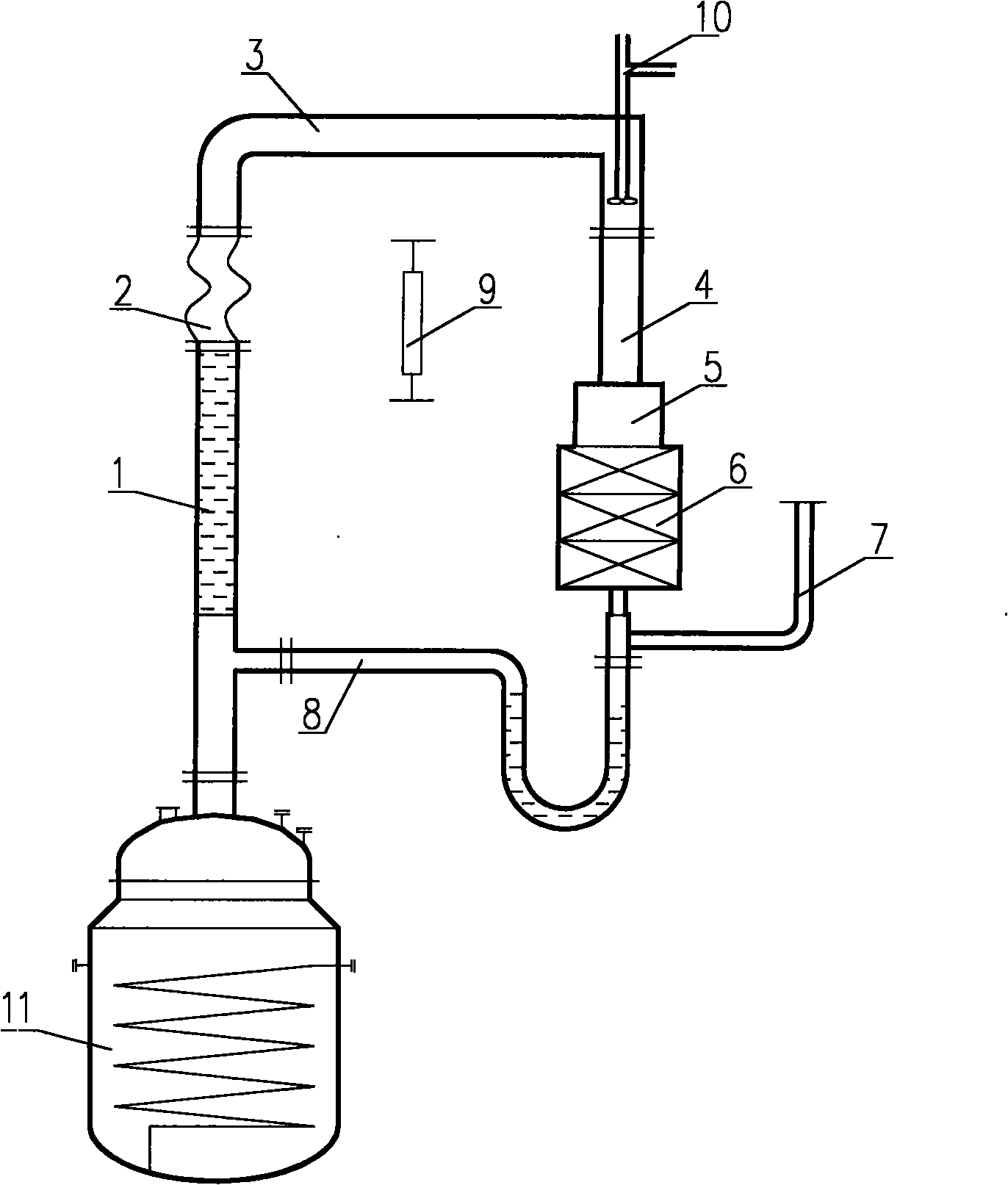

Method of preparing chloropinacolone by gas-phase photocatalysis chlorination and special device thereof

InactiveCN101781181AEasy to industrializeLow costOrganic compound preparationCarbonyl compound preparationVapor–liquid separatorGas phase

The invention relates to a preparation method of chloropinacolone and a special device thereof. The method comprises the following steps: pinacolone is adopted as a raw material inside a chlorination reaction device and has chlorination reaction with the chlorination gas under the radiation of the light source to obtain the chloropinacolone, the chlorination reaction device comprises a reaction kettle with a heating device, a rectifying column which is arranged above an outlet of the reaction kettle, a gas-phase reactor which is arranged at a chlorination gas access inlet and a condenser, and also comprises a gas-liquid separator and a backflow liquid sealing pipe; and in the reaction kettle, the rectifying raw material gas and the chlorination gas or the chlorination mixed gas are undertaken the gas-phase photocatalysis chlorination reaction inside a gas-phase reactor from top to bottom to generate the chloropinacolone.The method is not only simple and easy, is easy to be industrialized, has low cost, less side product and high conversion rate and can prepare the chloropinacolone with high content, but also the special device for preparing the chloropinacolone is applicable to the industrialized production.

Owner:盐城七善化工科技有限公司

Anti-aging composition and preparation method thereof

InactiveCN111939116AImprove anti-aging effectStimulate healingCosmetic preparationsToilet preparationsBiotechnologyHydroxyproline

The invention relates to the technical field of cosmetics, in particular to an anti-aging composition and a preparation method thereof. The anti-aging composition comprises the following raw materialsof an emulsifier, grease, a thickener, a humectant, an antioxidant, a preservative, functional active matter and water. The functional active matter is a composition of two or more of hydroxyl pinacolone retinoate, nicotinamide, crithmum maritimum stem cells and methylsilanol hydroxyproline aspartate. Through the cooperation of the functional active matter and the antioxidant, the anti-aging composition has the effects of whitening the skin, promoting collagen production, fading wrinkles and the like; moreover, the functional active matter can achieve the effects of fading the wrinkles on theepidermis and stimulating collagen production by the dermis from the skin surface layer, cuticle and dermis layer; through the functional active matter and the antioxidant, the anti-aging effect is remarkable; and therefore, the anti-aging composition has a good anti-aging effect and can meet the requirements of people on the anti-aging effect of the cosmetics. The preparation method has the characteristics of simple process, low production cost and suitability for industrial production.

Owner:东晟源研究院(广州)有限公司

Preparation process of pinacolone

PendingCN108191621ASimple preparation processSimple processPreparation by halogen halide additionCarbonyl compound preparation by condensationGas phaseDistillation

The invention relates to a preparation process of pinacolone. The preparation process comprises steps as follows: (1) technical hydrochloric acid is cooled to subzero 5 DEG C to 5 DEG C, isopentene isslowly dropwise added under the stirring condition, the mixture is stirred for 1-3 h after isopentene is dropwise added, and 2-isoamyl chloride is produced; (2) 2-isoamyl chloride is pumped into a condensation reaction kettle, stirring is started, heating is performed slowly, formaldehyde is dropwise added when the temperature of a gas phase reaches 70-80 DEG C, the mixture is kept at the constant temperature for a reaction for 1-2 h after formaldehyde is dropwise added, cooling and still standing for layering are performed after the reaction ends, an upper-layer crude product enters a rectification device at the temperature of 70-80 DEG C for rectification, and a lower-layer acid liquid is pumped into a waste acid distillation kettle for fractionation; (3) rectified pinacolone is sent into a special azeotropic point distillation decoloration device and subjected to decoloration treatment at the temperature of 100-110 DEG C for 2-4 h, and a colorless pinacolone product with the purityhigher than or equal to 98% can be obtained. The preparation process has the advantages as follows: the colorless pinacolone product with the purity higher than or equal to 98% can be prepared.

Owner:南通鸿富达利化工有限公司

Preparation method of branched alkane

InactiveCN110590489AReduce generationMild reaction conditionsOrganic compound preparationHydroxy compound preparationOrganic synthesisSilanes

The invention provides a preparation method of branched alkane, and belongs to the technical field of organic synthesis. The preparation method of the branched alkane comprises the following steps: mixing pinacolone, an alkyl metal reagent and an organic solvent under the condition of a protective atmosphere, performing an alkylation reaction so as to obtain an alkyl alcohol intermediate, mixing the alkyl alcohol intermediate, alkyl silane, an acid catalyst and an organic solvent under the condition of a protective atmosphere, and then performing an elimination reduction reaction so as to obtain the branched alkane. Pinacolone is adopted as a raw material, the alkyl metal reagent is applied to the alkylation reaction so as to obtain the corresponding alkyl alcohol intermediate, the alkyl silane is adopted as a reducing agent of the alkyl alcohol intermediate, and the elimination reduction reaction is performed in the presence of the acid catalyst so as to synthesize the branched alkane. The method has a simple synthesis route, high yield of branched alkane, high purity, no use of expensive catalysts, low raw material cost and simple operation, and is suitable for scale-up and industrial production.

Owner:DALIAN CHEMPHY CHEM

Process for regenerating pinacolone by absorption of pinacolone production tail gas by concentrated hydrochloric acid

InactiveCN109678682AHigh purityRelieve stressOrganic compound preparationCarbonyl compound separation/purificationChlorideKetone

The invention relates to a process for regenerating pinacolone by absorption of pinacolone production tail gas by concentrated hydrochloric acid. The process is characterized by comprising the following specific processes: S1, precooling and concentration increase of concentrated hydrochloric acid; S2, preparation of 2-isopentane chloride; S3, synthesis of pinacolone; S4, decoloring. The pinacolone product produced with the method has high purity, color and luster of the product are ensured, tail gas generated in production can be recycled for production of pinacolone, and green production istruly realized; besides, reaction time can be effectively shortened by precooling of concentrated hydrochloric acid, and production efficiency is improved; the preparation process is simple, no wasteacid is generated in the preparation process of pinacolone, and environmental pressure is relieved. A decoloring process is added after rectification, hydrochloric acid is prevented from being mixed in the product, and on the basis of ensuring purity of the product, the color and luster of the product can also be ensured, so that the colorless pinacolone product with purity higher than or equal to98% can be prepared.

Owner:南通鸿富达利化工有限公司

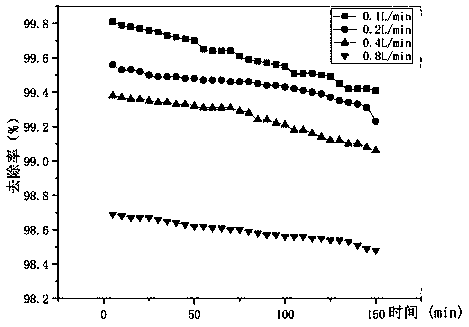

Treatment method for pinacolone chloride production tail gas

InactiveCN111375301AReduce difficultyReduce processing loadDispersed particle separationActivated carbonPhysisorption

The invention discloses a treatment method for pinacolone chloride production tail gas, comprising the following steps: molecular capture: carrying out molecular capture on the tail gas by using an organic matter capture agent to obtain pinacolone chloride gas in the tail gas; falling film water absorption: absorbing hydrogen chloride gas in the tail gas by adopting a falling film water absorptionmethod to obtain a hydrogen chloride solution; alkali liquor absorption: carrying out alkali liquor absorption on the tail gas subjected to falling film water absorption, and removing unremoved hydrogen chloride gas in the tail gas; and activated carbon adsorption: physically adsorbing the tail gas by activated carbon to adsorb and remove harmful gases in the tail gas. The design is reasonable, and hydrogen chloride and organic gas are separated through molecular capture. Therefore, the difficulty of purifying the waste hydrochloric acid is greatly reduced. Resource reutilization is achievedthrough desorption regeneration, and the capture agent can be recycled, so that the waste gas treatment cost is saved. In addition, after the tail gas from pinacolone chloride production is fully absorbed and treated, the activated carbon treatment load is greatly reduced, and secondary pollution is reduced.

Owner:NJTECH ENVIRONMENT TECH CO LTD

Synthesis method of high-purity pinacolone

InactiveCN106365964ASolve the problem of not being able to produce high content pinatoneIncrease contentPreparation by halogen halide additionCarbonyl compound preparation by condensationChlorideHydrosilylation

The invention discloses a synthesis method of high-purity pinacolone. The synthesis method of the high-purity pinacolone comprises the following steps: adding isoamylene and 30-39% of hydrochloric acid in zinc chloride as a hydrosilylation catalyst, and reacting at the temperature of 4-8 DEG C to prepare chloro t-pentane; condensing the chloro t-pentane and formaldehyde under an acidic condition, adding a condensation catalyst, and reacting for 5-7 hours at the temperature of 60-95 DEG C to prepare a pinacolone crude product; and adding 8-12% of water in the pinacolone crude product, directly heating and distilling with steam, and rectifying in a rectifying tower. By the method, the problem that a rectifying section is large in energy consumption and low in efficiency is solved, the pinacolone with high content of 98% is increased to be 45% from 15% in total yield, and the rectifying time is shortened to be 12 hours from 16 hours.

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

Method for preparing high yield pinacolone, and pesticide bactericide

InactiveCN104961634ASimple processLow equipment requirementsBiocidePreparation by halogen halide additionIsoamyl alcoholChloride

The invention discloses a method for preparing high yield pinacolone, and a pesticide bactericide. The pinacolone preparation method is characterized in that pinacolone is synthesized through adopting an isoamyl alcohol technology, hydrochloric acid is adopted as a catalyst, JB is adopted as a polymerization inhibitor, a molar ratio of isoamyl chloride to formaldehyde is 1:1.2-1:1.5, and a condensation reaction is carried out at 60-90DEG C for 6-10h. The method has the advantages of simple process, low requirements on a device, and low cost, and the yield of pinacolone obtained through the method is greater than 85%.

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

Synthetic Method of 5,5-Dimethyl-2,4-Adipaldehyde-0,0-Boron Difluoride

InactiveUS20120071695A1Mild reaction conditionsSimple procedureOrganic compounds purification/separation/stabilisationDispersed particle separationAfter treatmentBoron trifluoride

This invention, which involves synthetic method of 5, 5- dimethyl-2, 4-adipaldehyde-0, 0-Boron difluoride, belongs to the field of organic synthesis. Synthetic method of 5, 5-dimethyl-2, 4-adipaldehyde-0, 0-Boron difluoride is to react pinacolone and boron trifluoride diethyl ether at low temperature, and then add aqueous alkaline solution in after treatment to extract product from ether, after that, separate fluid, condense organic phase and final product is obtained. Yield of this method is 2 to 3 times higher than that in literature, and apart from that, mild reaction condition, simple procedures, easy operation, and low cost make it easy for industrial production. The product can be used directly in next step reaction without any special purification.

Owner:BEIJING AGLAIA TECH DEV

Synthesis method and application of pinacolone catalyst composite support

InactiveCN102886278AHigh activityHigh strengthCatalyst carriersOrganic compound preparationSynthesis methodsAdhesive

The invention discloses a synthesis method and application of a pinacolone catalyst composite support. The synthesis method is characterized by comprising the following steps of: taking 200 g of aluminium nitrate or aluminium sulphate and titanium tetrachloride or titanium sulphate according to a titanium / aluminium molar ratio of 3: 1 to 1: 1, and preparing mixed solution, neutralizing with a precipitator, namely, sodium hydroxide or sodium carbonate, in the conditions that the temperature is 60-70 DEG C and the pH value is 7-8, washing a filter cake until the content of impurity ions is less than 0.1%, drying the filter cake in an oven at 120 DEG C for 8-12 hours, crushing the filter cake until the particle size is less than 200 meshes, using 3-5% dilute nitric acid as an adhesive for forming, extruding the filter cake into strips having a diameter phi of 2 mm, calcining the strips for 5 hours at 500-800 DEG C in a muffle furnace, and then obtaining the pinacolone catalyst composite support of activated aluminium oxide and titanium oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

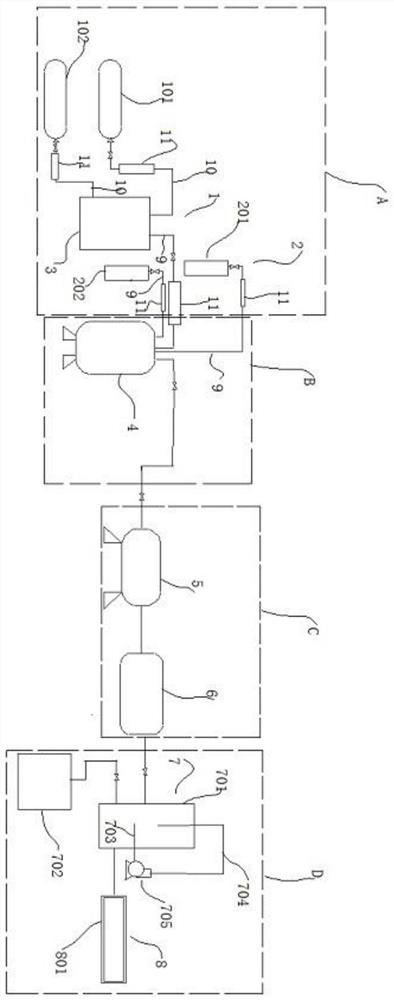

Process system and process for preparing chloropinacolone

PendingCN112430180AImplement responseAchieve purificationOrganic compound preparationCarbonyl compound separation/purificationProcess engineeringEnvironmental engineering

The invention provides a process system and process for preparing chloropinacolone. The process system comprises a feeding unit, a reaction unit, a purification unit and a post-treatment unit which are connected in sequence, wherein the feeding unit comprises a gas feeding device and a liquid feeding device, the gas feeding device comprises a gas mixing kettle, a first gas storage device and a second gas storage device, the gas mixing kettle is respectively connected with the first gas storage device and the second gas storage device, and the liquid feeding device comprises a first liquid storage bottle and a second liquid storage bottle. The process system has the advantages that reaction and purification of pinacolone and chlorine can be achieved, subsequent treatment of pollutants is achieved, nitrogen can be introduced into the device to dilute chlorine in the reaction period, and what is avoided is that the concentration of chlorine is too large, and by-products are generated.

Owner:HUBEI SHANSHUI CHEM

Synthesis method of hydroxyl pinacolone retinoate

PendingCN114436924ALow priceReduce manufacturing costOrganic chemistryPtru catalystOrganic synthesis

The invention belongs to the technical field of fine organic synthesis, and particularly relates to a synthesis method of hydroxyl pinacolone retinoate. The method comprises the following steps: (1) adding an organic solvent into retinoic acid, adding an amide catalyst, uniformly stirring, and carrying out ice bath; (2) adding phosphorus trichloride into the material obtained in the step (1) under the protection of nitrogen, and reacting; (3) standing to separate out a lower-layer inorganic solution, adding 1-hydroxy-3, 3-dimethyl butane-2-ketone under an ice bath condition, then adding an acid-binding agent, carrying out heat preservation reaction, carrying out reduced-pressure suction filtration on inorganic salt, and carrying out reduced-pressure concentration on a liquid phase; and (4) adding a recrystallization solvent, cooling and crystallizing to obtain the hydroxypinacolone retinoate. The raw materials and reagents adopted by the invention are common chemical reagents, are low in cost and are easy to obtain; the solvent used in the reaction is toluene, and the next reaction can be carried out without separation and purification; the two-step reaction can be completed in the same kettle, less equipment is used, and the equipment utilization rate is high.

Owner:青岛三人行化学有限公司

Production process of chloropinacolone

PendingCN113087604AAvoid it happening againReduce consumptionOrganic compound preparationCarbonyl compound preparationProcess engineeringPinacolone

The invention relates to a chloropinacolone production process, which comprises: 1, adding a pinacolone-methanol solution into a reaction kettle, starting a stirring and cooling system, and reducing the temperature of the pinacolone-methanol solution in the reaction kettle to less than 0 DEG C; 2, starting a circulating pump, repeatedly circulating the pinacolone-methanol solution from a circulating discharge port to a feed port of the reaction kettle, arranging a chlorine adding device on a circulating pipeline, introducing chlorine into the pinacolone-methanol circulating solution by the chlorine adding device, and repeatedly circulating until the reaction is finished; and 3, heating and desolventizing the reaction mother liquor obtained in the step 2, and cooling the desolventized feed liquid to obtain the chloropinacolone. The invention provides a production process of chloropinacolone, which can improve the production yield of chloropinacolone, reduce the production time, improve the production efficiency and reduce the consumption of raw materials.

Owner:鹤壁全丰生物科技有限公司

Preparation method of pinacolone

PendingCN106397150AHigh yieldPreparation by halogen halide additionCarbonyl compound preparation by condensationKetonePinacolone

The invention discloses a preparation method of pinacolone. The method includes: (1) isopentene addition reaction: adding isopentene into hydrochloric acid, performing heating for 4-6h to 25DEG C, then further conducting heating to 65DEG C for 4-6h, thus obtaining chloro-tert-pentane; and (2) condensation reaction of chloro-tert-pentane and formaldehyde: adding formaldehyde dropwise into chloro-tert-pentane for 4-6h, and performing heating at the same time to 88-90DEG C, then conducting heat preservation for 1.5-2.5h, and carrying out layering, thus obtaining a pinacolone crude product. The method provided by the invention can achieve high pinacolone yield up to 67% or more.

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

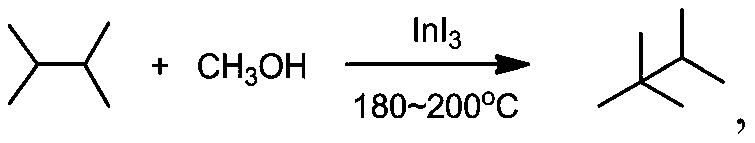

Pinacolone preparation method

InactiveCN105037118ASimple processLow equipment requirementsPreparation by halogen halide additionHydrocarbon from oxygen organic compoundsSodium methoxideIsoamyl alcohol

The present invention discloses a pinacolone preparation method, which comprises that: (1) isoamyl alcohol is dewatered to prepare isoamylene, and the isoamylene and hydrochloric acid are subjected to an addition reaction to obtain chloroisopentane, wherein the reaction temperature is 5-25 DEG C, and the reaction time is 2-8 h; and (2) the chloroisopentane reacts with a methanol solution of sodium methoxide to obtain the pinacolone, wherein the reaction temperature is 0-60 DEG C, and the reaction time is 15-35 min. According to the present invention, the method has characteristics of simple process, low equipment requirement and low cost, and the purity of the product obtained through the method is more than or equal to 99.8%.

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

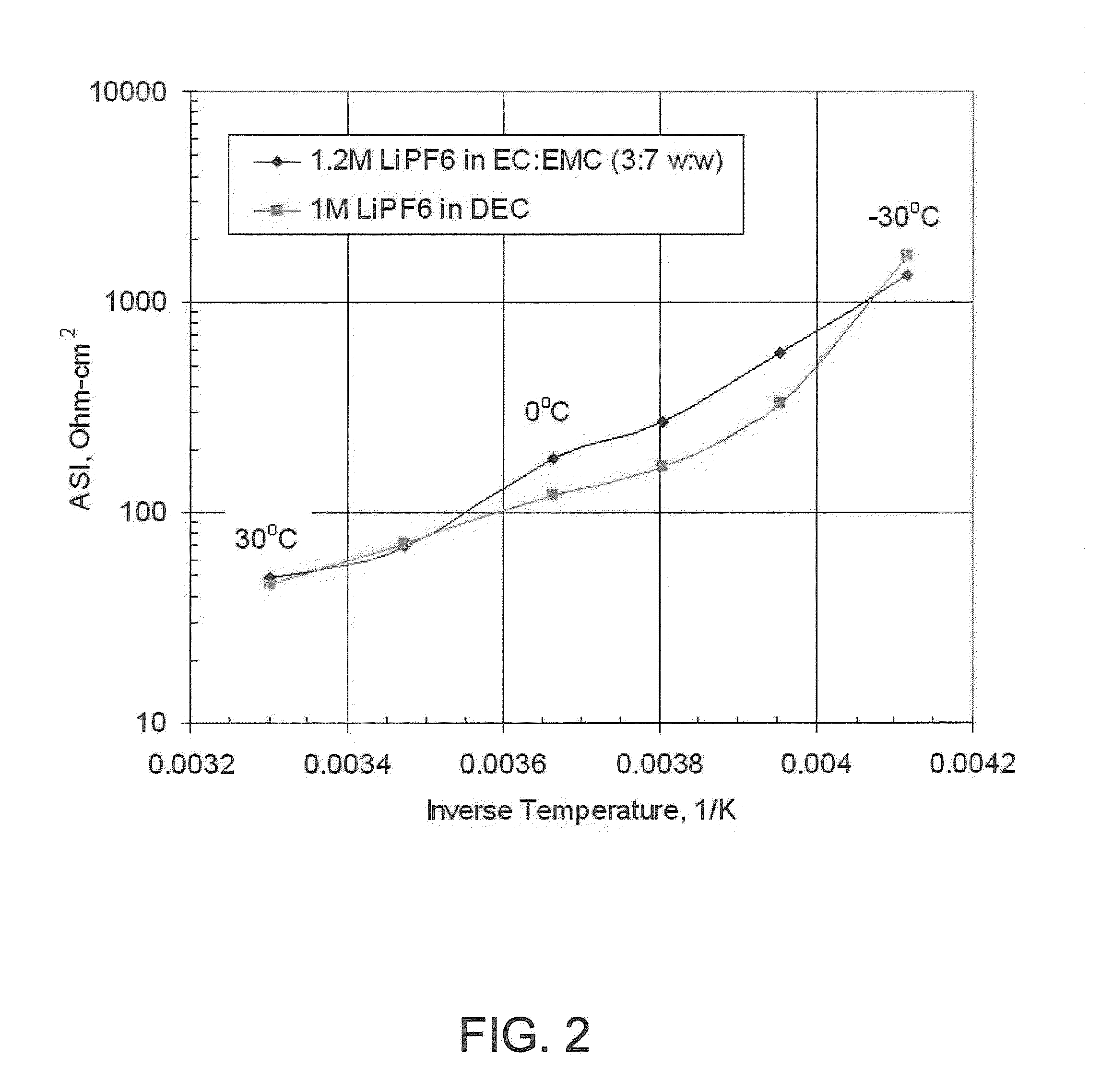

Electrolytes for lithium ion batteries

ActiveUS20100040955A1Low costImprove powerOrganic electrolyte cellsSecondary cellsPhysical chemistryKetone

A family of electrolytes for use in a lithium ion battery. The genus of electrolytes includes ketone-based solvents, such as, 2,4-dimethyl-3-pentanone; 3,3-dimethyl 2-butanone(pinacolone) and 2-butanone. These solvents can be used in combination with non-Lewis Acid salts, such as Li2[B12F12] and LiBOB.

Owner:UCHICAGO ARGONNE LLC

Green method for preparing pinacolone

ActiveCN109809972ALess waste waterReduce equipment investmentChemical industryPreparation from heterocyclic compoundsAcid waterKetone

Owner:上海旭流化学科技有限公司

Production method for chloropinacoline

InactiveCN107686443AHigh yieldHigh purityOrganic compound preparationCarbonyl compound preparationDesolvationPinacolone

The invention provides a production method for chloropinacoline, which includes the following steps: after pinacolone and chlorine are subjected to chlorination reaction under the catalysis of methanol, methanol is recovered by desolvation, so that crude chloropinacoline is obtained; and the crude chloropinacoline is kept still to be layered, so that a lower final product, chloropinacoline, is obtained. The advantages of the production method for chloropinacoline are as follows: the yield of product is high, the purity is high, and the efficiency of production is high.

Owner:江苏嘉晟化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com