Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about "Hydroxylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

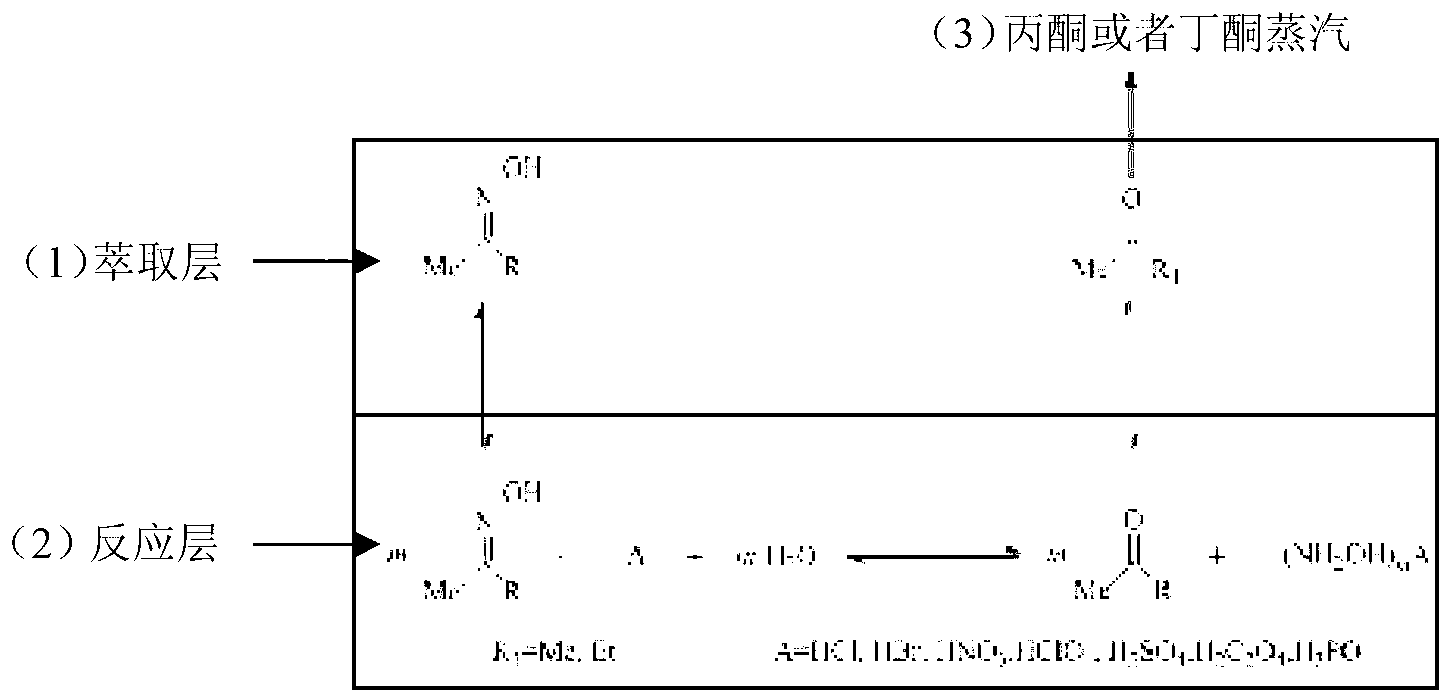

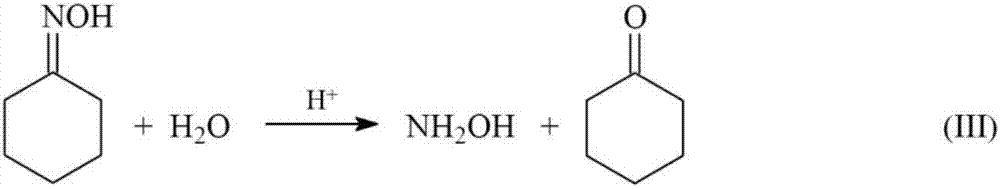

Preparation of hydroxylamine by one-step method using oxime hydrolysis reaction and infiltration gasification film separation coupling technique

In this invention, oxime is used as raw material being hydrolyzed in acid solution. Said hydrolytic process is coupled with osmotic vaporization membrane separation technique. The produced organic by-product ketone is removed by said membrane directionally and high efficiently. Thus recovers the limitation of the reaction chemical equilibrium of the hydrolysis, proceeding the reaction to the direction of production of hydroxylamine salts. This technique enhances the conversion rate greatly with high yield of hydroxylamine salts. This inventive method is better than prior art method with advantages of: simple process, less kinds of raw materials being needed, easy to operation, no side reaction, mild reaction condition and high yield of hydroxylamine salts being up to 80%.

Owner:BEIJING UNIV OF CHEM TECH

Method of preparing hydroxylamine salt by using reaction-extractive distillation coupling technology

ActiveCN103318858AHigh yieldReduce generationHydroxylamineCarboxylic acid salt preparationHydroxylamineExtractive distillation

The invention provides a method of preparing hydroxylamine salt by using reaction-extractive distillation coupling technology. The method comprises the steps of performing a hydrolysis reversible equilibrium reaction to acetoxime / butanone oxime; using reaction-extraction-distillation ternary coupling technology; extracting, distilling and separating acetone (or butanone) as one of reaction products continuously to make it leave the reactant, so as to break the limit of the reaction equilibrium to the reversible reaction, thereby the raw material conversion rate is greatly lifted, the target product hydroxylamine salt is constantly generated and collected in water phase, and the yield is high. The yield of hydroxylamine hydrochloride is 98%, and the yield of other hydroxylamine salts is over 90%; at the same time, reaction product acetone or butanone is separated as the synthesis raw material of acetoxime (or butanone oxime), and the cycle utilization technology is realized.

Owner:CHANGZHOU UNIV

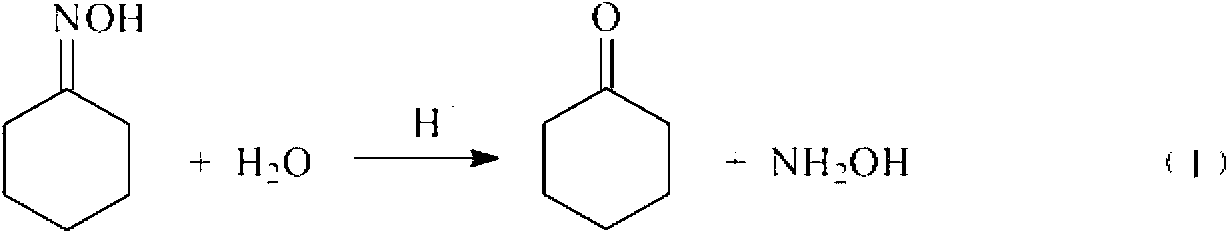

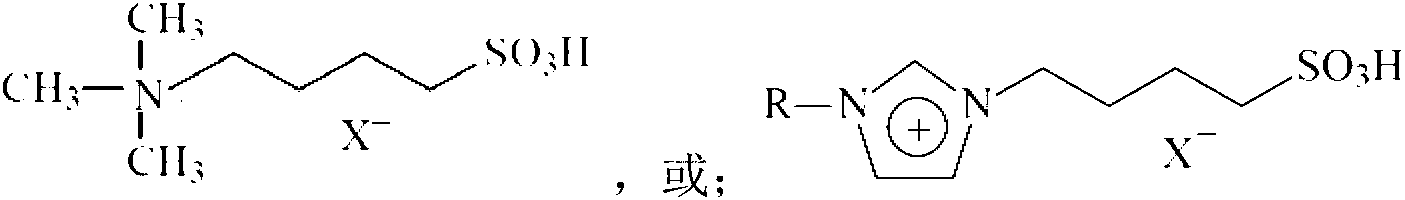

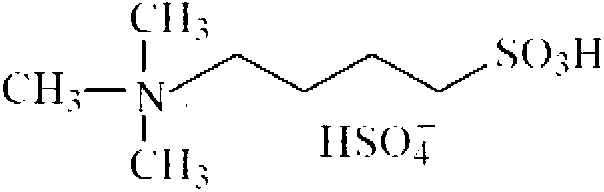

Method for catalyzing hydrolysis reaction of cyclohexanone-oxime in acidic ionic liquid

InactiveCN103073405AOvercoming the disadvantages of being difficult to recycleAvoid pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydroxylamineCyclohexanone oxime

The invention discloses a method for catalyzing a hydrolysis reaction of cyclohexanone-oxime in acidic ionic liquid. The method comprises the following steps of: placing the cyclohexanone-oxime in a reactor, adding an acidic ionic liquid catalyst and deionized water; carrying out constant-temperature stirring reaction for 0.15-4h under the conditions of normal pressure and a temperature of 10-80 DEG C, and separating an organic phase from an inorganic phase in reaction liquid to respectively obtain cyclohexanone and hydroxylamine, wherein the acidic ionic liquid is SO3H-type ionic liquid, the material ratio, namely a mol ratio of the cyclohexanone-oxime to the ionic liquid is 1:(0.16-5.4), and the mol ratio of the deionized water to the ionic liquid is (11-369):1. The method for catalyzing the hydrolysis reaction of the cyclohexanone-oxime in the acidic ionic liquid uses the SO3H-type ionic liquid as a catalyst of the hydrolysis reaction of the cyclohexanone-oxime. Compared with the existing cyclohexanone-oxime hydrolysis route, the method has the advantages that the acidic ionic liquid can be recycled, and the transform ratio of the cyclohexanone-oxime is close to 100 percent.

Owner:HEBEI UNIV OF TECH

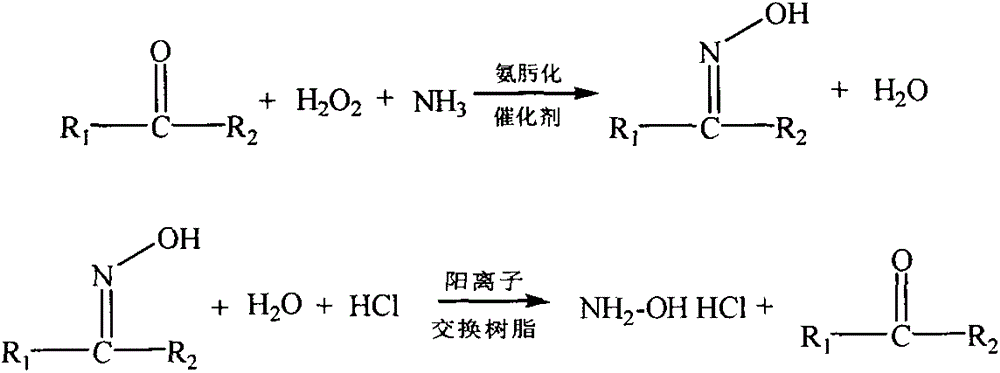

Method for preparing salt of hydroxylamine by using 'coupling' technique of reactive extraction

This invention provides a method for preparing hydroxylamine salt by reaction-extraction 'coupled' technique. The method utilizes hydroxylamine hydrochloride and HNO3, H2SO4 or H3PO4 as the reactants to prepare hydroxylamine nitrate, hydroxylamine sulfate or hydroxylamine phosphate. During the reaction, a mixture of amide and diluting agent is utilized as the extraction phase to extract byproduct HCl generated during the reaction to obtain high-concentration hydroxylamine salt mother liquor. Then multi-stage cross-flow or vacuum distillation is performed to obtain concentrated hydroxylamine salt solution or crystal. During the reaction, byproduct inorganic acid can be extracted into the organic phase, which can reduce the amount of inorganic acid in aqueous phase, and break the previous thermodynamic equilibrium limit so that the reaction advances toward the positive reaction direction, and the yield is increased. The method has such advantages as simple process, few buproducts and easy operation, and is suitable for industrialization production.

Owner:BEIJING UNIV OF CHEM TECH

Method of preparing solid hydroxylamine hydrochloride

A process for preparing hydroxyamine hydrochloride solid includes such steps as reaction between the aqueous solution of hydroxyamine sulfate and ammonia water, regulating pH=5.3-5.7 to obtain liquid phase, reaction between complexing agent, deluent, cosolvent and ammonia water to obtain organic phase, reaction between said liquid phase and organic phase while extracting 5-15 times to obtain organic phase, neutralizing reaction on the aqueous solution of hydroxyamine sulfate to obtain organic phase, reaction on deluted hydrochloric acid while extracting, concentrating, evaporating and crystallizing.

Owner:ZHEJIANG UNIV +1

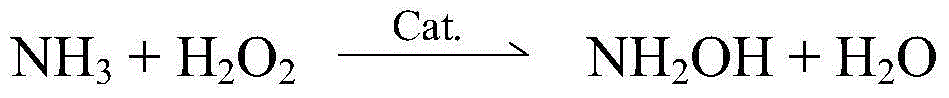

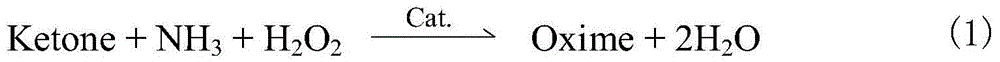

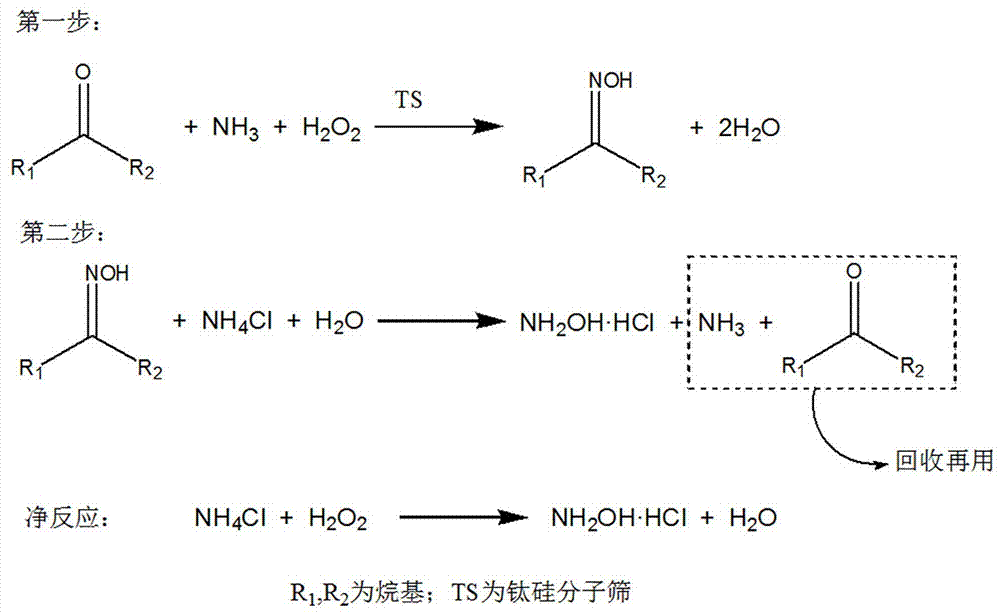

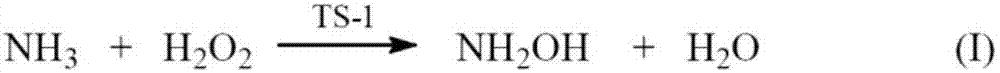

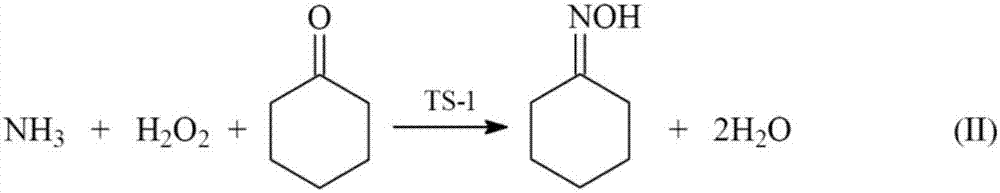

Method for preparing hydroxylamine or hydroxylamine salt from ketone, ammonia and hydrogen peroxide

ActiveCN104129764AImprove product qualityLow energy and material consumptionHydroxylamineHydroxylamineOrganic solvent

The invention relates to a method for preparing hydroxylamine salt / hydroxylamine from ketone, ammonia and hydrogen peroxide. The method has the following basic characteristics: ketone is used as a cyclic reaction medium, and an organic solvent insoluble or slightly soluble in water is used as a circulating solvent medium; the heterogeneous catalytic ammoximation technology and hydrolysis-extraction coupling technology are integrated to realize hydroxylamine and / or hydroxylamine salt preparation from basic raw materials of ammonia, hydrogen peroxide and inorganic acid.

Owner:XIANGTAN UNIV

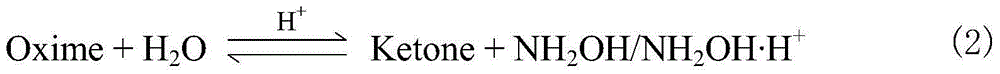

Method for preparing N-hydroxylamine hydrochloride by hydrolyzing N-nitromethane

The invention relates to a method for preparing N-hydroxylamine hydrochloride by hydrolyzing N-nitromethane. The method adopts N-nitrite as an isotope raw material to react with a methylating agent so as to obtain the N-nitromethane, and the N-nitromethan is hydrolyzed, condensed, crystallized and filtered to obtain the N-hydroxylamine hydrochloride. Compared with the prior art, the invention has the advantages of reasonable and simple technology, easily obtained raw materials, high isotope conversion rate, product purity, abundance and yield, and the like, can prepare a great amount of N-hydroxylamine hydrochloride with high purity and high abundance and is suitable for mass production.

Owner:SHANGHAI RES INST OF CHEM IND

Process for preparing hydroxylamine hydrochloride by adopting oxime acidolysis method

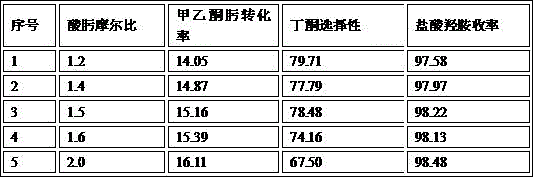

InactiveCN107522181AIncrease profitReduce manufacturing costOrganic compound preparationHydroxy compound preparationAlcoholHydroxylamine Hydrochloride

The invention belongs to the technical field of hydroxylamine hydrochloride, and discloses a process for preparing hydroxylamine hydrochloride by adopting an oxime acidolysis method. The method comprises the following steps: a) a raw material cache configuration process; b) an acidolysis reaction process; c) a ketoxime rectification process; d) a dehydration and drying process; e) an alcohol recycling process; and f) an acetaldehyde oximation process. By adopting the process, the process route and technical parameters of hydroxylamine hydrochloride production by methyl ethyl ketone acidolysis are optimized, a pervaporation coupling technology is applied, the product yield and quality can be improved, further improvement of the industrial technology is promoted, related industries can be driven to develop, and resource reasonable utilization can be realized.

Owner:临沭县华盛化工有限公司

Method for producing hydroxylamine hydrochloride by using industrial tail gas absorption waste liquid

The present invention relates to a method for producing hydroxylamine hydrochloride by using industrial tail gas absorption waste liquid, and belongs to the technical field of hydroxylamine hydrochloride production. The method comprises: decolorizing industrial tail gas absorption waste liquid with urea; adding hydrochloric acid and nitromethane to the decolorized industrial tail gas absorption waste liquid, and carrying out a hydrolysis reaction under a heating reflux state; and carrying out concentration and post-treatment on the hydrolyzed liquid so as to obtain the hydroxylamine hydrochloride. According to the present invention, the industrial tail gas absorption waste liquid is completely utilized, the industrial water consumption is reduced, the cost is saved, and advantages of energy saving and environmental protection are provided.

Owner:SHANDONG BAOYUAN CHEM

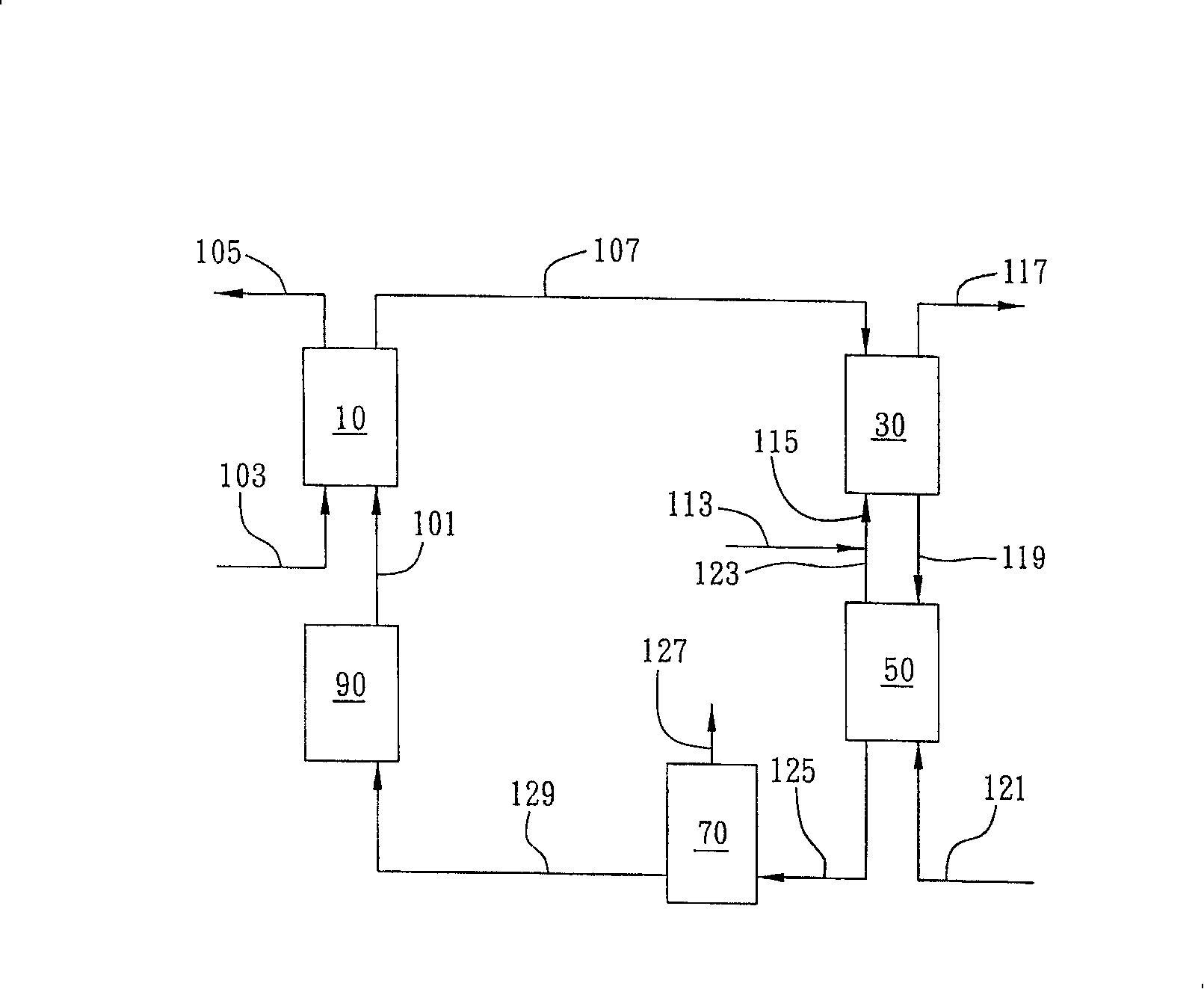

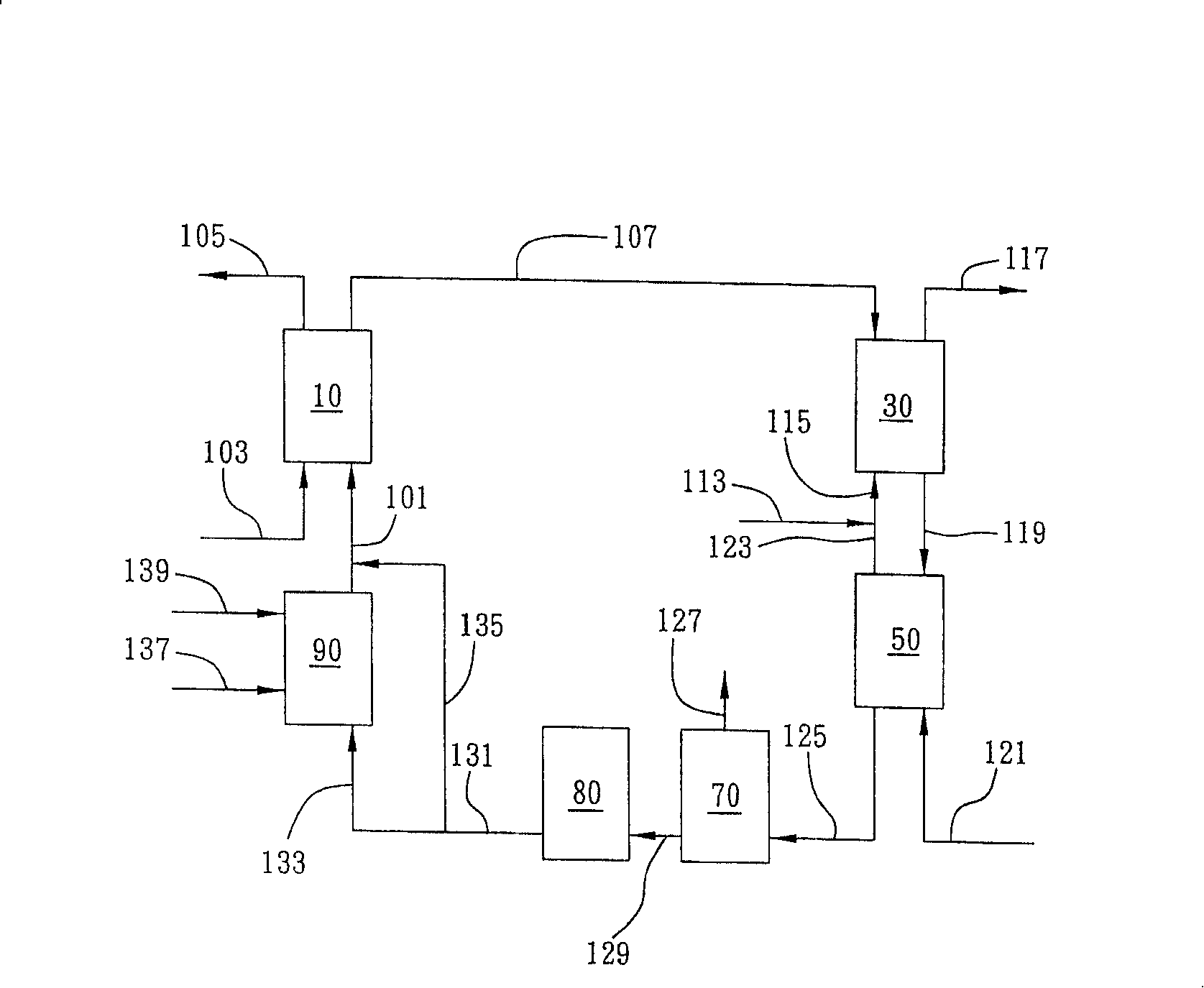

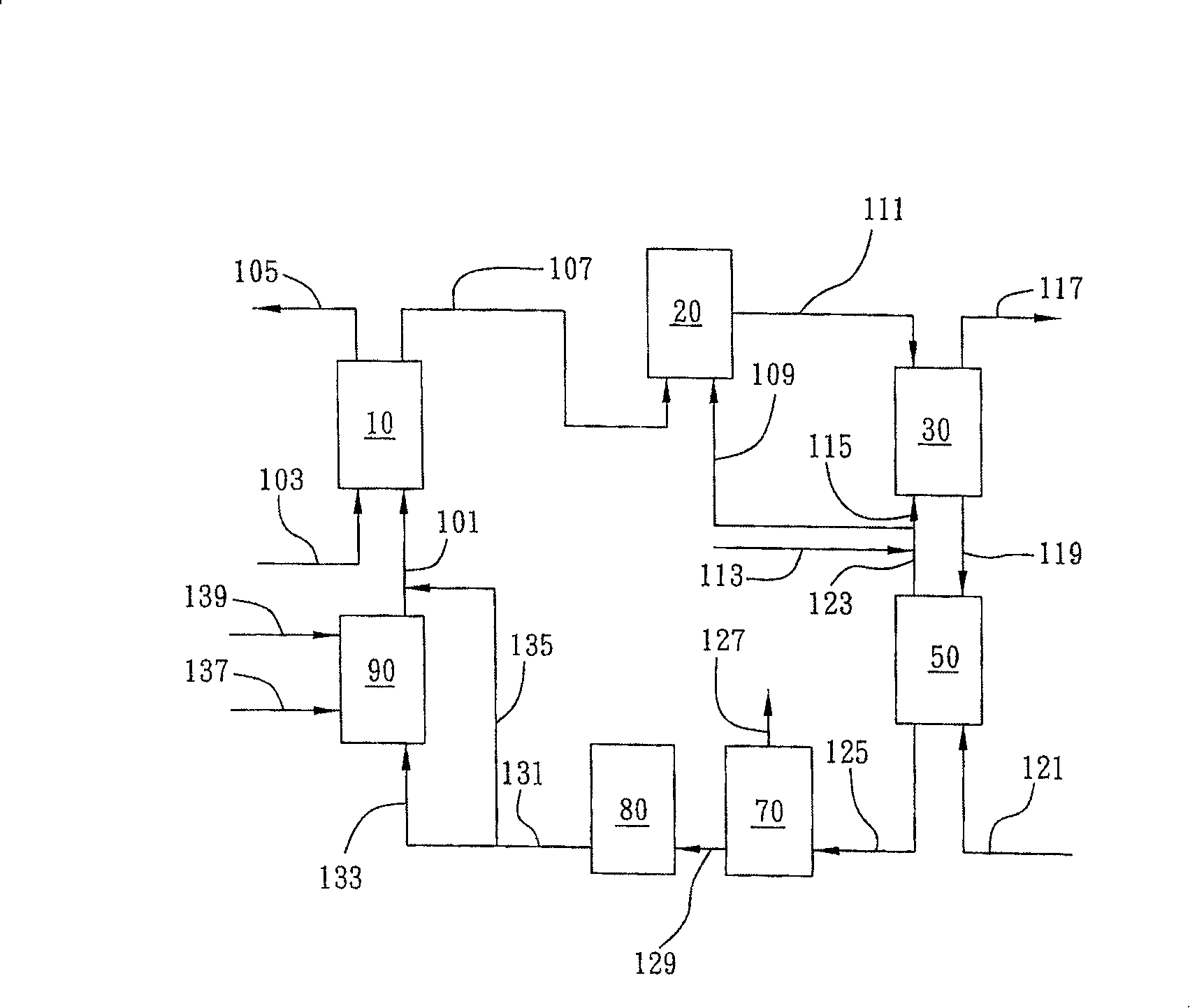

Hydroxylamine-oximation circulatoing system

ActiveCN101224880AReduce loss ratioReduce the ratioHydroxylamineOximes preparationHigh concentrationHydroxylamine

The invention provides a hydroxylamine-oximation circulating system, which includes: (a)a hydroxylamine reaction zone; (b) an oximation reaction zone; (c) a decontamination area; and (d) a regulation area with a nitric acid absorber; only part of the inorganic treatment fluid used by the reaction system enters the nitric acid absorber in the regulation area to supplement the nitrate ion, and is mixed with the residual inorganic treatment fluid after the composition is adjusted, so the loss proportion of the hydroxylamine by the decomposition in the inorganic treatment fluid can be reduced. Furthermore, the decontamination area of this system can effectively remove the high boiling point organic pollutant in the inorganic treatment fluid, thus avoiding the catalyst needed by the hydroxylamine reaction from being poisoned, reducing the activity of the catalyst and the selectivity of the hydroxylamine reaction, and being more beneficial to the production of high concentration hydroxylamine.

Owner:CHINA PETROCHEM DEVMENT

Method for preparing hydroxylamine hydrochloride

The invention provides a method for preparing hydroxylamine hydrochloride, and specifically relates to a method for preparing hydroxylamine hydrochloride from hydrogen peroxide and ammonium chloride. The method comprises the following steps: catalyzing hydrogen peroxide, free ammonia and acetone or butanone to synthesize ketoxime first, and then enabling the ketoxime to react with ammonium chloride under a negative pressure to generate hydroxylamine hydrochloride, free ammonia, acetone or butanone, wherein the acetone or butanone and the free ammonia are recycled for reuse. The invention solves the problems of high raw material cost and more byproducts for preparation of hydroxylamine hydrochloride in the prior art; meanwhile, low-value ammonium chloride is used for preparing hydroxylamine hydrochloride to ensure that the cost is low, and the sustainable development of the soda industry can be promoted.

Owner:ZHENGZHOU UNIV

Method for preparing free hydroxylamine

ActiveCN103193212AReduce pollutionMild reaction conditionsHydroxylamineHydroxylamineHydroxylamine Hydrochloride

The invention discloses a method for preparing free hydroxylamine. The method is characterized by comprising the steps of mixing hydrogen peroxide and water solution of ammonia and tertiary butanol under the catalysis effect of a titanium-silicon molecular sieve, and then synthetizing free hydroxylamine solution of which the mass concentration is 0.15-10% by one step, wherein the weight ratio of the titanium-silicon molecular sieve to the tertiary butanol water solution to the ammonia to the hydrogen peroxide is 1 to (20-170) to (6-600) to (3-10). Compared with the prior art, the method has the advantages of mild reaction condition, high hydroxylamine yield, and simple reaction process; hydroxyl ammonium salt is not formed; the method is friendly to the environment and easy to achieve large-scale industrial production; the pollution to the environment is reduced; and green chemical development is facilitated.

Owner:EAST CHINA NORMAL UNIV

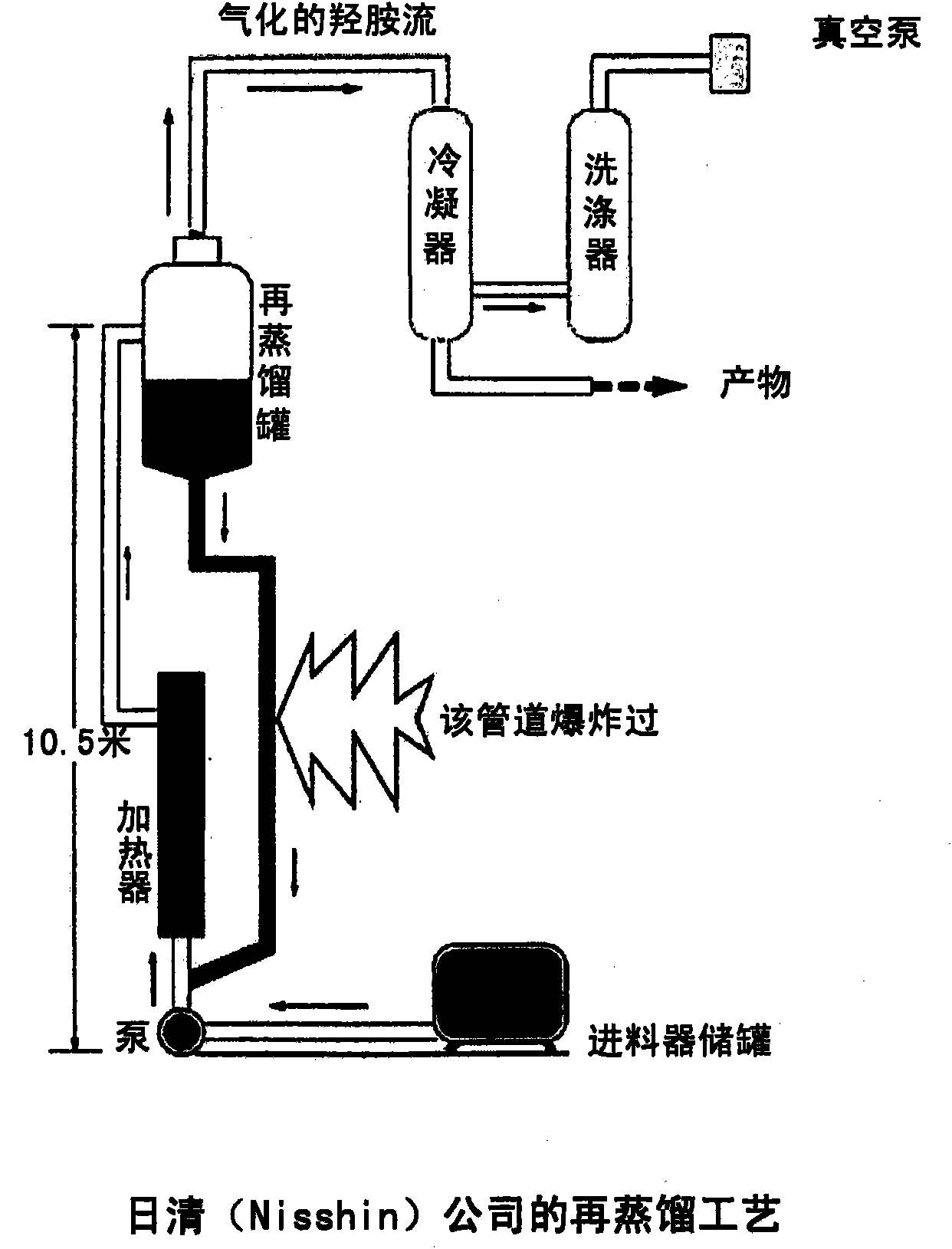

Process for producing hydroxylamine

InactiveUS7491846B2Safely and efficiently producedHigh yieldOrganic chemistryHydroxylamineHigh concentrationHydroxylamine

It is an object of the present invention to provide a process for producing a hydroxylamine by reacting a salt of hydroxylamine with an alkali compound, where the yield reduction due to formation of a complex between the produced hydroxylamine and a salt produced as a by-product or adsorption of the hydroxylamine to the by-product salt is decreased, and a high-concentration and high-purity hydroxylamine is safely produced at a high yield.The process for producing a hydroxylamine of the present invention comprises a reaction step of reacting a salt of hydroxylamine with an alkali compound to obtain a hydroxylamine while keeping the reaction solution at a pH of 7 or more, a purification step of purifying the hydroxylamine by ion exchange, and a concentration step of concentrating the hydroxylamine by distillation at the column bottom.

Owner:SHOWA DENKO KK

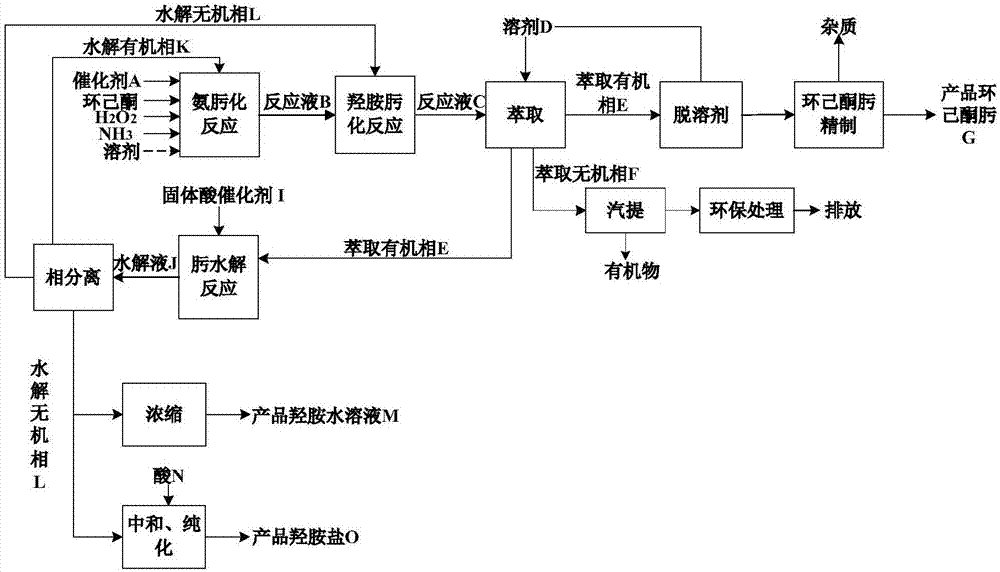

Joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime

ActiveCN107089924AIncrease the rate of hydrolysisLow costHydroxylamineOximes preparationHydroxylamineCyclohexanone oxime

The invention discloses a joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime. The material comprises the steps that reaction liquid obtained by raw materials through an ammoximation reaction and a hydrooximation reaction is extracted and separated to obtain an organic phase, the organic phase is prepared into product cyclohexanone-oxime, or part of the organic phase and part of product cyclohexanone-oxime are adopted as raw materials for an oxime hydrolysis reaction to be hydrolyzed, the organic phase in hydrolysis liquid is circulated to return to a oximation reactor, part of an inorganic phase in the hydrolysis liquid is adopted as a raw material to be circulated to return to a hydroxylamine oximation reactor, and the other part of the inorganic phase is prepared into a hydroxylamine aqueous solution and hydroxylammonium salt. The joint production technology of hydroxylamine, hydroxylammonium salt and cyclohexanone-oxime is simple in procedure, the requirement of the ammoximation reaction for the purity of the raw material cyclohexanone and the catalyst performance is lowered, a high quality cyclohexanone-oxime product without cyclohexanone is obtained, the simplification of the downstream caprolactam technology and the improvement of the product quality are benefited, and the hydroxylamine and hydroxylammonium salt product which have high additional value are obtained simultaneously.

Owner:河北美邦工程科技股份有限公司

Environment-friendly synthetic method for hydroxylamine salt

The invention belongs to the field of organic chemical industry and provides an environment-friendly synthetic method for hydroxylamine salt. Aliphatic ketone, ammonia and hydrogen peroxide are adopted as raw materials and catalyzed through a nano-pore skeleton bi-metal hybrid ammoximation catalyst to prepare ketoxime in an ammoximation mode, the ketoxime directly reacts with inorganic acid in a hydrolysis mode after being desolvated and deaminized to prepare the hydroxylamine salt, aliphatic ketone can be reused, the effective utilization rate of hydrogen peroxide is larger than or equal to 97%, and the product purity is larger than or equal to 99%. The environment-friendly synthetic method for the hydroxylamine salt is suitable for large-scale industrial production.

Owner:NANJING UNIV OF TECH +1

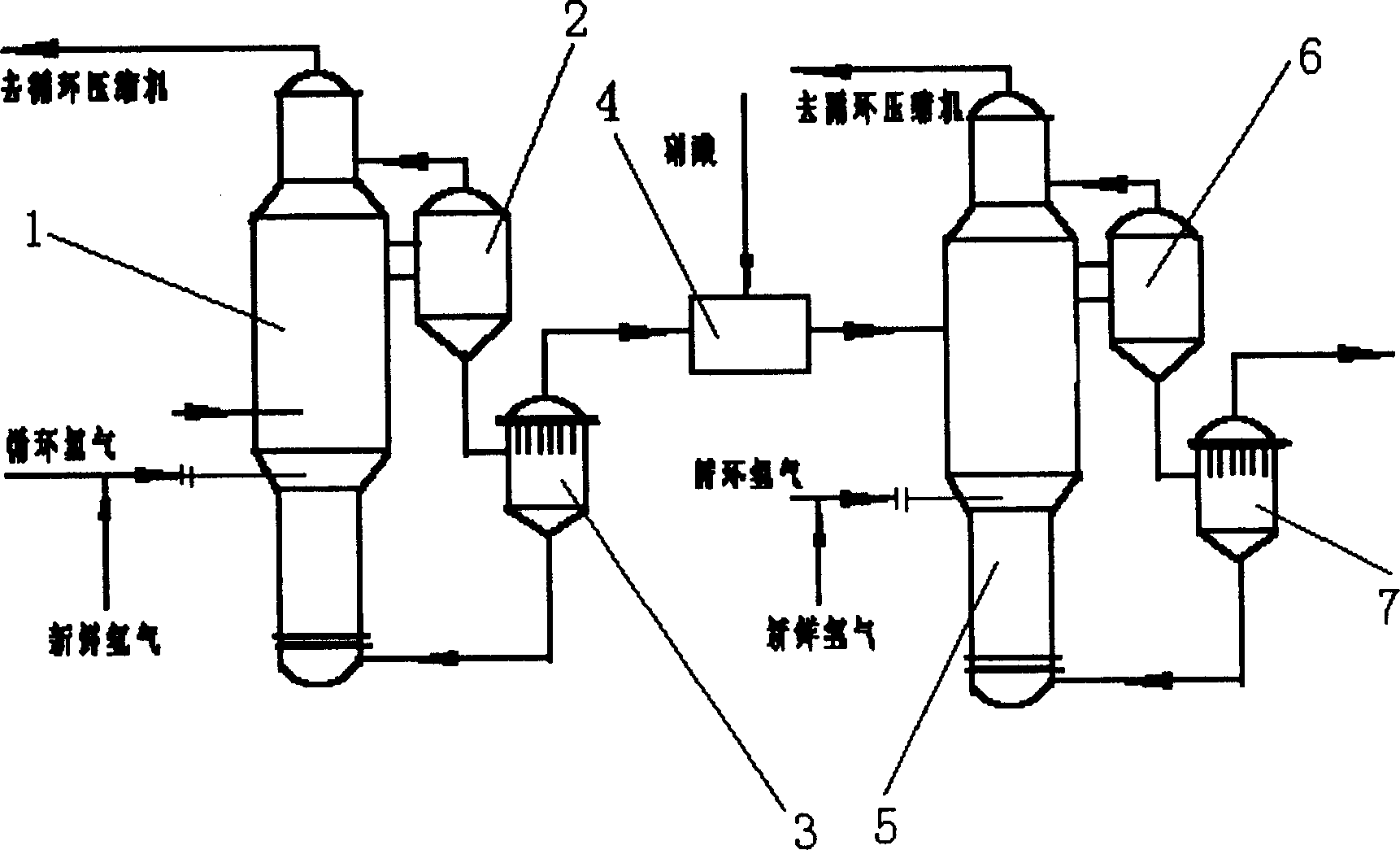

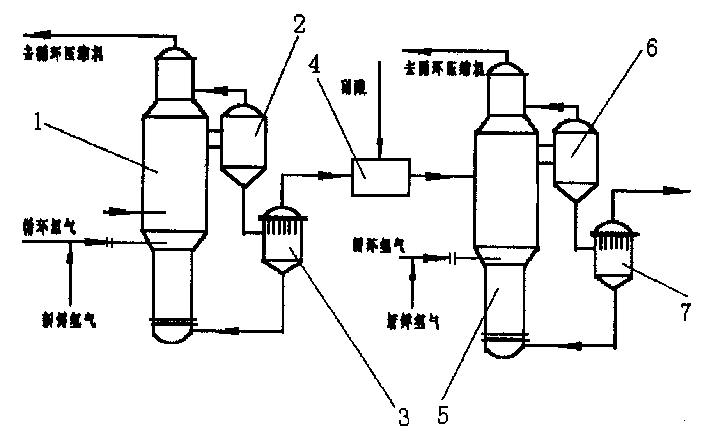

Method for prepn. of high concentration hydroxymaline in the prodn. process of hexanolactam

InactiveCN1418809AIncrease concentrationReduce circulationOrganic chemistryHydroxylamineHigh concentrationHydroxylamine

The method for preparing high-concentration hydroxylamine in the course of production of caprolactam adopts series-connection of two reactors, and adopts high superficial velocity, and adds a liquid-liquid quick mixer between two reactors to quicken micromixing of intermediate supplemental nitric acid and first reactor outlet inorganic liquid so as to obviously raise concentration of hydroxylamine and reduce circulation quantity of inorganic liquid, and can reduce operation cost, and can retain high reaction selectivity.

Owner:中国石油化工股份有限公司巴陵分公司 +1

Preparation method of hydroxylamine hydrochloride

InactiveCN109573967AHigh puritySimple process conditionsOrganic compound preparationHydroxylamineHydroxylamineHydroxylamine Hydrochloride

The invention relates to the field of preparation of hydroxylamine salt, in particular to a preparation method of hydroxylamine hydrochloride. The preparation method includes hydrolyzing a certain mass of diacetylmonoxime hydrochloride and water before crystallizing and drying, allowing generated butanone and impurities in raw materials to pass through an oil-water separator after condensation, and finally recycling the butanone and diacetylmonoxime materials through alkali wash by an alkali wash separating column and rectification by a rectifying column. The preparation method has the advantages that the diacetylmonoxime hydrochloride and the water are added into a mixer in advance for uniform mixing to facilitate thorough reaction between the diacetylmonoxime hydrochloride and the waterin later period, a catalyst is added during reaction to accelerate the reaction process, and other reaction products are recycled through tertiary condensation, the oil-water separator and the alkaliwash separating column, so that high efficiency and energy conservation are achieved, and the product yield is high.

Owner:江苏艾科维科技有限公司

Reaction-extraction coupling method for preparation of hydroxylamine salt / hydroxylamine

A oxime hydrolysis and solvent extraction coupling method for one step preparation of hydroxylamine salt / hydroxylamine. The invention is characterized in that oxime (ketoxime or aldoxime) is used as a raw material, and the hydrolysis reaction of oxime in an acidic solution and organic solvent extraction and separation are coupled, so that an extraction agent extracts the correspondingly generated ketone or aldehyde into an organic phase while the hydrolysis reaction is carried out, thus breaking the restrictions of oxime hydrolysis reaction chemical equilibrium under mild conditions, introducing the reaction to the direction for generation of hydroxylamine salt / hydroxylamine, and improving the reaction conversion rate and yield of hydroxylamine salt / hydroxylamine. The hydroxylamine salt preparation method provided by the invention has the characteristics of simple process and operation, mild reaction conditions, high conversion rate and selectivity, and low energy consumption, etc.

Owner:XIANGTAN UNIV

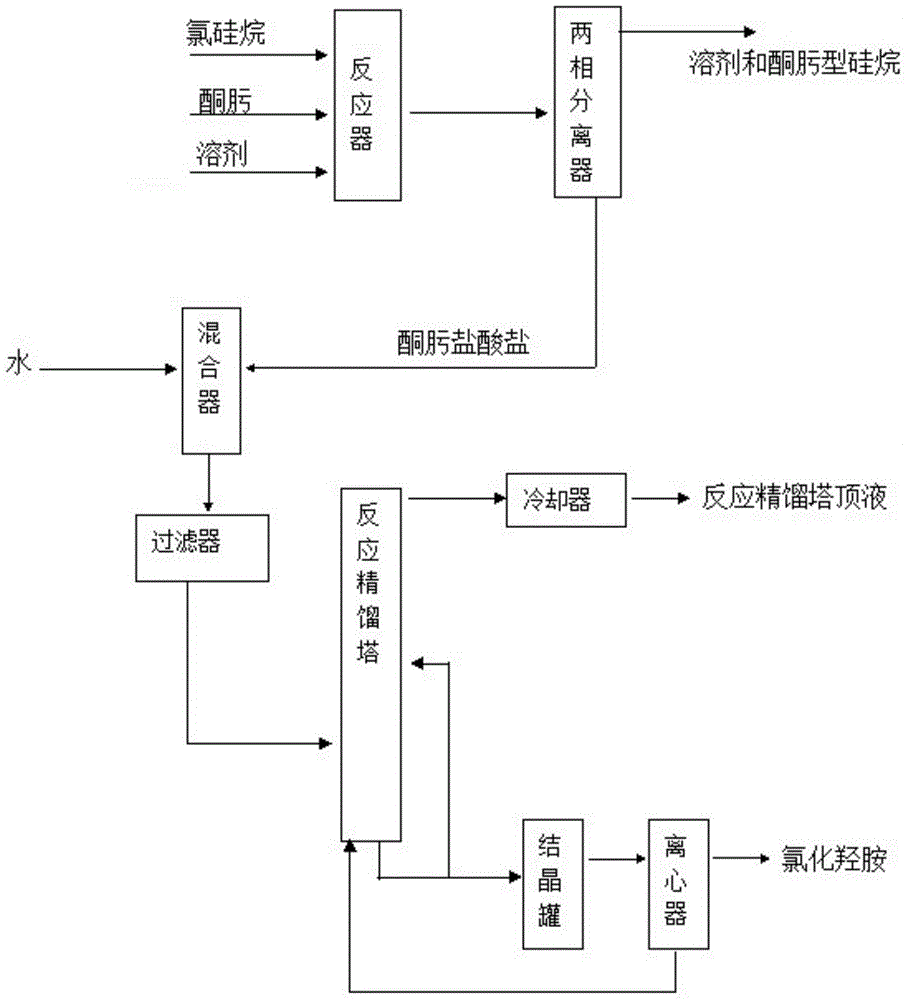

Processing method for ketoxime type silane byproduct ketoxime salt

ActiveCN105315139AReduce processing costsEmission reductionHydroxylamineCarbonyl compound preparation by hydrolysisChemistrySilanes

The invention discloses a processing method for a ketoxime type silane byproduct ketoxime salt. The method comprises the following steps: after settling separation and layering through a two-phase separator in the production process of ketoxime type silane, separating lower-layer ketoxime hydrochloride precipitate, then carrying out complete mixing with water in a mixer, carrying out filtering, allowing the filtered mixture to enter a reactive rectifying column and carrying out hydrolysis reaction so as to generate a mixture of hydroxylammonium chloride and ketone, discharging ketone from the top of the rectifying column, subjecting a part of a hydroxylammonium chloride solution produced from the bottom of the rectifying column to recycling and the other part of the solution to crystallization, filtering and drying so as to obtain a hydroxylammonium chloride product, and allowing obtained filtrate to return to the rectifying column for recycling. According to the invention, the byproduct ketoxime hydrochloride in the production process of ketoxime type silane is used as a raw material, so cost of treating ketoxime hydrochloride in the production process of ketoxime type silane is reduced, and acid cost of production of hydroxylammonium chloride is saved at the same time; and the use of the byproduct ketoxime hydrochloride in the production process of ketoxime type silane as the raw material is favorable for circulation of process water in a production system and greatly reduces wastewater discharge of production equipment.

Owner:江苏艾科维科技股份有限公司

Method for improving quality of oxammonium hydrochloride

The invention relates to a method for improving the quality of oxammonium hydrochloride, which belongs to preparation of hydroxylamine compounds, in particular to a method for improving the quality ofproducts in the process of preparing the oxammonium hydrochloride. The method is characterized in that: in the conventional oxammonium hydrochloride production technology process, at least one filtering device is added, so that oxammonium hydrochloride solution generated by acidifying and hydrolyzing nitromethane through hydrochloric acid is filtered by the filtering device and then enters a condensation working section. The invention provides a method, which has less investment and simple operation process, eliminates black spots in the products, ensures that products cannot turn yellow in the storage life and obviously improves the quality of the oxammonium hydrochloride. The products have no black spots and impurities and cannot change color after being stored for two years. The invention not only suitable for process improvement on preparing the oxammonium hydrochloride by acidifying and hydrolyzing the nitromethane through the hydrochloric acid, but also suitable for purifying industrial oxammonium hydrochloride products the quality index of which do not reach the reagent level; the industrial oxammonium hydrochloride products are dissolved, filtered and recrystallized according to the conventional recrystallization process to reach the quality standard of the reagent level oxammonium hydrochloride products.

Owner:SHANDONG XINGHUI CHEM

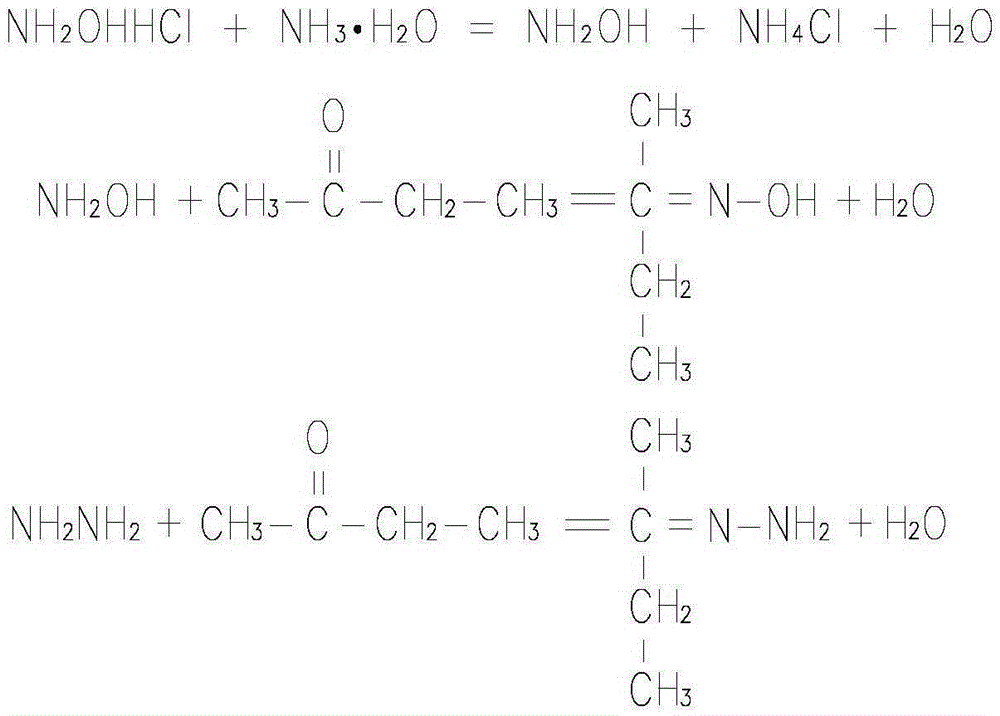

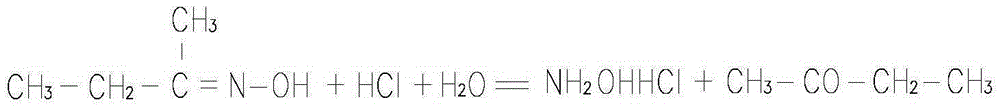

Recycling and treatment technology for hydroxylamine hydrochloride mother liquor

The invention relates to a recycling and treatment technology for hydroxylamine hydrochloride mother liquor, and belongs to the technical field of chemical engineering waste liquor treatment. The recycling and treatment technology includes the steps that the hydroxylamine hydrochloride mother liquor, ketone and water are added into an oximation reaction kettle, ammonium hydroxide is dropwise added to conduct an oximation reaction, oxime, hydrazone and ammonium salt are obtained, an organic phase containing oxime and hydrazone is obtained after standing and layering, acidification washing is performed on the organic phase through acid liquor, a hydrazonium salt solution is separated out after standing and layering, the hydrazonium salt solution and the ammonium salt are mixed and subjected to aftertreatment, a product obtained after separation is distilled to remove residual hydrazonium salt and ammonium salt in the product, oxime is obtained, hydrolysis and acidification are performed on oxime finally, and after concentration and purification, solid hydroxylamine salt is obtained. The recycling and treatment technology solves the problem that the hydroxylamine hydrochloride mother liquor is difficult to store and treat, the purpose of making waste profitable is achieved by converting and recycling the hydroxylamine hydrochloride mother liquor, no three waste discharge exists in the technological process, and the recycling and treatment technology has the advantages of environmental friendliness and safety.

Owner:SHANDONG XINGHUI CHEM

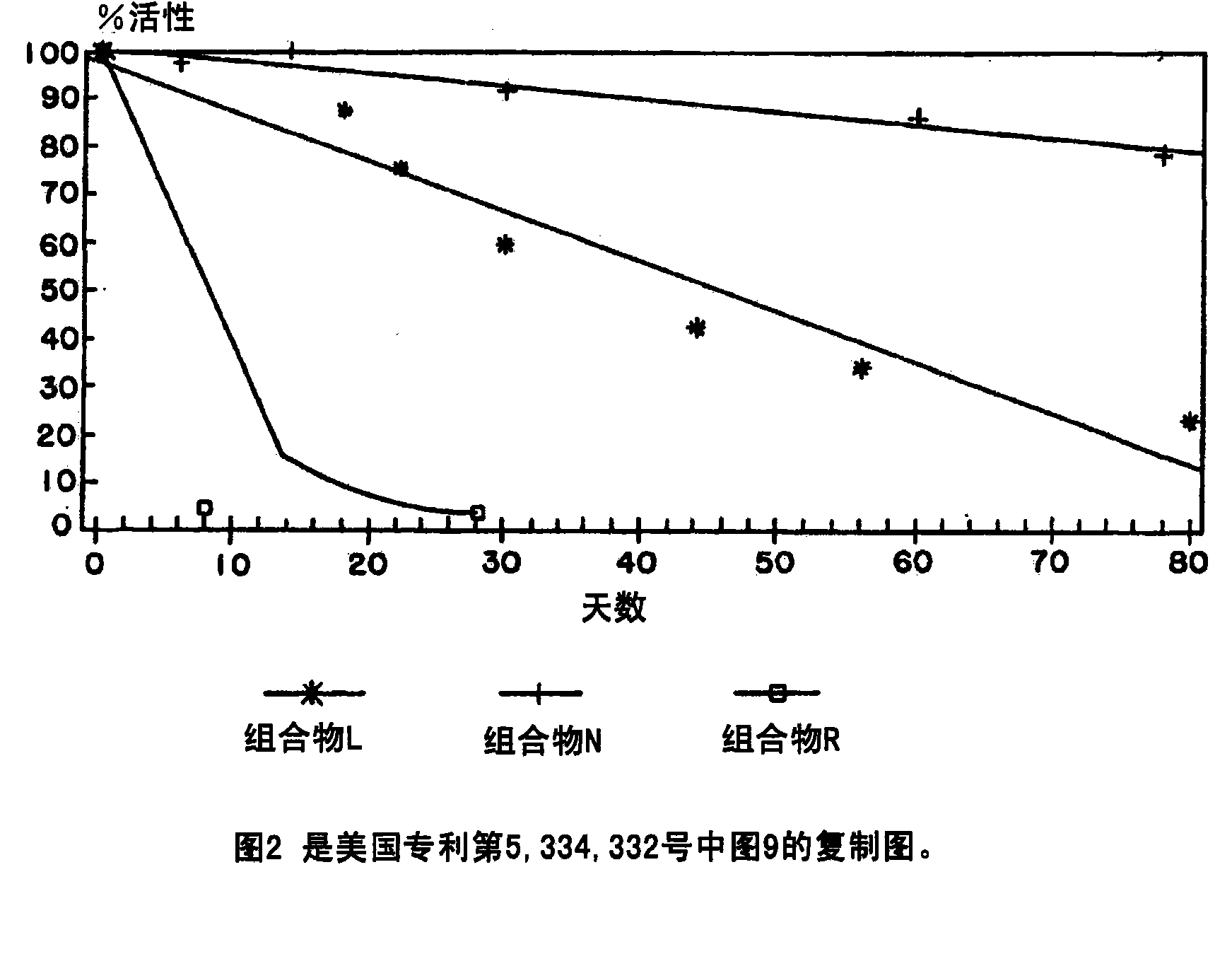

Stabilization of hydroxylamine containing solutions and method for their preparation

InactiveCN101910057AOrganic detergent compounding agentsDetergent mixture composition preparationDecompositionHydroxylamine compound

The invention relates to the use of amidoximes for prevention of or stabilization of hydroxylamine compounds against undesired decomposition.

Owner:EKC TECH

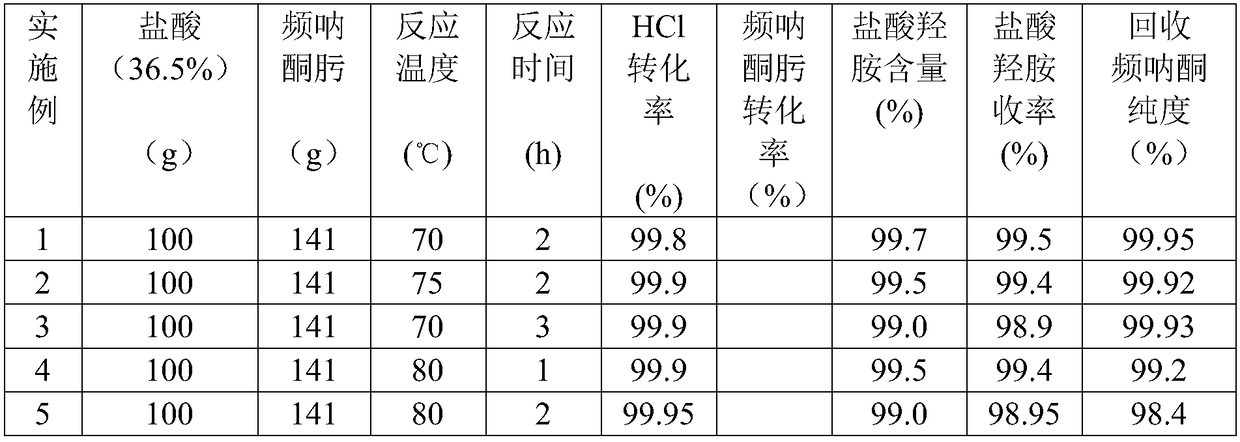

Hydroxylamine hydrochloride synthesis method

ActiveCN108584893ALess waste waterHigh yieldHydroxylamineSynthesis methodsHydroxylamine Hydrochloride

The invention discloses a hydroxylamine hydrochloride synthesis method which comprises the following steps: putting pinacolone oxime and a concentrated hydrochloric acid solution into a kettle in a mole ratio of 1.2-1.5 to 1, intensely stirring, heating to 70-80 DEG C, and carrying out hydrolysis; cooling, leaving to stand and layer, collecting an upper layer, namely pinacolone, and a lower layer,namely a hydroxylamine hydrochloride solution, carrying out vacuum distillation on a water layer, separating a white crystal in the kettle, adding ethanol, cooling, crystallizing, and filtering, so as to obtain hydroxylamine hydrochloride of high purity and high yield. By adopting the hydroxylamine hydrochloride synthesis method, side reactions in a hydrolysis process can be avoided, the purity of hydroxylamine hydrochloride can be improved, the yield of the hydroxylamine hydrochloride can be increased, in addition, the method has the characteristics of being simple in step, easy in raw material obtaining, small in wastewater amount, good in environmental-friendliness, and the like.

Owner:CHINA CATALYST HLDG CO LTD

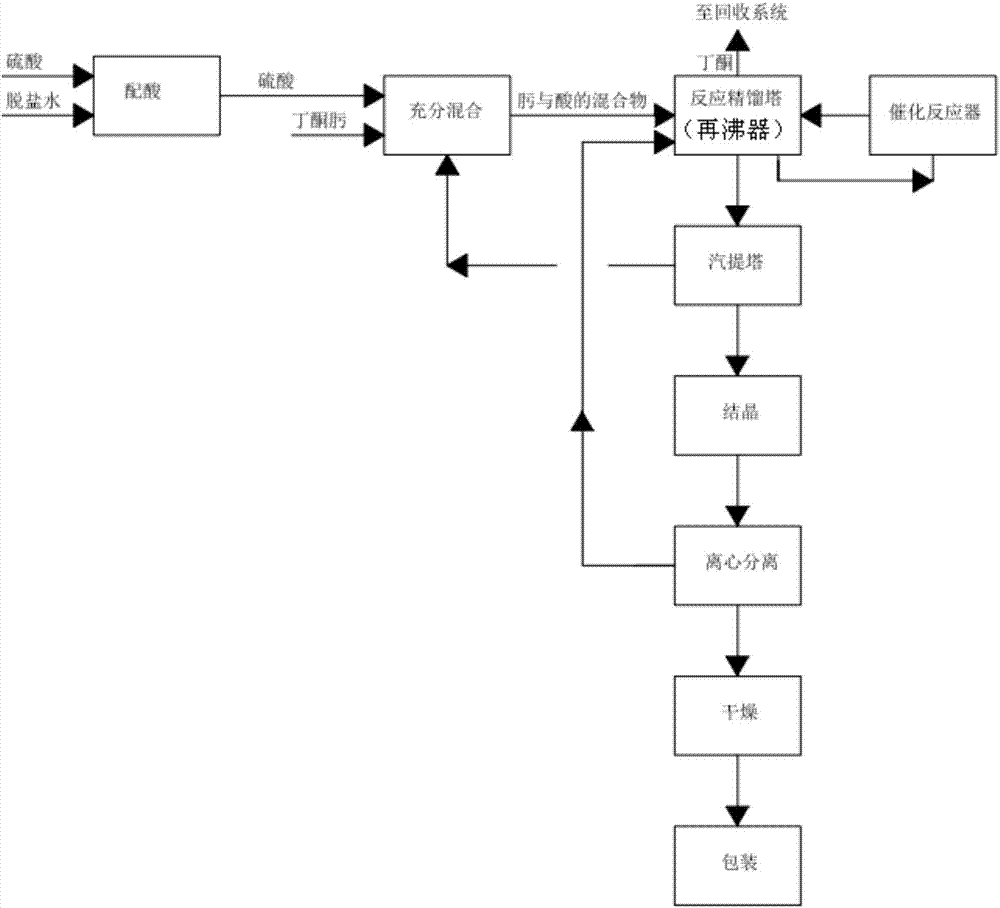

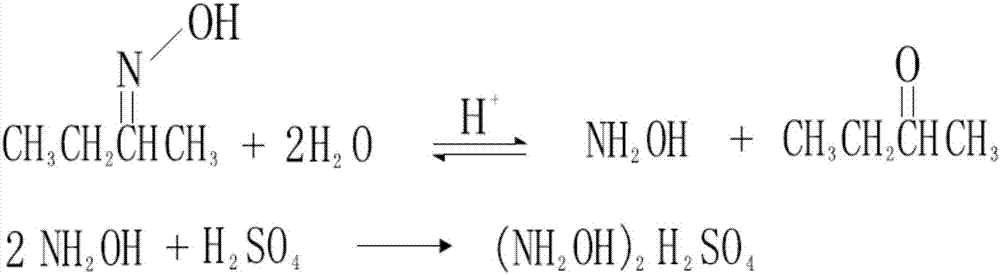

Preparation method of hydroxylamine sulphate

ActiveCN107539966AEasy to handleImprove qualityPhysical/chemical process catalystsHydroxylamineOrganic matterSolution flow

The invention discloses a preparation method of hydroxylamine sulphate. The preparation method comprises the following steps: 1), evenly mixing the raw materials of an acid solution and oxime, rectifying in a reaction rectifying column, obtaining a mixed solution of hydroxylamine sulphate and unreacted oxime and acid in a column reactor; 2), conveying part of the mixed solution obtained in the column reactor to a stripping tower through a pump, stripping to remove an organic matter and part of water, conveying part of the mixed solution to a reactor filled with a catalyst to have a further reaction; enabling a liquid material obtained in the reaction to return to the column reactor of the rectifying column, and enabling a gaseous phase to return to the upper middle part of the rectifying column; 3), crystalizing a concentrated hydroxylamine sulphate solution flowing out from a tower kettle of the stripping tower, separating the liquid and the solid, and drying to obtain hydroxylamine sulphate.

Owner:江苏艾科维科技股份有限公司

Method for generating hydroxylamine by cyclohexanone-oxime through hydrolyzing

ActiveCN107265420AAvoid separabilityAvoid environmental problemsHydroxylaminePhosphomolybdic acidHydroxylamine

The invention relates to a method for generating hydroxylamine by cyclohexanone-oxime through hydrolyzing. The method comprises the following steps of adding cyclohexanone-oxime, a catalyst and deionized water into a reactor, stirring, refluxing, condensing, and reacting for 0.5 to 2h at the temperature of 15 to 25 DEG C, so as to obtain the hydroxylamine; adding an methylbenzene extracting agent into the reactor, extracting at the reaction temperature, extracting an organic phase from a reaction liquid, and extracting a water phase, so as to obtain a product, namely a hydroxylamine water solution, wherein the catalyst is HZSM-5, silicotungstic acid, phosphotungstic acid or phosphomolybdic acid with a ratio of silicon to aluminum (silicon dioxide / aluminum oxide)) is 25 to 50. The method has the advantages that the reaction conditions are moderate, the operation is simple, the energy consumption is decreased, the environment-friendly and economical meanings are realized, and the environment-friendly catalyzing reaction process is performed.

Owner:HEBEI UNIV OF TECH

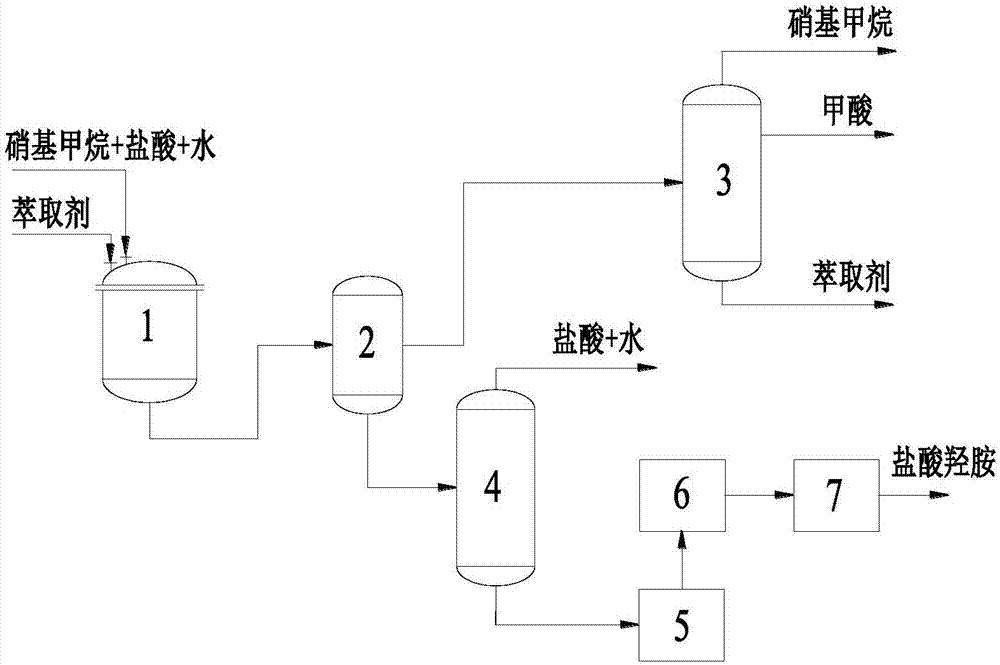

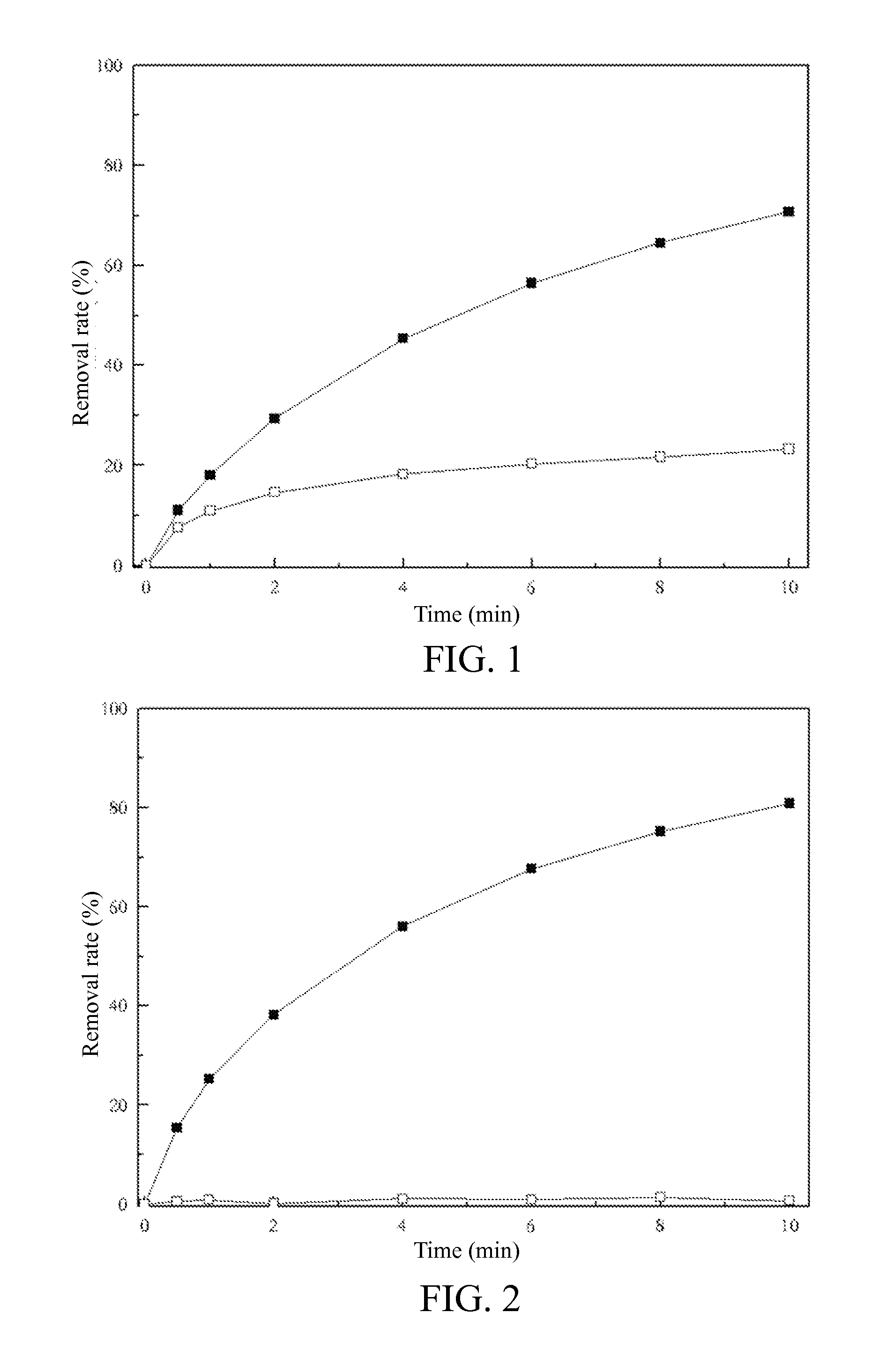

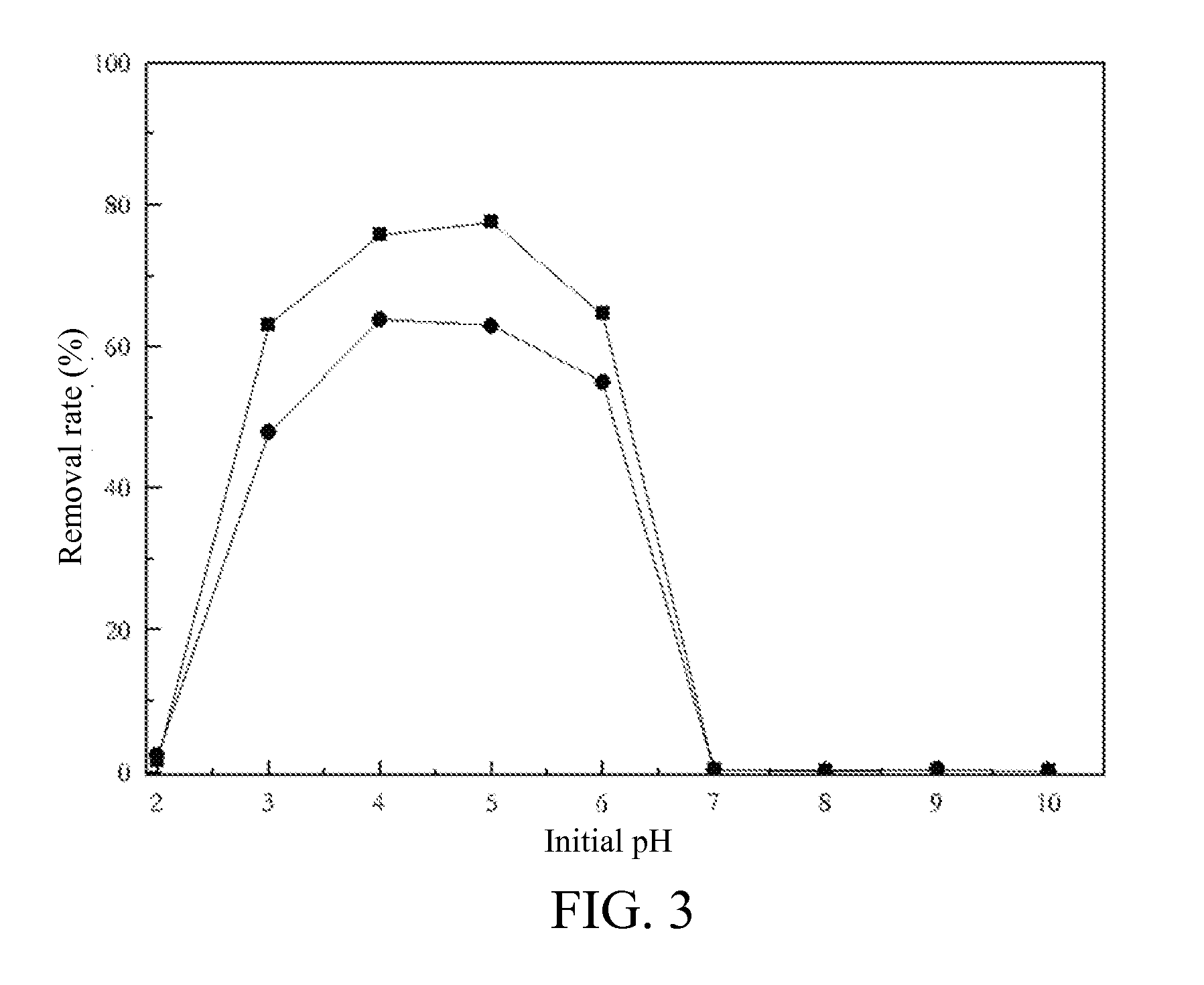

Method for synthesizing hydroxylamine hydrochloride from nitromethane and hydrochloric acid through phase transfer

ActiveCN106946235AHigh yieldReduce manufacturing costHydroxylamineReaction temperatureHydroxylamine Hydrochloride

The invention relates to a method for synthesizing hydroxylamine hydrochloride from nitromethane and hydrochloric acid through phase transfer. The method comprises the following steps: 1, carrying out a synthesis reaction: adding raw materials which are nitromethane, hydrochloric acid and water into a batch reactor with a stirrer, stirring and mixing the raw materials, adding an extractant, heating the reactor to a reaction temperature, and carrying out the reaction for a period of time to obtain a reaction product; and 2, separating the product: standing the reaction product to layer the reaction product, conveying the obtained water phase to a concentration tower, carrying out crystallizing, filtering, washing and drying on the obtained concentrate to obtain the hydroxylamine hydrochloride, recycling hydrochloric acid and water obtained in the concentration tower, conveying the obtained oil phase to a rectifying tower, and carrying out separation to obtain the extract and nitromethane which can be recycled and formic acid as a byproduct.

Owner:BEIJING CHEM REACTION ENG SCI & TECH CO LTD

Preparation method of hydroxylammonium chloride

InactiveCN105776160ALow costReduce the amount of wasteHydroxylamineHydroxylammonium chlorideMedicinal chemistry

The invention discloses a preparation method of hydroxylammonium chloride. The hydroxylammonium chloride is prepared by taking diacetylmonoxime hydrochloride and water as raw materials to react. The preparation method of the hydroxylammonium chloride has the advantages of simple process, moderate reaction conditions, low cost, and environmental friendless.

Owner:JUHUA GROUP TECH CENT +1

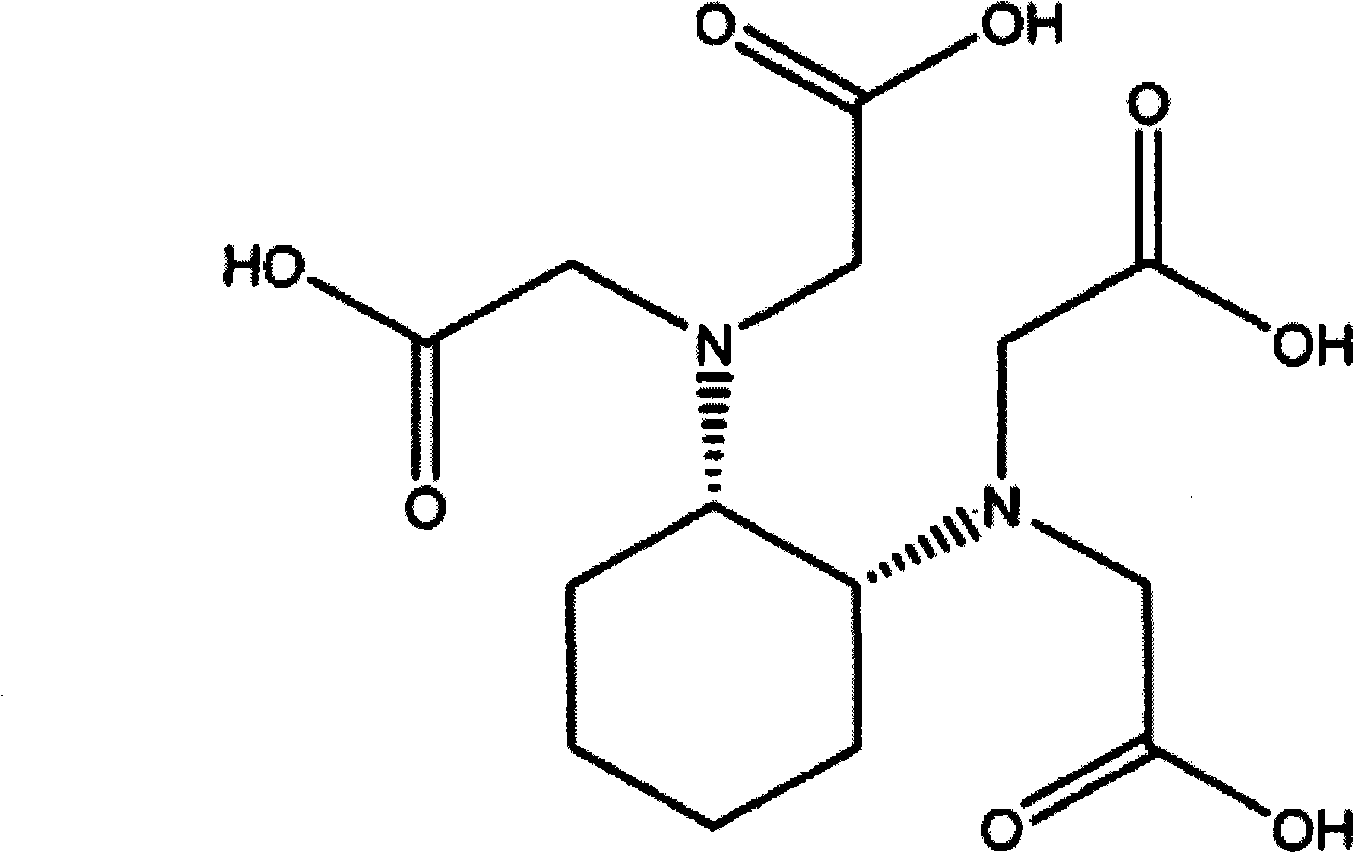

Fenton and Fenton-Like System Hardening Agent and Usage Thereof

InactiveUS20120305497A1Efficient use ofWide rangeWater treatment parameter controlOrganic chemistryHydrazine compoundSulfite salt

Fenton and Fenton-like system enhancing agent and the usage thereof are provided. It relates to a water treatment enhancer (enhancing agent) and the usage thereof. It widens water pH range of Fenton and Fenton-like system reaction. It reduces amount of Fe2+ required for Fenton reaction. It increases rate of Fenton-like reaction. The enhancing agent is selected from sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine hydrochloride, hydroxylamine perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, amino ethanolamine, hydroxylamine solution or N,N,N′,N′-tetrasubstituted p-phenylenediamine. The method of use of enhancing agent comprises the steps of: adding Fenton or Fenton-like system enhancing agent, an agent for enhancement and hydrogen peroxide into water subject to treatment; and mixing and allowing reaction. The enhancing agent can increase the rate of reaction for the water treatment and reduce the dosage of the agent for enhancement.

Owner:HARBIN INST OF TECH

Preparation of a high purity and high concentration hydroxylamine free base

Owner:SAN FU CHEM CO LTD

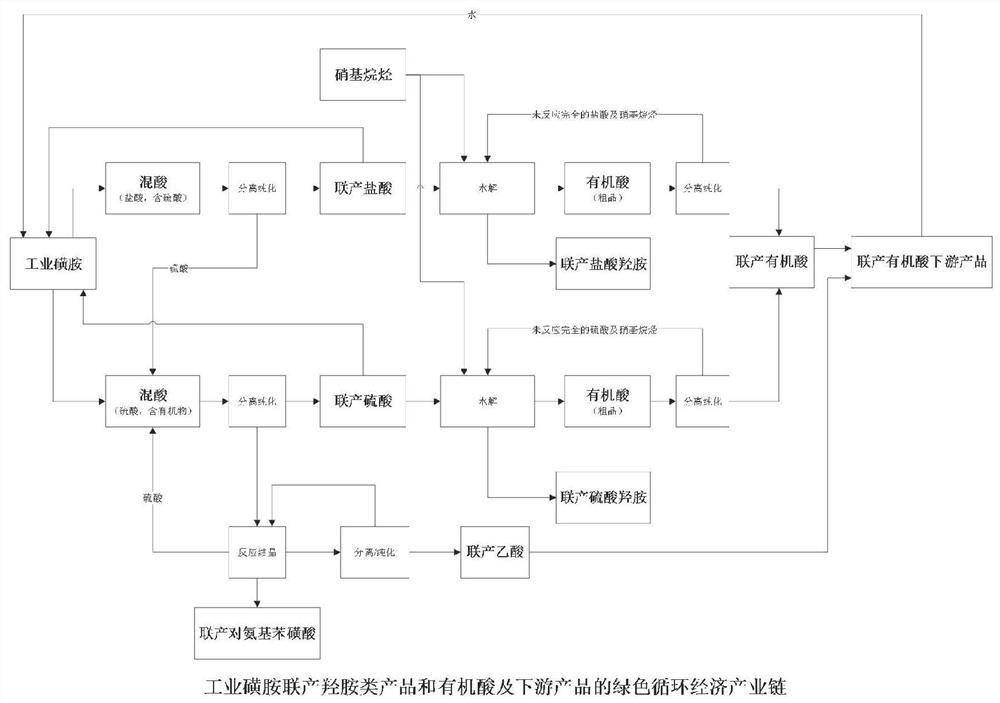

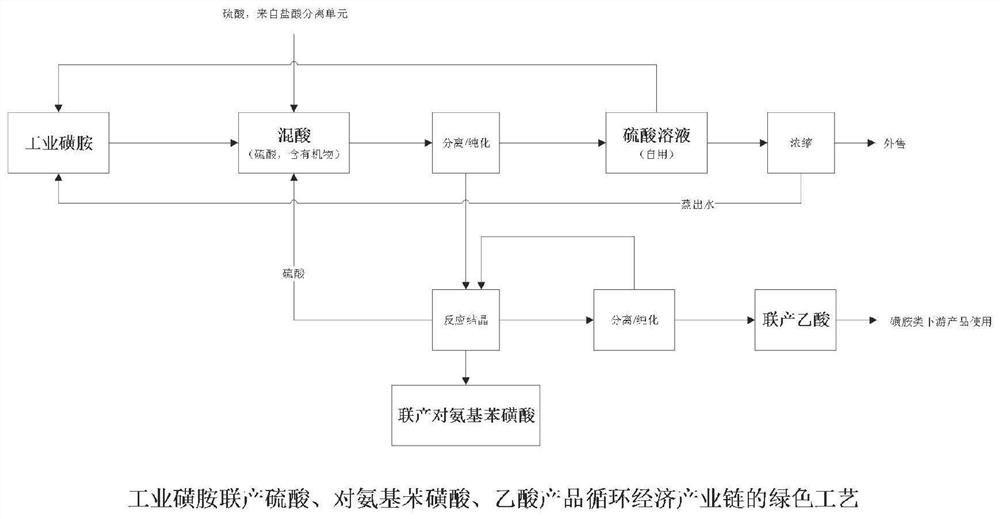

Green process of circular economy industry chain for co-production of industrial sulfanilamide and hydroxylamine products and organic acid downstream products

ActiveCN113321578ASolve the technical problems of separation and purificationHigh economic valueChlorine/hydrogen-chloride purificationOrganic compound preparationAlkaneNitroalkane

The invention provides a green process of a circular economy industry chain for co-production of industrial sulfanilamide and hydroxylamine products and organic acid downstream products. The process comprises the following steps that hydrochloric acid mixed acid is separated and purified to obtain sulfuric acid and co-produced hydrochloric acid, and the obtained sulfuric acid enters a sulfuric acid mixed acid treatment route; partial co-produced hydrochloric acid and nitroalkane are subjected to a hydrolysis reaction to obtain organic mixed acid and co-produced hydroxylamine hydrochloride, and the organic mixed acid is separated and purified to obtain co-produced organic acid; the sulfuric acid mixed acid is separated and purified to obtain organic matters and co-produced sulfuric acid; the organic matters are subjected to reactive crystallization to co-produce p-aminobenzene sulfonic acid; and partial co-production sulfuric acid and nitroalkane are subjected to a hydrolysis reaction to obtain a co-production hydroxylamine sulfate product and organic mixed acid, and the organic mixed acid is separated to obtain co-produced organic acid. According to the process, a green circular economy industrial chain of industrial sulfanilamide is realized, and meanwhile, a green circular economy industrial chain of hydroxylamine products and organic acid downstream products can be co-produced.

Owner:湖南吴赣药业有限公司

Popular searches

Carbonyl compound preparation Carbonyl compound separation/purification Photomechanical apparatus Semiconductor/solid-state device manufacturing Water treatment compounds Scale removal and water softening Sulfite preparation Magnesium/calcium/strontium/barium sulfides/polysulfides Hydrazine Water/sewage treatment by reduction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com