Preparation method of hydroxylamine sulphate

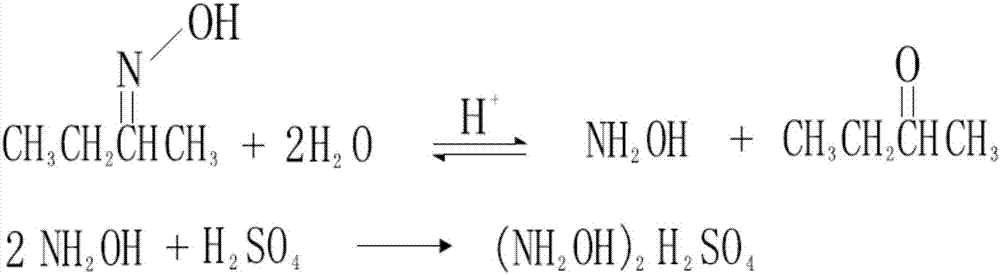

A technology of hydroxylamine sulfate and sulfuric acid, applied in hydroxylamine, chemical instruments and methods, hydrolysis to prepare carbonyl compounds, etc., can solve the problems of high moisture content, deterioration of quality indicators, damage to product quality, etc., and achieve the reduction of free acid content and moisture content. , No process wastewater discharge, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

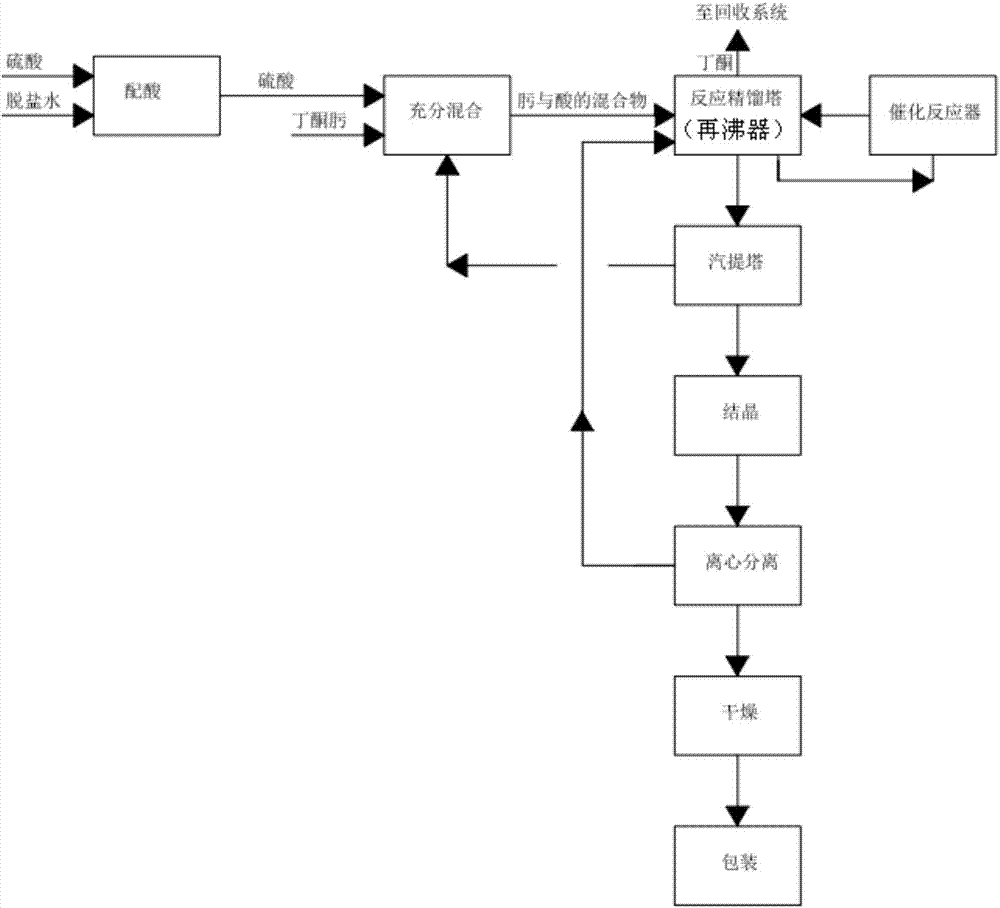

[0059] Embodiment 1, a kind of preparation method of hydroxylamine sulfate, carry out following steps successively:

[0060] 1), according to butanone oxime and sulfuric acid molar ratio is 1:0.5 (that is, C=NOH:H+=1:1), the flow rate of control purity is 99.9% butanone oxime 871kg / h, the flow rate of 28% sulfuric acid After fully mixing the above materials, add them to the middle of the reactive distillation tower for rectification, control the absolute pressure of the rectification tower to 30-32Kpa, the temperature of the distillation tower to 85-90°C, and control the top reflux ratio to 1.2. Extraction, the butanone obtained at the top of the kettle reclaims;

[0061] 2), the mixed solution obtained in the tower kettle is divided into the following two paths:

[0062] Use a pump to control the flow rate of 1500-1600kg / h to the stripper for stripping to remove organic matter and part of the water (thus achieving concentration); use a pump to control the flow rate of 15000k...

Embodiment 2

[0083] Embodiment 2, a kind of preparation method of hydroxylamine sulfate, carry out following steps successively:

[0084] 1), according to butanone oxime and sulfuric acid molar ratio is 1:0.45, the flow rate 871kg / h of the butanone oxime that control purity is 99.9%, the flow rate of 28% sulfuric acid is 1575kg / h, after above-mentioned material is fully mixed, Add it to the middle of the reactive distillation tower for rectification, control the absolute pressure of the rectification tower to 30-32Kpa, the temperature of the distillation tower to 85-90°C, control the reflux ratio at the top of the tower to 1.2 for extraction, and recover the butanone obtained at the top of the tank;

[0085] 2), the mixed solution obtained in the tower kettle is divided into the following two paths:

[0086] Use a pump to control the flow rate of 1500-1600kg / h to the stripper for stripping to remove organic matter and part of the water (thus achieving concentration); use a pump to control ...

Embodiment 3

[0099] Embodiment 3, a kind of preparation method of hydroxylamine sulfate, carry out following steps successively:

[0100]1), according to butanone oxime and sulfuric acid molar ratio is 1:0.5, the flow rate of control purity is 99.9% butanone oxime 871kg / h, the flow rate of 15% sulfuric acid is 3267kg / h, after the above-mentioned materials are fully mixed, Add it to the middle of the reactive distillation tower for rectification, control the absolute pressure of the rectification tower to 30-32Kpa, the temperature of the distillation tower to 85-90°C, control the reflux ratio at the top of the tower to 1.2 for extraction, and recover the butanone obtained at the top of the tank;

[0101] 2), the mixed solution obtained in the tower kettle is divided into the following two paths:

[0102] Use a pump to control the flow rate of 2800-3500kg / h to the stripper for stripping to remove organic matter and part of the water (thus achieving concentration); use a pump to control the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com