Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Low in free acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for concentrating and purifying titanium dioxide waste acid by using complex acid

InactiveCN103011272AHigh yieldReduce enrichment costsSulfur compoundsEnergy inputPhysical chemistryAcid concentration

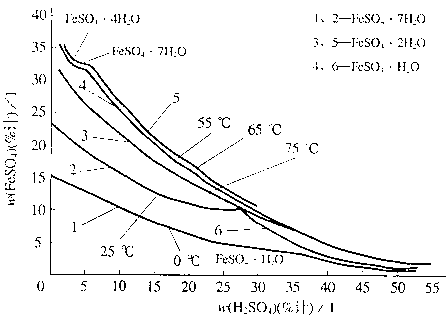

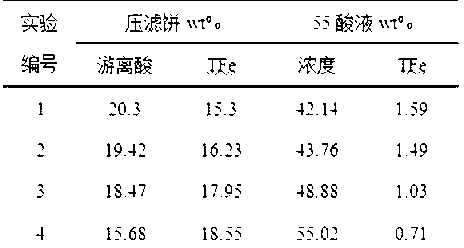

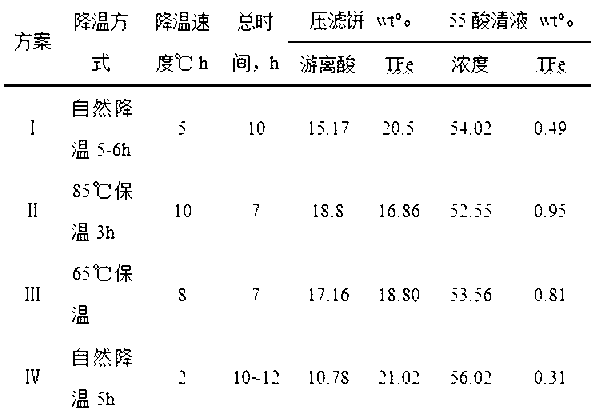

The invention discloses a method for concentrating and purifying titanium dioxide waste acid by using complex acid. The method comprises the following specific steps of: titanium recovery: primarily concentrating waste acid produced in a titanium dioxide production process by using waste heat of calcining tail gas of a ring kiln to achieve the mass concentration being 25-32%, and then recovering titanium; acid mixing: uniformly mixing the waste acid subjected to titanium recovery and concentrated sulfuric acid in an acid mixing tank according to a mass proportion of (1.2-4):1 to obtain mixed acid; and crystallization: carrying out gradient cooling, crystallizing, curing and filtering on the mixed acid gradually in the acid mixing tank, and when the temperature of the mixed acid is reduced to 60-65 DEG C, pumping the mixed acid into a filter press for solid-liquid separation to obtain concentrated sulfuric acid and ferrous dregs. The method disclosed by the invention has the advantage of changing the traditional method for concentrating the titanium dioxide waste acid by depending on natural gas, steam, fire coal hot gas and other heat sources, is free from consuming a large amount of energy sources and capable of reducing the cost in waste acid concentration, and is high in recovery rate of the waste acid.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Water-retaining organic fertilizer and preparation method thereof

ActiveCN102850122ASpecial effects enhancementBreakthrough increaseBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceMycoprotein

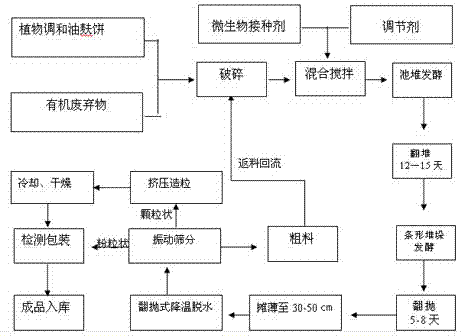

The invention provides a water-retaining organic fertilizer and a preparation method thereof, which belongs to the technical field of organic fertilizers. The method provided by the invention uses an edible vegetable blended oil bran cake as a main raw material for development of the water-retaining organic fertilizer, and the problems of existence of multiple harmful components caused by addition of chemical materials and single efficacy of products in traditional organic fertilizers are overcome. The water-retaining organic fertilizer is prepared from the edible vegetable blended oil bran cake, organic waste, a conditioning agent and a microbial inoculant. The preparation method comprises the following steps: crushing the edible vegetable blended oil bran cake and the organic waste; then mixing the crushed bran cake and organic waste with the conditioning agent and the microbial inoculant under stirring; and carrying out pool stacking fermentation, stripe-shaped stacking fermentation, screening and granulation so as to obtain the water-retaining organic fertilizer. According to the invention, because of usage of organic matter raw materials containing abundant mycoprotein, the organic fertilizer has a water-retaining function, and the problem of reduced output or poor output of crops caused by lack of water, no retention of water and fertility, no drought tolerance and loss of nutrients in agricultural production is overcome.

Owner:刘奋安

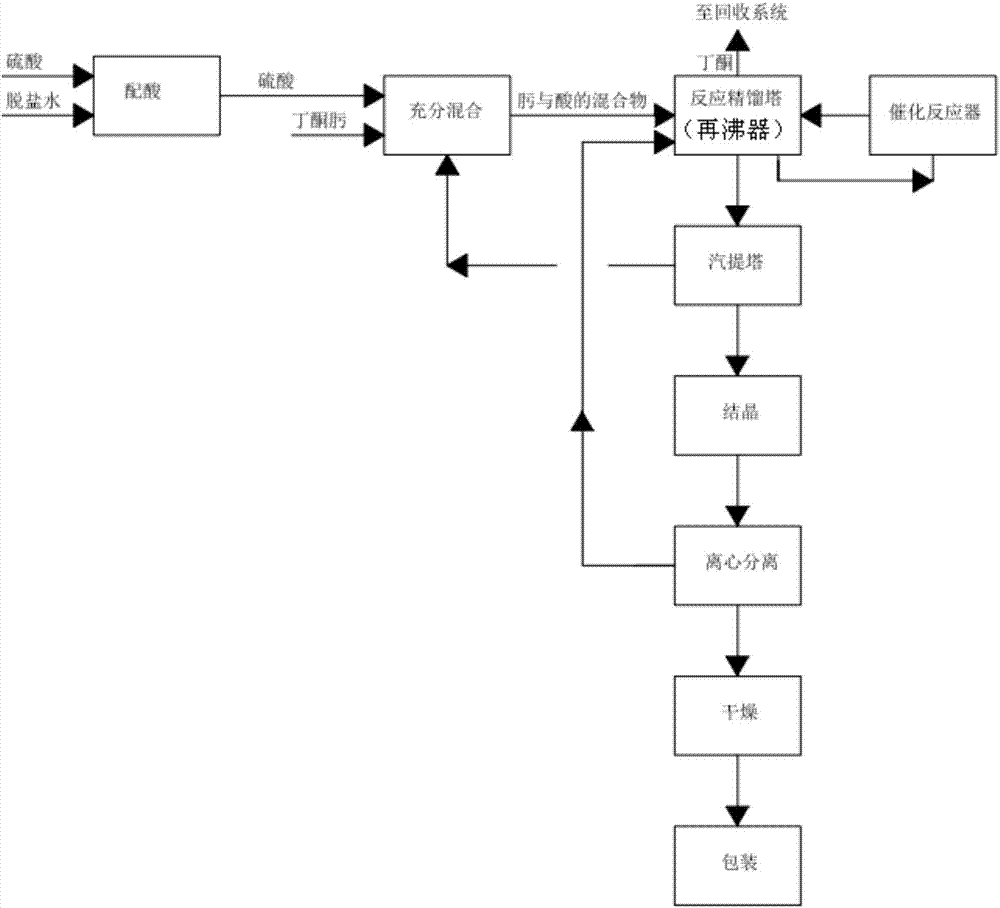

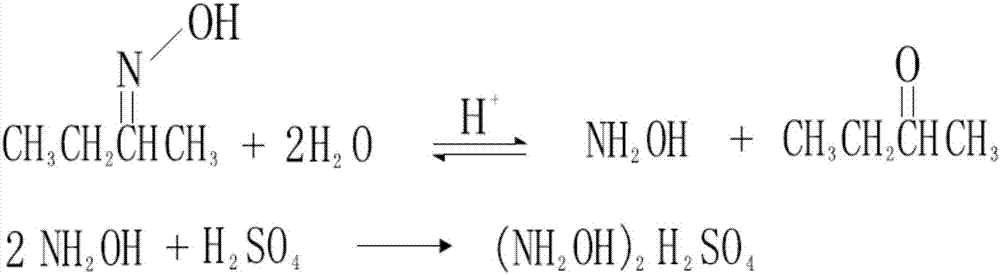

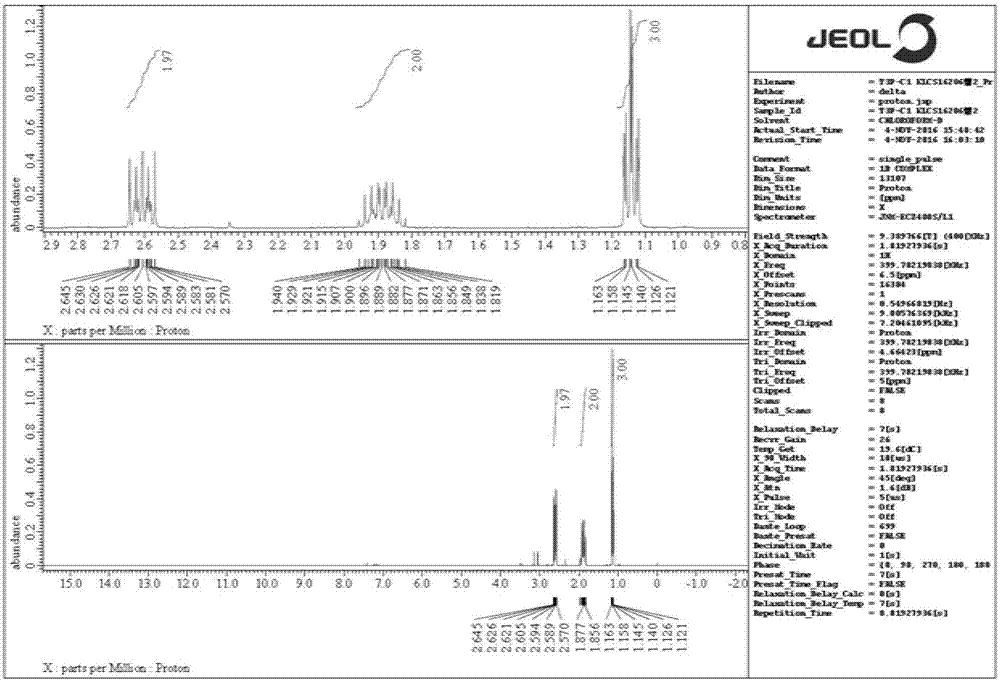

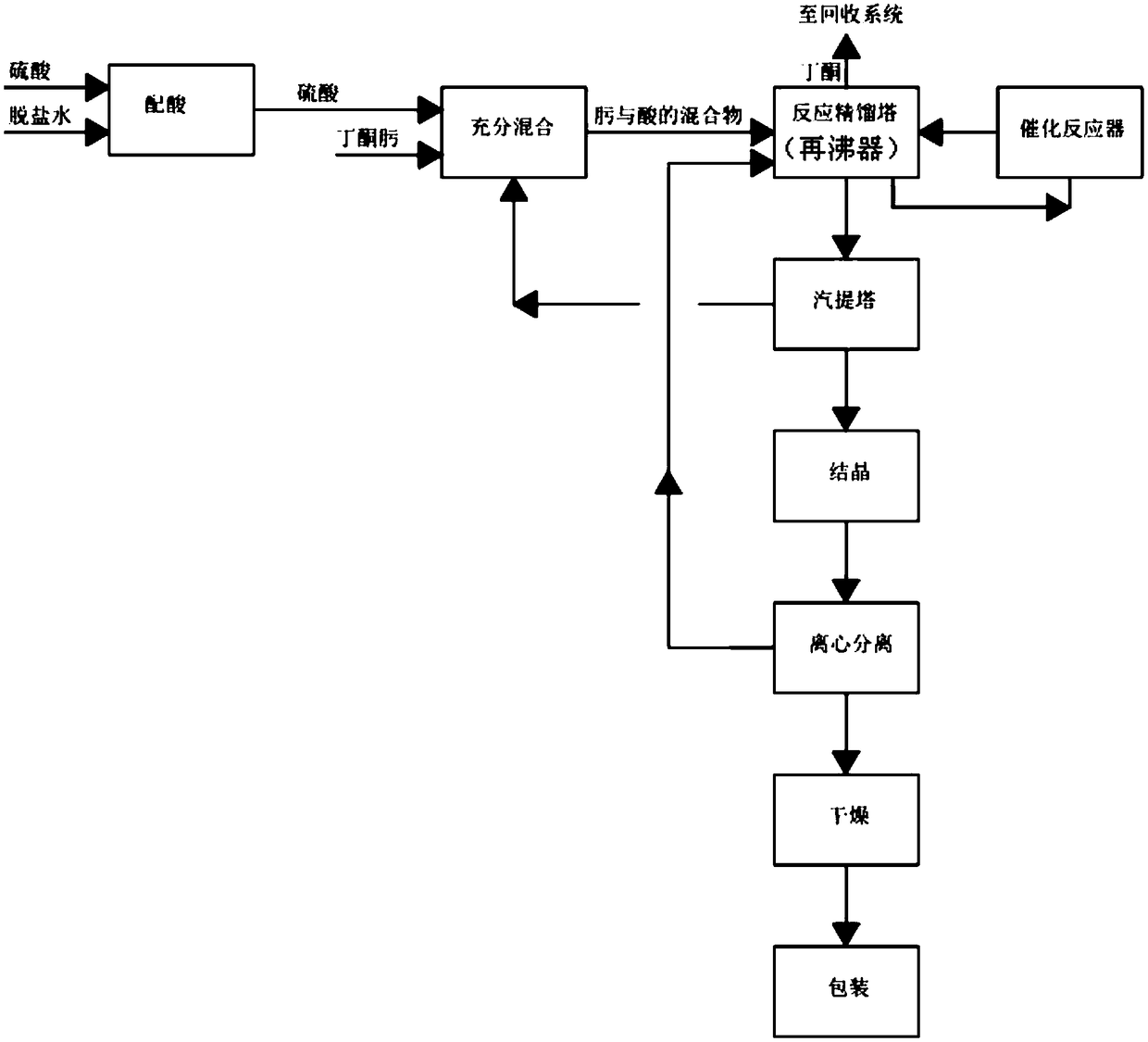

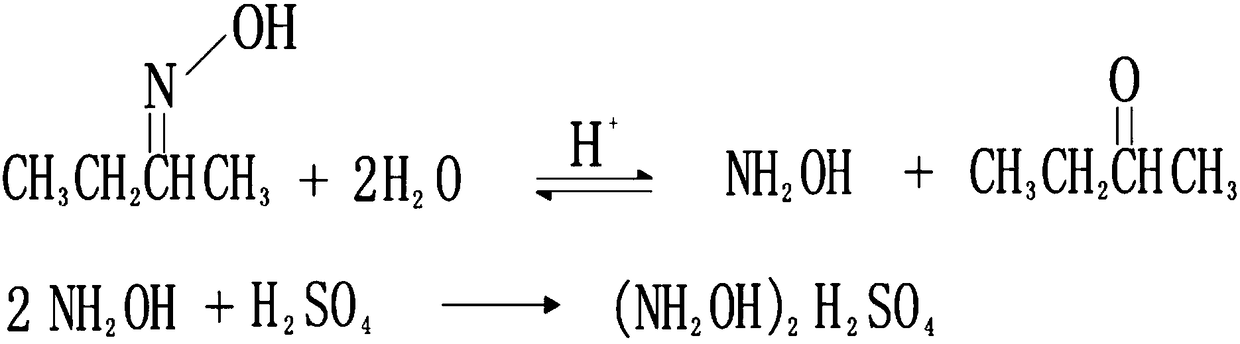

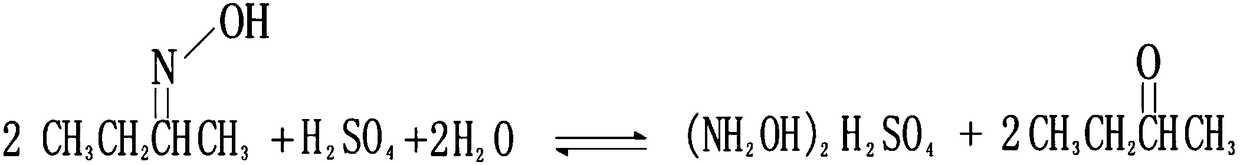

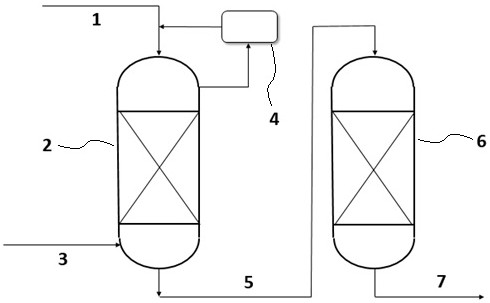

Preparation method of hydroxylamine sulphate

ActiveCN107539966AEasy to handleImprove qualityPhysical/chemical process catalystsHydroxylamineOrganic matterSolution flow

The invention discloses a preparation method of hydroxylamine sulphate. The preparation method comprises the following steps: 1), evenly mixing the raw materials of an acid solution and oxime, rectifying in a reaction rectifying column, obtaining a mixed solution of hydroxylamine sulphate and unreacted oxime and acid in a column reactor; 2), conveying part of the mixed solution obtained in the column reactor to a stripping tower through a pump, stripping to remove an organic matter and part of water, conveying part of the mixed solution to a reactor filled with a catalyst to have a further reaction; enabling a liquid material obtained in the reaction to return to the column reactor of the rectifying column, and enabling a gaseous phase to return to the upper middle part of the rectifying column; 3), crystalizing a concentrated hydroxylamine sulphate solution flowing out from a tower kettle of the stripping tower, separating the liquid and the solid, and drying to obtain hydroxylamine sulphate.

Owner:江苏艾科维科技股份有限公司

Preparation method of cyclic propyl phosphonic anhydride

ActiveCN107011384AHigh reaction yieldLow costGroup 5/15 element organic compoundsAcetic anhydrideOrganic synthesis

The invention belongs to the technical field of organic synthesis and particularly relates to a preparation method of cyclic propyl phosphonic anhydride. The method comprises the steps of preparing propyl pyrophosphate from propenylphosphonic acid and acetic anhydride as reactants; preparing propyl phosphonyl chloride from propenylphosphonic acid and thionyl chloride as reactants; carrying out further reaction on the propyl pyrophosphate and the propyl phosphonyl chloride to prepare the cyclic propyl phosphonic anhydride. According to the prepared cyclic propyl phosphonic anhydride, the reaction yield is high and the total yield can reach 68-72%, the cyclic propyl phosphonic anhydride is low in cost and high in purity, the titration purity is greater than 99.5%, the content of free acid is smaller than 100ppm, the polymer content is low, and use of a lithium battery additive can be met. The preparation method is simple, safe, environment-friendly, high in efficiency, cheap and available in raw materials, wide in market prospect and suitable for massive production.

Owner:VALIANT CO LTD

Matched curing agent for casting furan resin and preparing method thereof

The invention provides a matched curing agent for casting furan resin and a preparing method thereof. The method comprises: a, adding phenol into a reaction kettle, starting a stirrer, and adding sulfuric acid slowly to enable a material temperature in the reaction kettle to not exceed 60 DEG C; b, after the sulfuric acid is added, opening a steam valve, rising the temperature to 93-103 DEG C and timing and performing heat preservation; c, ending the heat preservation and cooling to 60 DEG C, and adding a fortifier and stirring; d, cooling to 50 DEG C and adding water; e, after the water adding is finished, adding a regulator and continuing to stir; f, cooling to 40 DEG C, sampling for inspection, and metering, packaging and putting into storage after the inspection is qualified. A phenolsulfonic acid curing agent generated by the preparing method can realize batch production, and usable time, hardening and strength of a sand mould all meet use requirements on site.

Owner:GANSU KOCEL CHEM

Zinc stearate sol low in free acid content and preparation method thereof

InactiveCN107253910AReduce contentPure ingredientsCosmetic preparationsNon-fibrous pulp additionChemistryFree acid

The invention discloses zinc stearate sol low in free acid content and a preparation method thereof. The zinc stearate sol is prepared by reaction under model temperature of krfft*2 DEG C. The zinc stearate sol comprises, by weight percentage, 86.7% of stearic acid emulsion and 13.3% of zinc oxide dispersion liquid, wherein the zinc oxide dispersion liquid comprises, by weight percentage, 4% of zinc oxide, 1% of dispersing agent, 0.1% of multifunctional catalyst, 0.1% of defoaming agent, 0.1% of environment-friendly sterilizing agent and 8% of deionized water. The preparation method has the advantages that the reaction is complete, the generation of three wastes is avoided, reaction byproducts are avoided, the prepared zinc stearate sol is low in free fatty acid content, pure in component and small in particle size, and the low viscosity of high-solid-content products is guaranteed; independent catalyst pollution is avoided, and low fatty acid residues are achieved; the conversion rate and fineness of zinc stearate are increased; the method is high in yield, minimum in energy consumption and simplified in process control, and the prepared zinc stearate sol is low in particle size distribution.

Owner:江苏三瑞生物技术有限公司

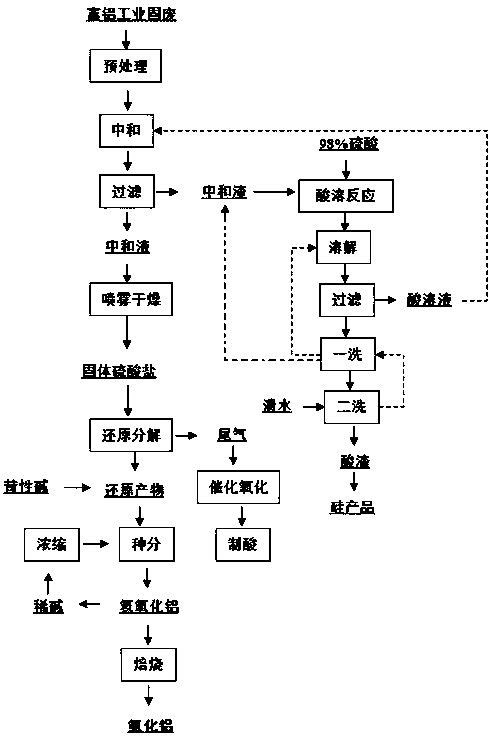

Method for producing aluminum oxide using industrial solid waste rich in aluminum oxide

ActiveCN109336147AWide adaptabilityHigh recovery rateAluminium compoundsSilicaMineral SourcesFiltration

The invention discloses a method for producing aluminum oxide using industrial solid waste rich in aluminum oxide, and belongs to the field of comprehensive utilization of mineral resources and metallurgy technology. The method comprises the steps of adding sulfuric acid to the industrial solid waste rich in aluminum oxide, and then performing acid dissolution, neutralization, filtration, drying,reduction, alkali dissolution, seed precipitation and calcination to produce aluminum oxide. By using the method, the comprehensive yield of aluminum oxide in the solid waste is high, the quality of the aluminum oxide product meets the requirements of lambda O-3 and above in metallurgical grade aluminum oxide standards, and the conversion rate of aluminum oxide is high; and the method can expand raw material sources and provide new ideas and technical support for aluminum oxide production.

Owner:KUNMING UNIV OF SCI & TECH +1

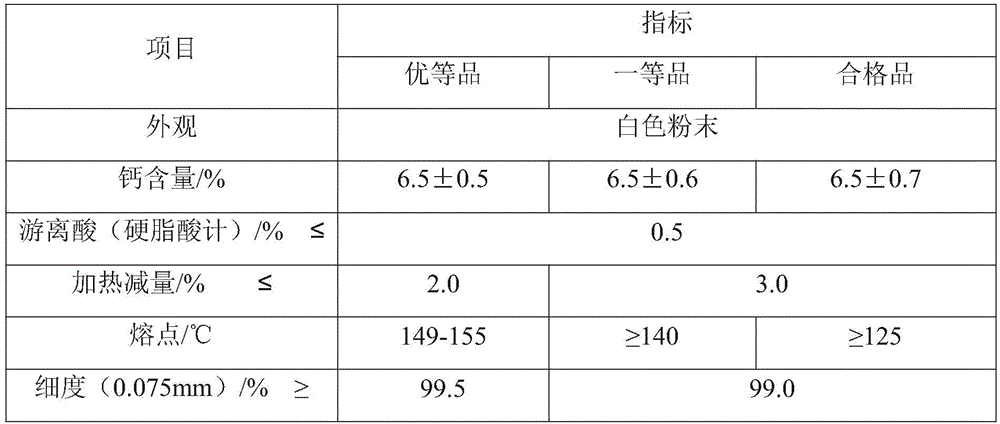

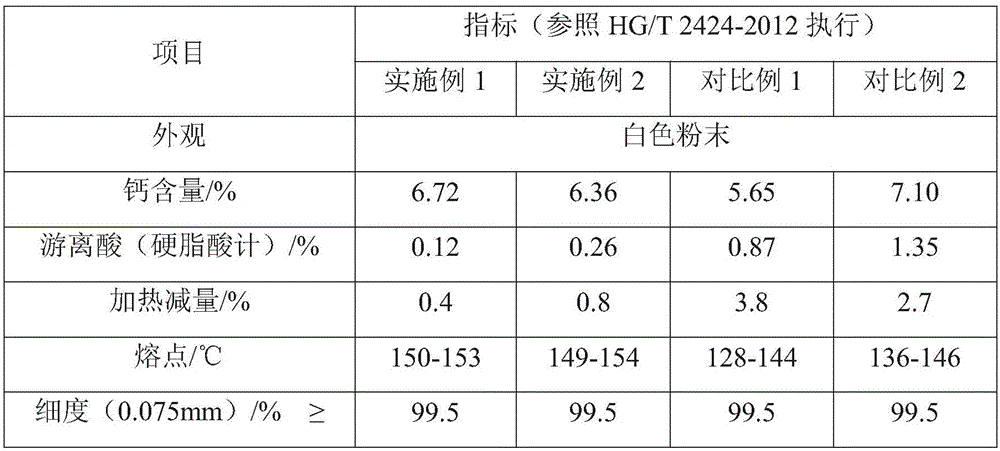

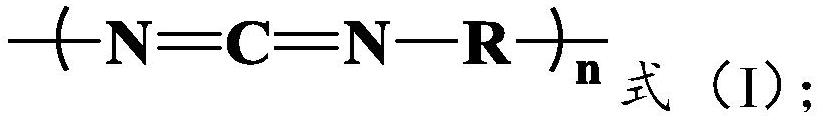

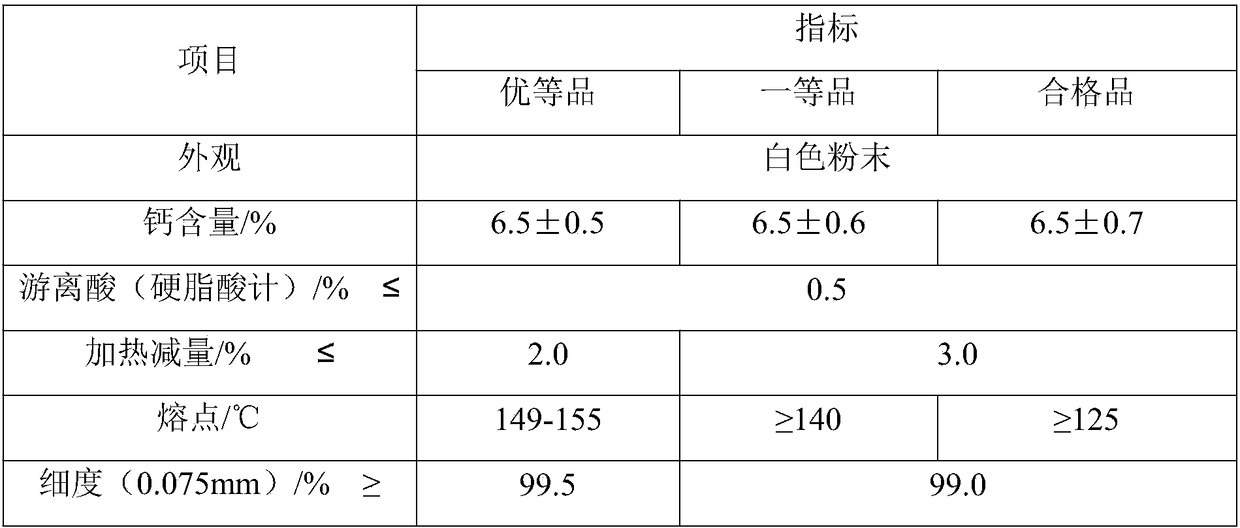

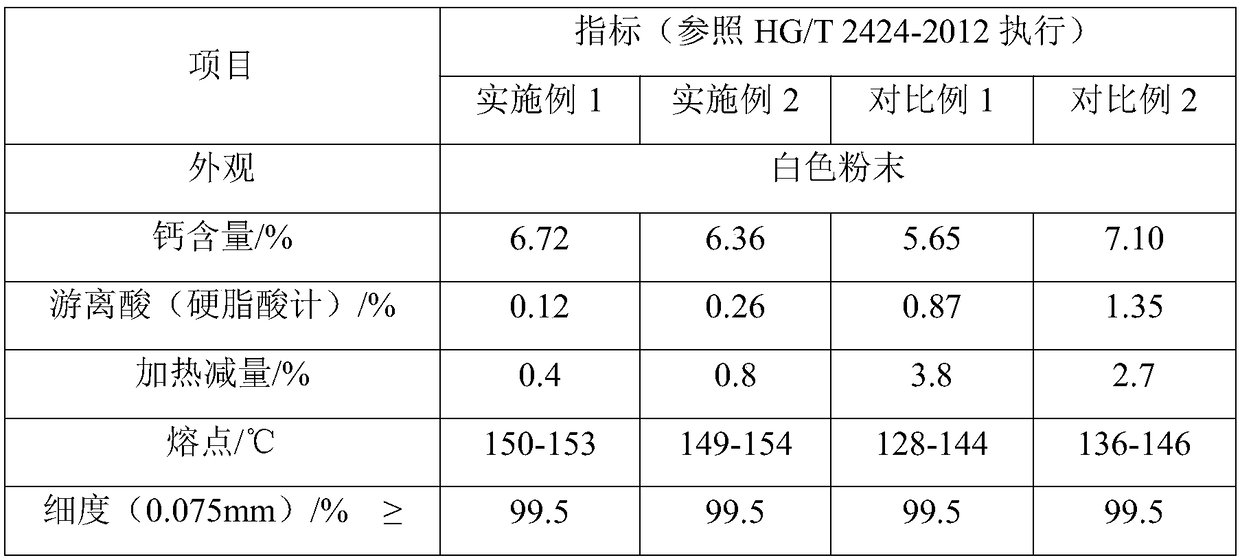

Calcium stearate and preparation process thereof

ActiveCN105949048AHigh purityGuaranteed chromaticityOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryCalcium hydroxide

The invention belongs to the technical field of chemical engineering and particularly relates to calcium stearate and a preparation process thereof. The calcium stearate is prepared from tristearin, a catalyst A, an antioxidant, water, calcium oxide, a catalyst B and sodium hydroxide, wherein the catalyst A is a mixture of calcium hydroxide and Al2O3-MgO, and the antioxidant is a mixture of DLTDP and an antioxidant T501; the catalyst B is selected from one or more of peroxides. The calcium stearate is low in raw material cost, high in yield, good in color, low in free acid content, high in melting point and stable in property, and related quality indexes meet the requirement of Chemical Industry Standard of the People's Republic of China HG / T 2424-2012 Calcium Stearate for superior products. The preparation process of the calcium stearate is safe and environment friendly in production process, low in energy consumption and low in overall production cost, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

Method for enhancing appearance quality of ordinary superphosphate

The invention discloses a method for enhancing appearance quality of ordinary superphosphate, which comprises the following steps: mixing aged ordinary superphosphate and a white fertilizer in a weight ratio of (2-3):(1-2), and stirring uniformly to obtain a semi-finished fertilizer; and mixing the semi-finished fertilizer with kaolin in a weight ratio of (3-5):1, and stirring uniformly to obtain the finished fertilizer product. By mixing the white fertilizer and ordinary superphosphate, citrate-soluble phosphorus and calcium biphosphate contained in the white fertilizer react with free acids in the ordinary superphosphate to lower the free acid content in the ordinary superphosphate.

Owner:LINGSHAN JIAOFENG CHEM

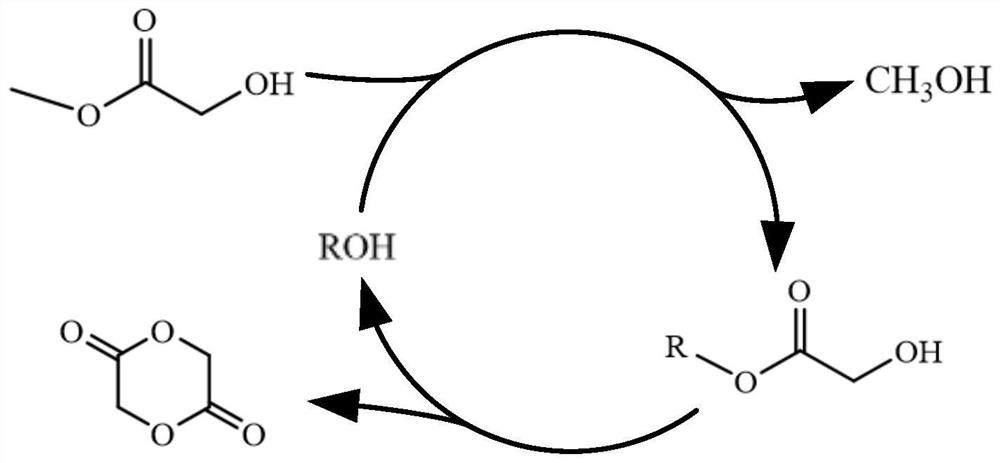

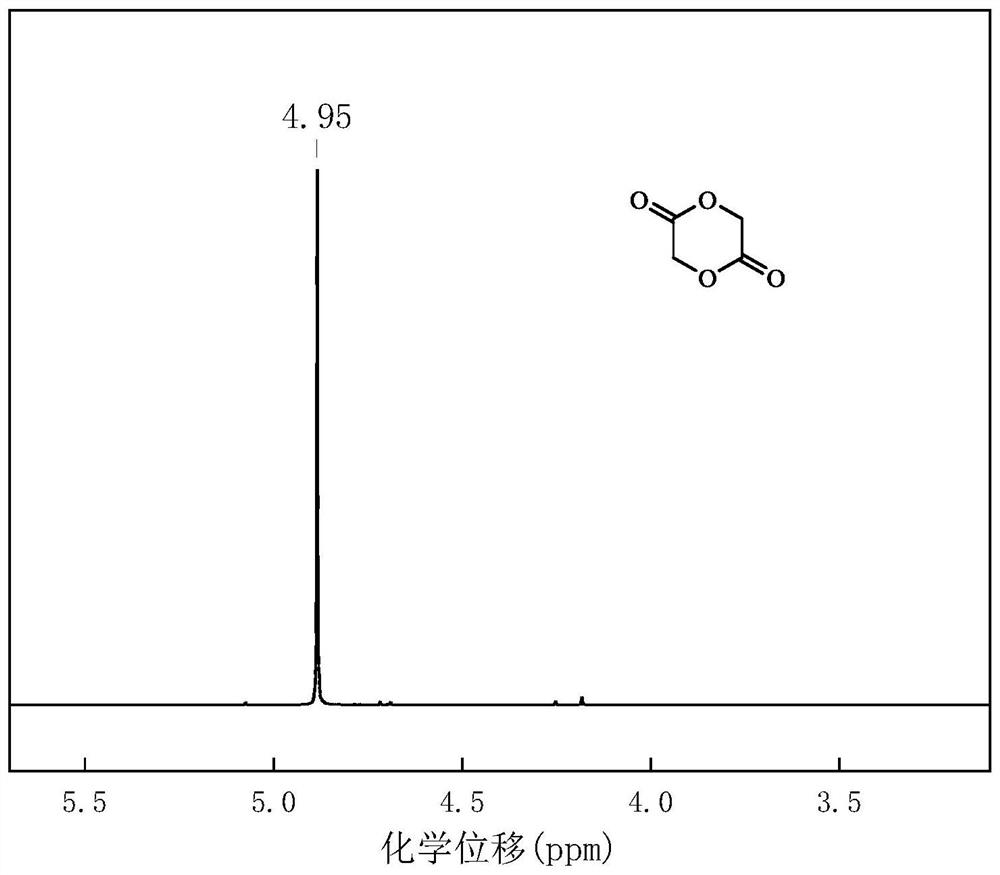

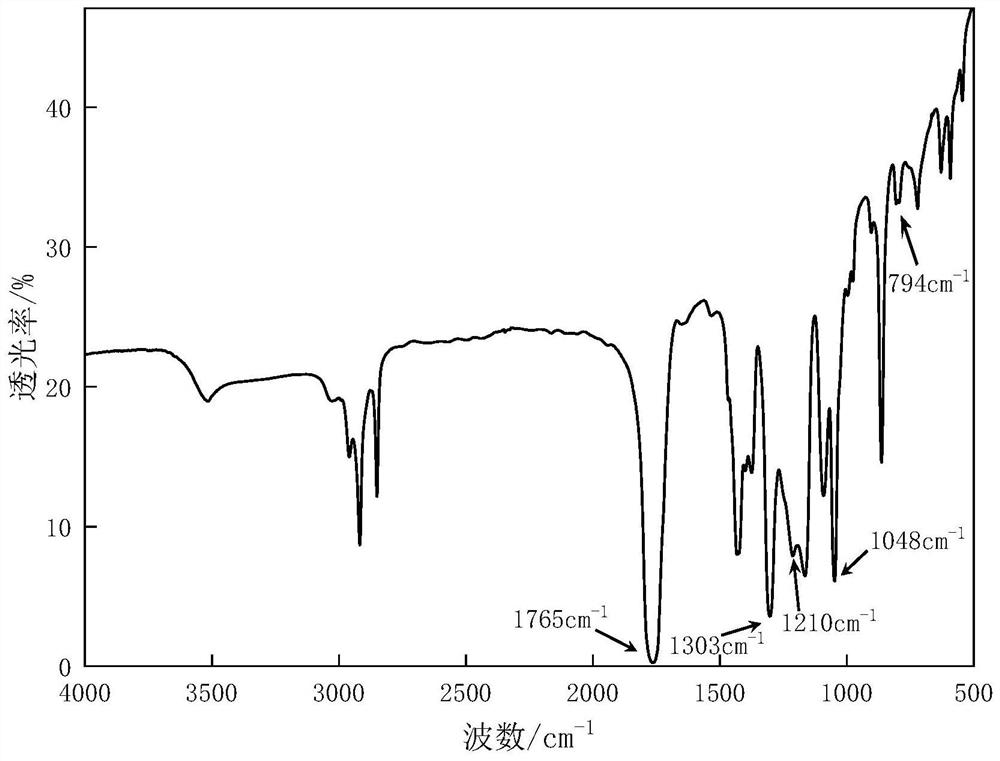

Method for synthesizing glycolide

ActiveCN113387921AImprove heat transfer efficiencyAvoid the problem of easy coking and carbonizationOrganic chemistryChemical recyclingPolymer scienceOligomer

The invention discloses a method for synthesizing glycolide, wherein methyl glycolate is used as a raw material, and the glycolide is obtained through the following two steps: (1) a reaction defined in the specification, and (2)a reaction defined in the specification, wherein ROH is 18-30 carbon straight chain or branched chain alcohol, acid or ester containing one or more hydroxyl groups. According to the glycolide synthesis process, high-boiling-point alcohol is introduced to participate in the reaction to generate a glycolic acid higher ester intermediate product, and the molecular weight of the glycolic acid higher ester intermediate product is far lower than that of an intermediate product glycolic acid oligomer in a traditional process, so that the viscosity of a reaction system is controlled to be at a low level, the heat transfer efficiency of the system is improved, and the problem that the traditional oligomerization route is easy to coke and carbonize is effectively avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

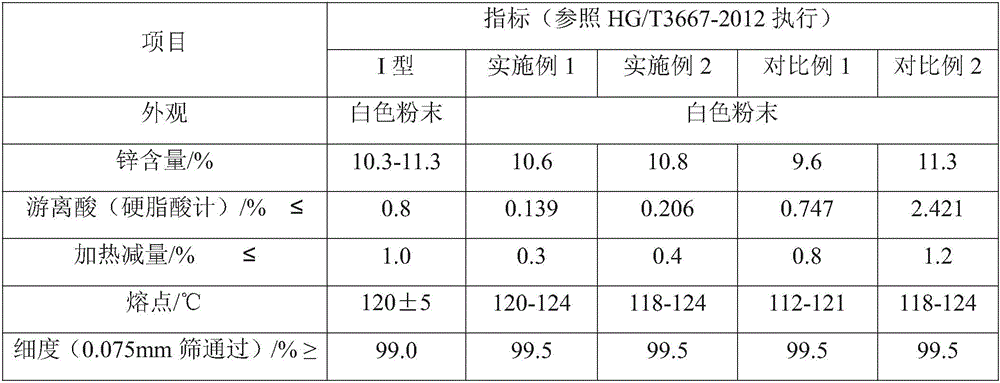

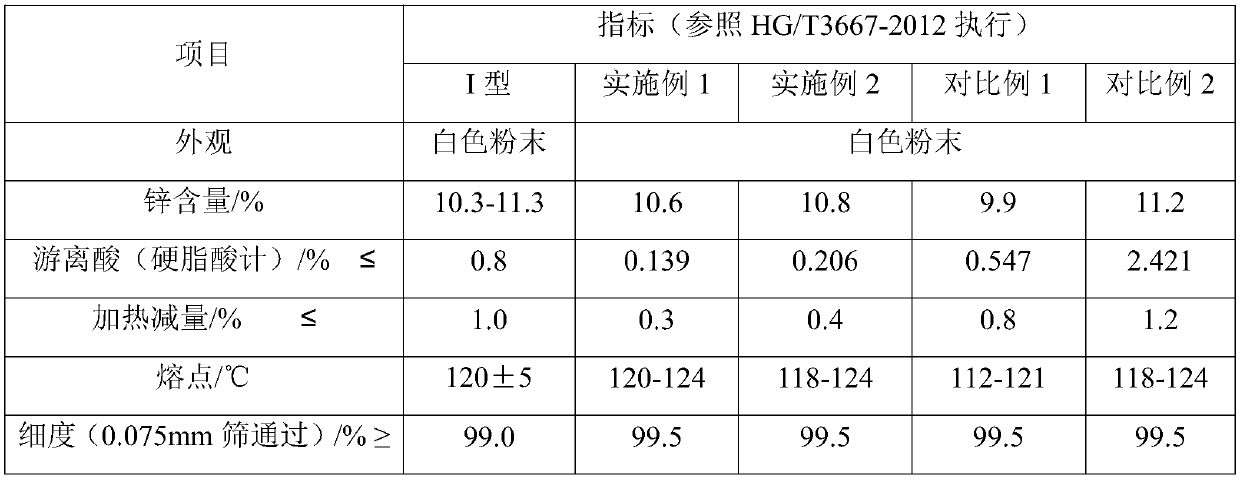

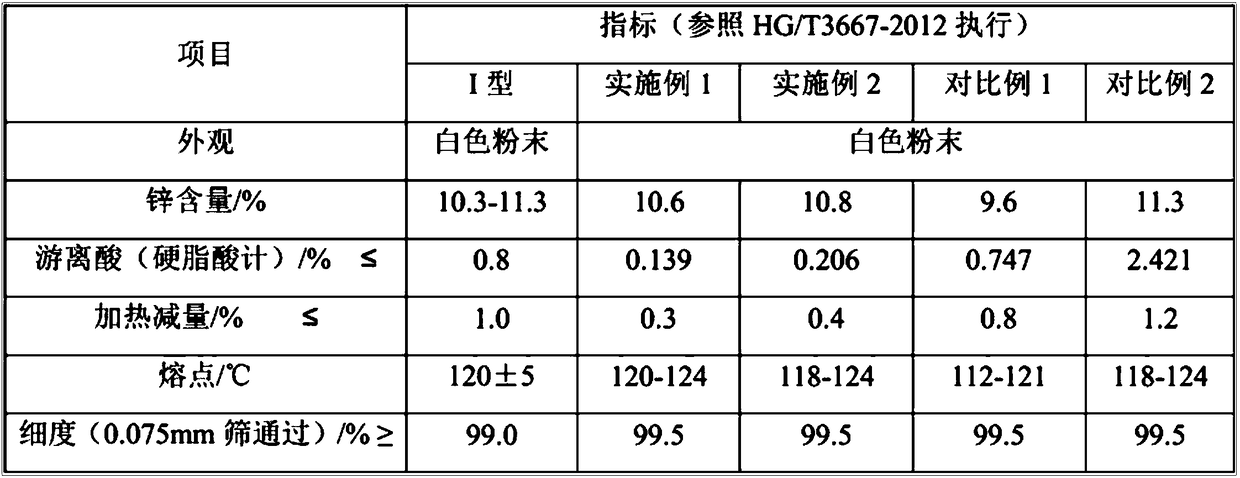

High-quality zinc stearate prepared from glyceryl tristearate

ActiveCN105924344AHigh yieldLow total production costOrganic compound preparationHeterogenous catalyst chemical elementsAntioxidantWastewater

The invention belongs to the technical field of chemical engineering, and particularly relates to high-quality zinc stearate prepared from glyceryl tristearate. A preparation technology of zinc stearate comprises the following steps that 1, glyceryl tristearate and water are hydrolyzed under the action of a catalyst and an antioxidant; 2, zinc oxide and a catalyst are added stepwise, condensing, dewatering and salt forming are conducted, and zinc stearate is synthesized. Zinc stearate is high in preparation yield, good in color and cluster, low in free acid content and stable in quality, and the related quality indexes meet the related requirements on I type zinc stearate in HG / T3667-2012; in addition, no wastewater containing chlorine and sulfate ions is discharged in the preparation process of zinc stearate, the production process is safe and environmentally friendly, and the total production cost is low. Zinc stearate is high in quality and has the better practicability and comparability compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

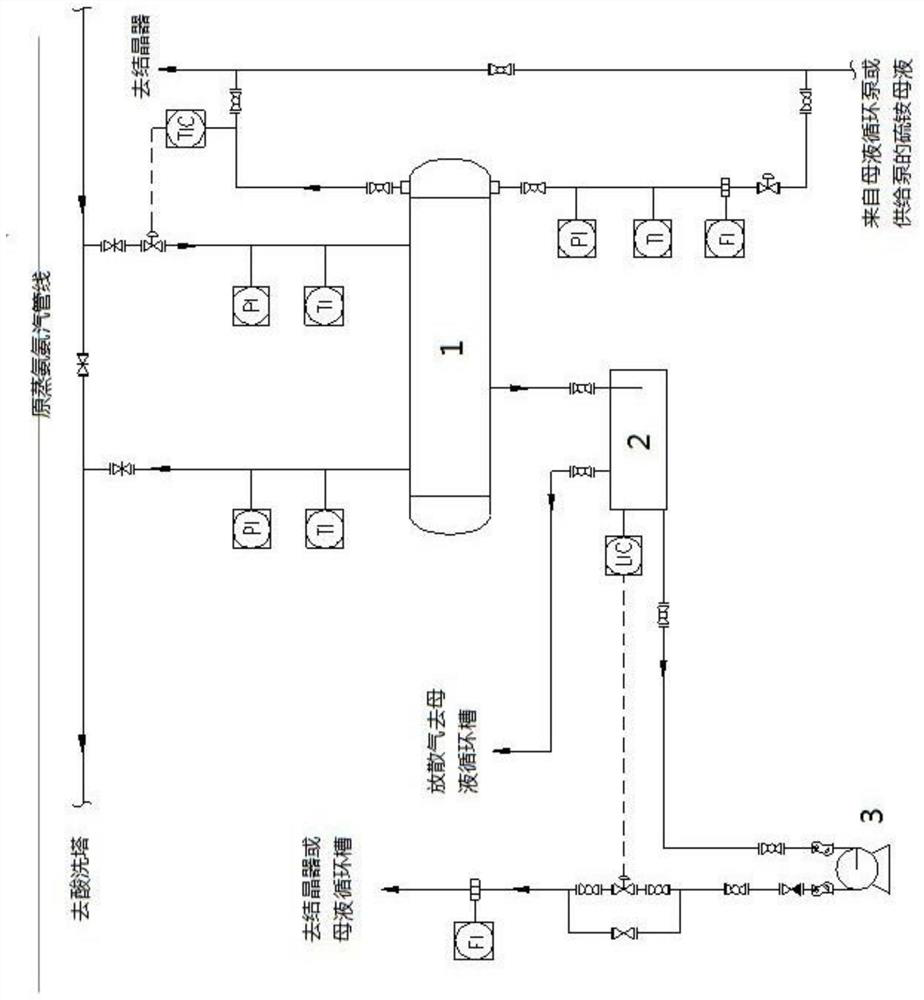

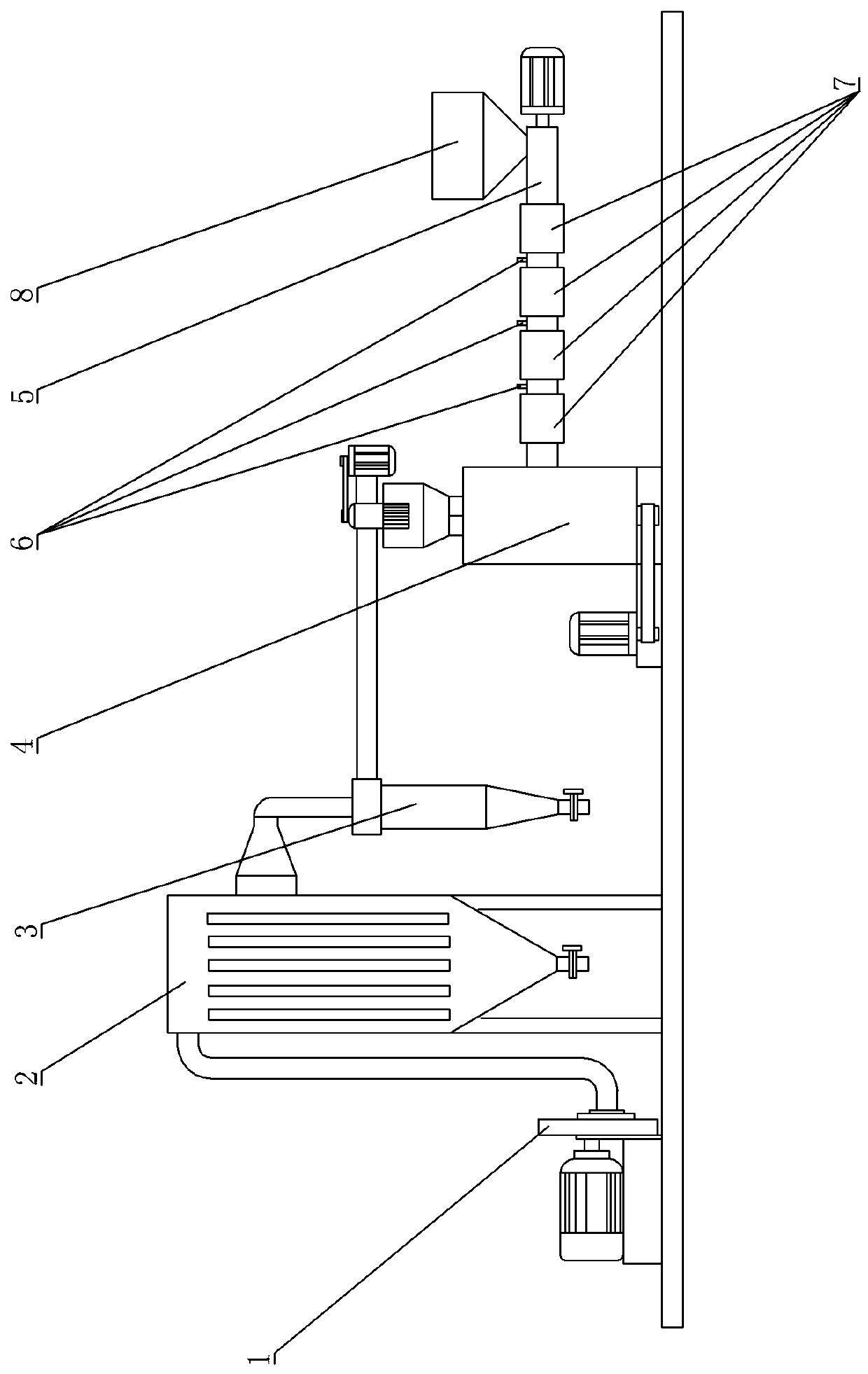

Ammonia steam waste heat utilization device for ammonia distillation

PendingCN112978761AReduce consumptionReduce adhesionEnergy inputSolution crystallizationThermodynamicsProcess engineering

The invention relates to an ammonia steam waste heat utilization device for ammonia distillation, which comprises an ammonium sulfate mother liquor heat exchanger, an ammonia condensate tank and an ammonia condensate pump, the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump are provided with the ammonia condensate tank, and the ammonia condensate tank is connected with the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump through a pipeline. The ammonium sulfate mother liquor heat exchanger is provided with an ammonia steam inlet, an ammonia steam outlet, a mother liquor inlet and a mother liquor outlet, an adjusting valve is arranged on a mother liquor inlet pipeline, the flow of mother liquor entering the heat exchanger is controlled through the opening degree of the adjusting valve, an adjusting valve is arranged on an ammonia steam inlet pipeline, and the opening degree of the adjusting valve is automatically adjusted according to the temperature of mother liquor in a mother liquor outlet pipeline.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for preparinglactide by using lactic acidoligomer

The invention provides a method for preparinglactide by using lactic acidoligomer. The method comprises the steps that the lactic acidoligomer and an active compound perform mixed reaction, and the lactide is obtained through cracking reaction; the active compound is organic matter capable of reacting with a terminal hydroxyl group or terminal carboxyl group of the lactic acidoligomer. Compared with the prior art, the cracking activity of the oligomer is not affected while the molecular weight of the lactic acidoligomeris increased by utilizing reaction between the active compoundand the terminal hydroxyl group or terminal carboxyl group of the lactic acidoligomer, the technical process is simple, and the free acid content of the obtained lactide is far lower than that of the lactide obtained by directing cracking the lactic acidoligomer. In addition, the lactide yield is equivalent to the yield of the lactide obtained by directing cracking the lactic acidoligomer.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for refining glycolide and glycolide obtained by method

PendingCN114478468ASolve residualEasy to recycleOrganic chemistryPlastic recyclingOligomerGlycolic acid

The invention provides a method for refining glycolide and glycolide obtained by the method. The method comprises the following steps: carrying out impurity extraction on crude glycolide by using a solvent A, and recrystallizing by using a solvent B, wherein the solvent A comprises at least two solvents which are mutually soluble. According to the method disclosed by the invention, two polar solvents are used for refining the crude glycolide, a very good extraction effect is achieved on acidic impurities such as glycolic acid oligomer and the like, and the solvents are easily and fully removed in solid-liquid separation and drying processes, so that the problem of solvent residue in a refined product is solved, and the technical effect of low free acid content of the product is achieved. The technical scheme of the invention has the technical advantages of easy solvent recovery and low free acid content of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of technique utilizing glyceryl tristearate to synthesize zinc stearate

ActiveCN106008198BHigh purityHigh yieldCarboxylic acid salt preparationChemical recyclingChemical industryAntioxidant

The invention belongs to the technical field of chemical industry, and particularly relates to a technique for synthesizing zinc stearate from glyceryl tristearate. The technique comprises the following steps: 1) hydrolyzing glyceryl tristearate and water under the actions of a catalyst and an antioxidant; and 2) adding zinc oxide and a catalyst in multiple steps, and carrying out condensation, dewatering and salification to synthesize the zinc stearate. By using the technique provided by the invention, no wastewater containing chlorine and sulfate ions is discharged in the process; the production process is safe and environment-friendly and has low total production cost; and the synthesized zinc stearate has the advantages of high yield, favorable color and low free fatty acid content, satisfies the relevant quality standard for Type I zinc stearate in HG / T3667-2012, and has higher practicality and comparability than like products in the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

The preparation method of hydroxylamine sulfate

ActiveCN107539966BSolve the problem of high free acidIncrease profitPhysical/chemical process catalystsHydroxylamineHydroxylamine sulfateOrganic matter

The invention discloses a preparation method of hydroxylamine sulphate. The preparation method comprises the following steps: 1), evenly mixing the raw materials of an acid solution and oxime, rectifying in a reaction rectifying column, obtaining a mixed solution of hydroxylamine sulphate and unreacted oxime and acid in a column reactor; 2), conveying part of the mixed solution obtained in the column reactor to a stripping tower through a pump, stripping to remove an organic matter and part of water, conveying part of the mixed solution to a reactor filled with a catalyst to have a further reaction; enabling a liquid material obtained in the reaction to return to the column reactor of the rectifying column, and enabling a gaseous phase to return to the upper middle part of the rectifying column; 3), crystalizing a concentrated hydroxylamine sulphate solution flowing out from a tower kettle of the stripping tower, separating the liquid and the solid, and drying to obtain hydroxylamine sulphate.

Owner:江苏艾科维科技股份有限公司

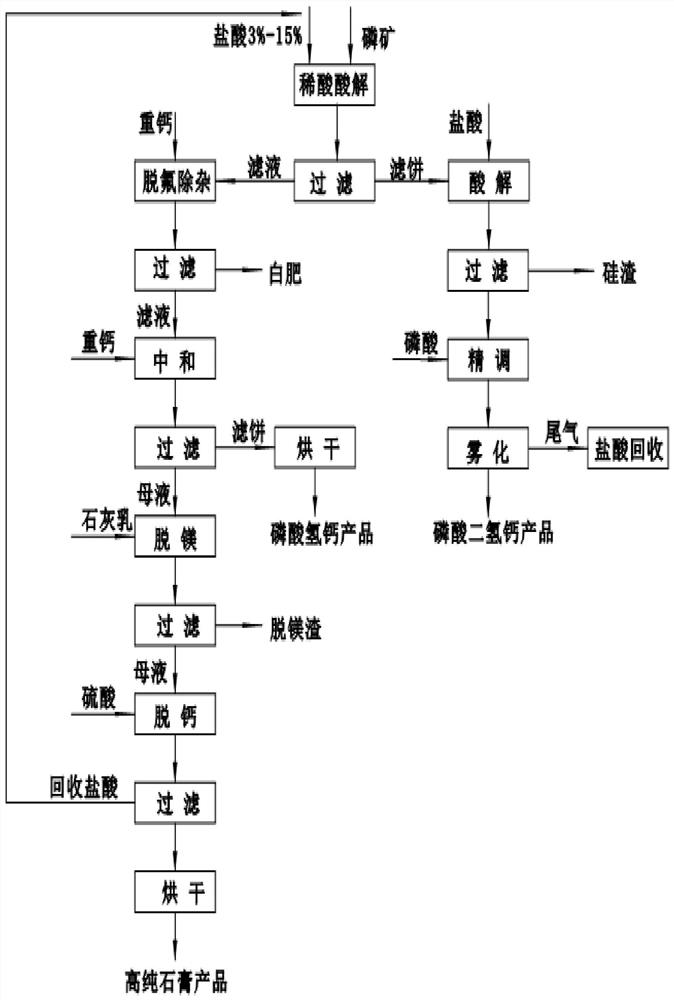

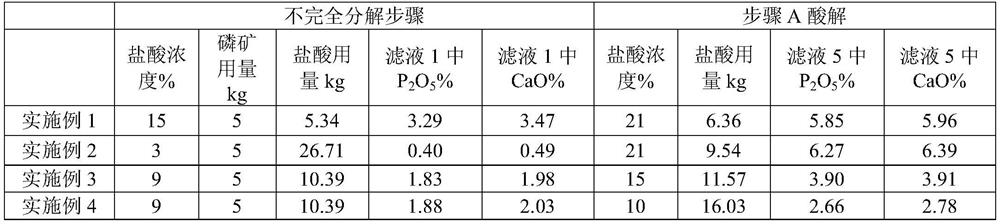

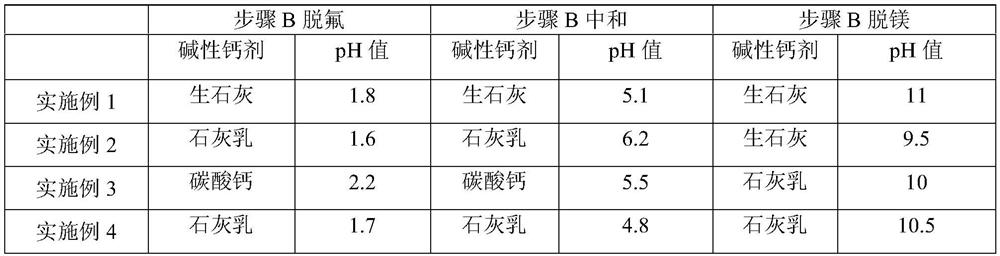

A method for producing calcium phosphate salt and high-purity gypsum by utilizing hydrochloric acid and phosphate rock

ActiveCN109836177BSave process investmentObvious cost advantageDi-calcium phosphate fertilisersAlkali orthophosphate fertiliserO-Phosphoric AcidFiltration

The invention belongs to the technical field of feed, in particular to a method for producing calcium phosphate salt and high-purity gypsum by using hydrochloric acid and phosphate rock. The technical problem to be solved by the present invention is to provide a method for producing calcium phosphate salt and high-purity gypsum by using hydrochloric acid and phosphate rock, comprising the following steps: incompletely decomposing the phosphate rock with hydrochloric acid, and separating solid and liquid to obtain solid 1 and liquid 1; 1. Treatment of solid 1: solid 1 is reacted with hydrochloric acid, filtered and separated to obtain filter residue and filtrate 2; filtrate 2 is mixed with phosphoric acid to obtain fine seasoning slurry, and the refined seasoning slurry is dechlorinated, defluorinated, and dehydrated by heating to obtain calcium phosphate; B 1. Treatment of liquid 1: ① remove fluorine in liquid 1; ② add calcium to obtain calcium hydrogen phosphate; ③ remove magnesium; ④ add sulfuric acid to obtain high-purity gypsum. The method of the invention has simple steps and low cost, and the prepared calcium phosphate fully meets the national standard, and the obtained gypsum has excellent quality.

Owner:CHANHEN ECO TECH CO LTD

A kind of barium stearate and preparation technology thereof

ActiveCN105859541BHigh yieldLow total production costOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryAntioxidant

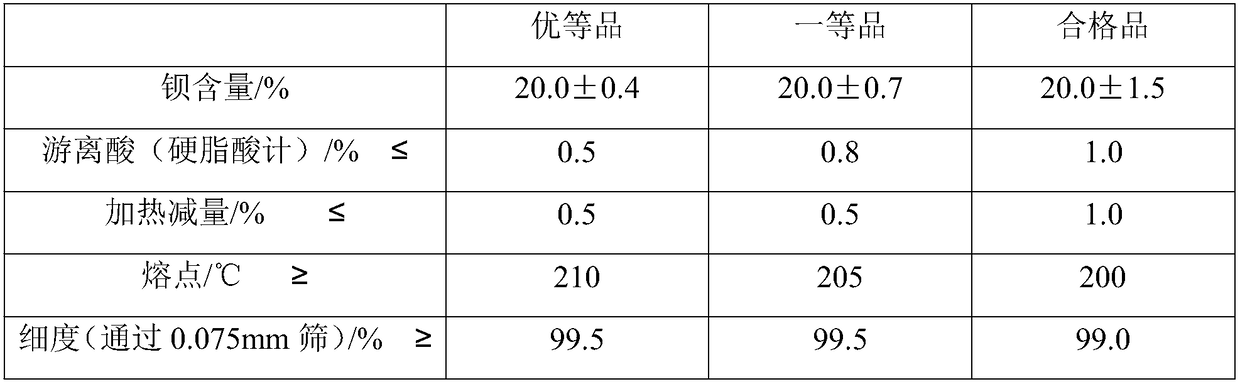

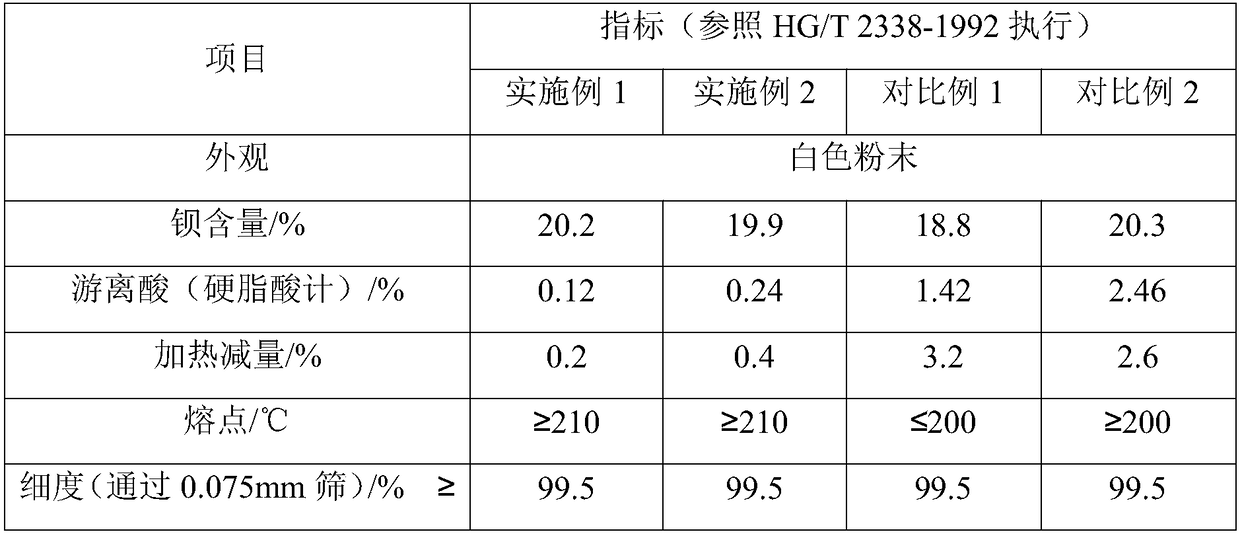

The invention belongs to the technical field of chemical engineering and particularly relates to barium stearate and a preparation process thereof. Barium stearate is prepared from glyceryl tristearate, a catalyst A, antioxidant, water, barium hydroxide, a catalyst B and sodium hydroxide. The catalyst A is a mixture of magnesium oxide and Al2O3-MgO, and the antioxidant is a mixture of antioxidant DLTDP and antioxidant T501. The catalyst B is selected from one or more of peroxide. Barium stearate is low in raw material cost, high in yield, low in free acid content and stable in performance, and relevant quality indexes meet the requirements of the People's Republic of China chemical industry standard <HG / T2338-1992 barium stearate (light)> for superior products. According to the preparation process of barium stearate, the production course is safe and environmentally friendly, energy consumption is low, the total production cost is low, and higher practicality and comparability are achieved compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

A kind of preparation method utilizing glyceryl tristearate to prepare zinc stearate

ActiveCN105924344BHigh yieldLow total production costOrganic compound preparationHeterogenous catalyst chemical elementsTalc / Zinc OxideStearic acid

The invention belongs to the technical field of chemical engineering, and particularly relates to high-quality zinc stearate prepared from glyceryl tristearate. A preparation technology of zinc stearate comprises the following steps that 1, glyceryl tristearate and water are hydrolyzed under the action of a catalyst and an antioxidant; 2, zinc oxide and a catalyst are added stepwise, condensing, dewatering and salt forming are conducted, and zinc stearate is synthesized. Zinc stearate is high in preparation yield, good in color and cluster, low in free acid content and stable in quality, and the related quality indexes meet the related requirements on I type zinc stearate in HG / T3667-2012; in addition, no wastewater containing chlorine and sulfate ions is discharged in the preparation process of zinc stearate, the production process is safe and environmentally friendly, and the total production cost is low. Zinc stearate is high in quality and has the better practicability and comparability compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

A kind of preparation method of lithium difluorobisoxalate phosphate, non-aqueous electrolyte and battery

ActiveCN111004286BSolve inseparablePrevent spoilageGroup 5/15 element organic compoundsSecondary cellsElectrolytic agentPhosphate

The present invention relates to the technical field of energy storage batteries, and provides a method for preparing lithium difluorobisoxalate phosphate. The method includes: S1, providing a concentrated solution of lithium difluorobisoxalate phosphate and lithium difluorophosphate; Add solvent A and solvent B to the concentrated solution for extraction, collect phase B extract, carry out vacuum distillation, and dry to obtain lithium difluorobisoxalate phosphate solid. The preparation method of the invention solves the problem that lithium difluorobisoxalate phosphate is difficult to separate from lithium difluorobisoxalate phosphate, and the obtained lithium difluorobisoxalate phosphate product has high purity and low free acid content, and is suitable for industrial production.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

A kind of method for preparing lactide from lactic acid oligomer

The invention provides a method for preparing lactide from a lactic acid oligomer, comprising: mixing and reacting a lactic acid oligomer with an active compound, and then performing a cracking reaction to obtain lactide; the active compound is capable of oligomerizing with lactic acid The organic compound that reacts with the terminal hydroxyl or carboxyl group of the compound. Compared with the prior art, the present invention utilizes the active substance to react with the terminal hydroxyl or carboxyl group of the lactic acid oligomer to increase the molecular weight of the lactic acid oligomer without affecting its cracking activity, the process is simple, and the obtained lactide The content of free acid in the medium is far less than that of lactide obtained by direct cracking of lactic acid oligomers, and the yield of lactide is equivalent to that of lactide obtained by direct cracking of lactic acid oligomers.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

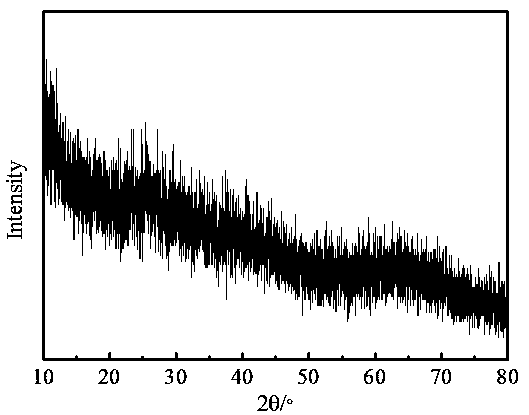

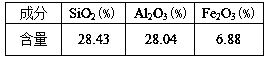

A kind of calcium stearate and preparation technology thereof

ActiveCN105949048BHigh purityGuaranteed chromaticityOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryCalcium hydroxide

The invention belongs to the technical field of chemical engineering and particularly relates to calcium stearate and a preparation process thereof. The calcium stearate is prepared from tristearin, a catalyst A, an antioxidant, water, calcium oxide, a catalyst B and sodium hydroxide, wherein the catalyst A is a mixture of calcium hydroxide and Al2O3-MgO, and the antioxidant is a mixture of DLTDP and an antioxidant T501; the catalyst B is selected from one or more of peroxides. The calcium stearate is low in raw material cost, high in yield, good in color, low in free acid content, high in melting point and stable in property, and related quality indexes meet the requirement of Chemical Industry Standard of the People's Republic of China HG / T 2424-2012 Calcium Stearate for superior products. The preparation process of the calcium stearate is safe and environment friendly in production process, low in energy consumption and low in overall production cost, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

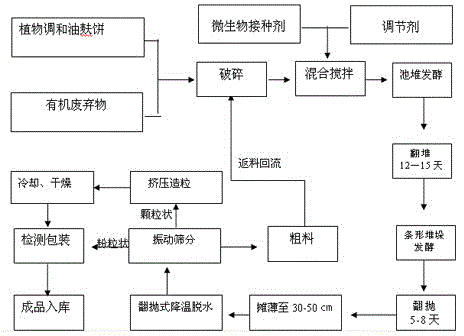

Water-retaining organic fertilizer and preparation method thereof

ActiveCN102850122BStrong water absorption and water retentionRich in organic matterBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceMycoprotein

The invention provides a water-retaining organic fertilizer and a preparation method thereof, which belongs to the technical field of organic fertilizers. The method provided by the invention uses an edible vegetable blended oil bran cake as a main raw material for development of the water-retaining organic fertilizer, and the problems of existence of multiple harmful components caused by addition of chemical materials and single efficacy of products in traditional organic fertilizers are overcome. The water-retaining organic fertilizer is prepared from the edible vegetable blended oil bran cake, organic waste, a conditioning agent and a microbial inoculant. The preparation method comprises the following steps: crushing the edible vegetable blended oil bran cake and the organic waste; then mixing the crushed bran cake and organic waste with the conditioning agent and the microbial inoculant under stirring; and carrying out pool stacking fermentation, stripe-shaped stacking fermentation, screening and granulation so as to obtain the water-retaining organic fertilizer. According to the invention, because of usage of organic matter raw materials containing abundant mycoprotein, the organic fertilizer has a water-retaining function, and the problem of reduced output or poor output of crops caused by lack of water, no retention of water and fertility, no drought tolerance and loss of nutrients in agricultural production is overcome.

Owner:刘奋安

Activated clay dry preparation process

InactiveCN109896530ANo emissionsNo pollutionSilicon compoundsGrain treatmentsWastewaterMontmorillonite

Owner:战国昌

Method for synthesizing lactide from L-lactic acid by adopting fixed bed reactor

ActiveCN114685423AImprove adsorption capacityLow toxicityOrganic chemistryDepolymerizationPtru catalyst

The invention relates to a method for synthesizing lactide from L-lactic acid by using fixed bed reactors, which comprises the following steps: L-lactic acid is sequentially introduced into two fixed bed reactors connected in series, the two fixed bed reactors are filled with a silicon-substituted aluminophosphate molecular sieve catalyst, and nitrogen which continuously flows in and out is also introduced into the first fixed bed reactor; and sequentially carrying out an L-lactic acid condensation polymerization reaction and an L-lactic acid oligomer depolymerization reaction in two fixed bed reactors to obtain the crude L-lactide. According to the method, the reaction of synthesizing lactide from L-lactic acid is realized by adopting two fixed bed reactors connected in series, continuous reaction is realized, and the selected catalyst is high in carbon deposition resistance and adsorption performance, resistant to high temperature, stable in catalytic performance, not prone to coking to block a pipeline and long in service life; water molecules generated by polycondensation and evaporated L-lactic acid molecules are taken away in time by utilizing nitrogen flow, so that the polymerization degree of the L-lactic acid oligomer is improved, the content of free acid in the L-lactide is reduced, and the optical purity of the L-lactide is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

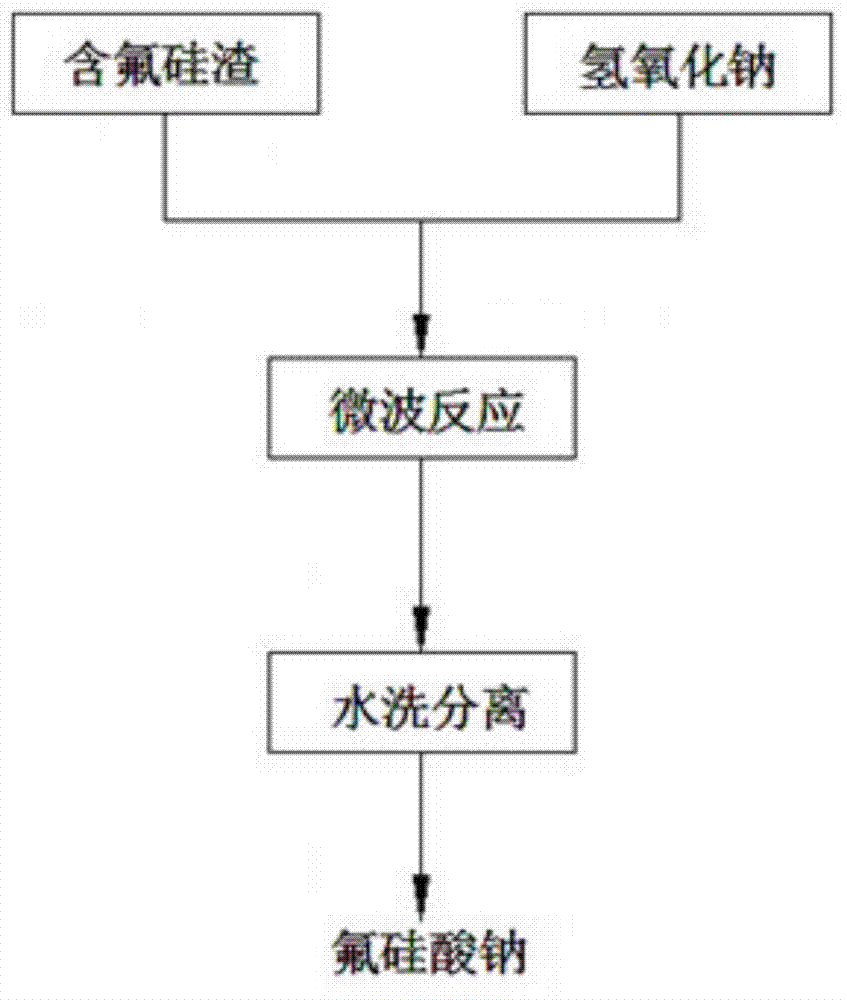

A method for preparing sodium fluorosilicate from fluorine-containing silicon slag

ActiveCN105000563BImprove qualityReduce consumptionSilicon halogen compoundsSlagMicrowave technology

The invention relates to industrial waste slag comprehensive utilization technologies, and specifically relates to a method for preparing sodium fluosilicate by using fluorine-containing silicon slag. The method comprises: fulling mixing the fluorine-containing silicon slag and sodium hydroxide with a concentration of 5% to 30%, adjusting microwave power to a metal temperature of 70 to 120 DEG C for microwave reaction for 3 to 60 min, and after a cooling temperature is 30 to 55 DEG C, obtaining solid sodium fluosilicate after solid-liquid separation and drying treatment . According to the process of the invention, waste fluorine-containing silicon slag is combined with the microwave technology, and sodium fluosilicate is generated in one step. Production costs are low and the process is simple, and harm of acidic silicon slag on the environment is eliminated. The invention is low-carbon environmental, and actually achieve an effect of fluorine-containing silicon slag environment friendly and high effective utilization and development.

Owner:GUIZHOU YUANSHENG POTASSIUM TECH

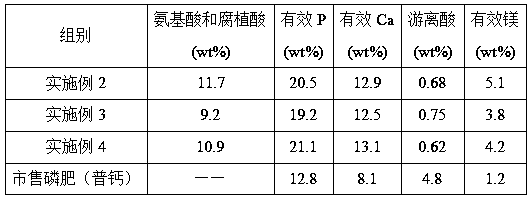

A kind of phosphate fertilizer containing amino acid and preparation method thereof

The invention discloses an amino acid-containing phosphate fertilizer and a preparation method thereof. The phosphate fertilizer consists of 5-15 parts of basic amino acid, 3-5 parts of basic mineral powder, 65-80 parts of phosphate fertilizer, 5-15 parts of humic acid, and a binder 5-8 parts and 10-30 parts of ammonia water; first mix the alkaline mineral powder with the binder, make agglomerates, put them back into the brick kiln for calcination, cool, crush, and sieve to obtain alkaline powder; mix it with Phosphate fertilizer is mixed evenly to react completely; mix humic acid and ammonia water to react completely under airtight conditions; mix the two reaction products, add basic amino acid, mix well to make the reaction complete, dry, crush and sieve. The humic acid and amino acid content of the phosphate fertilizer of the present invention is ≥8%, which can greatly increase the total nutrients of the phosphate fertilizer and improve the utilization rate; its effective phosphorus content is high, the activity is strong, the free acid content is less than 1%, and it can release the insoluble Phosphorus salt, magnesium salt, etc.; it can also improve the absorption of phosphorus by crops, reduce the amount of chemical fertilizers, and is suitable for large-scale industrial production.

Owner:ZHANJIANG BOTAI BIOCHEM IND

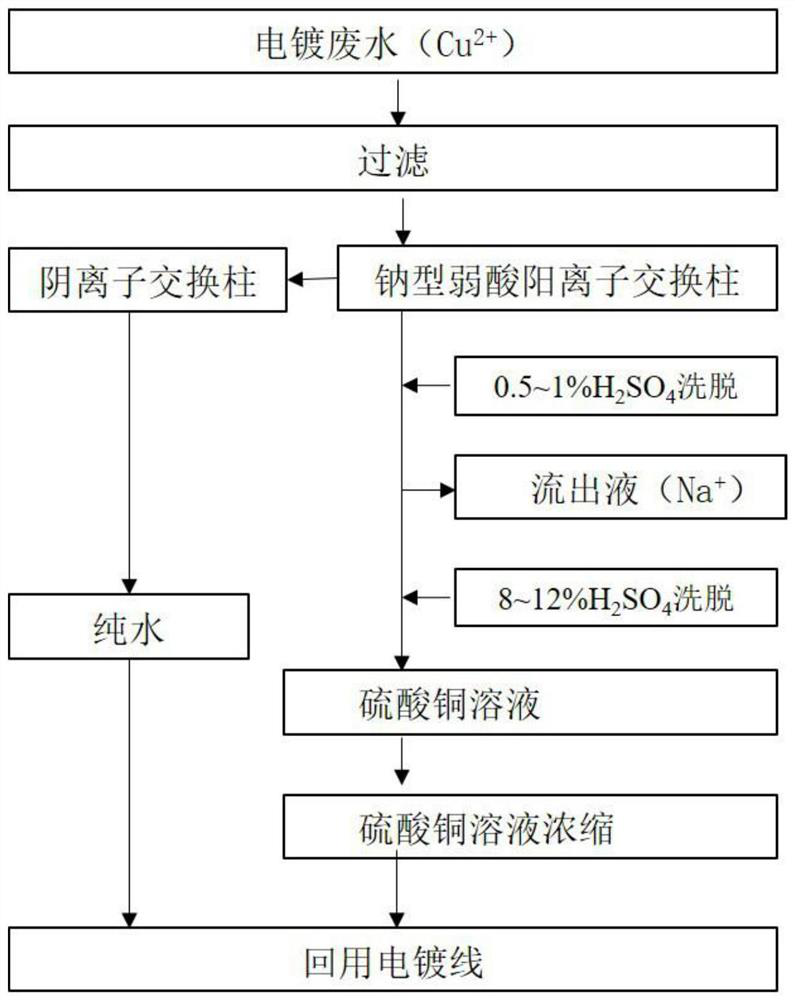

Electroplating heavy metal ion back-bath sodium removing process

ActiveCN113754122AReduce sodium ion contentLow in free acidsCellsSpecific water treatment objectivesIon exchangeFree acid

The invention relates to an electroplating heavy metal ion back-tank sodium removing process, which comprises the following steps: collecting electroplating heavy metal ion wastewater, carrying out rough filtration and fine filtration, and enabling a heavy metal ion solution to pass through a sodium type weak acid cation exchange resin column to exchange and adsorb heavy metal ions; and after the adsorption is saturated, eluting the cation exchange column by dilute acid and concentrated acid respectively, collecting effluent of heavy metal ions, and concentrating and returning theeffluent of heavy metal ions to an electroplating process line for use. The method can greatly reduce the concentration of sodium ions and free acid in the bath return liquid, and meets the use stability of electroplating heavy metal ions in the bath return.

Owner:南京昆腾化工科技有限公司 +1

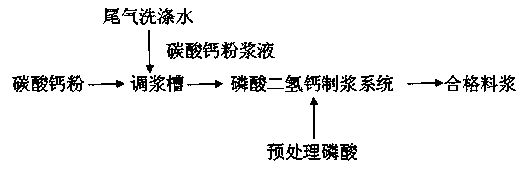

Preparation method for producing monocalcium phosphate slurry by using wet phosphoric acid slurry process

PendingCN110862074AReduce package volumeLow in free acidsPhosphorus compoundsO-Phosphoric AcidPhysical chemistry

The invention discloses a preparation method for producing monocalcium phosphate slurry by using a wet phosphoric acid slurry process. The method comprises the following steps: (1) uniformly mixing calcium carbonate powder having a purity of 98% or above and fineness of 200 meshes or above with a tail gas washing solution according to a certain ratio to prepare calcium carbonate powder slurry forlater use; (2) adding a defluorinating agent and an arsenic removing agent into strong phosphoric acid with a phosphorus pentoxide content of 48% or above according to a certain ratio, and carrying out impurity purification to prepare pretreated phosphoric acid for later use; and (3) fully mixing the calcium carbonate powder slurry with the pretreated phosphoric acid according to a certain ratio through a multi-stage cascade reaction system, and carrying out a reaction for 4 hours to complete the preparation of the monocalcium phosphate slurry. According to the invention, calcium powder coating in the reaction process can be remarkably reduced, the free acid content of the product is reduced, and product quality is improved; the consumption of main materials for production is reduced, andproduction cost is saved; in addition, tail washing water is recycled, and good economic benefits and environmental protection benefits are achieved.

Owner:WENGFU (GRP) CO LTD

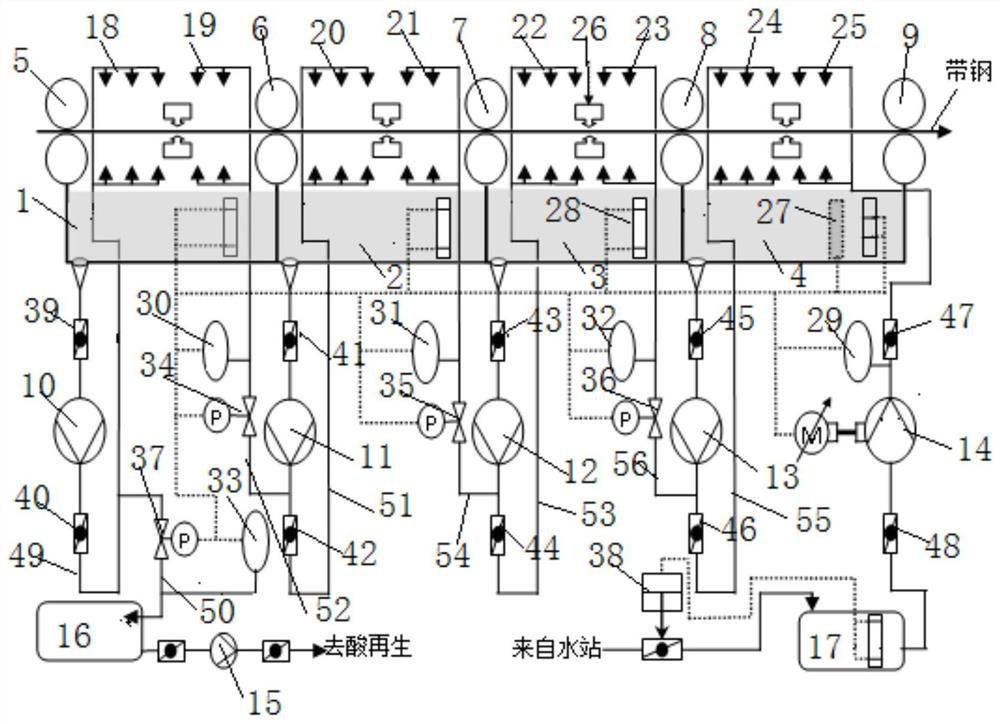

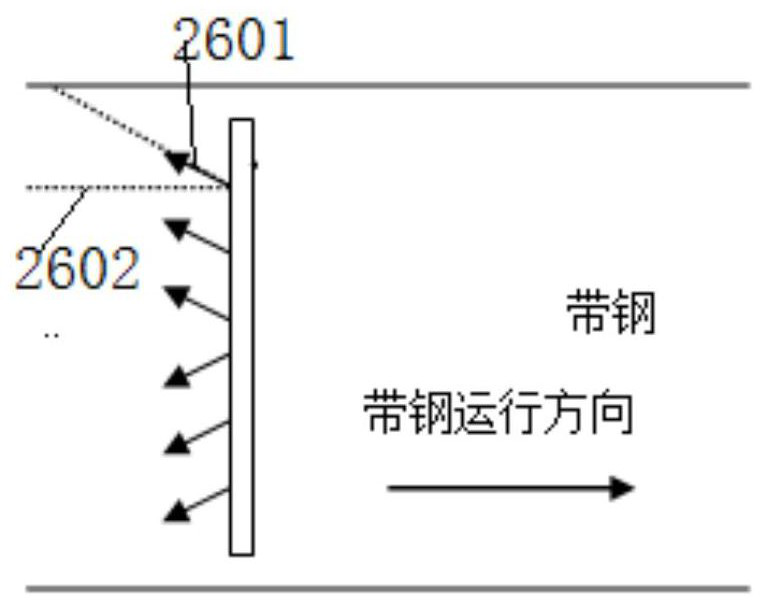

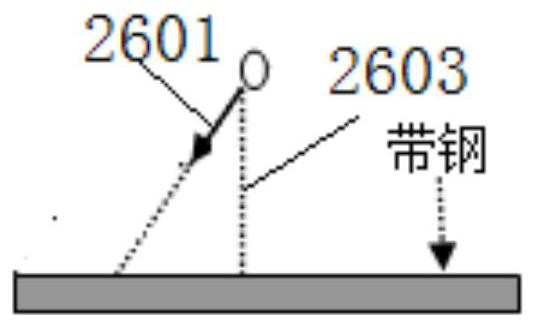

Rinsing system and rinsing method for cold-rolled strip steel pickling

The invention relates to a rinsing system and rinsing method for cold-rolled strip steel pickling. The rinsing system comprises a desalted water tank communicating with a fourth double-spray pipe, wherein a fourth circulating pump communicates with a fourth three-spray pipe through a fourth pipeline and communicates with a third double-spray pipe through a fourth branch pipeline; a third circulating pump communicates with a third three-spray pipe through a third pipeline and communicates with a second double-spray pipe through a third branch pipeline; a second circulating pump communicates with a second three-spray pipe through a second pipeline and communicates with a first double-spray pipe through a second branch pipeline; a first circulating pump communicates with a first three-spray pipe through a first pipeline and communicates with a flushing water tank through a first branch pipeline; a sixth circulating pump is arranged between the flushing water tank and a deacidification and regeneration room; and the heights of separating walls between every two adjacent rinsing tanks are the same. According to the rinsing system and the rinsing method, the number of stages of rinsing is increased, the use amount of rinsing water is reduced, digestion in an acid regeneration room is facilitated, and waste caused by excessive water discharge is avoided.

Owner:BENGANG STEEL PLATES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com