Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200 results about "Talc / Zinc Oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

How to use Talc-Zinc Oxide 81 %-15 % Topical Powder. Consult your pharmacist or physician. Find Lowest Prices. Read More. Side Effects. Side Effects. Consult your pharmacist or physician.

Particulate zinc oxide with manganese ion dopant

A particulate metal oxide is provided that includes a cationic portion containing a zinc portion, a first manganese dopant portion and a second dopant portion selected from the group consisting of iron and aluminum, wherein the zinc portion is about 99% by weight or more of the cationic portion and the manganese dopant portion and second dopant portion are present in a weight ratio of from about 5:1 to 1:5.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

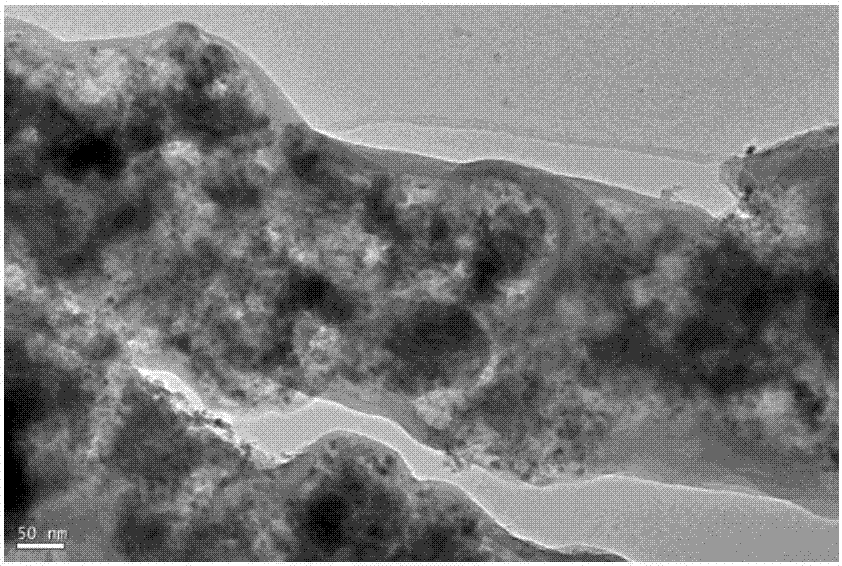

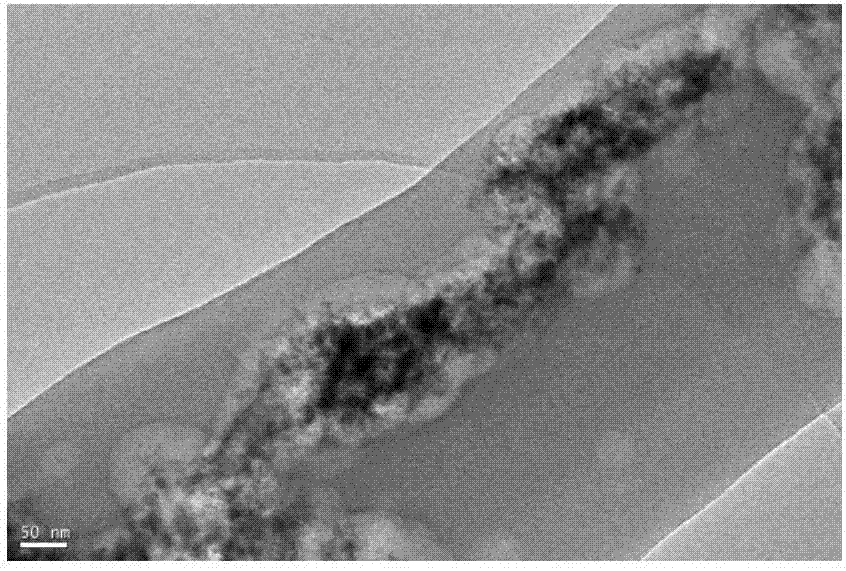

Preparation method for nano-zinc oxide modified graphene hybrid material

ActiveCN104098088ASimple processSynthetic conditions are mildMaterial nanotechnologyZinc oxides/hydroxidesZinc hydroxideVulcanization

The invention discloses a preparation method for a nano-zinc oxide modified graphene hybrid material. The method includes: preparing a graphene oxide suspension solution; dissolving a zinc salt in water, adding the solution into the graphene oxide suspension solution, conducting ultrasonic treatment, adding an alkali reagent dropwise to obtain a zinc hydroxide graphene oxide suspension solution; under ultraviolet light irradiation, performing static aging to obtain a zinc hydroxide-graphene oxide gel, adding an excessive reducing agent, carrying out reaction, using water and ethanol to conduct repeated washing, and performing drying to obtain a zinc hydroxide-graphene dry gel; placing the gel in a muffle furnace, and conducting treatment at high temperature to obtain the gray nano-zinc oxide modified graphene hybrid material. The nano-zinc oxide obtained by the invention has a large specific surface area, can effectively promote vulcanization crosslinking, greatly reduces the using amount of zinc oxide, and is of great importance to full utilization of zinc resources and ecological economy. At the same time, without affecting the performance of graphene, the method is in favor of further expanding the potential application scope of graphene.

Owner:SOUTH CHINA UNIV OF TECH

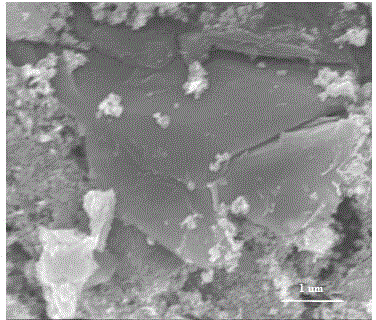

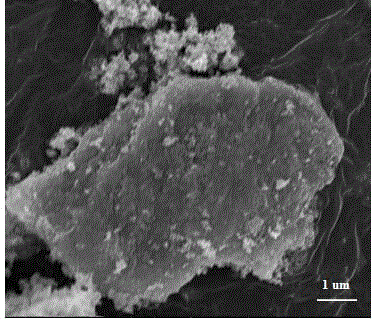

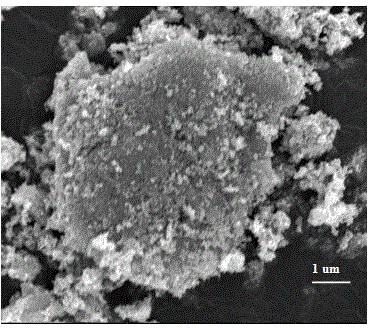

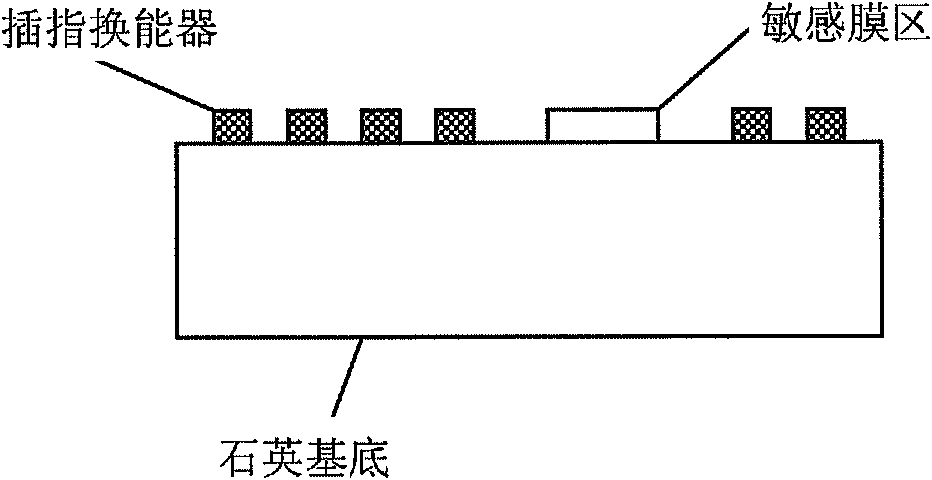

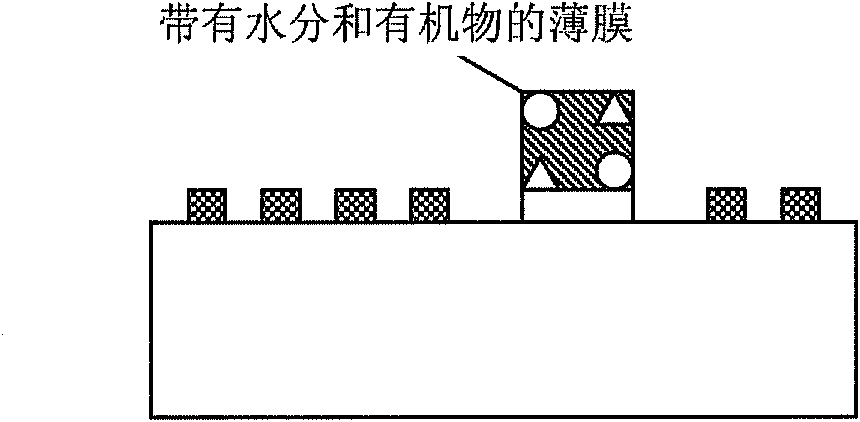

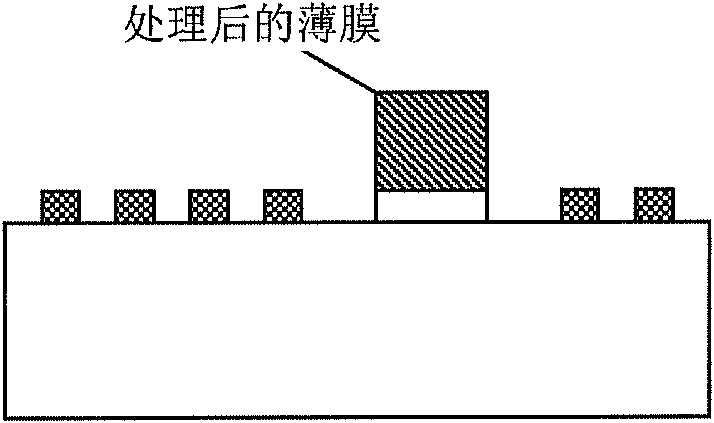

Making method of nano film of graphene doped zinc oxide

InactiveCN102654474ATo achieve the purpose of detecting gasIncreased sensitivityMaterial electrochemical variablesTalc / Zinc OxideControllability

The invention discloses a making method of a nano film of graphene doped zinc oxide. The making method comprises the steps of: preparing graphite oxide by using graphite, anhydrous sodium nitrate, concentrated sulfuric acid and potassium permanganate; preparing graphene by using the graphite oxide; dissolving the graphene and zinc oxide in an ethylene glycol solution, ultrasonically oscillating to obtain a mixture solution; and sucking the mixture solution by using a liquid-moving machine and dropping and coating on a sensitive film of a device, and vacuum-drying to obtain the nano file of the graphene doped zinc oxide. By using the excellent electronic conduction characteristic of the graphene, through change of conductivity, the change of the frequency is changed, and therefore, the purpose of detecting gas is achieved. Due to the adoption of the graphene doped with the zinc oxide, the sensitivity of the sensitive film can be greatly improved. The graphene is synthesized by adopting a chemical dispersal method; the making method has high controllability compared with that of the micro mechanical stripping method; and massive production of the nano film can be carried out.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

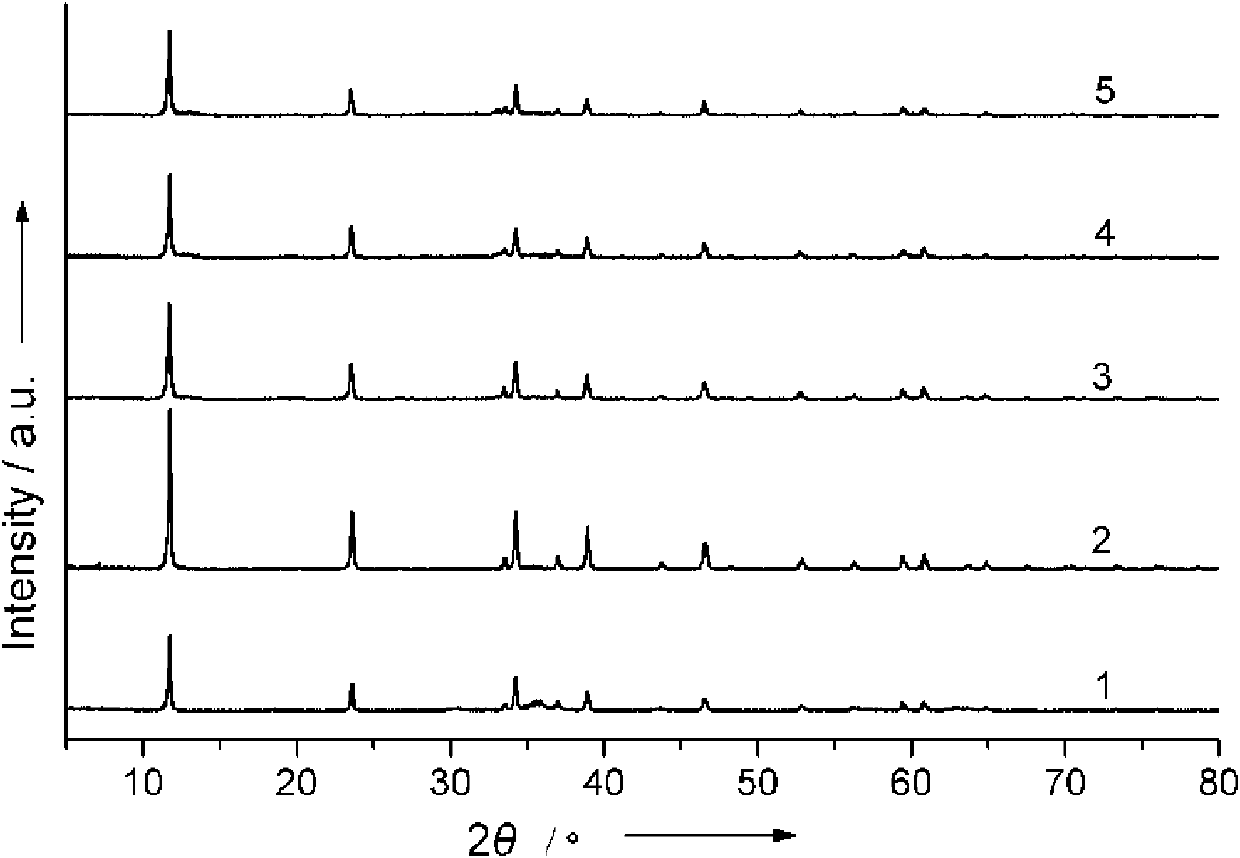

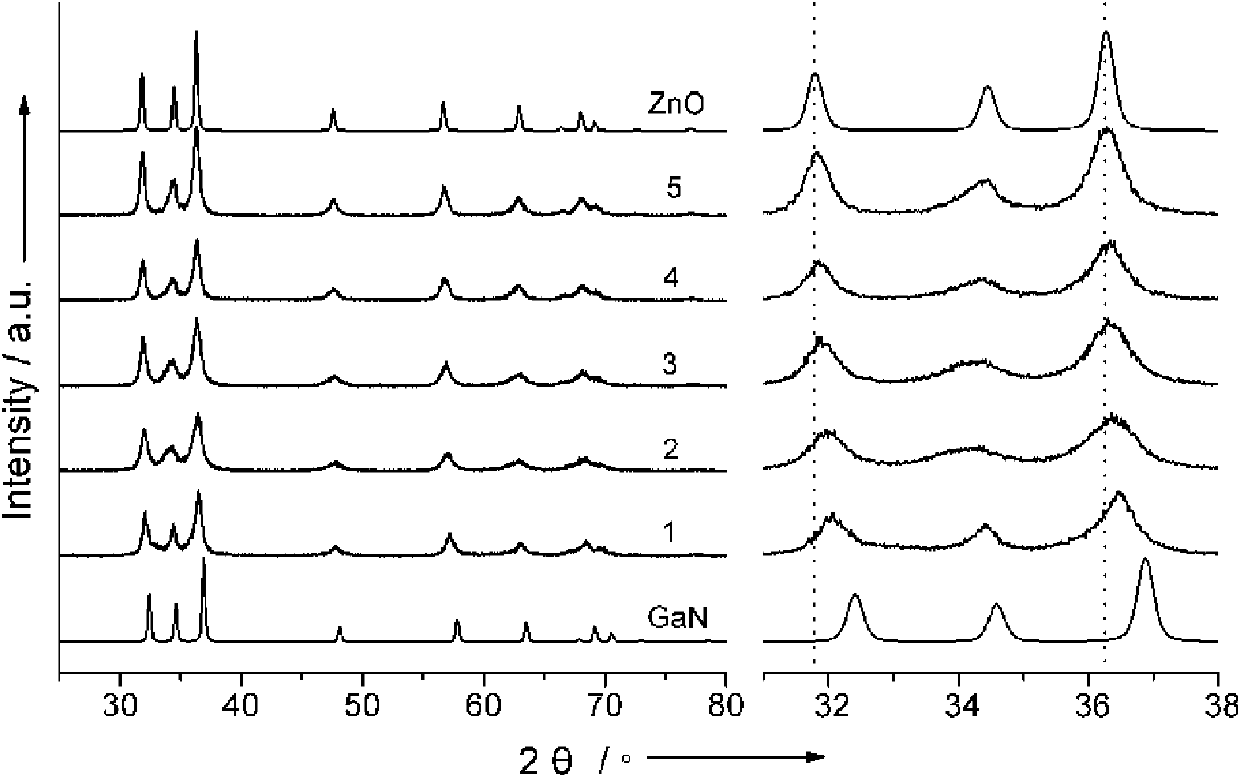

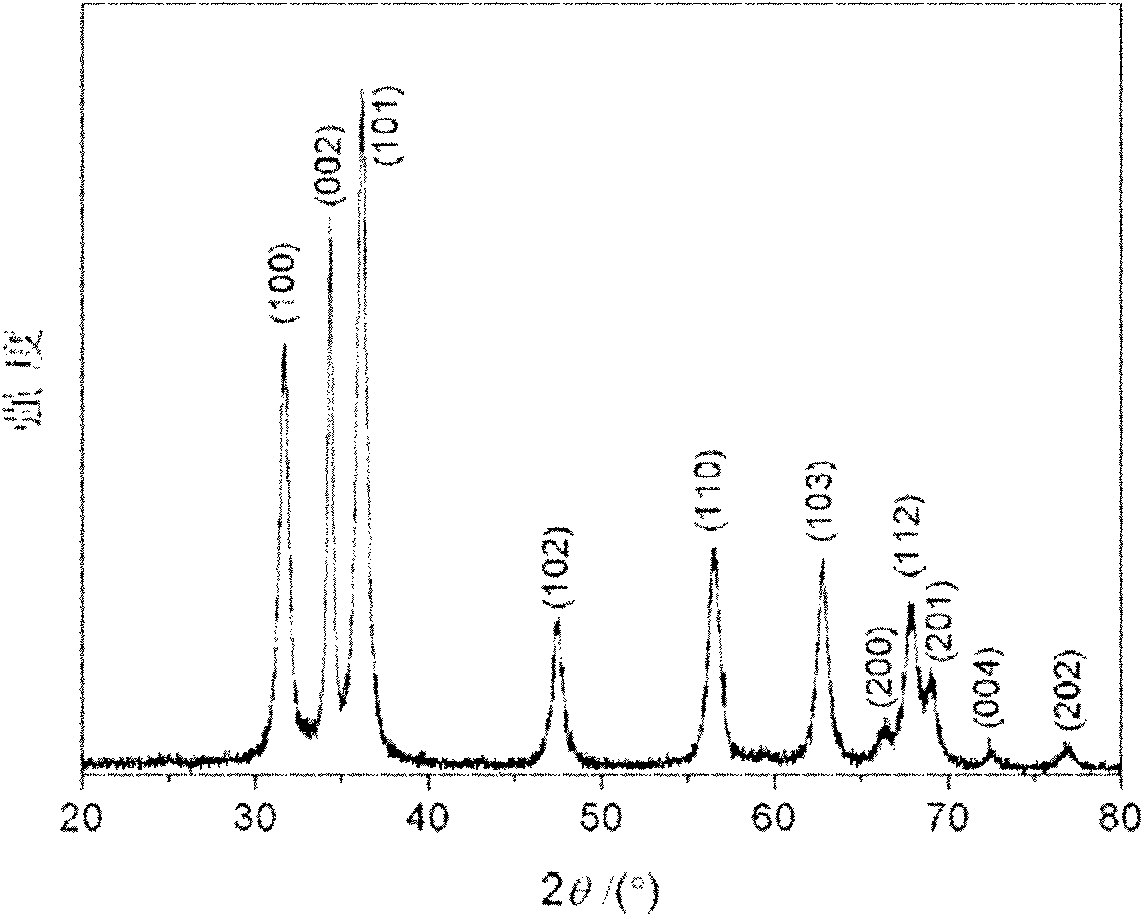

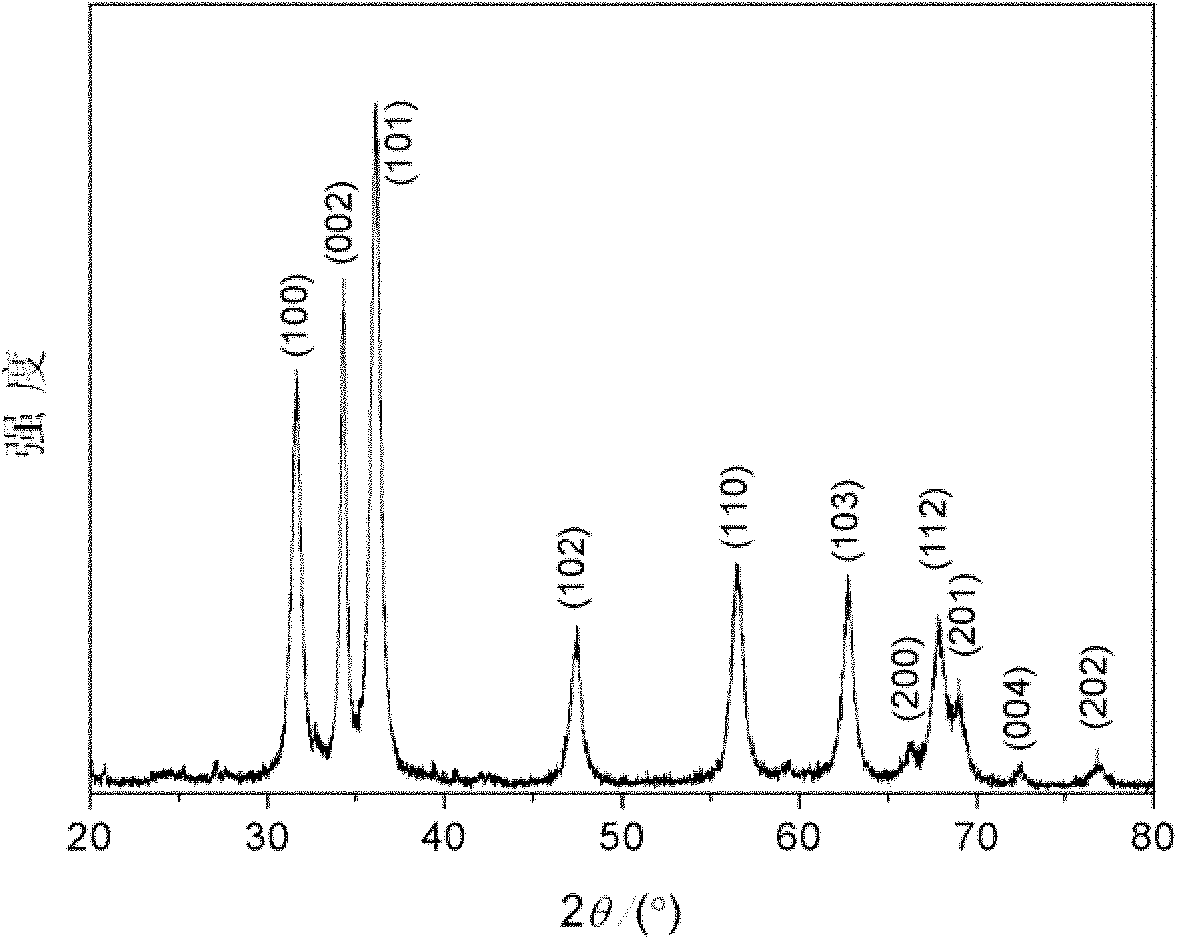

Gallium nitride/zinc oxide solid solution with high zinc content and preparation method thereof

InactiveCN102166527ANo lossComponent adjustablePhysical/chemical process catalystsHydrogen productionTalc / Zinc OxideSolid solution

The invention relates to a gallium nitride / zinc oxide solid solution with a high zinc content and a preparation method thereof. The mass content of zinc oxide is greater than 50% and less than or equal to 80%. The bimetal hydrate precursor of Zn / Ga / CO3 is prepared firstly, and then the precursor is nitridized to obtain the gallium nitride / zinc oxide solid solution with a high zinc content. The preparation method provided by the invention has simplicity and high preparation yield, and the prepared product has a high content of zinc oxide and adjustable contents of components.

Owner:SHANDONG UNIV

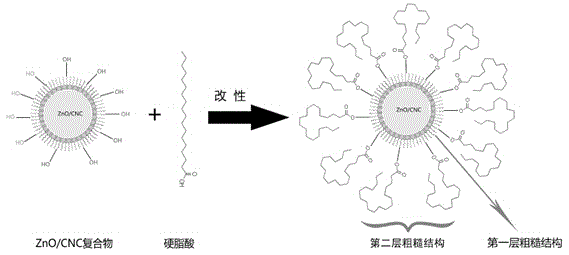

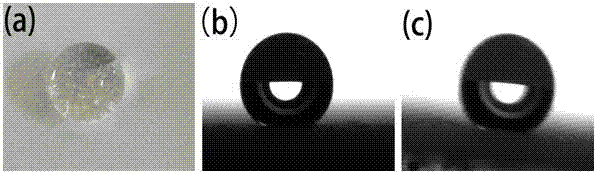

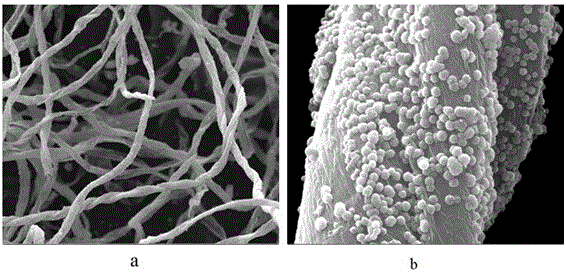

Preparation method of zinc oxide and cellulose nanocrystal composite super-hydrophobic coating

ActiveCN105670500ASimple preparation processEasy to operateAntifouling/underwater paintsPaints with biocidesZno nanoparticlesTalc / Zinc Oxide

The invention provides a preparation method of a zinc oxide and cellulose nanocrystal composite super-hydrophobic coating. The reparation method of the zinc oxide and cellulose nanocrystal composite super-hydrophobic coating is characterized by comprising the following steps that 1, nano zinc oxide with special morphology and a cellulose nanocrystal solution are mixed according to a certain proportion and added into a mixed solution of stearic acid and ethyl alcohol under the condition of magnetic stirring; 2, the mixture is taken out after a certain time and aged, dried and ground into powder, the powder is added into a mixed solution of deionized water, a catalyst ammonia water and a dispersing agent sodium dodecyl benzene sulfonate, and magnetic stirring is conducted after ultrasound is conducted till the mixture is a thick state; 3, a certain amount of polydimethylsiloxane and silane coupling agent are added for continuous magnetic stirring, and a solution is formed and coated on the base material surface to form the super-hydrophobic coating. The preparation method of the zinc oxide and cellulose nanocrystal composite super-hydrophobic coating has the advantages that the preparation technology is simple and easy to operate, the super-hydrophobic coating is suitable for being added into various coatings, and the properties of hydrophobicity, sterilization and abrasion resistance enhancing are achieved.

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

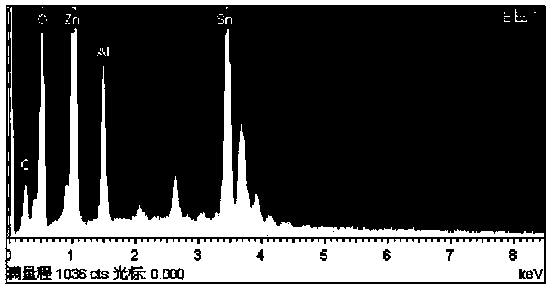

Preparation method for zinc oxide/stannic oxide composite microsphere

InactiveCN103566843ALarge specific surface areaUniform particle size distributionZinc oxides/hydroxidesMicroballoon preparationTin dioxideMicrosphere

The invention discloses a preparation method for a zinc oxide / stannic oxide composite microsphere. According to the method, a wet chemistry method is utilized; a block polymer is used as a template in an organic solvent; a water-soluble zinc salt and a stannum salt are used as precursors; the size of particles is controlled through an ordered composition of the template in the mesoscopic size, and through hydrophilic characteristic, lipophilic characteristic, and the like; and a metal oxide microsphere is obtained by removing the template. The method has advantages of simple technology, low cost, and easily controllable and adjustable size, components, and other characteristics of the microsphere. The zinc oxide / stannic oxide composite microsphere prepared by the method can be used for photocatalysis and hydrolysis of water or polymers, solar cell light anodes, gas-sensitive sensors, and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

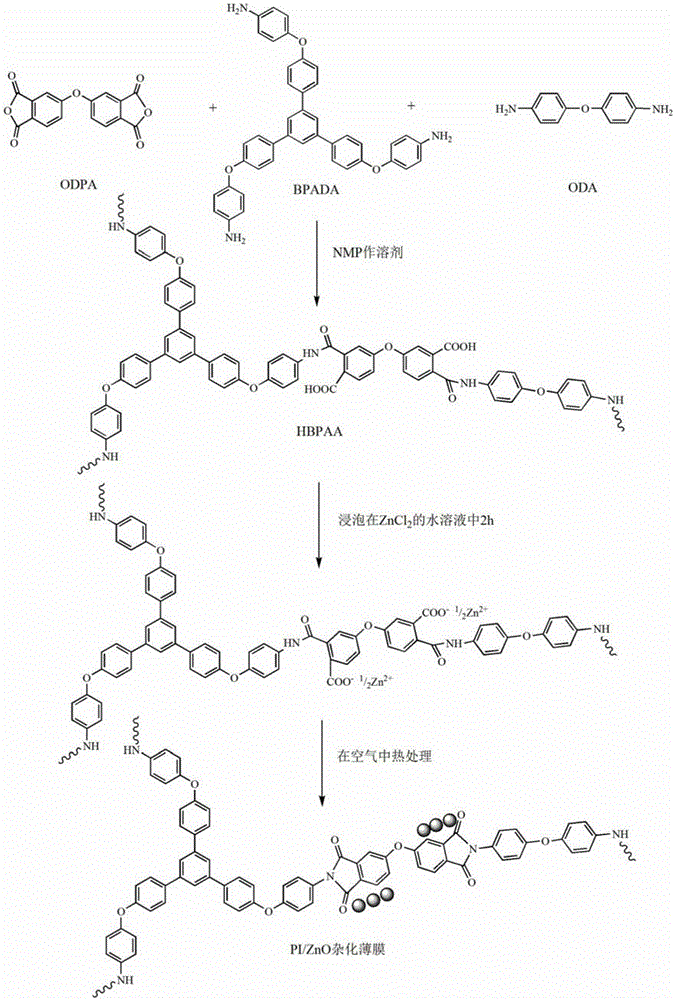

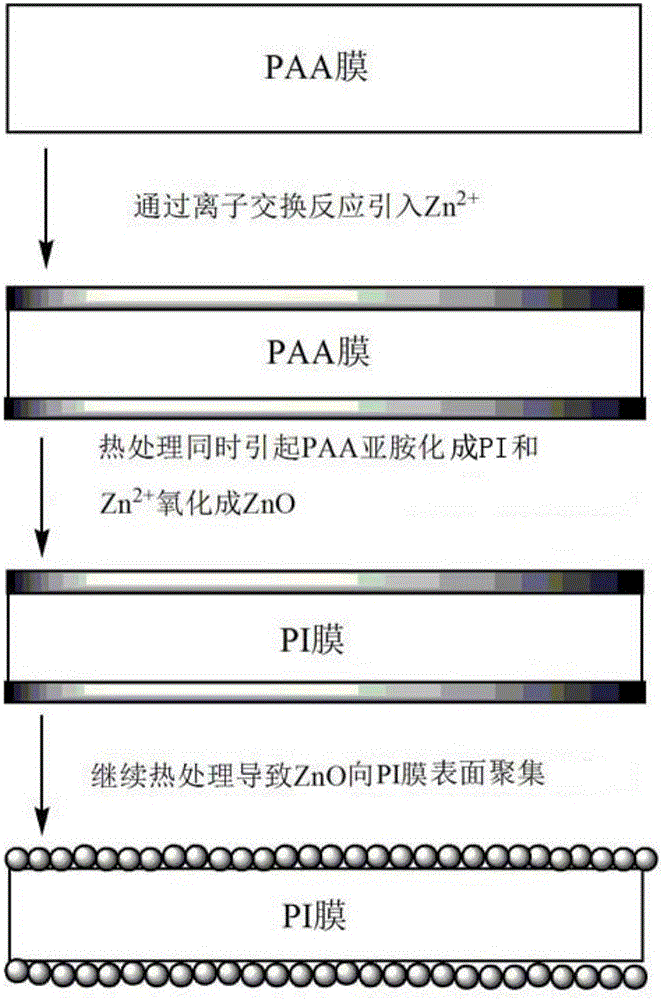

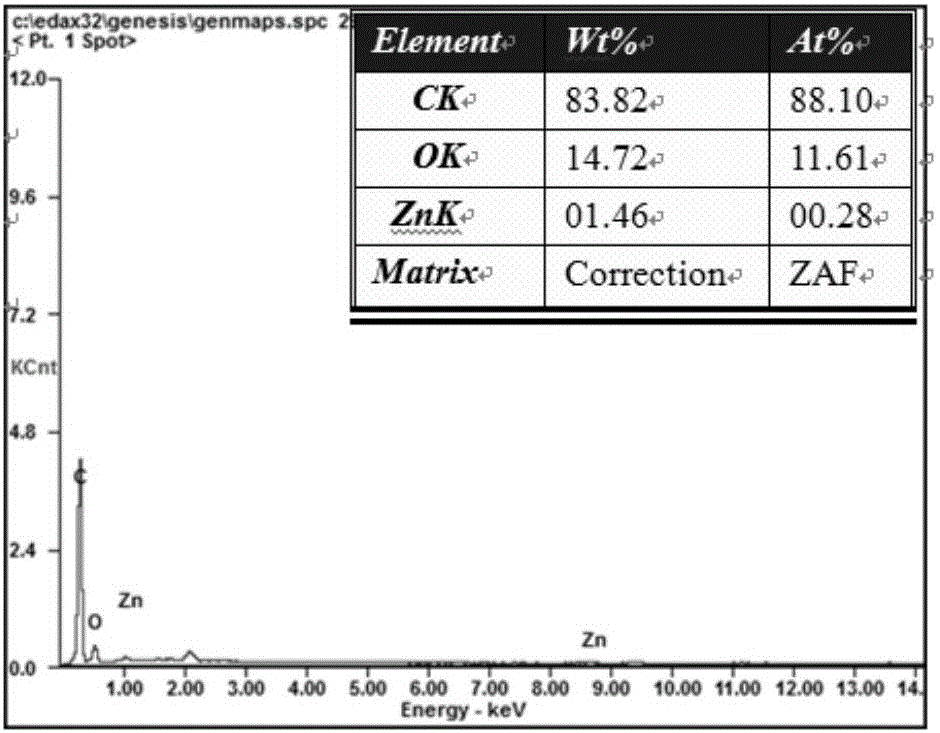

Preparation method of hyper branched copolymerized polyimide/zinc oxide (ZnO) hybrid insulated film

The invention provides a preparation method of a hyper branched copolymerized polyimide / zinc oxide (ZnO) hybrid insulated film, and the method comprises the following steps: preparing a hyper branched copolymerized polyamide acid film: employing 3,3',4,4'-tetracarboxydiphthalic ether dianhydride, triamine monomer 1,3,5-tri[4-(4-aminophenoxy)phenyl]benzene and 4,4'-diaminodiphenyl ether three monomers as raw materials, carrying out condensation polymerization according to a mole proportion 1:0.4:0.5, and obtaining a yellow viscous transparent solution; dropping the obtained solution on a glass plate with a silica gel frame, and obtaining the hyper branched copolymerized polyamide acid film after drying; completing imidization of the hyper branched copolymerized polyamide acid film by one step and forming zinc oxide nanoparticles: preparing a zinc chloride solution, totally soaking the hyper branched copolymerized polyamide acid film in a zinc chloride solution, after completing soaking, taking the hyper branched copolymerized polyamide acid film out for washing; and baking for preparing the product. By means of hybrid of hyper branched polyimide and nanometer zinc oxide, the dielectric constant is reduced and insulating property of the material is added, simultaneously heat resistance and mechanical performance are improved, thereby meeting requirements of different electronic components for materials.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD TAIZHOU POWER SUPPLY BRANCH +2

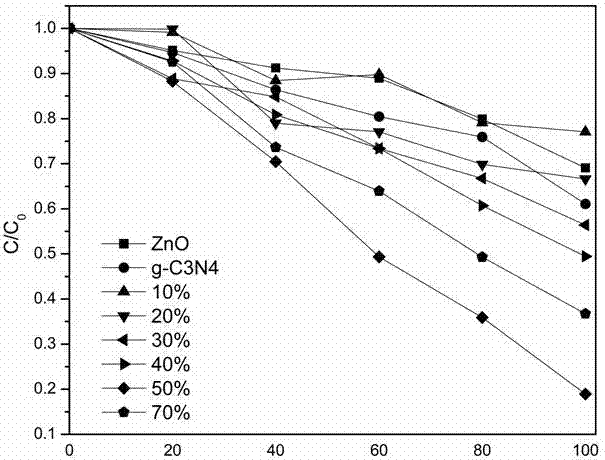

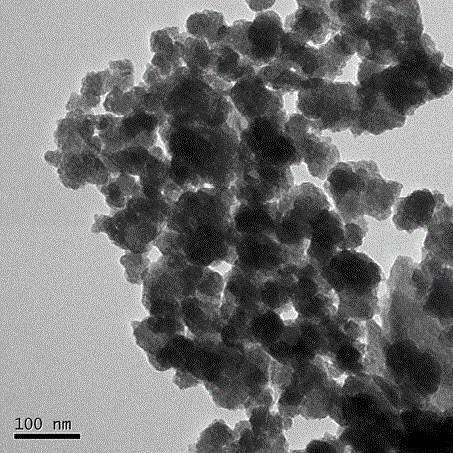

Preparation method of zinc oxide nanorod/g-C3N4 nanosheet composite photocatalyst material

ActiveCN106861742APromote absorptionImprove degradation efficiencyPhysical/chemical process catalystsZinc Acetate DihydrateTalc / Zinc Oxide

The invention provides a preparation method of a zinc oxide nanorod / g-C3N4 nanosheet composite photocatalyst material. The zinc oxide nanorod / g-C3N4 nanosheet composite photocatalyst material is prepared by adopting melamine, zinc acetate dehydrate, sodium hydroxide, hexadecyltrimethyl ammonium bromide and absolute ethyl alcohol as main raw materials through a hydro-thermal synthesis method; zinc oxide in the composite material is a one-dimensional zinc oxide nanorod with uniform morphology; the morphology of g-C3N4 is a two-dimensional nanosheet structure. The product respectively degrades an organic pollutant rhodamine B under simulated sunlight and visible light (lambda is larger than 420nm), so that the photocatalyst material is proved to have an excellent photocatalytic performance. The morphology and the size of the zinc oxide nanorod prepared by the method are uniform, and the thickness of the g-C3N4 nanosheet is less, so that the zinc oxide nanorod and the g-C3N4 nanosheet are tightly combined, the migration of photo-induced electron is facilitated, and the photocatalysis efficiency is improved. The material has good response in ultraviolet and visible light areas, so that the material not only has a better application prospect on the environmental protection field such as water pollution control, but also has a better development prospect on developing and utilizing renewable resources such as solar energy.

Owner:NANCHANG HANGKONG UNIVERSITY

Use of supported nano zinc oxide as anti-diarrhea agent for weaned pigs and using method

InactiveCN102335196AAvoid uneven loadGood dispersionInorganic active ingredientsDigestive systemSide effectFeces

The invention discloses use of supported nano zinc oxide as an anti-diarrhea agent for weaned pigs and a using method. According to the use of the supported nano zinc oxide as the anti-diarrhea agent for the weaned pigs, the supported nano zinc oxide is a composite material for supporting nano zinc oxide by using kaolin or montmorillonite or attapulgite or sepiolite or zeolite as a supporter. The zinc oxide accounts for 10 to 50 weight percent of the composite material for supporting the nano zinc oxide. The using method of the supported nano zinc oxide serving as the anti-diarrhea agent for the weaned pigs comprises that 160 to 800 mg / kg of supported nano zinc oxide based on zinc is added into a weaned pig feed. The supported nano zinc oxide can remarkably reduce the diarrhea rate of the weaned pigs, improve the daily gain, improve the form of the intestinal mucous membrane and protect the intestinal mucous membrane barrier; the fur of the pigs is red and bright; the toxic or side effect of high-zinc daily ration on the pigs is avoided; and the effect of the supported nano zinc oxide exceeds that of high-dose common zinc oxide, the consumption of the zinc oxide is greatly reduced, and zinc excretion and environmental pollution are reduced.

Owner:ZHEJIANG UNIV

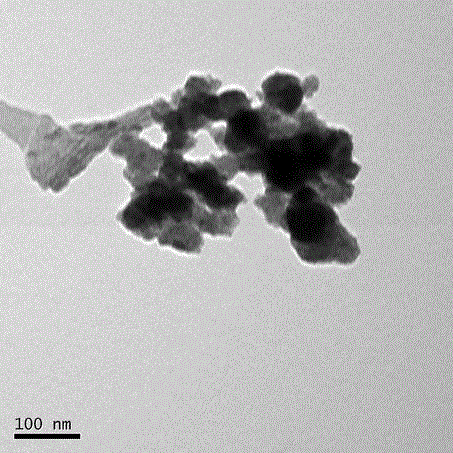

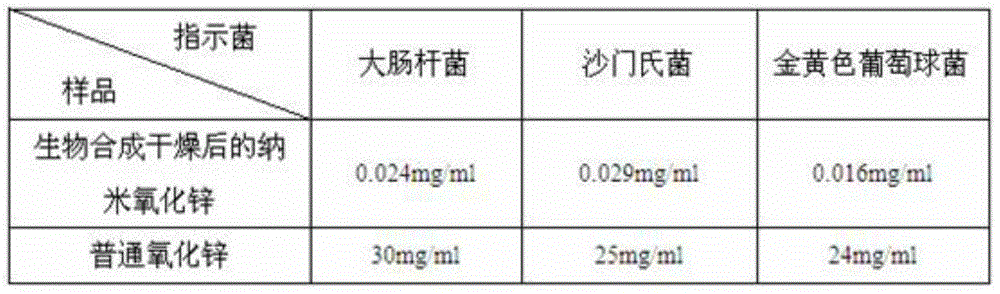

Bio-synthesis method of nano zinc oxide by utilizing lactic acid bacteria and nano zinc oxide composite feed addictive

ActiveCN103602707AIncrease profitRegulate immune functionMicroorganism based processesFermentationZno nanoparticlesAntibiotic Y

The invention relates to the technical fields of microorganism fermentation and nano, and provides a bio-synthesis method of nano zinc oxide by utilizing lactic acid bacteria and a nano zinc oxide composite feed addictive. The invention utilizes lactic acid bacteria to synthesize nano grade zinc oxide, and then develops a novel feed addictive which is rich in nano zinc oxide. The addictive is applied to a feed for suckling pigs, and the addition amount is less than 1000 ppm (by the weight of zinc oxide). The addictive can effectively prevent animals from zinc poisoning and reduce the environmental pollution caused by zinc, can also effectively prevent weaned pigs from diarrhea and improve the health level of intestinal tracts through the co-function of lactic acid bacteria and zinc oxide, and can even wholly or partially replace the antibiotic to reduce the antibiotic residue so as to improve the food safety.

Owner:BIOFORTE BIOTECHNOLOGY (SHENZHEN) CO LTD

Method for producing zinc oxide from low-grade zinc-containing mineral

ActiveCN103145174AOvercome the disadvantages of high consumption and difficult process controlLow impurity contentZinc oxides/hydroxidesWater dischargeTechnical grade

The invention relates to a technical-grade zinc oxide preparation method and especially relates a method for producing zinc oxide from low-grade zinc-containing mineral. The method comprises the following steps that a zinc-ammonia complex purified liquid is slowly added into a zinc sulfate purified liquid being stirred at a fast speed; the mixture undergoes a reaction at a normal temperature for 20min to produce basic zinc carbonate precipitates and an ammonium sulfate solution; the mixture of the basic zinc carbonate precipitates and the ammonium sulfate solution is filtered so that crude basic zinc carbonate and the ammonium sulfate solution are obtained; the crude basic zinc carbonate is cleaned by distilled water to form qualified basic zinc carbonate; the qualified basic zinc carbonate is dried until water content is in a range of 5 to 15%; and the dried qualified basic zinc carbonate is calcined at a temperature of 1100 DEG C for 2 hours to form zinc oxide. The method adopts the raw materials having wide sources, adopts a neutral leaching process in zinc sulfate production, has simple processes, does not need complex equipment, has a low cost, high product purity and no waste water discharge, realizes auxiliary material recycle, reduces a cost and has environmental benefits.

Owner:TANGSHAN HAIGANG HEYUAN ZINC IND

Carbon nanofiber loaded nickel-based catalytic material containing zinc oxide and preparation method thereof

ActiveCN107020101AGood dispersionNot easy to gatherElectro-spinningMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon fibers

The invention relates to the technical field of hydrogenation, specifically relates to nickel-based catalyst and more specifically relates to a carbon nanofiber loaded nickel-based catalytic material containing zinc oxide and a preparation method thereof. The nickel-based catalytic material is prepared from the following raw materials in weight percentage: 15 to 80% of zinc oxide, 15 to 70% of nickel oxide and 5 to 40% of carbon fiber according to oxide. According to the nickel-based catalytic material disclosed by the invention, a double-metal organic framework is coated by nanofiber high polymer through an electrospinning technique, and metal ingredient content is easy to regulate. As the metal organic framework material is of a topological structure, metal in the carbonized catalytic material has stronger interaction, and the prepared carbon nanofiber loaded nickel-based catalytic material has good dispersion and is not prone to gathering. The prepared catalytic material with the carbon nanofiber as a substance is of a mesoporous structure, is beneficial to reactant diffusion and accordingly improves catalytic selectivity.

Owner:LANZHOU UNIVERSITY

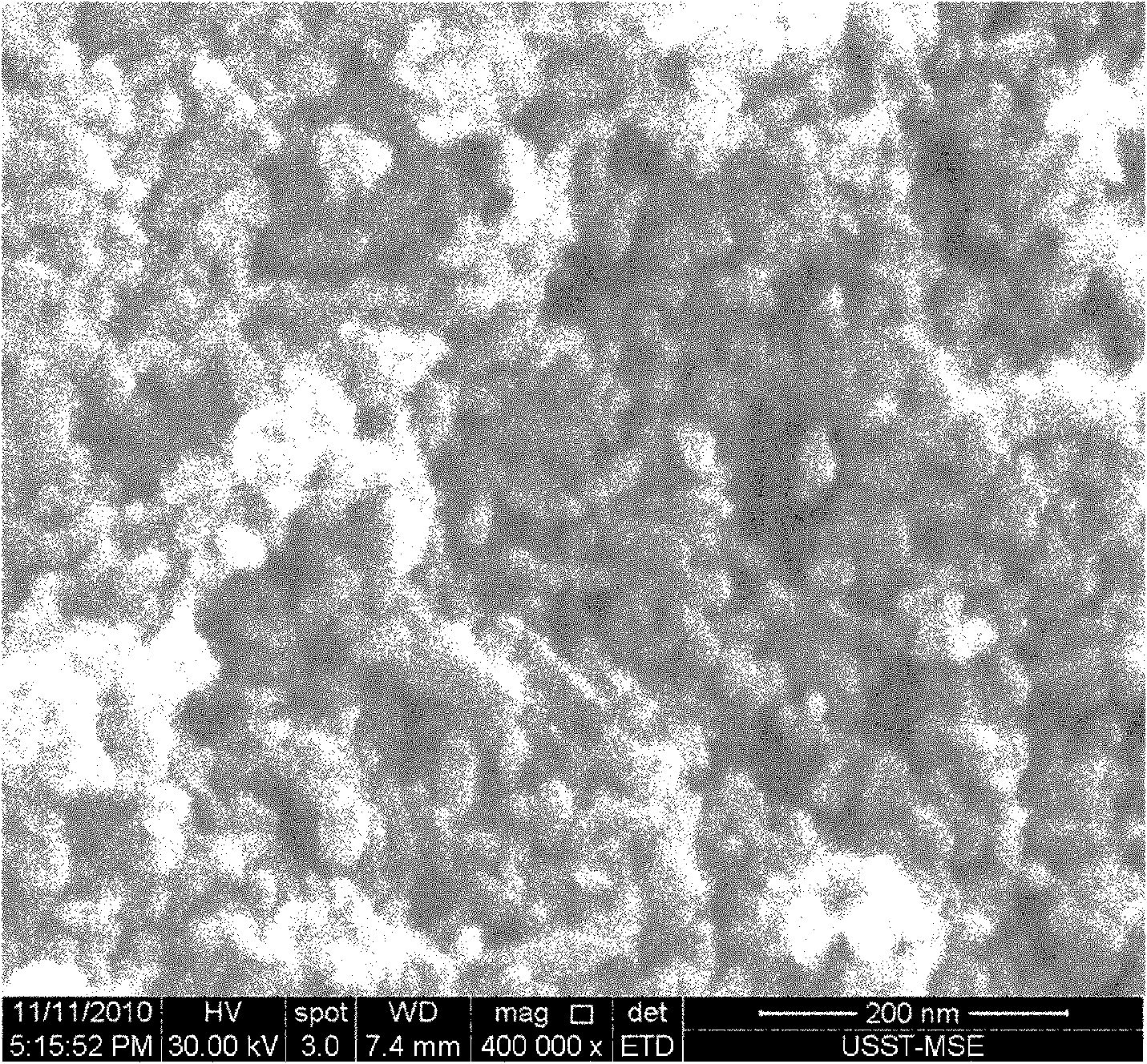

Ultrasound preparation method of nano zinc oxide particles

InactiveCN102101694AHigh purityUniform shapeZinc oxides/hydroxidesNanotechnologyRoom temperatureMegasonic cleaning

The invention relates to an ultrasound preparation method of nano zinc oxide particles. In the ultrasound preparation method, zinc powder is put in a roller vibration mill for grinding to obtain nano zinc powder. The ultrasound preparation method is characterized by comprising the following steps: placing the prepared nano zinc powder and deionized water in a beaker at a weight ratio of 1: 60, then putting the beaker in an ultrasonic cleaning device with the frequency of 70-99 Hz, and carry out ultrasonic treatment for 24-30 hours, so as to obtain a white turbid solution; and standing the turbid solution for 3-5 minutes at room temperature, sucking the turbid solution to another clean beaker again by using a suction tube, putting the beaker in a constant temperature drying oven at the temperature of 60 DEG C, drying for 24 hours, and grinding and dispersing the obtained product by using an agate mortar after finishing drying, so that the nano zinc oxide is obtained. In the invention, the nano zinc powder is processed by ultrasonic treatment so that the nano zinc oxide is obtained; and the operation is simple and convenient, the cost is low, the environment is not polluted, preparation is carried out at low temperature, and the obtained nano zinc oxide has high purity, no other impurity phases and even topography. The ultrasound preparation method is easy to achieve industrial production and has a wide application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

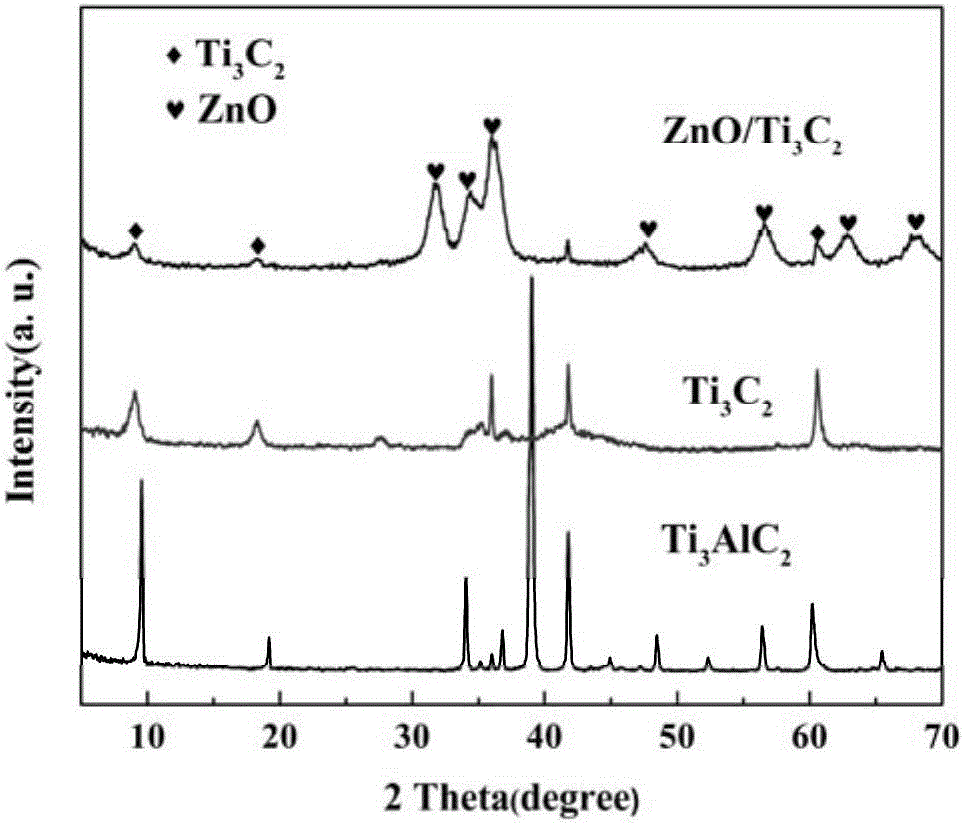

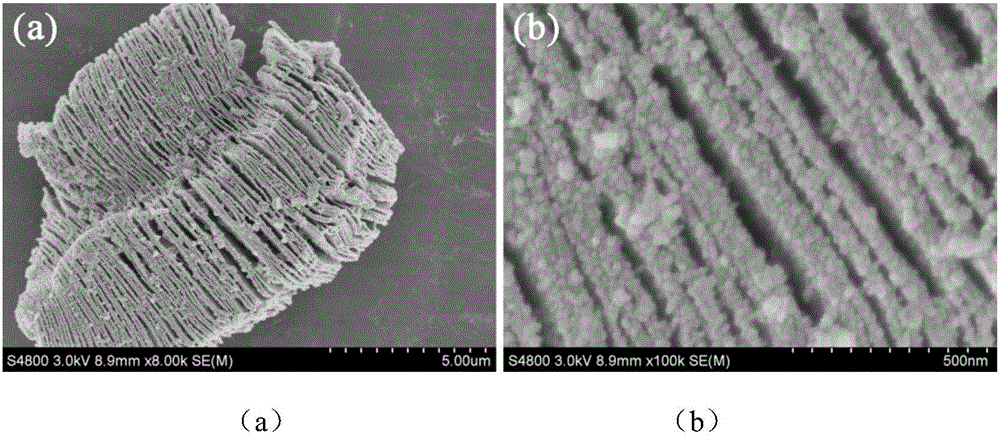

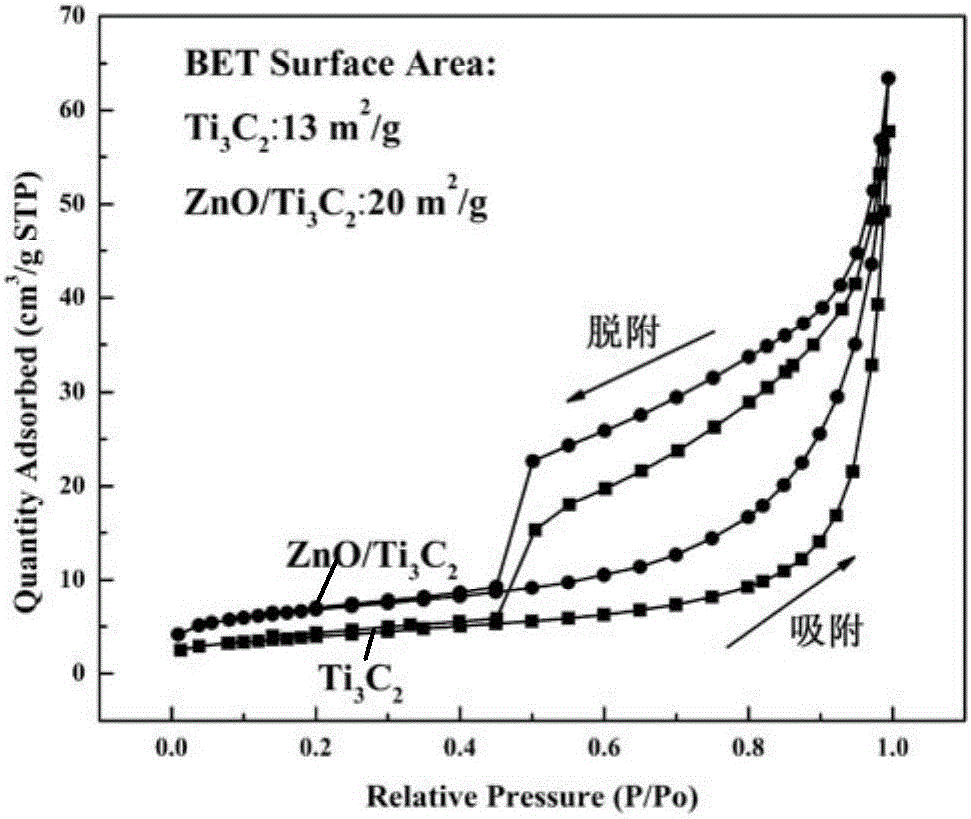

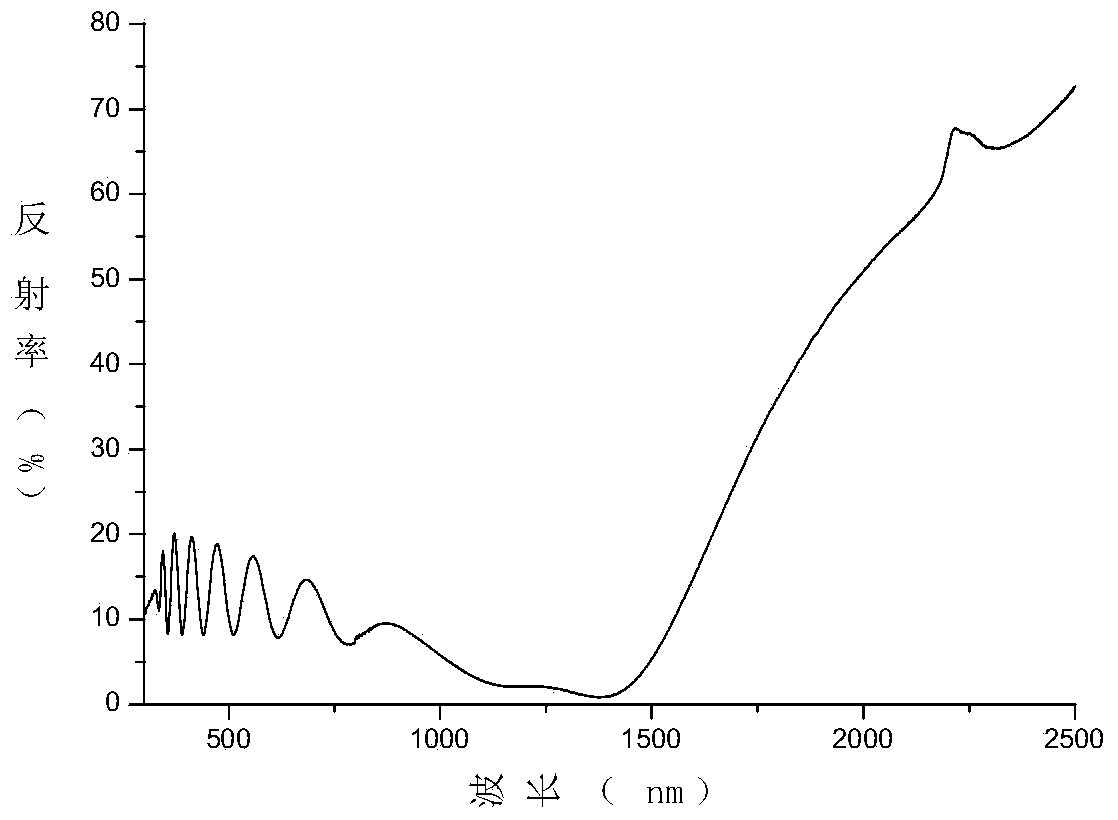

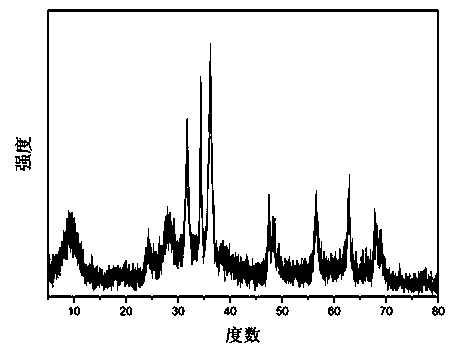

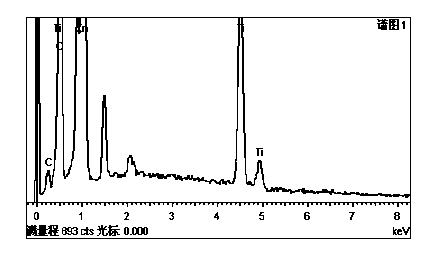

Hydrothermal preparation method of zinc oxide/two-dimensional layered titanium carbide composite material

InactiveCN106277028ALarge specific surface areaNo pollution in the processZinc oxides/hydroxidesTalc / Zinc OxideTitanium carbide

The invention provides a hydrothermal preparation method of a zinc oxide / two-dimensional layered titanium carbide composite material. The hydrothermal preparation method of the zinc oxide / two-dimensional layered titanium carbide composite material comprises the following steps of adding two-dimensional layered titanium carbide and Zn(NO<3>)<2>.6H<2>O to anhydrous ethanol, performing stirring for 2-5 hours, adding NaOH, then performing stirring for 0.5-1h, placing a mixed solution in a hydrothermal kettle, enabling the mixed solution to be subjected to a reaction at 100-140 DEG C for 6-10h, performing washing, and performing drying so as to obtain the zinc oxide / two-dimensional layered titanium carbide composite material. According to the hydrothermal preparation method disclosed by the invention, non-toxic raw materials are used, besides, a preparation process is simple, the technology is controllable, the cost is low, the synthesized zinc oxide / two-dimensional layered titanium carbide composite material is large in specific surface area, concurrently has excellent properties of zinc oxide and excellent properties of two-dimensional layered titanium carbide, and the application of the zinc oxide / two-dimensional layered titanium carbide composite material in the fields of photocatalysis, wastewater treatment, biosensors, supercapacitors, lithium ion batteries and the like is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of nano zinc oxide/epoxy resin composite superhydrophobic coating

InactiveCN107353766ASimple preparation processRaw materials are easy to getAntifouling/underwater paintsPaints with biocidesEpoxyZno nanoparticles

The invention relates to a preparation method of a nano zinc oxide / epoxy resin composite superhydrophobic coating. The preparation method comprises the following steps: 1) preparing 100 parts by mass of ethanol / acetone solution having a volume ratio of 1:1; sequentially adding 1.0-5.0 parts by mass of zinc oxide powder of which the particle diameter is 100nm and 1.0-5.0 parts by mass of zinc oxide powder of which the particle diameter is 10nm into the solution; and adding 0.001 part by mass of low surface energy activator, and performing mixing and stirring for 3 hours to obtain a suspension A; 2) adding 1-5 parts by mass of epoxy resin and a curing agent accounting for 10% of the epoxy resin in mass into the suspension A, and performing ultrasonic oscillation to form a suspension B; and 3) uniformly spraying the suspension B on a substrate, performing normal temperature curing for 2 hours, and performing curing at 100 DEG C for 30 minutes. The preparation method provided by the invention has the advantages of simple process, accessible raw materials and low cost; the coating is favorable in superhydrophobic performance, the water contact angle is 160 degrees or above, and the water roll angle is 10 degrees or below; and the coating is high in mechanical strength, high in adhesion force and long in service life.

Owner:NANCHANG HANGKONG UNIVERSITY

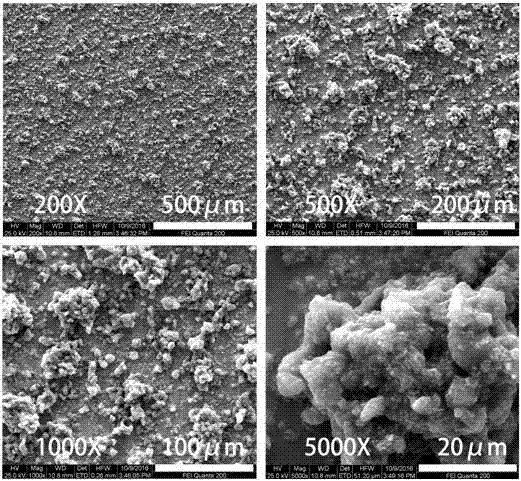

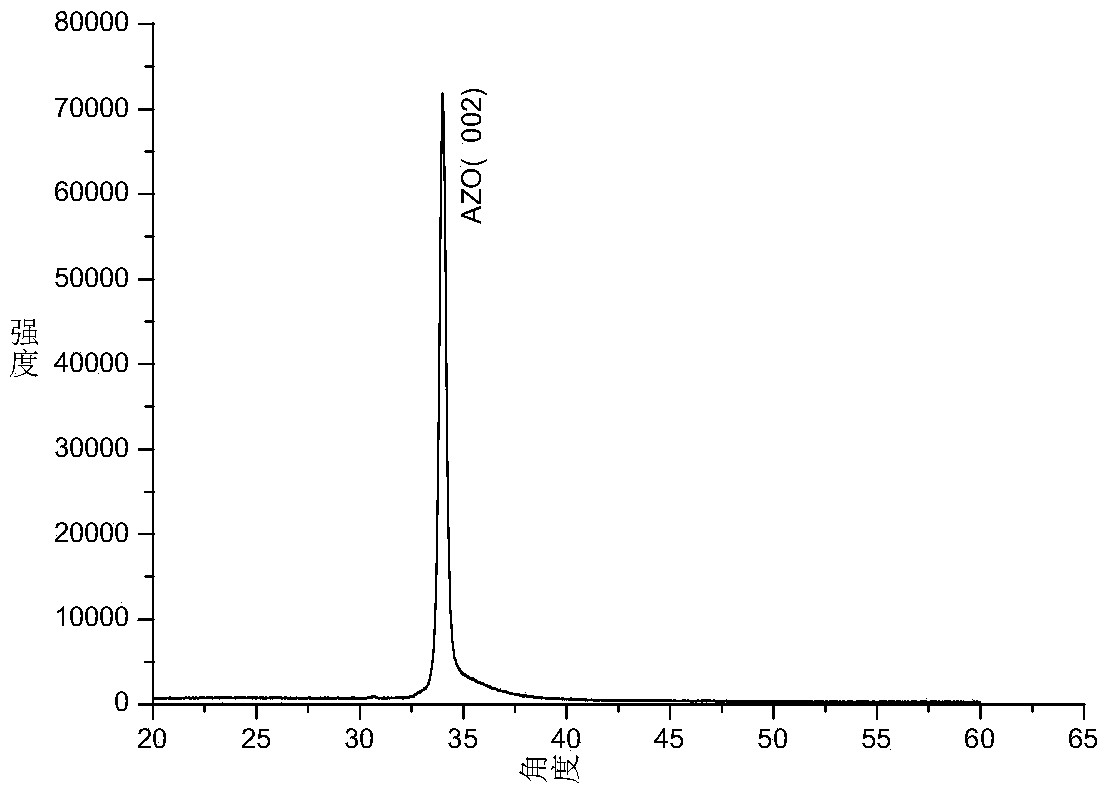

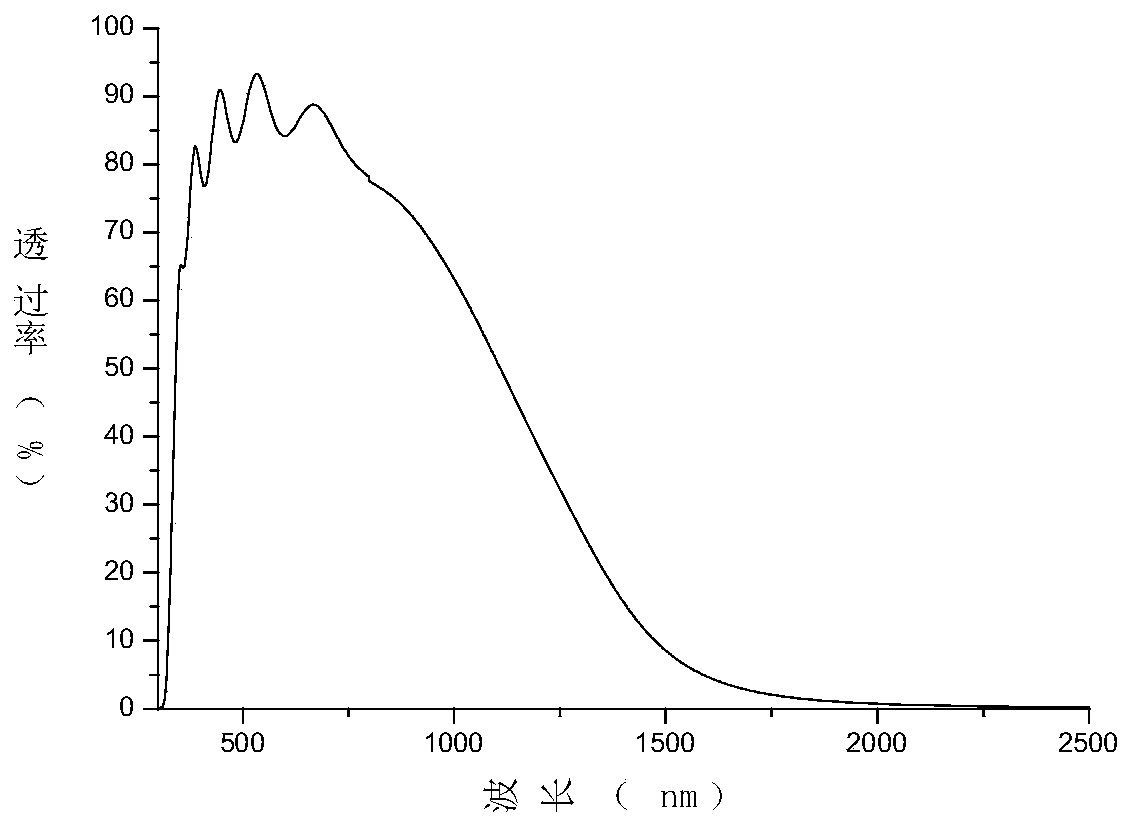

Preparation method of aluminum-doped zinc oxide (AZO) transparent conducting film

InactiveCN103526169AImprove uniformityImprove processing stabilityVacuum evaporation coatingSputtering coatingDeposition temperatureHydrogen

The invention relates to a preparation method of an aluminum-doped zinc oxide (AZO) transparent conducting film. The AZO film is prepared through an AZO ceramic target direct-current magnetron sputtering process in an argon-hydrogen mixed atmosphere at room temperature. The process parameters are as follows: the vacuum degree is 0.08-0.4Pa, the flow ratio of hydrogen gas to argon gas is (40:0.5)-(40:8)(SCCM), the sputtering power is 180W, the target-substrate distance is 160mm, and the deposition temperature is room temperature.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

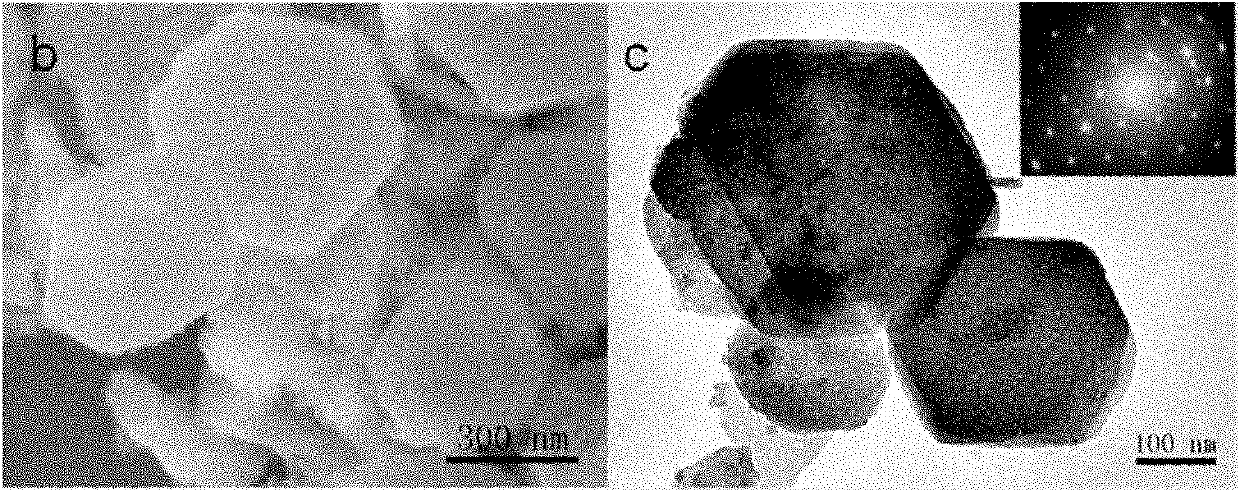

Preparation method of zinc oxide/titanium dioxide nanometer composite material

InactiveCN103803633ANoveltyIncrease output ratioZinc oxides/hydroxidesNanotechnologyEthylenediamineDispersity

The invention provides a preparation method of a zinc oxide / titanium dioxide nanometer composite material. The preparation method comprises the following steps: preparing a zinc ion solution, aqueous alkali and an ethidene diamine solution, and respectively adding the aqueous alkali and the ethidene diamine solution to the zinc ion solution in a stirring process; after stirring, adding P25 type titanium dioxide powder to the mixed solution; stirring and uniformly mixing, putting suspension liquid in a supercritical reactor basket, and reacting for 4-10 hours at the temperature of 100-130 DEG C and the pressure intensity of 12-18Mpa; after ending reaction, washing a precipitation product with deionized water, and then drying for 6-24 hours at the temperature of 60-100 DEG C, thus obtaining the zinc oxide / titanium dioxide nanometer composite material. The ZnO / TiO2 composite material prepared by the method is high in output-input ratio and has the advantages of high degree of crystallinity, low cost, small clustering among powder, good dispersity and the like; the preparation method is simple.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

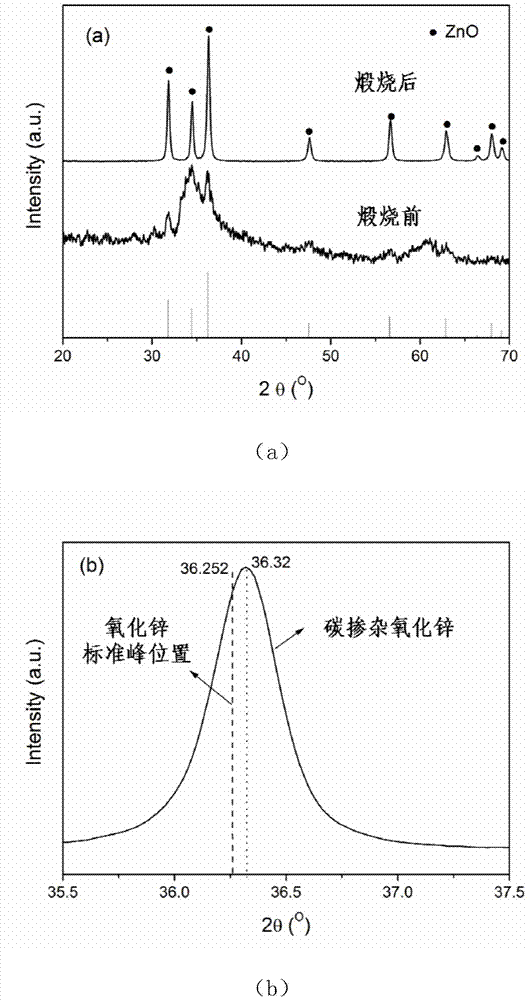

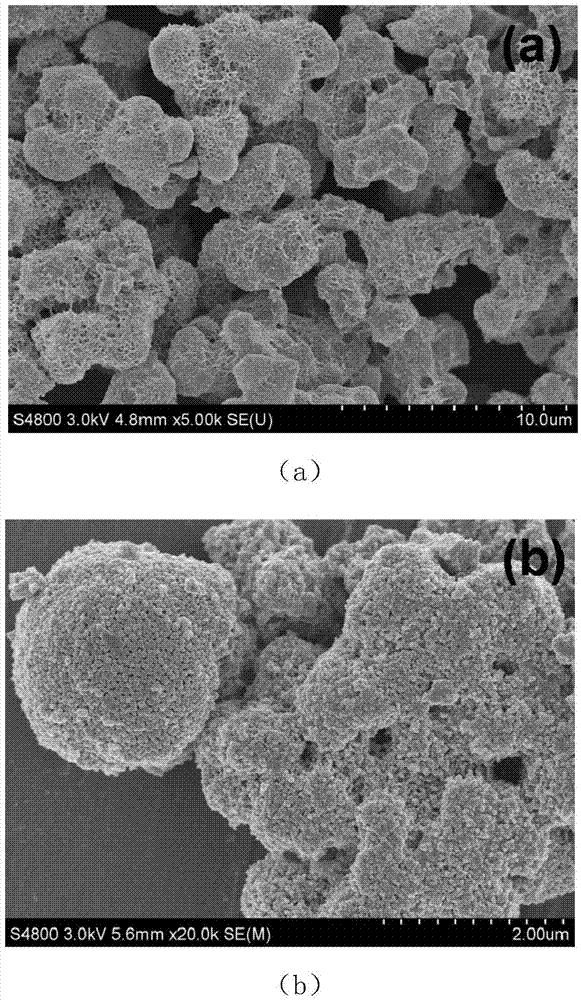

Method for preparing carbon doped zinc oxide

InactiveCN103496733AUniform particle sizeLarge specific surface areaZinc oxides/hydroxidesTalc / Zinc OxideControllability

The invention provides a method for preparing carbon doped zinc oxide. The method comprises the following steps: dissolving zinc gluconate in water to obtain a zinc gluconate solution, and then, regulating pH value of the zinc gluconate solution to be 6-8; adding the zinc gluconate solution, of which pH value is regulated, into a microwave hydrothermal synthesis instrument, performing a synthetic reaction at 180-250 DEG C, and then, cooling naturally to room temperature to get a product; centrifugally separating the product, collecting solid, and then, washing and drying the solid to obtain a brown zinc oxide precursor; and calcining the brown zinc oxide precursor to obtain the carbon doped zinc oxide. The method has the characteristics of short reaction time, high efficiency and excellent repeatability; the zinc gluconate is used as the raw material, thus, the method is environmental-friendly and pollution-free. The carbon doped zinc oxide prepared by the method has uniform granularity, has a loose and porous structure, and has the characteristics of high specific surface area, high purity, excellent carbon doping amount controllability and good visible light absorption.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing nano-zinc oxide used as photocatalyst

InactiveCN104307501AEnsure safetySimple processCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater bathsOrganic dye

A method for preparing nano-zinc oxide used as a photocatalyst comprises the following steps: dissolving zinc nitrate, a complexing agent and glucose in deionized water at room temperature under stirring so as to form a solution; adding acrylamide and methylene-bisacrylamide into the solution in sequence; uniformly stirring the solution to obtain colorless and transparent sol; heating the obtained colorless and transparent sol in a water bath to form white wet gel; drying the obtained wet gel to obtain dry gel; grinding the dry gel to powder; sintering the powder for 4-5 hours at 600-700 DEG C so as to obtain nano-zinc oxide powder. The nano-zinc oxide prepared by using the method provided by the invention has the advantages of very high degree of crystallinity, uniform distribution of grain size and very good photocatalytic degradation activity for various organic dyes under the ultraviolet light.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Method for producing high-purity nano-zinc oxide by ammonia decarburization of electrolytic zinc acid-leaching residues

ActiveCN102838158AExcellent liquidityExcellent dispersionMaterial nanotechnologyZinc oxides/hydroxidesSocial benefitsElectrolysis

The invention discloses a method for producing high-purity nano-zinc oxide by ammonia decarburization of electrolytic zinc acid-leaching residues, wherein when leaching, 0.3-0.5kg of sodium fluorosilicate is added to per cubic meter of ammonia-ammonium bicarbonate solution, and then 30-60kg of slaked lime is added to per cubic meter of a leaching agent for performing decarburization and refining treatment; the method can obtain nano-zinc oxide powder with the purity greater than and equal to 99.7%, uniform particle size distribution (wherein the average particle size is 10-30nm), the specific surface area greater than and equal to 105m<2> / g, and excellent fluidity and dispersibility; the treatment method provided by the invention has the characteristics of low energy consumption, high efficiency, and higher economic and social values; all the valuable and harmful heavy metals in the electrolytic zinc acid-leaching residues are leached to be rationally used and cleaned with water; and finally, the obtained final leaching residues are turned from the electrolytic zinc acid-leaching residues as high-risk wastes into general solid wastes, thereby creating good economic and social benefits.

Owner:SICHUAN JUHONG TECH

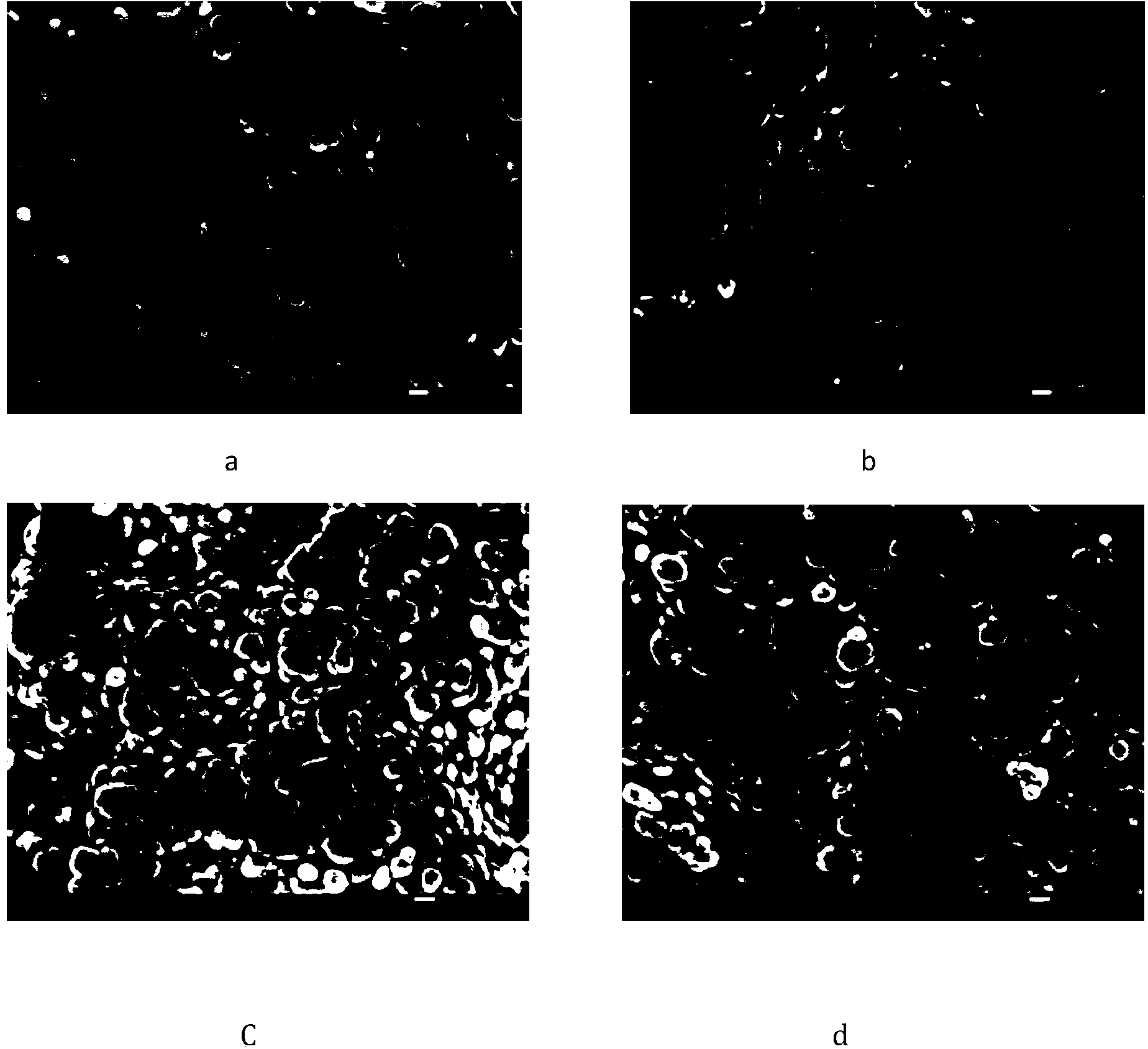

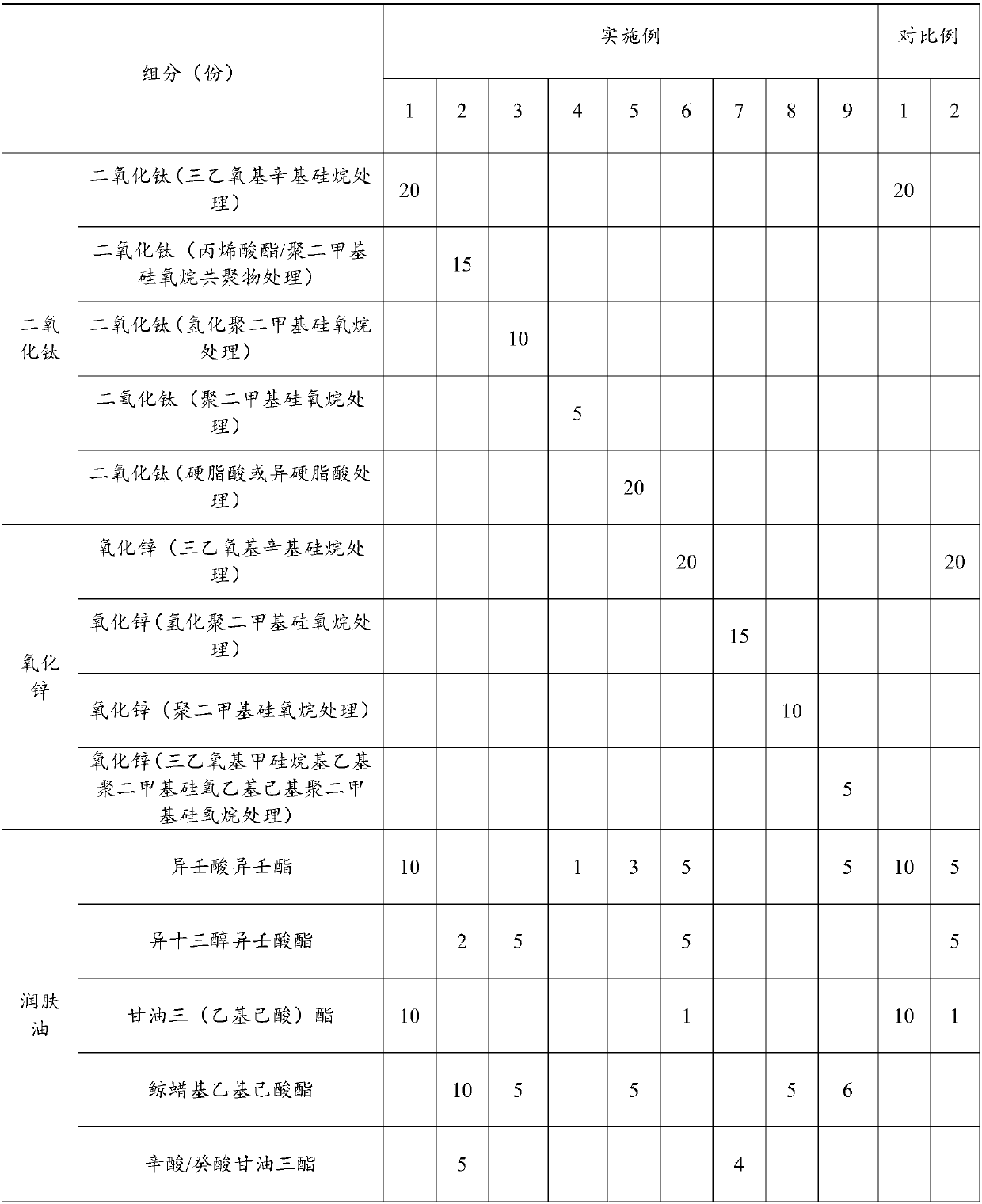

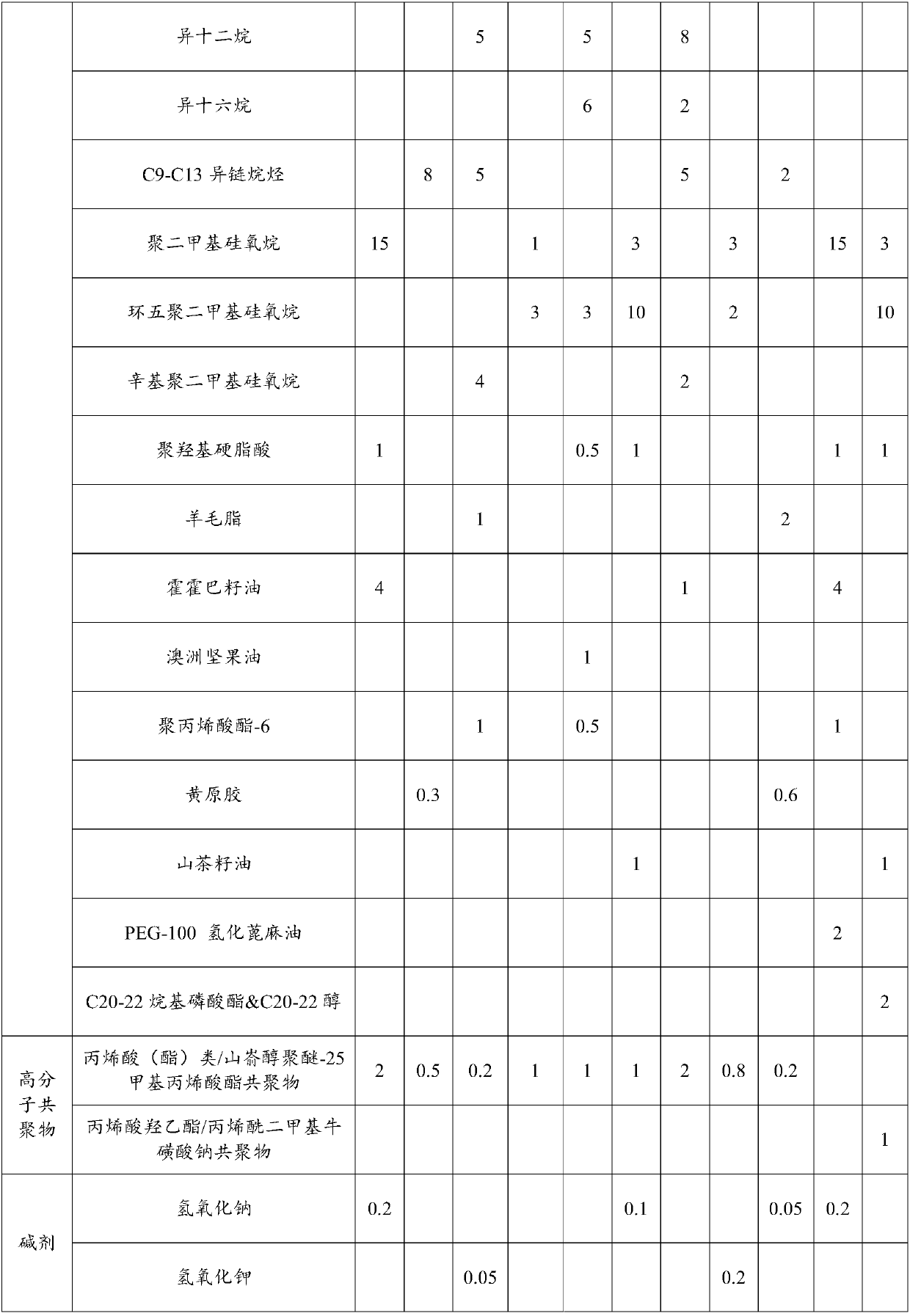

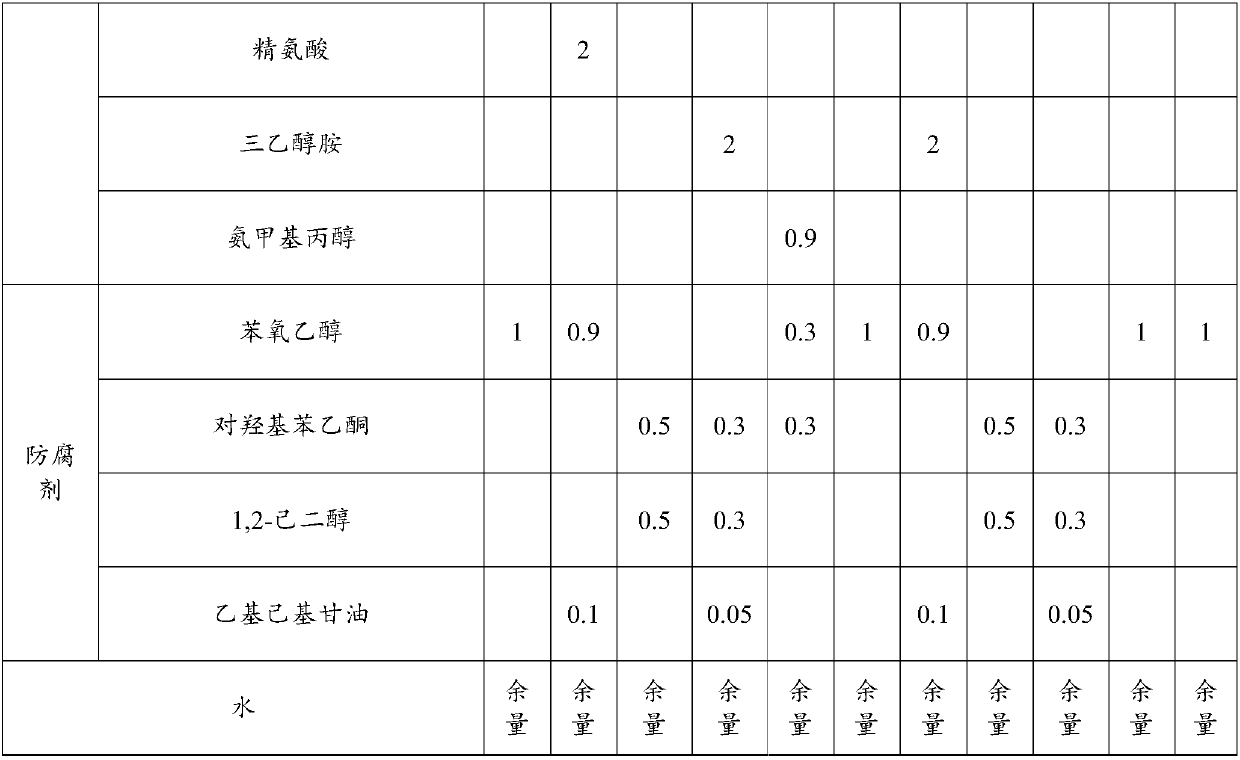

Sun-screening agent with high-content titanium dioxide or zinc oxide and preparation method thereof

ActiveCN109512684ARefreshing skinLess irritatingCosmetic preparationsToilet preparationsPreservativeTalc / Zinc Oxide

The invention provides a sun-screening agent with high-content titanium dioxide or zinc oxide. The sun-screening agent with the high-content titanium dioxide or zinc oxide is prepared from the following components in parts by weight: 5 to 20 parts of hydrophobically modified titanium dioxide or zinc oxide, 0.2 to 2 parts of a crylic acid (ester) / beheneth-25 methacrylate polymer, 0.05 to 2 parts ofan alkaline agent, and 0.3 to 1 part of a preservative. The sun-screening agent provided by the invention has relatively high content of hydrophobic inorganic sun-screening particles, can reach a high SPF (Sun Protect Factor) value easily and has a refreshing skin feeling; because the use of an emulsifying agent is avoided, the sun-screening agent has more refreshing skin feeling and lower irritation, and is suitable to be applied to sun-screening cosmetics for sensitive skin.

Owner:HUANAN IND TECH RES INST OF ZHEJIANG UNIV +1

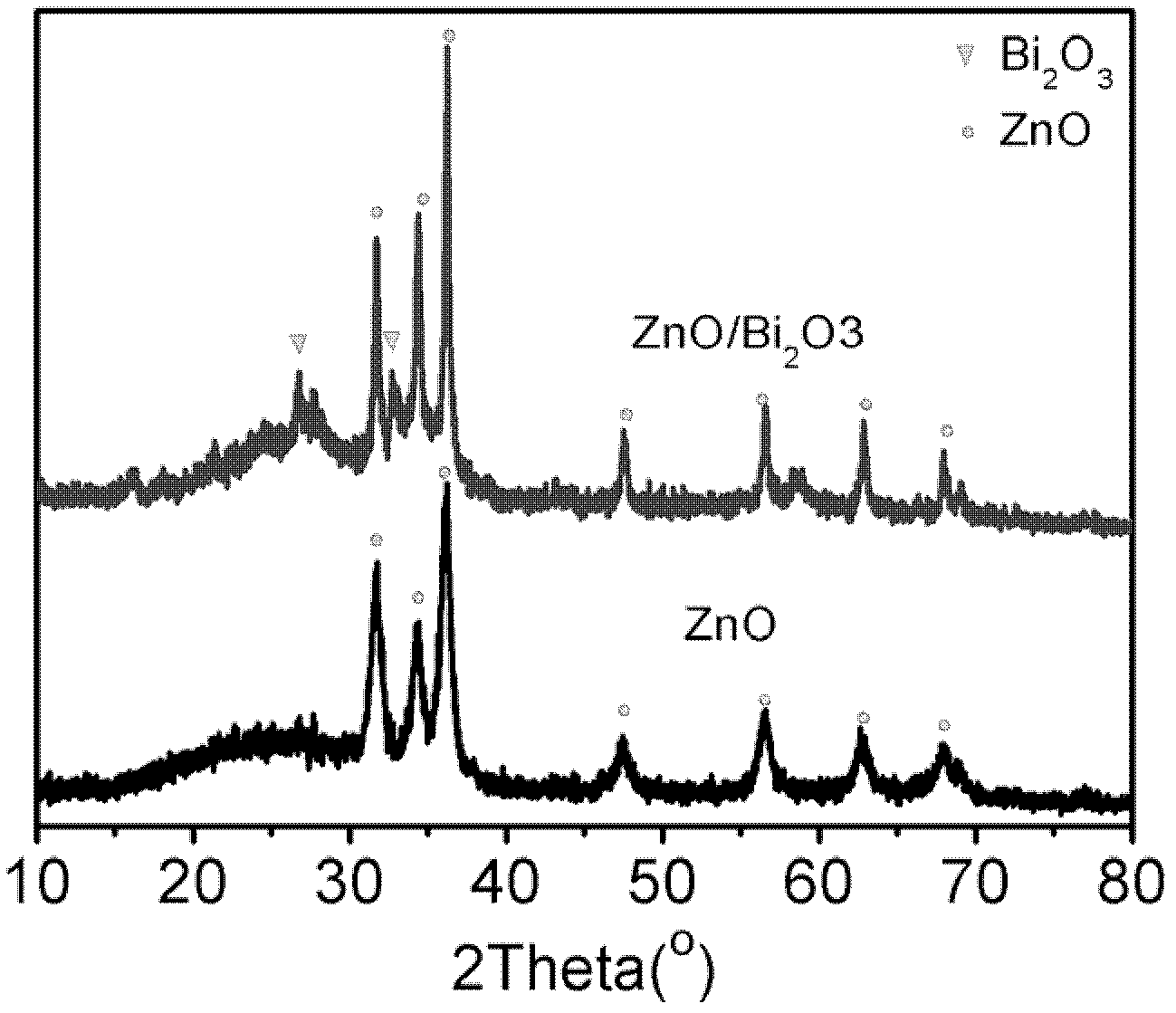

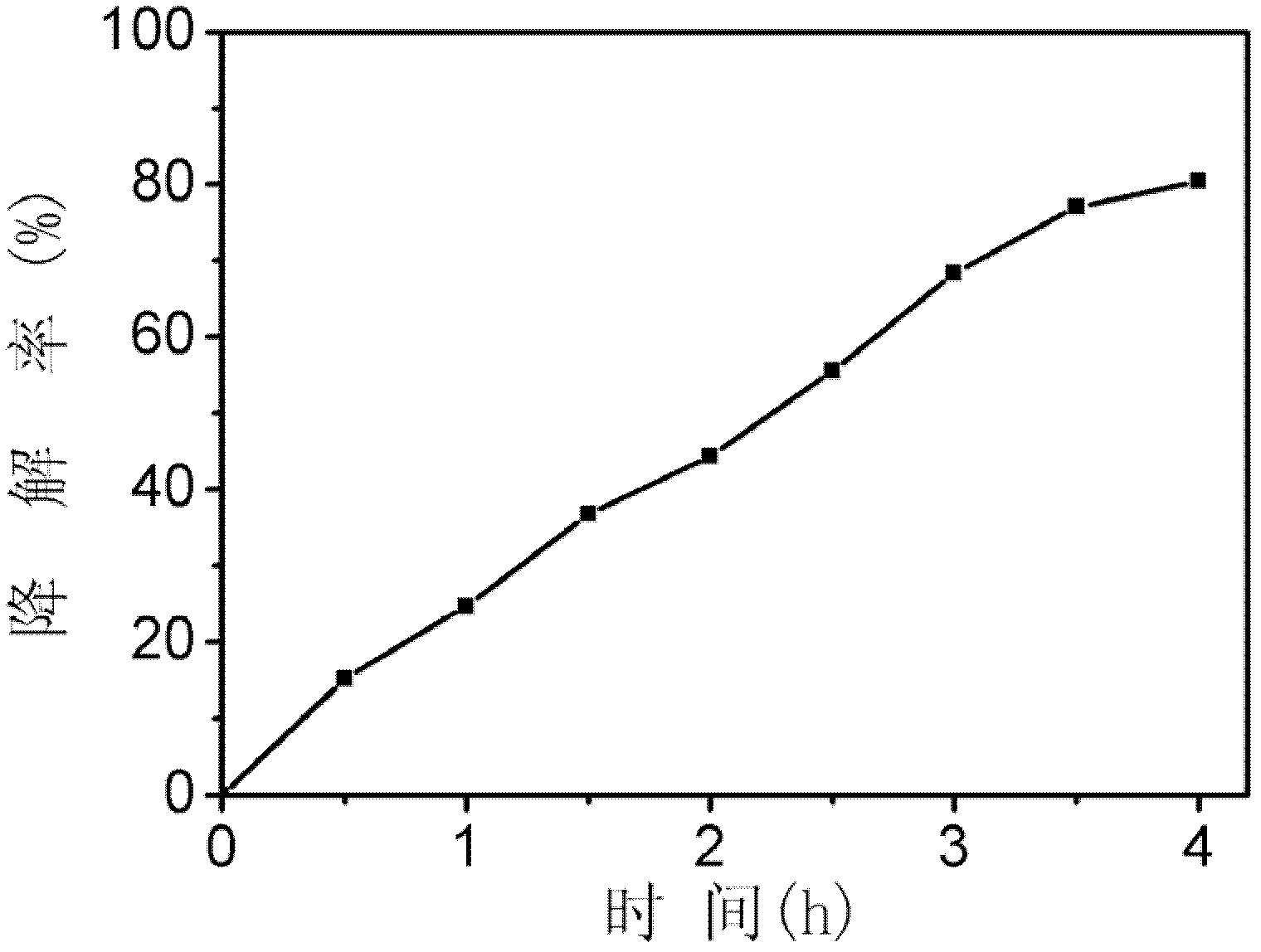

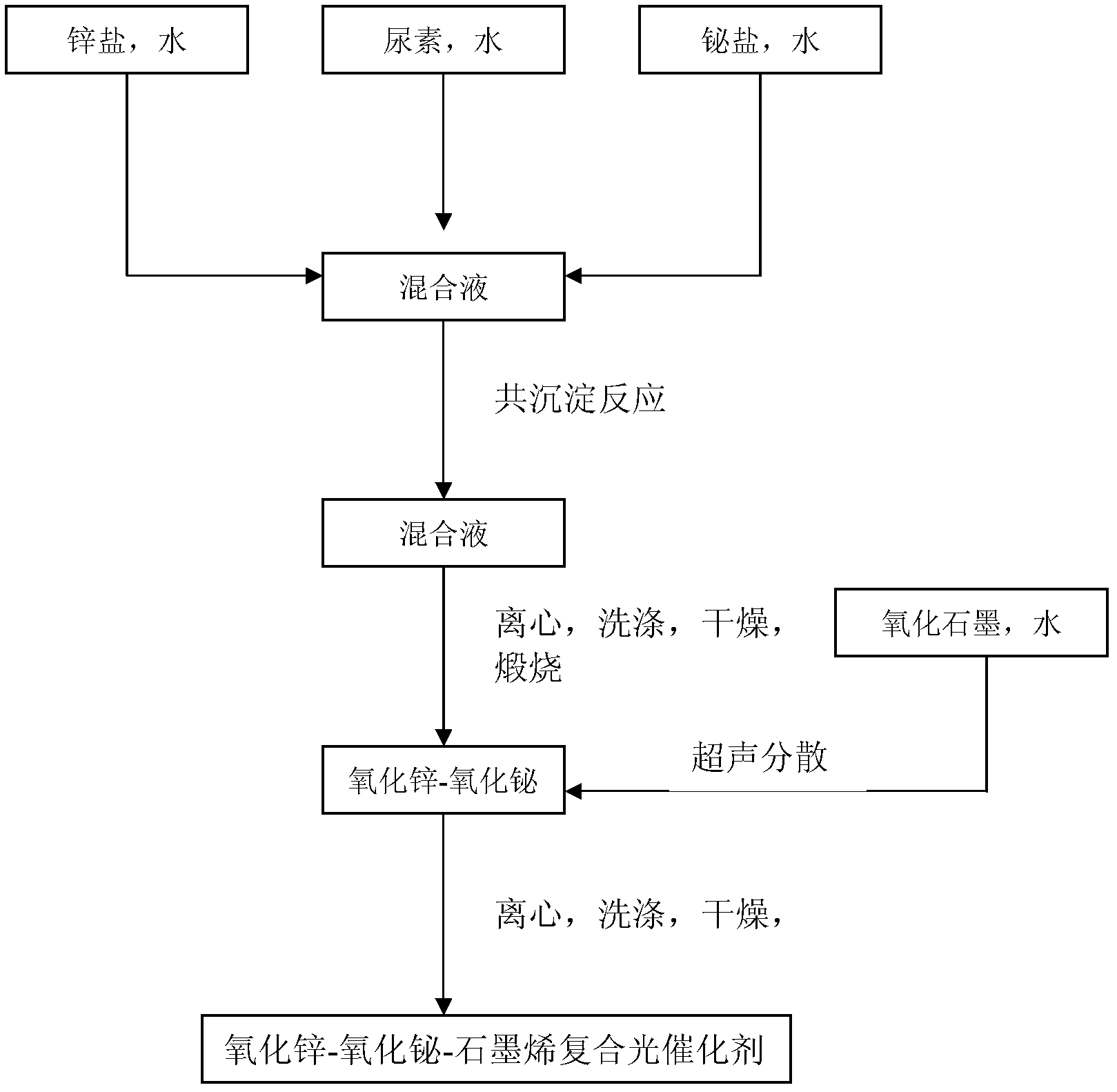

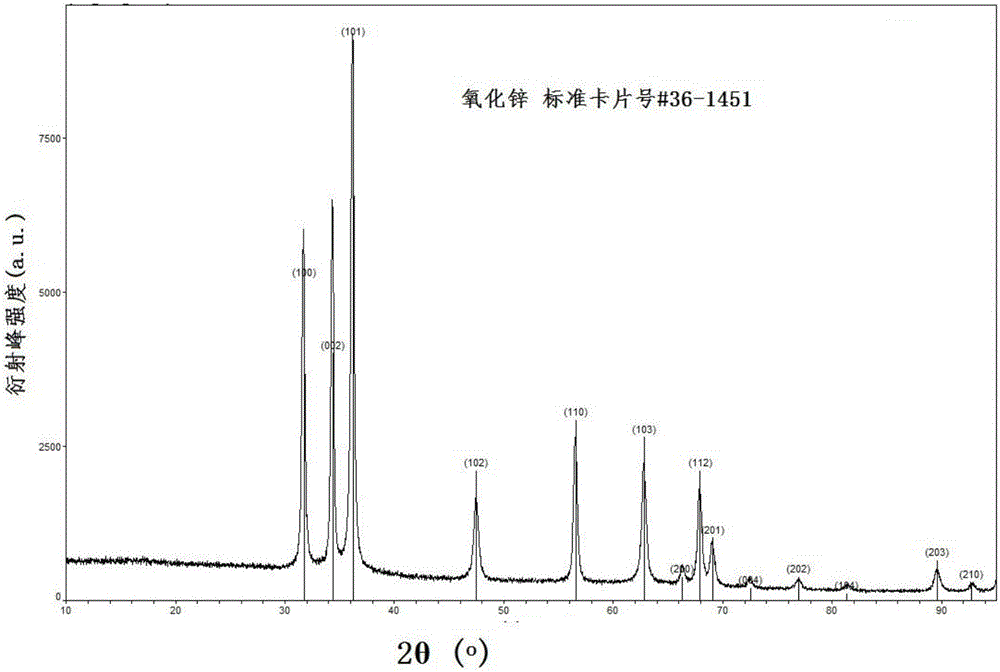

Nanometer zinc oxide-bismuth oxide composite photocatalyst with visible light response and preparation method thereof

ActiveCN102580720APromote absorptionImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsOxide compositeZno nanoparticles

The invention relates to a nanometer zinc oxide-bismuth oxide composite photocatalyst with visible light response and a preparation method thereof. The composite is formed by compounding nanometer zinc oxide, bismuth oxide and graphene oxide at a mass ratio of 1: 0.05-1: 0-2. The preparation method comprises the steps of: respectively adding water-soluble zinc salts, bismuth salts and urea in an aqueous solution; after a co-precipitation reaction, centrifuging, washing, drying and roasting products; then placing the reaction products in an ultrasonically dispersed grapheme oxide aqueous solution to be heated and stirred for a reaction; after the reaction is finished, centrifuging, washing and drying the products to obtain the zinc oxide-bismuth oxide composite photocatalyst. The zinc oxide-bismuth oxide composite photocatalyst disclosed by the invention has better application prospect and economic benefits in the aspect of sewage treatment.

Owner:江苏中来新材科技有限公司

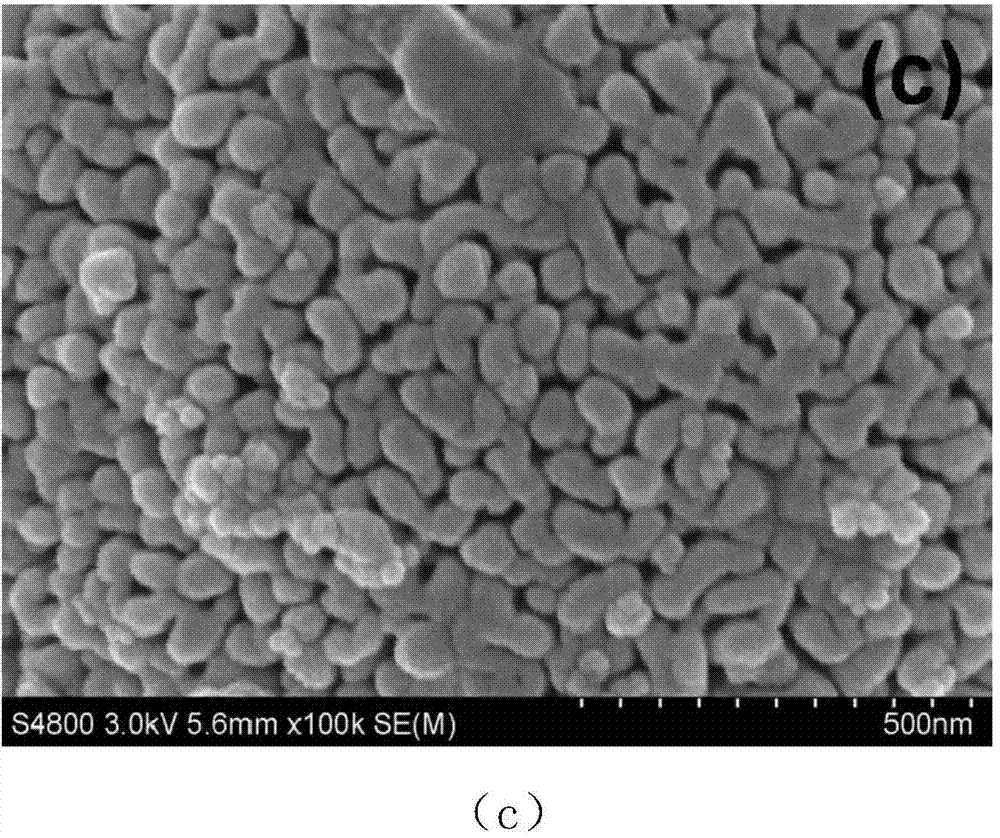

Preparation method of zinc oxide-graphite-like structure carbon nitride flaky nano composite material

ActiveCN105858714AHas a two-dimensional sheet structureSimple preparation processMaterial nanotechnologyPhysical/chemical process catalystsNano compositesTalc / Zinc Oxide

The invention discloses a preparation method of a zinc oxide-graphite-like structure carbon nitride flaky nano composite material. The preparation method mainly comprises: mixing zinc acetate and urea, wherein the ratio of urea accounts for 55-75% of the total mass and the balance is zinc acetate; putting the mixture after full mixing into a muffle furnace for calcination at 500-550 DEG C with a heating rate of 5-15 DEG C / min, performing heat preservation for 1-3 hours, and then performing cooling naturally to room temperature; and performing washing by using deionized water and anhydrous ethanol, then performing drying, and preparing the zinc oxide-graphite-like structure carbon nitride flaky nano composite material by virtue of a one-step method, wherein the nano composite material is a composite material containing zinc oxide particles of which the particle size is 30-50nm, and a graphite-like structure carbon nitride two-dimensional material serving as a support material. The preparation method disclosed by the invention is simple in preparation process, low in price, low in energy consumption and nontoxic, and the prepared nano composite material is wide in light absorption waveband, and can realize effective degradation of organic pollutants in waste water under a visible light condition.

Owner:YANSHAN UNIV

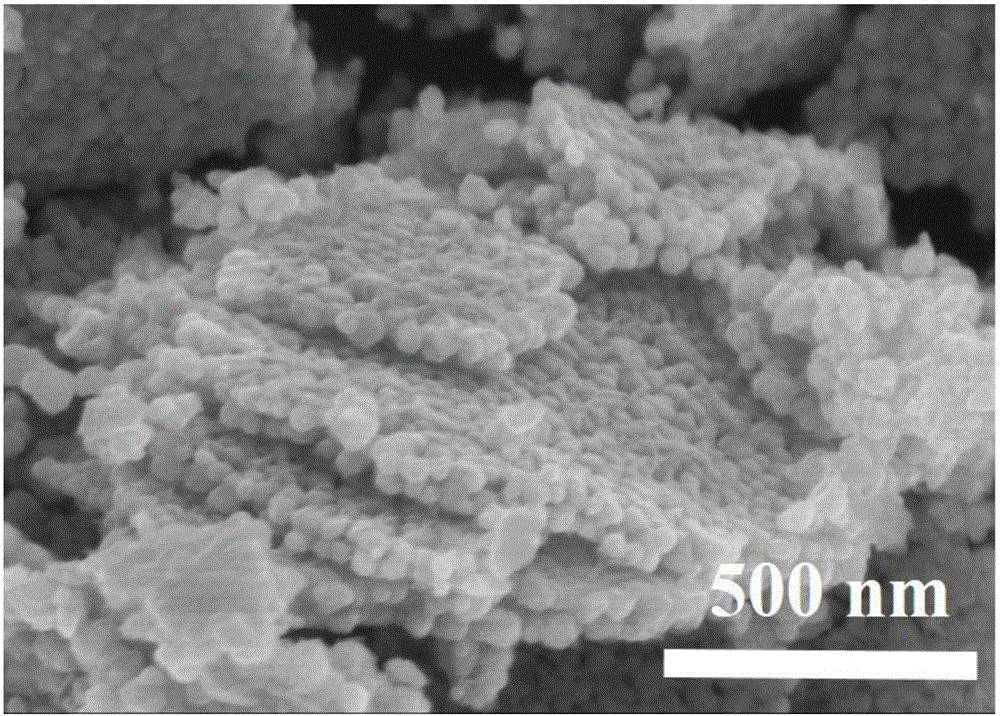

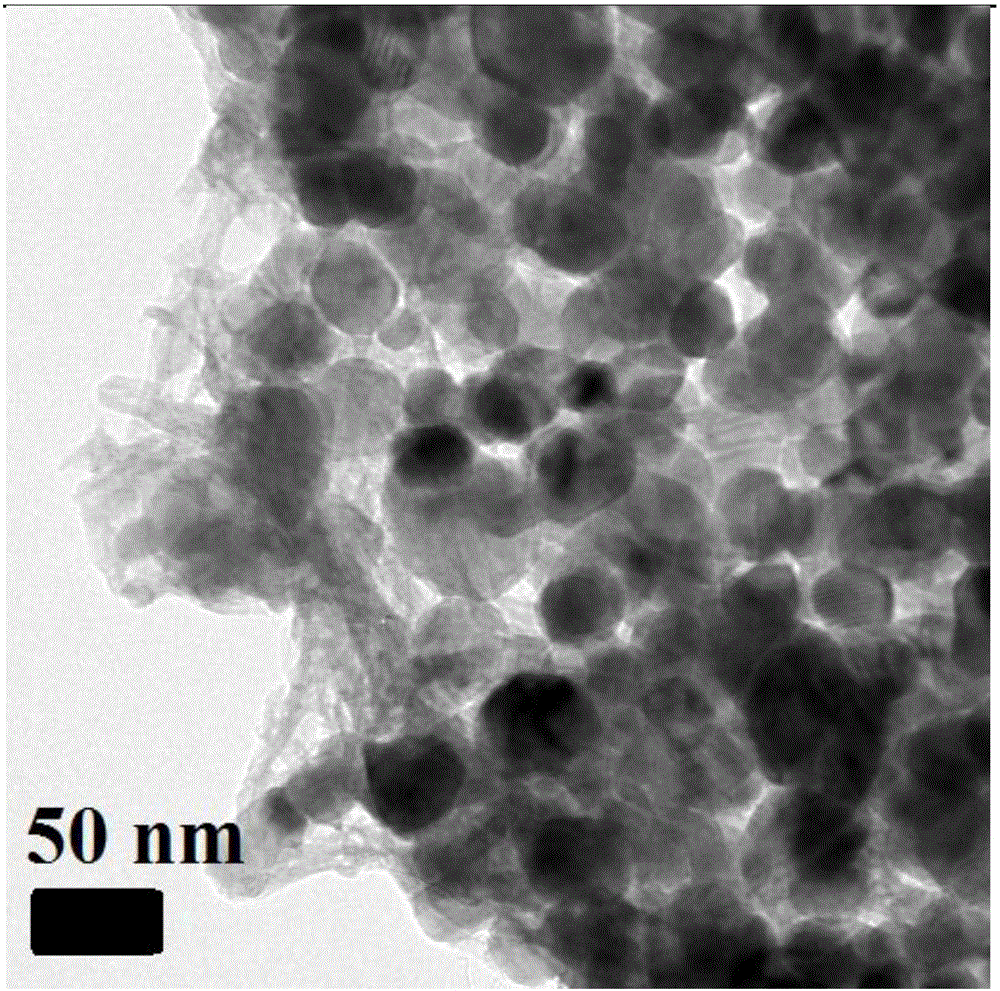

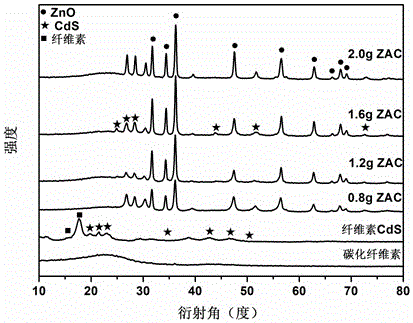

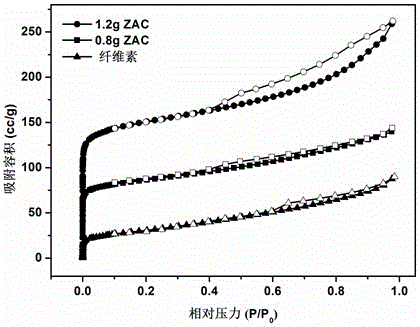

Preparation method of cellulose-based core-shell CdS/ZnO (cadmium-sulfur/zinc oxide) photocatalyst

InactiveCN105854898AStrong physical adsorptionWide spectral response rangeWater/sewage treatment by irradiationWater treatment compoundsCelluloseTalc / Zinc Oxide

The invention discloses a preparation method of a cellulose-based core-shell CdS / ZnO (cadmium-sulfur / zinc oxide) photocatalyst. The preparation method comprises the following steps of using a renewable resource of cotton cellulose as a template agent, selecting proper cadmium source / sulfur source reagents, and adopting a hydrothermal synthesis method to prepare the cellulose-based CdS; mixing with an inorganic zinc source solution, drying, and performing microwave high-temperature calcining under the nitrogen atmosphere, so as to obtain the cellulose-based core-shell CdS / ZnO photocatalyst. The cellulose-based core-shell CdS / ZnO photocatalyst has the advantages that the shape is controllable, the photocatalytic and recycling properties are good, and the photocatalytic activity under visible light is obviously higher than the photocatalytic activity of cellulose-based CdS / ZnO; the preparation method has certain theoretical and realistic meaning on the synthesis of heterogeneous core-shell materials and the purification of dye wastewater.

Owner:KUNMING UNIV OF SCI & TECH

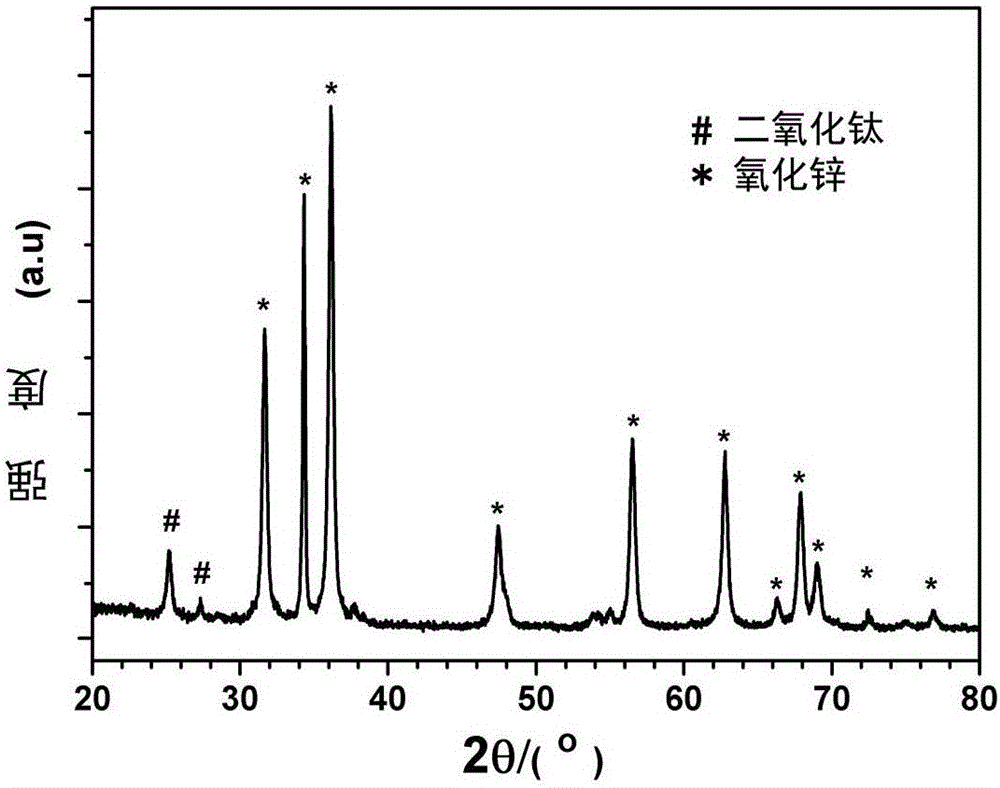

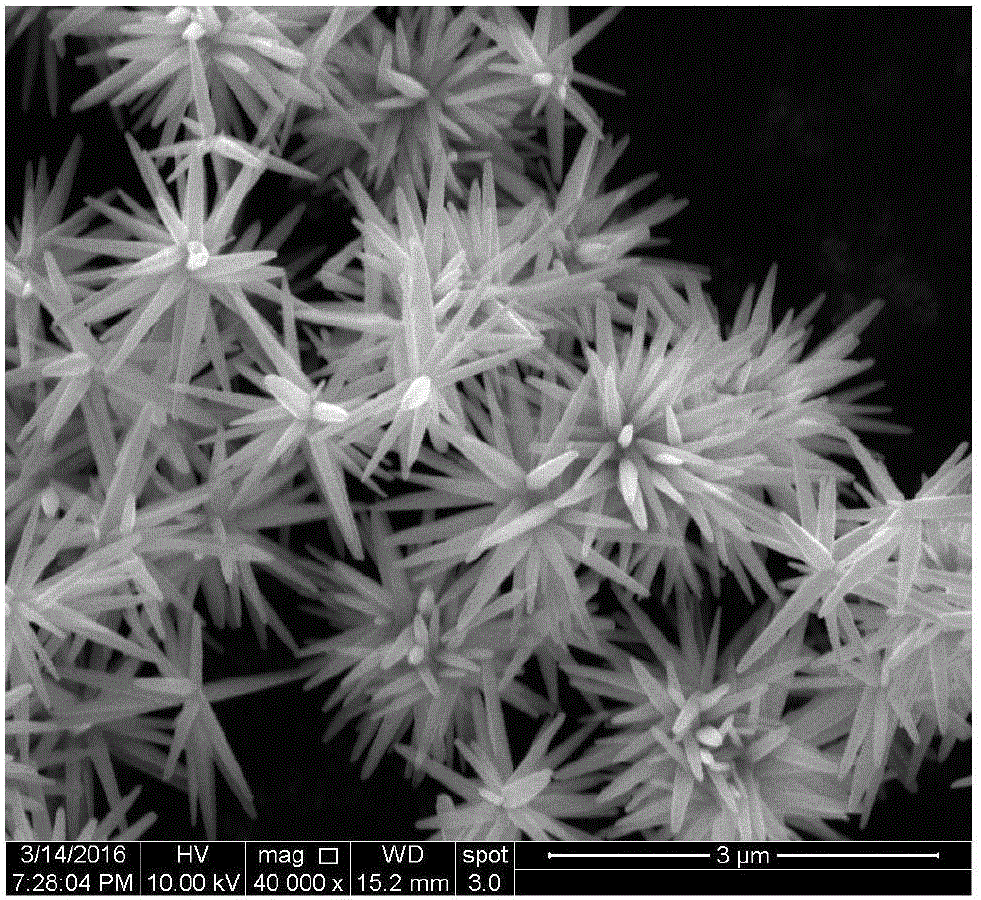

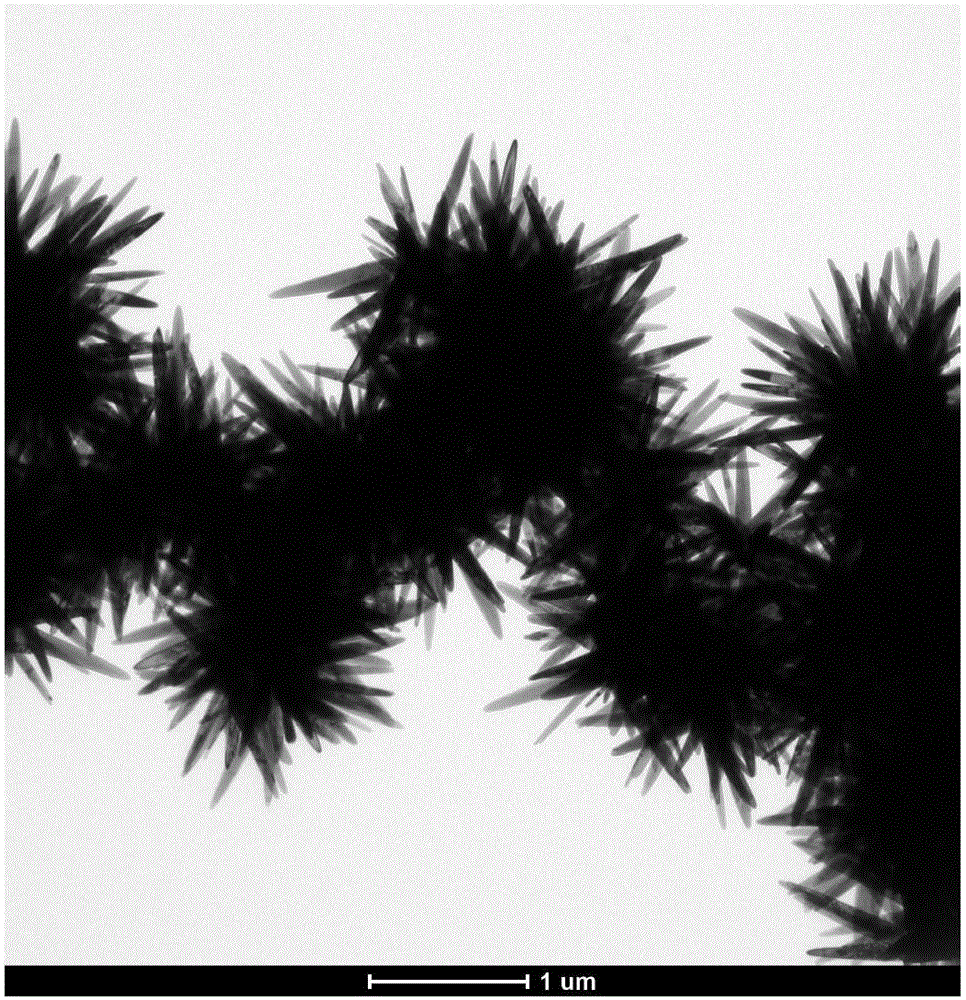

Preparation method of zinc oxide/titanium dioxide composite nanomaterial

ActiveCN105731535AIncrease surface areaHigh purityMaterial nanotechnologyZinc oxides/hydroxidesHexamethylenetetramineTalc / Zinc Oxide

The invention discloses a preparation method of a zinc oxide / titanium dioxide composite nanomaterial.The method includes the following steps that 1, a certain quantity of titanium dioxide powder is dispersed in water, the required quantity of soluble zinc salt and hexamethylenetetramine are then added to a solution, stirring is conducted, and a dispersed solution is obtained; 2, the dispersed solution obtained in step 1 is heated while stirring is conducted, and a reaction is conducted for 10-80 minutes at the temperature of 60-95 DEG C; 3, sediment obtained after the reaction in step 2 is filtered, cleaned and dried, and the zinc oxide / titanium dioxide composite nanomaterial can be obtained.By means of the preparation method, large-batch synthesis of the zinc oxide / titanium dioxide composite nanomaterial of a one-dimensional structure can be achieved, the mode of direct synthesis in a water solution under normal pressure is adopted, the reaction condition is mild, energy consumption is low, cost is low, and the yield is high; an obtained product has the advantages of being large in specific surface area, good in dispersibility and high in degree of crystallinity.

Owner:SOUTHEAST UNIV

Preparation method of zinc oxide-titanium dioxide composite

InactiveCN107337234AEnhance photodegradation activityImprove absorption rateZinc oxides/hydroxidesTitanium dioxideWater bathsUltraviolet lights

The invention discloses a preparation method of a zinc oxide-titanium dioxide composite material, comprising: (1) in the presence of acid, dissolving tetrabutyl titanate in absolute ethanol, magnetically stirring for 10-15 minutes, and adding diethanolamine dropwise , magnetically stirred for 30-45min, added deionized water, and magnetically stirred for 1-2h in a water bath at 30-60°C to obtain a titanium dioxide sol; (2) adding zinc oxide powder to the above-mentioned titanium dioxide sol, magnetically stirred for 10-30min, Vacuum concentration to obtain zinc oxide-titanium dioxide gel; (3) put the above-mentioned zinc oxide-titanium dioxide gel into a muffle furnace, calcinate at 500-800°C for 2-5 hours, and cool to obtain zinc oxide-titanium dioxide composite material . The preparation process of the invention is simple and the cost is low, and the doping of the titanium dioxide in the titanium dioxide helps to improve the photodegradation activity of the composite material, thereby increasing the absorption rate of ultraviolet light.

Owner:张家港市六福新材料科技有限公司

Mass production method of zinc oxide nanowires

InactiveCN101941732AFast preparationSimple equipment requirementsZinc oxides/hydroxidesActivated carbonPhysical chemistry

The invention relates to a mass production method of zinc oxide nanowires in the technical field of the semiconductor nanometer material. The method comprises the following steps: selecting proper zinc source and oxygen source to ensure that zinc oxide and activated carbon fully react in a high temperature state and zinc is prepared by the reduction of carbon, and performing the recrystallization and preferred growth of zinc under the action of carrier gas and the mixed oxygen to obtain zinc oxide nanowires. The method of the invention has simple process, low cost and environmental friend, and is suitable for industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

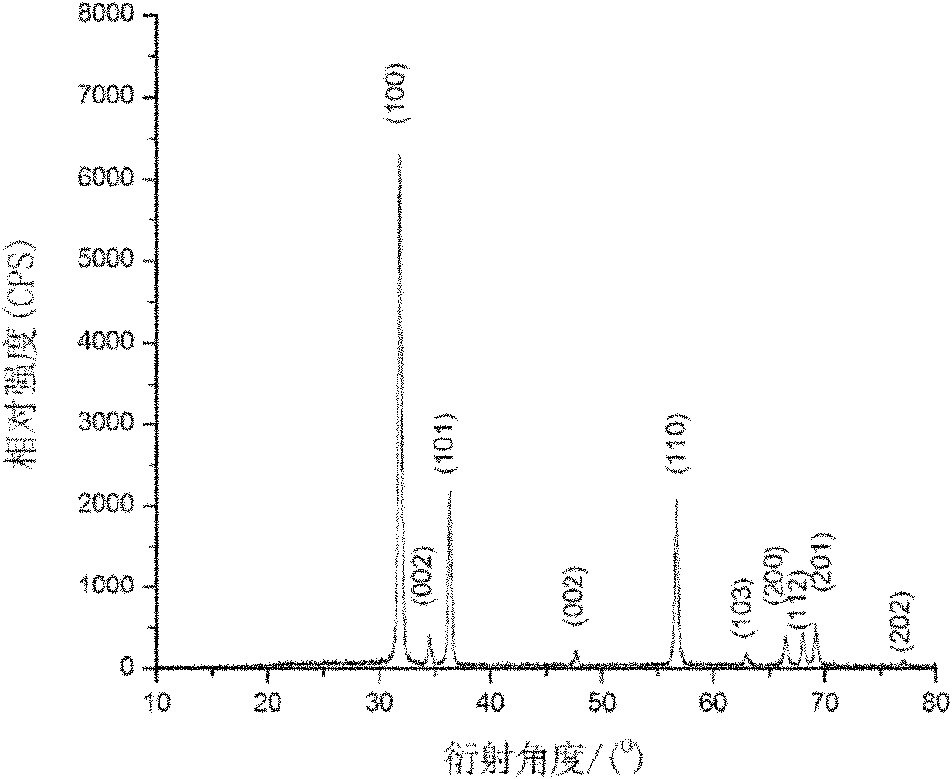

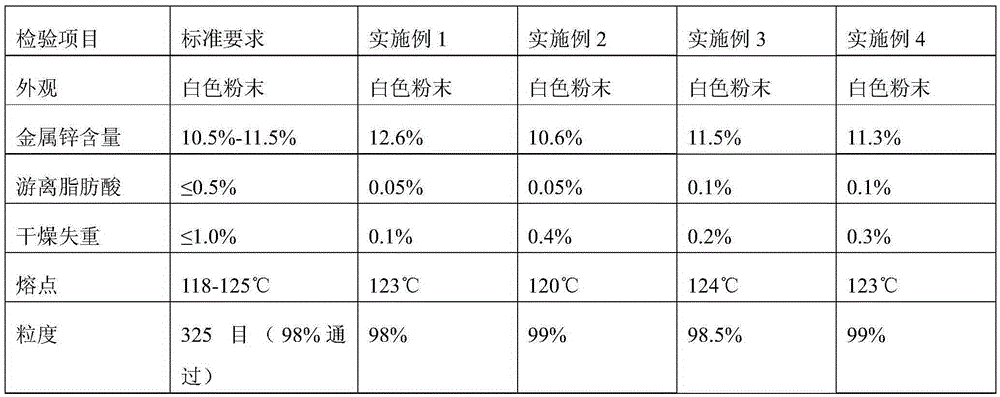

Modified zinc stearate production technology

InactiveCN105348072AImprove conversion rateQuick responseOrganic compound preparationCarboxylic acid salt preparationSocial benefitsGranularity

The invention provides a modified zinc stearate production technology comprising the following steps: (a) carrying out heating melting on stearic acid in a reaction kettle, adding zinc oxide at the temperature of 120 DEG C-150 DEG C while high-speed stirring, carrying out a reaction for 10-15 minutes, and then adding pure water; and (b) vacuumizing: sealing the reaction kettle, vacuumizing to the vacuum degree of 50-500 Pa, carrying out a reaction for 20-30 minutes, after cooling and temperature dropping, allowing the product to enter a pulverizer, and pulverizing. Compared with a traditional zinc stearate dry-process production technology, the prepared zinc stearate has the advantages of loose particles, easy pulverizing, fine product granularity, high reactivity and less energy consumption, and has quite obvious economic benefits and social benefits.

Owner:JIANGMEN SHENGPENG CHEM IND CO LTD

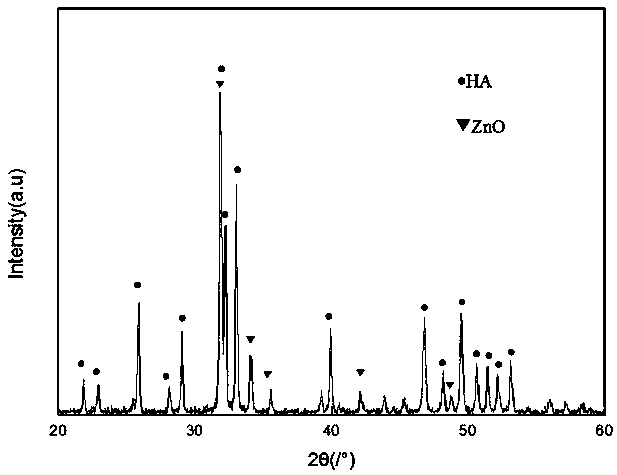

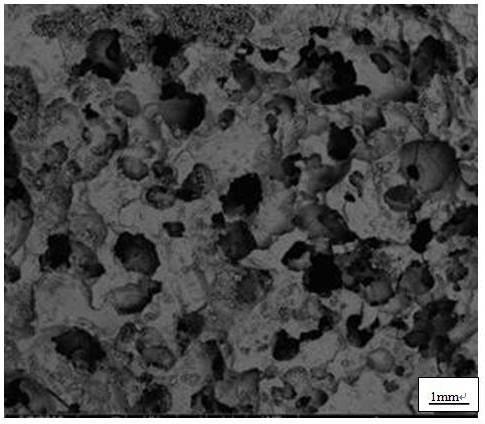

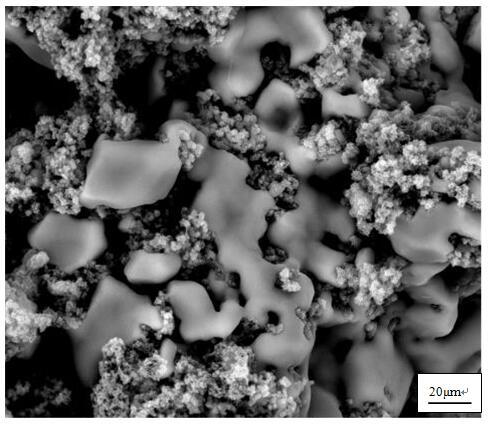

Preparation method of nano-zinc oxide-doped hydroxyapatite porous ceramic

ActiveCN110054491APure ingredientsAvoid churnPharmaceutical delivery mechanismTissue regenerationApatiteZno nanoparticles

The invention relates to a preparation method of a nano-zinc oxide-doped hydroxyapatite porous ceramic and belongs to the technical field of preparation of biomedical materials. The preparation methodtakes nano-zinc powder and hydroxyapatite powder as the raw materials and comprises weighing out ZnO and HA (hydroxyapatite) at a weight ratio of 1-7%:99%-93%, performing ball milling to obtain composite powder, uniformly mixing and pressing the composite powder and a pore forming agent of ammonium bicarbonate to obtain a blank, and then preparing the nano-zinc oxide-doped hydroxyapatite porous ceramic through a spark plasma sintering method. The prepared nano-zinc oxide-doped hydroxyapatite porous ceramic is pure in composition and achieves a controllable porosity of 40-70%, and added nano-zinc oxide can improve the osteogenic induction capacity of the nano-zinc oxide-doped hydroxyapatite porous ceramic and further improve the bone-forming capacity of parts around an implanted part; by controlling the porosity of the nano-zinc oxide-doped hydroxyapatite porous ceramic, the preparation method can prepare biological ceramics which meet different requirements and are applied to bone scaffold, filling and repair materials.

Owner:KUNMING UNIV OF SCI & TECH

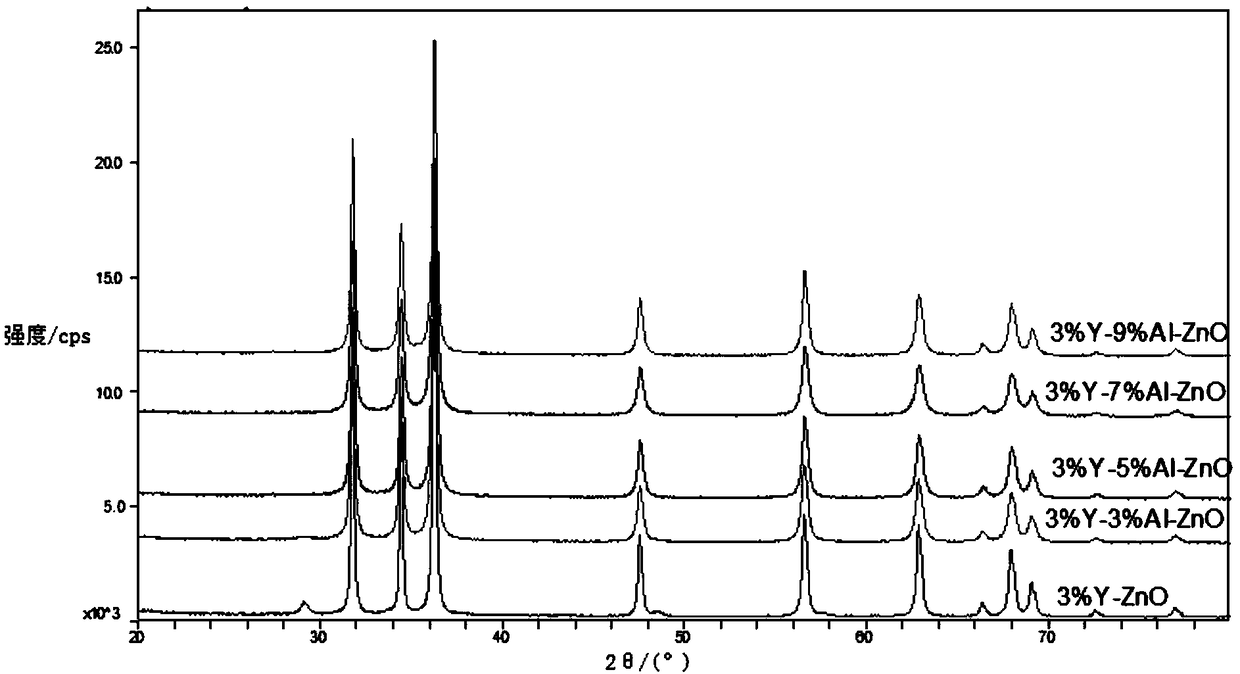

Preparation method for metallic element doped nano-zinc oxide and graphene oxide composite anti-bacterial powder

InactiveCN109046325ASolve reunionHigh electron mobilityBiocideHeterogenous catalyst chemical elementsDispersitySpectral response

The invention relates to the technical field of nano-zinc oxide materials and in particular to a preparation method for metallic element doped nano-zinc oxide and graphene oxide composite anti-bacterial powder. The preparation method comprises the following steps: firstly doping a metallic element in nano-zinc oxide, performing surface modification treatment on the metallic element doped nano-zincoxide, and enabling the metallic element doped nano-zinc oxide to react with graphene oxide, to obtain the metallic element doped nano-zinc oxide and graphene oxide composite anti-bacterial powder. The prepared composite anti-bacterial powder has the better photocatalysis effect and anti-bacterial effect, a response wave band of photocatalytic activity is increased to a visible region, and a sunlight spectral response range is extended, so the composite anti-bacterial powder also has the photocatalysis effect in a visible spectral region, and has the more extensive application in aspects of anti-bacterial anti-ultraviolet products. The method is simple and efficient, and easy to industrial production. The prepared composite anti-bacterial powder is good in dispersity, low in energy consumption, and good in anti-bacterial sterilizing effect.

Owner:沈海红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com