Preparation method for metallic element doped nano-zinc oxide and graphene oxide composite anti-bacterial powder

A composite technology of nano-zinc oxide and graphene, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, botany equipment and methods, etc. Uneven dispersion and other problems, to achieve the effect of inhibiting recombination, high electron mobility, and solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-30

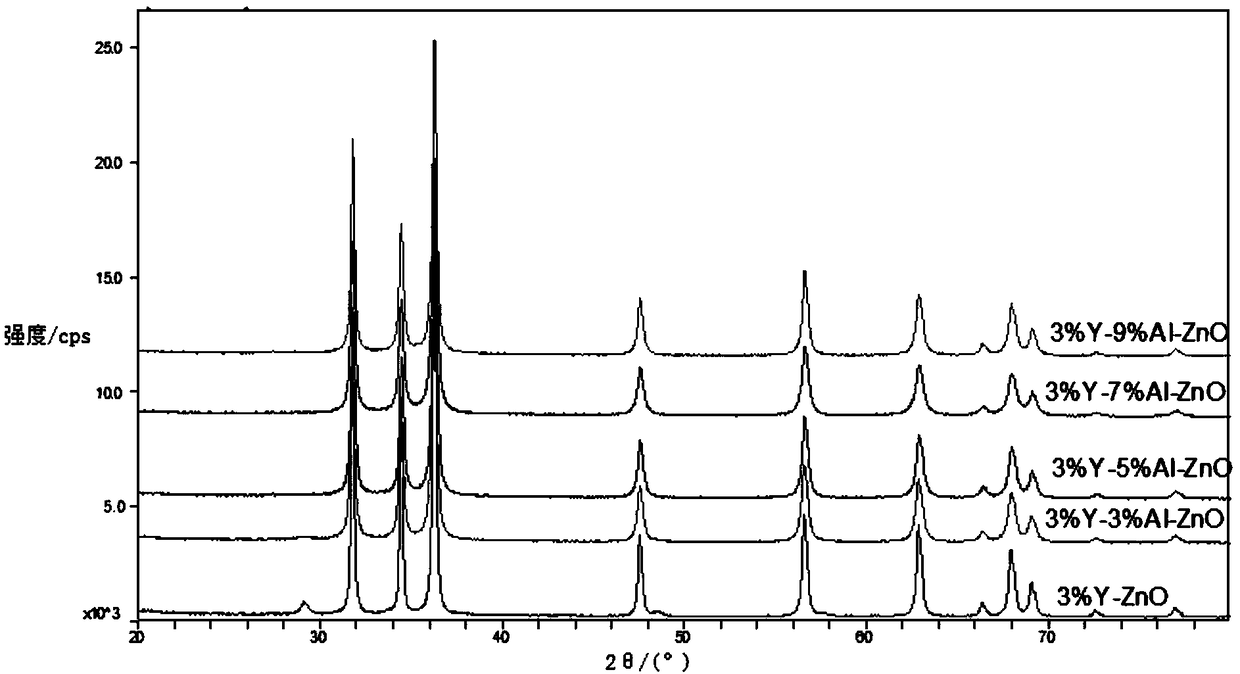

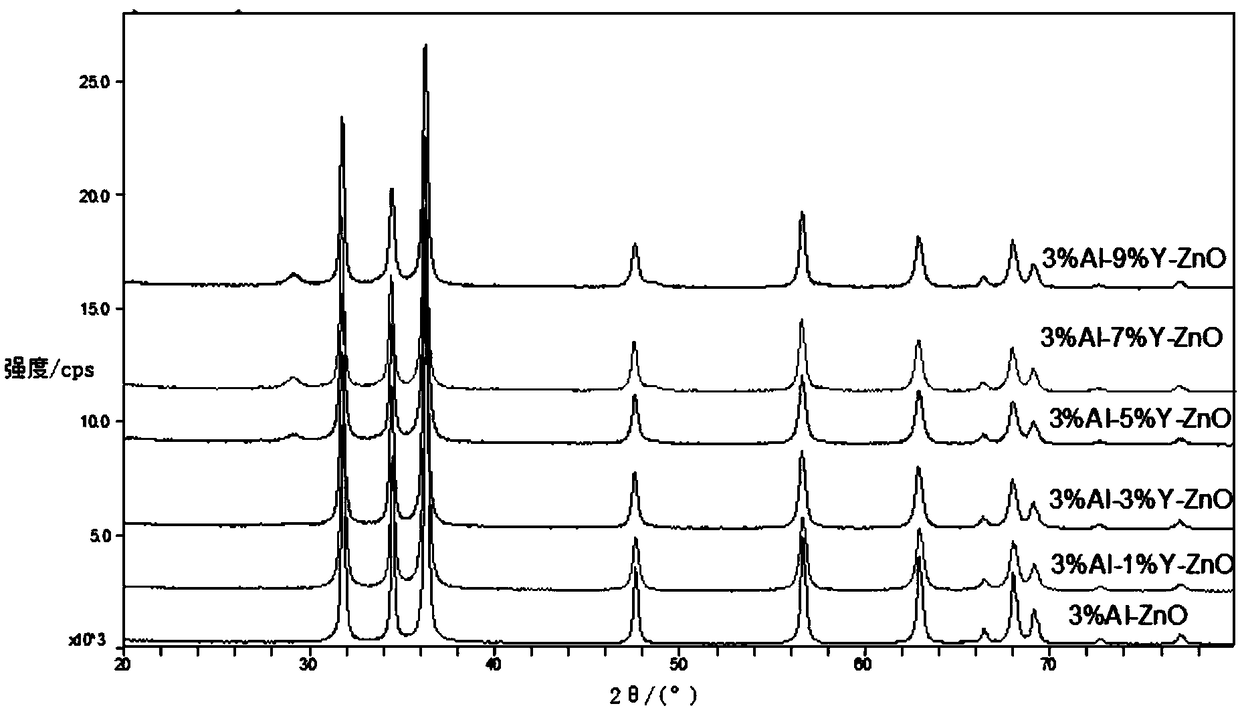

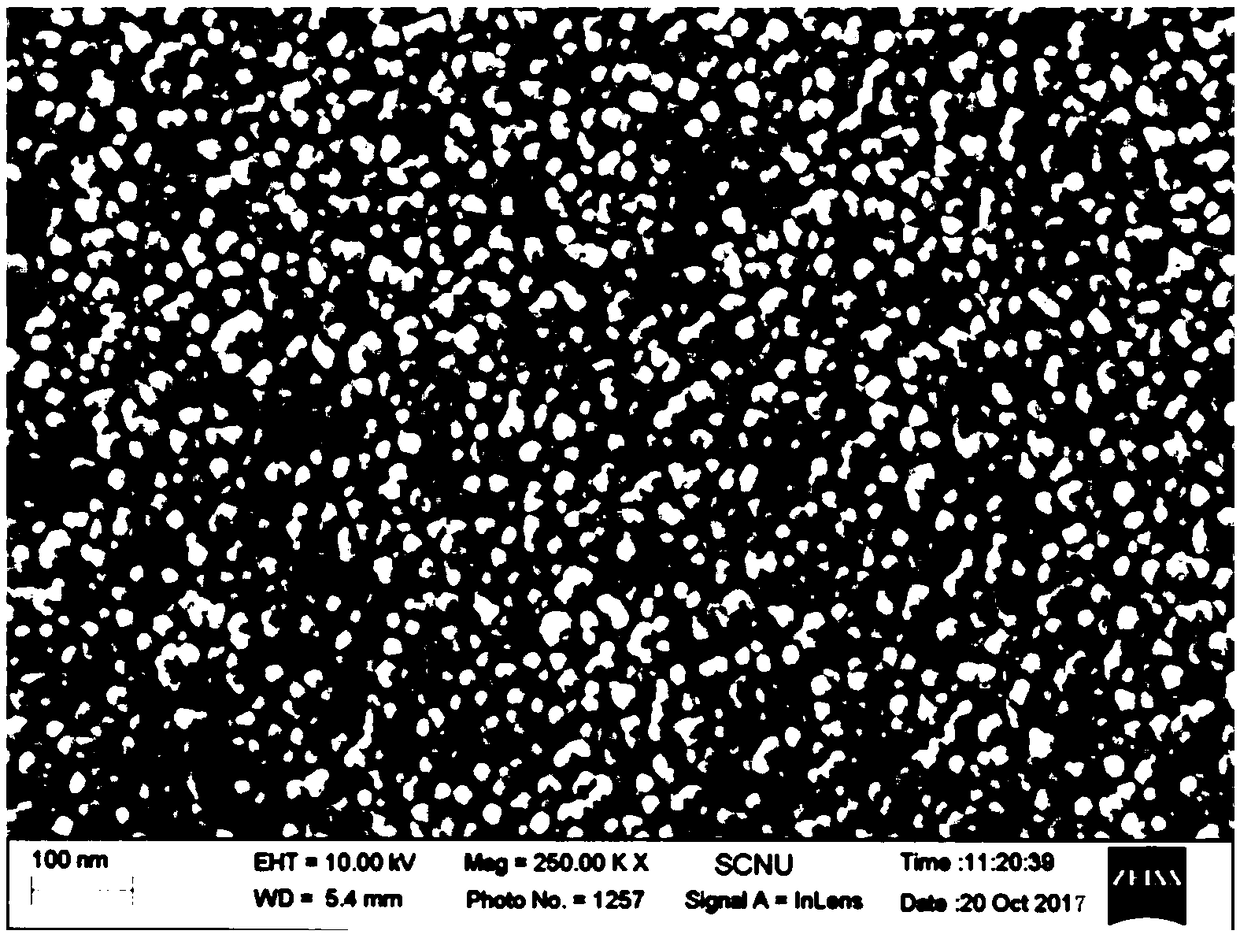

[0036] Embodiment 1-30 provides a kind of preparation method of metal element-doped nano-zinc oxide and graphene oxide composite antibacterial powder respectively, in each embodiment, PAAS, salt containing the first metal (yttrium nitrate hexahydrate or cobalt nitrate hexahydrate ), salt containing the second metal (aluminum nitrate nonahydrate or cerium nitrate hexahydrate), silane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane (KH-570), sodium nitrate, concentrated sulfuric acid , potassium permanganate, and graphene oxide are shown in Table 1 and Table 2 below.

[0037] The concrete steps of each embodiment are as follows:

[0038] 1. Metal element doped nano zinc oxide

[0039] Add sodium polyacrylate (PAAS) with a molecular weight of 30000-50000 into 250g of deionized water, stir evenly to dissolve it in the water, then transfer the sodium polyacrylate solution into a 1L stainless steel ball mill tank, and add 48g (0.6mol) nano-zinc oxide (provided by Zhaoqing...

Embodiment 31

[0054] This example provides a method for preparing metal element-doped nano-zinc oxide and graphene oxide composite antibacterial powder. In this implementation, except for the difference between the doped metal component and Example 3, the other groups and dosages are the same as those in Example 3. The same as in Example 3, the specific preparation method is also the same as in Example 3. The doping metal component of this embodiment consists of 30 mmol of cobalt nitrate hexahydrate and 18 mmol of aluminum nitrate nonahydrate.

Embodiment 32

[0056] This example provides a method for preparing metal element-doped nano-zinc oxide and graphene oxide composite antibacterial powder. In this implementation, except for the difference between the doped metal component and Example 3, the other groups and dosages are the same as those in Example 3. The same as in Example 3, the specific preparation method is also the same as in Example 3. The doping metal component of this embodiment consists of 30 mmol of yttrium nitrate hexahydrate and 18 mmol of cerium nitrate hexahydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com