Preparation method of nano zinc oxide/epoxy resin composite superhydrophobic coating

A nano-zinc oxide and super-hydrophobic coating technology, applied in the field of materials, can solve the problems that limit the wide application of super-hydrophobic coatings, the inability to form large-scale films, and the complicated preparation process, etc., to achieve anti-corrosion optical properties, light weight, and toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the present invention includes the following steps.

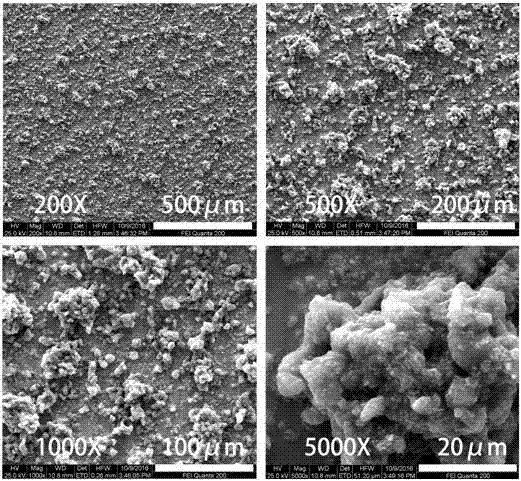

[0025] (1) Prepare 100 parts by mass of ethanol / acetone solution with a volume ratio of 1:1; add 2.5 parts by mass of zinc oxide powder with a particle size of 100 nm and 2.5 parts by mass of zinc oxide powder with a particle size of 10 nm in sequence middle; then add 0.001 parts by mass of a low surfactant, and mix and stir for 3 hours to obtain a suspension A.

[0026] (2) Add 2.5 parts by mass of epoxy resin and 10% of the mass of epoxy resin curing agent to suspension A, and oscillate ultrasonically for 10 minutes to form suspension B.

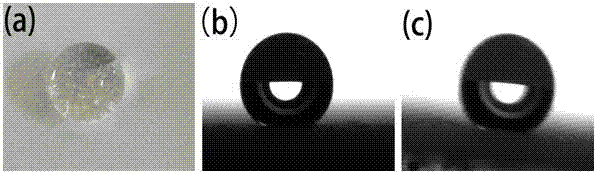

[0027] (3) Use a spray gun to evenly spray the suspension B onto the substrate, and after curing at room temperature for 2 hours, cure at 100°C for 30 minutes to obtain a super-hydrophobic coating with strong stability.

Embodiment 2

[0029] The preparation method of the present invention includes the following steps.

[0030] (1) Prepare 100 parts by mass of ethanol / acetone solution with a volume ratio of 1:1; add 2.0 parts by mass of zinc oxide powder with a particle size of 100 nm and 3.0 parts by mass of zinc oxide powder with a particle size of 10 nm in sequence middle; then add 0.001 parts by mass of a low surfactant, and mix and stir for 3 hours to obtain a suspension A.

[0031] (2) Add 1 part by mass of epoxy resin and 10% of the mass of epoxy resin curing agent to suspension A, and oscillate ultrasonically for 10 minutes to form suspension B.

[0032] (3) Use a spray gun to evenly spray the suspension B onto the substrate, and after curing at room temperature for 2 hours, cure at 100°C for 30 minutes to obtain a super-hydrophobic coating with strong stability.

Embodiment 3

[0034] The preparation method of the present invention includes the following steps.

[0035] (1) Prepare 100 parts by mass of ethanol-acetone solution with a volume ratio of 1:1; add 3.0 parts by mass of zinc oxide powder with a particle size of 100 nm and 2.0 parts by mass of zinc oxide powder with a particle size of 10 nm into the solution in sequence ; Then add 0.001 parts by mass of a low surface energy active agent, mix and stir for 3 hours to obtain a suspension A.

[0036] (2) Add 5 parts by mass of epoxy resin and 10% of the mass of epoxy resin curing agent to suspension A, and oscillate ultrasonically for 10 minutes to form suspension B.

[0037] (3) Use a spray gun to evenly spray the suspension B onto the substrate, and after curing at room temperature for 2 hours, cure at 100°C for 30 minutes to obtain a super-hydrophobic coating with strong stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com