Method for preparing carbon doped zinc oxide

A technology of zinc oxide and zinc gluconate, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of harsh conditions, complicated process, unfavorable industrialization, etc., and achieve the effect of short reaction time, good repeatability and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Dissolve zinc gluconate in water to obtain a zinc gluconate solution, and then use 0.2mol / L NaOH solution as a pH regulator to adjust the pH of the zinc gluconate solution to 6; among them, the gluconic acid in the zinc gluconate solution The concentration of zinc is 0.1mol / L;

[0023] 2) Add the pH-adjusted zinc gluconate solution into a microwave digestion tank, then move the microwave digestion tank into a microwave hydrothermal synthesizer, perform a synthesis reaction at 180°C for 3 hours, and then cool naturally to room temperature to obtain the product;

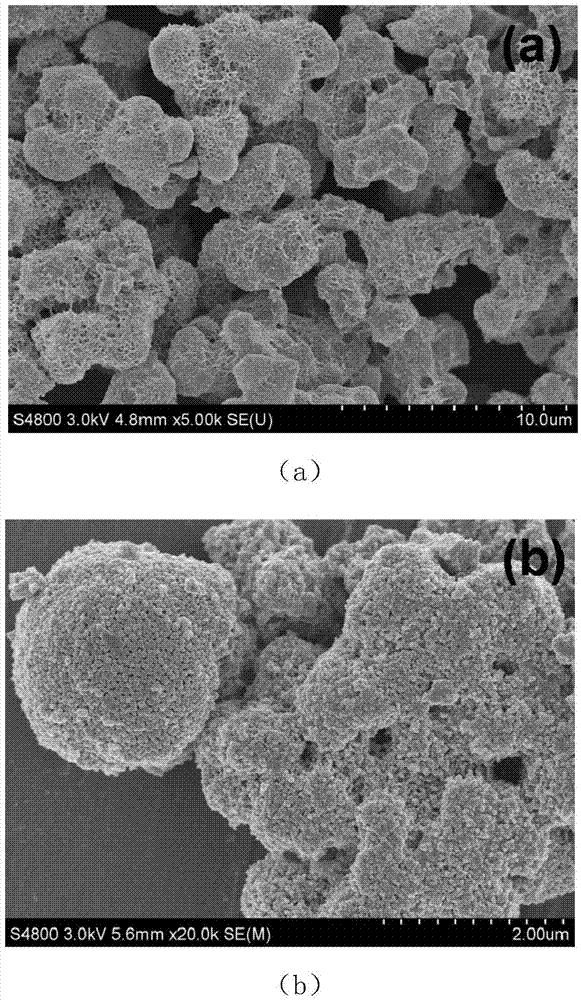

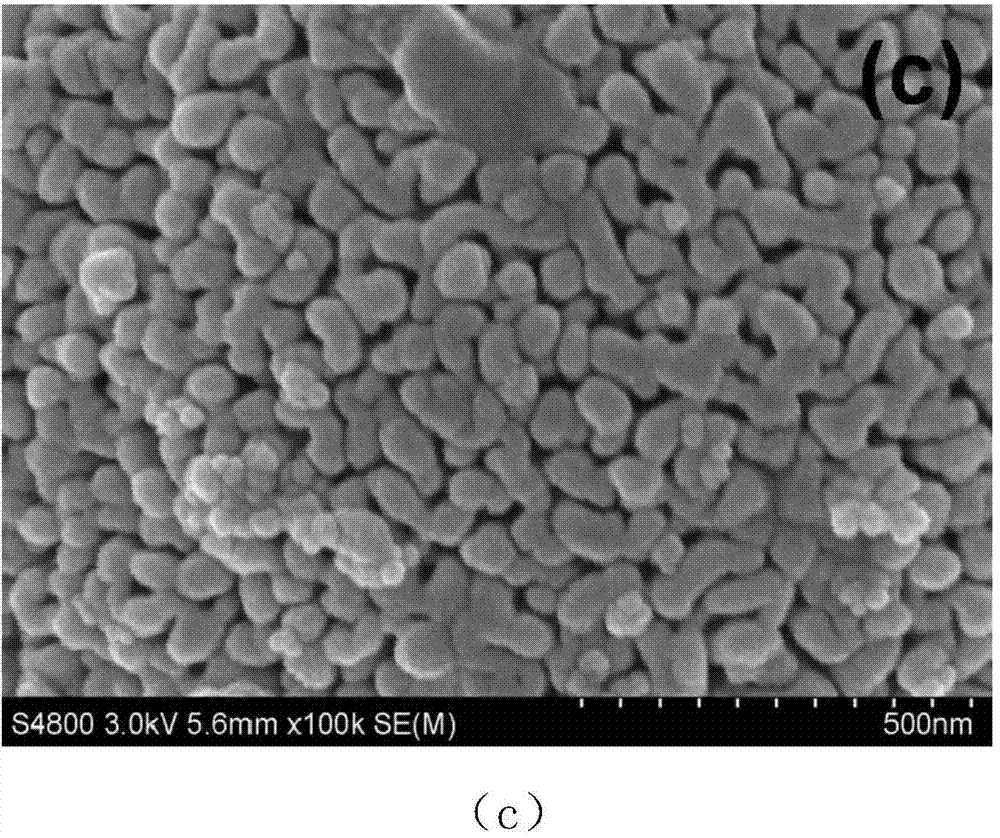

[0024] 3) Centrifuge the product to collect the solid, then wash the solid with deionized water and absolute ethanol, and dry it to obtain a brown zinc oxide precursor;

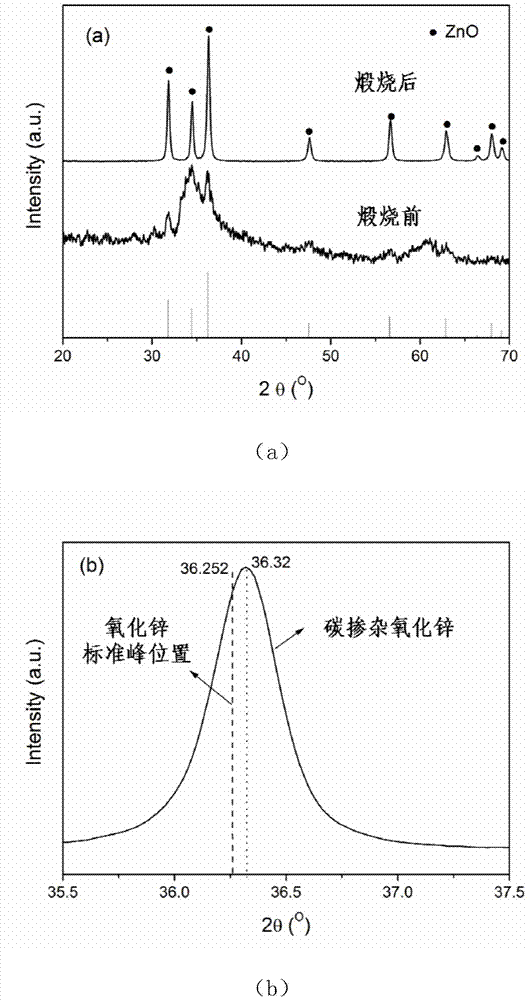

[0025] 4) The product was calcined in an air atmosphere at 200°C for 2 hours, and cooled naturally to room temperature to obtain carbon-doped zinc oxide.

[0026] The visible light absorption intensity of the carbon-doped zinc oxide obtaine...

Embodiment 2

[0028] 1) Dissolve zinc gluconate in water to obtain a zinc gluconate solution, and then use 1mol / L NaOH solution as a pH regulator to adjust the pH of the zinc gluconate solution to 8; among them, zinc gluconate in the zinc gluconate solution The concentration is 1mol / L;

[0029] 2) Add the pH-adjusted zinc gluconate solution into a microwave digestion tank, then move the microwave digestion tank into a microwave hydrothermal synthesizer, perform a synthesis reaction at 250°C for 1 hour, and then cool naturally to room temperature to obtain the product;

[0030] 3) Centrifuge the product to collect the solid, then wash the solid with deionized water and absolute ethanol, and dry it to obtain a brown zinc oxide precursor;

[0031] 4) The product was calcined at 400°C in an air atmosphere for 0.5 hours, and cooled naturally to room temperature to obtain carbon-doped zinc oxide.

[0032] The visible light absorption intensity of the carbon-doped zinc oxide obtained in this exam...

Embodiment 3

[0034] 1) Dissolve zinc gluconate in water to obtain a zinc gluconate solution, and then use 0.5mol / L NaOH solution as a pH regulator to adjust the pH of the zinc gluconate solution to 7; among them, the gluconic acid in the zinc gluconate solution The concentration of zinc is 0.5mol / L;

[0035] 2) Add the pH-adjusted zinc gluconate solution into a microwave digestion tank, then move the microwave digestion tank into a microwave hydrothermal synthesizer, perform a synthesis reaction at 200°C for 2 hours, and then cool naturally to room temperature to obtain the product;

[0036] 3) Centrifuge the product to collect the solid, then wash the solid with deionized water and absolute ethanol, and dry it to obtain a brown zinc oxide precursor;

[0037] 4) The product was calcined in an air atmosphere at 300°C for 1 hour, and cooled naturally to room temperature to obtain carbon-doped zinc oxide.

[0038] The visible light absorption intensity of the carbon-doped zinc oxide obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com