Ultrasound preparation method of nano zinc oxide particles

A technology of nano-zinc oxide and nano-zinc powder, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of complex growth process, high reaction temperature, expensive equipment, etc., and achieve high purity, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A. Put 150g of zinc powder with an average particle size of about 40 μm into the equipment with a volume of 2.5L, equipped with a rolling vibration mill with a power of 0.12kW, and grind for 15 hours to obtain nano zinc powder.

[0021] B. Weigh 1g of the prepared nano-zinc powder and place it in a beaker, add 60ml (equivalent to 60g) deionized water.

[0022] C. Put the beaker into an ultrasonic cleaner for ultrasonic treatment. The frequency of the ultrasonic treatment process is 99 Hz, and the ultrasonic time is 24 hours to obtain a white turbid liquid.

[0023] D. Let the white turbid solution stand for 5 minutes, and re-absorb the turbid solution into another clean beaker with a straw.

[0024] E. Set the temperature of the constant temperature drying oven to 60°C. After the temperature stabilizes, put the beaker containing the turbid liquid into the constant temperature drying oven for drying. The drying time is 24 hours.

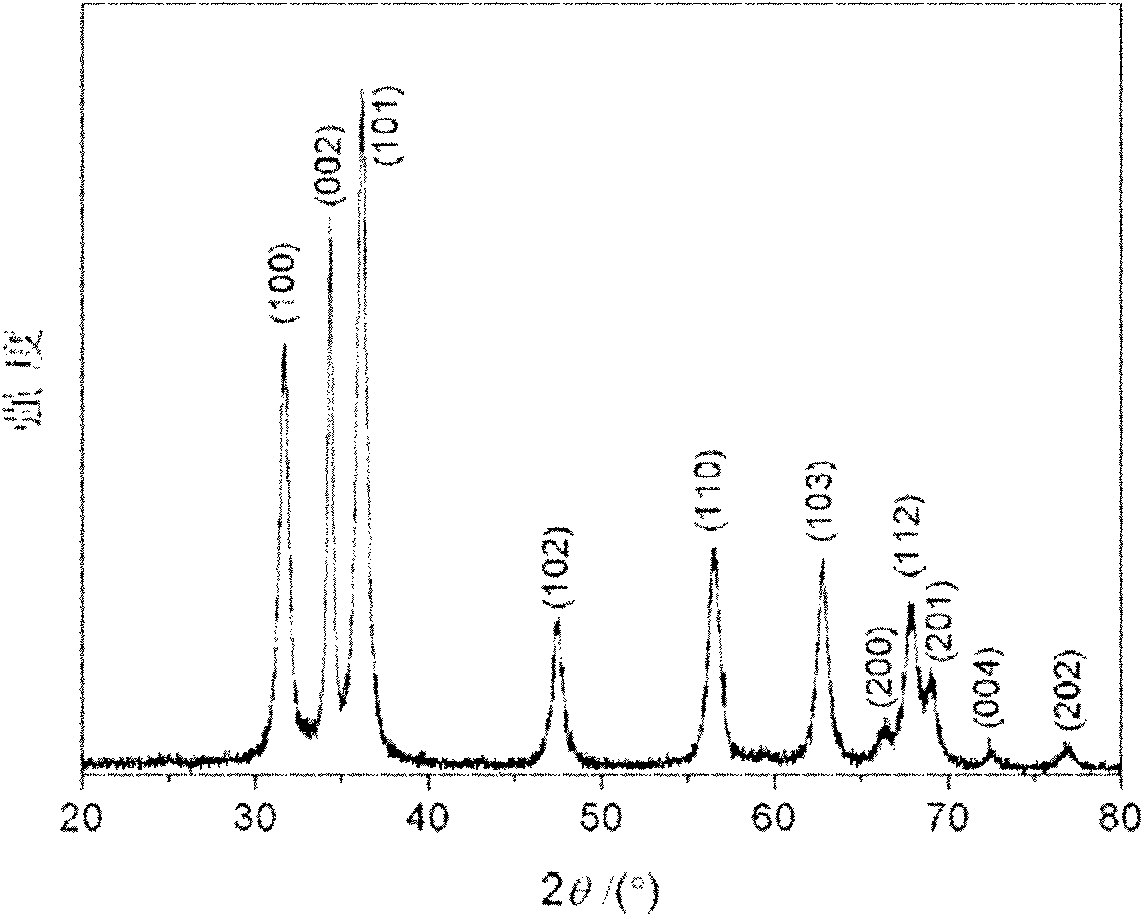

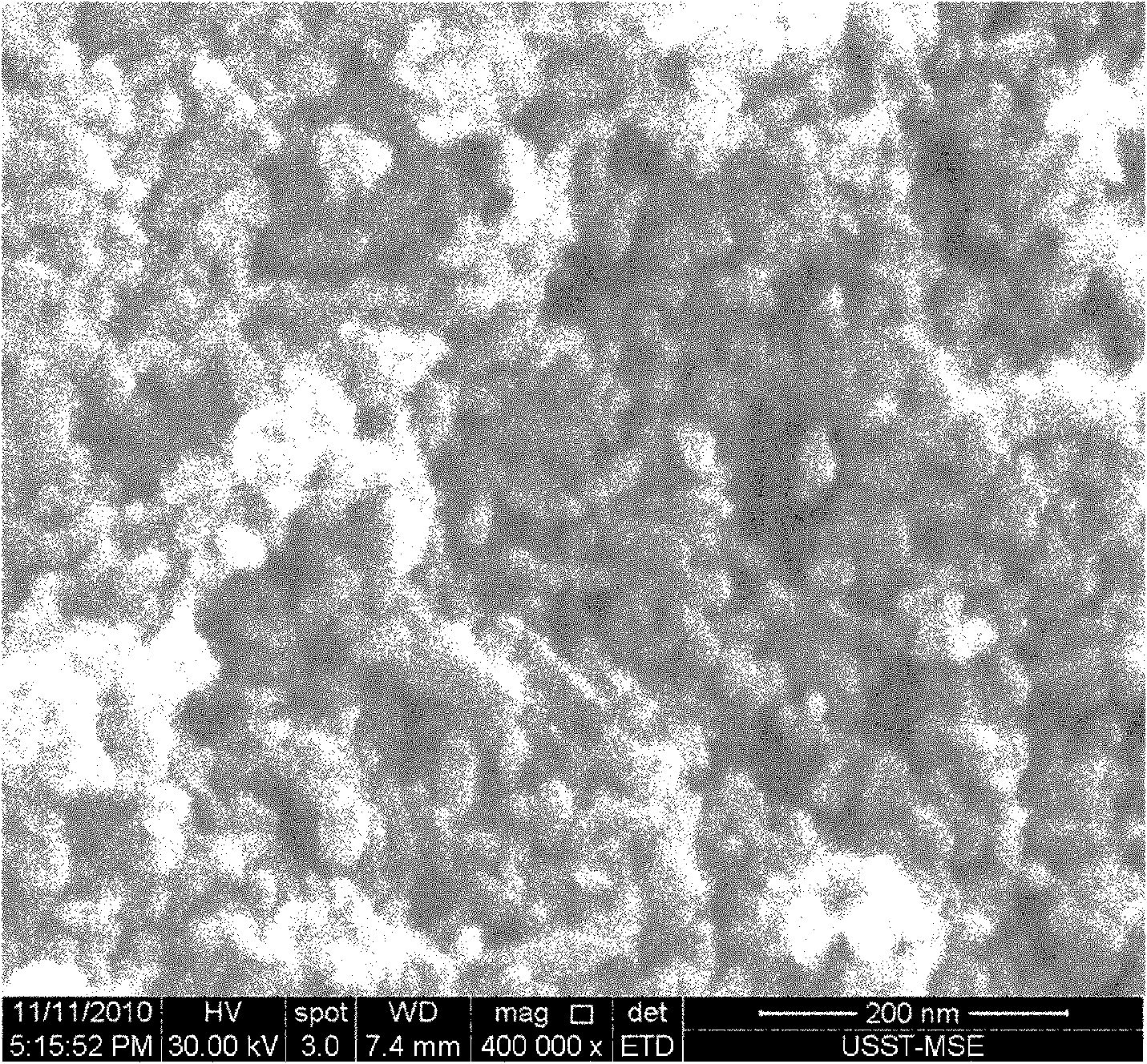

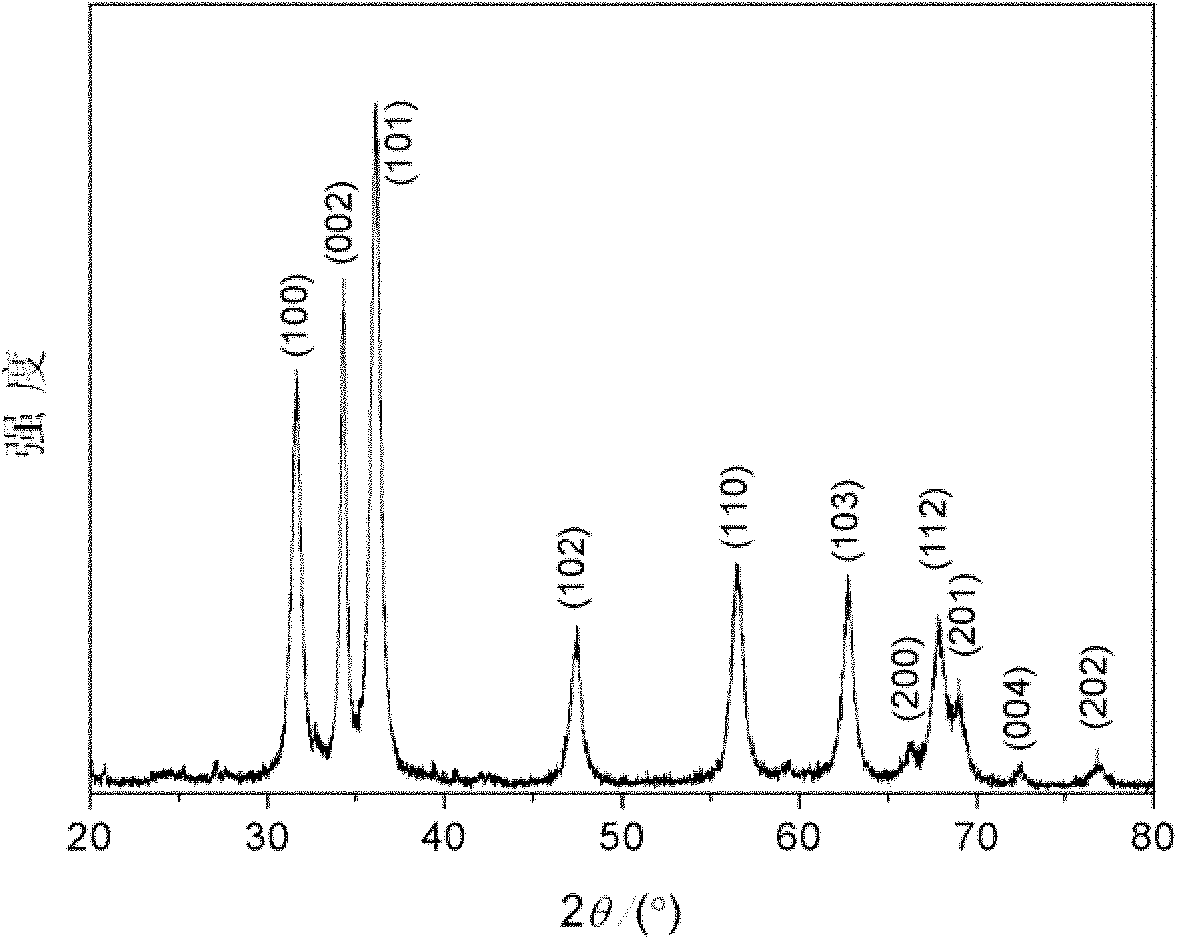

[0025] F. After drying, grind the produ...

Embodiment 2

[0029] A. Put 150g of zinc powder with an average particle size of about 40 μm into the equipment with a volume of 2.5L, equipped with a rolling vibration mill with a power of 0.12kW, and grind for 15 hours to obtain nano zinc powder.

[0030] B. Weigh 1g of the prepared nano-zinc powder and place it in a beaker, add 60ml (equivalent to 60g) deionized water.

[0031] C. Put the beaker into an ultrasonic cleaner for ultrasonic treatment, the frequency of the ultrasonic treatment process is 70 Hz, and the ultrasonic time is 24 hours, and a white turbid liquid is obtained.

[0032] D. Let the white turbid solution stand for 5 minutes, and re-absorb the turbid solution into another clean beaker with a straw.

[0033] E. Set the temperature of the constant temperature drying oven to 60°C. After the temperature stabilizes, put the beaker containing the turbid liquid into the constant temperature drying oven for drying. The drying time is 24 hours.

[0034] F. After drying, grind th...

Embodiment 3

[0037] A. Put 150g of zinc powder with an average particle size of about 40 μm into the equipment with a volume of 2.5L, equipped with a rolling vibration mill with a power of 0.12kW, and grind for 15 hours to obtain nano zinc powder.

[0038] B. Weigh 1g of the prepared nano-zinc powder and place it in a beaker, add 60ml (equivalent to 60g) deionized water.

[0039] C. Put the beaker into an ultrasonic cleaner for ultrasonic treatment, the frequency of the ultrasonic treatment process is 99Hz, and the ultrasonic time is 30h, and a white turbid liquid is obtained.

[0040] D. Let the white turbid solution stand for 5 minutes, and re-absorb the turbid solution into another clean beaker with a straw.

[0041] E. Set the temperature of the constant temperature drying oven to 60°C. After the temperature stabilizes, put the beaker containing the turbid liquid into the constant temperature drying oven for drying. The drying time is 24 hours.

[0042] F. After drying, grind the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com