Mass production method of zinc oxide nanowires

A zinc oxide nanowire, mass production technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of lack of technology, inability to be practical in large quantities, and devices staying in the laboratory stage, and achieve the effect of simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

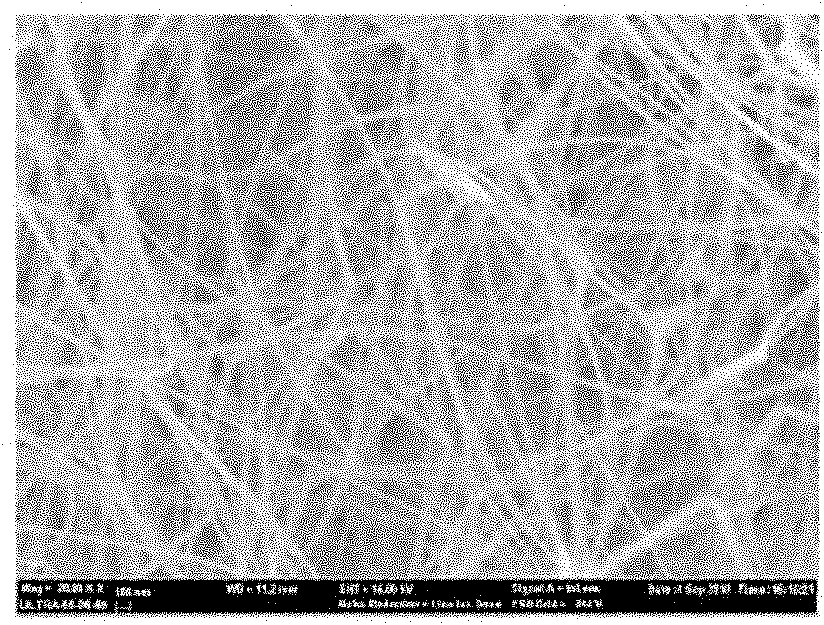

[0019] Fully mix high-purity zinc oxide powder and activated carbon with a mass ratio of 1:1, then ball mill for 15 hours under the protection of high-purity nitrogen, put the ball-milled materials in a ceramic boat, and then put the ceramic boat with materials in in a tube furnace. Then the tube furnace is fed with a carrier gas consisting of high-purity nitrogen (99.999%) and high-purity oxygen (99.999%) (high-purity oxygen flow: 20ml / min, high-purity nitrogen flow: 2L / min), And quickly heat up to 950 ℃ Finally, react for 35 minutes, and a large amount of white cotton-like zinc oxide nanowires can be sprayed out at the tube furnace mouth during the reaction. , the scanning electron micrograph of the material is attached image 3 .

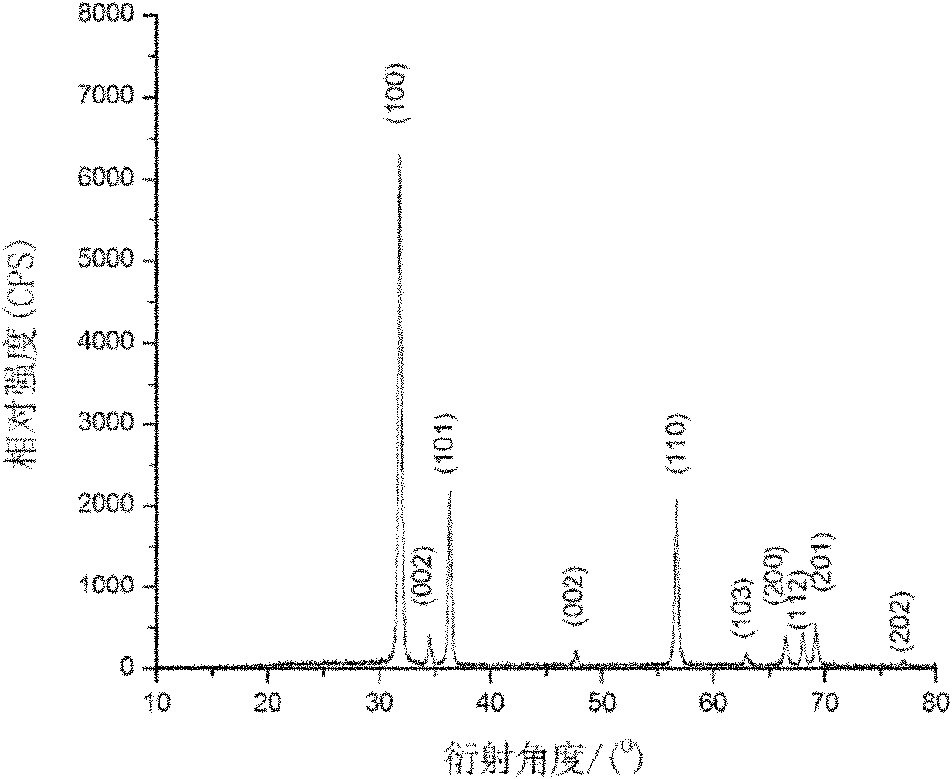

[0020] from figure 1 It can be seen that the ZnO nanowires prepared in large quantities by this method are consistent with the standard map ZnO JCPDS 65-3411.

Embodiment 2

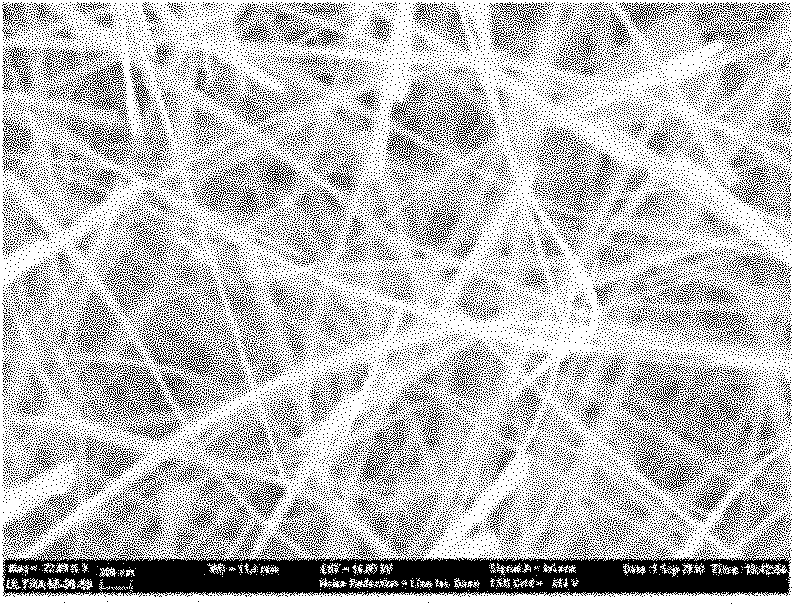

[0022] Fully mix high-purity zinc powder and bamboo charcoal with a mass ratio of 0.5:1.5, then ball mill for 6 hours under the protection of high-purity argon, put the ball-milled materials in a quartz boat, and then put the ceramic boat with materials in in a tube furnace. Then the tube furnace is fed with a carrier gas consisting of a mixture of high-purity nitrogen (99.999%) and high-purity oxygen (99.999%) (high-purity oxygen flow: 1ml / min, high-purity nitrogen flow: 1L / min), And quickly heat up to 800 ℃ Finally, react for 10 minutes, and a large amount of white cotton-like zinc oxide nanowires can be sprayed out at the tube furnace mouth during the reaction. , the scanning electron micrograph of the material is attached Figure 4 .

Embodiment 3

[0024] Fully mix high-purity zinc carbonate powder and carbon fiber with a mass ratio of 1.5:0.5, then ball mill for 24 hours under the protection of high-purity nitrogen, put the ball-milled material in a quartz boat, and then put the ceramic boat with the material in in a tube furnace. Then the tube furnace is fed with a carrier gas consisting of high-purity nitrogen (99.999%) and high-purity oxygen (99.999%) (high-purity oxygen flow: 30ml / min, high-purity nitrogen flow: 3L / min), And quickly heat up to 1100 ℃ Finally, react for 60 minutes, and a large amount of white cotton-like zinc oxide nanowires can be sprayed out at the tube furnace mouth during the reaction. , the scanning electron micrograph of the material is shown in Figure 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com