Bio-synthesis method of nano zinc oxide by utilizing lactic acid bacteria and nano zinc oxide composite feed addictive

A technology of nano-zinc oxide and biosynthesis, which is applied in the field of microbial fermentation and nano-technology, can solve problems such as unseen technical reports, achieve the effects of reducing pollution, improving the utilization rate of nutrients, and preventing zinc poisoning in animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

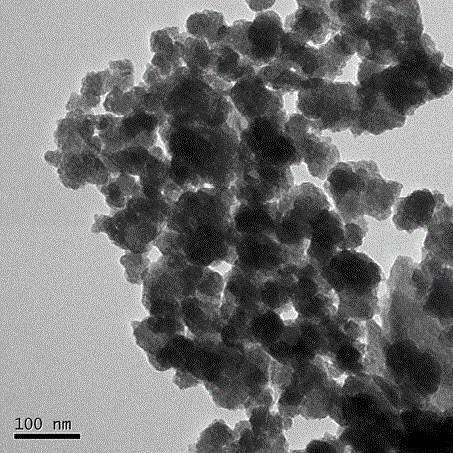

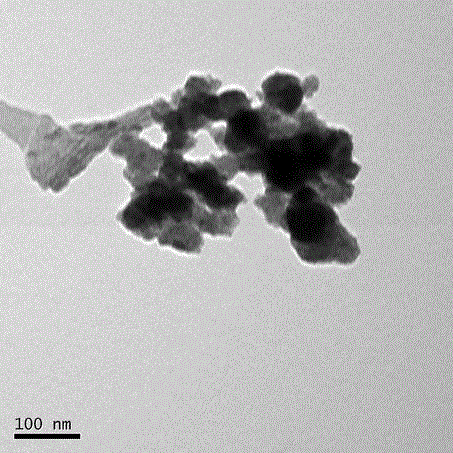

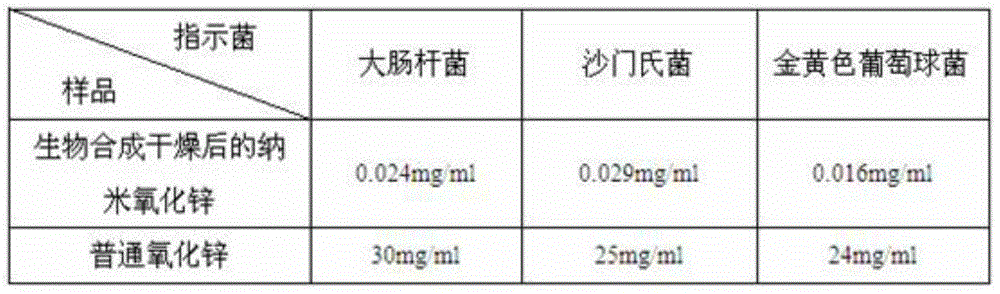

Image

Examples

Embodiment 1

[0048] The preparation method of the nano-zinc oxide product biosynthesized by the highly zinc-resistant Lactobacillus salivarius L3 obtained after screening domestication from the weaned suckling pig feces in June 2011 by the inventor comprises the following steps: the high zinc-resistant Lactobacillus salivarius L3 The strain was deposited in the China Center for Type Culture Collection on April 8, 2013, and the preservation number is CCTCCM2013126.

[0049] S1. Fermentation culture of Lactobacillus. The seed medium and fermentation medium are MRS liquid medium, the pH value is 6.2-6.4, sterilized by moist heat at 121°C for 20-30min, and cooled to 37°C for later use. After activating the glycerol strains for 12 to 16 hours, insert the fermentation medium with an inoculum of 3% to 5% (V / V). After 10 hours of cultivation, add an equal volume of fresh medium to continue the cultivation for 8 hours, and the number of cells reaches 10. 9 CFU / ml, to obtain the fermentation broth;...

Embodiment 2

[0057] Utilize Lactobacillus plantarum (purchased from China Industrial Microorganism Culture Collection Management Center) to prepare nano-zinc oxide steps as follows:

[0058] S1. Fermentation and cultivation of Lactobacillus plantarum. After activating the glycerol strains for 16 to 24 hours, insert the fermentation medium with an inoculum of 3% to 5% V / V, add the same amount of fresh medium after 14 hours of cultivation and continue to cultivate for 12 hours, and the number of cells reaches 10 9 CFU / ml.

[0059] S2. Slowly add an equal amount of 0.35MZnCl to the fermentation broth while stirring 2 solution.

[0060] S3. After adjusting the pH value of the mixture to 6.0, place it in an 80° C. water bath and heat it for 25 minutes to incubate.

[0061] S4. After hatching, put them into a 37° C. incubator to age for 9 hours.

[0062] S5. After aging, the cells and nano-zinc oxide precipitates are collected by centrifugation.

[0063] S6. The centrifuged product is calci...

Embodiment 3

[0066] Utilize Lactobacillus plantarum (purchased from China Industrial Microorganism Culture Collection Management Center) to prepare nano-zinc oxide steps as follows:

[0067] S1. Fermentation and cultivation of Lactobacillus plantarum. After activating the glycerol strains for 16 to 24 hours, insert the fermentation medium with an inoculum of 3% to 5% V / V, add the same amount of fresh medium after 14 hours of cultivation and continue to cultivate for 12 hours, and the number of cells reaches 10 9 CFU / ml.

[0068] S2. Slowly add an equal amount of 0.35MZnSO to the fermentation broth while stirring 4 liquid.

[0069] S3. After adjusting the pH value of the mixture to 6.0, place it in an 80° C. water bath and heat it for 25 minutes to incubate.

[0070] S4. After hatching, put them into a 37° C. incubator to age for 9 hours.

[0071] S5. After aging, the cells and nano-zinc oxide precipitates are collected by centrifugation.

[0072] S6. The centrifuged product was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com