Modified zinc stearate production technology

A production process, zinc stearate technology, applied in the technical field of dry production of zinc stearate, can solve the problems of affecting the activity of zinc stearate, increasing the difficulty of processing, large energy consumption, etc., and achieve obvious economic benefits and social benefits, fast crushing, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

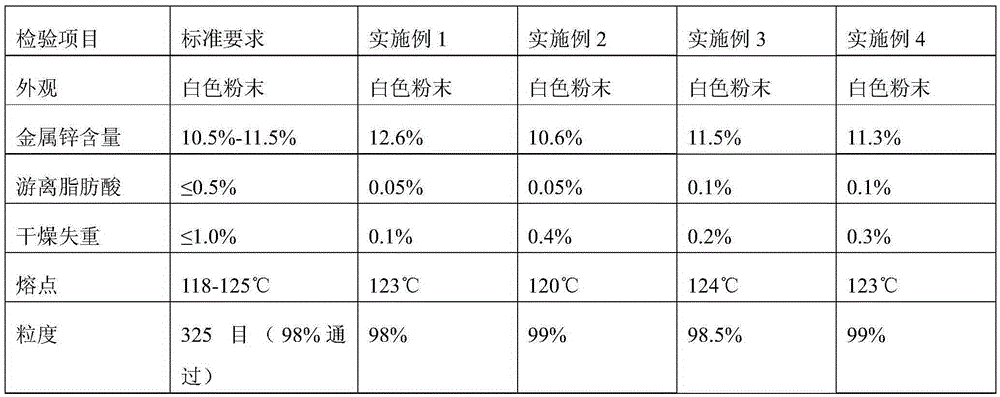

Examples

Embodiment 1

[0019] In terms of mass percentage, add 80% stearic acid to the pressure-resistant reactor, stir and heat to the melting temperature, set the stirring speed to 1250 rpm, and add 15% at 120°C with a purity of 99.7% by weight and average particle size. Zinc oxide with a diameter of 20-100 nanometers, after reacting for 10 minutes, add 5% pure water, seal the reaction kettle, evacuate to a vacuum of 50 Pa, continue the reaction for 20 minutes, cool down and enter the pulverizer for pulverization. The resulting product is It is zinc stearate.

Embodiment 2

[0021] According to the mass percentage, 87% stearic acid was added to the pressure-resistant reactor, stirred and heated to the melting temperature, the stirring speed was set to 1250rpm, and 10% was added at 130°C with a purity of 99.7wt%, particle size Zinc oxide at 20-100 nanometers,

[0022] After reacting for 15 minutes, add 3% pure water, seal the reactor, evacuate to a vacuum of 500 Pa, continue the reaction for 30 minutes, cool down and enter the pulverizer for pulverization, and the resulting product is zinc stearate.

Embodiment 3

[0024] In terms of mass percentage, add 85% of stearic acid to the pressure-resistant reactor, stir and heat to the melting temperature, set the stirring speed to 1250rpm, add 16% of the purity to 99.7% by weight, particle size at 150℃ Zinc oxide at 20-100 nanometers,

[0025] After reacting for 10 minutes, add 1% pure water, seal the reaction kettle, evacuate to a vacuum of 150 Pa, continue the reaction for 20 minutes, cool down and enter the pulverizer for pulverization. The resulting product is zinc stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com