Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Low total production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

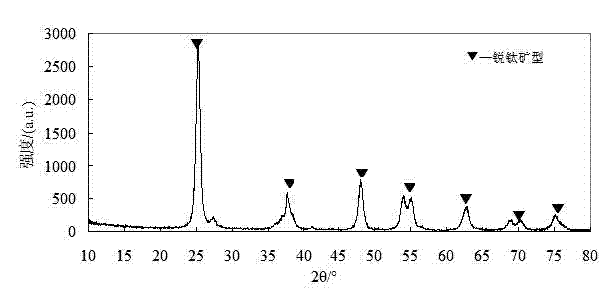

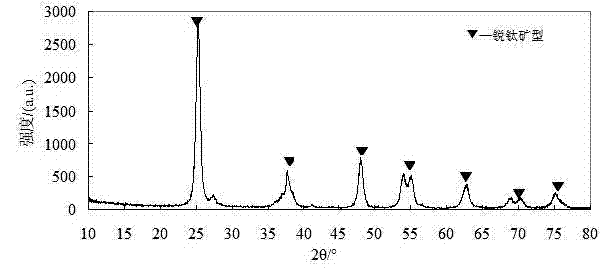

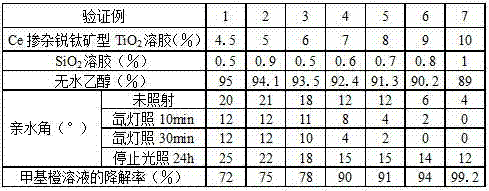

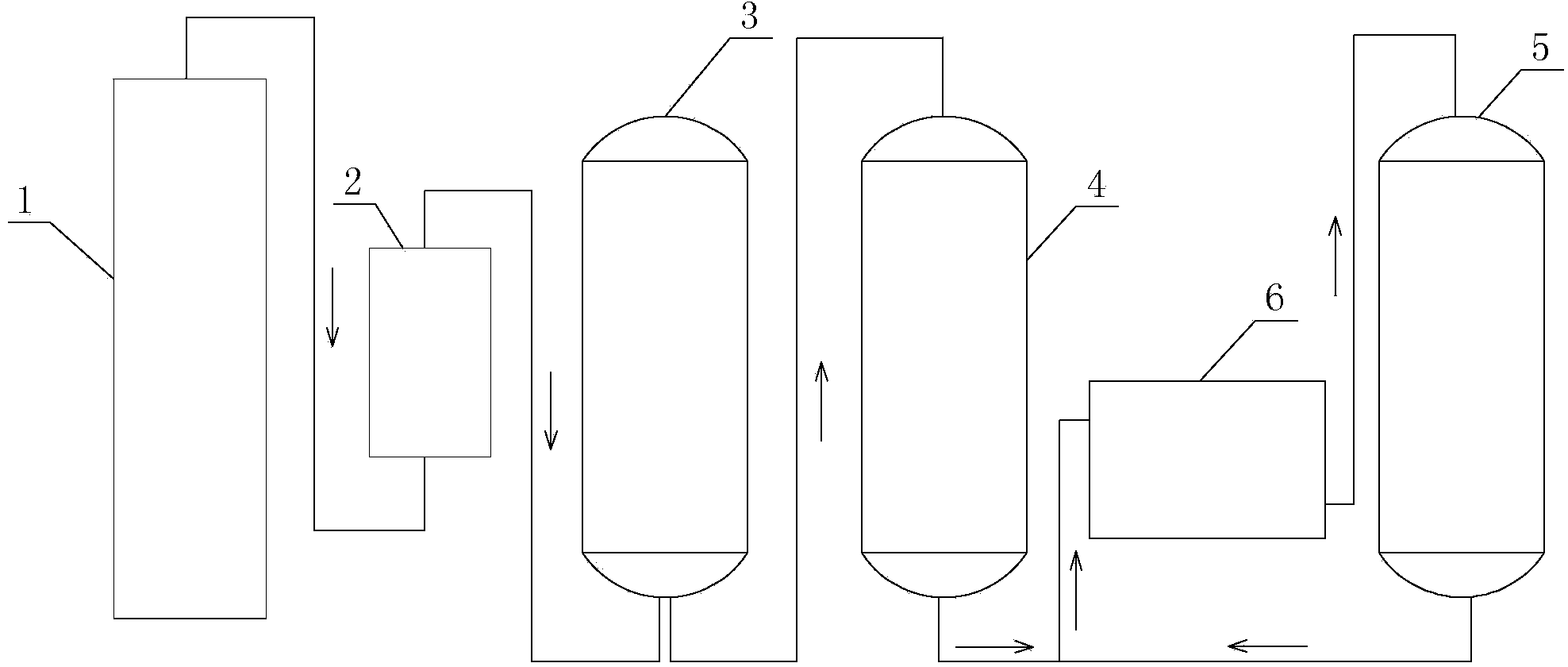

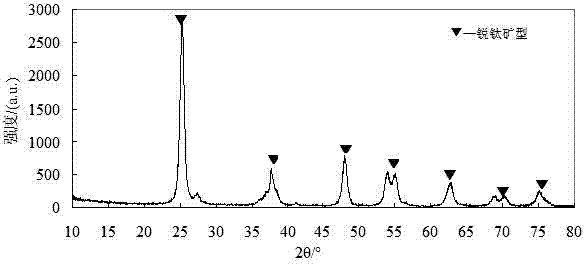

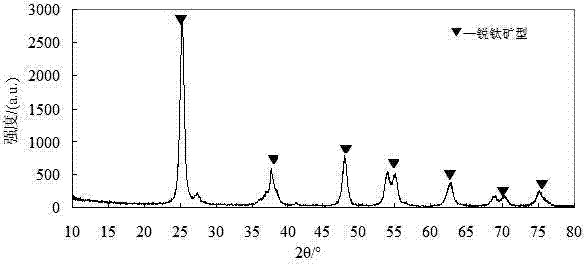

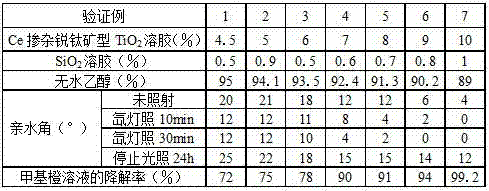

Method for preparing photoinduced ultra hydrophilic automatically cleaning paint

The invention provides a method for preparing a photoinduced ultra hydrophilic automatically cleaning paint, comprising the following steps: (1) preparing titanium dioxide suspension by using titanium hydroxide; (2) preparing cerium-doped anatase titanium dioxide for subsequent use; (3) placing waterless ethanol, ammoniacal liquor, distilled water and ethyl orthosilicate which is added later into a reactor and magnetic stirring uniformly; (4) magnetic stirring the mixed liquor prepared in step (3) for more than 3 h in a constant temperature bath of 80 DEG C to obtain silica sol; (5)mixing the cerium-doped anatase titanium dioxide prepared in step (2), silica sol prepared in step (4) with waterless ethanol and stirring uniformly to obtain the photoinduced ultra hydrophilic automatically cleaning paint. The photoinduced ultra hydrophilic automatically cleaning paint has the advantages of simple use and convenient. The preparation method has the advantages of low energy consumption, saving heat treatment equipment, and low cost.

Owner:CHONGQING UNIV

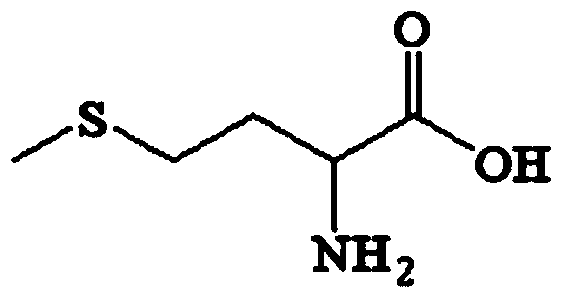

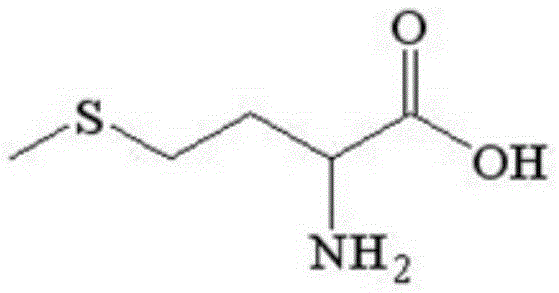

Cheap preparation method for high purity D,L-methionine

ActiveCN103641758AAvoid it happening againShorten production timeOrganic compound preparationSulfide preparationMethionine biosynthesisPressure reduction

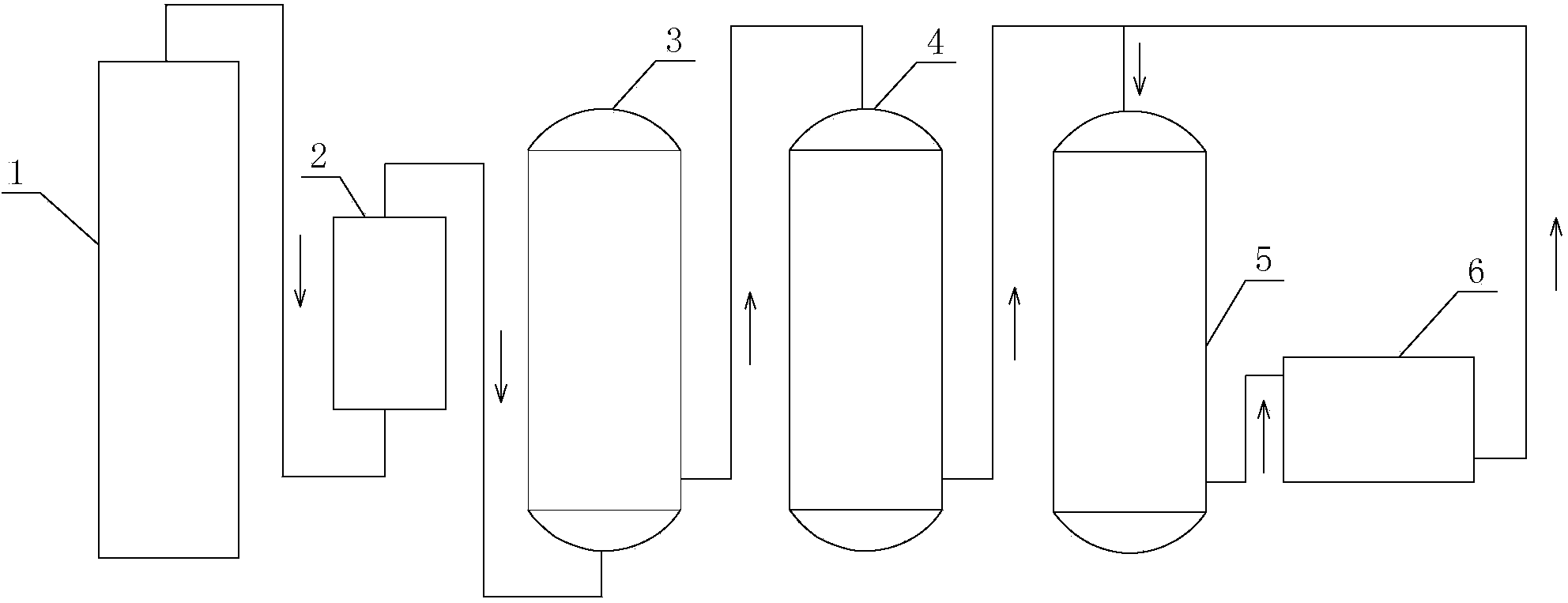

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Comprehensive recovery method for zinc, nickel and cobalt-containing purification slag

ActiveCN107746969AHigh separation recovery rateEfficient separationPhotography auxillary processesProcess efficiency improvementRecovery methodSulfate radicals

The invention relates to a comprehensive recovery method for zinc, nickel and cobalt-containing purification slag. The method comprises the following steps: washing the zinc, nickel and cobalt-containing purification slag with hot water till the content of sulfate radicals or chlorine ions of a lotion is smaller than 1g / L and then leaching the purification slag with sodium hydroxide; obtaining zinc and cobalt-containing alkaline leaching liquor and leached slag primarily containing nickel; putting the alkaline leaching liquor in a magnetic field and performing diaphragm electrolysis by takinga magnetic material as an anode and a stainless steel plate as a cathode to obtain metal zinc powder in a cathode region and the cathode and anode slurry primarily containing Co2O3 and Co3O4 in an anode region and the anode; washing and drying the anode slurry, reducing the same directly with hydrogen to obtain metal cobalt powder or sulfuric acid leached out, precipitating oxalic acid to obtain cobalt oxalate, then reducing the cobalt oxalate with hydrogen to obtain metal cobalt powder, and electrolyzing metal cobalt; returning the alkaline residual electrolyte to leach zinc, nickel and cobalt purification slag; and washing the nickel-containing leach residue and leaching the same with sulfuric acid, and enriching the same and performing electrolysis to obtain metal nickel. The method provided by the invention is short in process flow, high in separating recovery rate of zinc, nickel and cobalt and small in wastewater and waste residue amount.

Owner:六盘水中联工贸实业有限公司 +1

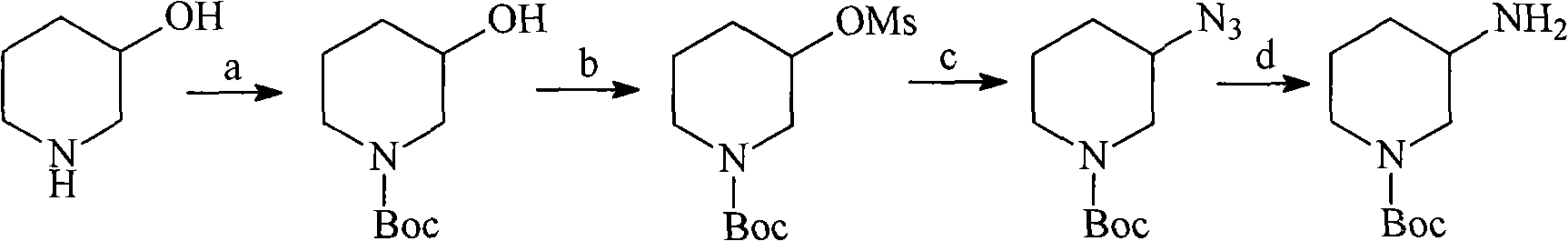

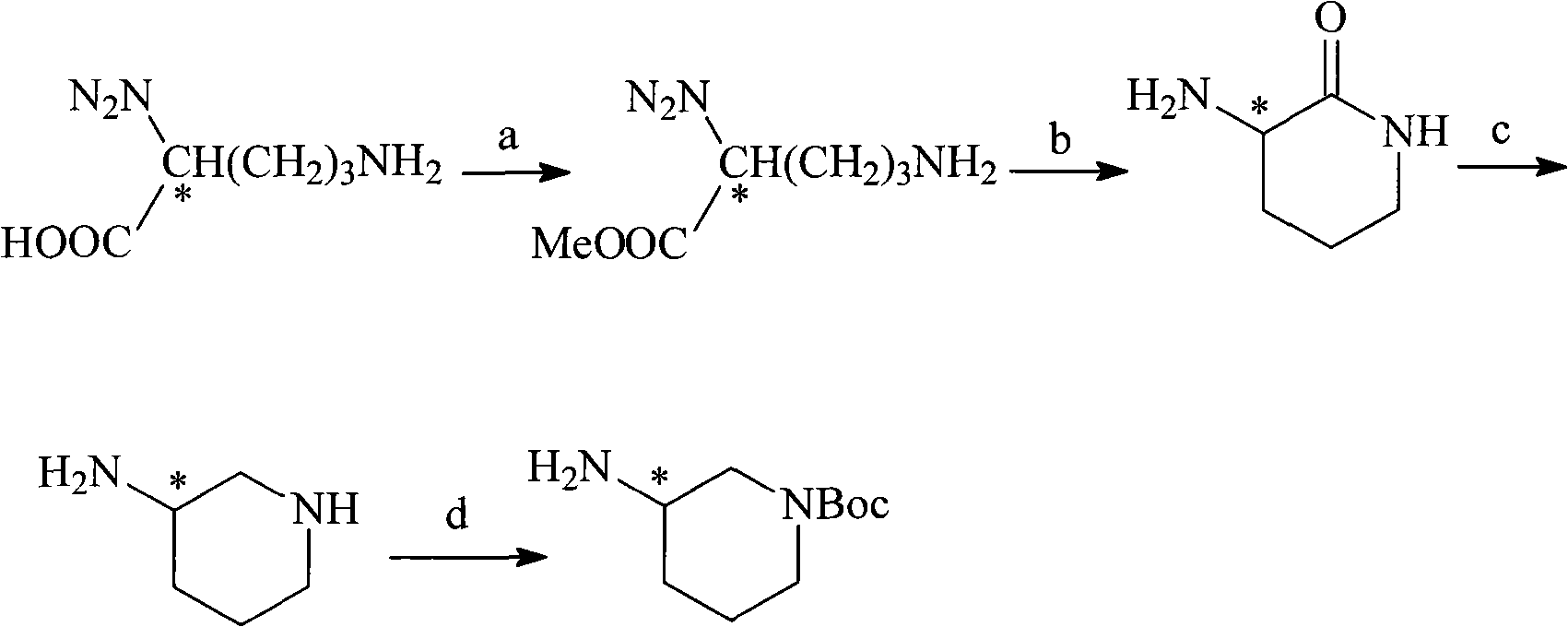

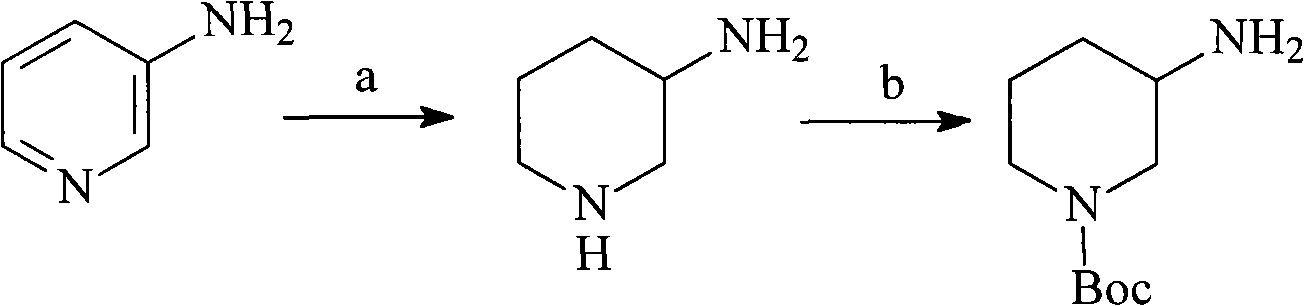

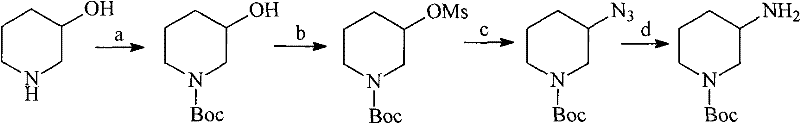

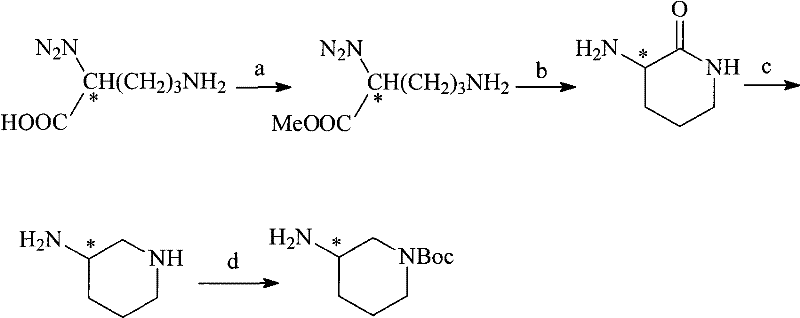

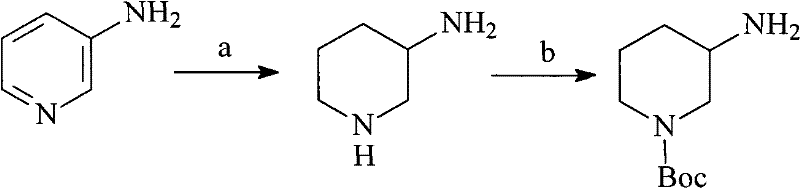

N-Boc-3-aminopiperidine and synthesizing method of optical isomer thereof

The invention discloses an intermediate N-Boc-3-aminopiperidine and a synthesizing method of optical isomer thereof. The prior synthesizing route has the disadvantages of high requirements on reaction conditions, high possibility of racemization, a great number of byproducts, as well as difficult post-treatment and difficult industrialization. The synthesizing method comprises the following steps: taking halogenated hydrocarbon as a solvent and organic alkali as an acid-binding agent, 3-piperidine ethyl formate is added with di-tert-butyl dicarbonate by dripping at temperature of 0-10 DEG C to obtain N-Boc-3-piperidine ethyl formate; 1,4-dioxane is used as a solvent, the N-Boc-3-piperidine ethyl formate undergoes ammonolysis reaction to obtain N-Boc-3-piperidine formamide; and the N-Boc-3-piperidine formamide is added by dripping in a solution with sodium hypochlorite and sodium hydroxide to obtain N-Boc-3-aminopiperidine. The invention has the advantages of no racemization during the reaction, high optical purity of the product, relatively moderate reaction conditions, simple operation, low total production cost, and easy large-scale industrial production.

Owner:NOVOCODEX BIOPHARMACEUTICALS CO LTD

Preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate

ActiveCN103641757AStable in natureShorten production timeSulfide preparationTrace element2-hydroxy-4-methylthiobutyrate

The invention is directed at the field of chemical engineering and provides a preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; preparing a 2-hydroxy-4-methylthiobutyronityile system with the hydrocyanic acid gas mixture and methylthiopropionaldehyde as starting raw materials; hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system with inorganic base so as to obtain D,L-2-hydroxy-4-methylthiobutyrate; and chelating D,L-2-hydroxy-4-methylthiobutyrate with a soluble calcium salt so as to produce calcium D,L-2-hydroxy-4-methylthiobutyrate. The method has the advantages of a few processing step, cheap and easily available raw materials, stable intermediate properties and low total production cost. Prepared calcium D,L-2-hydroxy-4-methylthiobutyrate has the advantages of high yield, high purity, a powder crystal form and great bulk density, can be used as an animal feed additive for effective mixing with a feed so as to supplement trace elements and amino acid in daily ration and improve production performance and immune performance of animals and can also be used as a medicine reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

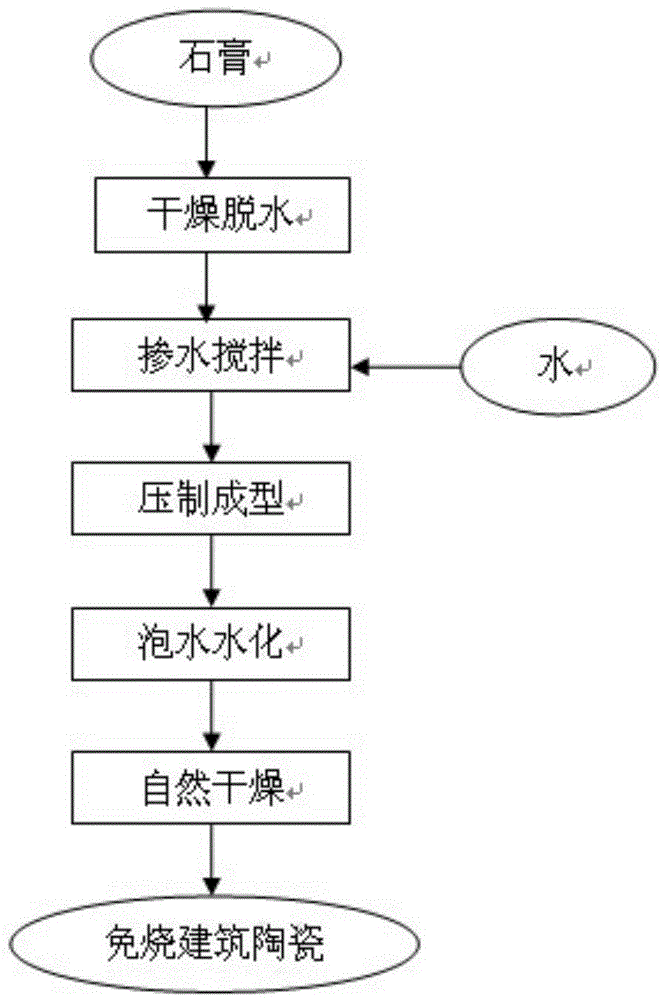

Production process of unfired building ceramic

The invention relates to a production process of unfired building ceramic. The production process comprises the following steps: (1) drying and dehydrating: drying and dehydrating gypsum to obtain semi-hydrated gypsum; (2) carrying out compression moulding: mixing the semi-hydrated gypsum with water in a mass ratio of 100 to (6-25) and quickly stirring uniformly, and then carrying out compression moulding to obtain ceramic blanks; (3) soaking in water to hydrate: overlying the obtained ceramic blanks which are separated by cotton cloth, putting the ceramic blanks into a hydrating slot, and putting the overlaid ceramic blanks and the hydrating slot under a press, applying pressures by virtue of the press, maintaining the pressure unchanged, introducing water into the hydrating slot and soaking the ceramic blanks for 1-3 hours; and (4) naturally drying. By using gypsum as a raw material, the production process of unfired building ceramic is low in production cost, simple in process and free of high-temperature firing and has better energy conservation and emission reduction effects, and the prepared unfired building ceramic is good in performance.

Owner:周俊

N-Boc-3-aminopiperidine and synthesizing method of optical isomer thereof

The invention discloses an intermediate N-Boc-3-aminopiperidine and a synthesizing method of optical isomer thereof. The prior synthesizing route has the disadvantages of high requirements on reactionconditions, high possibility of racemization, a great number of byproducts, as well as difficult post-treatment and difficult industrialization. The synthesizing method comprises the following steps:taking halogenated hydrocarbon as a solvent and organic alkali as an acid-binding agent, 3-piperidine ethyl formate is added with di-tert-butyl dicarbonate by dripping at temperature of 0-10 DEG C toobtain N-Boc-3-piperidine ethyl formate; 1,4-dioxane is used as a solvent, the N-Boc-3-piperidine ethyl formate undergoes ammonolysis reaction to obtain N-Boc-3-piperidine formamide; and the N-Boc-3-piperidine formamide is added by dripping in a solution with sodium hypochlorite and sodium hydroxide to obtain N-Boc-3-aminopiperidine. The invention has the advantages of no racemization during thereaction, high optical purity of the product, relatively moderate reaction conditions, simple operation, low total production cost, and easy large-scale industrial production.

Owner:NOVOCODEX BIOPHARMACEUTICALS CO LTD

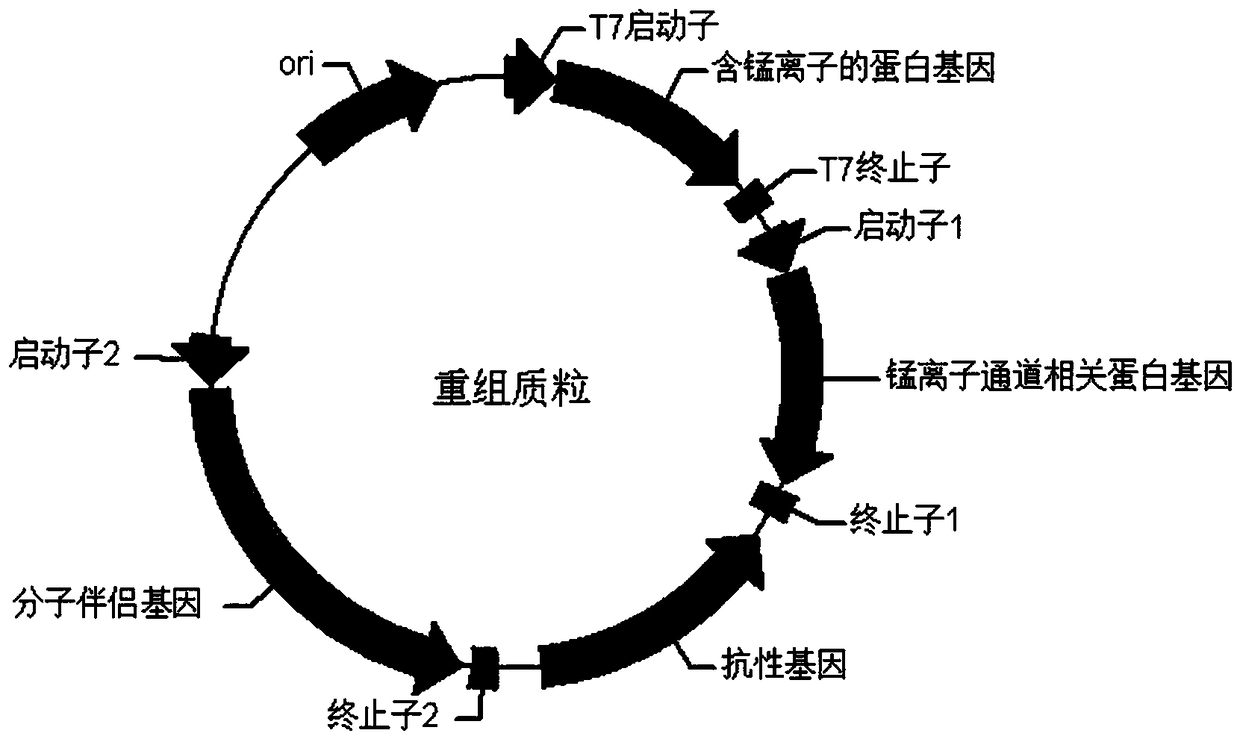

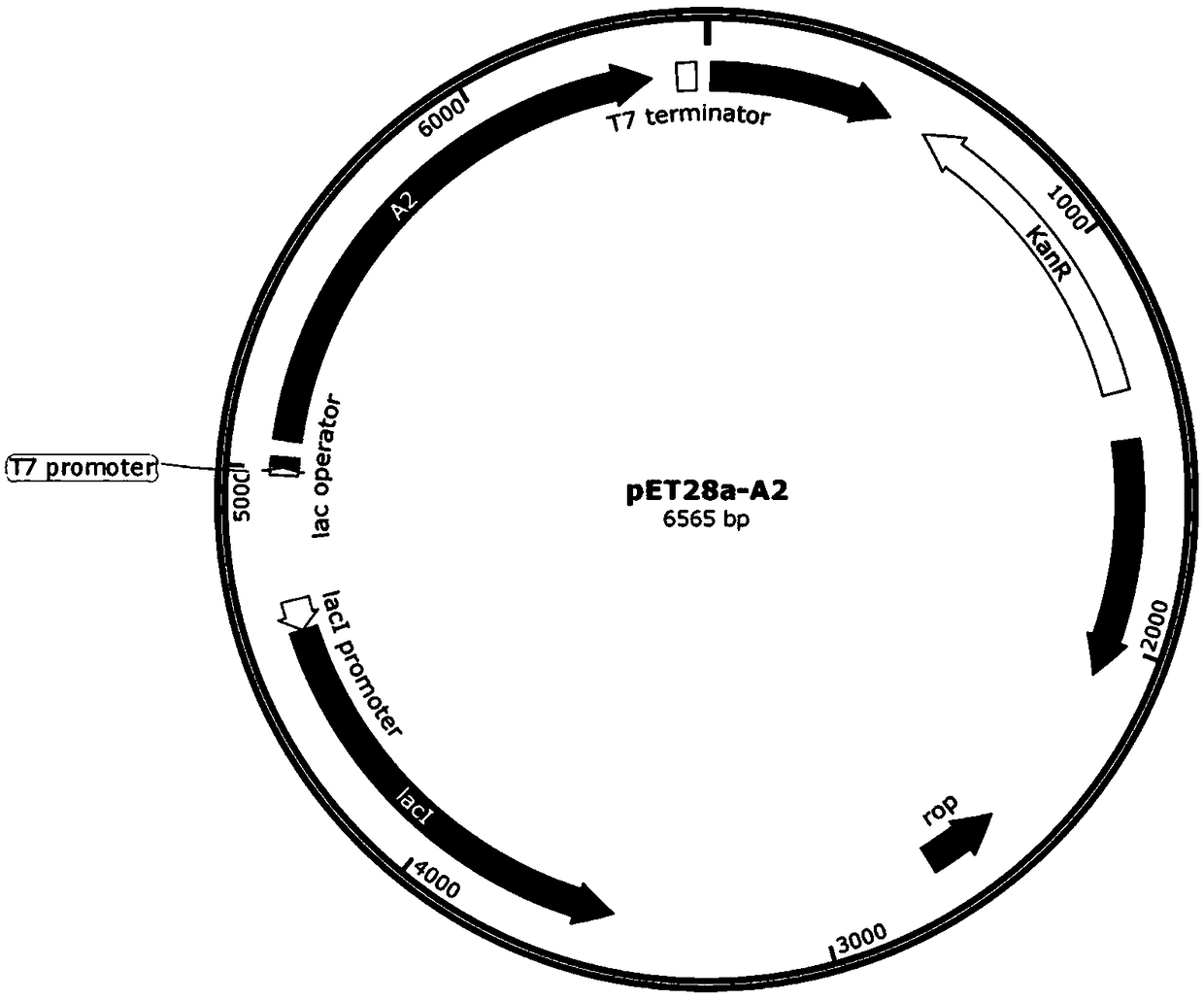

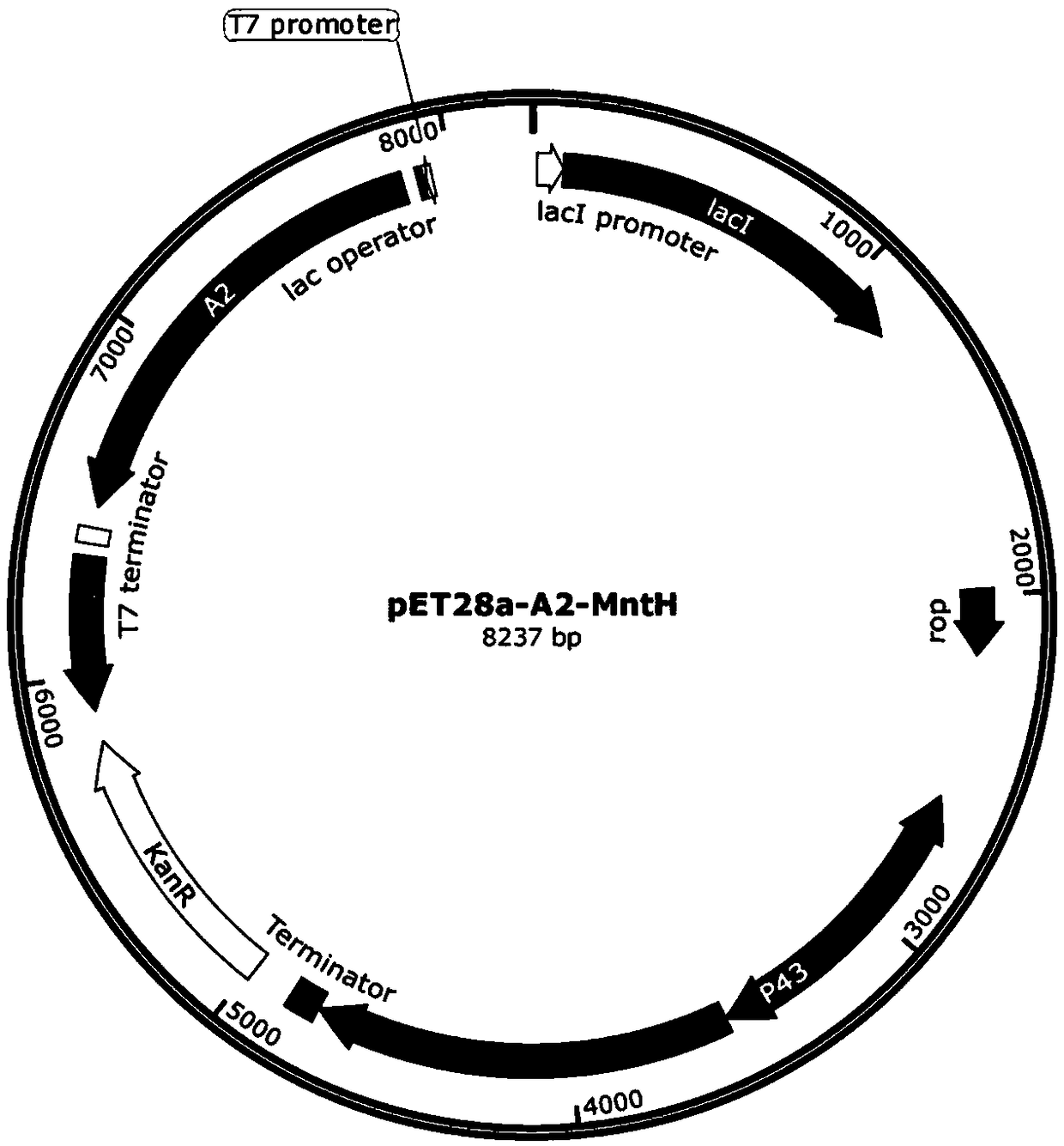

Escherichia coli expression system containing manganese ion recombinant protein, and application method thereof

ActiveCN108998462ASimple separation and purification processLow total production costBacteriaHydrolasesEscherichia coliManganese

The invention discloses an Escherichia coli expression system containing a manganese ion recombinant protein, and an application method thereof. A recombinant expression plasmid in the Escherichia coli expression system is one or a combination of the following cases: (1) an Escherichia coli molecular chaperone gene and an manganese ion-containing enzyme protein gene; (2) an E. coli chaperone geneAn enzyme protein gene containing manganese ions, and a channel-associated protein gene for overexpressing or inhibiting manganese ions; and (3) the Escherichia coli molecular chaperone gene, the manganese ion-containing enzyme protein gene, and a concentration-associated protein gene for affecting intracellular manganese ions. The Escherichia coli expression system is constructed and optimized torealize the efficient, soluble and active expression of the manganese ion-containing enzyme protein; and compared with conventional methods, the method has the advantages of high efficiency, simple purification process, low cost, and facilitation of the industrial production and application of manganese ion-containing enzymes.

Owner:WUHAN KANGFUDE BIOTECH CO LTD

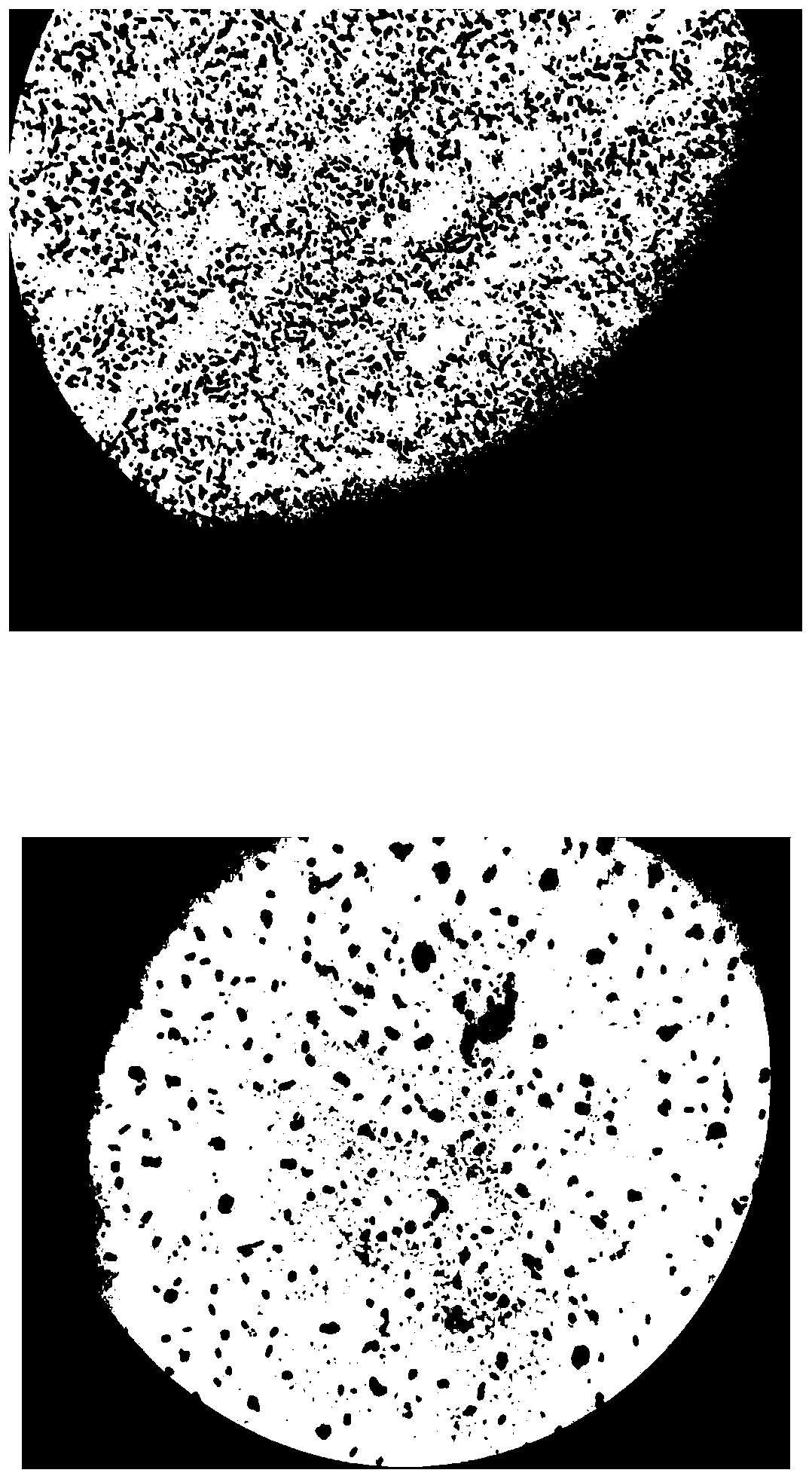

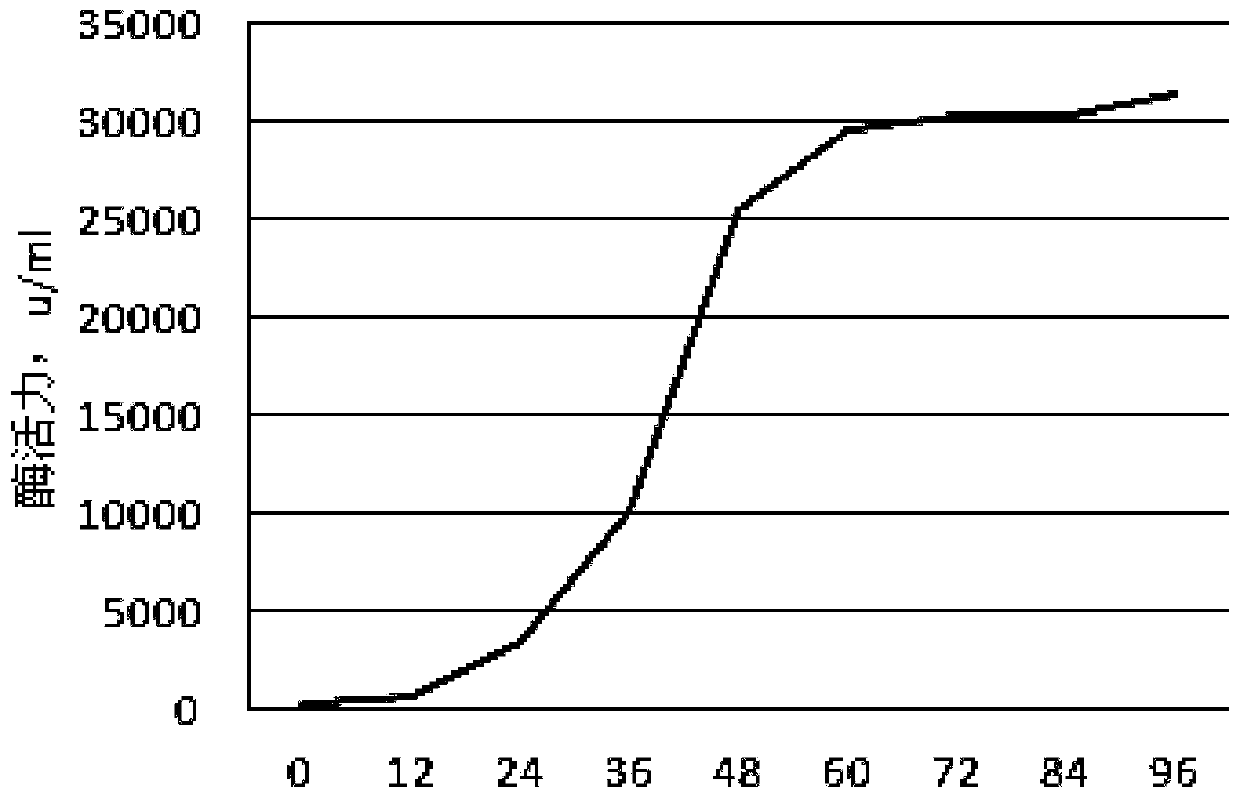

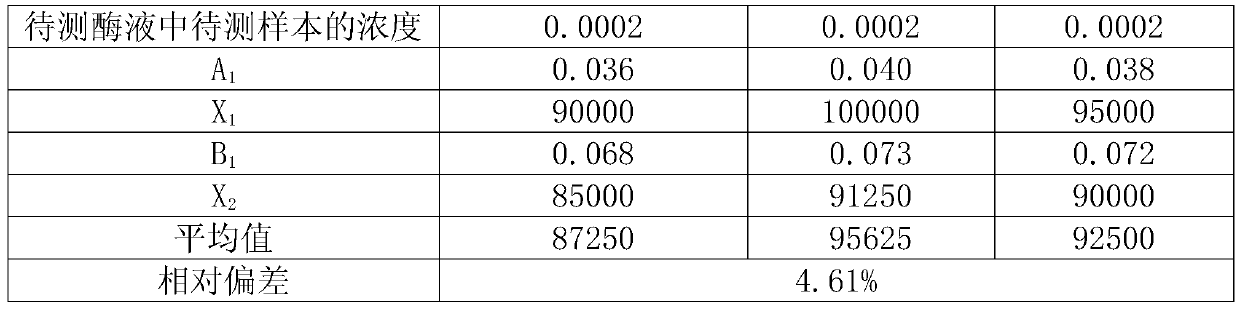

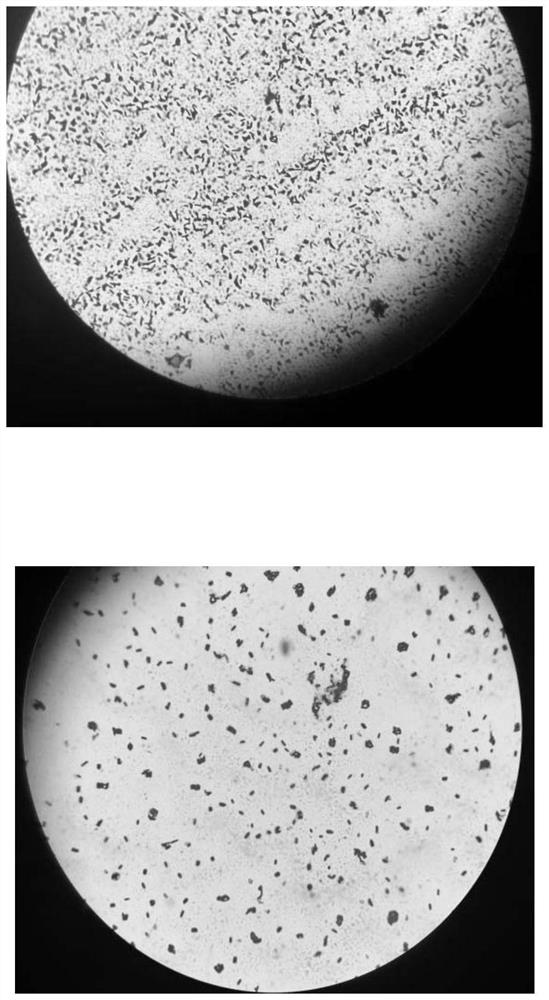

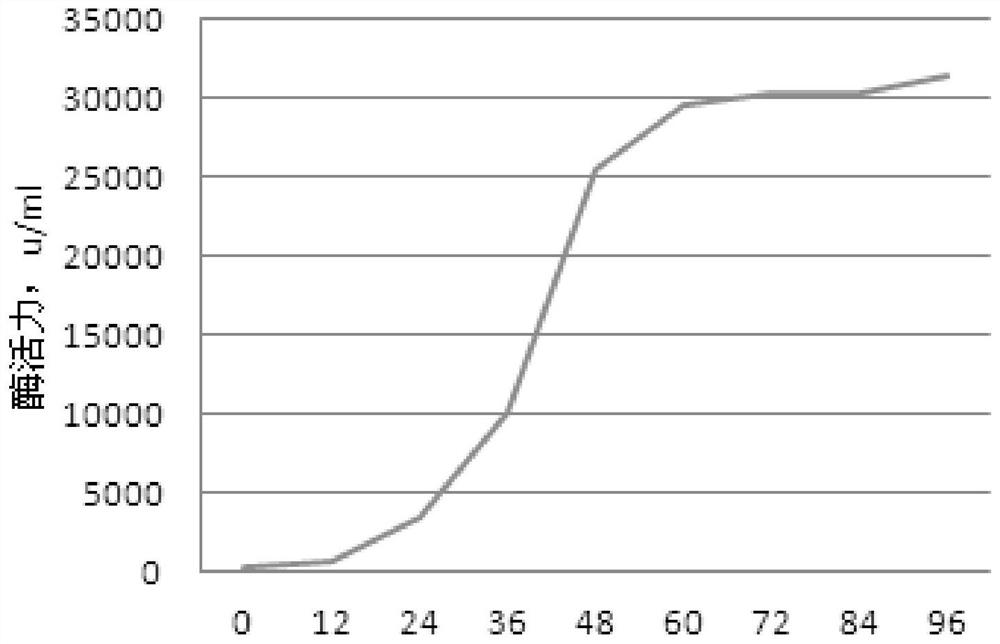

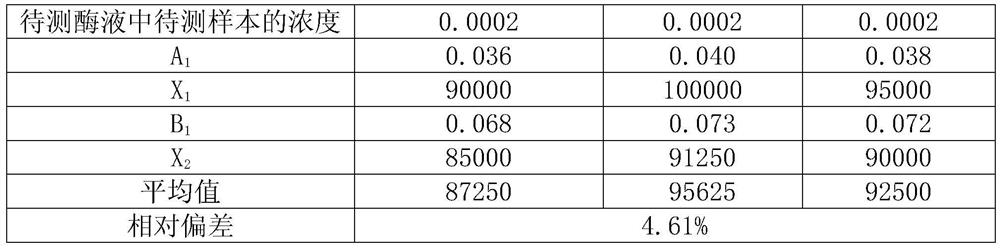

Bacillus licheniformis with high yielding of protease and fermentation enzyme-production method thereof

ActiveCN110408568AHigh extraction and purification process yieldLow total production costBacteriaHydrolasesBacillus licheniformisProteinase activity

The invention discloses bacillus licheniformis with high yielding of protease and a fermentation enzyme-production method thereof. The bacillus licheniformis GZ73 provided by the invention is referredto as bacillus licheniformis GZ73, and has the preservation number of CGMCC NO.18048. The invention also discloses an application of the bacillus licheniformis GZ73 in production of protease. The protease is prepared by fermentation of the bacillus licheniformis GZ73, the enzyme production efficiency of fermentation is high, the cost of raw materials is low, the enzyme activity in fermentation broth is high, the yield of the enzyme extraction and purification process is high, and the total production cost is low. The enzyme preparation provided by the invention can be widely applied in feeds,foods, detergents and other industries.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Solid methionine hydroxy analogue calcium salt compound with antibacterial and acidizing properties and preparation method of solid methionine hydroxy analogue calcium salt compound

The invention discloses a solid methionine hydroxy analogue calcium salt compound with antibacterial and acidizing properties and a preparation method of the solid methionine hydroxyl analogue calcium salt compound. The compound is prepared from calcium 2-hydroxy-4-(methylthio) butyrate, 2-hydroxy-4-(methylthio) butyric acid and water. A preparation method of the compound comprises the following steps: mixing an aqueous solution of liquid methionine with calcium oxide or calcium hydroxide to obtain a reaction solution, carrying out a neutralization reaction at 80-100 DEG C to obtain a liquid product, and carrying out spray drying on the liquid product to obtain the target product. According to the preparation method, the raw material ratio is scientific and reasonable, the final product powdery methionine hydroxyl analogue calcium salt compound powder is loose and good in dispersity, the yield reaches up to 99% or above, the methionine content is larger than or equal to 88 wt%, the problems that in the actual production process, methionine hydroxy analogue calcium salt is low in yield and purity, a filter cake is sticky and greasy, smoothness is poor and the like are solved, and the requirements of customers on powdery methionine and liquid methionine can both be met, so that the compound is worthy of popularization and application.

Owner:山西铁峰化工有限公司

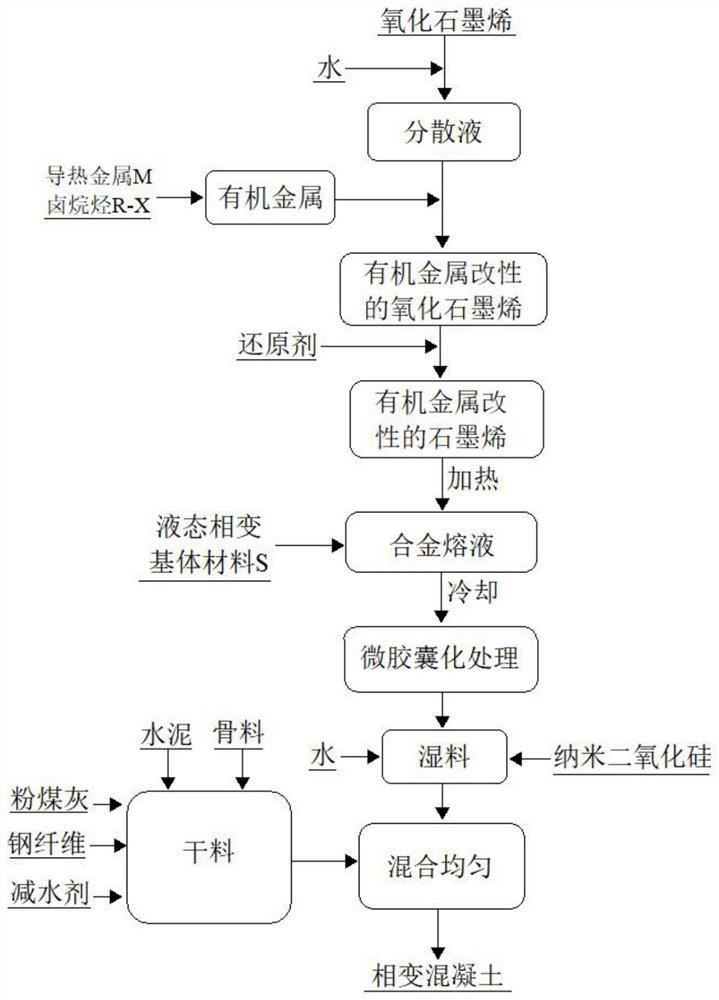

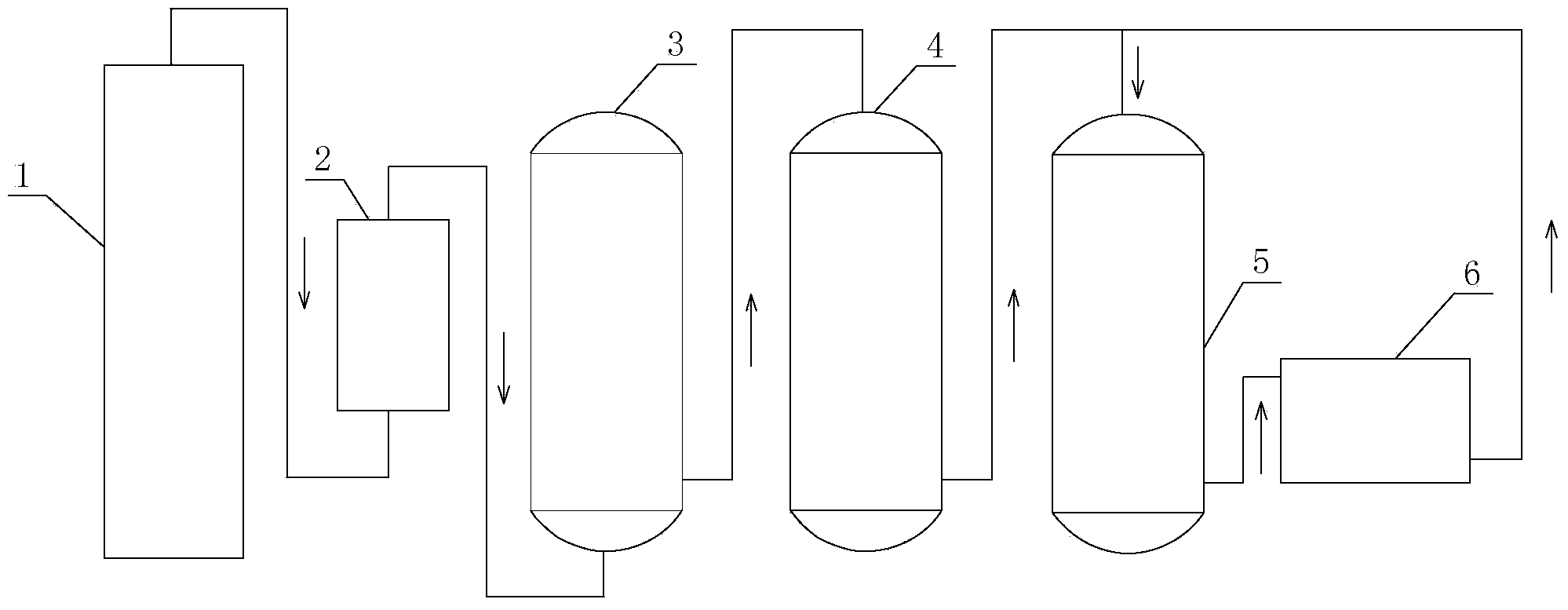

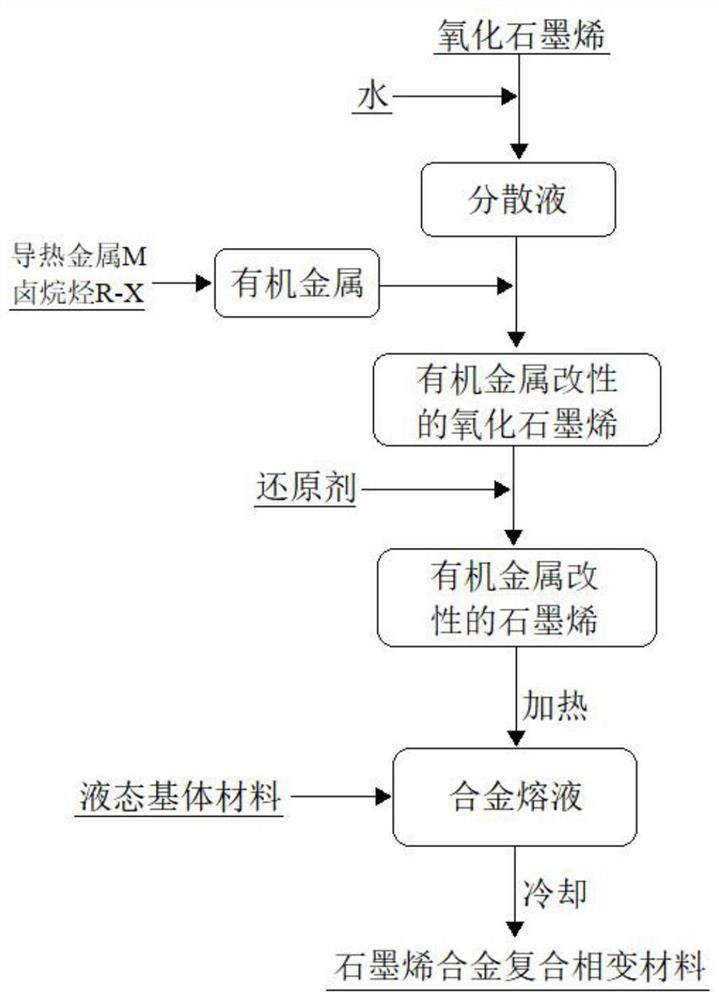

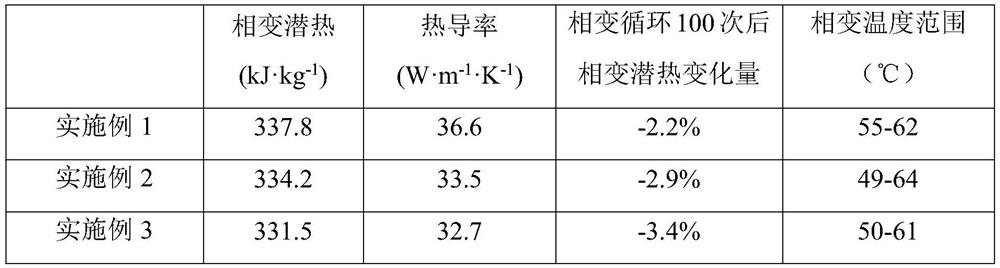

Phase change concrete and preparation method thereof

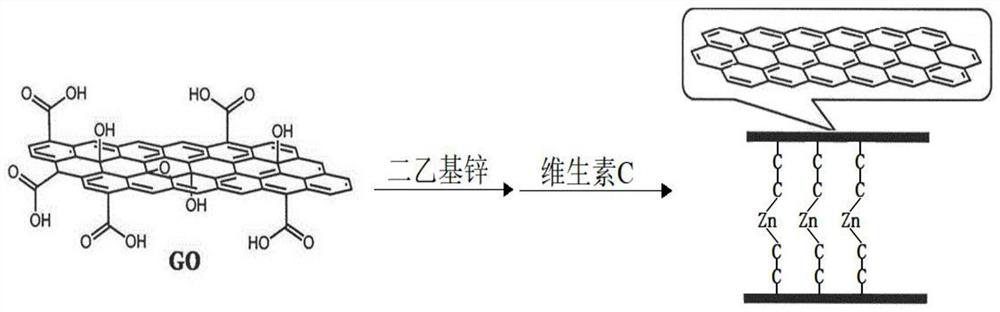

ActiveCN114031339AImprove internal thermal conductivityEnhance heat storage and heat release rateSolid waste managementHeat-exchange elementsGrapheneGraphite

The invention discloses phase change concrete and a preparation method thereof. The preparation method comprises the steps that firstly, organic metal is adopted for modifying graphene, then the modified graphene is compounded with a phase change base material, and a phase change material with high heat conductivity is obtained; and then microcapsules are adopted as a packaging form of the phase change material, and the strength of the concrete material is enhanced by adding steel fibers and nano silicon dioxide, so that the phase change concrete material with good heat storage capacity and good strength performance is obtained.

Owner:XIANGTAN UNIV

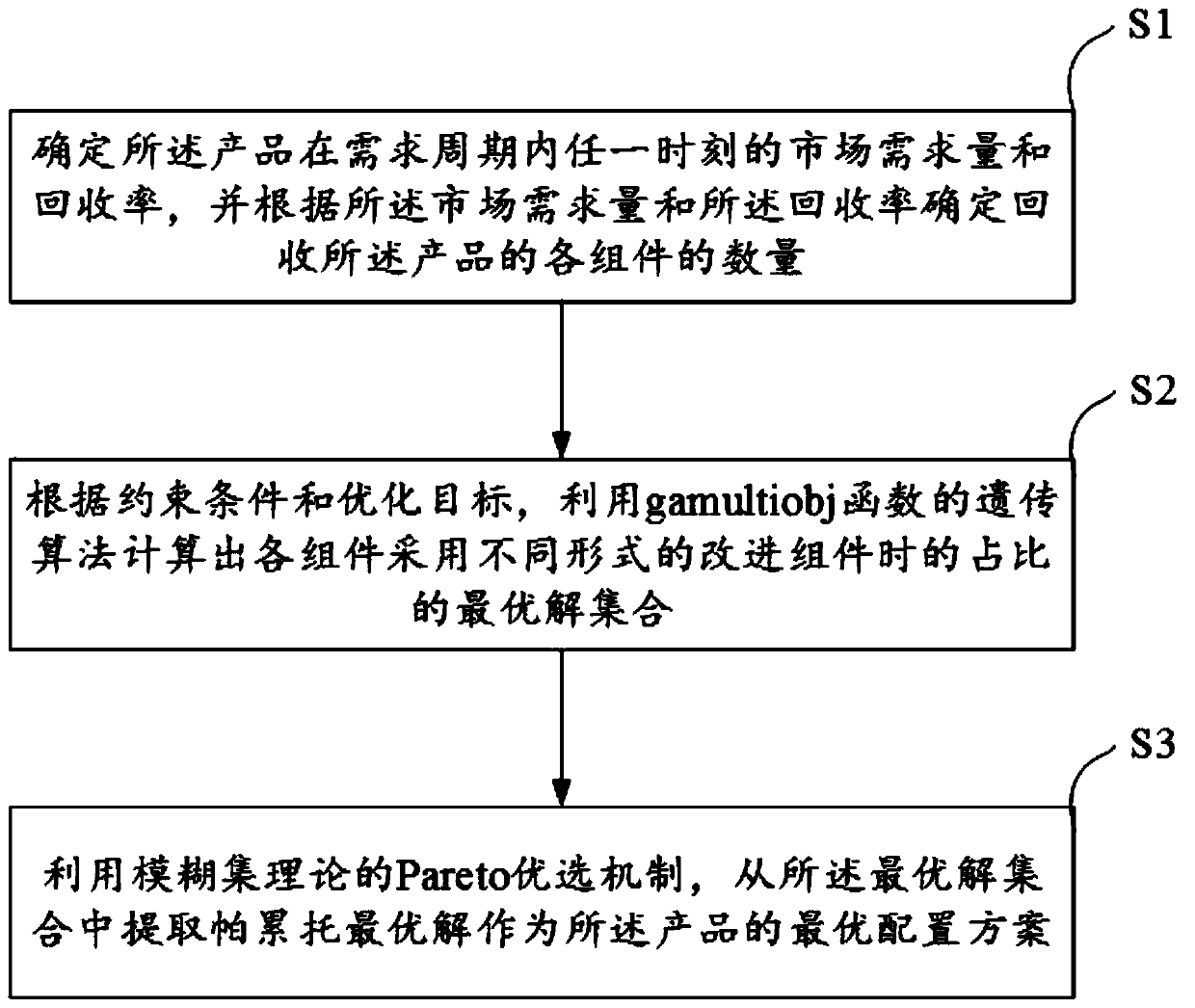

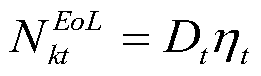

Product configuration method for reusing recycled products

InactiveCN110619395AQuality assuranceComputational reliabilitySustainable waste treatmentData processing applicationsConfiguration optimizationAlgorithm

The invention relates to a product configuration method for reusing recycled products. According to a constraint condition and an optimization target, the method has the step of calculating an optimalsolution set of proportions when the components adopt the improved components in different forms by utilizing a genetic algorithm of a gamutiobj function; on one hand, a plurality of optimization objectives can be set, and optimal configuration on a plurality of objectives of the product is satisfied; corresponding constraint conditions are set for calculating an optimal solution set of proportions when the components adopt different forms of improved components; that is, the influence of different forms of improved components on the configuration scheme is repeatedly considered; then, a Pareto optimization mechanism of a fuzzy set theory is used; a step of extracting a Pareto optimal solution from the optimal solution set as an optimal configuration scheme is carried out; visibly, the product configuration optimization is carried out on the improved components in different forms while multiple targets are optimized, and the influence of the improved components on the configuration scheme is also considered, so that the more accurate product configuration method for recycling the product is realized.

Owner:WUHAN UNIV OF SCI & TECH

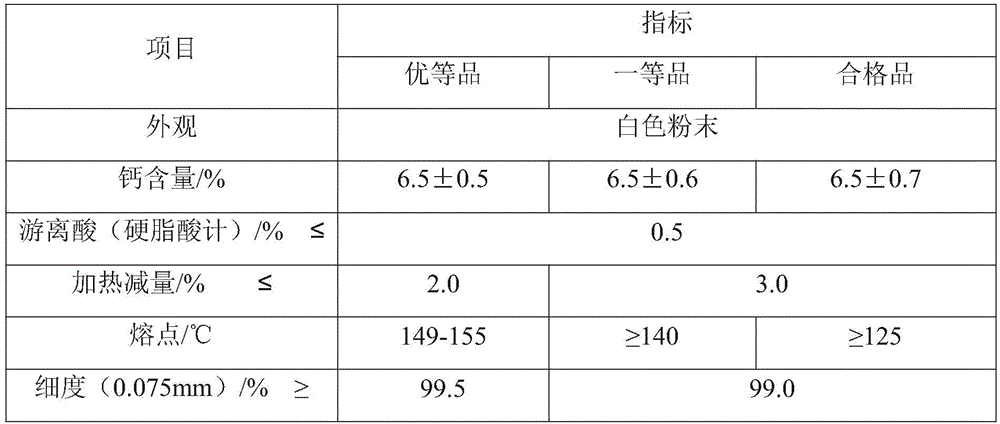

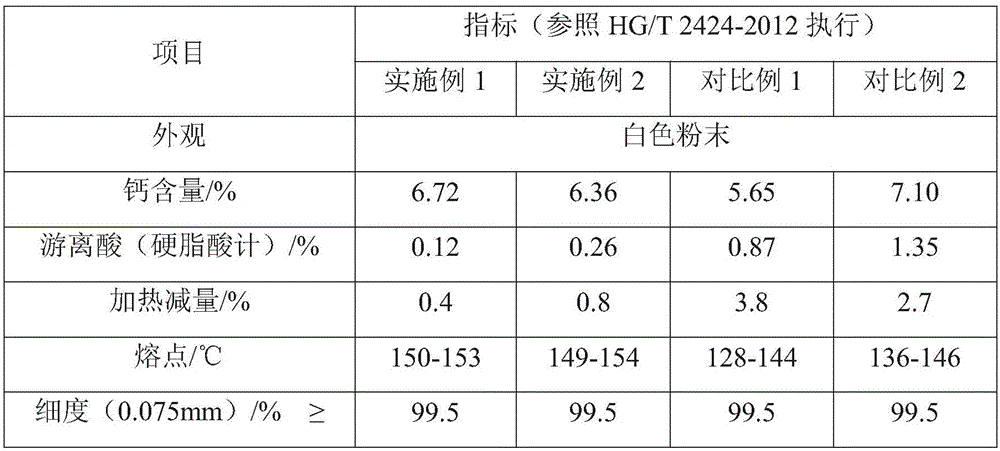

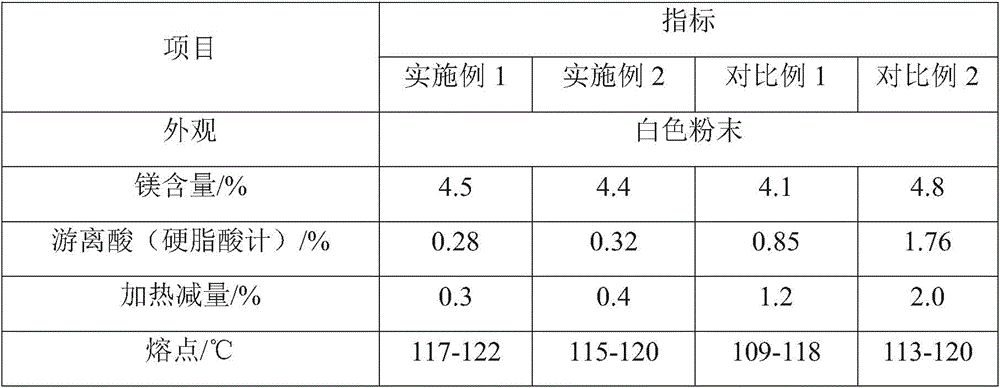

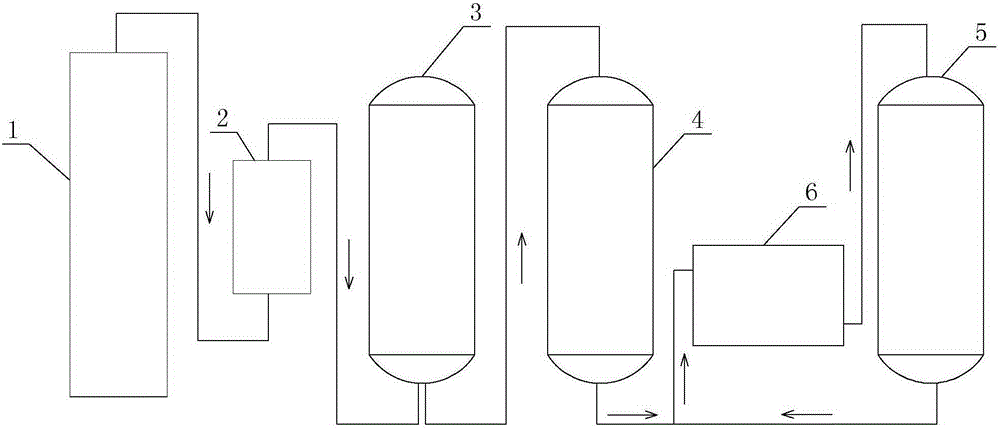

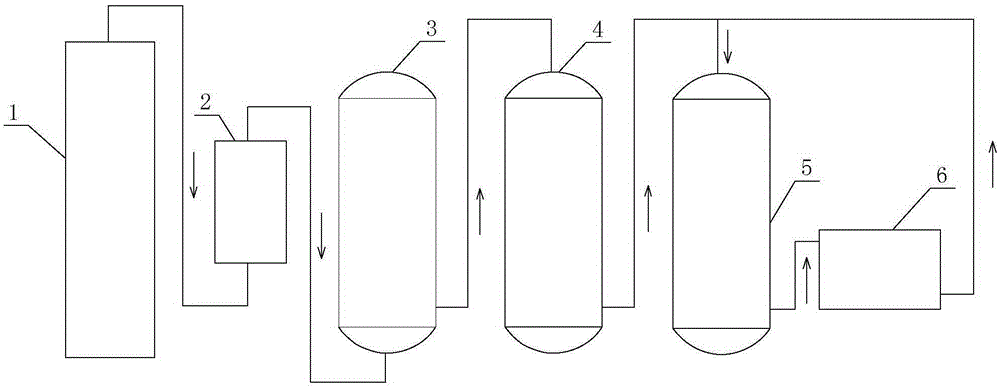

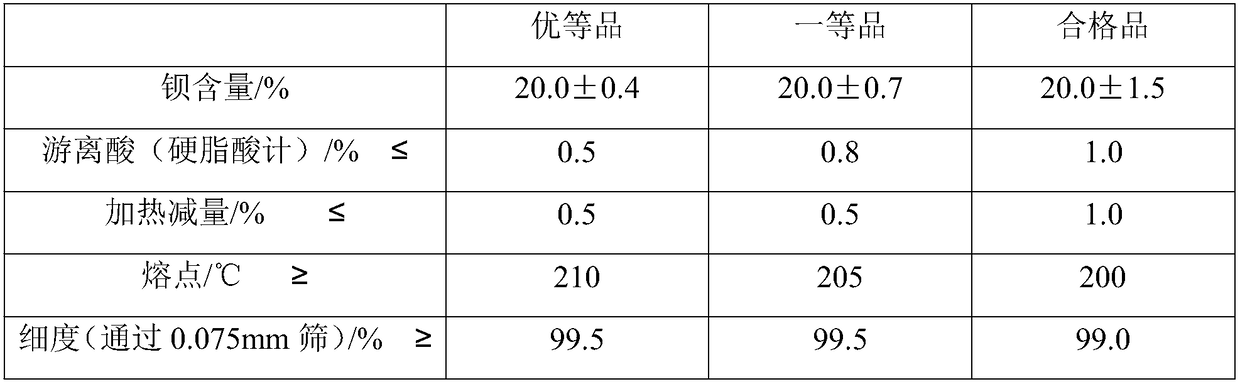

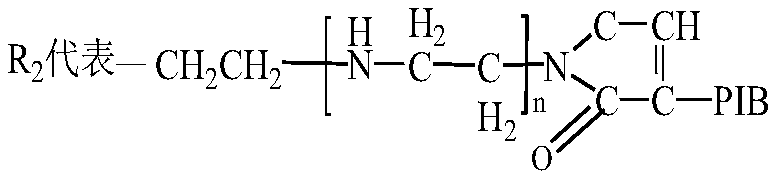

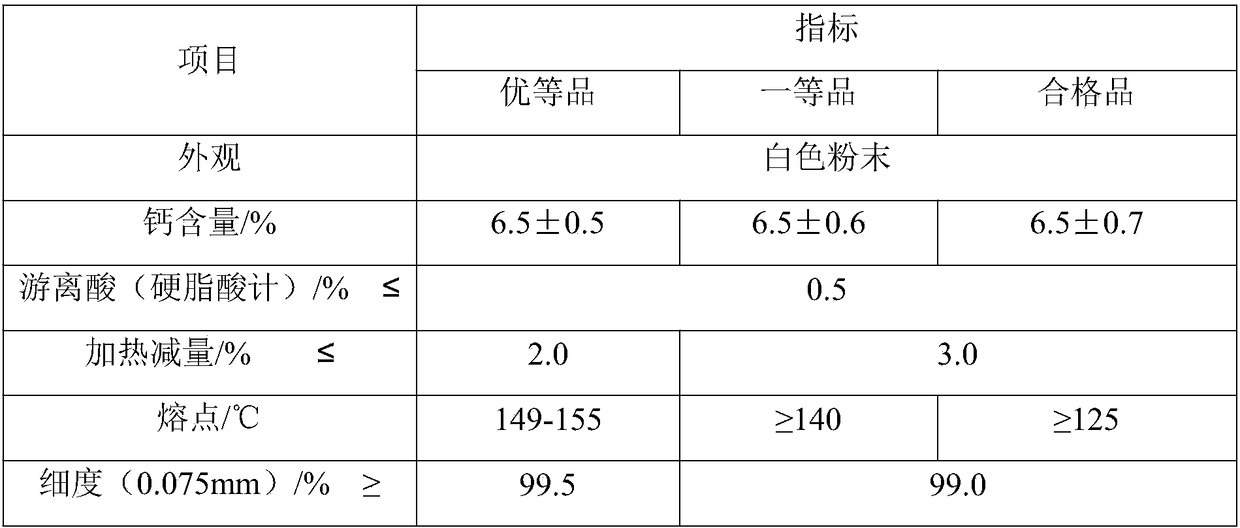

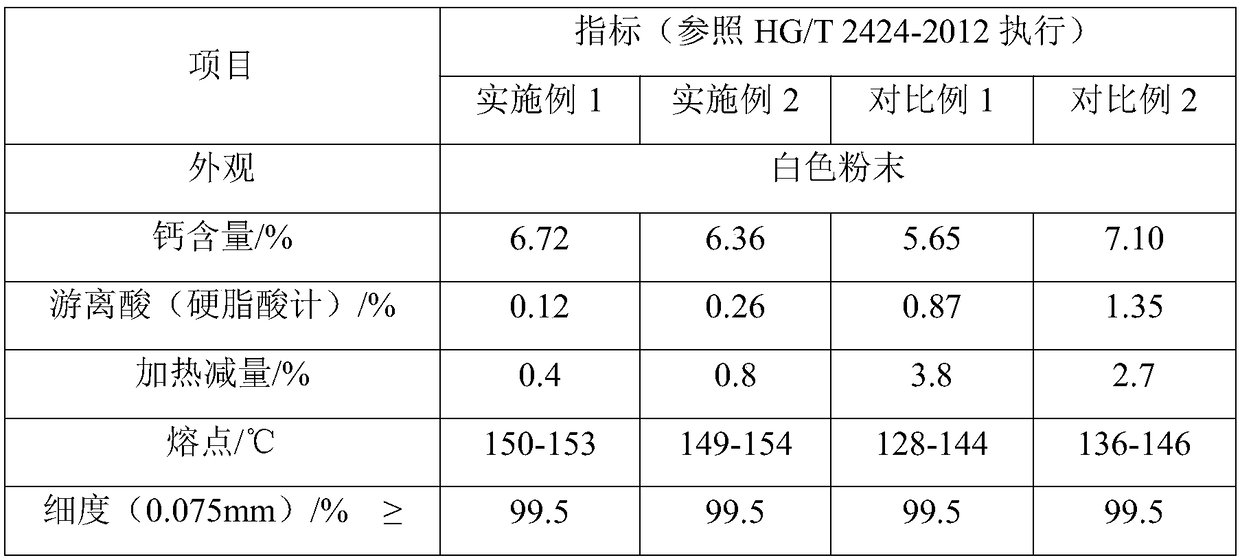

Calcium stearate and preparation process thereof

ActiveCN105949048AHigh purityGuaranteed chromaticityOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryCalcium hydroxide

The invention belongs to the technical field of chemical engineering and particularly relates to calcium stearate and a preparation process thereof. The calcium stearate is prepared from tristearin, a catalyst A, an antioxidant, water, calcium oxide, a catalyst B and sodium hydroxide, wherein the catalyst A is a mixture of calcium hydroxide and Al2O3-MgO, and the antioxidant is a mixture of DLTDP and an antioxidant T501; the catalyst B is selected from one or more of peroxides. The calcium stearate is low in raw material cost, high in yield, good in color, low in free acid content, high in melting point and stable in property, and related quality indexes meet the requirement of Chemical Industry Standard of the People's Republic of China HG / T 2424-2012 Calcium Stearate for superior products. The preparation process of the calcium stearate is safe and environment friendly in production process, low in energy consumption and low in overall production cost, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

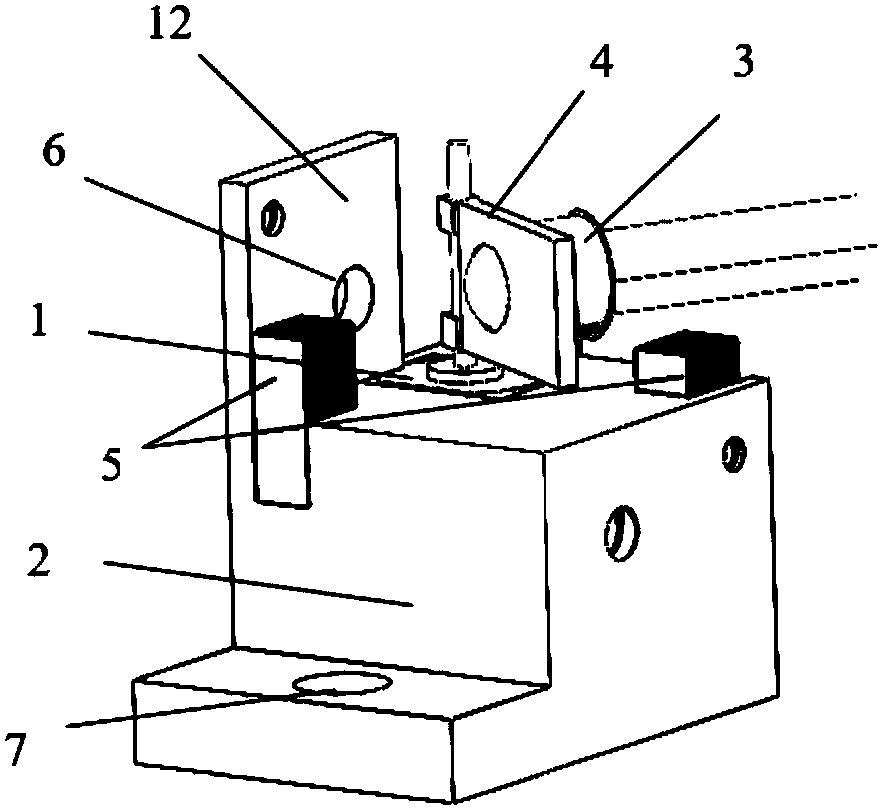

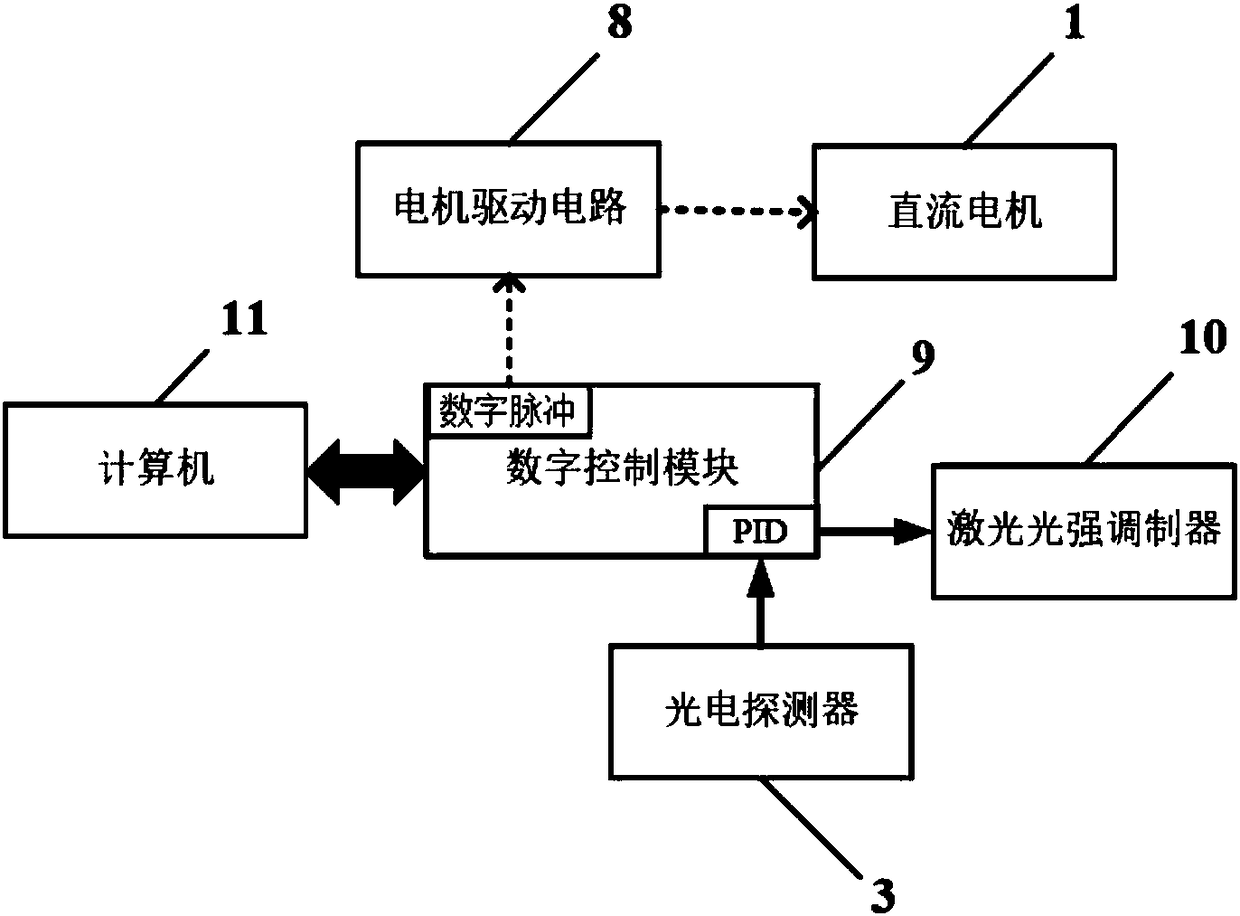

Ultra quiet fast laser switch capable of performing time-sharing power control and control method

The invention discloses an ultra quiet fast laser switch capable of performing time-sharing power control, which belongs to the technical field of photoelectric detection and control. The ultra quietfast laser switch capable of performing time-sharing power control comprises a DC motor, a fixing frame, a photoelectric detector, a detector mounting blade, rubber gaskets, a motor driving circuit, adigital control module, a laser intensity modulator and the like. The invention also discloses a control method for the ultra quiet fast laser switch capable of performing time-sharing power control.Quick laser switching can be realized, noise during a switching process is greatly reduced, and the laser intensity can be directly controlled.

Owner:中科酷原科技(武汉)有限公司

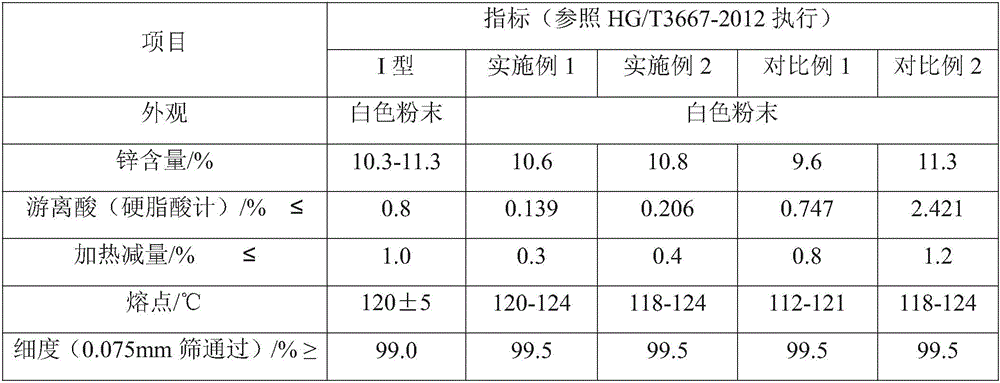

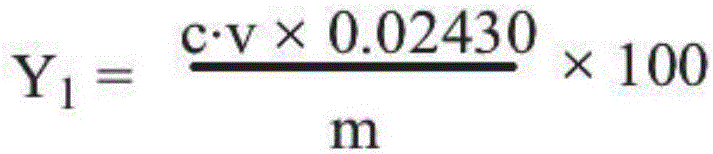

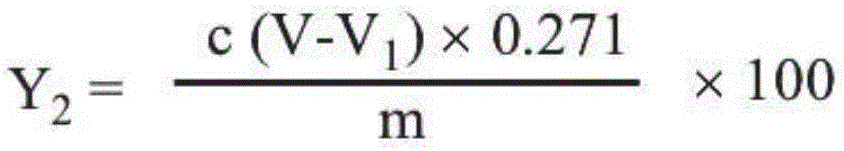

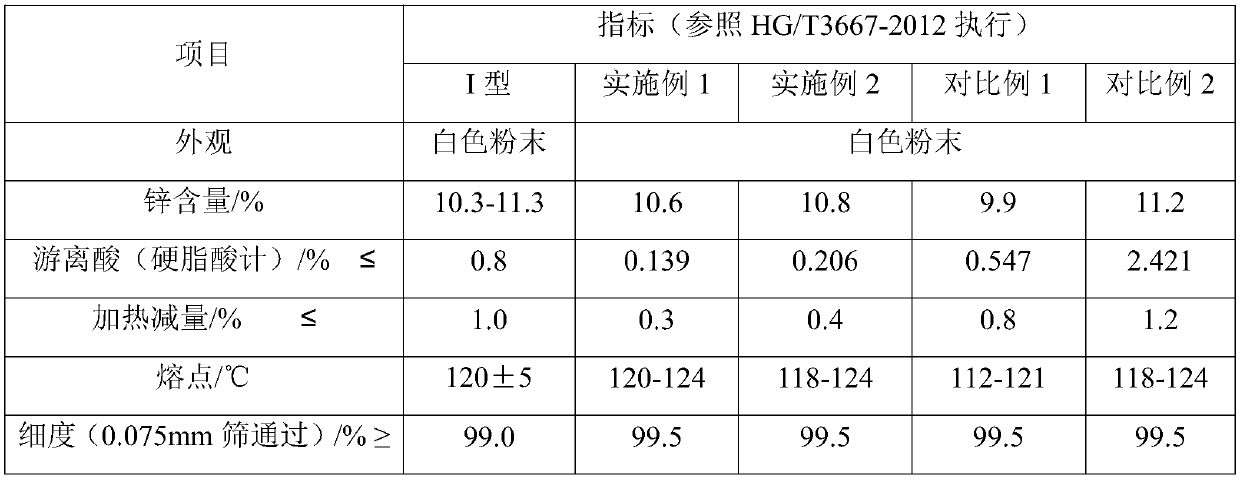

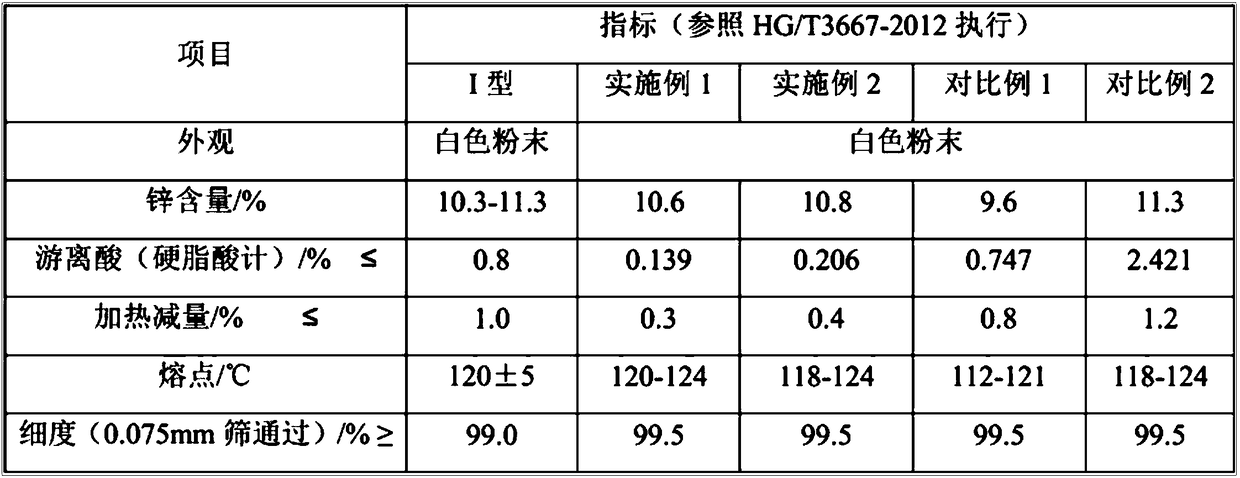

High-quality zinc stearate prepared from glyceryl tristearate

ActiveCN105924344AHigh yieldLow total production costOrganic compound preparationHeterogenous catalyst chemical elementsAntioxidantWastewater

The invention belongs to the technical field of chemical engineering, and particularly relates to high-quality zinc stearate prepared from glyceryl tristearate. A preparation technology of zinc stearate comprises the following steps that 1, glyceryl tristearate and water are hydrolyzed under the action of a catalyst and an antioxidant; 2, zinc oxide and a catalyst are added stepwise, condensing, dewatering and salt forming are conducted, and zinc stearate is synthesized. Zinc stearate is high in preparation yield, good in color and cluster, low in free acid content and stable in quality, and the related quality indexes meet the related requirements on I type zinc stearate in HG / T3667-2012; in addition, no wastewater containing chlorine and sulfate ions is discharged in the preparation process of zinc stearate, the production process is safe and environmentally friendly, and the total production cost is low. Zinc stearate is high in quality and has the better practicability and comparability compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

Magnesium stearate and preparation process thereof

ActiveCN105949049ALow raw material costReduce energy and water consumptionOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemistryMagnesium

The invention belongs to the technical field of chemical engineering, and particularly relates to magnesium stearate and a preparation process thereof. The preparation process includes the following steps: (1) subjecting tristearin and water to hydrolysis under the action of catalyst and antioxidant; (2) adding magnesium oxide and catalyst step by step, and performing condensation, dehydration and salifying to synthesize magnesium stearate. The magnesium stearate provided is industrial-grade magnesium stearate, and is low in raw material cost, high in production yield, good in color, low in free acid content and stable in quality. In the preparation process of magnesium stearate, discharge of wastewater containing chlorine and sulfate ions is avoided, the production process is safe and environment friendly, and overall production cost is low. The provided magnesium stearate is high in quality, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

Preparation method of D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate

ActiveCN103641755AStable in natureShorten production timeSulfide preparationChemical industryChelation

The invention aims at the chemical industry field, and relates to a preparation method of a D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method comprises the following steps: preparing a hydrocyanic acid mixed gas by adopting an Andrussow process, and reacting the hydrocyanic acid mixed gas with methylthiopropionaldehyde to obtain a 2-hydroxy-4-methylthiobutyronityile system, hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system by an inorganic alkali to obtain D,L-2-hydroxy-4-methylthiobutyrate, and chelating the D,L-2-hydroxy-4-methylthiobutyrate with a trace metal element salt to generate the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate. The method has the advantages of few technological steps, cheap and easily available raw materials, stable properties of the above intermediate, and low total production cost; the obtained D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate has the advantages of high yield, high purity and large bulk density; and the D,L-2-hydroxy-4-methylthiobutyric acid-trace element chelate can be effectively mixed with feeds as an animal feed additive to supplement trace elements and amino acids in the daily ration and improve the endozoic production and immunity performances, and can also be used as a medicinal reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

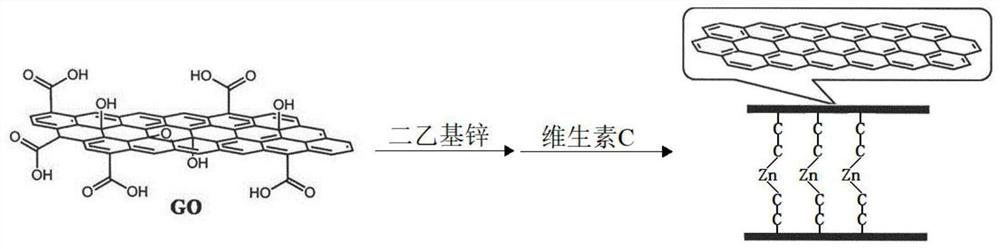

Graphene alloy composite phase change material as well as preparation method and application thereof

ActiveCN113980654AImprove internal thermal conductivityEnhance heat storage and heat release rateChemical industryHeat-exchange elementsLiquid metalAlloy composite

The invention discloses a graphene alloy composite phase change material as well as a preparation method and application thereof, an organic metal compound is adopted to modify graphene, the internal heat conductivity coefficient between graphene layers is greatly improved, and meanwhile, liquid metal with a very high heat conductivity coefficient is used for dopping, and the graphene alloy is compounded with a phase change matrix material to obtain the novel graphene alloy composite phase change material. The anisotropic heat-conducting property of the graphene is greatly improved by the organic metal modified graphene, and the heat-conducting property of the composite phase change material is further improved.

Owner:XIANGTAN UNIV

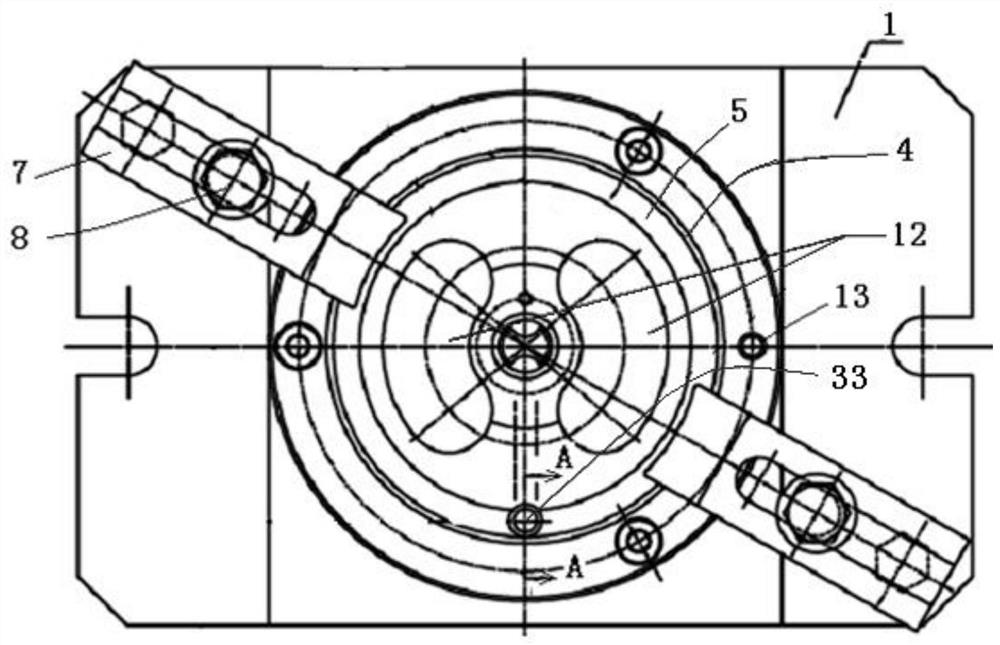

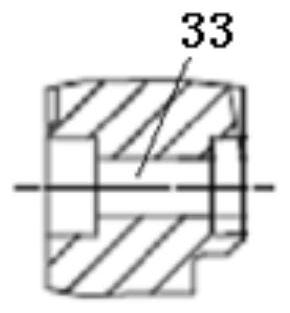

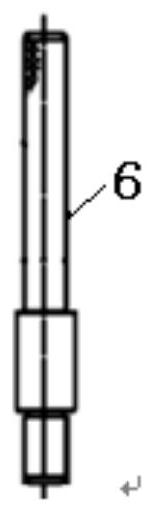

Multipurpose milling clamp

InactiveCN111660118ALow costReduce management costsPositioning apparatusMetal-working holdersEngineeringDistributor

The invention discloses a multipurpose milling clamp which comprises a directional plug pin (6) and a base plate (1). A dabber (2) is arranged on the base plate (1). A positioning block (3) through which the dabber (2) penetrates is arranged at the top of the base plate (1). The outer ring of the top face of the positioning block (3) is an annular plane (4). A inwards-concave conical face (5) is connected to the inner side of the plane (4). The dabber (2) penetrates through the positioning block (3) along the axis of the conical face (5). A positioning hole (13) running through the base plate(1) is formed in the top face of the positioning block (3). A cylindrical pin (14) connecting the positioning block (3) with the base plate (1) is arranged inside the positioning hole (13). The two sides of the positioning block (3) are each provided with a compressing mechanism. The milling clamp is used for machining a fuel distributor and has the advantages of being low in total manufacturing cost, low in management cost and high in production efficiency, and the yield of finished products can be increased.

Owner:AVIC LIYUAN HYDRAULIC

Preparation method of cheap and high-purity d,l-methionine

ActiveCN103641758BStable in natureLong storage timeOrganic compound preparationSulfide preparationCombinatorial chemistrySulfuryl

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

A kind of comprehensive recovery method of zinc, nickel, cobalt purification slag

ActiveCN107746969BHigh separation recovery rateEfficient separationPhotography auxillary processesProcess efficiency improvementRecovery methodElectrolysis

The invention relates to a comprehensive recovery method for zinc, nickel and cobalt-containing purification slag. The method comprises the following steps: washing the zinc, nickel and cobalt-containing purification slag with hot water till the content of sulfate radicals or chlorine ions of a lotion is smaller than 1g / L and then leaching the purification slag with sodium hydroxide; obtaining zinc and cobalt-containing alkaline leaching liquor and leached slag primarily containing nickel; putting the alkaline leaching liquor in a magnetic field and performing diaphragm electrolysis by takinga magnetic material as an anode and a stainless steel plate as a cathode to obtain metal zinc powder in a cathode region and the cathode and anode slurry primarily containing Co2O3 and Co3O4 in an anode region and the anode; washing and drying the anode slurry, reducing the same directly with hydrogen to obtain metal cobalt powder or sulfuric acid leached out, precipitating oxalic acid to obtain cobalt oxalate, then reducing the cobalt oxalate with hydrogen to obtain metal cobalt powder, and electrolyzing metal cobalt; returning the alkaline residual electrolyte to leach zinc, nickel and cobalt purification slag; and washing the nickel-containing leach residue and leaching the same with sulfuric acid, and enriching the same and performing electrolysis to obtain metal nickel. The method provided by the invention is short in process flow, high in separating recovery rate of zinc, nickel and cobalt and small in wastewater and waste residue amount.

Owner:六盘水中联工贸实业有限公司 +1

d, the preparation method of l-2-hydroxyl-4-methylthiobutyrate calcium

ActiveCN103641757BStable in natureShorten production timeSulfide preparationTrace element2-hydroxy-4-methylthiobutyrate

The invention is directed at the field of chemical engineering and provides a preparation method for calcium D,L-2-hydroxy-4-methylthiobutyrate. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; preparing a 2-hydroxy-4-methylthiobutyronityile system with the hydrocyanic acid gas mixture and methylthiopropionaldehyde as starting raw materials; hydrolyzing the 2-hydroxy-4-methylthiobutyronityile system with inorganic base so as to obtain D,L-2-hydroxy-4-methylthiobutyrate; and chelating D,L-2-hydroxy-4-methylthiobutyrate with a soluble calcium salt so as to produce calcium D,L-2-hydroxy-4-methylthiobutyrate. The method has the advantages of a few processing step, cheap and easily available raw materials, stable intermediate properties and low total production cost. Prepared calcium D,L-2-hydroxy-4-methylthiobutyrate has the advantages of high yield, high purity, a powder crystal form and great bulk density, can be used as an animal feed additive for effective mixing with a feed so as to supplement trace elements and amino acid in daily ration and improve production performance and immune performance of animals and can also be used as a medicine reagent.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

A kind of technique utilizing glyceryl tristearate to synthesize zinc stearate

ActiveCN106008198BHigh purityHigh yieldCarboxylic acid salt preparationChemical recyclingChemical industryAntioxidant

The invention belongs to the technical field of chemical industry, and particularly relates to a technique for synthesizing zinc stearate from glyceryl tristearate. The technique comprises the following steps: 1) hydrolyzing glyceryl tristearate and water under the actions of a catalyst and an antioxidant; and 2) adding zinc oxide and a catalyst in multiple steps, and carrying out condensation, dewatering and salification to synthesize the zinc stearate. By using the technique provided by the invention, no wastewater containing chlorine and sulfate ions is discharged in the process; the production process is safe and environment-friendly and has low total production cost; and the synthesized zinc stearate has the advantages of high yield, favorable color and low free fatty acid content, satisfies the relevant quality standard for Type I zinc stearate in HG / T3667-2012, and has higher practicality and comparability than like products in the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

Method for preparing photoinduced ultra hydrophilic automatically cleaning paint

The invention provides a method for preparing a photoinduced ultra hydrophilic automatically cleaning paint, comprising the following steps: (1) preparing titanium dioxide suspension by using titanium hydroxide; (2) preparing cerium-doped anatase titanium dioxide for subsequent use; (3) placing waterless ethanol, ammoniacal liquor, distilled water and ethyl orthosilicate which is added later intoa reactor and magnetic stirring uniformly; (4) magnetic stirring the mixed liquor prepared in step (3) for more than 3 h in a constant temperature bath of 80 DEG C to obtain silica sol; (5)mixing thecerium-doped anatase titanium dioxide prepared in step (2), silica sol prepared in step (4) with waterless ethanol and stirring uniformly to obtain the photoinduced ultra hydrophilic automatically cleaning paint. The photoinduced ultra hydrophilic automatically cleaning paint has the advantages of simple use and convenient. The preparation method has the advantages of low energy consumption, saving heat treatment equipment, and low cost.

Owner:CHONGQING UNIV

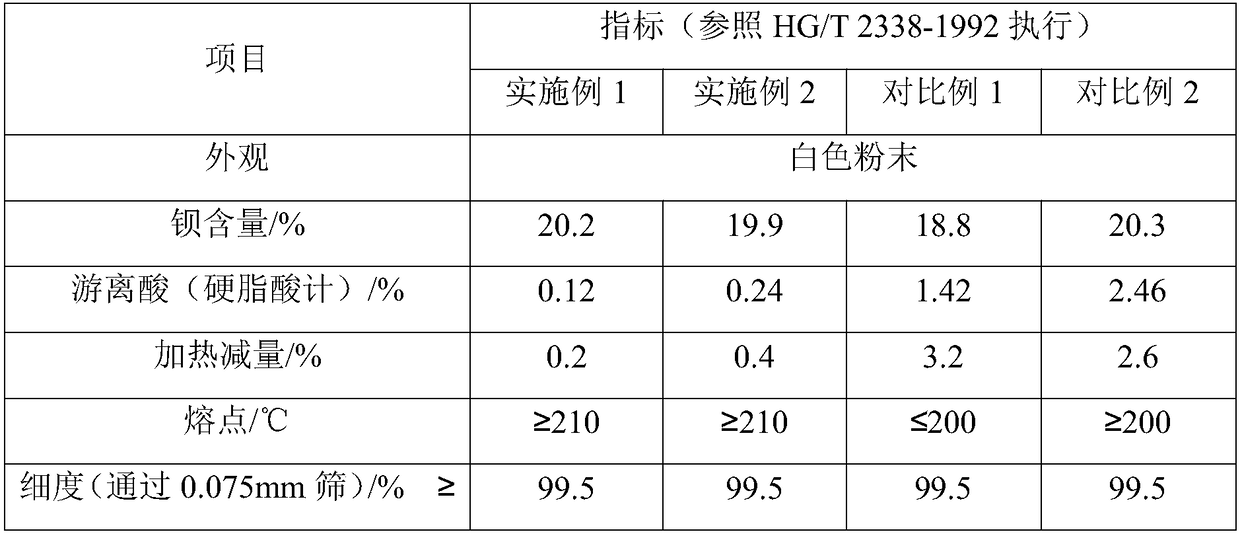

A kind of barium stearate and preparation technology thereof

ActiveCN105859541BHigh yieldLow total production costOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryAntioxidant

The invention belongs to the technical field of chemical engineering and particularly relates to barium stearate and a preparation process thereof. Barium stearate is prepared from glyceryl tristearate, a catalyst A, antioxidant, water, barium hydroxide, a catalyst B and sodium hydroxide. The catalyst A is a mixture of magnesium oxide and Al2O3-MgO, and the antioxidant is a mixture of antioxidant DLTDP and antioxidant T501. The catalyst B is selected from one or more of peroxide. Barium stearate is low in raw material cost, high in yield, low in free acid content and stable in performance, and relevant quality indexes meet the requirements of the People's Republic of China chemical industry standard <HG / T2338-1992 barium stearate (light)> for superior products. According to the preparation process of barium stearate, the production course is safe and environmentally friendly, energy consumption is low, the total production cost is low, and higher practicality and comparability are achieved compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

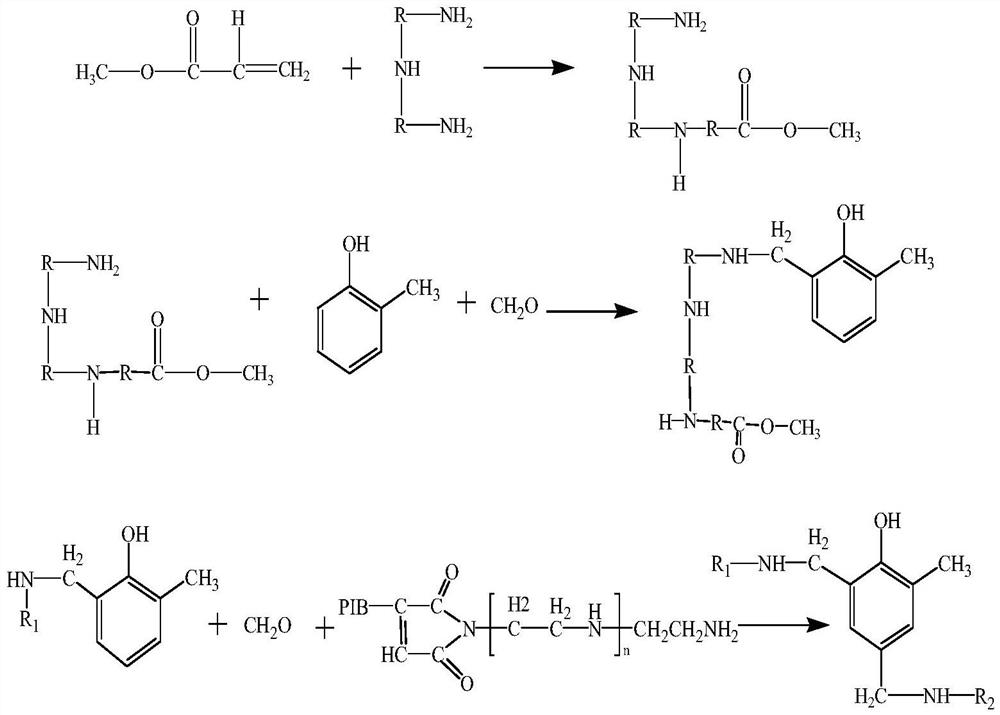

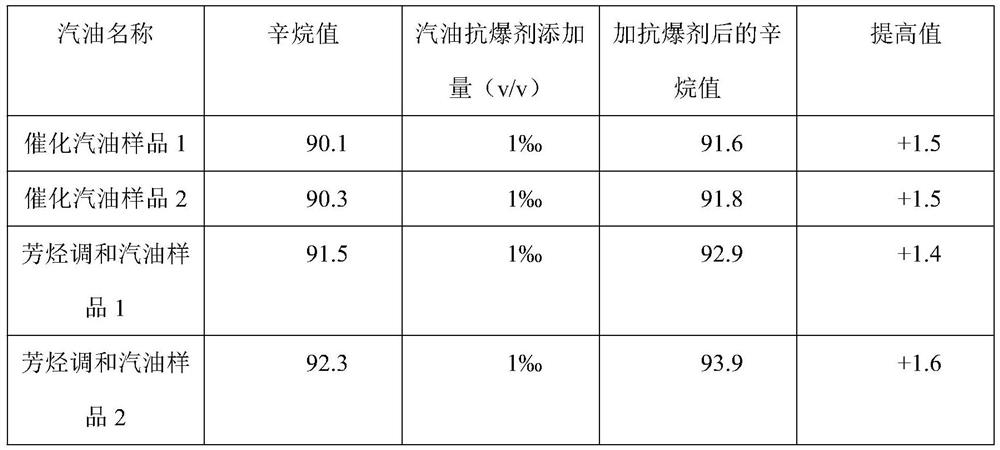

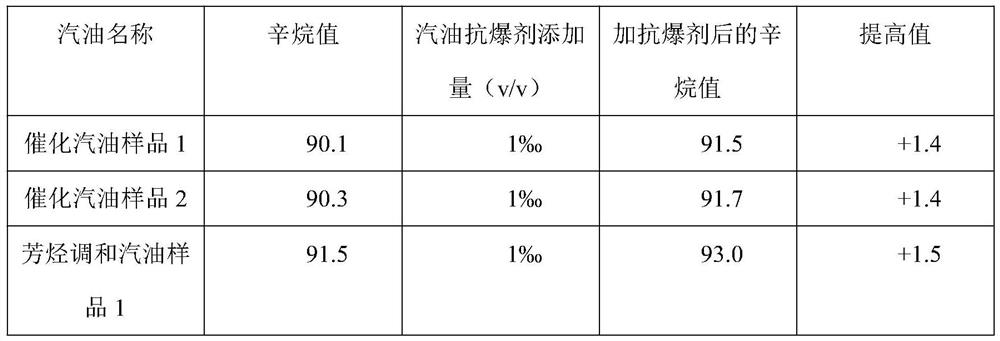

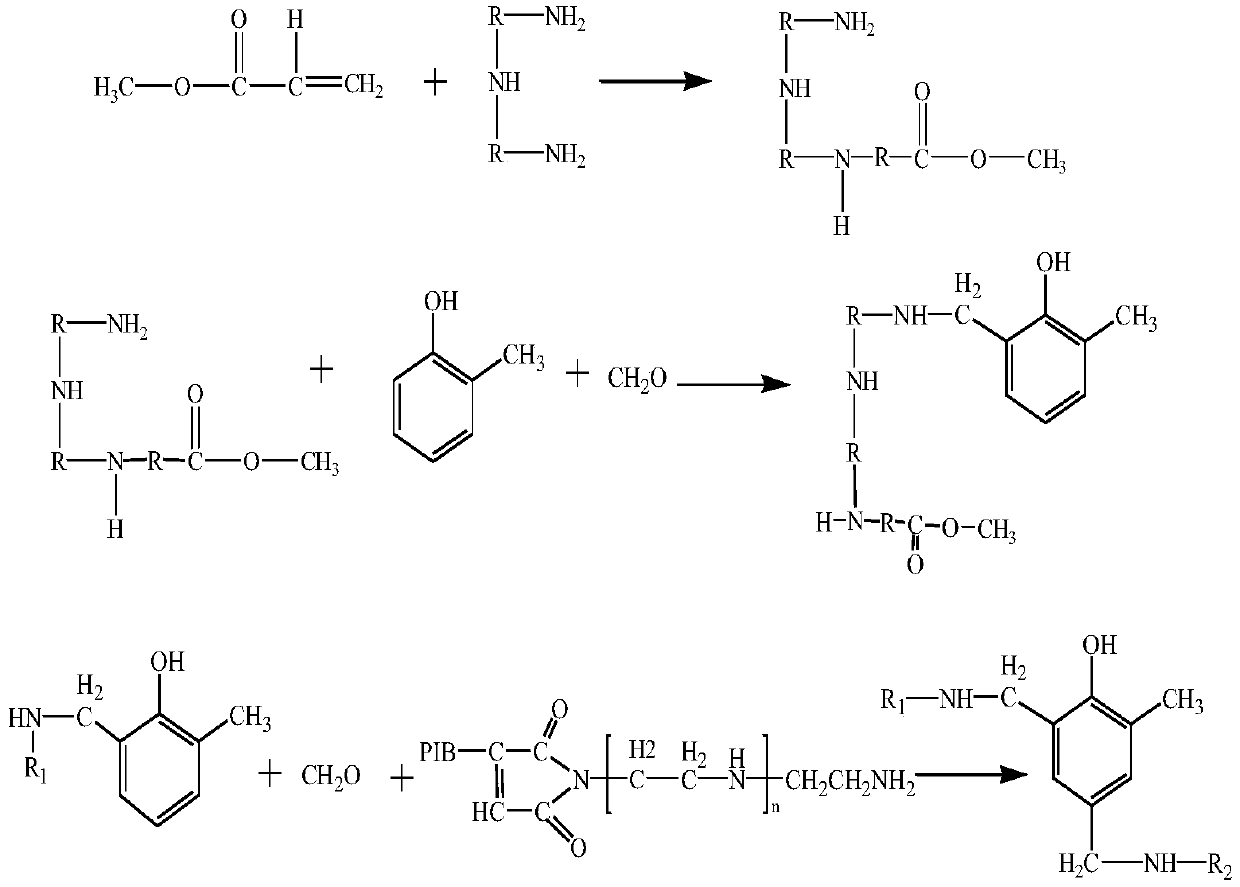

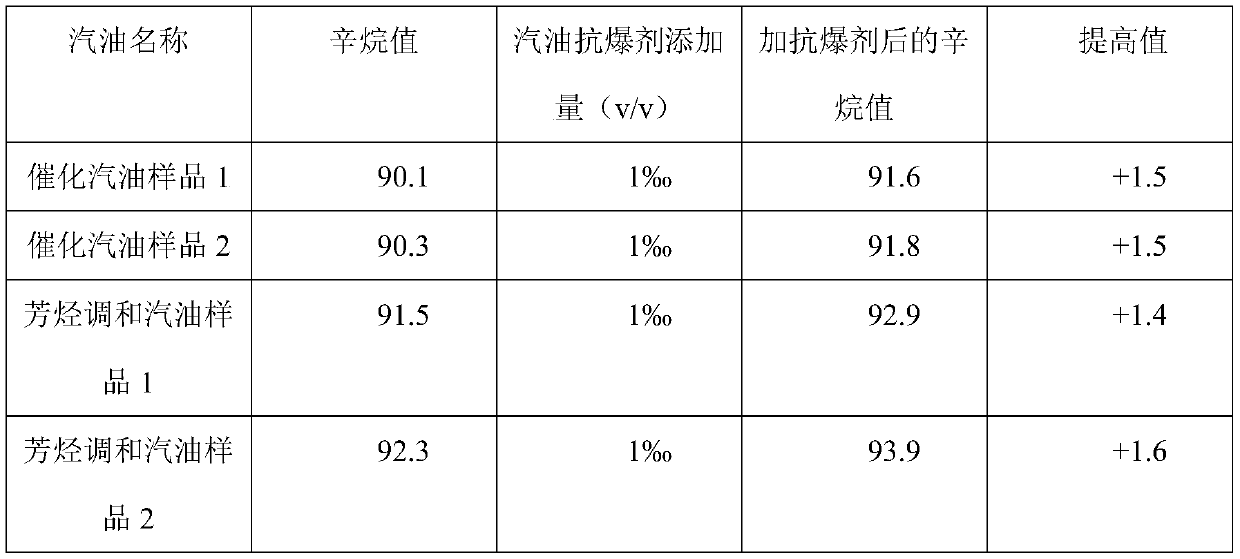

A kind of preparation technology of organic ashless antiknock agent

ActiveCN109852446BExtended induction periodReduce contentLiquid carbonaceous fuelsPtru catalystDiethylenetriamine

The invention discloses a preparation process of an organic ash-free antiknock agent. A mixed solution of methyl acrylate and ethanol is slowly dropwise added into a diethylenetriamine solution with stirring and nitrogen protection, an alumina catalyst and an antioxidant are added, a transparent yellowish liquid is obtained by carrying out a reaction with stirring, the liquid is added to a reaction kettle, a mixed solution of o-cresol, formaldehyde and ethanol is added, the reaction temperature is risen to be 80-90 DEG C, the mechanical stirring is performed for 3-4 h, T151A is added to S2, the ethanol reflux is performed, a reaction is carried out while stirring, standing is performed, and solvents are removed by rotary evaporation or vacuum distillation to obtain the organic ash-free antiknock agent. The preparation process has the following advantages that the preparation process is reasonable, the yield is high, the production process has no chlorine and sulfur emissions, the preparation process is safe and environmental-friendly, the energy consumption is relatively low, and the total production cost is low. The induction period of gasoline can be prolonged, and the real gum content can be reduced, so that the quality of the antiknock gasoline can be ensured, and the antiknock agent has the functions of anti-oxidation and oil sludge cleaning dispersion.

Owner:盘锦辽河油田大力集团有限公司

A kind of preparation method utilizing glyceryl tristearate to prepare zinc stearate

ActiveCN105924344BHigh yieldLow total production costOrganic compound preparationHeterogenous catalyst chemical elementsTalc / Zinc OxideStearic acid

The invention belongs to the technical field of chemical engineering, and particularly relates to high-quality zinc stearate prepared from glyceryl tristearate. A preparation technology of zinc stearate comprises the following steps that 1, glyceryl tristearate and water are hydrolyzed under the action of a catalyst and an antioxidant; 2, zinc oxide and a catalyst are added stepwise, condensing, dewatering and salt forming are conducted, and zinc stearate is synthesized. Zinc stearate is high in preparation yield, good in color and cluster, low in free acid content and stable in quality, and the related quality indexes meet the related requirements on I type zinc stearate in HG / T3667-2012; in addition, no wastewater containing chlorine and sulfate ions is discharged in the preparation process of zinc stearate, the production process is safe and environmentally friendly, and the total production cost is low. Zinc stearate is high in quality and has the better practicability and comparability compared with similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

Preparation process of organic ash-free antiknock agent

ActiveCN109852446AExtended induction periodReduce contentLiquid carbonaceous fuelsAntioxidantEvaporation

The invention discloses a preparation process of an organic ash-free antiknock agent. A mixed solution of methyl acrylate and ethanol is slowly dropwise added into a diethylenetriamine solution with stirring and nitrogen protection, an alumina catalyst and an antioxidant are added, a transparent yellowish liquid is obtained by carrying out a reaction with stirring, the liquid is added to a reaction kettle, a mixed solution of o-cresol, formaldehyde and ethanol is added, the reaction temperature is risen to be 80-90 DEG C, the mechanical stirring is performed for 3-4 h, T151A is added to S2, the ethanol reflux is performed, a reaction is carried out while stirring, standing is performed, and solvents are removed by rotary evaporation or vacuum distillation to obtain the organic ash-free antiknock agent. The preparation process has the following advantages that the preparation process is reasonable, the yield is high, the production process has no chlorine and sulfur emissions, the preparation process is safe and environmental-friendly, the energy consumption is relatively low, and the total production cost is low. The induction period of gasoline can be prolonged, and the real gum content can be reduced, so that the quality of the antiknock gasoline can be ensured, and the antiknock agent has the functions of anti-oxidation and oil sludge cleaning dispersion.

Owner:盘锦辽河油田大力集团有限公司

A kind of calcium stearate and preparation technology thereof

ActiveCN105949048BHigh purityGuaranteed chromaticityOrganic compound preparationPreparation from carboxylic acid esters/lactonesChemical industryCalcium hydroxide

The invention belongs to the technical field of chemical engineering and particularly relates to calcium stearate and a preparation process thereof. The calcium stearate is prepared from tristearin, a catalyst A, an antioxidant, water, calcium oxide, a catalyst B and sodium hydroxide, wherein the catalyst A is a mixture of calcium hydroxide and Al2O3-MgO, and the antioxidant is a mixture of DLTDP and an antioxidant T501; the catalyst B is selected from one or more of peroxides. The calcium stearate is low in raw material cost, high in yield, good in color, low in free acid content, high in melting point and stable in property, and related quality indexes meet the requirement of Chemical Industry Standard of the People's Republic of China HG / T 2424-2012 Calcium Stearate for superior products. The preparation process of the calcium stearate is safe and environment friendly in production process, low in energy consumption and low in overall production cost, and is more practical and comparable than similar products on the market in practical application.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

A strain of Bacillus licheniformis with high protease production and its fermentative enzyme production method

ActiveCN110408568BHigh extraction and purification process yieldLow total production costBacteriaHydrolasesBiotechnologyBacillus licheniformis

The invention discloses a strain of bacillus licheniformis with high protease production and a method for fermenting and producing the enzyme. The Bacillus licheniformis GZ73 provided by the present invention is referred to as Bacillus licheniformis GZ73 for short, and the preservation number is CGMCC No.18048. The invention also protects the application of Bacillus licheniformis GZ73 in the production of protease. The protease is prepared by fermenting Bacillus licheniformis GZ73, which has high enzyme production efficiency, low raw material cost, high enzyme activity of fermented liquid, high yield of enzyme extraction and purification process, and low total production cost. The enzyme preparation provided by the invention can be widely used in industries such as feed, food, detergent and the like.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com