Phase change concrete and preparation method thereof

A technology of concrete and phase change, applied in the direction of chemical instruments and methods, heat exchange materials, etc., to achieve the effects of enhanced absorption rate, low production cost, conducive to popularization and industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

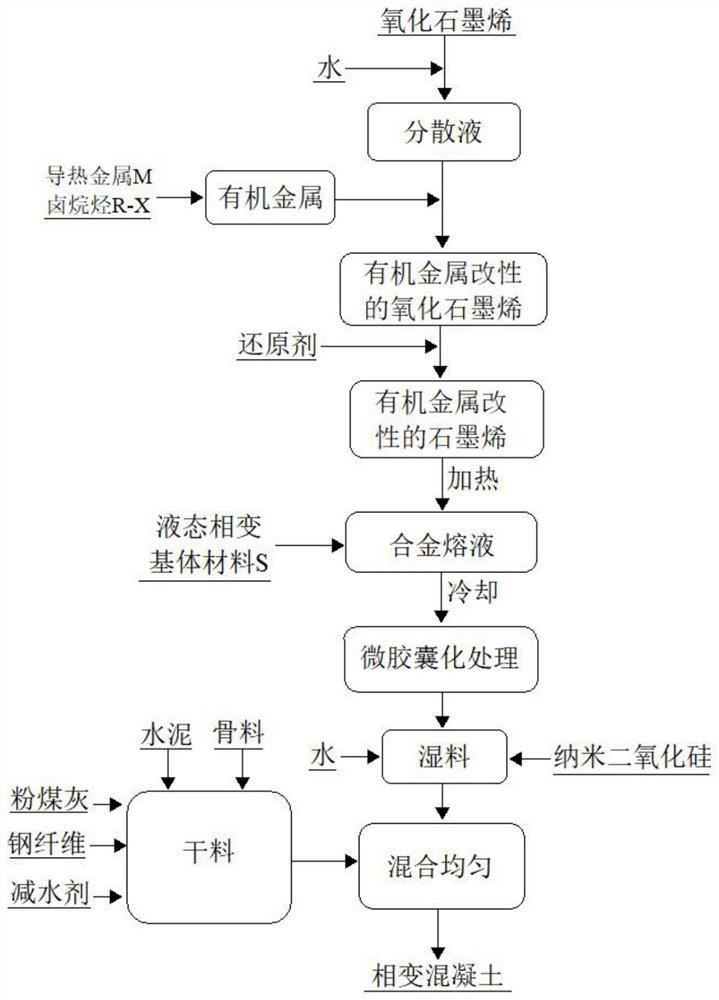

Method used

Image

Examples

preparation Embodiment 1

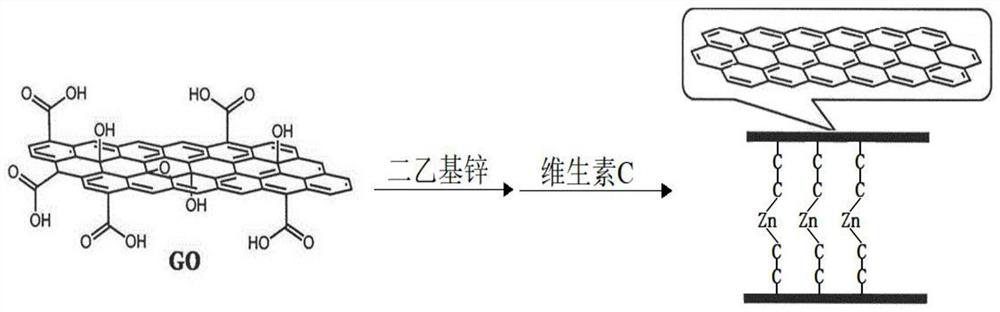

[0072] A mixed metal powder containing 6.538 parts of zinc powder (also containing 0.7264 parts of indium, bismuth, tin metal powder mixed in a mass ratio of 1:1:1) and 0.33 mol of ethyl chloride were dissolved in a mixed solvent of ether and tetrahydrofuran In a dry and airtight environment, the reaction was carried out, and the solvent was removed to obtain a mixture containing diethylzinc. Then 200 parts of graphene oxide was added into water and ultrasonically dispersed for 30 min. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 3.5 hours. After the reaction is complete, add 20 parts of vitamin C and continue to stir and react for 2 hours at 75°C. After the reaction is completed, use Wash with toluene three times, and then dry to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0073] Weigh 15 parts of the graphene mixture containing diethylzinc modification and...

preparation Embodiment 2

[0075] A mixed metal powder containing 6.538 parts of zinc powder (also containing 0.7264 parts of indium, bismuth, tin metal powder mixed in a mass ratio of 1:1:1) and 0.25 mol of ethyl chloride are dissolved in a mixed solvent of ether and tetrahydrofuran In a dry and airtight environment, the reaction was carried out, and the solvent was removed to obtain a mixture containing diethylzinc. Then 200 parts of graphene oxide was added into water and ultrasonically dispersed for 30 min. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 3.5 hours. After the reaction is complete, add 20 parts of vitamin C and continue to stir and react for 2 hours at 75°C. After the reaction is completed, use Wash with toluene three times, and then dry to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0076] Weigh 15 parts of the graphene mixture containing diethylzinc modification and ...

preparation Embodiment 3

[0078] A mixed metal powder containing 6.538 parts of zinc powder (also containing 0.7264 parts of indium, bismuth, tin metal powder mixed in a mass ratio of 1:1:1) and 0.20 mol of ethyl chloride are dissolved in a mixed solvent of ether and tetrahydrofuran In a dry and airtight environment, the reaction was carried out, and the solvent was removed to obtain a mixture containing diethylzinc. Then 200 parts of graphene oxide was added into water and ultrasonically dispersed for 30 min. Then add the aforementioned diethylzinc-containing mixture to the dispersion, then heat to 100°C and stir for 3.5 hours. After the reaction is complete, add 20 parts of vitamin C and continue to stir and react for 2 hours at 75°C. After the reaction is completed, use Wash with toluene three times, and then dry to constant weight in a vacuum oven at 80°C to obtain a graphene mixture modified with diethylzinc.

[0079] Weigh 15 parts of the graphene mixture containing diethylzinc modification and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com