Preparation process of organic ash-free antiknock agent

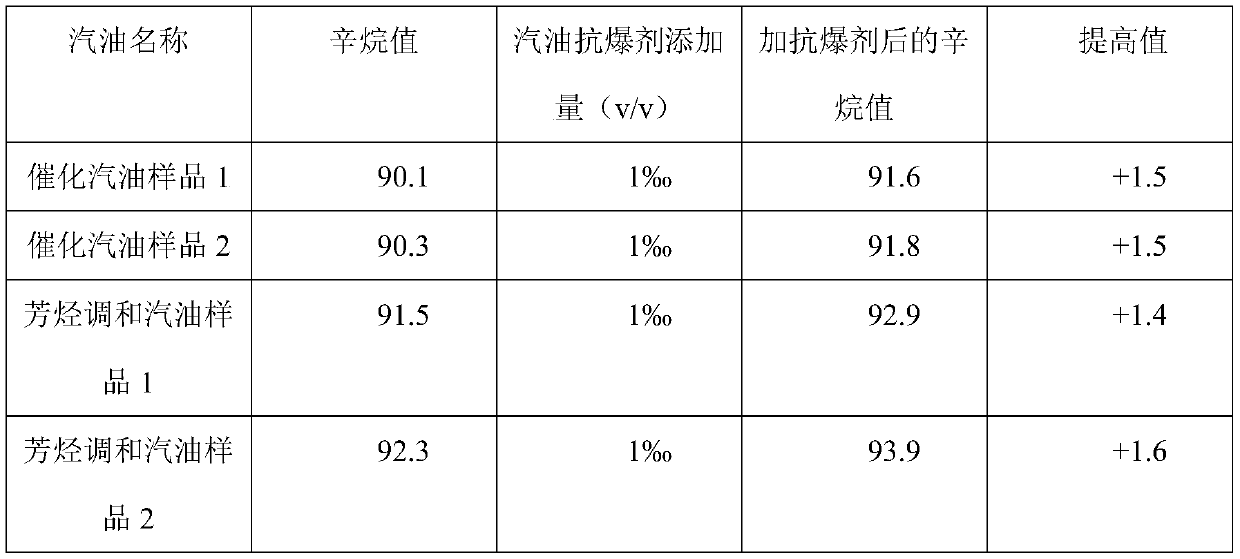

A preparation process and technology of antiknock agent are applied in the preparation process of organic ashless antiknock agent, and the preparation technology field of organic ashless gasoline antiknock agent, and can solve the problems of increasing oil consumption, increasing the solubility of oil products in layers, and the like, Achieve the effects of anti-oxidation and sludge removal, low energy consumption and good octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

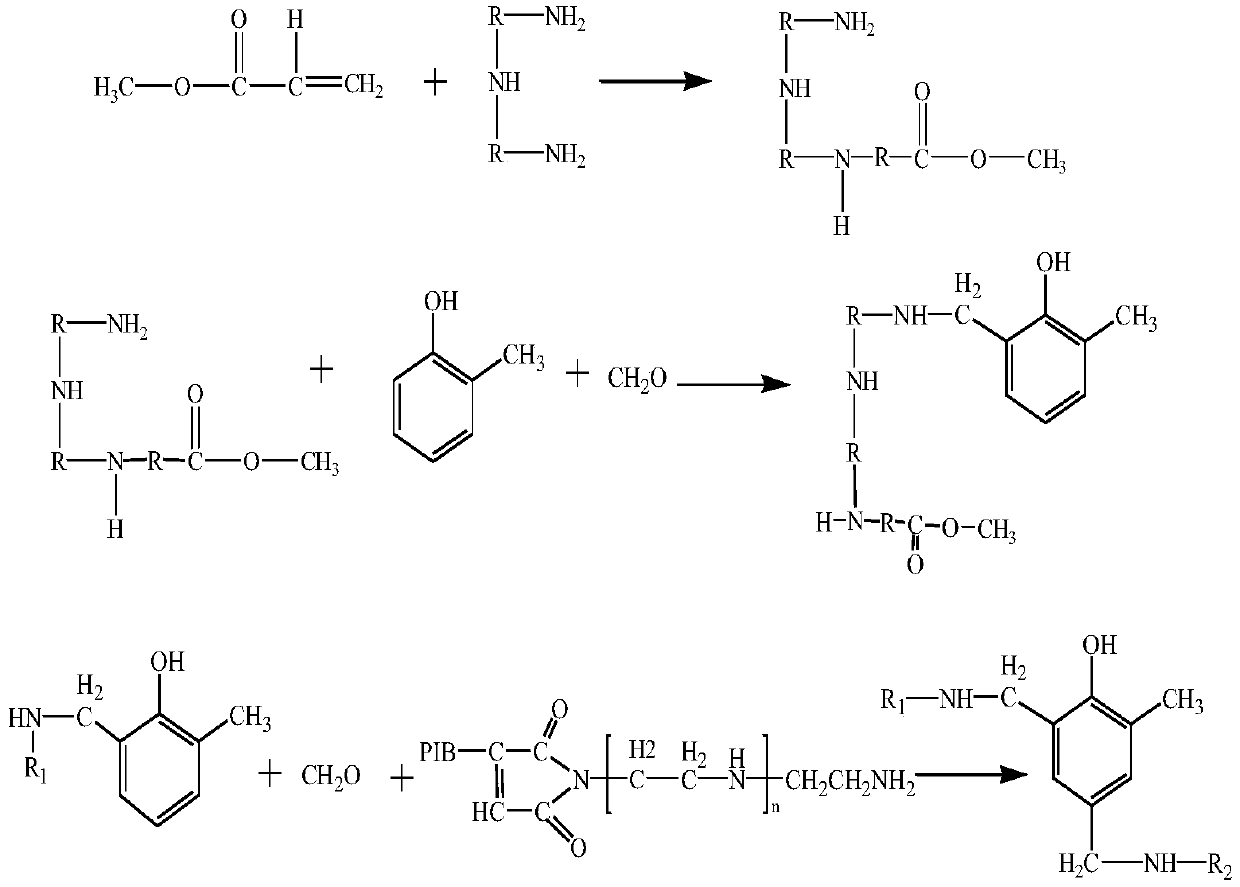

Method used

Image

Examples

Embodiment 1

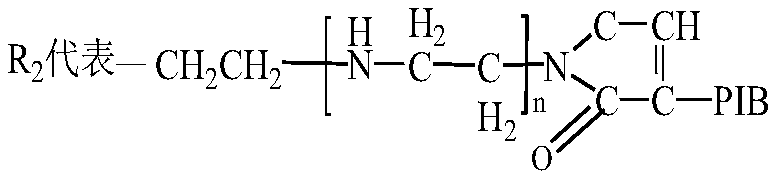

[0025] The preparation of embodiment 1 organic ashless compound

[0026] S1: Slowly add the mixed solution of methyl acrylate and ethanol dropwise to the diethylenetriamine solution with stirring and nitrogen protection, keep the temperature at 0°C, add catalyst alumina powder and antioxidant T501, stir for 3 hours, and keep the temperature at 0°C. The addition reaction was carried out under pressure to obtain a light yellow liquid.

[0027] Wherein, by mass, the addition of diacetyl triamide is 41.27g, and by mole, the addition of diacetyl triamide is 0.4mol;

[0028] The add-on of ethanol is 27.6g, and on a molar basis, the add-on of ethanol is 0.6mol;

[0029] In molar ratio, diethylenetriamine: methyl acrylate is 1:0.7, and by mass, the addition of methyl acrylate is

[0030] 24.1g, by mole, the addition of methyl acrylate is 0.28mol;

[0031] By mass, the catalyst alumina powder is used in an amount of 4% of the mass of diethylenetriamine;

[0032] By mass, the amount...

Embodiment 2

[0040] The preparation of embodiment 2 organic ashless compounds

[0041] S1: Slowly add the mixed solution of methyl acrylate and ethanol dropwise to the triethylenetetramine solution with stirring and nitrogen protection, keep the temperature at 2°C, add catalyst alumina powder and antioxidant T501, stir for 3.5 hours, and keep the temperature at 2°C. The addition reaction was carried out under pressure to obtain a light yellow liquid.

[0042] Wherein, by mass, the addition of triethylenetetramine is 58.49g, and by mole, the addition of triethylenetetramine is 0.4mol;

[0043] The add-on of ethanol is 22.1g, and on a molar basis, the add-on of ethanol is 0.48mol;

[0044] In molar ratio, triethylenetetramine: methyl acrylate is 1:0.9, by mass, the addition of methyl acrylate is 30.1g, by mole, the addition of methyl acrylate is 0.36mol;

[0045] By mass, the catalyst alumina powder is used in an amount of 3% of the mass of triethylenetetramine;

[0046] By mass, the amou...

Embodiment 3

[0053] The preparation of embodiment 3 organic ashless compound

[0054] S1: Slowly add the mixed solution of methyl acrylate and ethanol dropwise to the triethylenetetramine solution with stirring and nitrogen protection, keep the temperature at 5 °C, add catalyst alumina powder and antioxidant T501, stir for 4 hours, and keep the temperature at 5 °C. The addition reaction was carried out under pressure to obtain a light yellow liquid.

[0055] Wherein, by mass, the addition of triethylenetetramine is 58.49g, and by mole, the addition of triethylenetetramine is 0.4mol;

[0056] The addition of ethanol is 25g;

[0057] In molar ratio, triethylenetetramine: methyl acrylate is 1:0.8, by mass, the addition of methyl acrylate is 26.8g, by mole, the addition of methyl acrylate is 0.32mol;

[0058] By mass, the catalyst alumina powder is used in an amount of 5% of the mass of triethylenetetramine;

[0059] By mass, the amount of antioxidant T501 is 0.4% of the mass of triethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com