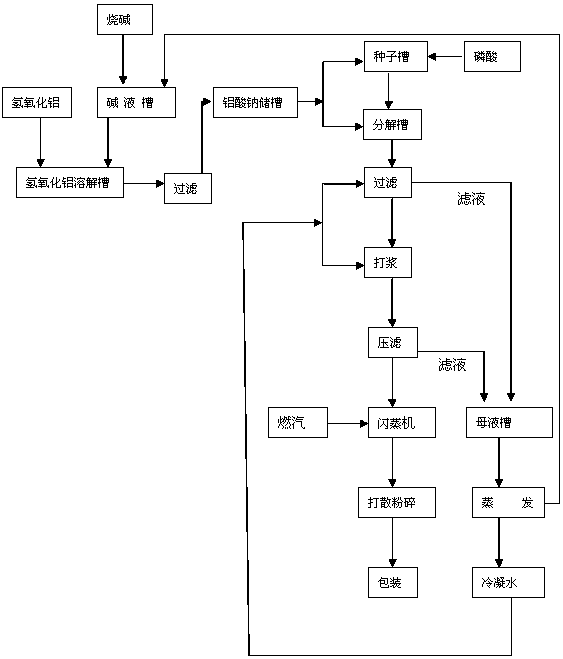

A kind of method that uses phosphoric acid to make crystal seed to produce superfine aluminum hydroxide

A technology of ultra-fine aluminum hydroxide and aluminum hydroxide, which is applied in the preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, etc., can solve the problems of high production cost of ultra-fine aluminum hydroxide and achieve supersaturation Low density, low decomposition rate and good particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] Below by embodiment the present invention is further illustrated.

[0025] Example 1

[0026] Add 180g of Bayer-process aluminum hydroxide to 400ml caustic soda solution with a caustic concentration of 220g / L, and re-dissolve at 105°C, the α of the sodium aluminate solution k is 1.31. Under the condition of 40-45°C constant temperature water bath, add 2mol / L phosphoric acid and redissolved sodium aluminate solution into the seed tank in a homogeneous flow mode, the reaction time is 30min, and the pH of the reaction solution is 8.5-9.5 at the end of the control. 40 Aged at -45°C for 24 hours, separated, washed, and filtered to obtain highly active seed crystals (D50=1.00 μm). With the seed crystal coefficient as 10%, the above-mentioned seeds are added to the sodium aluminate solution after dilution (caustic alkali concentration is 120g / L, α k =1.34), in a 60°C hot water bath, the stirring speed is 360r / min, and the reaction time is controlled at 20h. After the react...

Embodiment 2

[0028] Add 200g of Bayer-process aluminum hydroxide to 500ml caustic soda solution with a caustic concentration of 220g / L, and re-dissolve at 105°C, the α of the sodium aluminate solution k is 1.38. Under the condition of 40-45°C constant temperature water bath, add 2mol / L phosphoric acid and redissolved sodium aluminate solution into the seed tank in a homogeneous flow mode, the reaction time is 45min, and the pH of the reaction solution at the end of the control is 8.5-9.40 Aged at -45°C for 24 hours, separated, washed, and filtered to obtain highly active seed crystals (D50=0.82 μm). With the seed crystal coefficient as 20%, the above-mentioned seed crystals are added to the sodium aluminate solution after dilution (caustic alkali concentration is 130g / L, α k =1.41), in a 60°C hot water bath, the stirring speed is 360r / min, and the reaction time is controlled at 20h. After the reaction is over, the liquid and solid are separated, the filter cake is washed with hot water u...

Embodiment 3

[0030] Add 200g of Bayer-process aluminum hydroxide to 500ml caustic soda solution with a caustic concentration of 220g / L, and re-dissolve at 105°C, the α of the sodium aluminate solution k is 1.44. Under the condition of 40-45°C constant temperature water bath, add 2mol / L phosphoric acid and redissolved sodium aluminate solution into the seed tank in a homogeneous flow mode, the feeding time is 60min, and the pH of the reaction solution at the end of the control is 8.5-9.40 Aged at -45°C for 24 hours, separated, washed, and filtered to obtain highly active seed crystals (D50=0.91 μm). Be that 30% with seed crystal coefficient add above-mentioned seed crystal to the sodium aluminate solution after dilution (caustic alkali concentration is 110g / L, α k =1.5), in a hot water bath at 60°C, the stirring speed is 360r / min, and the reaction time is controlled at 20h. After the reaction was completed, the liquid and solid were separated, and the filter cake was washed with hot water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com