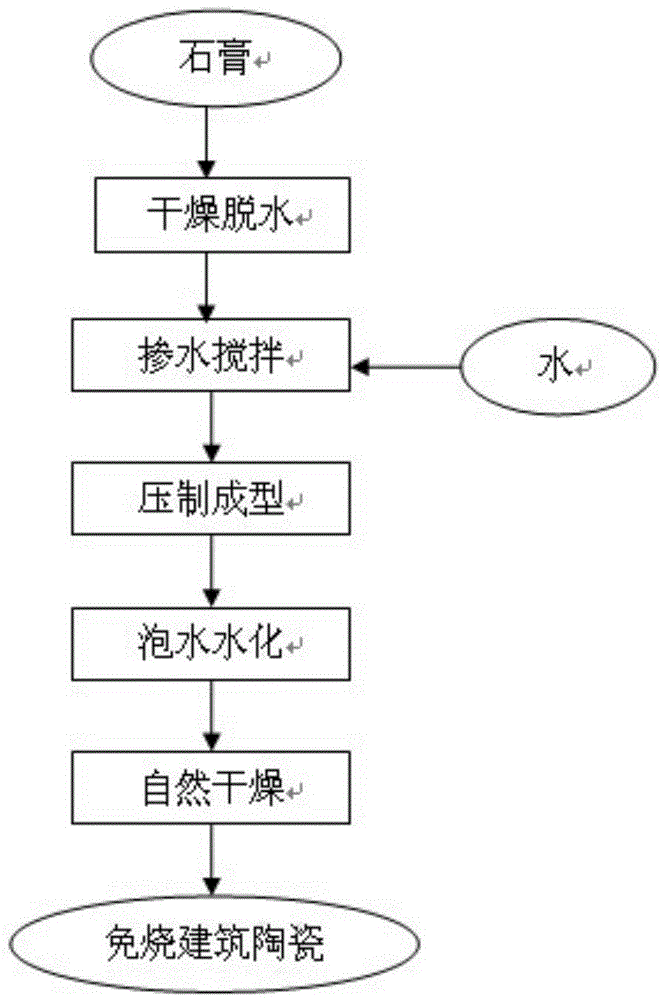

Production process of unfired building ceramic

A technology for building ceramics and production technology, which is applied in the field of building materials to achieve the effects of simple production technology, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Drying and dehydration: dry and dehydrate natural gypsum at 150°C for 6 hours under normal pressure to obtain hemihydrate gypsum;

[0032] (2) Compression molding: Mix the hemihydrate gypsum obtained in step (1) with water at a mass ratio of 100:6, and stir quickly evenly, then immediately fill the obtained hemihydrate gypsum mixed with water into the ceramic brick press, and Press molding under 30MPa pressure to obtain pottery blank;

[0033] (3) Soaking water for hydration: stack the pottery blanks obtained in step (2) together, the number of overlaps is 10, use cotton cloth to separate the pottery blanks, and put them in a hydration tank; then put the stacked pottery blanks together with The hydration tank is placed under the press together, and the same pressure as that in step (2) is applied by the press; keep the pressure constant, feed water into the hydration tank, and soak the ceramic blank for 1 hour;

[0034] (4) Natural drying: remove the pressure, take...

Embodiment 2

[0038] (1) Drying and dehydration: dry and dehydrate natural gypsum at 160°C for 4 hours under normal pressure to obtain hemihydrate gypsum;

[0039] (2) Compression molding: Mix the hemihydrate gypsum obtained in step (1) with water at a mass ratio of 100:10, and stir quickly and evenly, then immediately fill the obtained hemihydrate gypsum into the ceramic brick press, and Compression molding under 25MPa pressure to obtain pottery blank;

[0040] (3) Soak water for hydration: stack the pottery blanks obtained in step (2) together, the number of overlaps is 20, use cotton cloth to separate the pottery blanks, and put them into a hydration tank; then put the stacked pottery blanks together with The hydration tank is placed under the press together, and the same pressure as that in step (2) is applied by the press; keep the pressure constant, feed water into the hydration tank, and soak the ceramic blank for 1.5 hours;

[0041] (4) Natural drying: remove the pressure, take out...

Embodiment 3

[0044] (1) Drying and dehydration: drying and dehydrating desulfurized gypsum (containing 93 wt% calcium sulfate dihydrate) at 170° C. under normal pressure for 2 hours to obtain hemihydrate gypsum;

[0045] (2) Compression molding: mix the hemihydrate gypsum obtained in step (1) with water at a mass ratio of 100:20, and stir quickly and evenly, then immediately fill the obtained hemihydrate gypsum into the ceramic brick press, and Press molding under 20MPa pressure to obtain pottery blank;

[0046] (3) Soaking water for hydration: stack the pottery blanks obtained in step (2) together, the number of overlaps is 40, use cotton cloth to separate the pottery blanks, and put them into a hydration tank; then put the stacked pottery blanks together with The hydration tank is placed under the press together, and the same pressure as that in step (2) is applied by the press; keep the pressure constant, feed water into the hydration tank, and soak the ceramic blank for 2 hours;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com