Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Enough energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complete feeds for milking sow

InactiveCN101077136AFull of nutritionReliable qualityFood processingAnimal feeding stuffSOYBEAN SEED OILChemistry

The present invention discloses one kind of complete feed for milking sow. The complete feed consists of corn 50-70 wt%, bran 3-7 wt%, soybean oil 1-2 wt%, soybean dregs 25-28 wt%, DDGS 3-5 wt%, stone powder 0.5-1.5 wt%, light calcium carbonate 1-1.4 wt%, salt 0.2-0.4 wt%, lysine 0.05-0.15 wt%, choline 0.05-0.15 wt%, phytase 0.01-0.02 wt%, additive 0.03-0.05 wt%, sow vitamins 0.05-0.1 wt%, and sow minerals 0.1-0.4 wt% The complete feed can provide milking sow with sufficient energy, protein, vitamins and minerals and make milking sow possess high milk secreting ability and capability of raising immunity of piglets..

Owner:侯彦卫

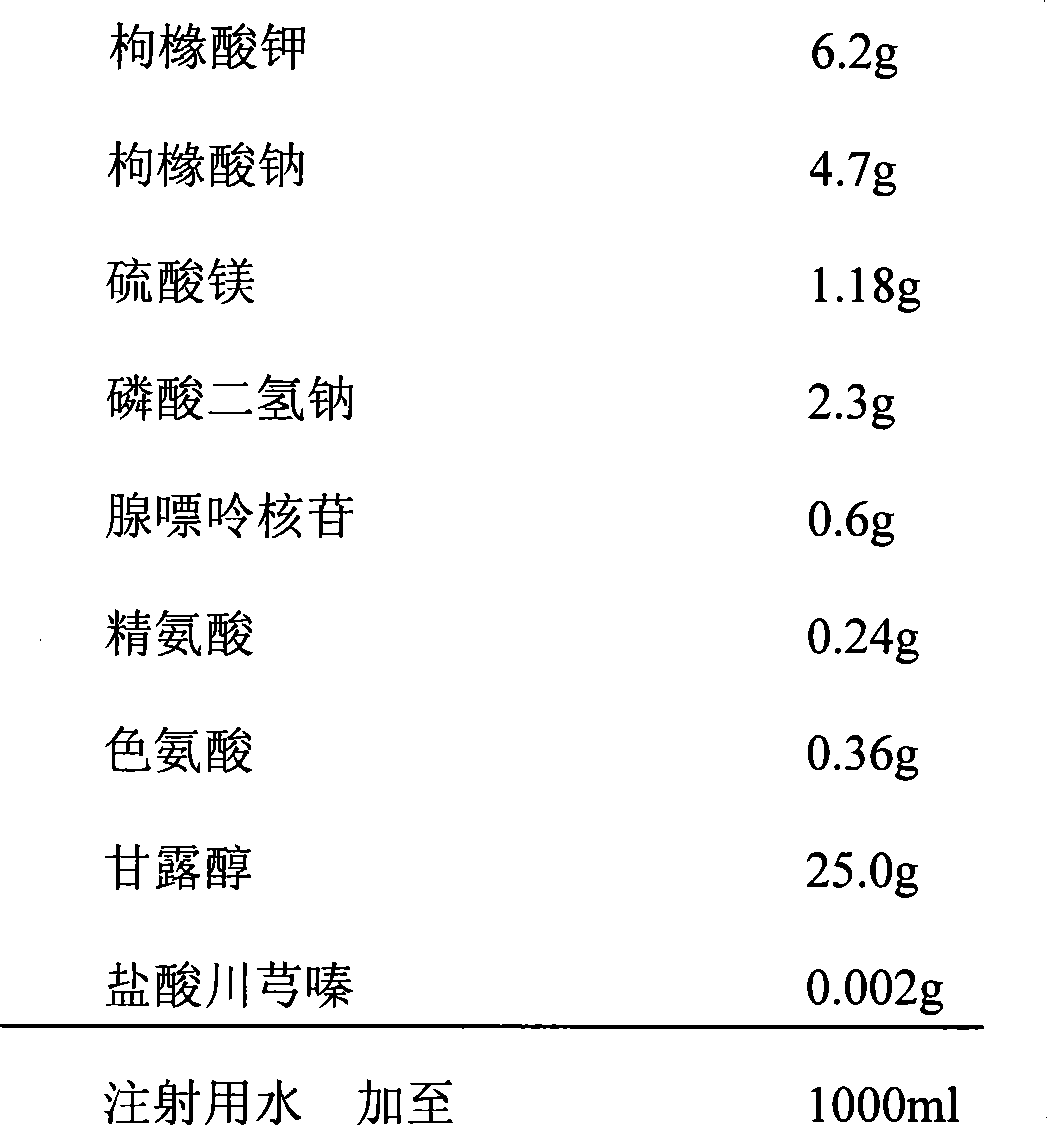

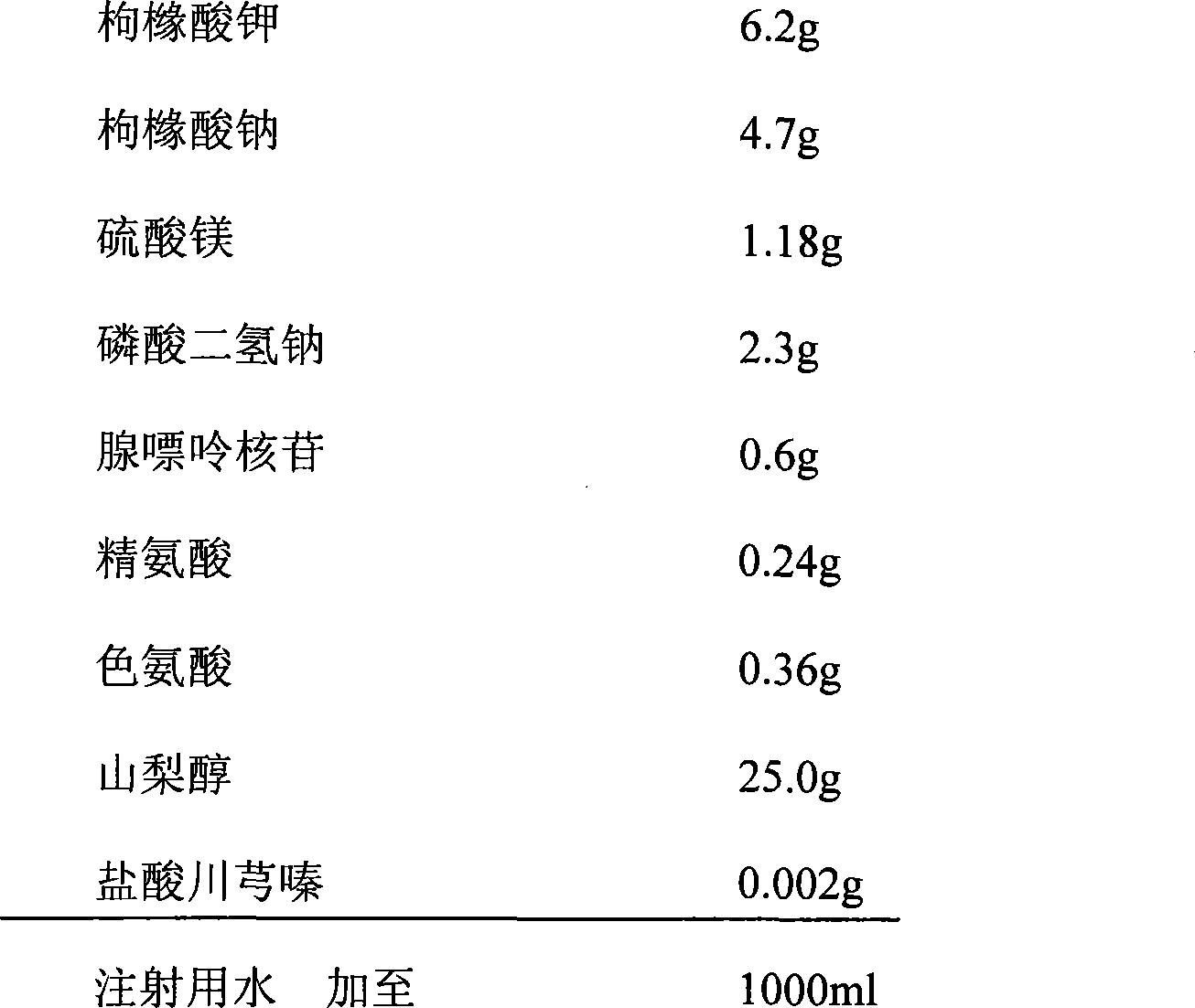

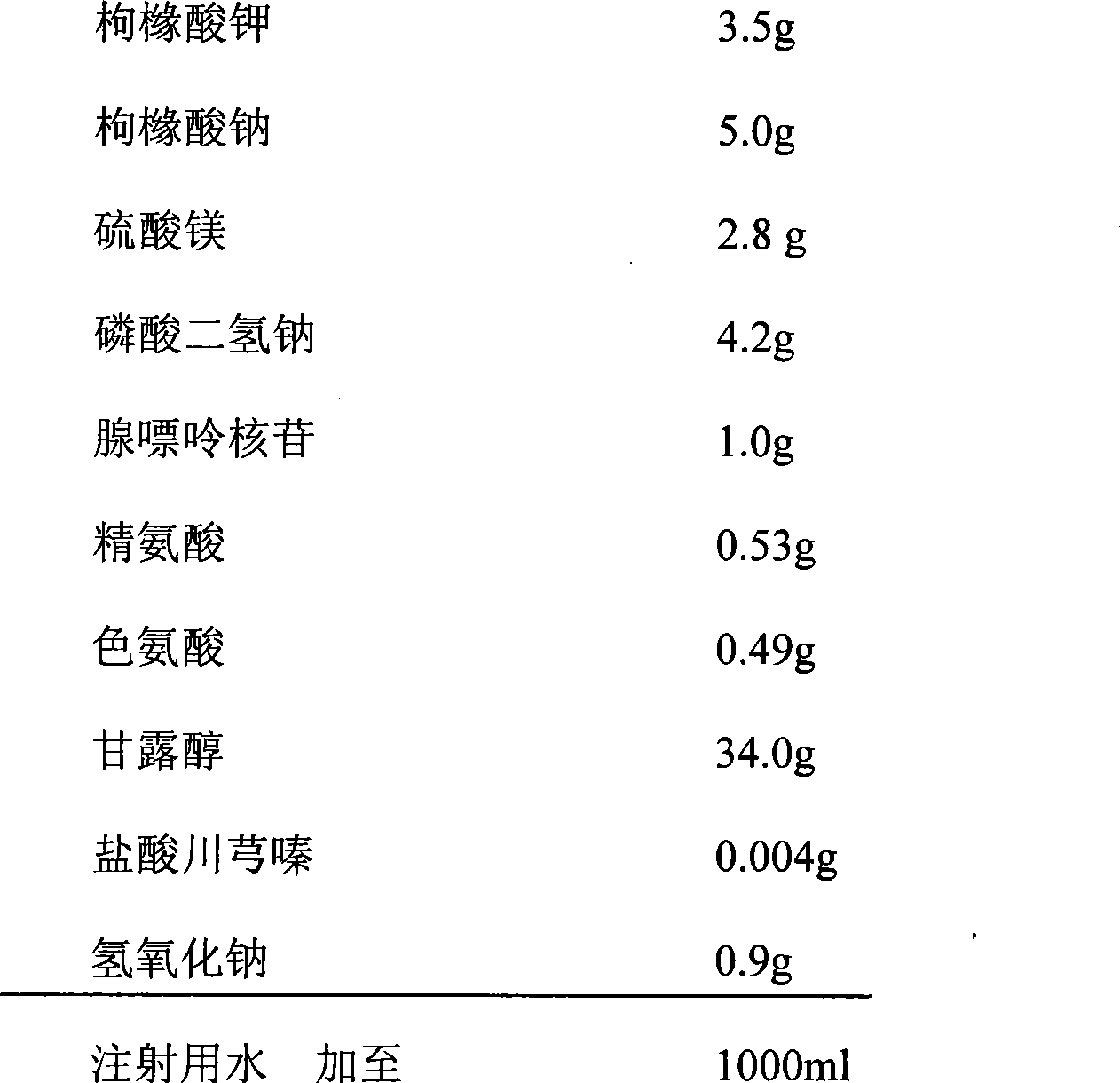

Organ preservative fluid and preparation method thereof

InactiveCN101496512AEffective preservationPrevent ischemia-reperfusion injuryDead animal preservationReperfusion injuryTetramethylpyrazine hydrochloride

The invention relates to a preservation solution for organs, tissues or cells of human bodies or animals. The organ preservation solution comprises sodium citrate, potassium citrate, magnesium sulfate, sodium dihydrogen phosphate, sodium hydroxide, adenosine, arginine, tryptophan, mannitol, tetramethylpyrazine hydrochloride and other components. The organ preservation solution can be used for cooling, lavaging and preserving the organs of the human bodies or the animals, can effectively preserve human in vitro kidneys for 48 hours and animal in vitro kidneys for 72 hours, can prevent ischemia-reperfusion injury, and has great value for clinical application.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

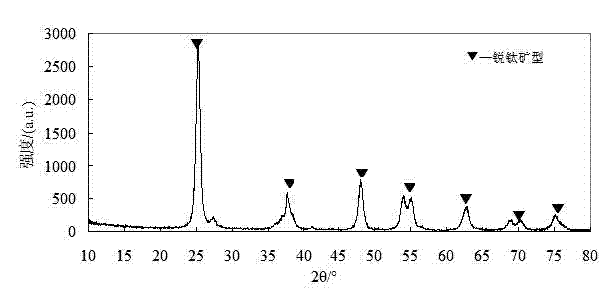

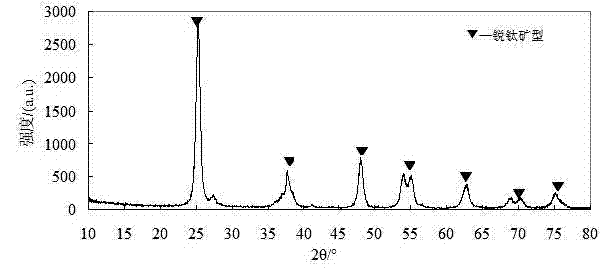

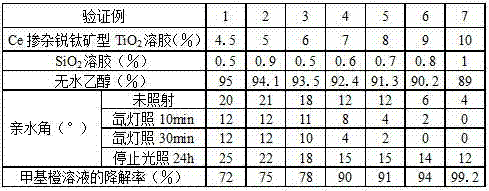

Method for preparing photoinduced ultra hydrophilic automatically cleaning paint

The invention provides a method for preparing a photoinduced ultra hydrophilic automatically cleaning paint, comprising the following steps: (1) preparing titanium dioxide suspension by using titanium hydroxide; (2) preparing cerium-doped anatase titanium dioxide for subsequent use; (3) placing waterless ethanol, ammoniacal liquor, distilled water and ethyl orthosilicate which is added later into a reactor and magnetic stirring uniformly; (4) magnetic stirring the mixed liquor prepared in step (3) for more than 3 h in a constant temperature bath of 80 DEG C to obtain silica sol; (5)mixing the cerium-doped anatase titanium dioxide prepared in step (2), silica sol prepared in step (4) with waterless ethanol and stirring uniformly to obtain the photoinduced ultra hydrophilic automatically cleaning paint. The photoinduced ultra hydrophilic automatically cleaning paint has the advantages of simple use and convenient. The preparation method has the advantages of low energy consumption, saving heat treatment equipment, and low cost.

Owner:CHONGQING UNIV

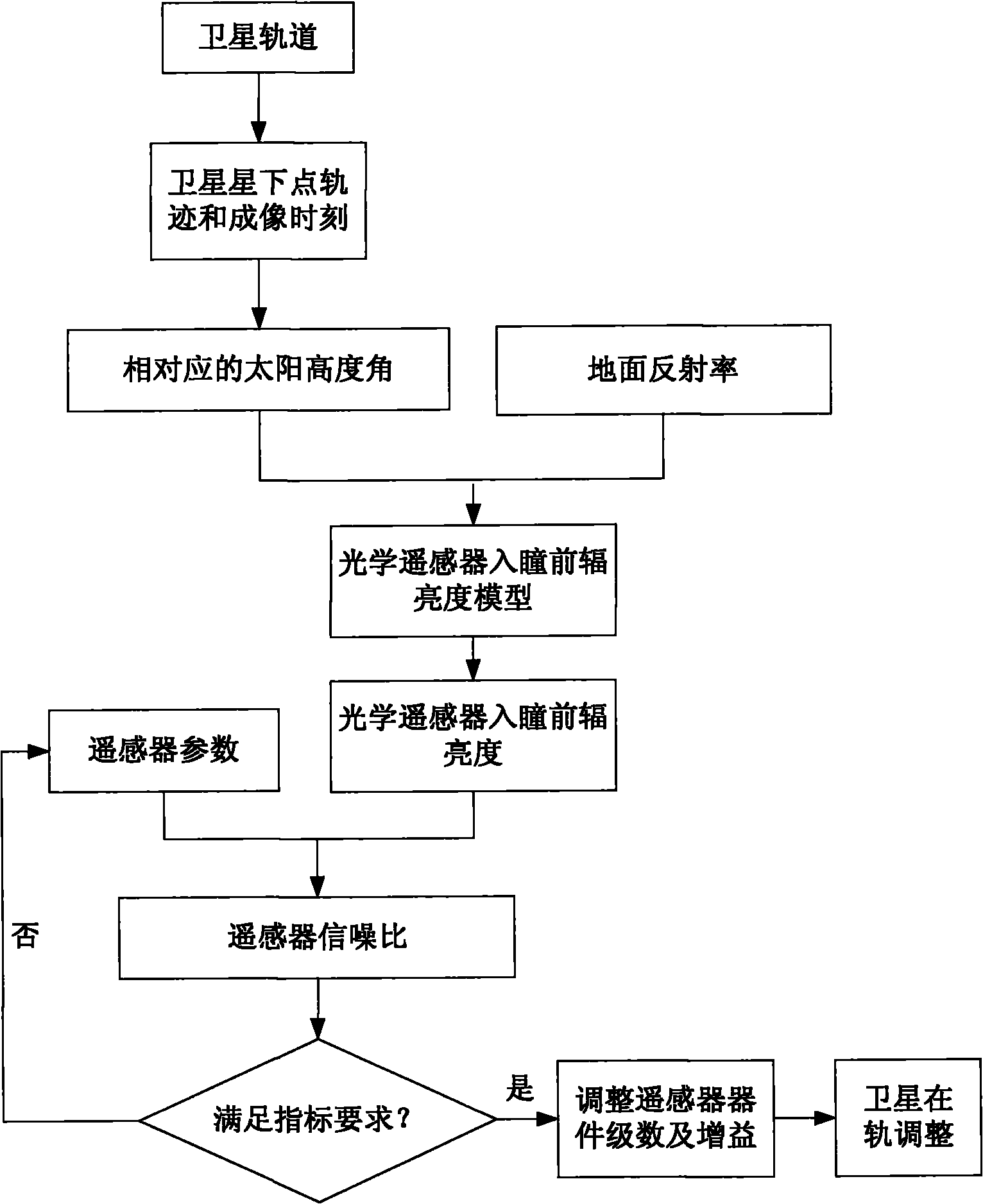

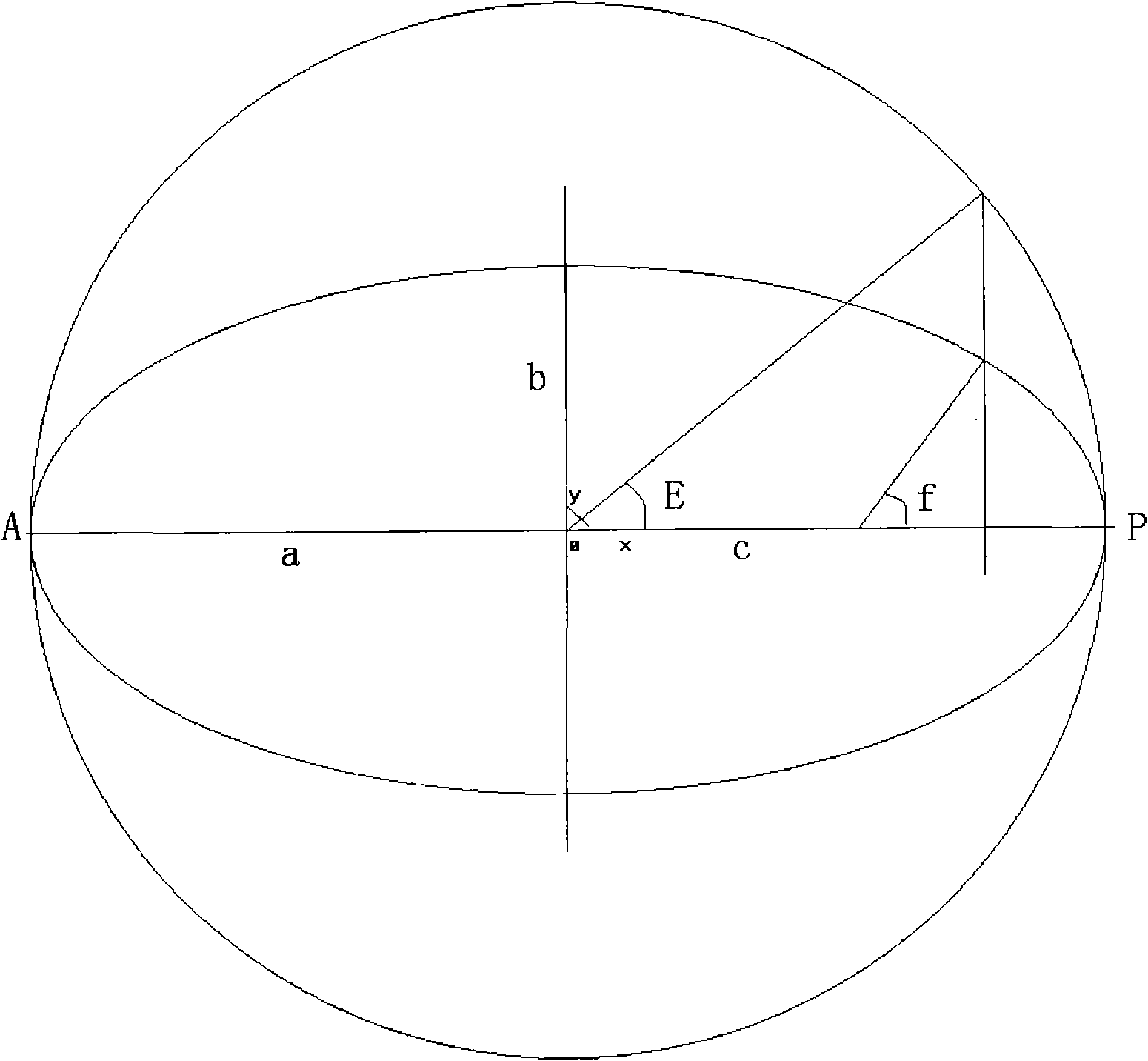

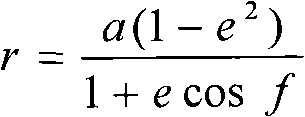

Method for determining signal-to-noise ratio of optical remote sensor by combining satellite orbit characteristics

InactiveCN102141613AEnough energyImprove image qualityElectromagnetic wave reradiationSignal-to-noise ratio (imaging)Imaging quality

The invention discloses a method for determining the signal-to-noise ratio of an optical remote sensor by combining satellite orbit characteristics. During determination of the signal-to-noise ratio of the optical remote sensor, the characteristics of the flight orbit of a satellite and a ground object are taken into full consideration, and the capability of the optical remote sensor is developed to the greatest extent, so that the optical remote sensor can acquire enough energy during flight of the satellite on orbit, the imaging quality of a remote sensing satellite is greatly improved, and the problem of dark images acquired by a high-resolution on-orbit remote sensor is solved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

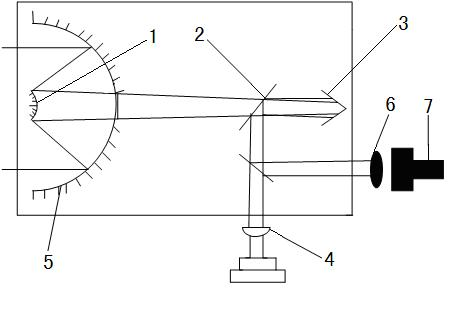

Automatic light beam capturing device and light beam capturing method

InactiveCN101852924AEnough energyEasy electrical integrationElectromagnetic transmissionOptical elementsCommunications systemOptical antenna

The invention discloses an automatic light beam capturing device, which comprises an optical antenna connected with an automatic tracking system. A Brewster window and a corner reflector are arranged on the emergent light side of the optical antenna. A focusing lens and a signal detector are arranged on the reflected light side of the Brewster window. A position-sensitive detector is arranged on the emergent light side of the Brewster window and is communicated with the automatic tracking system through a feedback channel. The light beam capturing method comprises that the optical antenna injects light signals to the corner reflector through the Brewster window after the optical antenna focuses the light signals; the corner reflector reflects the received light signals to the Brewster window, the reflected light is downward projected onto the position-sensitive detector, the Brewster window reflects partial light to the focusing lens and the light signals are received through the detector; and the position-sensitive detector calculates to obtain the position information of light, the position information is fed back to the automatic tracking system, and the automatic tracking system adjusts the transmitting direction and the pitch angle of the optical antenna. Since the invention combines an ATP with a signal laser, the invention has the advantages of simple structure, high economy and high feasibility and the device is suitable for ground atmosphere laser communication systems.

Owner:XIAN UNIV OF TECH

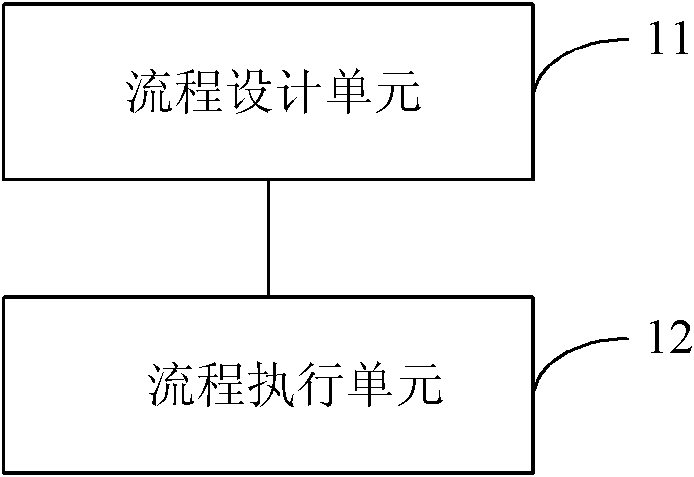

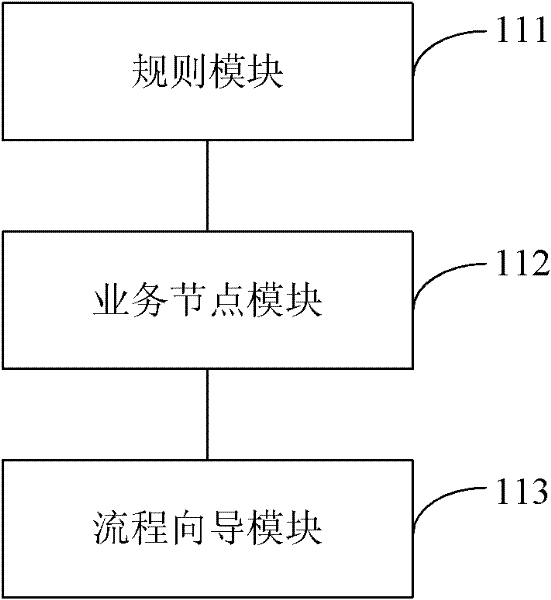

Network optimization analysis system and method

InactiveCN102547757AShorten the timeEnough energySpecial data processing applicationsNetwork planningLogical analysisProcess design

The invention provides a network optimization analysis system and method. The network optimization analysis system comprises a process designing unit and a process executing unit, wherein the process designing unit is used for determining process steps and forming standardized processes through principle convention and logical analysis on a basis of experiments of network optimization analysis process in practice, thereby obtaining a network optimization process guide file; and the process executing unit is used for selecting the network optimization process guide file obtained based on the process designing unit by aiming at network problems, executing the process and carrying out network optimization analysis. By the adoption of the network optimization analysis system provided by the invention, the efficiency for optimizing common network problems is effectively increased, the time of network optimization engineers is saved, the network optimization engineers are guaranteed to have enough energy to solve difficult network problems, the cost of wireless network optimization is decreased, the quality and level of wireless network optimization are improved, and a great application value is obtained.

Owner:BOCO INTER TELECOM

Low-calorie oat nutrition tablets and preparation method thereof

The invention provides low-calorie oat nutrition tablets and a preparation method thereof. The nutrition tablets mainly comprise 35 to 45 parts of original oatmeal, 8 to 15 parts of whole milk powder, 10 to 20 parts of vegetable fat powder, 0.1 to 10 parts of stevioside, 0.5 to 15 parts of erythritol, 5 to 10 parts of maltodextrin, 0.1 to 0.5 part of fresh milk essence and 0.1 to 0.3 part of malt essence. In the invention, the pure natural and zero-calorie stevioside is taken as a sweetener instead of sucrose or an artificial sweetener in an ordinary oat product; and the product can be eaten by diabetics, fat people and crowds who are required to reduce energy intake, has a higher health-care effect, and overcomes the disadvantages of the conventional oatmeal on the market.

Owner:JINAN HANDING BIOENG

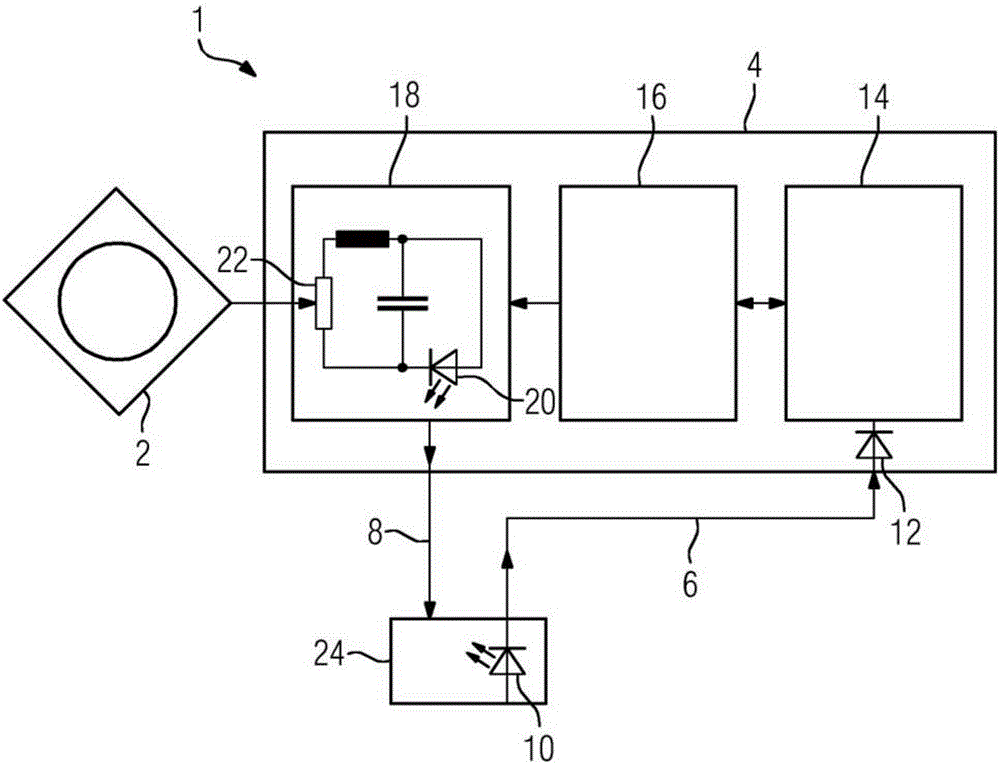

Apparatus and method for monitoring shaft doors

InactiveCN103827011AEnough energyAvoid probing possible problemsElevatorsBuilding liftsComparators circuitsEngineering

The invention relates to a lift installation having at least one shaft door and an apparatus for monitoring movements for opening the shaft door, comprising a first self-powered counter which is intended for counting the movements and, irrespective of the power supply being intact, in the case of one of these movements, increments a first counter value, and also comprising a second counter which is intended for counting the movements and, with the power supply intact, in the case of one of these movements, increments a second counter value, and further comprising a comparator circuit which retrieves, and compares, the first and the second counter values, and can generate a signal based on the comparison of the counter values, and to a method for monitoring movements for opening the shaft door, according to which the comparator circuit transmits request signals to the first counting and memory circuit and to the second counting and memory circuit, and therefore communication of the associated counter values to the comparator circuit is triggered, and the first counter value is communicated to the comparator circuit, and the second counter value is communicated to the comparator circuit, and the first counter value is compared with the second counter value by means of an algorithm of the comparator circuit.

Owner:INVENTIO AG

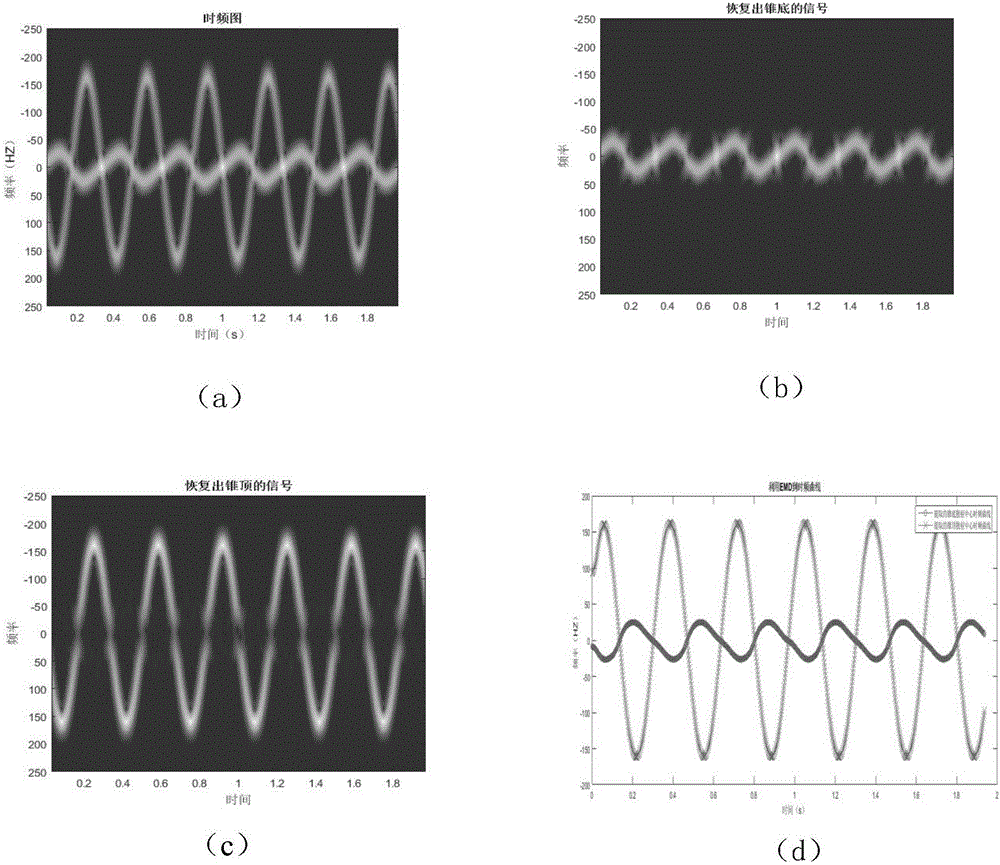

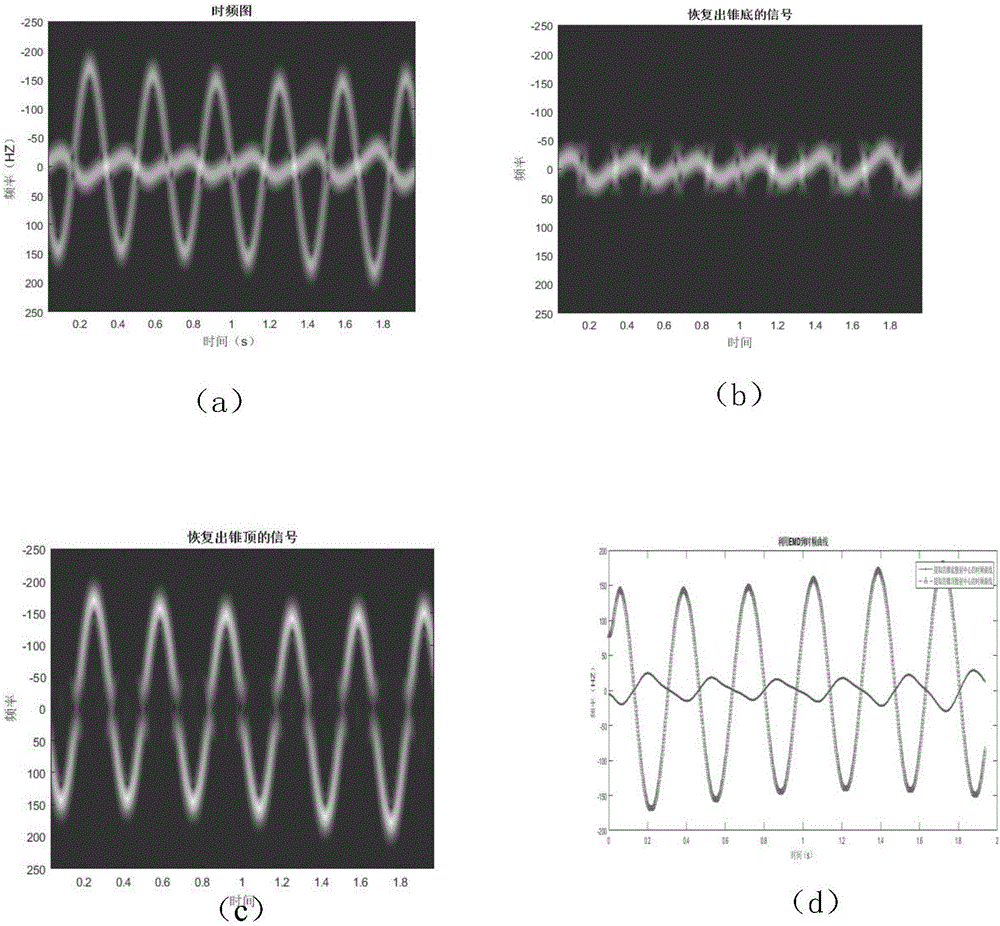

Method for extracting space conical reentry target micro-motion features based on empirical mode decomposition

InactiveCN106842181AAvoid the failure of fretting feature extractionImprove feature extraction efficiencyRadio wave reradiation/reflectionFeature extractionDecomposition

The invention discloses a method for extracting space conical reentry target micro-motion features based on empirical mode decomposition, which mainly solves the problem of easiness in failure of feature extracting in the prior art. The method adopts the scheme with the following steps of 1, according to a narrow-band linear frequency modulating signal model, calculating a transmitting signal sequence in a pulse repeating cycle; 2, according to a transmitting signal and a received target echo signal, establishing a pulse compression signal matrix, and establishing a Doppler echo signal of a conical reentry target according to the matrix; 3, according the calculated Doppler echo signal of the conical reentry target, utilizing the empirical mode decomposition to obtain a plurality of feature mode functions; 4, according to the obtained feature mode functions, reestablishing a Doppler signal of a conical reentry target scattering center; 5, according to the reestablished scattering center signal, establishing a time-frequency map of the conical reentry target scattering center; 6, extracting the micro-motion features of the target from the time-frequency map. The method has the advantage that while the micro-motion features are accurately extracted, the feature extracting efficiency is improved, so that the method can be used for identifying the target.

Owner:XIDIAN UNIV

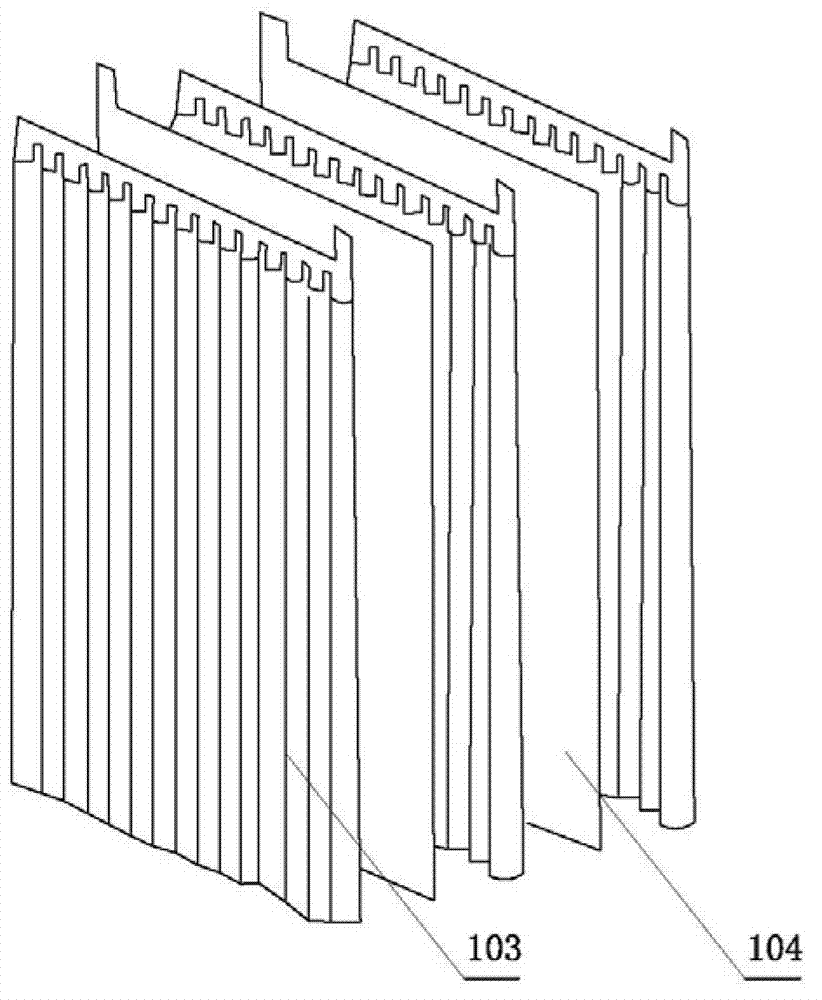

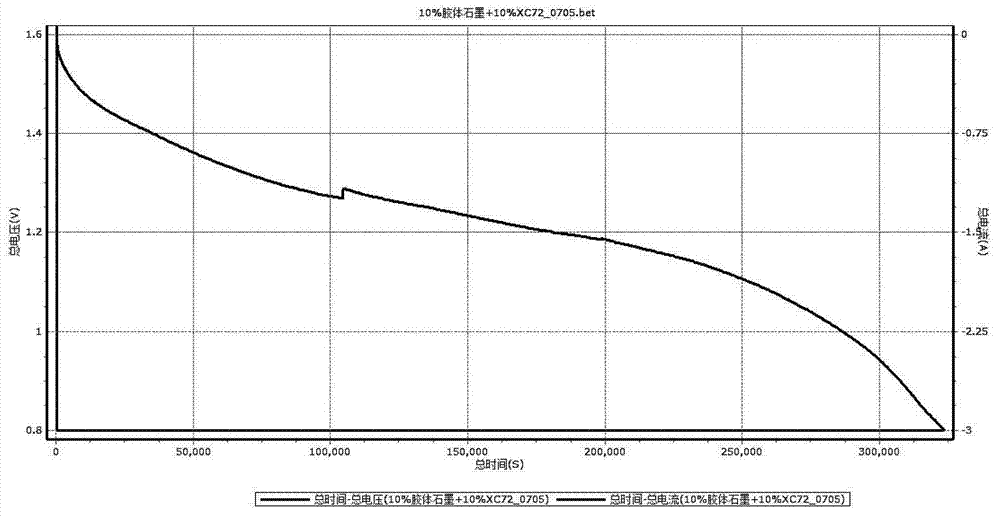

Zinc and manganese reserve battery and manufacture method thereof

InactiveCN103165918AQuick activationIncrease output powerDeferred-action cellsCell electrodesElectrolysisManganese

The invention provides a zinc and manganese reserve battery and a manufacture method of the zinc and manganese reserve battery. The zinc and manganese reserve battery comprises a battery outer shell and an electrolyte storing box. The electrolyte storing box is connected with the battery outer shell through an electrolyte pipeline, and a positive electrode leading-out end and a negative leading-out end are arranged on the surface of the battery outer shell. An electrolyte is arranged in the electrolyte storing box, and a manganese positive electrode and a zinc negative electrode are arranged in the battery outer shell. The manganese positive electrode comprises electrolysis MnO2 and electric conduction carbon materials. The part ratio, by weight, of the electrolysis MnO2 and the conduction carbon materials is 75-85 / 9-25. The zinc and manganese reserve battery can be rapidly activated, output power is large, and long-time continuous work is achieved. Electric energy is not output when the zinc and manganese reserve battery is stored, self discharging does not exist, and therefore energy consumption is not produced. After the zinc and manganese reserve battery is stored for a long time, enough energy can be provided when the zinc and manganese reserve battery is activated.

Owner:BEIJING JINGHAI BAOSHAN ENERGY TECH DEV

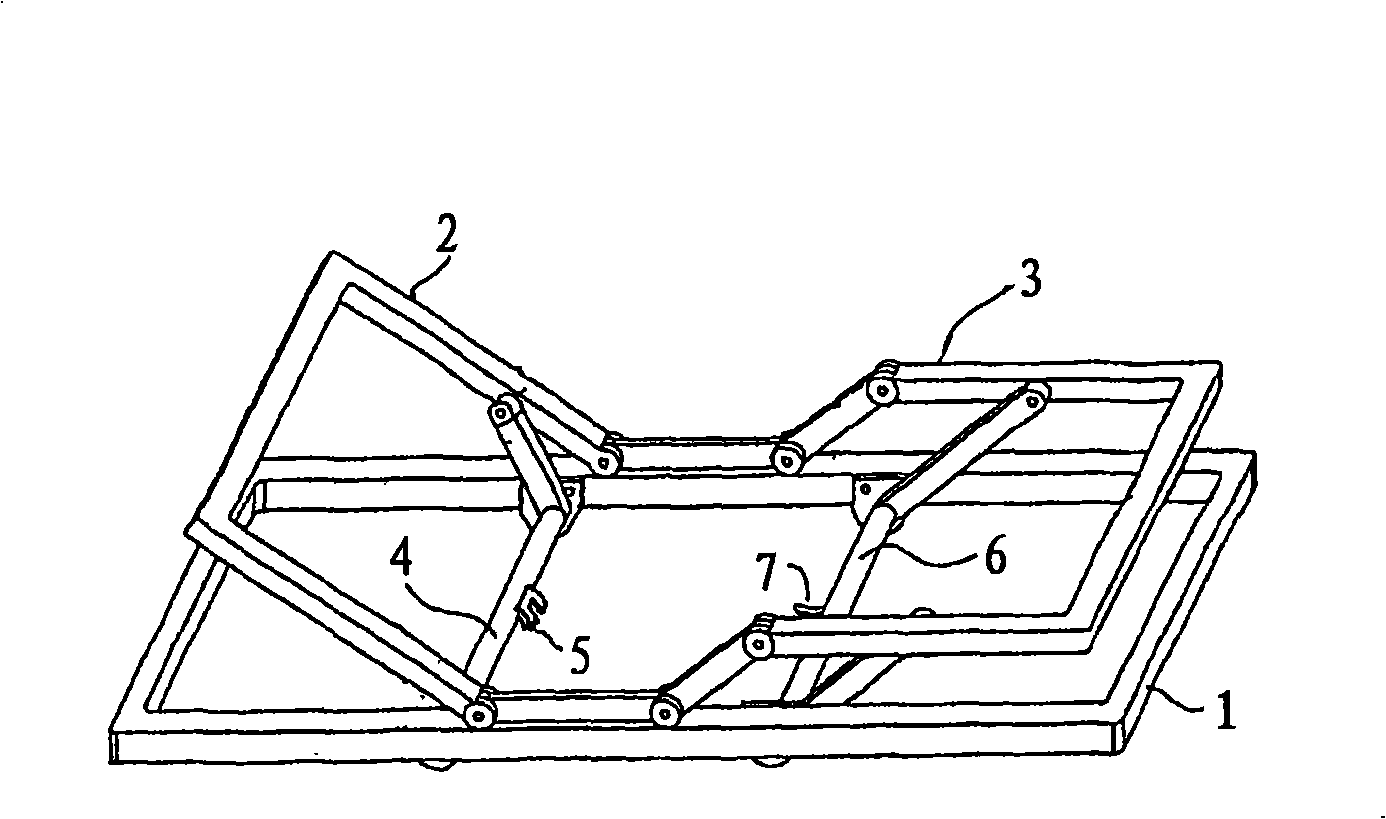

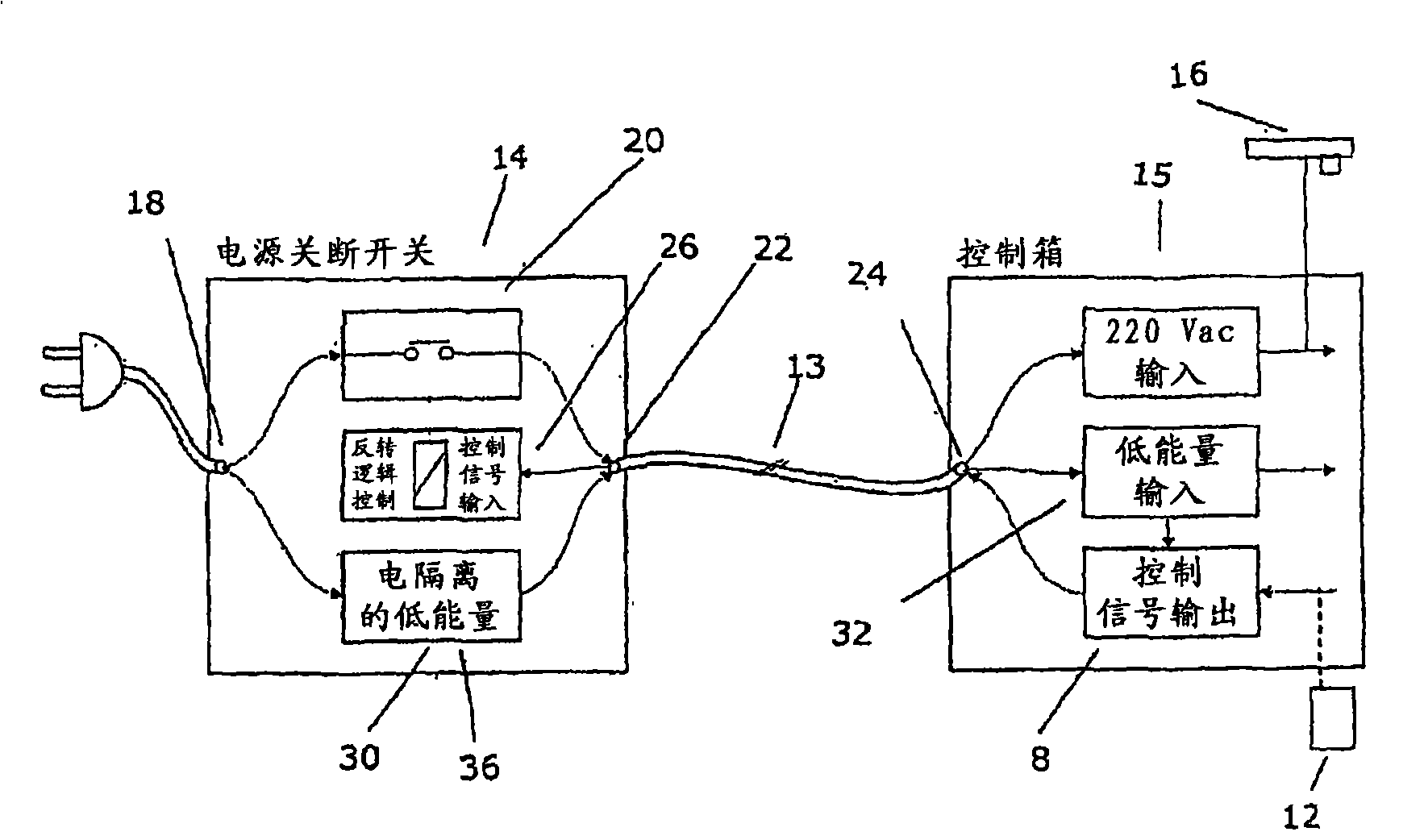

An off-mains switch and a control box for electrically driven articles of furniture

An off-mains switch (14) and a control box (15) for electrically adjustable articles of furniture, such as beds, chairs or tables, which automatically interrupt the connection to the power supply when the article of furniture is not adjusted, such that this will not constantly be under the mains voltage. These off-main switches require a multi-part cable which is rigid and thick. In the present structure (14, 15) a single two-part cable (13) is sufficient, as the off-mains switch (14) is configured such that the control signals between control unit / control box (15) and the off-mains switch are transmitted through a mains cable (13). A standard cable having two conductors is then sufficient. This means in turn that standard plugs may be used, and thus that the cable (13) may be connected to the power supply via an ordinary plug. Since, hereby, the off-mains switch may appear as a separate unit, production and logistics are facilitated.

Owner:LINAK AS

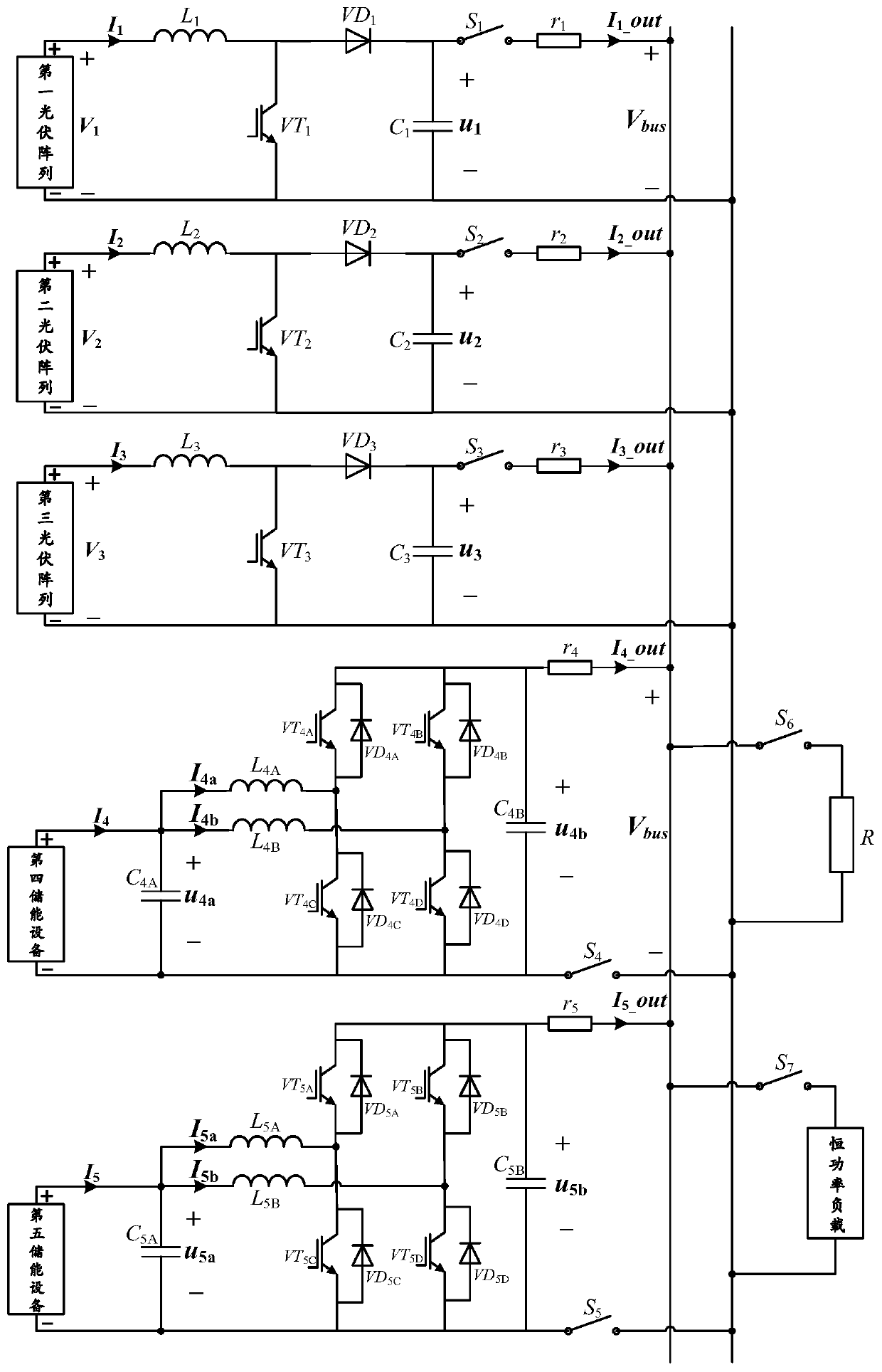

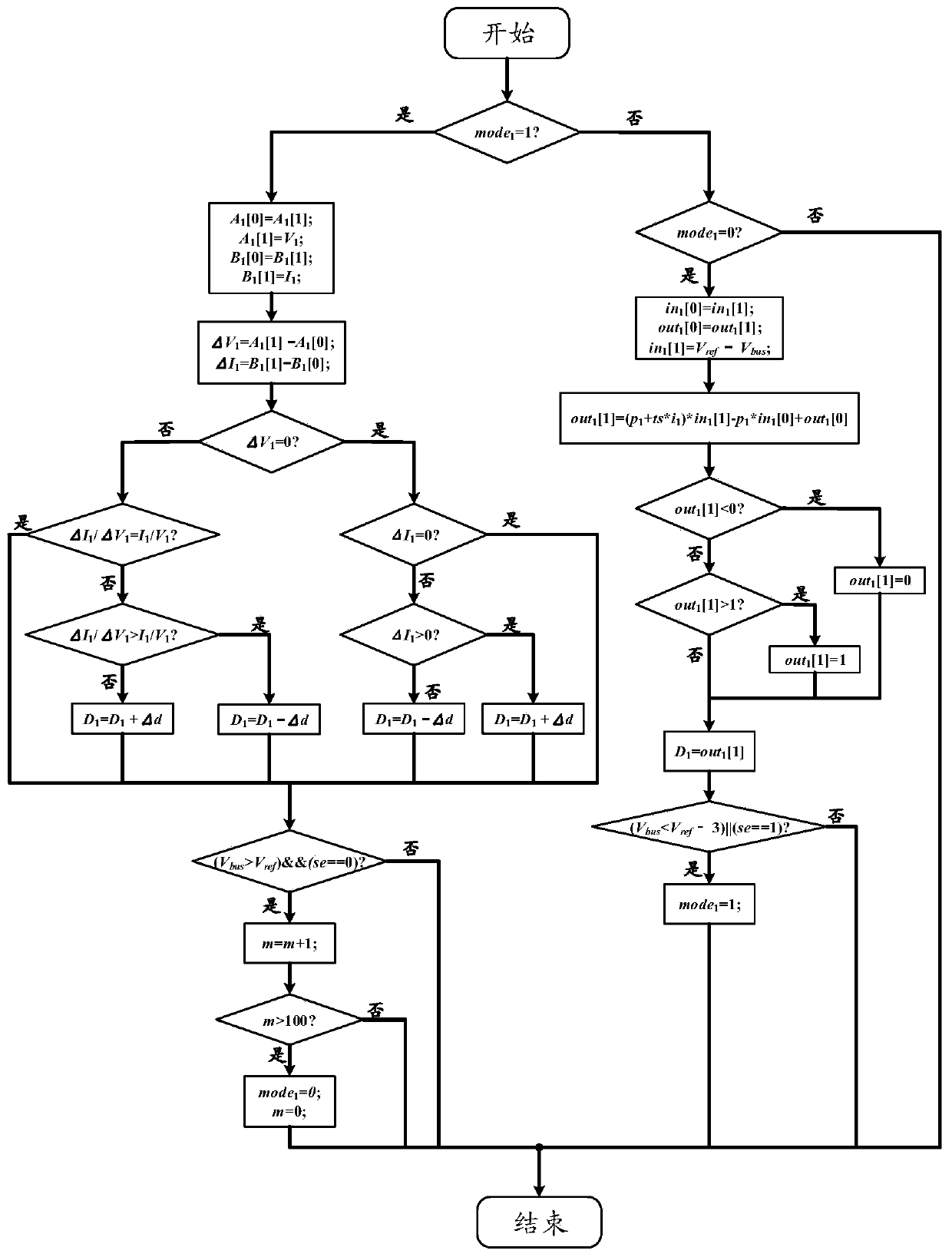

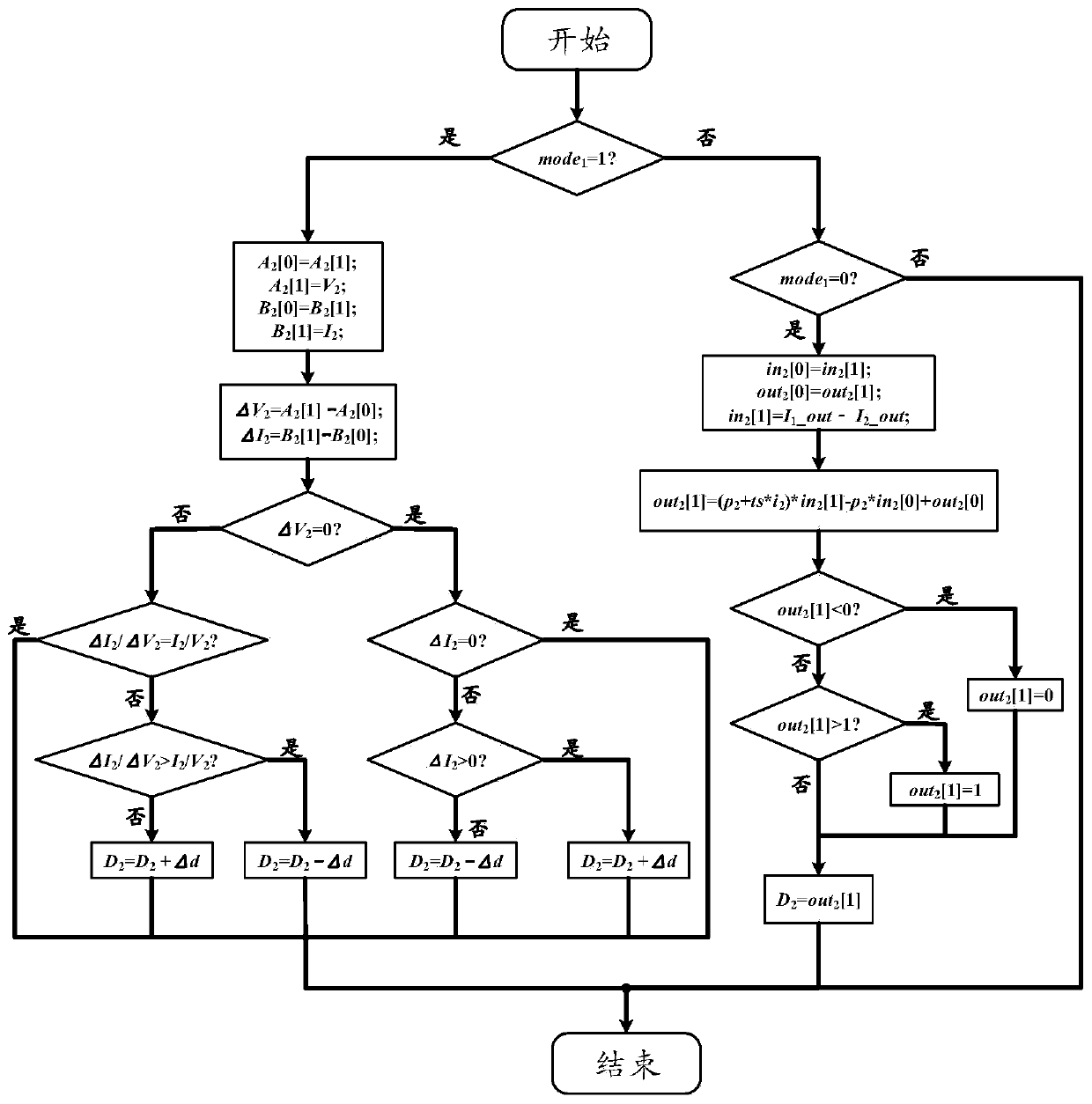

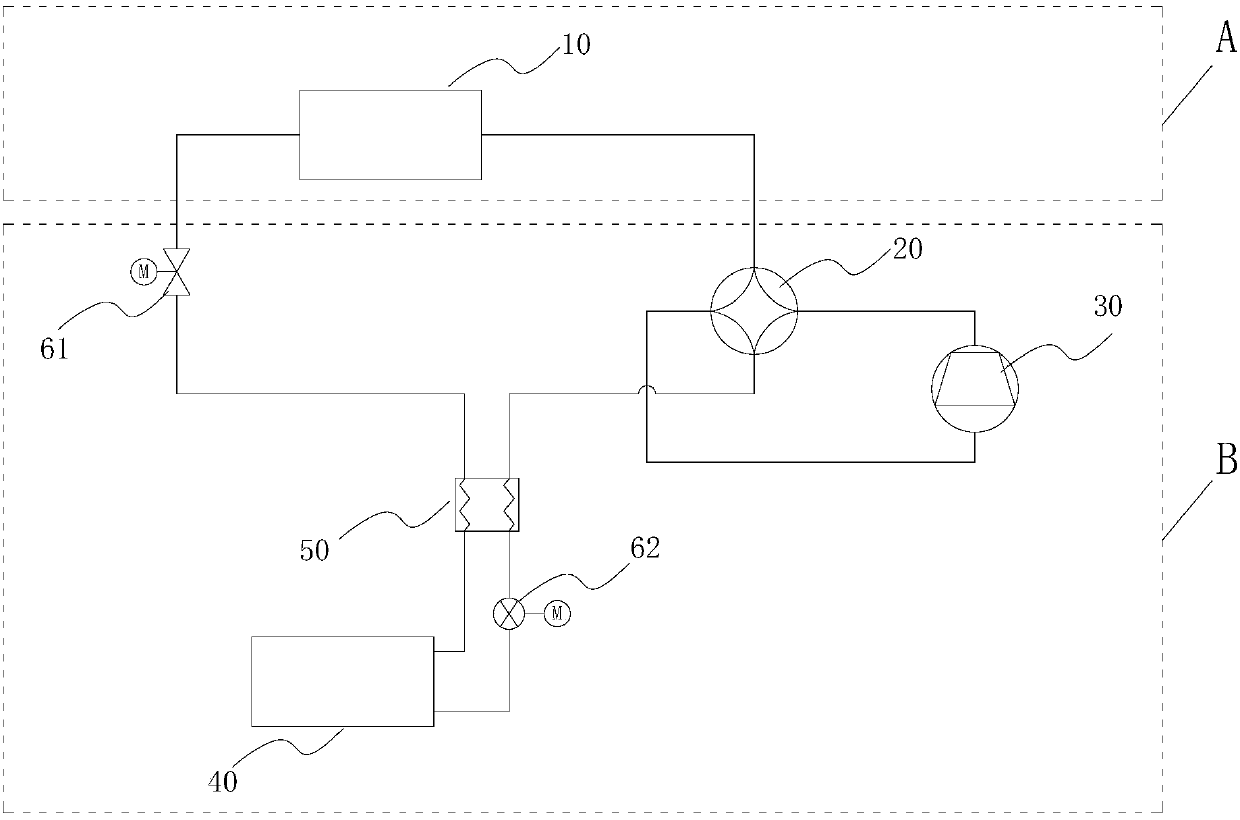

Photovoltaic direct current power generation system with energy storage equipment and control method thereof

PendingCN110071497AMeet the characteristics of self-sufficiencyEnough energyLoad balancing in dc networkConstant powerResistive load

The invention discloses a photovoltaic direct current power generation system with energy storage equipment and a control method thereof. The photovoltaic direct current power generation system with the energy storage equipment comprises three photovoltaic arrays, three BOOST converters, two pieces of energy storage equipment, two bi-directional DC / DC converters, a resistive load and a constant power load. According to the control method provided by the invention aiming at the system, two working modes, namely, an MPPT control mode and a constant voltage output mode, are set for the BOOST converters; three working modes, namely, a BUCK mode, a BOOST mode and a cutting-off mode, are set for the bi-directional DC / DC converters; the working modes of the BOOST converters and the bi-directionalDC / DC converters are reasonably switched by a controller according to the working state of the system; the integration of the photovoltaic arrays and the energy storage equipment is realized, so thatthe stability of a direct current bus is ensured, and meanwhile, the solar energy received by the photovoltaic arrays is utilized at maximum efficiency; and the controller can make fast adjustment toensure the stability of the voltage of the direct current bus under special conditions that the light intensity is weakened, a load changes suddenly and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

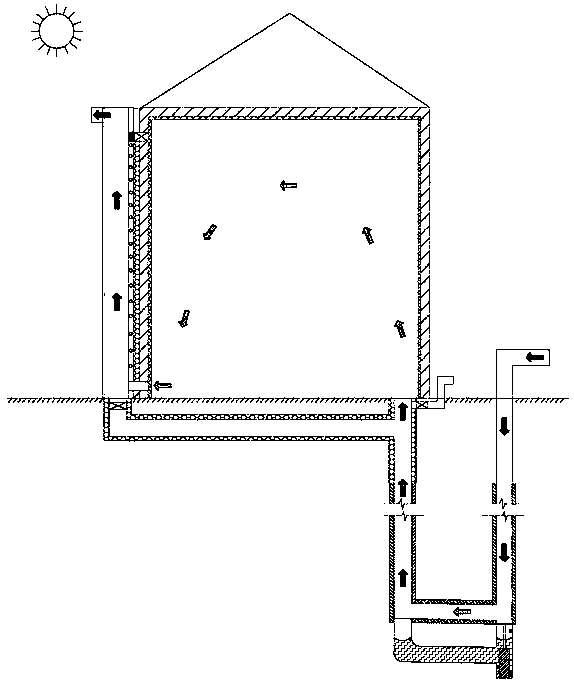

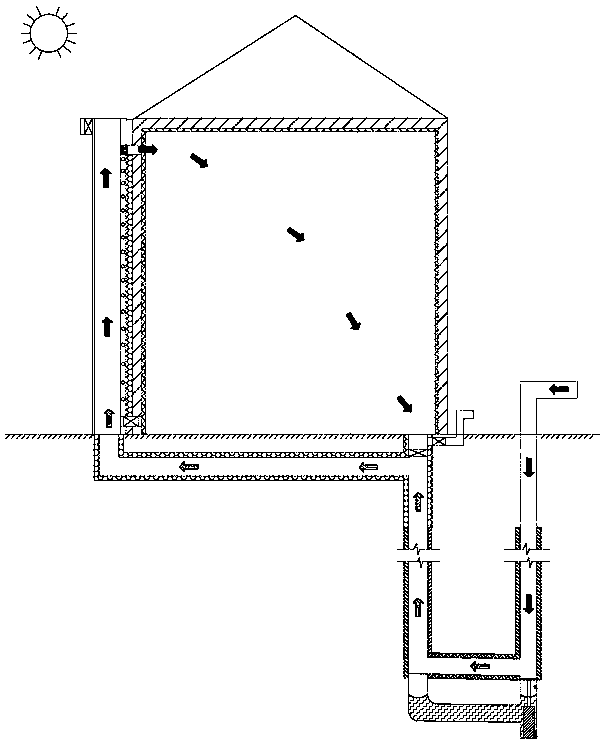

Energy complementary passive house of Trombe wall and soil-air heat exchange system based on energy storage

PendingCN110779131AZero energy consumptionImprove operational efficiencySolar heating energyHeat storage plantsEngineeringAtmospheric sciences

The invention relates to an energy complementary passive house of Trombe wall and soil-air heat exchange system based on energy storage, and the energy complementary passive house comprises a soil-airheat exchange system, a Trombe wall cavity, a phase change energy storage external wall hot water system, a phase change energy storage internal wall and a building main body. According to the invention, the Trombe wall cavity and the soil-air heat exchange system are coupled and applied for the first timely, fresh and high-quality cooling air can be provided indoors without using a fan in summer, zero energy consumption of a building is realized, and more comfortable air supply temperature can be provided indoors in winter. Different phase change energy storage units are applied to the system, which can not only improve the heat exchange efficiency of the system and reduce the fluctuation of indoor temperature, but also realize the purpose of intermittent operation of the air heat exchange system, and the efficiency of the system is prevented from being obviously reduced due to long-term continuous operation. In addition, the system can be used as a heat-generating end to prepare domestic hot water in summer, and provide a suitable supply air temperature indoors when solar radiation is insufficient in winter.

Owner:HUNAN UNIV

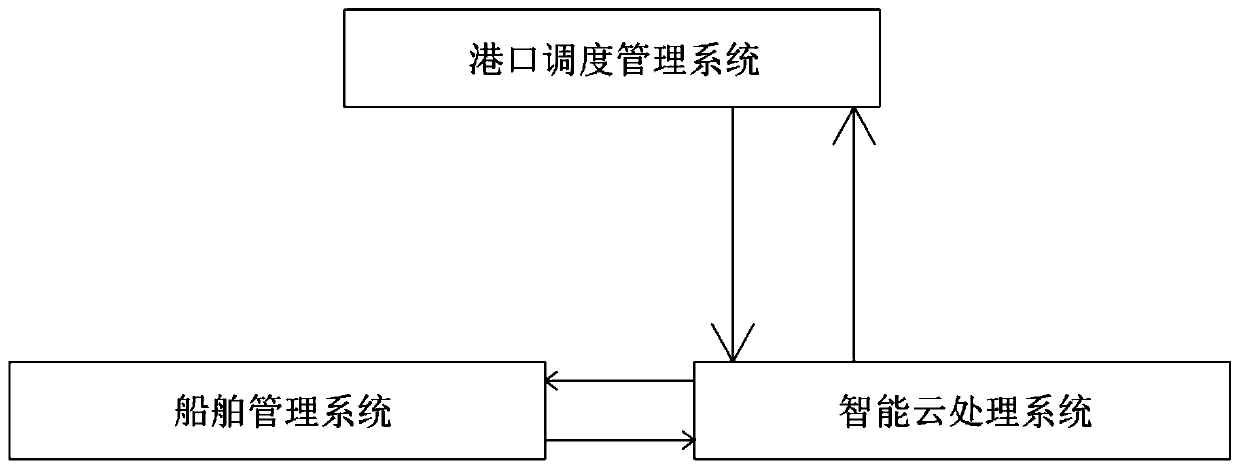

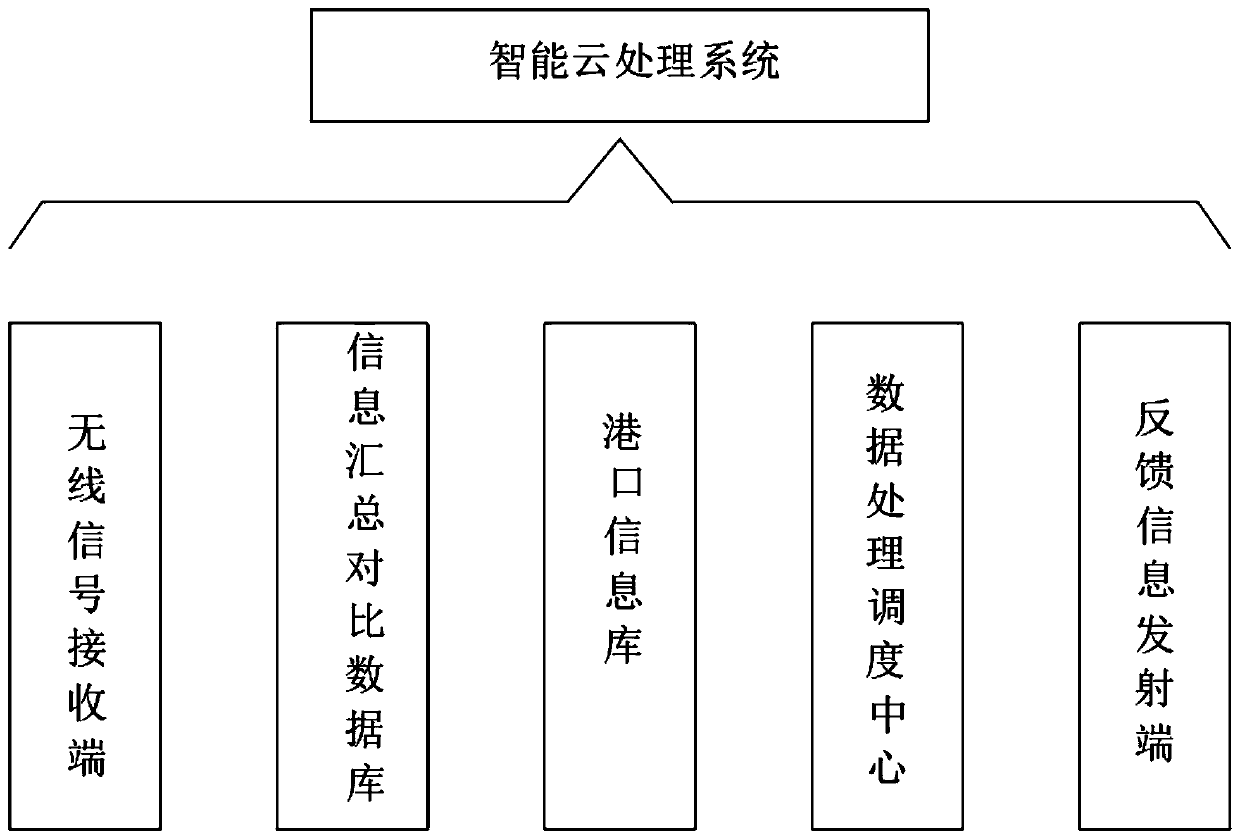

Dynamic management method and system for international trade ship

The invention discloses a dynamic management method and system for an international trade ship, and specifically relates to the technical field of trade ship management. The system comprises a port scheduling management system, an intelligent cloud processing system and a ship management system; the port scheduling management system comprises a ship identification base station, a ship arrival recording base station, a ship real-time monitoring system, a regulation and control broadcast voice system and a ship departure recording base station, and the intelligent cloud processing system comprises a wireless signal receiving end. According to the invention, the intelligent cloud processing system is arranged; in the operation process of the whole system, the intelligent cloud processing system is matched with the remote wireless data connection and transmission technology; the port dispatching management system and the ship management system are connected into a whole to form a macroscopic management system, and then the ship real-time monitoring system is used for transmitting the use condition of each ship berth in a port to the port information base in real time through the wireless signal receiving end for information updating and storage.

Owner:JIAOZUO UNIV

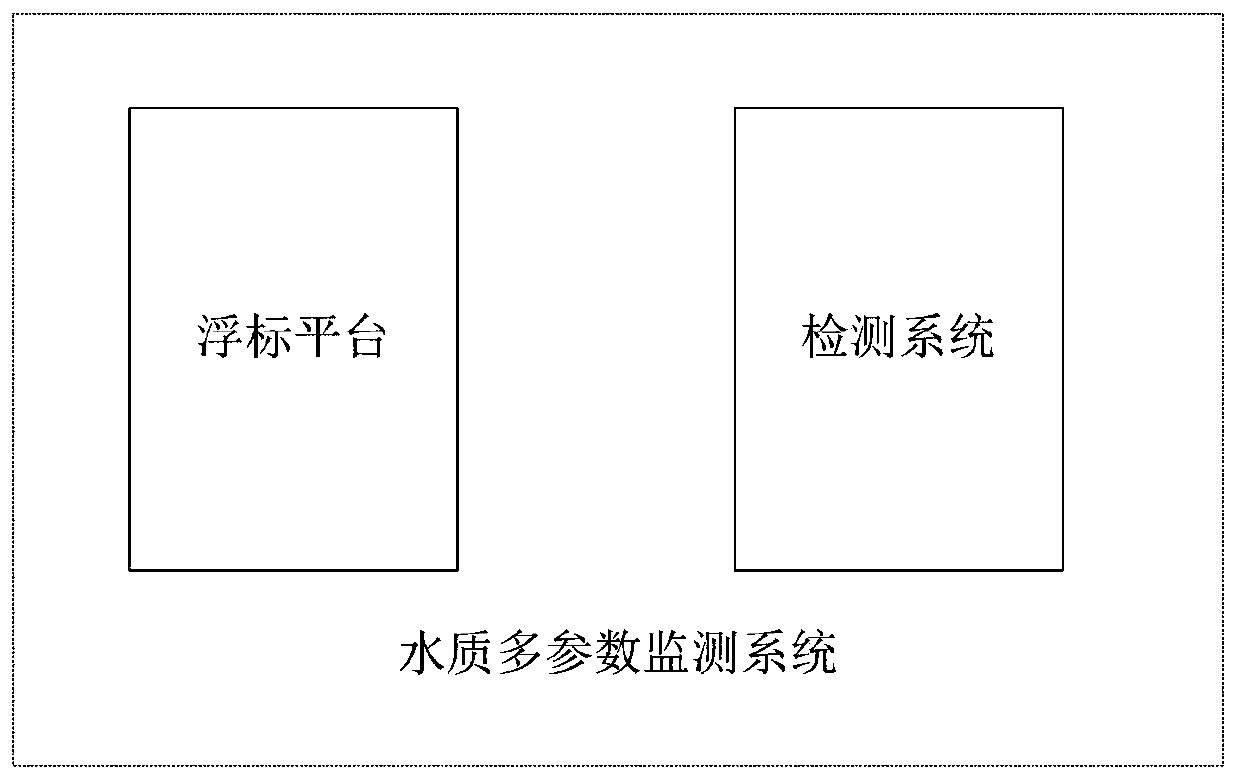

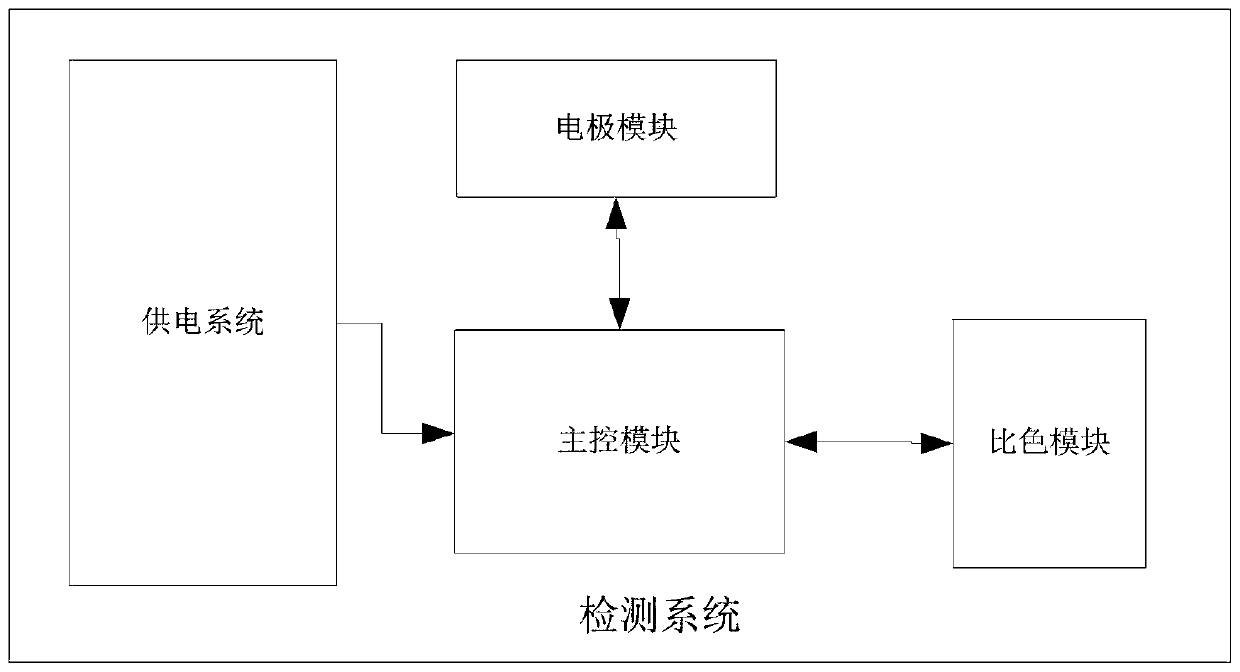

Reagent-free multi-parameter water quality in-situ monitor

PendingCN111398549AEnsure fairness and opennessReal-time monitoring of water quality changesBatteries circuit arrangementsTesting waterChemical oxygen demandSolar power

The invention discloses a reagent-free multi-parameter water quality in-situ monitor. A water quality condition is monitored in real time through an electrode module and a spectrophotometry module, meanwhile, a wind speed is detected and can be directly displayed through a display screen, public fairness of data is guaranteed, the data is stored to a cloud end and can be checked by a user on a mobile phone or a computer end, and data management is performed. The monitor provided by the invention has a unique structural design; and six solar panels are arranged, solar power generation is ensured to provide enough energy for a storage battery, an electrode method module and the spectrophotometry method module are adopted to correspond to detection items such as a temperature, conductivity, dissolved oxygen, a pH value, ammonia nitrogen turbidity, a chemical oxygen demand and the like, no reagent needs to be added, a water quality change condition is effectively monitored in real time, and an emergency is warned.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

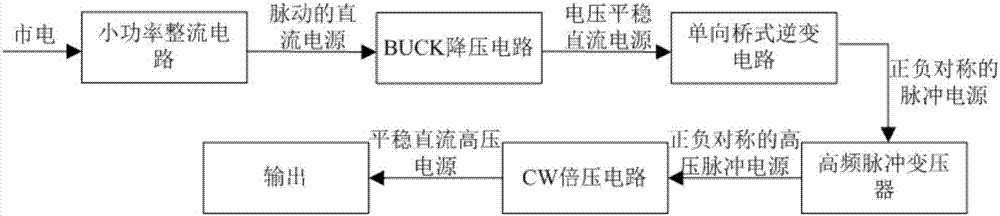

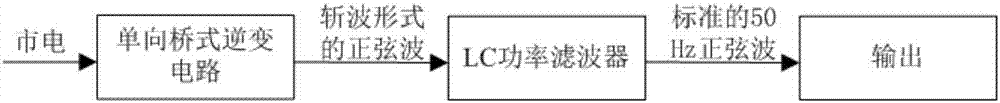

Device using high-voltage pulsed discharge to break excess sludge and application method thereof

A current method for breaking excess sludge has the problems of being high in energy consumption, high in cost and low in breaking rate. The invention provides a device using high-voltage pulsed discharge to break the excess sludge and an application method thereof, or provides a novel device and a technology using a shock wave formed by the instantaneous ultra high temperature and high pressure generated by the high-voltage pulsed discharge to achieve efficient breaking of the excess sludge, and belongs to the technical field of animal vegetable tissue and microorganism crushing. The device is capable of efficiently dispersing zoogloeas in the excess sludge, and ablating and breaking cell walls of germs and macro molecular substances, so that intracellular organic matters in the germs are prompted to flow out, the biodegradability of the excess sludge is greatly improved, and an approach for large-scale efficient treating of the excess sludge is provided. In addition, by changing different technological parameters, the device is applicable to processes such as sterilization and tissue breaking of various industries, and the excellent effect can be delivered by the device.

Owner:NORTHEASTERN UNIV

Air-conditioner system and air-conditioner with same

ActiveCN107655233AEnough energyImprove reliabilityMechanical apparatusCorrosion preventionFour-way valveEngineering

The invention provides an air-conditioner system and an air-conditioner with the same. The air-conditioner system comprises an indoor heat exchanger, a four-way valve, a compressor and an outdoor heatexchanger which are communicated; the air-conditioner system further comprises a heat exchange part, the heat exchange part is arranged on a pipe for communicating the outdoor heat exchanger with theindoor heat exchanger, and / or the heat exchange part is arranged on a pipe for communicating the outdoor heat exchanger with the four-way valve; and when defrosting is carried out on the outdoor heatexchanger, a refrigerant sequentially flows through the indoor heat exchanger and the outdoor heat exchanger through the four-way valve and then flows back to the compressor through the four-way valve. By means of the technical scheme, in the defrosting mode, the four-way valve cannot reverse, and therefore the air-conditioner can continuously supply heat to an indoor place, meanwhile, the refrigerant in the pipe is heated through the heat exchange part, it is guaranteed that the air-conditioner system has sufficient energy for heat exchange, and the condition of liquid hammering, caused by insufficient heat exchange energy, of the compressor is prevented. By means of the technical scheme, the reliability and the practicability of the air-conditioner system are improved.

Owner:GREE ELECTRIC APPLIANCES INC

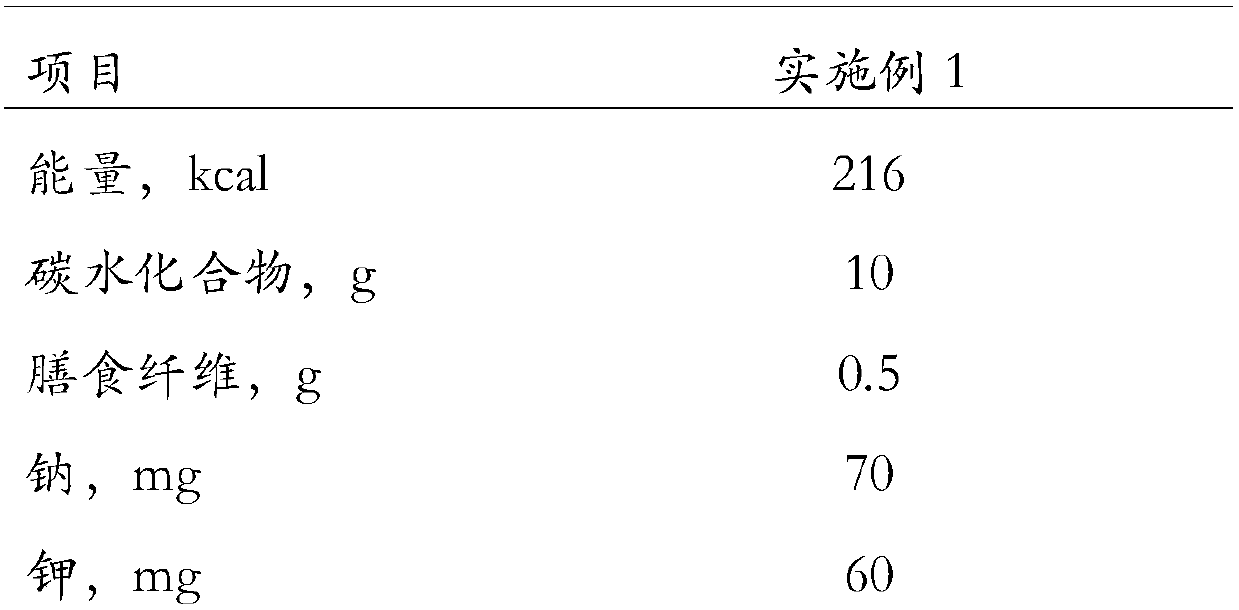

Energy beverage suitable for patients before operation to drink and making method of energy beverage

InactiveCN107836610AMeet energy needsReduce loadInorganic compound food ingredientsFood ingredient functionsSurgical operationDietary fiber

The invention discloses an energy beverage suitable for patients before operation to drink and belongs to the field of processing a special medicine formula food. Each 100ml of the energy beverage comprises 10-15g of carbohydrate, 0.2-0.5g of dietary fibers, 70-80mg of sodium ions and 60-70mg of potassium ions. The energy beverage provides energy ingestion for patients before operation, the gastrointestinal tract loads can be reduced, energy requirements of the patients during operation can be met, and the insulin resistance and proteolysis metabolism of the patients after operation can be effectively alleviated. The energy beverage is particularly suitable for energy supplement of patients before surgical operation.

Owner:广东君悦营养医学有限公司

Nutritional goat milk powder for young pet cats and dogs, and preparation method thereof

InactiveCN106551146AImprove palatabilityIncrease nutritionFood processingAnimal feeding stuffIsomaltooligosaccharideWhey protein powder

The invention relates to a nutritional goat milk powder for young pet cats and dogs, and a preparation method thereof, and belongs to the technical field of dairy product processing. The nutritional goat milk powder for young pet cats and dogs is prepared from, by weight, 680-820 parts of fresh goat milk, 56-80 parts of whey powder, 12-30 parts of parts of lactalbumin powder, 18-35 parts of lactoferrin powder, 10-15 parts of soybean polypeptides, 1-3 parts of fructo-oligosaccharide, 0.5-0.8 parts of xylo-oligosaccharide and 0.4-0.8 parts of isomaltooligosaccharide. The nutritional goat milk powder for young pet cats and dogs has the characteristics of small fat granules and easy absorption of goat milk, has good palatability, nutrition and easy absorption for the young pet cats and dogs by adding different nutrient components, is conducive to promoting the growth and development of the young pet cats and dogs and enhancing immunity, and can provide enough energy and reduce environmental stress.

Owner:陈键

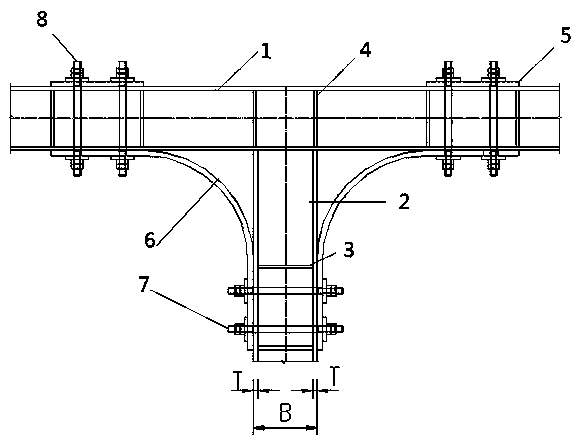

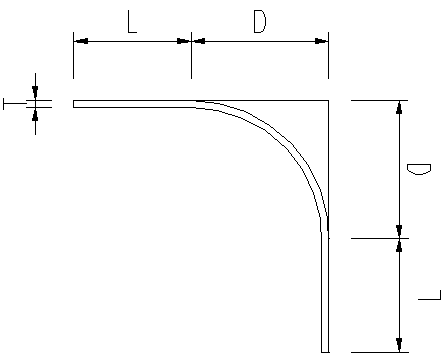

Steel structure davit joint with arc dissipative element

PendingCN108729549AImprove connection strengthImplement design principlesProtective buildings/sheltersShock proofingUltimate tensile strengthSteel structures

The invention belongs to the field of steel structure assembly buildings, in particular to a davit connection joint for quake-proof dissipative treatment in steel structure connection, the steel structure davit joint comprises a steel beam or a steel truss chord, a steel davit, stiffening ribs for the steel davit, stiffening ribs for the steel beam or the steel truss chord, a flitch for the steelbeam or the steel truss chord, an arc dissipative element, a friction-type high-strength bolt, and an end-supporting high-strength bolt, the steel beam or steel truss chord is connected to the steel davit by groove welding, and two sides of the steel davit are connected and fixed with the arc dissipative element by the friction-type high-strength bolt; the lower end of the steel beam or the steeltruss chord is connected and fixed with the arc dissipative element by the flitch for the steel beam or the steel truss chord and the end-supporting high-strength bolt, the steel structure davit jointcan strengthen the connection strength between the davit and the beam or the truss chord, effectively realize the design principle of strong joint and weak member and dissipate enough energy under the action of earthquake, after the action of earthquake, the dissipative element can be replaced after being damaged, and can be put into normal use after being connected by a bolt.

Owner:远象建设集团有限公司

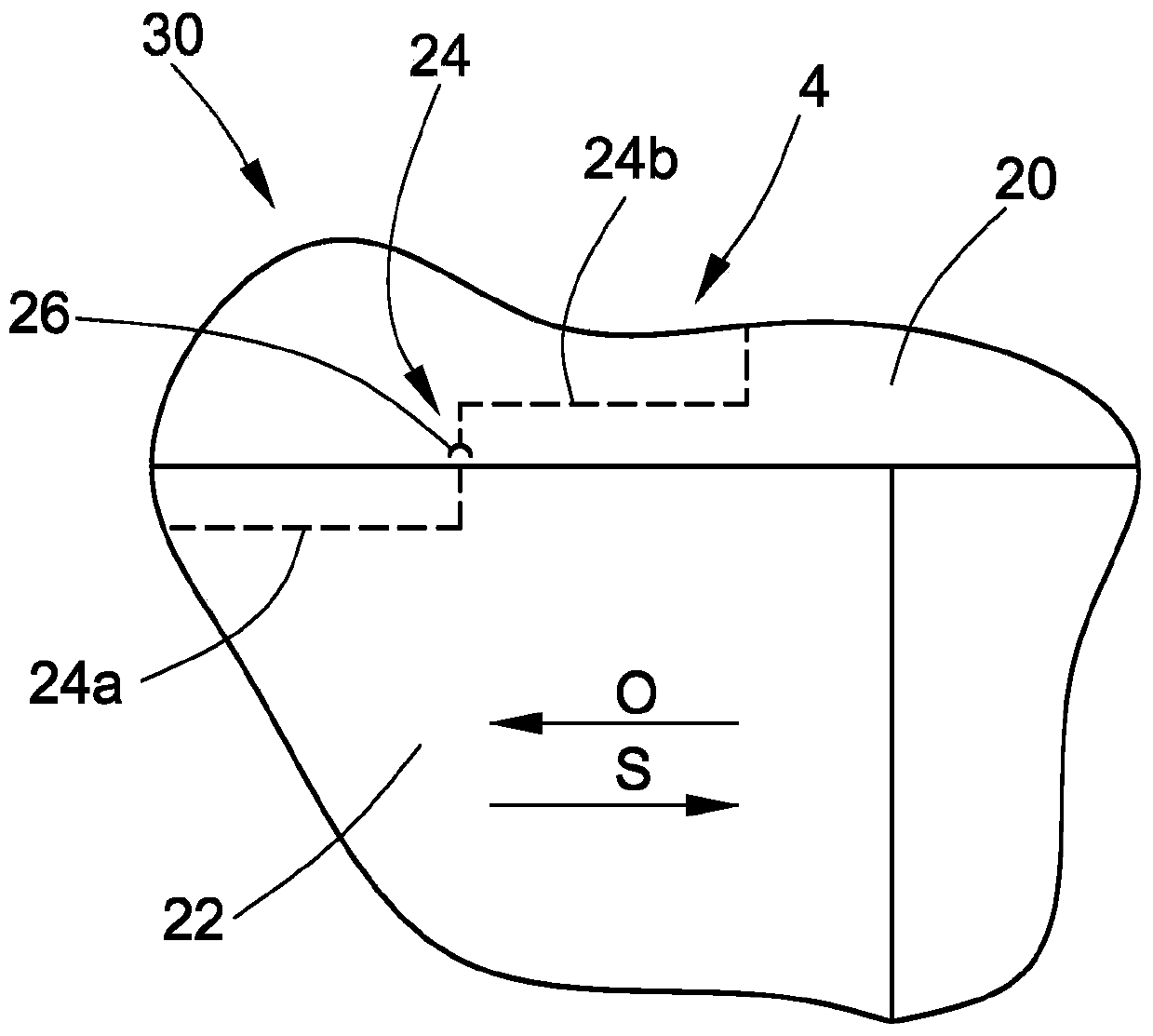

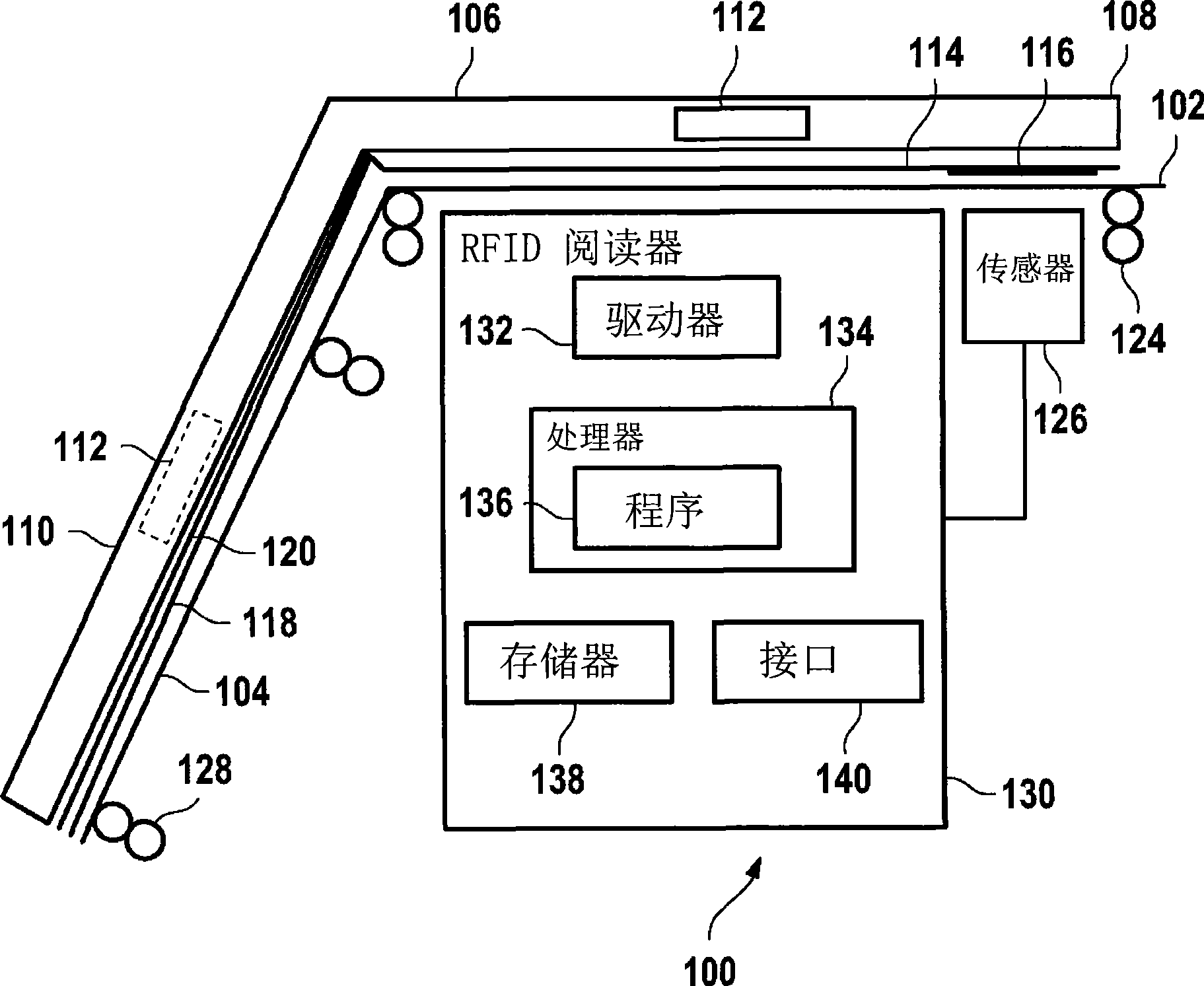

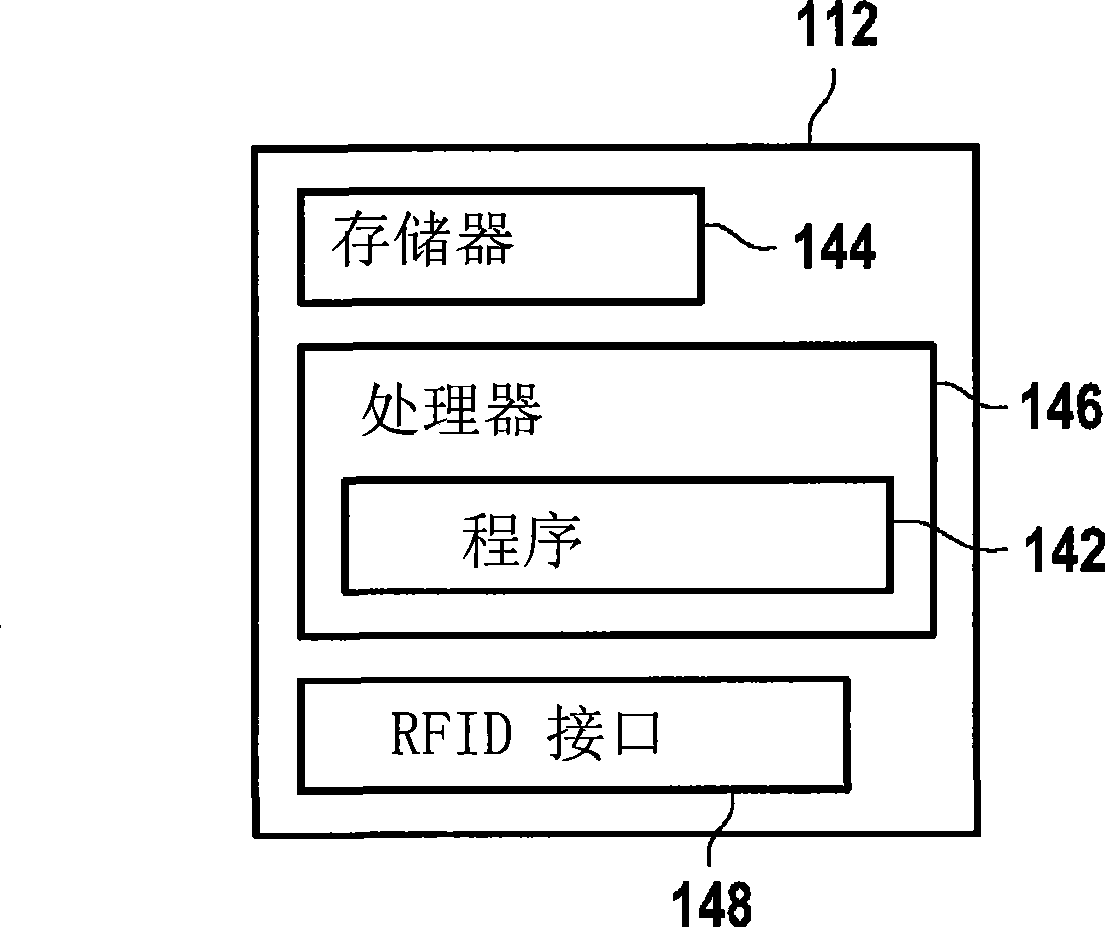

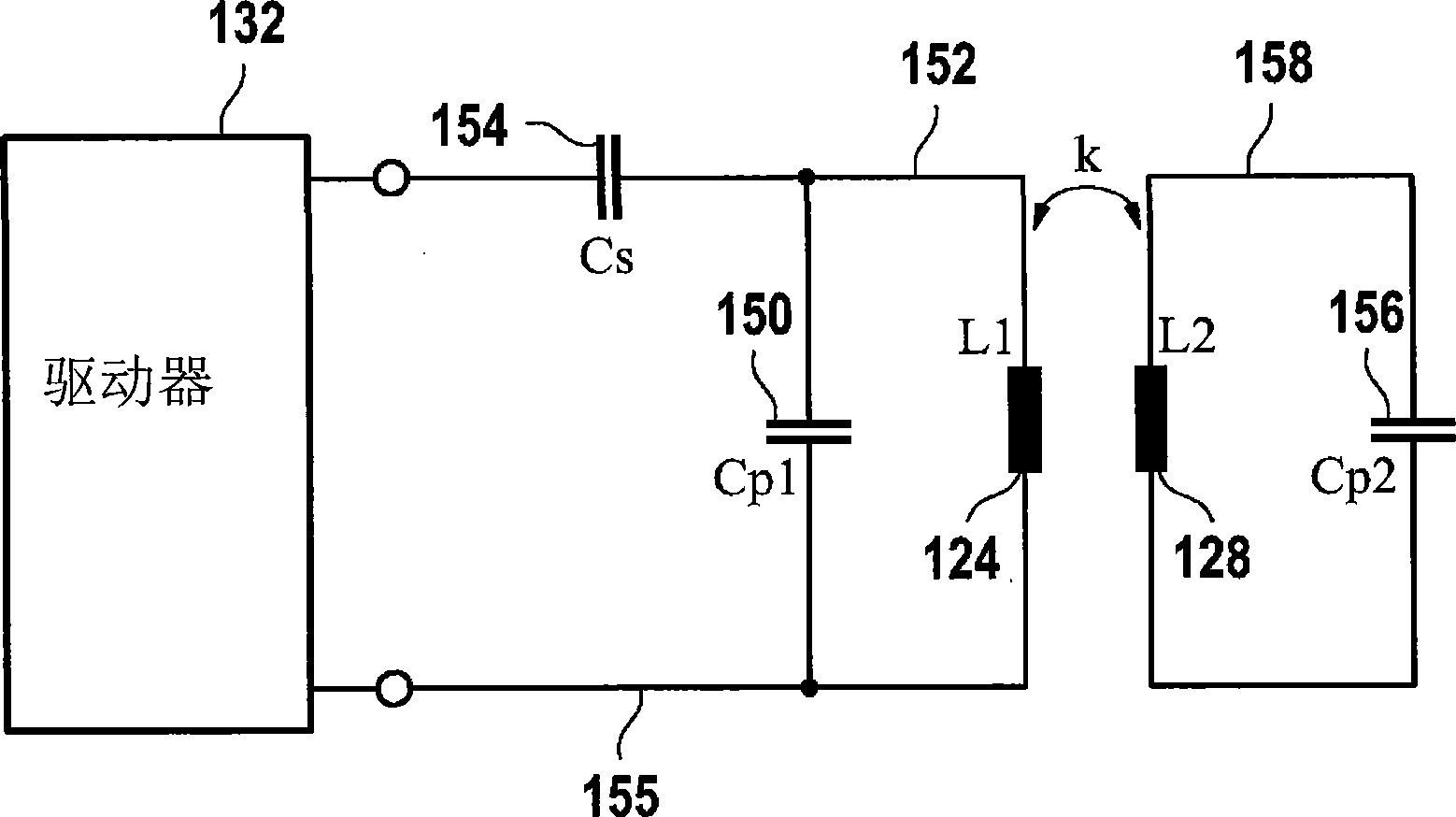

RFID reading device for a document

ActiveCN101523406AEnough energyUniform magnetic fieldPaper-money testing devicesMemory record carrier reading problemsComputer scienceSupport surface

The invention relates to an RFID reading device for a document (106) with at least one RFID chip (112), with a first support surface (102) for a first page (108, 114) of the document, and a second support surface (104) for a second page (110, 118, 120,...) of the document, a first antenna (124) arranged underneath the first support surface, and a second antenna (128) arranged underneath the second support surface, wherein the first and second antennae are each constructed for inductively scanning the at least one RFID chip over a near field.

Owner:BUNDESDRUCKEREI GMBH

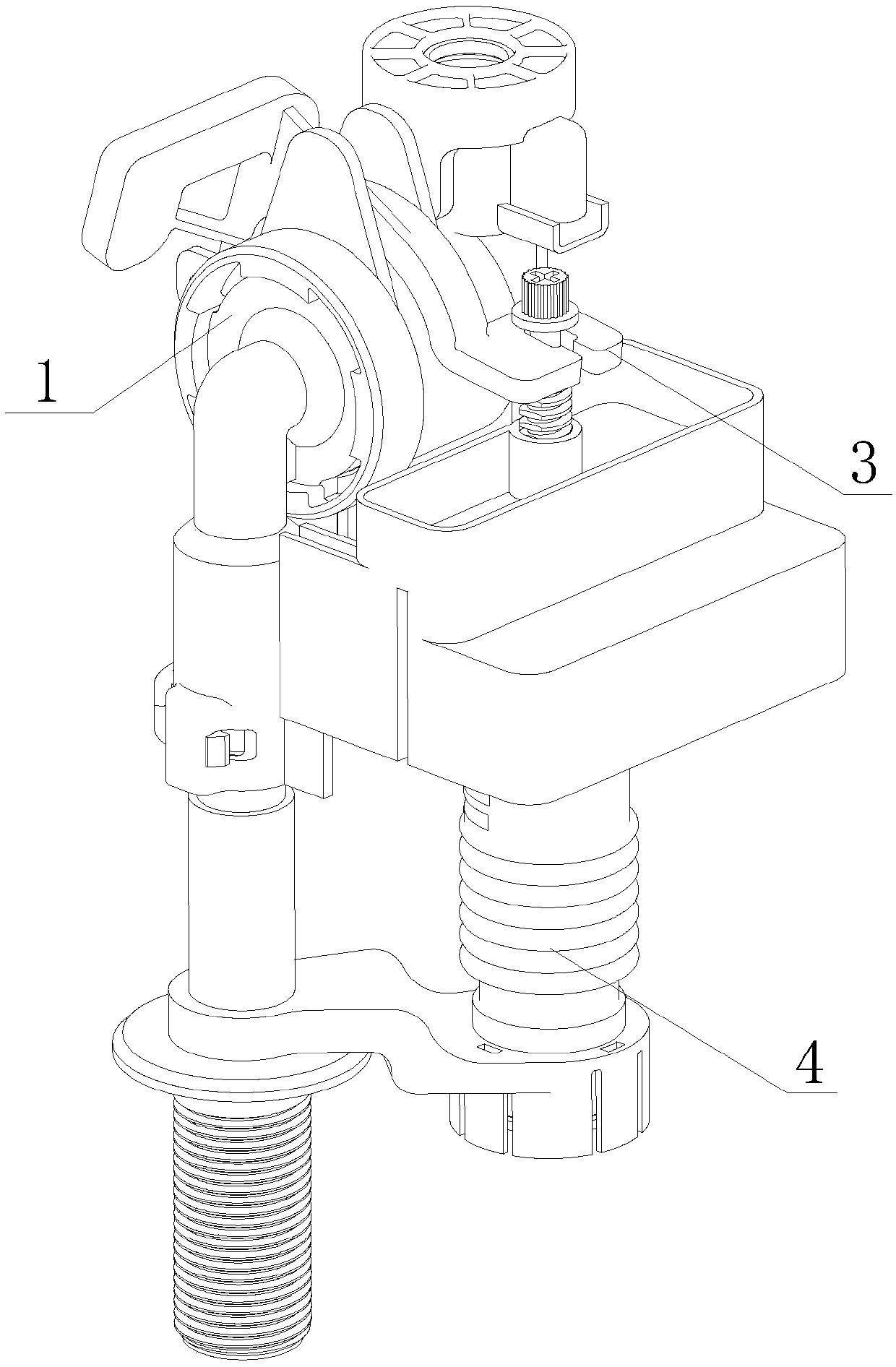

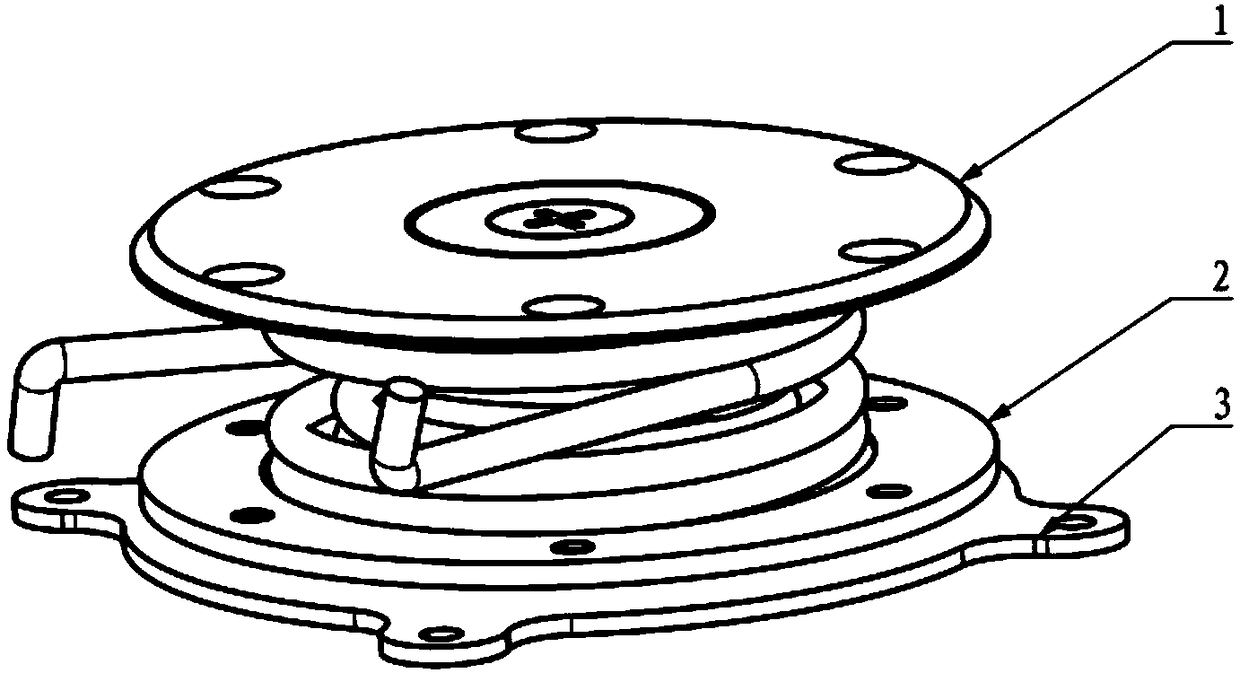

Delayed water inlet mechanism

PendingCN109519590ASimple structureImprove reliabilityOperating means/releasing devices for valvesFlushing devicesEngineeringInlet valve

The invention relates to a delayed water inlet mechanism, and relates to the technical field of water inlet valves. A water inlet valve and a delay assembly are included. The delay assembly acts on the water inlet valve and is used for making the water inlet valve closed in a delayed manner when external force controls the water inlet valve to be opened. The delayed water inlet mechanism is simplein structure and high in reliability. Through the additionally-arranged delay assembly, after water stop of the water inlet valve, the water inlet valve can provide water inflow for a long time larger than or equal to 1S under driving of external force, and the self water stop performance is not influenced.

Owner:XIAMEN R&J PRECISION TECH CO LTD

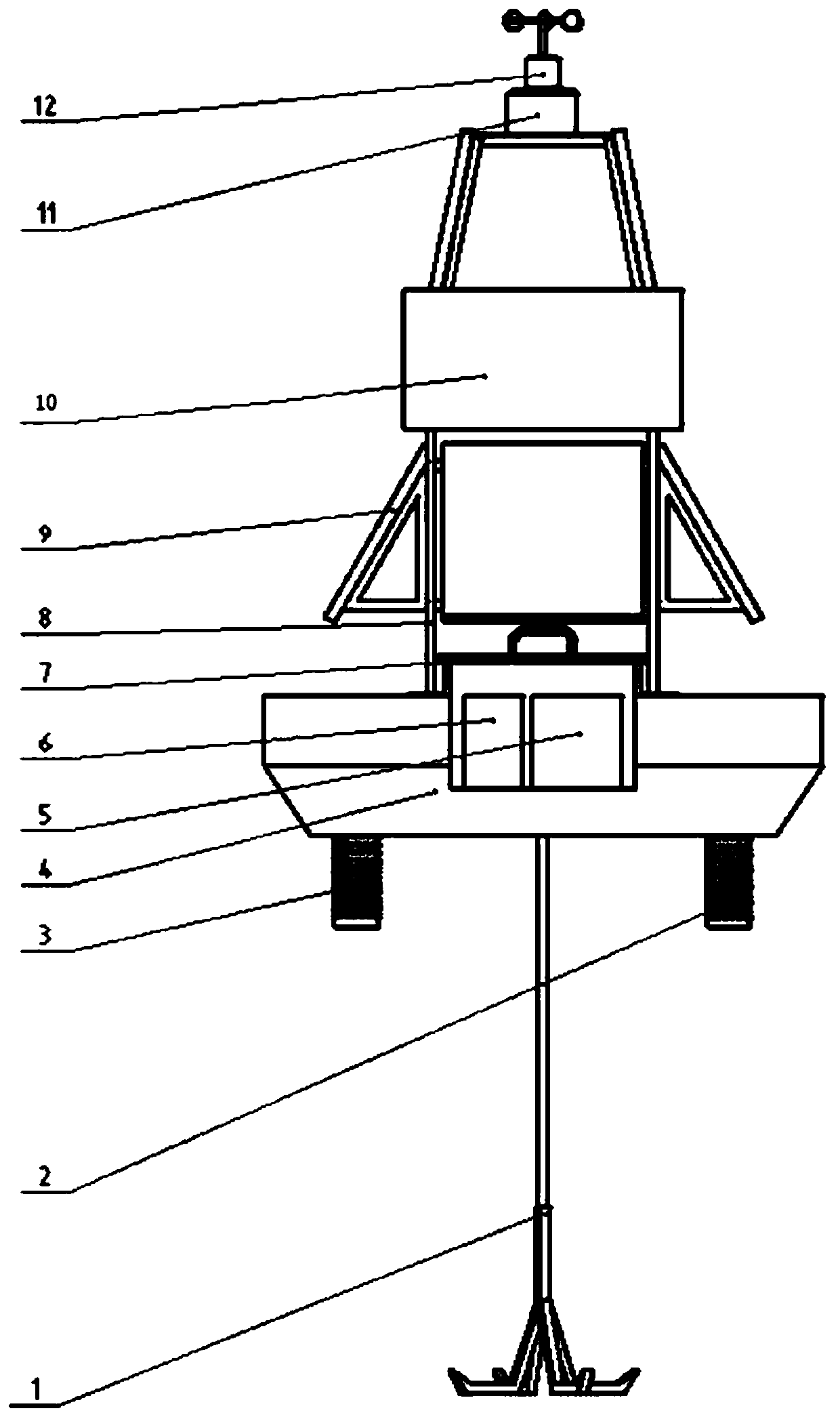

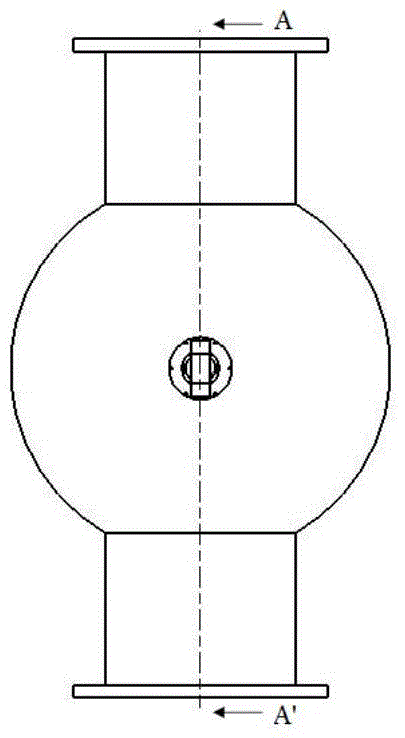

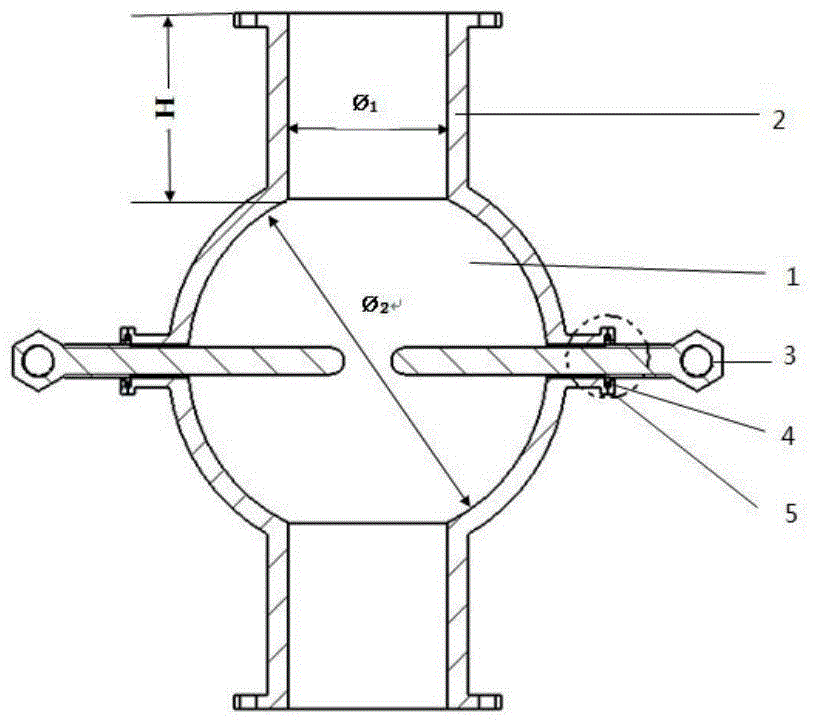

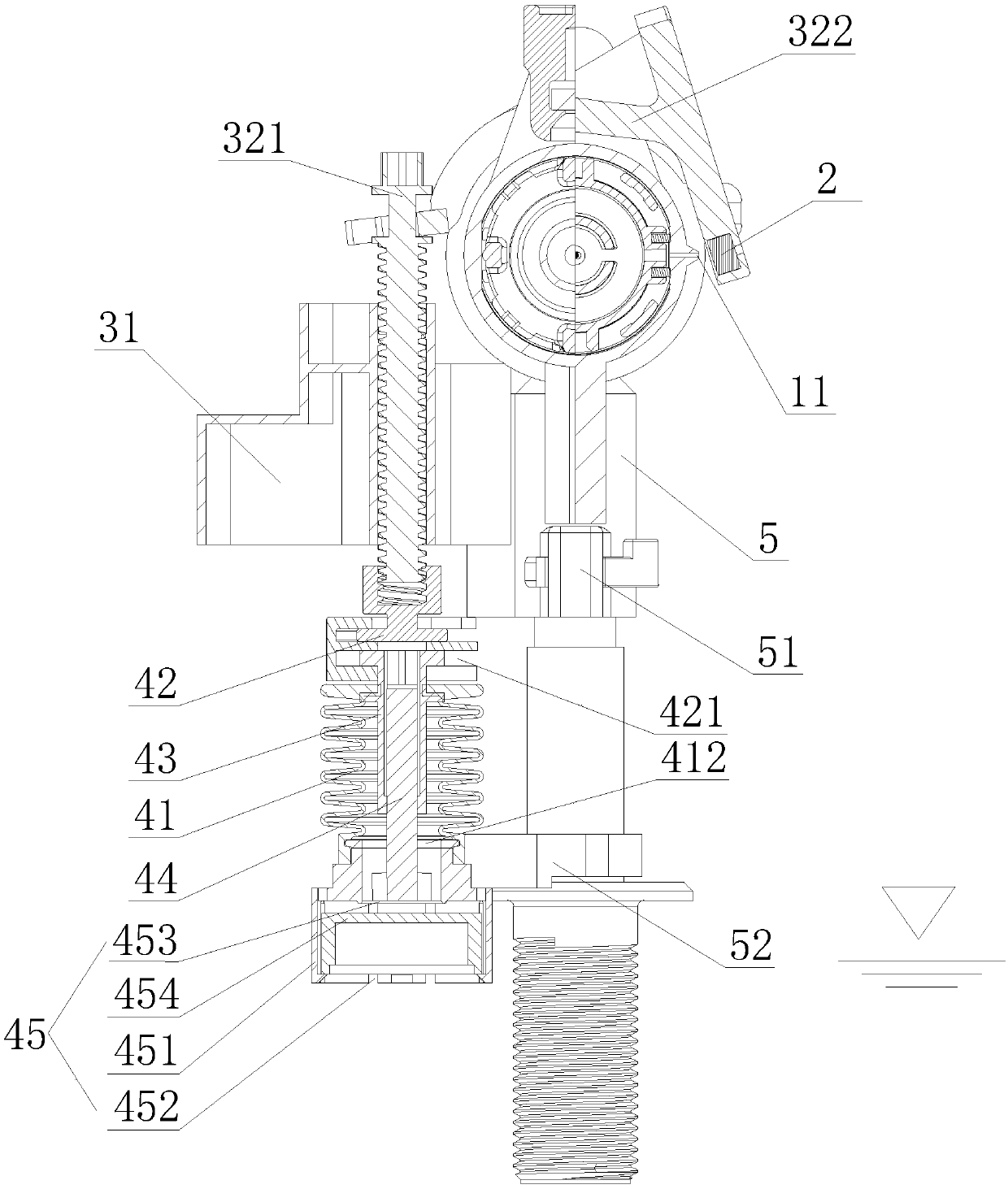

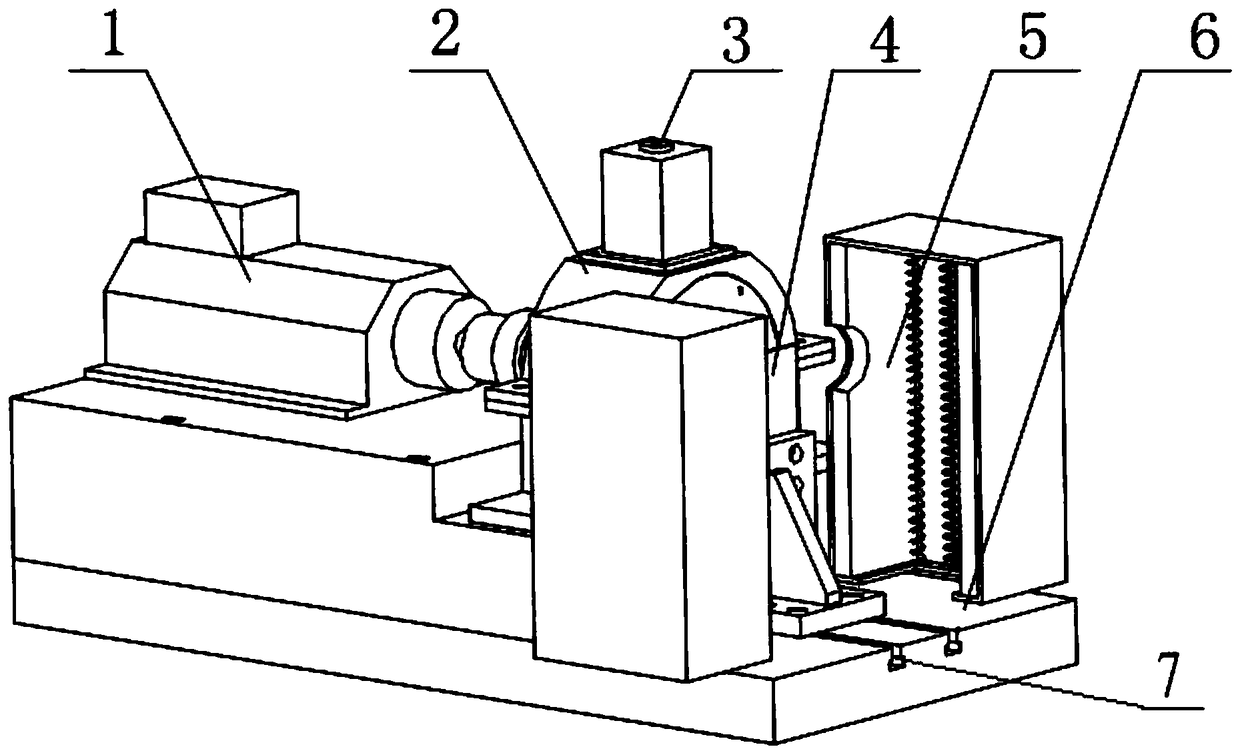

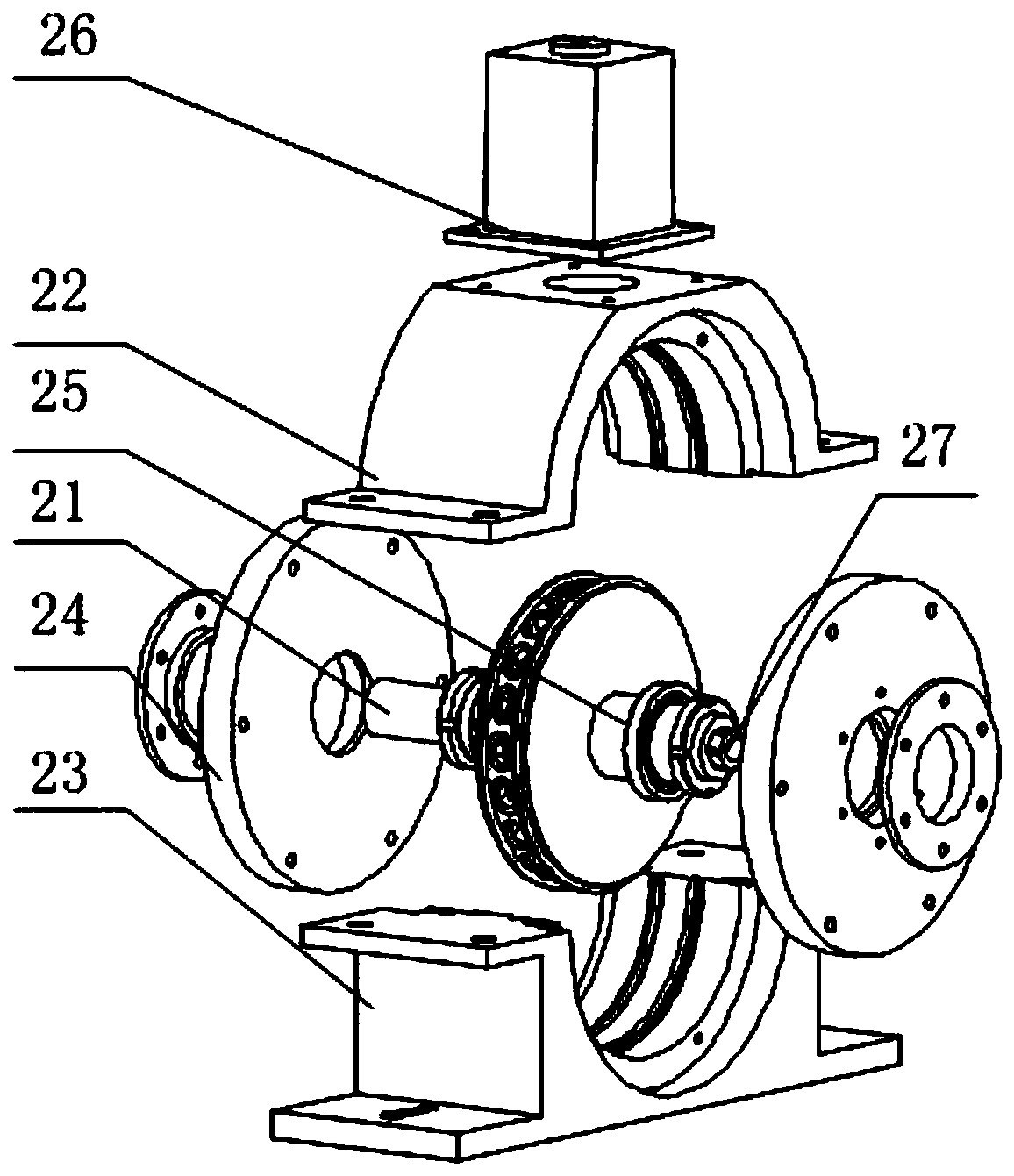

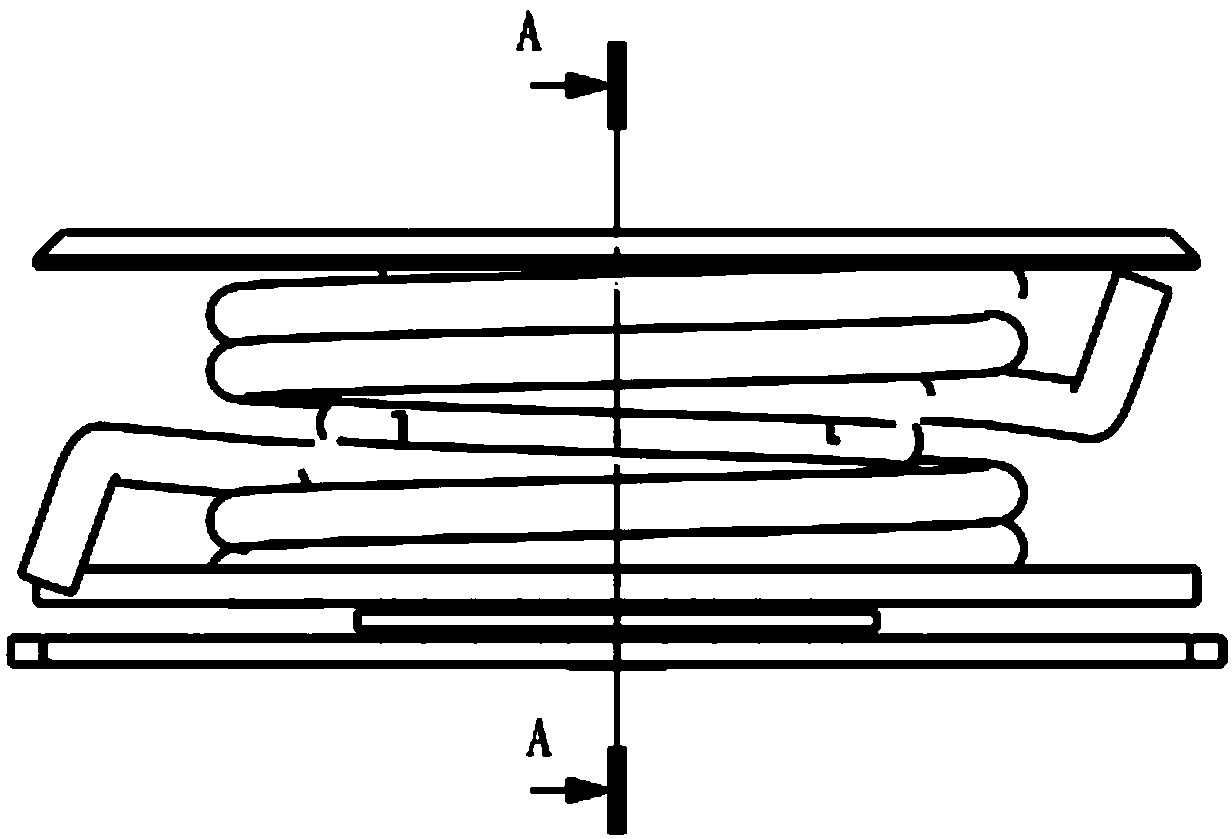

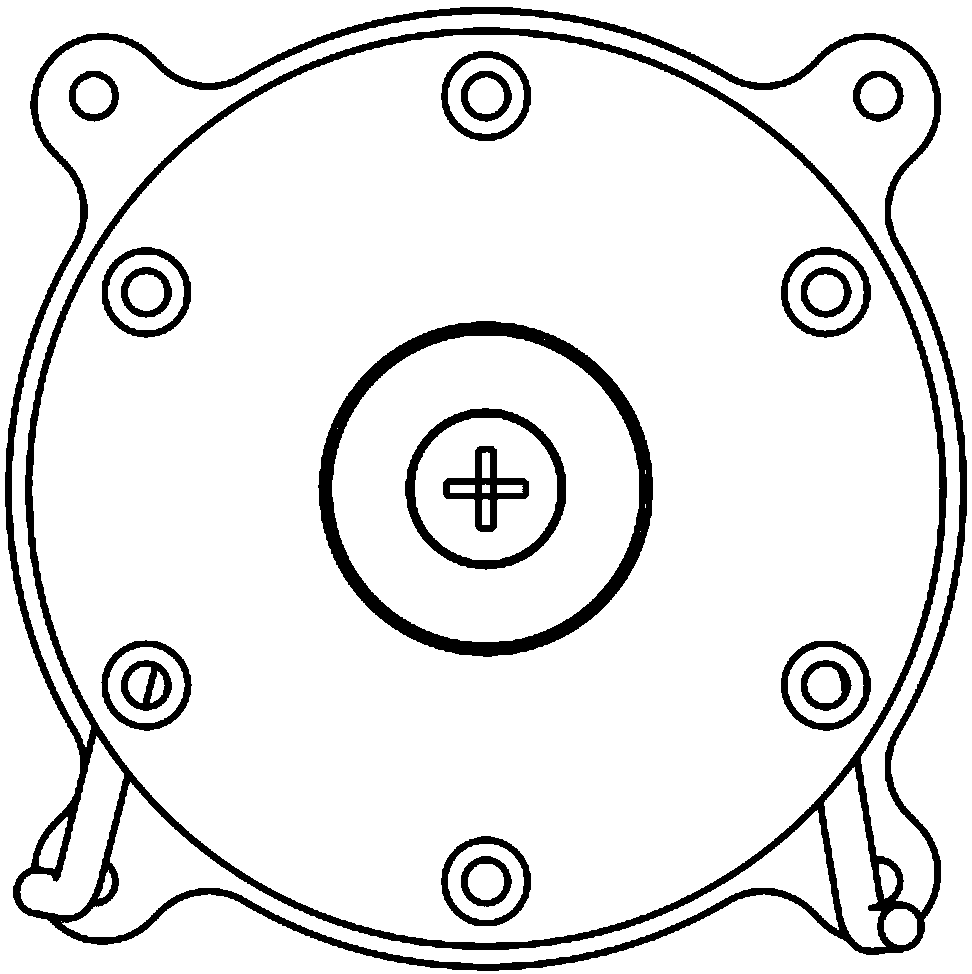

Airflow-thermo-mechanical coupling excitation test device

The invention discloses an airflow-thermo-mechanical coupling excitation test device. The device comprises a driving system, a rotary alternating airflow generating device, an air source system, an airflow heating device and a tested piece heating device, and the airflow heating device is utilized for simulating high-temperature airflow excitation; the tested piece heating device is utilized for simulating a high-temperature environment of a tested piece; an air storage box arranged on the front portion of the airflow-thermo-mechanical coupling excitation test device is adopted for storing compressed air, and air inflow amount is increased to avoid the defect of insufficient air inflowing amount; the mode of arrangement on the circumferential surface of a turntable is adopted, grate toothsealing is combined to prevent air leakage, and the efficiency of using the compressed air is improved; structures of a main shaft, a main air inlet hole of the box body, an auxiliary air inlet hole of the box body, an oval kidney-shaped hole of the main shaft, a taper hole of the box body and the like are adopted, air flowing is smooth, it is ensured that air has enough energy, and efficient high-intensity high-temperature airflow alternating excitation and simulation of the temperature environment of the tested piece are achieved.

Owner:DALIAN JIAOTONG UNIVERSITY

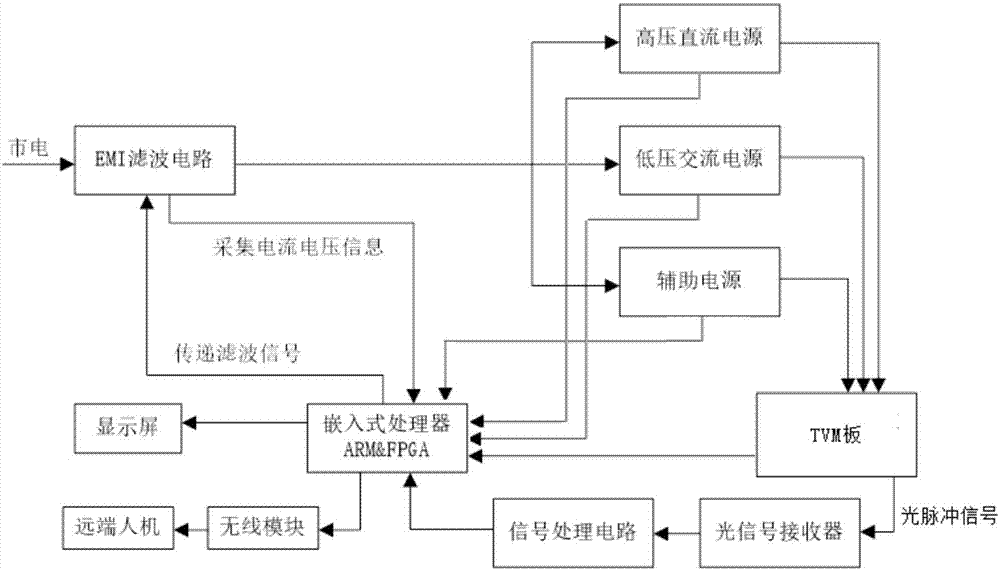

High-voltage thyristor voltage monitoring board detection device and detection method

ActiveCN107144777AImplement triggerGuaranteed triggerElectronic circuit testingLow voltageHigh-voltage direct current

The invention relates to a high-voltage thyristor voltage monitoring (TVM) board detection device and detection method which are used for detecting the performance of a high-voltage thyristor voltage monitoring (TVM) board. The detection device comprises an EMI filtering circuit, a controllable high-voltage direct-current power source, a controllable low-voltage alternating-current power source, an auxiliary power source, an optical fiber receiver, a wireless module, a display screen and an embedded processor; and the embedded processor controls the EMI filtering circuit to filter mains supply, acquires related voltage and current signals, inputs filtered mains supply signals to the high-voltage thyristor voltage monitoring board, analyzes and compares obtained high-voltage thyristor voltage monitoring board signals and the acquired voltage and current signals so as to obtain the operating state of the high-voltage thyristor voltage monitoring board and transmits the state to a near end client and a distant end man-machine interface through the display screen and the wireless module. The high-voltage thyristor voltage monitoring board detection device and detection method of the invention can independently detect the performance of the TVM board, and judge and locate a fault.

Owner:ANNING BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION

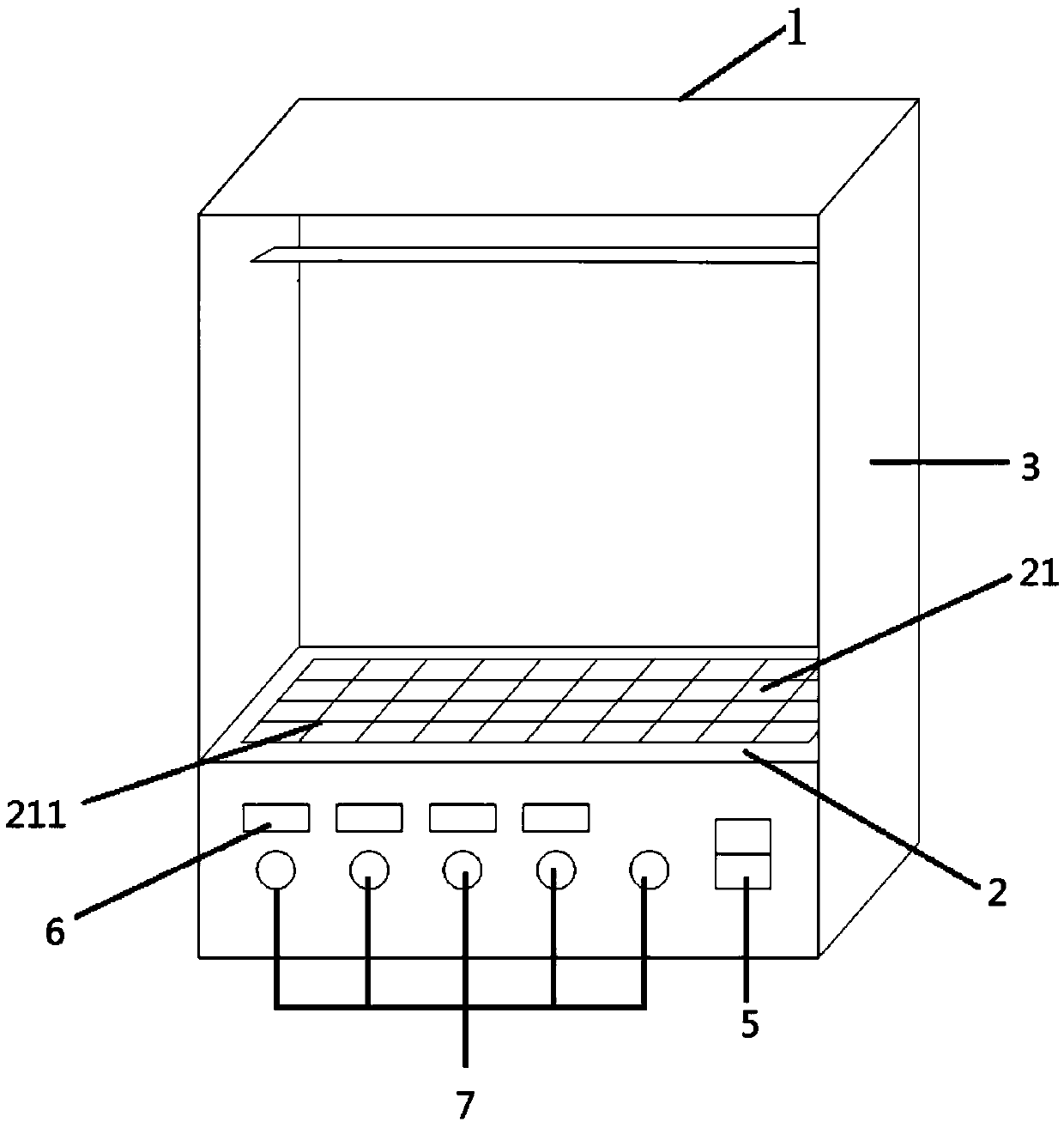

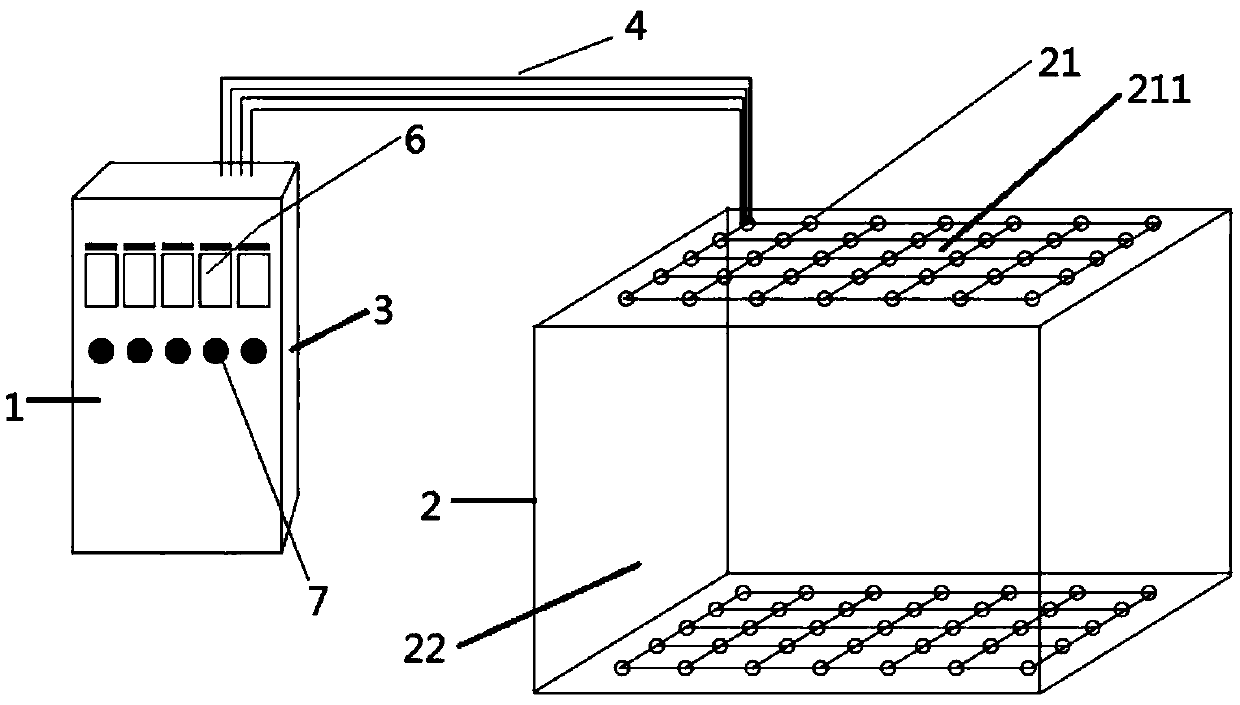

Device and method for quantizing object

PendingCN108671406AEnough energyLong storage timeRadiation therapyTemperature controlQuantum entanglement

The invention is "a device and a method for quantizing an object" and belongs to the technical field of object quantization devices. The device includes a device body integrated with a temperature control device, an air circulation device, a plurality of energy forms of supplies, and a carrier for carrying an object. The plurality of energy forms act on the object on the carrier, and comprise sound waves, light waves, electromagnetic waves and magnetic fields. The device body is provided with a sound wave generating mean for providing the sound waves, a light wave generating mean for providingthe light waves, an electromagnetic wave generating mean for providing the electromagnetic waves and a magnetic field generating mean for providing the magnetic fields. The carrier is a built-in structure built in the device body or a peripheral structure arranged outside the device body. The quantum article processed by the device of the invention can release high frequency energy, generate quantum entanglement effect, is completely quantized, and has the characteristics of sufficient energy and long energy storage time.

Owner:金冠量子科技有限公司

Temperature measurement at high-voltage potential

ActiveCN105247328AMeet needsEnough energyThermometers using electric/magnetic elementsUsing electrical meansHigh pressurePhotodiode

Described is an arrangement for temperature measurement at high-voltage potential. The energy for measuring the temperature of an optical current transformer is provided by precisely one photodiode. The photodiode is supplied by means of light from a light source, the light from the light source being guided to the photodiode via an optical waveguide.

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

Low-GI total-nutrition bar and preparation method thereof

The invention discloses a low-GI full-nutrition bar and a preparation method thereof. The nutrition bar comprises the following raw materials: mixed bean powder, oats, rye grains, quinoa, puffed blackrice, chia seeds, compound protein powder, high-oleic-acid sunflower seed oil, soyabean lecithin, isomalto-oligosacharide, fructo-oligosaccharide and a compound nutrition enhancer. The GI value of the nutrition bar is less than 55 due to the proper proportion. Mixed beans are treated with a microwave irradiation method, cell walls of the mixed beans are destroyed, resistant starch in the mixed beans is released, and the mixed beans cooperate with other components to achieve a low-GI effect. The low-GI total-nutrition bar provided by the invention can provide enough protein, heat and vitaminswhile maintaining stable postprandial blood sugar, and has the characteristics of high satiety and comprehensive nutrition. The preparation method is simple in process and easy to implement, and the nutrition bar has a good weight control effect and can be used as a meal replacement food in the weight losing period.

Owner:湖南汇富康达健康管理研究院

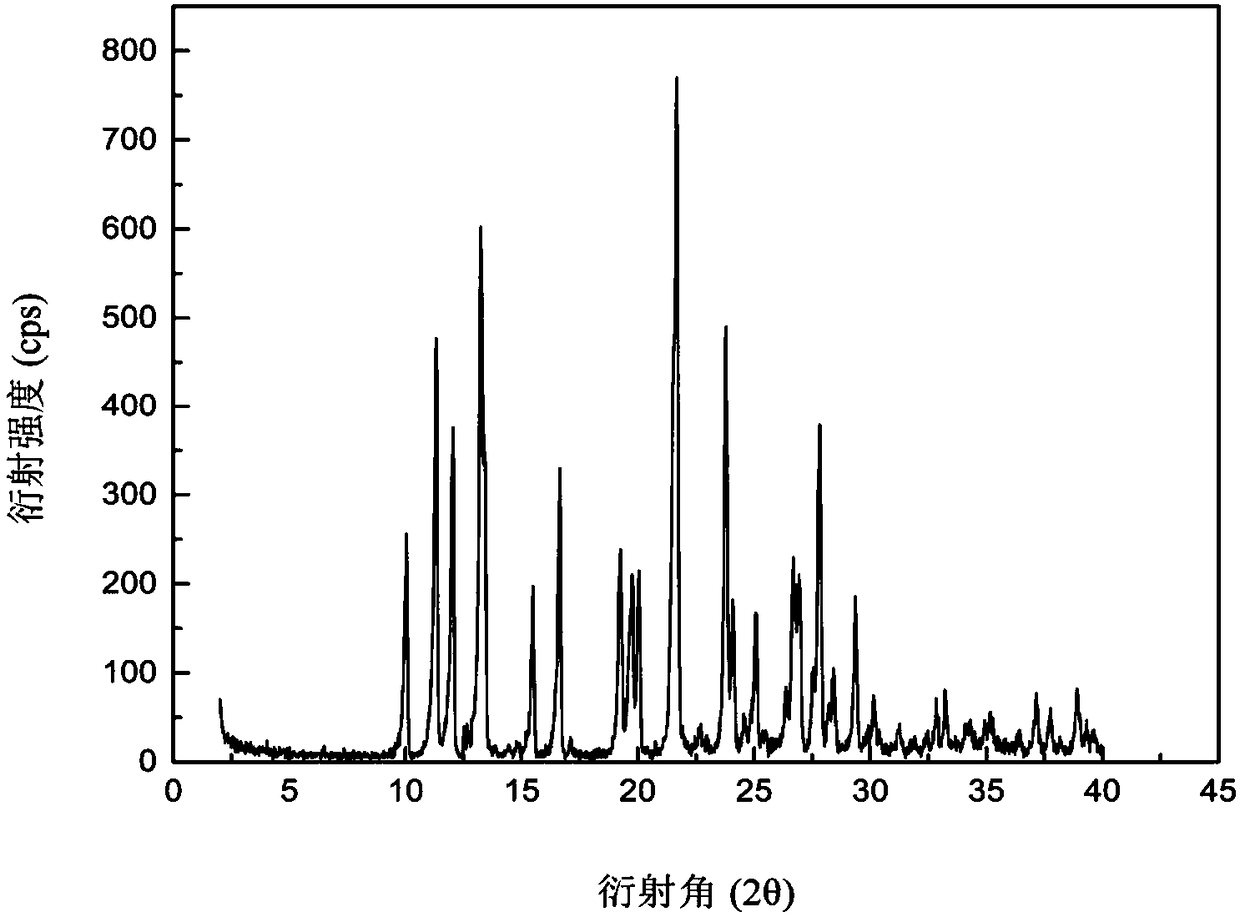

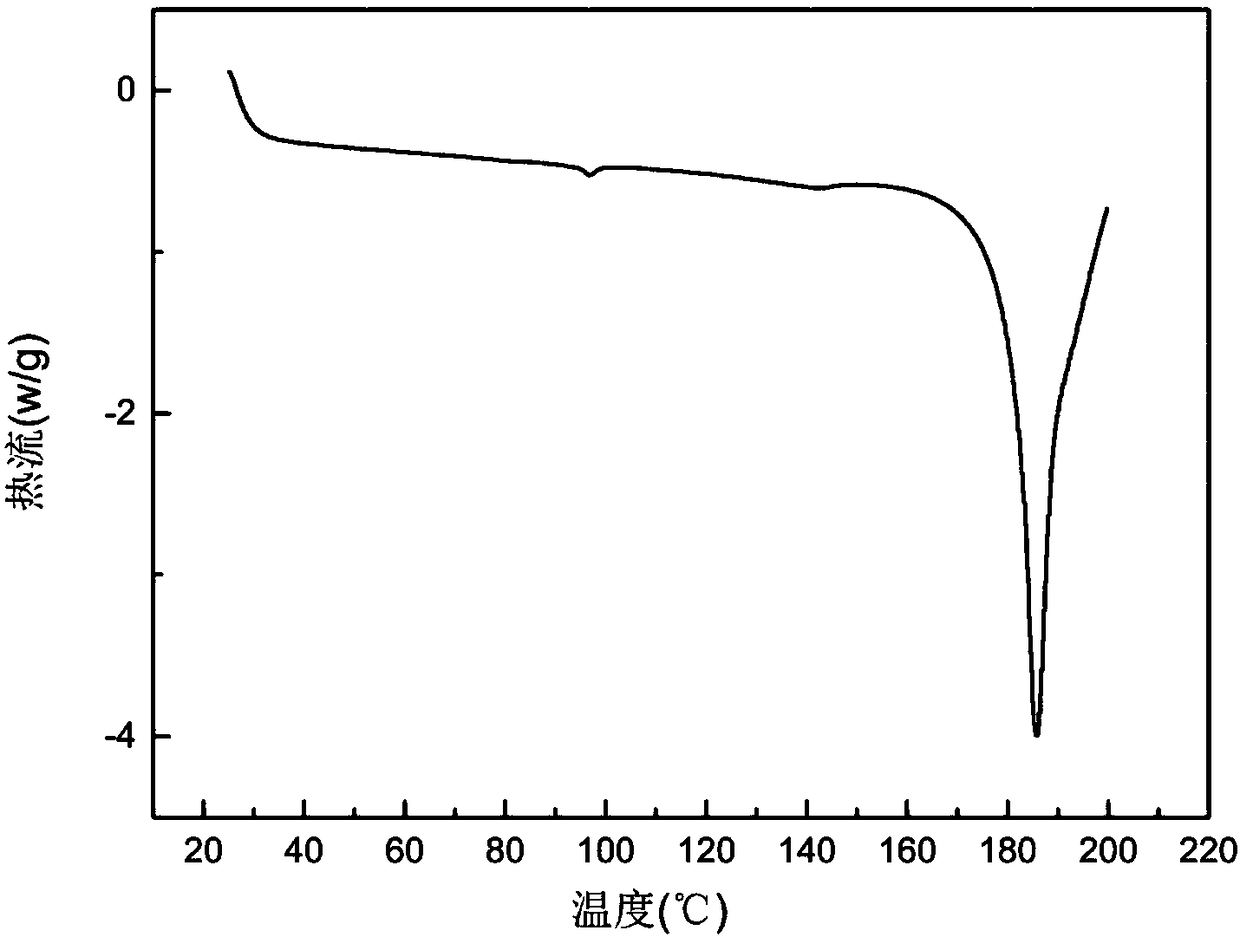

Nicosulfuron crystal form and preparation method thereof

The invention relates to a nicosulfuron crystal form and a preparation method thereof. A characteristic endothermic peak at 187 + / - 2 DEG C exists in the DSC map of the nicosulfuron crystal form. Themethod adopts a constant temperature suspension crystal transformation technology, and concretely comprises the following steps: adding crude nicosulfuron to ethanol according to a mass ratio of nicosulfuron to the solvent ethanol of 0.12-0.17, stirring the nicosulfuron and ethanol at a constant temperature suspension crystal transformation temperature of 40-50 DEG C for 36-48 h to generate a white solid, filtering the obtained product while hot, and drying the filtered product to obtain the nicosulfuron crystal. The product is a well-growth block crystal, has a good fluidity, is not prone tocoalesce, has a high bulk density reaching 0.6421 g / ml, and has an angle of repose of 24 DEG, and the method is beneficial to the preparation production, filtration and other operations, and solves the problems of easiness in coalescence and difficulty in preparation production of existing acicular crystals.

Owner:内蒙古新农基科技有限公司

Crude copper blowing process

ActiveCN110923455ALow melting pointSpeed up meltingCombination devicesProcess efficiency improvementCopper oxideWaste treatment

The invention relates to a crude copper blowing process in the technical field of crude copper smelting. The process comprises the following steps of mixing copper-containing waste materials and copper-containing waste treatment tailings, then adding into a side blowing melting furnace, adding a co-solvent, a reducing agent and fuel, simultaneously blowing oxygen into the furnace, and carrying outmixing and blowing at 1200 to 1250 DEG C; and separately discharging blowing tailings, the crude copper and flue gas, and carrying out discharging after the flue gas is treated. The melting point oflimestone is low, so that melting of quartz stone and iron oxide can be promoted, and the fluidity can be improved. Iron, molybdenum, magnesium, calcium, silicon and the like in the furnace charge areoxidized to form oxide in an oxygen-rich environment, and the oxide is combined with the quartz stone to form tailings, so that the non-copper metal elements are separated from copper, copper in copper oxide and copper sulfide can be reduced through the iron oxide, and the copper content is improved; semi coke is used as fuel, and the content of fixed carbon is high, so that sufficient energy isprovided for combustion, the chemical activity is high, and the effect of a reducing agent can also be achieved; and the reduction rate of the copper can be improved through the cooperation of the several chemical meterials.

Owner:洛南环亚源铜业有限公司

Wing folding and unfolding mechanism for light unmanned aerial vehicle

InactiveCN109367760AEnough energyThe overall structure is simple and reliableWing adjustmentsEngineeringTorsion spring

The invention discloses a wing folding and unfolding mechanism for a light unmanned aerial vehicle, and belongs to the technical field of unmanned aerial vehicle deformation structures. The unfoldingmechanism comprises an upper cover, a lower cover, a fixed assembly, bearings and torsion springs, wherein the upper cover and the lower cover are separately mounted at upper and lower ends of the fixed assembly through the bearings; the upper cover and the lower cover are in rolling fit to the fixed assembly; the upper cover and the lower cover are fixedly connected with two wings separately; upper and lower positions of the two torsion springs are arranged on the outer peripheral surface of the fixed assembly in a concentric sleeving mode, and separately correspond to the position of the upper cover and the position of the lower cover; ends of the torsion springs are fixedly connected with the fixed assembly; the other ends of the torsion springs are fixedly connected with the wings; andthe unfolding mechanism is fixedly connected with the machine body through the lower end of the fixed assembly. The wing folding and unfolding mechanism is small in size, light in mass, is easily modified, and can be suitable for different light unmanned aerial vehicle platforms.

Owner:北京大翔航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com