Nicosulfuron crystal form and preparation method thereof

The technology of nicosulfuron-methyl crystal and nicosulfuron-methyl is applied in the field of nicosulfuron-methyl crystal form and its preparation, which can solve the problems of easy coalescence, poor fluidity and the like, and achieves good repeatability, good growth and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

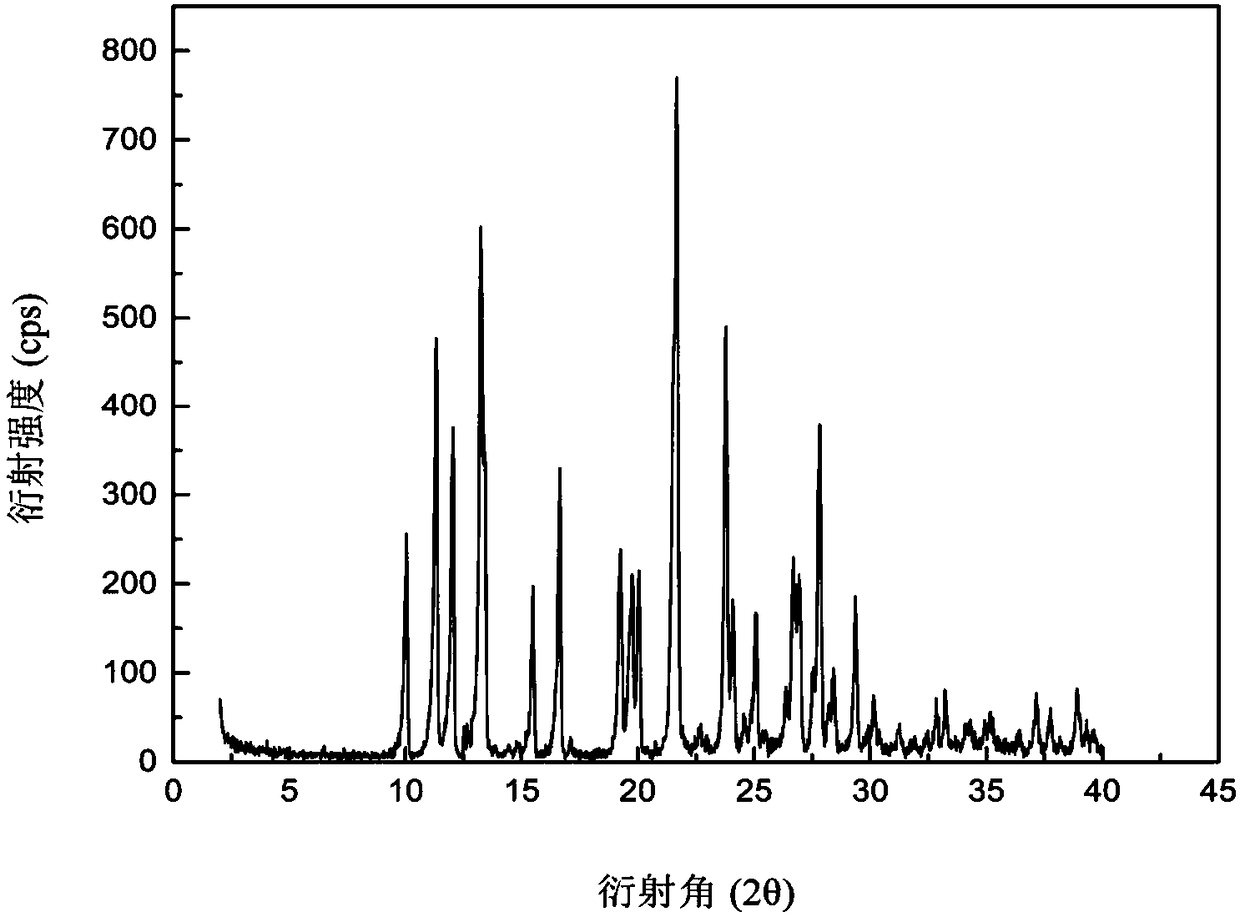

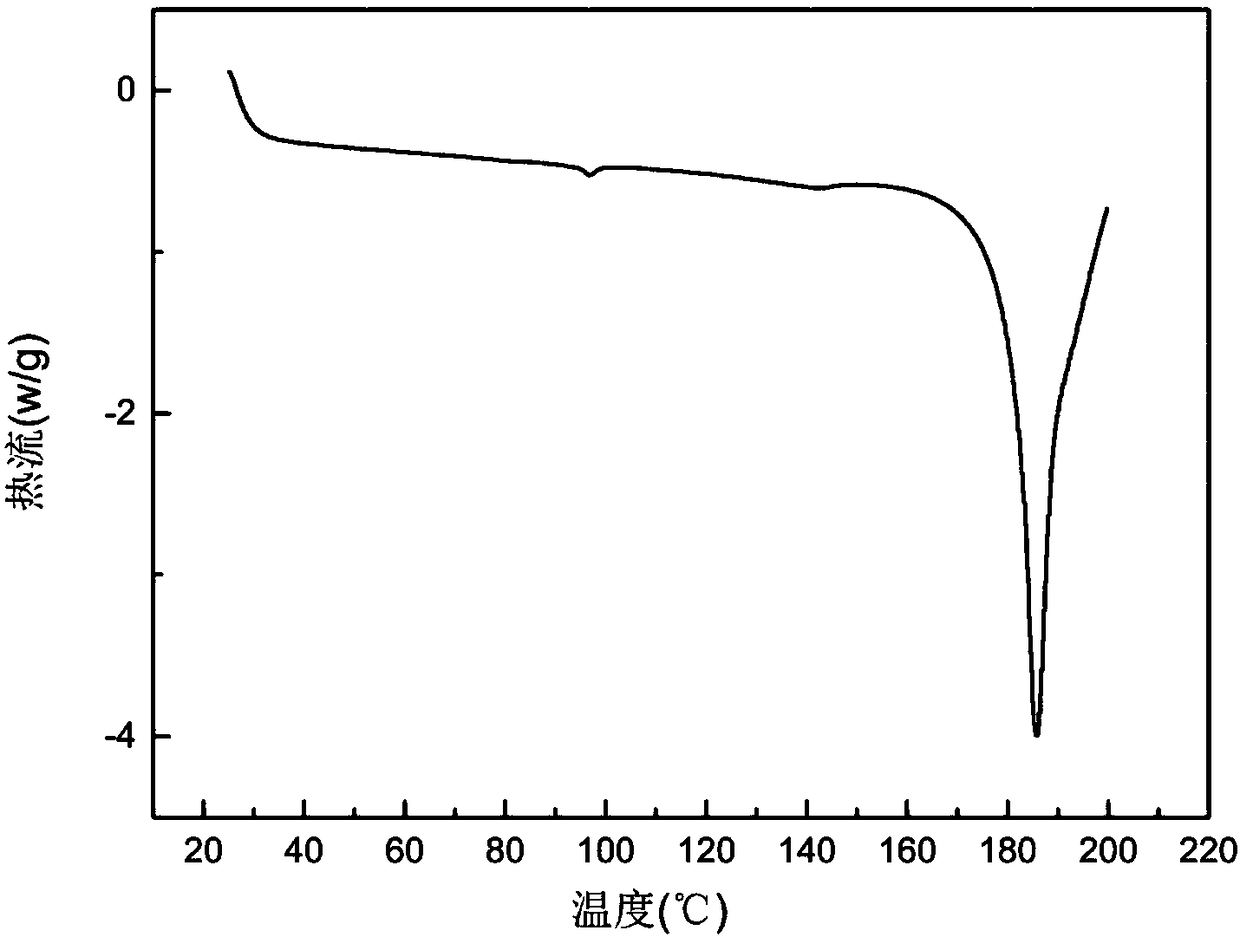

[0025] Put 2.4g of nicosulfuron in 20g of ethanol solvent, stir at 40°C for suspension crystallization, filter while hot after 40h to obtain white crystals, dry at 20°C for 12h to obtain nicosulfuron crystals. The powder X-ray diffraction pattern of the product is represented by diffraction angle 2θ at 10.0, 11.3, 12.0, 13.24, 15.5, 16.6, 19.3, 19.7, 20.0, 21.7, 22.7, 23.8, 24.1, 24.6, 25.1, 26.4, 26.7, 26.9 , 27.8, 28.4, 29.4, 30.1, 31.3, 32.8, 33.2, 34.3, 35.2, 36.4, 37.1, 37.8, 38.9, 39.3 degrees have characteristic peaks, and figure 1 Consistent, the DSC spectrum has a characteristic endothermic peak at 187 ° C, which is consistent with figure 2 consistent, confirming that the obtained product is the Nicosulfuron-methyl Form III crystal. The crystals are massive, with Figure 4 Similarly, it has a bulk density of 0.6411 g / ml and an angle of repose of 24°.

Embodiment 2

[0027] Put 3 g of nicosulfuron in 20 g of ethanol solvent, stir at 40°C for suspension crystallization, filter while hot after 40 hours to obtain white crystals, dry at 40°C for 6 hours to obtain nicosulfuron crystals. The powder X-ray diffraction pattern of the product is represented by diffraction angle 2θ at 10.1, 11.4, 12.1, 13.3, 15.5, 16.7, 19.3, 19.8, 20.1, 21.8, 22.8, 23.9, 24.2, 24.7, 25.2, 26.5, 26.8, 26.9 , 27.9, 28.5, 29.5, 30.2, 31.4, 32.9, 33.3, 34.4, 35.3, 36.5, 37.2, 37.9, 38.9, 39.4 degrees have characteristic peaks, and figure 1 Consistent, the DSC spectrum has a characteristic endothermic peak at 188 ° C, which is consistent with figure 2 consistent, confirming that the obtained product is the Nicosulfuron-methyl Form III crystal. The crystals are massive, with Figure 4 Similarly, it has a bulk density of 0.6420 g / m and an angle of repose of 24°.

Embodiment 3

[0029]Put 3.4g of nicosulfuron in 20g of ethanol solvent, stir at 40°C for suspension crystallization, filter while hot after 48h to obtain white crystals, dry at 30°C for 10h to obtain nicosulfuron crystals. The powder X-ray diffraction pattern of the product is represented by diffraction angle 2θ at 10.0, 11.3, 12.0, 13.24, 15.5, 16.6, 19.3, 19.7, 20.0, 21.7, 22.7, 23.8, 24.1, 24.6, 25.1, 26.4, 26.7, 26.9 , 27.8, 28.4, 29.4, 30.1, 31.3, 32.8, 33.2, 34.3, 35.2, 36.4, 37.1, 37.8, 38.9, 39.3 degrees have characteristic peaks, and figure 1 Consistent, the DSC spectrum has a characteristic endothermic peak at 186 ° C, which is consistent with figure 2 consistent, confirming that the obtained product is the Nicosulfuron-methyl Form III crystal. The crystals are massive, with Figure 4 Similarly, it has a bulk density of 0.6420 g / ml and an angle of repose of 25°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of repose | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com